ERHPA2-8C ERHPA2-8RAC LKTEA8C LKTEA8RAC

Installation/Care/Use Manual

Square Front® Refrigerated Fountains with FLEXI-GUARD

SEE FIG. 3

SEE FIG. 9

37

38

34

35

36

35

®

ERHPA2-8C, LKTEA8C

ERHPA2-8RAC, LKTEA8RAC

Installer

To assure you install this model easily and correctly, PLEASE READ

THESE SIMPLE INSTRUCTIONS BEFORE STARTING THE INSTALLATION. CHECK YOUR INSTALLATION FOR COMPLIANCE WITH

PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. After

installation, leave these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO WATER LINES

IS A COMMON PROCEDURE. THIS GROUNDING MAY BE IN THE BUILDING OR MAY OCCUR AWAY FROM THE

BUILDING. THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK INTO A FOUNTAIN, CREATING AN ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN INCREASE IN THE METAL CONTENT OF THE WATER.

THIS CONDITION IS AVOIDABLE BY USING THE PROPER MATERIALS AS INDICATED. ANY DRAIN FITTINGS

PROVIDED BY THE INSTALLER SHOULD BE MADE OF PLASTIC TO ELECTRICALLY ISOLATE THE FOUNTAIN

FROM THE BUILDING PLUMBING SYSTEM.

