Elka P 2500, P 3500, P 3000, P 4000, P 5000 Installation And Operating Instructions Manual

...Page 1

Installation and operating instructions

(UL/CSA)

Barriers P 2500 - P 5000

Part 1

Installation

Translation of original installation and operating instructions

D-ID: V1_6 – 01.16

Page 2

0

P 2500 - P 500

Index of contents

1 Preface 3

1.1 General notes 3

1.1.1 Symbol explanation 4

1.2 Copyright 4

1.3 Information regarding installation instruction 4

2 Safety 5

2.1 General notes on safety 5

2.2 Notes on safety for the operation 5

2.3 Notes on safety for the operation with radio remote control 5

2.4 Intended use – Vehicle traffic 6

2.5 Danger, which could emanate from the site of operation 6

2.6 Non-factory technical alterations and extensions 6

2.7 Personnel requirements – professional skills, knowledge and

qualifications 7

2.8 Personal protective equipment 7

2.9 Hazard warnings inside the barrier 8

3 Transportation and storing 11

3.1 Transportation inspection 11

3.2 Scope of delivery P 2500-5000 11

3.3 Storing 12

3.4 Lifting heavy loads 12

4 Declaration of incorporation 13

4.1 Installation information for partly completed machinery 14

4.2 Declaration of conformity 14

4.3 Name plate 14

5 Function description 15

6 Technical data P 2500-5000 16

7 Installation P 2500-5000 18

7.1 Tools 18

7.2 Mounting dimensions 19

7.3 Foundation 20

7.4 Opening / closing the housing 23

7.5 Boom connector 24

7.5.1 Installation – Boom connector left side 26

7.6 Barrier boom 27

7.7 Balancing springs 28

7.8 Opening and closing times 32

1

Page 3

0

2

P 2500 - P 500

7.9 Accessories 33

7.9.1 Swinging support P 4000 - P 5000 33

7.9.2 Fixed support P 4000 - P 5000 34

7.9.3 Fixed support with electromagnet 35

7.9.4 LED boom lighting 37

7.10 Emergency release 38

7.11 Vandalism 38

8 Terminal row 41

8.1 Interior view 41

8.2 Mains connection 41

8.3 Controller terminal row 43

8.4 Circuit diagram 46

9 Barrier maintenance 53

10 Layout (exploded drawing) 54

Page 4

0

3

1 Preface

1.1 General notes

These operating instructions must be available on site at all times. It should be

read thoroughly by all persons who use, or service the products. Improper

usage or servicing or ignoring the operating instructions can be a source of

danger for persons, or result in material damage. If the meaning of any part of

these instructions isn’t clear, then please contact ELKA-Torantriebe GmbH u.

Co. Betriebs KG before you use the product.

This applies to all setup procedures, fault finding, disposal of material, care

and servicing of the product. The accident prevention regulations and

applicable technical regulations (e.g. safety or electrical) and environment

protection regulations of the country in which the product is used also apply.

All repairs on the protuct must be carried out by qualified persons. ELKATorantriebe GmbH u. Co. Betriebs KG accepts no liability for damage which is

caused by using the product for purposes other than those for which it is built.

ELKA-Torantriebe GmbH u. Co. Betriebs KG cannot recognise every possible

source of danger in advance. If the product is used other than in the

recommended manner, the user must ascertain that no danger for himself or

others will result from this use. He should also ascertain that the planned use

will have no detrimental effect on the product itself. The product should only

be used when all safety equipment is available and in working order. All faults

which could be a source of danger to the user or to third persons must be

eliminated immediately. All warning and safety notices on the products must

be kept legible.

The electrical periphery equipment must comply with local regulations /

legislation. Only the use of ELKA accessories and original ELKA spare parts is

allowed. In case of any contravention ELKA disclaims liability of any kind.

INFORMATION!

The operation of the system must also be conformant with the safety-relevant

directives and standards.

We reserve the right to make technical improvements without prior notice.

