Page 1

No Lead Single Station Soft Sides®Water Cooler

®

SPECIFICATIONS

ENERAL

G

Single station barrier-free stainless steel water cooler has

recessed in-the-wall refrigeration system and stainless steel

grill. All stainless steel polished to a satin finish.

Fountain has contoured basin to minimize splashing. Flexi-

®

Guard

vandal-resistant front push button. Flow regulator provides

constant stream from 20 to 105 psi water pressure. Vandalresistant bottom cover plate included.

E

ank continuous-tube type evaporator, refrigerant drier, and

t

c

T

M

WHEN PROPERLY INSTALLED.

NO LEAD DESIGN

THIS WATER COOLER COMPLIES WITH THE LEAD-FREE

DEFINITION IN THE SAFE DRINKING WATER ACT OF

1986 AND LEAD CONTAMINATION CONTROL ACT OF 1988.

Elkay Water Coolers are manufactured with a waterway system utilizing copper components and completely lead-free

material. These waterways have no lead because all lead

materials, such as leaded brass, have been removed. All

joints are brazed using silver solder only. No lead solder is

permitted. A strainer with an easily cleanable screen is provided to allow trapping and convenient removal of waterborne

particulate of 140 microns and larger prior to their entry into

the water cooler.

CAPACITIES CHART

**Based on 80°F inlet water temperature.

†Glass filler available at extra cost. Requires factory preparation to receive glass

filler. Order Model ERFPM8FK. Glass filler LK1110 or LK1114 sold separately.

Rated watts shown are based on operational (run) time, in compliance with A.R.I.

Standard 1010 conditions. Specific applications will determine the actual watts

consumed per hour. Watts consumed will be based on number of people

served per hour (usage), ambient temperatures, and inlet water temperature.

COOLING SYSTEM

Motor Compressor: Hermetically sealed, reciprocating type,

115V, 60 Hz or 230V, 50 Hz (International Model) single phase.

Sealed in lifetime oil supply.

Condenser: Fan cooled, copper tube with aluminum fins. Fan

motor is permanently lubricated.

Cooling Unit: Combination tube-tank type. Self cleansing. Tube

portion is continuous coil of copper tubing. Tank is stainless

steel. Fully insulated with EPS foam which meets Underwriters

Laboratories Inc. requirements for self extinguishing material.

Temperature Control: Enclosed adjustable thermostat is

factory preset. Requires no adjustment other than for altitude

requirements.

Refrigerant Control: Refrigerant HFC-134a is controlled by

accurately calibrated capillary tube for positively trouble-free

performance.

safety bubbler and easy to operate, fully functional,

nergy efficient refrigeration system utilizes a combination

apillary tube.

HIS WATER COOLER COMPLIES WITH THE REQUIRE-

ENTS OF A.D.A. (AMERICANS WITH DISABILITIES ACT)

**GPH of 50°F Drinking Water

Model Base

Number Rate 70°F 80°F 90°F Watts Amps Option Lbs.

ERFPM8K 7.5 9.3 8.3 7.5 370 4.0 Yes 83

Room Temperature °F

Full Glass† Ship.

Rated Load Filler Wt.

Wall Mount – Barrier-Free Access

Model ERFPM8K

Model ERFPM8K

CONSTRUCTION

Fountain Body: #18 gauge, type 304 nickel bearing stainless

steel polished to a lustrous satin finish with high shined outer

edge. Contoured basin offers large strike area to minimize

splashing. Fully functional front push button is easy to operate.

®

Exclusive Flexi-Guard

utilizes a pliable polyester elastomer to prevent accidental

mouth injuries. Flexes on impact, then returns to original position. Strong. Abrasion-resistant. Anti-sweat. Optional

Vandal-Resistant Bubbler available at extra cost. Heavy

duty, one-piece construction, chrome plated brass. Order

Model Number ERFPVR8K. Bubbler meets UL requirements

and all sanitary codes and are keyed in location to prevent

rotation.

Front Panel Grill: Made of type 304 stainless steel, polished

to a uniform Elkay satin finish. Removable louvered ventilating grill encloses refrigeration unit and plumbing.

Wall Mounting Frame: MF100 frame furnished with each

unit. Frame allows flush mounting to finished wall.

Drain: LK464 drain and trap assembly included.

Protected by Elkay’s 5 Year Limited Warranty on the refrig-

eration system of the unit.

Elkay Pressure-Type Water Coolers are designed to operate

on 20 psi to 105 psi supply line pressure. If inlet pressure is

above 105 psi, a pressure regulator must be installed in the

supply line. Any damage caused by reason of connecting this

product to supply line pressures lower than 20 psi or higher

than 105 psi is not covered by the warranty.

STANDARDS

Elkay Electric Air Cooled Water Coolers are listed

by Underwriters Laboratories Inc. and comply with

both Canadian and U.S. requirements.

These units comply with A.R.I. Standard 1010.