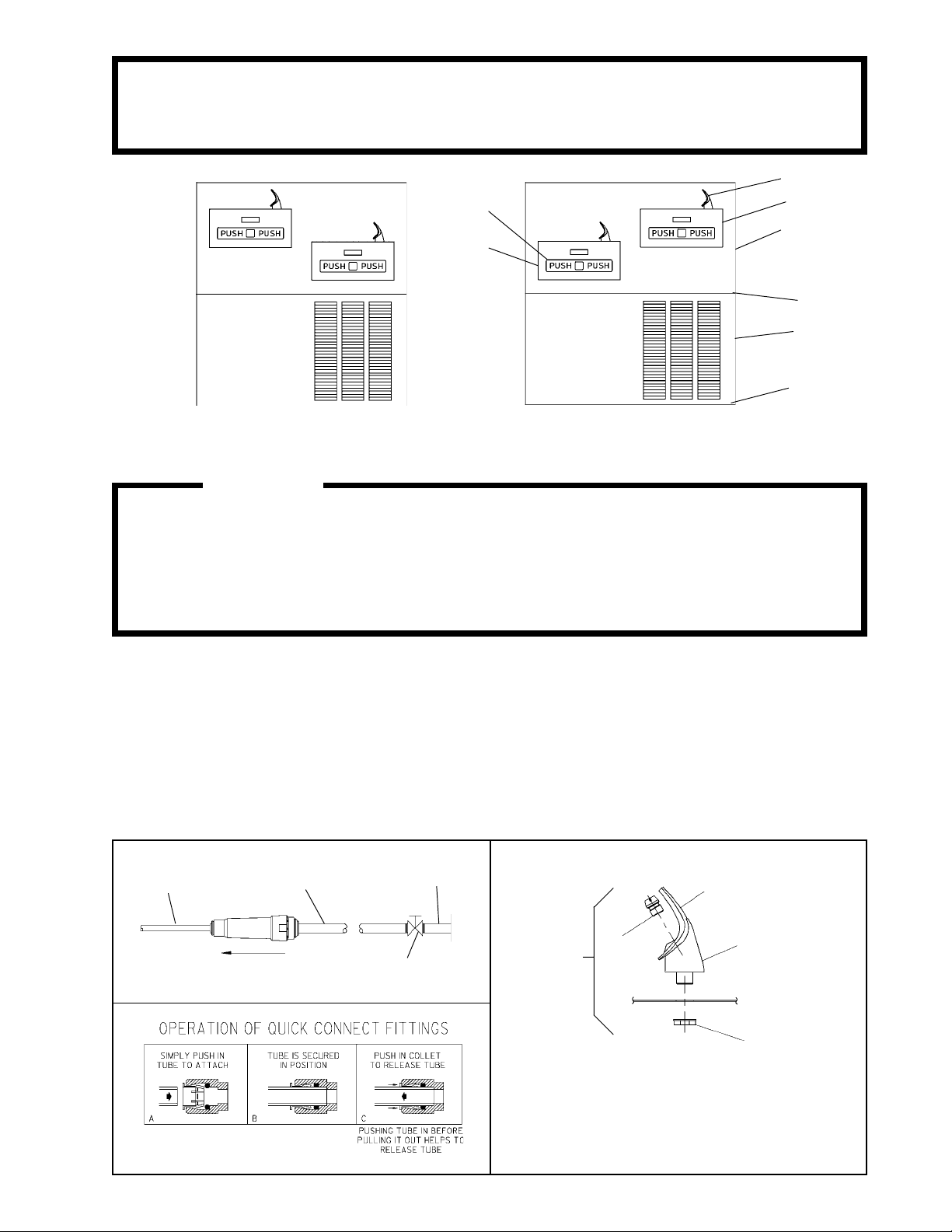

1/4" O.D. TUBE

WATER INLET

TO COOLER

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPLY

BUILDING WATER

INLET

3

FIG. 1

FIG. 2

NOTE: WATER FLOW

DIRECTION

SERVICE STOP

(NOT FURNISHED)

FIG. 3

2

1

NOTE: WHEN INSTALLING

REPLACEMENT BUBBLER

AND PEDESTAL, TIGHTEN

NUT (ITEM 5 ) ONLY TO HOLD

PARTS SNUG IN POSITION.

DO NOT OVER TIGHTEN.

4

5

97679C (REV. B - 02/02)