P 2500 - P 500

Page 5

0

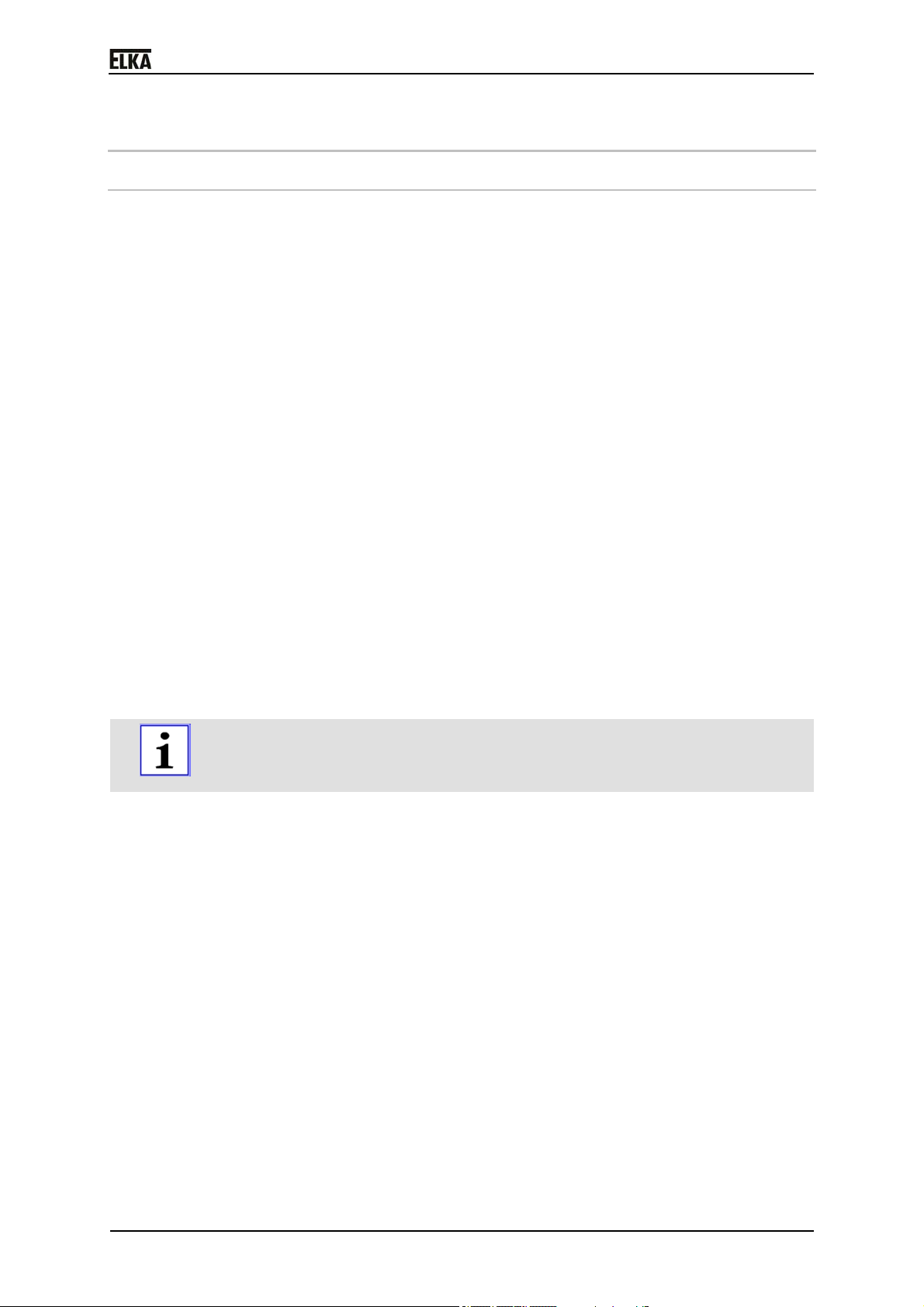

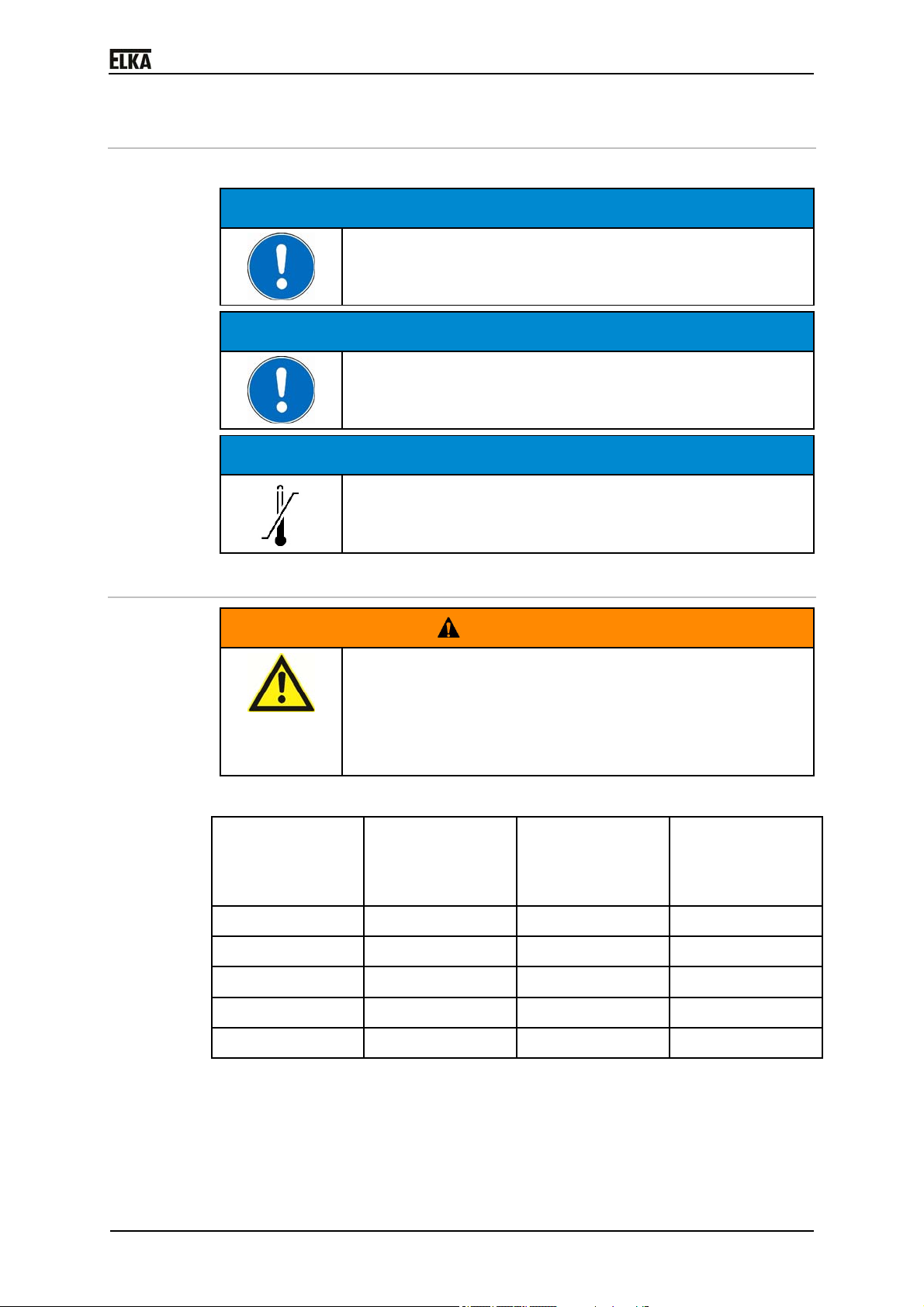

1.1.1 Symbol explanation

Remarks regarding the safety of persons and the gate opener itself are

marked by symbols. These remarks have to be absolutely observed in order to

avoid accidents and material damage.

…points to an imminent dangerous situation, which can

cause death or serious injuries if it is not avoided.

…points to a potentially dangerous situation, which can

cause death or serious injuries if it is not avoided.

…points to a potentially dangerous situation, which can

cause minor or slight injuries if it is not avoided.

P 2500 - P 500

DANGER!

WARNING!

CAUTION!

CAUTION!

…points to a potentially dangerous situation, which can

cause property damage if it is not avoided.

REMARK!

Important notice for installation or functioning.

1.2 Copyright

The operating manual and the contained text, drawings, pictures, and other

depictions are protected by copyright. Reproduction of any kind – even in

extracts – as well as the utilization and/or communication of the content

without written release certificate are prohibited. Violators will be held liable for

damages. We reserve the right to make further claims.

1.3 Information regarding installation instruction

This document is to be used as installation instruction for partly completed

machinery (according to machinery directive 2006/42/EG, article 13, (2)).

4

Page 6

0

5

2 Safety

2.1 General notes on safety

The valid regulations and standards have to be observed during installation

and operation, e.g. DIN EN 13241-1, DIN EN 12445, DIN EN 12453 etc. Only

the use of spare parts made by the original manufacturer is allowed.

Do not put a defective barrier into operation.

After set-up (installation) every user of the equipment has to be instructed

about the operation and function of the barrier.

In order to reduce the risk potential related to the movement of the barrier

boom, additional optical and/or acoustical warning devices should be installed.

2.2 Notes on safety for the operation

Children and not instructed persons are not allowed to operate the barrier.

No persons, objects, or animals are allowed within the range of the barrier

movement during opening or closing.

Never reach into moving parts of the barrier.

Drive through the barrier only after complete opening.

The barrier has to be secured depending on the type of usage, corresponding

to the valid standards and regulations.

The safety devices have to be checked regularly for functioning according to

the standards and regulations, at least twice a year.

P 2500 - P 500

2.3 Notes on safety for the operation with radio remote

control

The radio remote control should only be used, if the area of movement of the

barrier is always completely visible by the operator and thus it is assured, that

no person, object, or animal is present within this range of movement.

The radio remote control transmitters have to be carefully kept, so that an

unintentional use is impossible.

Radio remote controls should not be operated at radio-technical sensitive

locations, like airports or hospitals.

Interferences by other (properly operated) radio communication installations,

which are used within the same frequency range, cannot be ruled out.

Page 7

0

6

2.4 Intended use – Vehicle traffic

The operational safety can only be ensured when the barrier is used as

intended.

After installation, the barriers of series P 2500-5000 serve as passage control

of vehicle paths exclusively of usage class Vehicular III and IV.

CAUTION!

Danger of impact and crushing!

With inadequate safety measures the movement of the

barrier boom can result in impact or crushing points

between the boom and solid objects within the movement

area.

In order to reduce the risk potential by a moving barrier

arm, additional safety devices of type B1 or B2

according to UL 325 (see table 31.1 of UL 325) should

be installed. The internal entrapment protection system

of the barrier P 2500-5000 corresponds to type A.

Two independent entrapment protections must be

installed before commissioning.

For the reversal of the gate, P541 must be set to "1"

andP542 must be set to "0". See "Installation and

operation instructions Part 2" sec. 2.2.5.6 and 2.2.5.7.

The gate operator must be equipped with an audio

alarm. See "Installation and operation instructions Part2"

The controller is a product component and serves to control the barrier.

Any use above and beyond the above mentioned use is prohibited and

constitutes improper use.

sec. 2.2.5.11.

P 2500 - P 500

2.5 Danger, which could emanate from the site of operation

The barriers P 2500-5000 operate with moving parts.

WARNING!

Rotating and/or linear movable components can cause

serious injuries.

Do not reach into moving parts or handle any moving

components during operation.

Turn the appliance off before any maintenance work,

repair work or other work and secure it against

2.6 Non-factory technical alterations and extensions

Non-factory technical alterations and/or extensions may result in hazards as

well as interfere with the function of the barrier.

unintentional restarting.

Page 8

0

7

P 2500 - P 500

DANGER!

Danger through voltage!

Risk of death by electric shock!

Technical alterations may only be performed by skilled

personnel and only according to the manufacturer’s

instructions.

CAUTION!

Danger of injury through defective components!

Mechanical and electrical alterations can influence the

functioning of the barrier!

Technical alterations may only be performed by skilled

personnel and only according to the manufacturer’s

instructions.

CAUTION!

Malfunctioning of the barrier!

Mechanical and electrical alterations can influence the

functioning of the barrier!