This cooler is certified by WQA to lead-free compliance including

NSF/ANSI 61-ANNEX G, AB 1953.

Safety Bubbler: Innovative design

In keeping with our policy of continuing product improvement, Elkay reserves the right to change

product specifications without notice. Please visit elkayusa.com for most current version of Elkay

product specification sheets.

Elkay

elkayusa.com

2222 Camden Court

Oak Brook, IL 60523

This specification describes an Elkay product with design, quality and functional benefits to the

user. When making a comparison of other producers’ offerings, be certain these features are not

overlooked.

Printed in U.S.A.

©2011 Elkay

(Rev. 4/11) 12-14H

Page 2

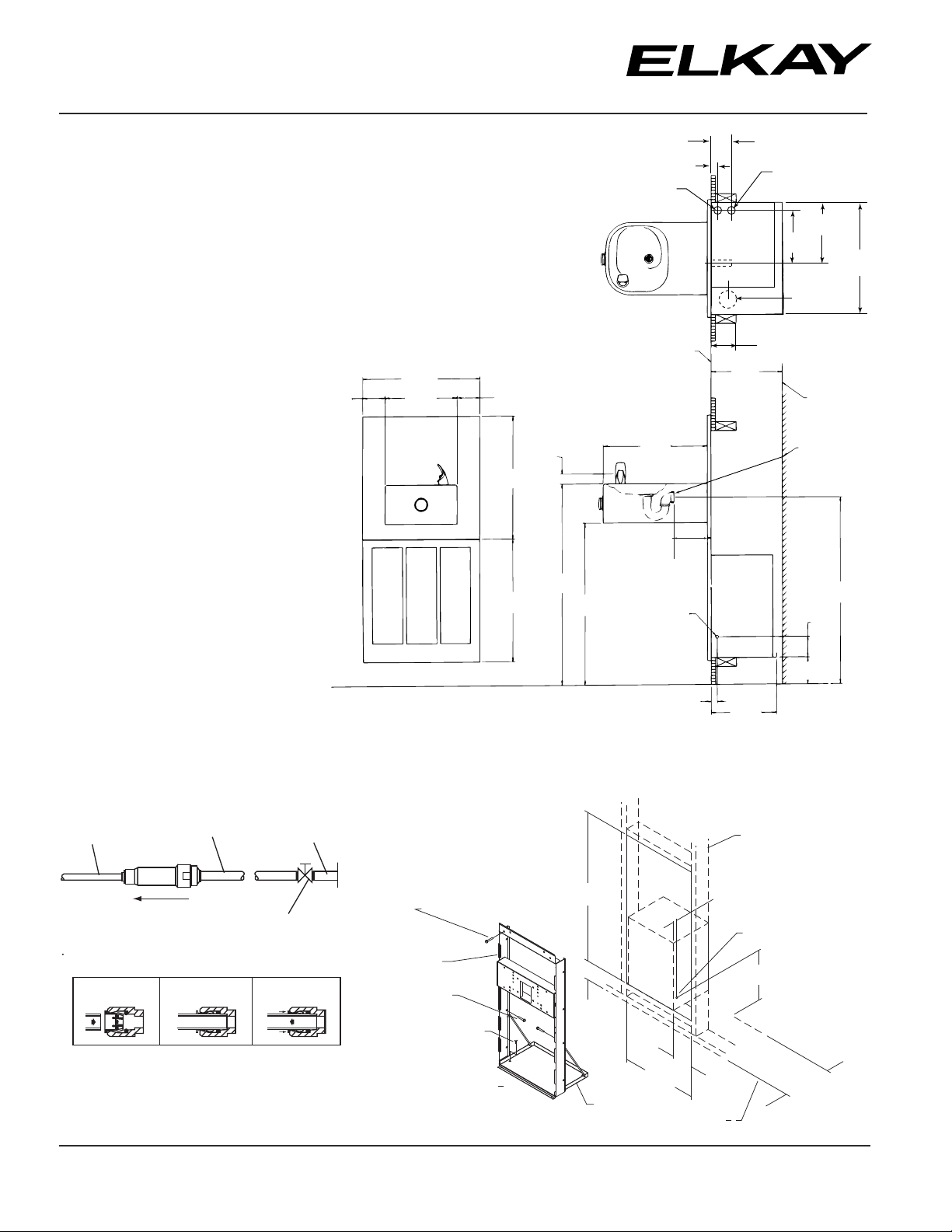

1/4" O.D. TUBE CONNECT

(CHI LLER WAT ER OUT LET)

8-1/8"

(206mm)

9-3/8"

(238mm)

18-3/4"

(476mm)

3-1/8"

(80mm)

1-1/8"

(29mm)

3/8" O.D. TUBE CONNECT

(CHI LLER WAT ER INL ET)

SHUT OFF VALVE BY OTHERS

FILTER LOCATION

(OPTIONAL)

WALL LINE

12"

(305mm)