ERHPA2-8C ERHPA2-8RAC LKTEA8C LKTEA8RAC

LKTEA8RAC

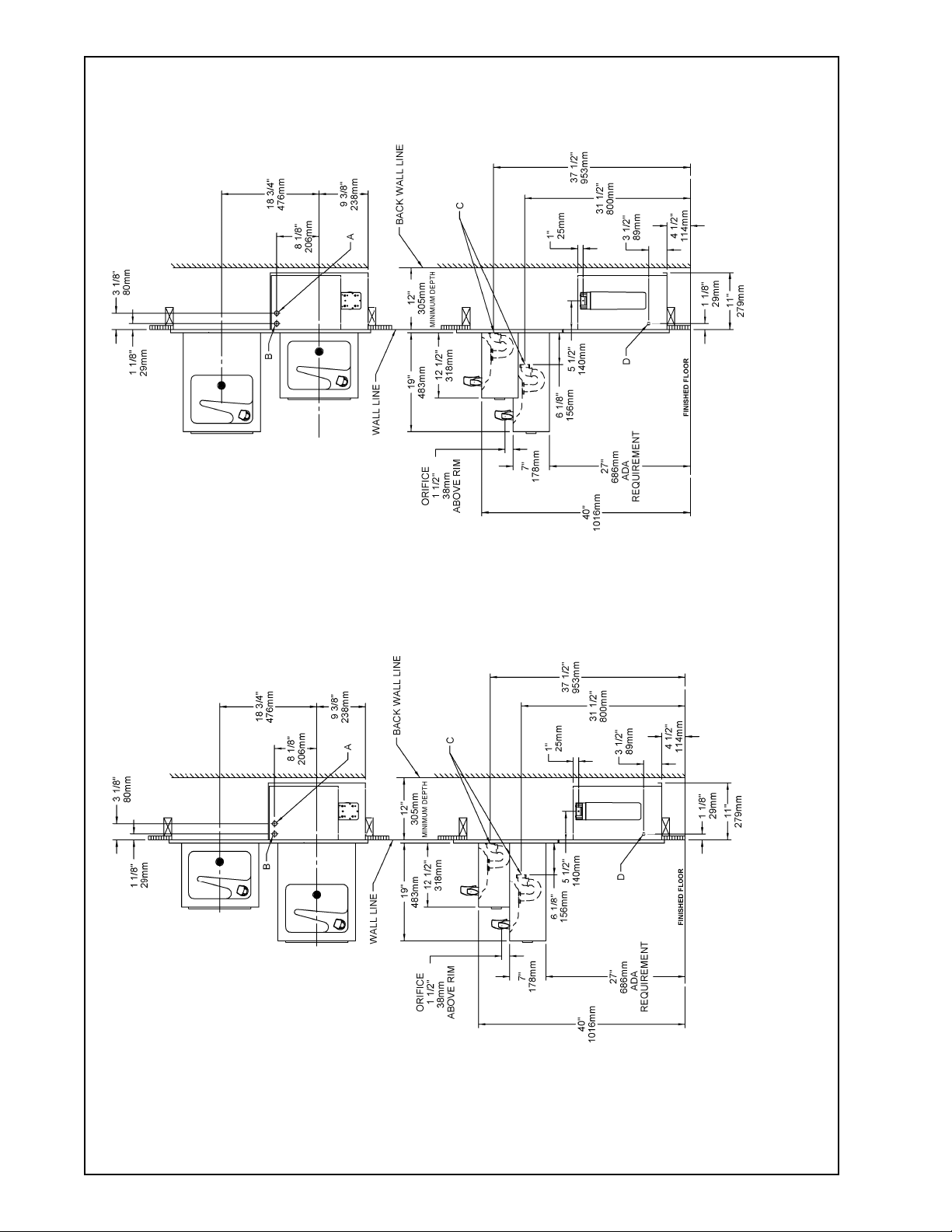

FIG. 4

LKTEA8C

97679C (REV. B - 02/02)

PAGE 2

LEGEND

A = 3/8" O.D. TUBE CONNECT (CHILLER WATER OUTLET)

B = 3/8" O.D. TUBE CONNECT (CHILLER WATER INLET) SHUT OFF VALVE BY OTHERS

C = 1-1/4" TRAP FURNISHED

D = ELECTRICAL INLET

ERHPA2-8C ERHPA2-8RAC LKTEA8C LKTEA8RAC

INSTALLATION INSTRUCTIONS

1. Install remote chiller. Remove front panel of chiller. Remove and discard cardboard inner pack from between compressor and

side panel. Slide chiller onto the shelf and position it to the left side of shelf. (See Figure 4)

NOTE: Building construction must allow for adequate air flow on both sides, top, and back of chiller. See chiller instructions for

additional instructions.

2. Make water supply connections. Install a shut-off valve and union connection to building water supply (valve and union not

provided). Turn on the water supply and flush the line thoroughly.

3. ERHPA MODELS: Make connection between remote chiller and building supply line. Inlet port is marked on the chiller (1/4" O.D.

copper tube). Bend the copper tube (provided) at an appropriate length from chiller to opening in frame. Install a 1/4" x 3/8" union

(provided) on the marked chiller inlet port. Connect building supply line to union. (See Figure 5)

LKTEA MODEL: Mount filter head assembly to side of chiller (See Figure 7). Make connection between filter and building supply

line (3/8" O.D. tube not provided). Inlet port is marked on the chiller (1/4" O.D. copper tube). Install a 1/4" x 1/4" union (provided).

Bend the copper tube (provided) at an appropriate length from the filter and connect to the union on the chiller. (See Figure 6).

4. Hang the upper panel on the mounting frame hanger. Align holes in the panel with the holes in the mounting frame. Be sure that

panel is engaged with hanger at top of frame before releasing it.

5. Install the fountain. Mount the fountain to the upper panel and the wall frame with (4) 1/4" x 3/4" (19mm) long bolts and nuts

(provided). Tighten securely.

6. Remove elbow from end of p-trap and attach it to drain tube. Re-attach elbow to p-trap and cut waste tube to required length

using plumbing hardware and trap as a guide.

7. ERPA MODELS: Make connections between remote chiller outlet tube and fountain strainer. Outlet port is marked on the chiller

(3/8" O.D. copper tube). Install a 3/8" tee (provided) on the marked chiller outlet port. Insert the 3/8" unplated copper water lines

(provided) into the tee and the inlet sides of the strainers by pushing it in until it reachs a positive stop, approximately

3/4" (19mm). Connect 1/4" copper tubing coming from fountain to the strainer. Turn on water supply and check for leaks. DO NOT

SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE O-RINGS MAY RESULT. (See Figure 5).

LKTEA MODEL: Make connections between remote chiller outlet tube and fountain strainer. Outlet port is marked on the chiller

(3/8" O.D. copper tube). Install a 3/8" tee (provided) on the marked chiller outlet port. Insert the 3/8" unplated copper water lines

(provided) into the tee and the inlet sides of the strainers by pushing it in until it reaches positive stop, approximately

3/4" (19mm). Connect 1/4" copper tubing coming from fountain to the strainer. Turn on water supply and check for leaks. DO NOT

SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE O-RINGS MAY RESULT. (See Figure 6).