Technical alterations may only be performed by skilled

personnel and only according to the manufacturer’s

instructions.

2.7 Personnel requirements – professional skills, knowledge

and qualifications

WARNING!

Risk of injury through inadequate qualification!

Improper handling during installation, maintenance, repair

work or dismantling can result in personal injury and/or

property damage.

Work during installation, maintenance, repair and

dismantling must be performed by skilled personnel

Specialist - is a person with suitable professional training, knowledge and

experience, who can recognize and avoid danger.

Instructed person - is a person, which was instructed in the operation and

use of the barrier.

only.

2.8 Personal protective equipment

During installation, maintenance, repair work and dismantling of the barrier

suitable personal protective equipment must be worn.

Page 9

0

8

P 2500 - P 500

CAUTION!

Bruising/jamming/driving over (e.g. by material

handling equipment, industrial trucks) the feet,

contusion by falling heavy objects, cutting injuries by

stepping into pointed/sharp objects.

Foot injuries

Wearing of suitable safety shoes during the installation,

maintenance, repair work and dismantling protects

against serious foot injuries with long-lasting

consequences.

CAUTION!

Falling heavy objects hitting the head

Head injuries

Wearing of a suitable safety helmet during the

installation, maintenance, repair work and dismantling

protects against serious head injuries with long-lasting

consequences.

CAUTION!

Cutting injuries resulting from pointed/sharp objects

Hand injuries

Wearing of suitable safety gloves during the installation,

maintenance, repair work and dismantling protects

against serious hand injuries with long-lasting

consequences.

CAUTION!

Injuries resulting from drilling chips or saw dust

Eye injuries

Wearing of suitable safety goggles during the installation

and repair work protects against serious eye injuries

with long-lasting consequences.

2.9 Hazard warnings inside the barrier

WARNING!

Personal injuries and/or property damage

Danger of accidents resulting from illegible or removed

safety instruction labels.

Immediately renew illegible or removed safety

guidelines.

Page 10

0

9

P 2500 - P 500

WARNING!

Danger of impact and crushing!

During the barrier movement, energy is saved in the

springs. The springs are not tight and thus energy-free only

in barrier position OPEN.

Mount and dismount the springs in barrier position

OPEN only. If necessary open the barrier by mechanical

emergency release and move the barrier manually into

position OPEN.

WARNING!

Risk of crushing

During the barrier movement crushing points arise at many

points of the barrier mechanics.

Before installation, maintenance or repair work at the

barrier mechanics turn the power supply off and secure

it against unintentional restarting.

WARNING!

Danger through voltage!

Danger of an electric shock.

Before installation, maintenance or repair work at the

barrier mechanics turn the power supply off and secure

it against unintentional restarting.

WARNING!

Danger of impact!

Accident hazard by barrier boom movement.

Keep a sufficient safety distance (min. 19.7in) during the

barrier movement

Children are not allowed to play within the barrier area

or operate the barrier.

Opening and closing of the barrier is only allowed with

the barrier in view. No persons or objects are allowed in

the danger zone.

WARNING!

Danger of crushing!

Crushing points arise at many areas of the barrier

mechanics during the barrier movement.

Disconnect the barrier from the power supply before

installation, maintenance or repair work at the barrier

mechanics and secure against reactivation.

Page 11

0

0

P 2500 - P 500

WARNING!

Improper operation, inadequate maintenance or non

observance of the notes on safety!

Improper operation, inadequate maintenance or non

observance of the notes on safety indicated in this manual

may lead to danger to persons or material damage.

Should a part of the manual be unclear or should any

instructions, procedures or safety guidelines not be

clearly comprehensible, please contact ELKA

Torantriebe GmbH u. Co. Betriebs KG, before putting

the barrier into operation.

1

Page 12

0

3 Transportation and storing

3.1 Transportation inspection

The shipment has to be inspected for transportation damage immediately after

receipt. In case of any damage record the type and extent on the delivery

receipt or refuse acceptance.

Inform ELKA-Torantriebe immediately in the event of damage.

In case the above points are not observed claims will be denied due to

insurance regulations.

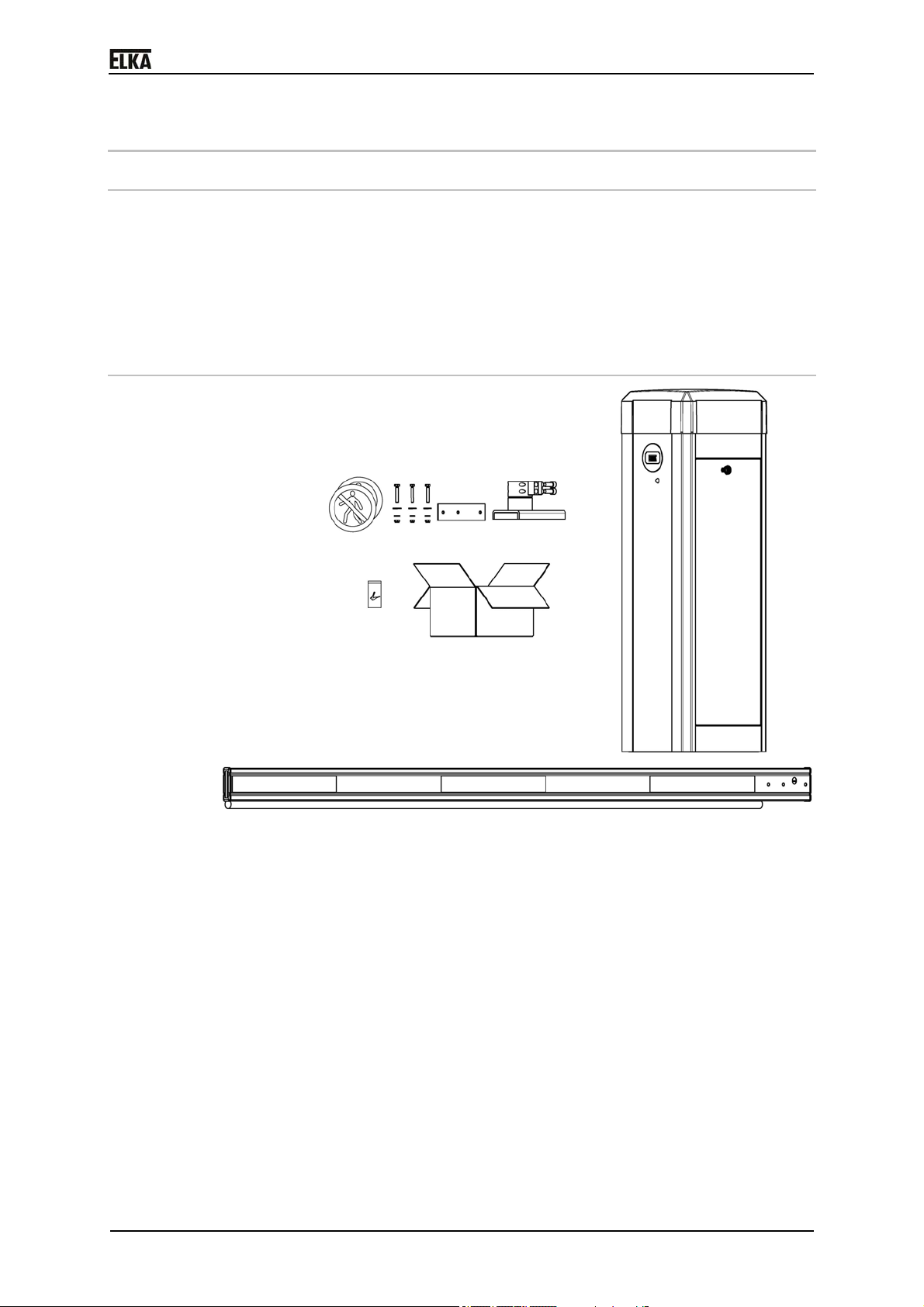

3.2 Scope of delivery P 2500-5000

P 2500 - P 500

Drawing 1

Scope of delivery:

1x barrier model P 2500-5000

1x barrier boom

2x keys (in a pouch) for the access panel

1x accessory box with:

- 2x warning signs "No passage for pedestrians"

- 3x plastic screws or 3x steel screws for P 5000 incl. washers and nuts

for the boom connection

- 1x boom connector incl. reinforcement plate and fastening screws

11

Page 13

0

2

3.3 Storing

The barrier has to be stored as follows:

P 2500 - P 500

CAUTION!