MINIMUM DEPTH

BACK WALL L INE

4" (102mm)

1

-1/4" (32mm)

TRAP FURNISHED

31-1/4"

(794mm)

3-1/2"

(89mm)

4-1/2"

(114mm)

11"

(279mm)

1-1/8"

(29mm)

ELECTRICAL INLET

18"

(457mm)

*

A.D.A. REQUIREMENT

33-1/2"

(851mm)

FINISHED FLOOR

20-7/16"

(519mm)

20-3/8"

(517mm)

3-13/16"

(97mm)

19-3/4"

(

502mm)

1

2-1/8"

(308mm)

3-13/16"

(97mm)

1

-5/8"

(42mm)

27"

*

(

686mm)

7-1/16"

(179mm)

NOTE: SERVICE STOP NOT INCLUDED.

NOTE: WATERFLOW

DIRECTION

SERVICE STOP

(NOT FURNISHED)

3/8" O.D. TUBE CONNECT

COLD WATER SUPPLY

1/4" O.D. TUBE

WATER INLET

TO COOLER

BUILDING WATER

INLET

NOTE: WATERFLOW

DIRECTION

SERVICE STOP

(NOT FURNISHED)

3/8" O.D. TUBE CONNECT

COLD WATER SUPPLY

1/4" O.D. TUBE

WATER INLET

TO COOLER

BUILDING WATER

INLET

No Lead Single Station Soft Sides®Water Cooler

®

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

AB

C

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

AB

C

BEFORE INSTALLING IN OPENING

(P/N 111008343890) IN FRAME

INSTALL (2) SCREWS

FRAME

(10 REQ'D-NOT PROVIDED)

5/16" SCREWS OR BOLTS

(NOT PROVIDED)

SCREWS OR BOLTS

P/N 101567443730

HOOK RODS (2)

P/N 27638C

CHILLER SHELF

(25mm)

1"

LOCATION ON CHILLER

ELECTRICAL INLET

WOOD OR STEEL

FRAME SHOWN

(NOT PROVIDED)

FLOOR LINE

TO FLOOR LINE

(203mm)

8"

MIN DEPTH

BE 12" (305mm)

BACK OF WALL TO

(130mm)

5-1/8"

(476mm)

18-3/4"

(114mm)

4-1/2

(959mm)

37-3/4"

Wall Mount – Barrier-Free Access

Model ERFPM8K

IMPORTANT!

NSTALLER PLEASE NOTE:

I

he grounding of electrical equipment such as tele-

T

hone, computers, etc., to water lines is a common

p

rocedure. This grounding may be in the building or

p

ay occur away from the building. This grounding

m

an cause electrical feedback into a water cooler,

c

reating an electrolysis which causes a metallic

c

aste or an increase in the metal content of the water.

t

his condition is avoidable by using the proper

T

aterials as indicated below.

m

he drain fittings which are provided by the installer

T

hould also be plastic to electrically isolate the cooler

s

rom the building plumbing system.

f

RFPM8K MOUNTING FRAME INSTRUCTIONS

E

1. Cut a square rectangular wall opening 18-3/4"

(476mm) W x 37-3/4" (959mm) H and 4-1/2"

(114mm) above the floor line. These dimensions

are required to obtain proper rim and bubbler

heights for compliance with ANSI standard

A117.1. (See Figure 2)

2. Reinforce the wall opening on all sides so that it

will adequately support the water fountain. This

reinforcement must support up to 150 lbs static

load and provide a means for securing the frame

assembly in place.

NOTE: Building construction must allow for adequate air flow on both sides and top of remote

chiller unit. Minimum of 4" (102mm) is required.

(See Figures 1 & 2)

3. Install plumbing and electrical rough-ins.

See Figure 1 for location of the supply water inlet

to chiller and for the location of the waste water

outlet. A junction box for a (3) wire, 10 amp branch

circuit is provided on the inside of the chiller.

(Standard 120 Volts, 60 Hz and single phase) See

Figure 2 for the electrical inlet location.

4. Remove frame and related hardware from

packaging. Release the two shelf rods by cutting

cable ties. Install the frame squarely in wall

opening with frame upright edges flush with the

finished wall face. (See Figure 2) Place shelf

inside frame and line up the (2) holes on each.

Insert loose ends of rods into holes on sides of

shelf panel. Using appropriately sized wood

screws (not provided), fasten the shelf and frame

to bottom of wall opening. (See Figure 2) Secure

the frame sides and top to the wall using (10)

5/16" x 2" lag bolts or screws (not provided).

NOTE: Be sure that frame is squared in location.

Do not use less than the required screw quantity

and size.

FIG. 1

ROUGH-IN DIMENSIONS

Elkay

12-14H (Rev. 4/11)

FIG. 2

2222 Camden Court

Oak Brook, IL 60523

elkayusa.com

Printed in U.S.A.

©2011 Elkay

Loading...

Loading...