8. These products are designed to operate on 20-105 PSIG supply line pressure. If inlet pressure is above 105 PSIG, a pressure

regulator must be installed in the supply line. Any damage caused by reason of connecting these products to supply line

pressures lower than 20 PSIG or higher than 105 PSIG is not covered by warranty.

9. Make electrical connections to the chiller. See chiller instructions.

10. Check stream height from bubbler. Stream height is factory set at 35 PSI. If supply pressure varies greatly from this, turn

adjustment screw on regulator (Item 12). Clockwise adjustment will raise stream height and counter-clockwise

will lower stream height. For best adjustment stream should hit basin approximately 6 1/2" from the bubbler.

11. Mount lower panel. Loosen the (2) #10-24 x 5/8" (16mm) screws at frame bottom lip. Slide upper tongue of lower panel under

lower edge of already installed upper panel. Tighten previously loosened screws securely.

12. Replace bottom access panel to fountain basin using screws provided. Tighten securely.

TROUBLE SHOOTING AND MAINTENANCE

1. Orifice Assy: Mineral deposits on orifice can cause water flow to spurt or not regulate. Mineral deposits may be removed

from orifice with a small round file not over 1/8" diameter or a small diameter wire. CAUTION: Do not file or cut orifice materials.

2. Stream Regulator: If orifice is free of material deposits, regulate flow according to instruction 10 stated above.

3. Actuation of Quick Connect Water Fittings: Cooler is provided with lead-free connectors which utilize an o-ring water

seal. To remove tubing from the fitting, relieve water pressure, push in on the gray collar while pulling on the tubing (See Fig. 2)

To insert tubing, push tube straight into the fitting until it reaches a positive stop, approximately 3/4".

ERHPA28C/ERHP28RAC TUBE ROUTING

TO BUBBLER

33

30

CHILLER

OUTLET

TO BUBBLER

33

31

CHILLER

INLET

TO BUBBLER

LKTEA8C/LKTEA8RAC TUBE ROUTING

TO BUBBLER

33

30

CHILLER

OUTLET

32

33

WATER

INLET

FIG. 5

PAGE 3

FIG. 6

97679C (REV. B - 02/02)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

NS

NS

PART NO.ITEM NO.

51349C

40322C

50934C

50168C

75580C

21696C

21708C

112627543890

21695C

50986C

40045C

61314C

15005C

75555C

50198C

70379C

70278C

70378C

21705C

70002C

40206000

70023C

22490C

51294C

51299C

70792C

70818C

70822C

70823C

70852C

70745C

70683C

55996C

28191C

28193C

111008343890

27026C

55001083

55001082

56092C

62177C

74070002

70018C

LH ADA

RH ADA

ERHPA2-8C ERHPA2-8RAC LKTEA8C LKTEA8RAC

PARTS LIST

DESCRIPTION

Bubbler Assembly

Orifice Assembly

Housing Assembly

Pedestal

Bubbler Locknut

Bracket - Push Bar Mounting

Push Bar Assembly

Screw - #10-24 x .50 PHTC

Lever - Push

Holder-Regulator

Hex Nut

Regulator

Retaining Nut

Clip

Bushing - Nylon

Rod - Pivot

Rod - Pivot

Rod - Push

Clip - Push Rod

Screw - #10 X .50 HHSM

Retainer

Set Screw

Filter Mounting Bracket

Filter Head Assy

Filter Assy

Screw - #8-18 x .75" PH

Elbow - 3/8" (10mm)

Fitting - Superseal 1/4" (6mm)

Fitting - Superseal 3/8" (10mm)

Tee - 3/8

Union - 3/8 X 1/4

Union - 1/4 X 1/4

Strainer

Upper Panel - RH ADA

Upper Panel - LH ADA

Screw - #10-24 X .62 HHMS

Lower Panel

FTN Body Assembly - Long

FTN Body Assembly - Short

Poly Tubing (Cut to Length)

Tube - CU 1/4" X 12.00

Screw - 1/4-20 X .75 PHMS

Nut - Hex 1/4-20

17

19

FIG. 7

FIG. 8

16

24

28

26

23

27

29

25

1

22

9

5

6

12

11

21

15

13

ELKAY MANUFACTURING COMPANY 2222 CAMDEN COURT OAK BROOK, IL 60523 630.574.8484

97679C (REV. B - 02/02)

7

18

20

10

15

40

FIG. 9

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

PAGE 4

14

20

14

8

39

Loading...

Loading...