Do not expose the barrier to aggressive substances.

Do not expose the barrier to heat sources.

Storage temperature -30°C to +70°C / -22°F to +158°F.

3.4 Lifting heavy loads

Risk of injury by lifting heavy loads!

Lifting heavy loads may cause serious injuries.

Never lift the barrier single-handedly.

To lift the barrier, use a suitable lifting device.

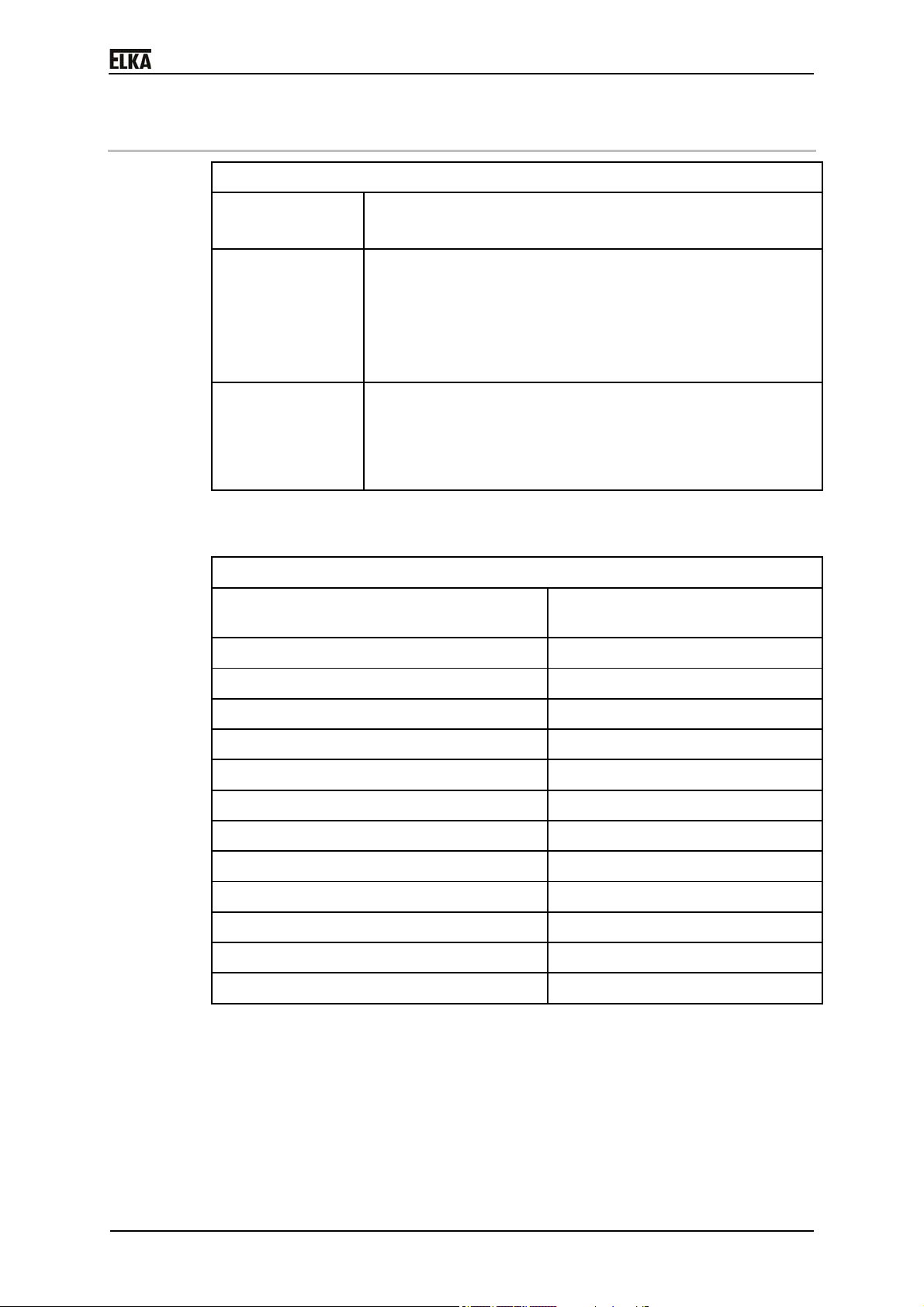

Barrier model Weight barrier

Wear suitable safety shoes.

without boom

[lb]

CAUTION!

CAUTION!

WARNING!

Weight standard

boom / round

boom

[lb]

Total(with

standard boom /

round boom)

[lb]

P 2500 125.7 8.4 / 4.4 134.1 / 130.1

P 3000 127.8 9.9 / 5.3 137.7 / 133.1

P 3500 127.8 11.0 / 6.2 138.8 / 134,0

P 4000 130.1 12.8 / 7.1 142.9 / 137.2

P 5000 132.3 22.1 / --- 154.4 / ---

Table 1

1

Page 14

0

3

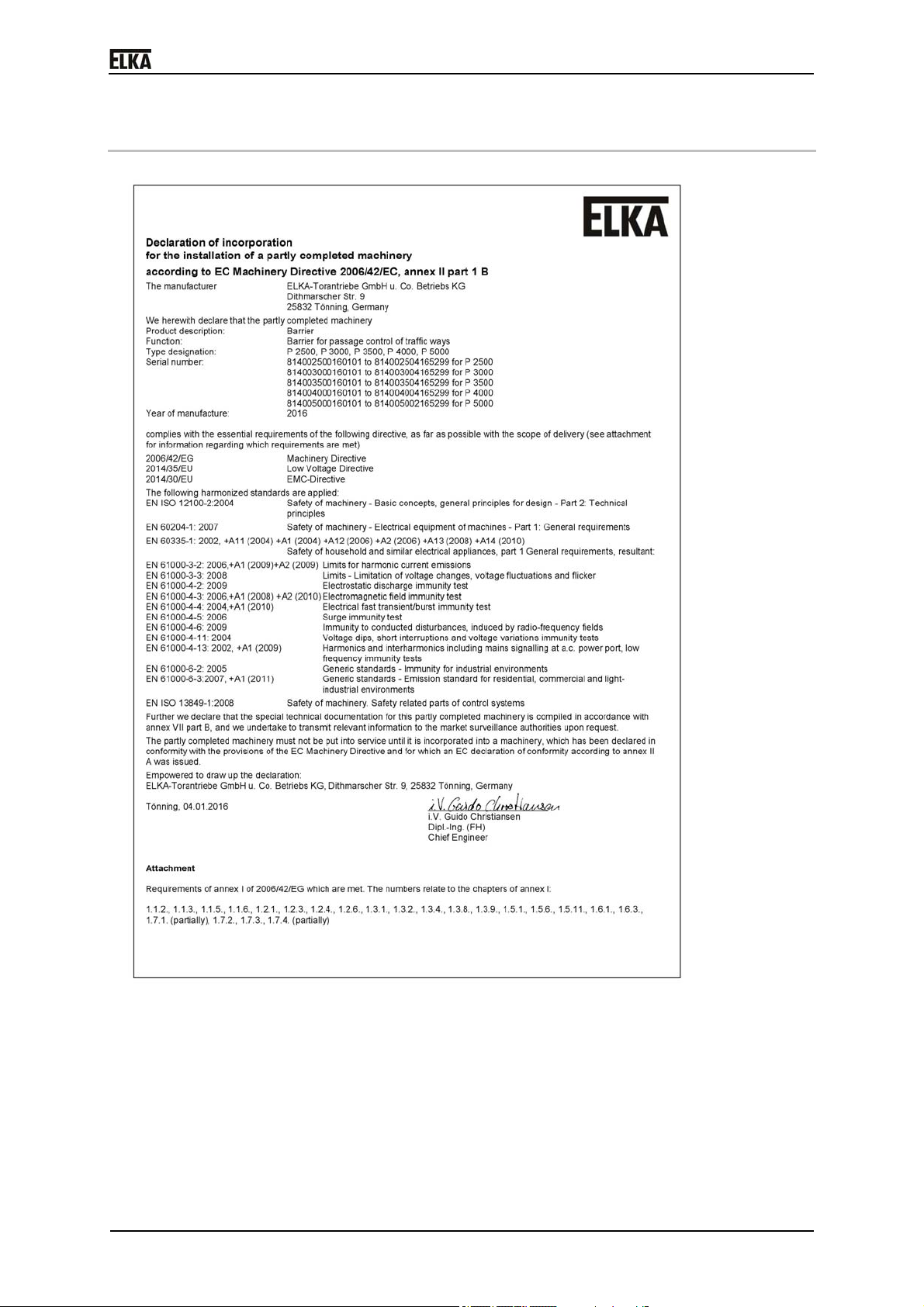

4 Declaration of incorporation

P 2500 - P 500

Drawing 2

1

Page 15

0

P 2500 - P 500

4.1 Installation information for partly completed machinery

The partly completed machinery must not be put into service until the

final machinery into which it has to be incorporated has been declared

inconformity with the provisions of the machinery directive.

The safety functions of the controller comply with EN ISO 13849-1:2008 Kat.2

PLc.

DANGER!

Not-disengeable power supply

Risk of death by electric shock

According to EC Directive 2006/42/EG the mains supply

has to be equipped with an all-pole circuit breaker.

DANGER!

Danger through voltage!

Danger of an electric shock.

Only certified electricians should connect the barrier to

the mains supply.

CAUTION!

Danger of crushing and shearing!

With inadequate safety measures the movement of the

barrier boom can result in impact or crushing points

between the boom and solid objects within the movement

area.

According to DIN EN 12453, for an application with

pedestrian traffic, depending on the type of use and type

of activation, suitable safety devices have to be installed

additionally, in order to provide the minimum level of

protection.

4.2 Declaration of conformity

Minimum clearances to solid objects must be observed.

After the installation an EG-declaration of conformity according to ECmachinery directive 2006/42/EG for the complete system has to be issued by

the person responsible for the integration (according to product standard DIN

EN 13241-1).

4.3 Name plate

The name plate of the barrier is attached at the inside front of the barrier

housing.

14

Page 16

0

5

5 Function description

Barriers serve as passage control of vehicle paths. By raising and lowering of

the barrier boom the passage is granted or obstructed.

For a boom length of 157.48in we recommend the use of a fixed or swinging

support, for a boom length of more than 157.48in the use of a fixed or

swinging support is mandatory.

The controller offers the possibility to activate the barrier by radio remote

control.

The controller is able to observe the max. permitted force which was set

before in the learning sequence. If during the closing movement more force is

needed, the barrier reverses. Additionally several different safety features, e.g.

photoelectric barriers, can be connected.

CAUTION!

Danger of impact and crushing!

With inadequate safety measures the movement of the

barrier boom can result in impact or crushing points

between the boom and solid objects within the movement

area.

In order to reduce the risk potential related to the

movement of the barrier boom, additional optical and /

or acoustic warning devices should be installed.

P 2500 - P 500

1

Page 17

0

6

6 Technical data P 2500-5000

Range of application

P 2500 - P 500

Application for…

Parking garages, parking areas and camping sites

Company entrances

Drive pulse

from...

TCP/IP

RS485

Push button, card reader, desktop panel etc.

Transmitter (radio remote control)

Induction loops

Safety

Force monitoring for barrier CLOSE

Emergency release / vandalism protection

Internal evaluation for safety contact profile (8.2kOhm)

Connection of external safety systems

Table 2

General data

Supply voltage 120VAC

60Hz

Current consumption Max. 2.8A

Duty cycle 100%

Temperature range -30°C to +50°C / -22°F to +122°F

Controller MO 24

Housing dimensions (L/W/H) 14.14 x 11.81 x 43.34in

Foundation (frost-free) 21.65 x 19.96 x 31.50in

Boom connector Left or right

Housing Aluminium

Mechanics Steel, galvanized

Sound pressure level (distance 1m) ≤ 60 dB(A)

Degree of protection IP 54

Protection class 1

Table 3

1

Page 18

0

7

P 2500 - P 500

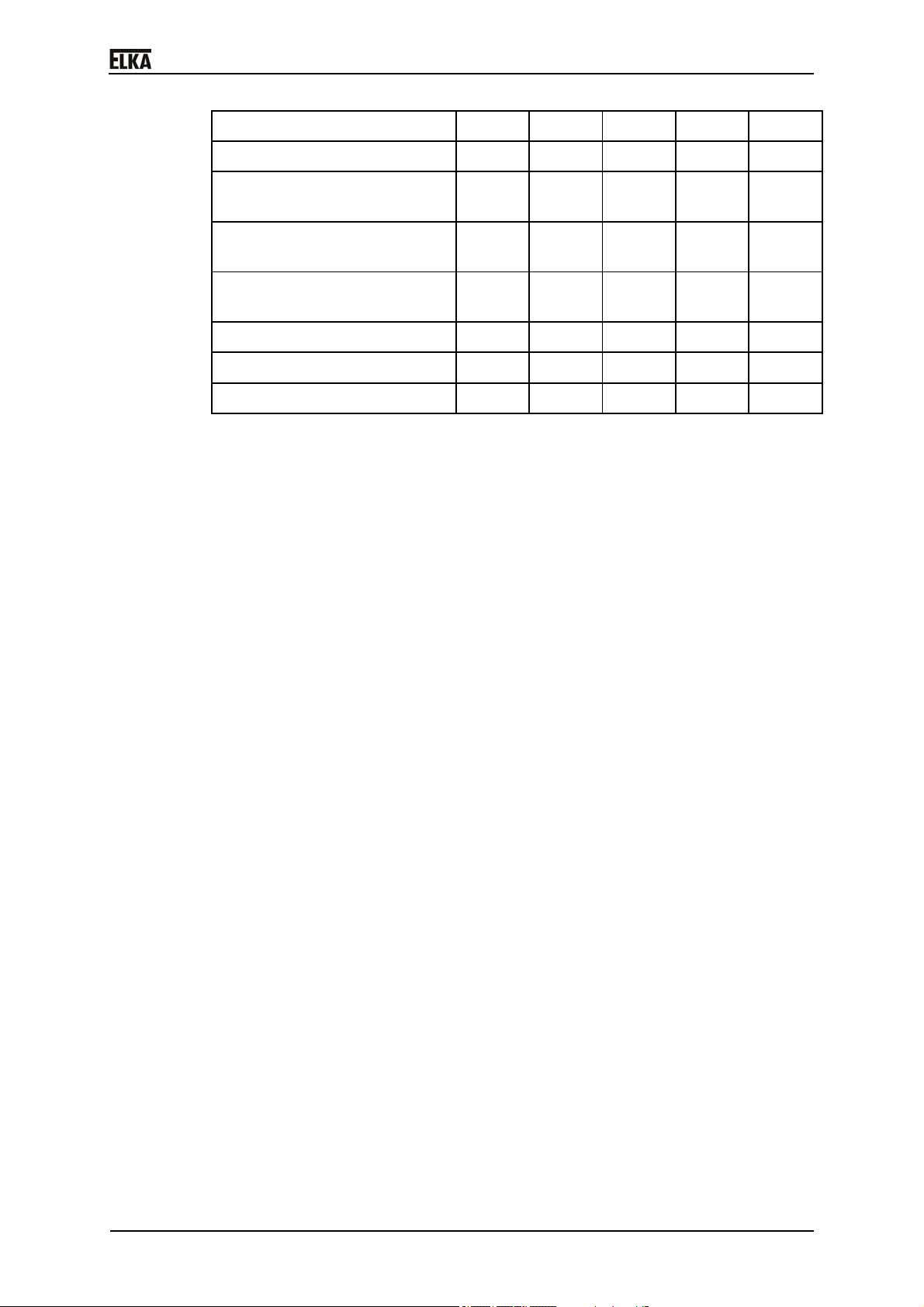

Model-related data P 2500 P 3000 P 3500 P 4000 P 5000

Power consumption, max. [W] 180 85 80 85 195

Opening and closing time -

1.3 1.8 2.5 3.8 4.5

standard, approx. [s]

Opening and closing time -

1.8 2.5 3.8 4.5 5.5

slow, approx. [s]

Opening and closing time -

0.9 1.3 1.8 2.8 3.8

fast, approx. [s]

Max. boom length [in] 98.41 118.11 137.80 157.48 196.85

Effective boom length [in] 89.76 109.45 129.13 148.82 188.19

Power reversal yes yes yes yes yes

Table 4

1

Page 19

0

8

7 Installation P 2500-5000

7.1 Tools

Quantity Description

2 Open-end wrench 13mm

1 Open-end wrench 16mm

1 Open-end wrench 17mm

1 Open-end wrench 18mm

1 Open-end wrench 19mm

1 Allen key 6mm

1 Torque wrench (1-25Nm) 1/4"-square head

1 Bit 1/4", 13mm

1 Torque wrench (40-200Nm) 3/4"-square head

P 2500 - P 500

1 Bit 3/4", 10mm,

Length 100mm

1 Bit 3/4", 19mm,

Length 100mm

1 Bit 3/4", 10mm,

hexagon socket,

length 100mm

1 Right-angle screwdriver for hexagon socket

4mm, long model

screws

1 Right-angle screwdriver for hexagon socket

6mm, long model

screws

1 Screwdriver 0,6 x 3,5mm

1 Screwdriver PH2 x 100

1 Cutter knife 18mm

1 Level

Table5

1

Page 20

0

9

7.2 Mounting dimensions

P 2500 - P 500

Drawing 3

1

Page 21

0

0

7.3 Foundation

Basic requirements

Keep a safety distance of min. 2ft (24in) between all moving barrier parts

and surrounding objects like walls, fences etc. Please check the following

drawing.

When preparing the foundation consider the alignment and distance

related to a (optional) fixed support (see drawing Drawing 3.

P 2500 - P 500

Drawing 4

a = min. 2ft (24in)

2

Page 22

0

P 2500 - P 500

Empty conduits

Use separate conduits for the power line and the control leads.

Use an additional (separate) conduit for each induction loop.

The distance between the conduits should be as large as possible.

Drawing 5

Requirements regarding the foundation

A minimum concrete strength class of C20/25 (or higher)

The use of heavy duty anchor bolts (M12).

Observe the foundation dimensions quoted in this manual. The installation

distance between the barrier housing and the foundation edge has to be

approx. 100mm.

WARNING!

Risk of injury by insufficient fastening!

Tilting barrier housings can result in severe injuries.

Before installation ensure a safe stand of the barrier

housing.

Do not lean the barrier boom against a wall or similar

before installation. Store the boom horizontally only.

Install the barrier housing as specified.

Use the recommended heavy duty anchor bolts M12, at

least M10 is required.

During maintenance check the housing for correct

fastening on the foundation.

21

Page 23

0

2

P 2500 - P 500

Drawing 6

1 Fastening point (10.45 x 7.99)

2 Fastening point, re-adjustable (9.06 x 7.09in)

3 Clearance for cable entry (empty conduits) (7.87 x 5.75in)

4 Drilling template

5 Foundation

6 Direction roadway

WARNING!

Danger of injury by incorrect fixation of the barrier

housing on the foundation!

Loosening of the anchor bolts from the foundation.

During the fastening of the barrier obey the minimum

distance of the heavy duty anchor to the edge of the

foundation.

2

Page 24

0

3

7.4 Opening / closing the housing

WARNING!

Rotating and/or linear movable components can cause

serious injuries.

Do not reach into moving parts or handle any moving

components during operation.

Turn the appliance off before any maintenance work,

repair work or other work and secure it against

Open the housing with the access panel key. The key is located in the

accessory box.

Removing the housing hood:

unintentional restarting.

P 2500 - P 500

Drawing 7

1. Remove the hood by pressing the release levers to the outside (1). The

hood raises itself.

2. Now take the hood off upwards - using both hands (2).

2

Page 25

0

P 2500 - P 500

Installing the hood:

Drawing 8

1. Using both hands place the hood on the housing by first pressing he rear

guidance points (1), then the front guidance points (2).

2. The hood snaps into place with an audible click.

7.5 Boom connector

1. The boom connector can be mounted left or right (factory setting is

right).To fasten the boom connector, plug it without the clamping piece on

the main shaft. Pay attention to a perfect fit of the shaft seal at the

housing. Now connect the clamping piece using the four screws (M12x30

ISO4762). Tighten the screws only so far that an alignment of the boom

connector on the main shaft is still possible.

24

Page 26

0

5

P 2500 - P 500

Drawing 9

2. The barrier mechanics is preset at the factory so that the barrier boom can

perform a 90° - movement from the vertical to the horizontal position. The

barrier is delivered in open (vertical) position. The drive lever is over the

dead center at the mechanical stop (see drawing below). If necessary,

correct the position by pulling the drive lever (1) in direction OPEN towards access panel/roadway (arrow 2).

Drawing 10

3. Adjust the boom connector vertically using a water-level.

2

Page 27

0

6

Drawing 11

4. Now retighten the four screws (M12x30 ISO 4762) at the clamping piece

with 88.5 lbf ft.

7.5.1 Installation – Boom connector left side

The barrier models TF 1203/0001-1204/0001 and XP 1203/0001-1204/0001

are prepared at the factory to mount the boom on the right side. At the left side

a cap is mounted to cover the main shaft opening.

Converting from barrier boom right to barrier boom left:

1. Remove the barrier hood.

2. Detach the cover cap at the left housing side as described in the following

drawing. First pull the spring sheet upwards (1), then turn the cover cap

approx. 60° (2) and pull it upwards (3).

P 2500 - P 500

Drawing 12

3. Disconnect the boom connector from the right side, if already mounted.

Connect it to the left side.

4. Mount the cover cap and the spring sheet at the right housing side.

2

Page 28

0

7

All drawings, tables and descriptions in this installation manual refer to the

factory-set (pre-) mounting of the boom holder at the right side.

7.6 Barrier boom

1. Remove all balancing springs from the spring assembly (see below

drawing).

P 2500 - P 500

Drawing 13

2. Turn the barrier mechanics (at the boom connector) into position CLOSED

(1). If necessary support the movement by pushing the drive lever in

direction CLOSED (2).

Drawing 14

3. Position the barrier boom with the reinforcement plate at the boom

connector. Make sure that the profile of the barrier boom fits tightly

(without play) at the boom connector.

2

Page 29

0

8

P 2500 - P 500

Drawing 15

4. Barriers P 2500 - P 4000:

Connect the barrier boom to the boom connector using the plastic screws

M8x50. Tighten the fastening nuts with a max. torque of 1.3lbf ft.

Use only the specific plastic screws M8x50. Screws with another specification

might prevent the tearing off of the barrier boom (predetermined shearing

point).

5. Barriers P 5000:

Connect the barrier boom to the boom connector using the screws M8x70.

Tighten the fastening nuts with a max. torque of 14.8lbf ft.

Due to the use of the steel screws M8x70 at the barrier P 5000 the

predetermined shearing point and such the vandalism protection is not

applicable – other than with the barriers P 2500 - P 4000.

7.7 Balancing springs

1. Activate the mechanical emergency release of the barrier and place the

barrier boom manually in position OPEN.

2. Mount the number of balancing springs according to the boom length and

additional (optional) equipment if applicable (see table below).

Please note that for the different versions two types of pressure springs (F1.1

and F1.2) are used.

Model

P 2500 2x

P 2500 with 2x 3x --- --- --- --- ---

2

Boom length [in]

78.74 98.41 118.11 137.80 157.48 177.17 196.85

F1.1

2x

F1.1

--- --- --- --- ---

Page 30

0

9

P 2500 - P 500

Model

articulated

Boom length [in]

78.74 98.41 118.11 137.80 157.48 177.17 196.85

F1.1 F1.1

boom

P 2500 with

round boom

2x

F1.1

P 3000 2x

F1.1

P 3000 with

articulated

2x

F1.1

boom

P 3000 with

round boom

2x

F1.1

P 3500 2x

F1.1

P 3500 with

articulated

2x

F1.1

boom

P 3500 with

round boom

2x

F1.1

2x

F1.1

2x

F1.1

3x

F1.1

2x

F1.1

2x

F1.1

3x

F1.1

2x

F1.1

--- --- --- --- ---

3x

--- --- --- ---

F1.1

3x

--- --- --- ---

F1.1

2x

--- --- --- ---

F1.1

3x

F1.1

3x

F1.1

2x

F1.1

4x

F1.1

4x

F1.1

3x

F1.1

--- --- ---

--- --- ---

--- --- ---

P 4000 2x

F1.1

P 4000 with

--- --- --- 2x

swinging

2x

F1.1

3x

F1.1

3x

F1.1

F1.2

support

P 4000 with

articulated

2x

F1.1

2x

F1.1

3x

F1.1

4x

F1.1

boom

P 4000 with

round boom

P 4000 with

round boom

2x

F1.1

2x

F1.1

2x

F1.1

3x

F1.1

--- --- --- 3x

F1.1

and with

swinging

support

P 5000 --- --- --- 2x

F1.2

P 5000 with

swinging

--- --- --- 3x

F1.2

support

2x

F1.2

2x

F1.2

2x

F1.2

3x

F1.1

2x

F1.2

3x

F1.2

3x

F1.2

--- ---

--- ---

--- ---

--- ---

--- ---

3x

F1.2

3x

F1.2

4x

F1.2

4x

F1.2

Table 6

Pressure spring type F1.1 = Balancing spring

Wire diameter 0,2in

For barriers up to 137.79in boom length

2

Page 31

0

0

P 2500 - P 500

Pressure spring type F1.2 = Balancing spring

Wire diameter 0,24in

For barriers above 137.79in boom length

3. During installation of the balancing springs please observe the correct

positioning in the spring assembly (see drawing below – positions of the

pressure springs on the support plate).

Drawing 16

a = 2 springs

b = 3 springs

c = 4 springs

It is not permitted to operate the barrier with only one spring mounted!

4. Activate the mechanical emergency release of the barrier and place the

barrier boom manually in position 45°. The barrier boom has to level itself

in this position. If necessary, correct the boom position by

tightening/loosening of the spring tension.

Drawing 17

3

Page 32

0

P 2500 - P 500

Adjusting the spring tension:

WARNING!

Danger of impact and crushing!

During the barrier movement, energy is saved in the

springs. The springs are not tight and thus energy-free only

in barrier position OPEN.

Mount and dismount the springs in barrier position

OPEN only. If necessary open the barrier by mechanical

emergency release and move the barrier manually into

position OPEN.

WARNING!

Risk of crushing

During the barrier movement crushing points arise at many

points of the barrier mechanics.

Before installation, maintenance or repair work at the

barrier mechanics turn the power supply off and secure

it against unintentional restarting.

Drawing 18

Tightening the spring tension: Turn the clamping nut (a) clockwise (1). The

boom moves in direction (1).

Loosening the spring tension: Turn the clamping nut (a) anti-clockwise (2).

The boom moves in direction (2).

31

Page 33

0

2

7.8 Opening and closing times

The opening and closing times of the barriers are factory-set to standard

values based on the model:

P 2500 = approx. 1.3 seconds

P 3000 = approx. 1.8 seconds

P 3500 = approx. 2.5 seconds

P 4000 = approx. 3.8 seconds

P 5000 = approx. 4.5 seconds

The opening and closing times of the barriers can be changed in the learning

sequence of the controller MO 24 under sequence point P101.

Sequence point P101 = 0 = fast

Sequence point P101 = 1 = standard (factory setting)

Sequence point P101 = 2 = slow

Model-related data P 2500 P 3000 P 3500 P 4000 P 5000

P 2500 - P 500

Running time –slow [s] approx.

1.8

Running time –standard [s] approx.

1.3

Running time – fast [s] approx.

0.9

Table 7

approx.

2.5

approx.

1.8

approx.

1.3

approx.

3.8

approx.

2.5

approx.

1.8

approx.

4.5

approx.

3.8

approx.

2.8

approx.

5.5

approx.

4.5

approx.

3.8

3

Page 34

0

3

7.9 Accessories

7.9.1 Swinging support P 4000 - P 5000

1. Move the barrier boom into the horizontal position.

P 2500 - P 500

Drawing 19

2. The bottom part ‘C’ can be connected at the approximate length using the

screws ‘B’.

3. Remove approx. 39.5in of the rubber tube under the boom and push the

securing pieces ‘A’ of the swinging support into the notch of the barrier

boom. Secure the swinging support using the two hexagon head screws.

Drawing 20

4. Push the rubber tube back into the notch and cut off the protruding part.

5. A fine adjustment of the swinging support height can now be made at the

foot ’D’.

6. Screw an M4mm screw into the whole ‘E’ and loosen the M10 stop nut at

the foot ’D’.

7. The foot can now be screwed to the appropriate position. Tighten the M10

stop nut upwards against the aluminium bushing. Remove the M4 screw.

3

Page 35

0

Drawing 21

Due to the additional load of the swinging support, the number of balancing

springs has to be adjusted. Install the correct number of balancing springs

depending on the boom length according to the table on page 29.

7.9.2 Fixed support P 4000 - P 5000

1. Mount the fixed support on a suitable foundation.

2. Observe the alignment and the distance to the barrier (see drawing below).

3. Mount the fixed support on the foundation.

4. Pay attention to the following points during installation. When the barrier is

closed:

a. the barrier boom has to be positioned in the middle of the support fork.

b. the profile end of the barrier boom must not protrude beyond the

support fork.

c. the barrier boom remains approx. 0.8-1.2in above the rubber insert.

P 2500 - P 500

34

Page 36

0

5

P 2500 - P 500

Drawing 22

7.9.3 Fixed support with electromagnet

1. Mount the fixed support on a suitable foundation.

2. Observe the alignment and the distance to the barrier (see drawing below).

3. Mount the fixed support on the foundation.

Mounting the anchor plate to the barrier boom:

1. Connect the flexible lead from the magnet with the cable of the barrier.

There is enough room at the lower part of the support for a junction box.

2. Fit the support fork onto the foot and secure it at the required height.

3. Remove a part of the rubber profile from the bottom part of the boom.

4. Push one of the securing pieces into the notch of the closed barrier boom.

5. Now insert the anchor plate into the notch until it is exactly above the

magnet.

Drawing 23

3

Page 37

0

6

P 2500 - P 500

6. Now insert the second securing piece.

7. Push both securing pieces against the anchor plate and secure them with

the screws.

Connecting the electromagnet in the barrier:

Drawing 24

Following the connection of an electromagnet as well as the required

parameter changes in the controller are described. As an example the multifunctional relay 4 (MULTI4) and as power supply for the standard

electromagnet the internal 24Vdc of the MO 24 is used.

CAUTION!

Over-voltage when switching off an inductive DC load!

Defect of the controller or the external (on-site) DC voltage

source by overvoltage!

Always connect the free-wheeling diode R1 (type

1N4004), as shown in the drawing, when using an

1. Connect the electromagnet to the terminal row, as shown in the drawing.

Use a minimum cable cross-section of AWG 16. The cable length shall not

exceed a length of 65.61ft.

2. Connect the multi-functional relay 4 to 24Vdc.

3. Activate the pre-warning time in the learning sequence of the controller

MO 24 under sequence point P302. Select a time longer than 1.5 seconds.

4. Activate the multi-functional relay 4 in the learning sequence under

sequence point P504. Select the operating mode “10” - The multifunctional relay is activated, when the barrier is closed. During the prewarning before opening the relay is already switched off.

Procedure:

1. The barrier is closed. On receipt of a signal to open the multi-relay is

switched off and it loses the residual magnetism during the pre-warning

time.

2. The barrier opens after the set pre-warning time (P302) has elapsed.

3. The barrier is open. After a closing impulse the multi-functional relay (the

magnet) is switched on only when the end position CLOSED is reached.

electromagnet.

3

Page 38

0

7

7.9.4 LED boom lighting

Drawing 25

The following instruction explains the connection of the LED boom lighting as

well as the necessary parameter changes in the controller. As an example the

multi-functional relay 4 (MULTI4) and the multi-functional relay 5 (MULTI5) are

being used for the activation as well as the internal 24Vdc power supply of the

controller MO 24 as power supply.

1. Connect the supply line of the LED boom lighting to the terminal row X1,

as shown in the drawing. Use a min. wire cross section of AWG 20.

2. Connect the multi-functional relays 4 and 5 to ground (Gnd) as shown.

3. Activate the multi-functional relay 4 under the sequence point P504 in the

learning sequence of the controller. Select the operating mode “9”. The

multi-functional relay is activated when the barrier is open. During prewarning before closing the relay is already deactivated.

4. Activate the multi-functional relay 5 under the sequence point P505 in the

learning sequence of the controller. Select the operating mode “10”. The

multi-functional relay is activated when the barrier is closed. During prewarning before opening the relay is already deactivated.

Procedure:

1. The barrier is closed. The LED boom lighting is RED. When an opening

impulse is given, the multi-functional relay 4 is switched off.

2. The barrier opens. The LED boom lighting is off.

3. The barrier is open. The LED boom lighting is GREEN. When a closing

impulse is given, the multi-functional relay 5 is switched off.

P 2500 - P 500

3

Page 39

0

8

7.10 Emergency release

P 2500 - P 500

Drawing 26

During a power failure open the barrier by pulling the release lever. Now, the

barrier can be opened by hand.

7.11 Vandalism

WARNING!

By pressing the boom up or down the correct position of the

boom may be moved (missadjusted - vandalism!).

Unforeseeable danger spots may arise.

If the position of the boom is misadjusted, the correct

setting of the barrier boom must be restored.

Drawing 27

3

Page 40

0

9

P 2500 - P 500

WARNING!

Rotating and/or linear movable components can cause

serious injuries.

Do not reach into moving parts or handle any moving

components during operation.

Turn the appliance off before any maintenance work,

repair work or other work and secure it against

unintentional restarting.

WARNING!

Danger due to uncontrolled movements of the

mechanics by pre stressed springs!

Parts of the mechanics can move through the spring tension

and pinching body parts.

BEFORE adjusting the boom position, the barrier

boom must be moved electrically or by hand

(emergency release) in the position OPEN.

Drawing 28

Restoring of the correct barrier boom position

1. Loosen the clamping screw of the drive lever M (Pos. 5).

2. Set manually the boom in position OPEN.

3. Rotate the gear box shaft (Pos. 13) up to the stop.

4. A distance (A) of 2mm must be set between the drive lever F and the cut in

the main plate. If this is not the case, loosen the two clamp bolts of the

drive lever F and set the distance to about 2mm. Tighten the clamping

screws of the drive lever F (88.5lbf ft).

3

Page 41

0

0

P 2500 - P 500

Drawing 29

5. Tighten the clamping screw of the drive lever M to the specified torque.

The torque is adapted to the mechanics and is marked on the label (B).

6. Turn on the barrier (power supply). Check the faultless running and the

correct positions (OPEN and CLOSE).

4

Page 42

0

8 Terminal row

8.1 Interior view

P 2500 - P 500

Drawing 30

Pos. Description

1 Controller MO 24 (with housing and cover)

2 Supply voltage 24VDC

3 Motor connection

4 Terminal row

5 Fixing clamp for power- and signal lines

6 Top hat rail for accessories (optional or on-site)

7 On-off switch

8 Main terminals (L1, N and PE)

Table 8

8.2 Mains connection

Danger through voltage!

Danger of an electric shock.

Only certified electricians should connect the barrier to

the mains supply.

DANGER!

41

Page 43

0

2

P 2500 - P 500

DANGER!

Danger through voltage!

Danger of an electric shock!

Observe the following connection instructions.

Connection instructions:

For a permanent electrical installation please observe the country-specific

regulations.

The connection terminals are designed for a rated cross-section per

terminal of AWG 22 to AWG 14.

The supply lead cross-section used has to be suitable for the load and

comply with the local regulations.

DANGER!

Danger through voltage!

Danger of an electric shock!

Connect the protective conductor of the mains lead

directly to the protective conductor terminal (PE) at the

barrier housing.

1. For the connection to the terminals and the protective conductor terminal

(PE) the flexible mains lead must have the following dimensions:

Drawing 31

1 Lead N, length a = 1.81in incl. conductor sleeve

2 Lead L1, length b = 2.17in incl. conductor sleeve

3 Lead PE, length c = 11.81in with eyelet for M6

When using a solid mains lead, use the dimensions according to the above

drawing.

4

Page 44

0

3

P 2500 - P 500

Drawing 32

1 Lead N

2 Lead L1

3 Lead PE

4 Protective conductor terminal (PE), green, thread M6

5 Mains lead

2. Lay the mains lead to the terminals using the shortest possible distance.

Make sure the mains lead does not touch the moving mechanics.

3. Connect the protective conductor PE to the green protective conductor

terminal (PE).

4. Connect the leads L1 and N of the mains lead to the terminals.

5. Fasten / Secure the mains lead to the provided flaps using cable ties.

8.3 Controller terminal row

Drawing 33

The following control inputs have to be bridged or occupied with contact (NC)

for operation:

1. Terminals

23 + 24

2. Terminals

25 + 26

4

Photoelectric barrier (LS) NC contact or

bridge

Boom missing contact (Bm) NC contact or

bridge

Page 45

0

P 2500 - P 500

3. Terminals

41 + 42

4. Terminals

43 + 44

5. Terminals

21 + 22

Table 9

Push button CLOSE (BTZ2) NC contact or

bridge

Push button STOP (BTS) NC contact or

bridge

Safety contact profile CLOSE (SLZ) 8.2kOhm

resistor

After installing and connecting all the equipment, the following LEDs have to

light:

1. Vp Is lit, when the supply voltage is switched on.

2. BTZ2 Is lit, when contact BTZ2 is closed.

3. BTS Is lit, when contact BTS is closed.

4. Bm. Is lit, when the boom-missing contact is closed.

Table 10

Plug Socket label Function

1 12V Uext 12V, max. 500mA

2 Gnd Ground

3 24V Uext 24V, in total with terminal 5 and 7 max.

1500mA

4 Gnd Ground

5 24V Uext 24V, in total with terminal 3 and 7 max.

1500mA

6 Gnd Ground

7 24V Uext 24V, in total with terminal 3 and 5 max.

1500mA

8 Gnd Ground

9 Multi1 Multi-functional relay 1, potential-free, max.

10

24VDC/1A

11 Multi2 Multi-functional relay 2, potential-free, max.

12

24VDC/1A

13 Multi3 Multi-functional relay 3, potential-free, max.

14

24VDC/1A

15 Multi4 Multi-functional relay 4, potential-free, max.

16

24VDC/1A

17 Multi5 Multi-functional relay 5, potential-free, max.

18

24VDC/1A

19 Multi6 Multi-functional relay 6, potential-free, max.

20

44

24VDC/1A

Page 46

0

5

P 2500 - P 500

Plug Socket label Function

21 SLZ Safety contact profile CLOSE, 8.2kOhm

22 Gnd Ground

23 LS Photoelectric barrier (NC contact)

24 Gnd Ground

25 Bm Boom-missing contact

26 Gnd Ground

27 LOOP-A Induction loop A

28

29 LOOP-B Induction loop B

30

31 LOOP-C Induction loop C

32

33 BT* Configurable input: BT or BTA3 or BTZ1B

(NO contact)

34 Gnd Ground

35 BTA1 Push button OPEN 1 (NO contact)

36 Gnd Ground

37 BTA2 Push button OPEN 2 (NO contact)

38 Gnd Ground

39 BTZ1A Push button CLOSE 1A (NO contact)

40 Gnd Ground

41 BTZ2 Push button CLOSE 2 (NC contact)

42 Gnd Ground

43 BTS Push button STOP (NC contact)

44 Gnd Ground

45 ANT Antenna

46 Gnd Ground

47 NAE Power failure detection (ANAE)

48 Gnd Ground

Table 11

4

Page 47

0

6

8.4 Circuit diagram

P 2500 - P 500

Drawing 34

4

Page 48

0

7

P 2500 - P 500

Drawing 35

4

Page 49

0

8

P 2500 - P 500

Drawing 36

4

Page 50

0

9

P 2500 - P 500

Drawing 37

4

Page 51

0

0

P 2500 - P 500

Drawing 38

5

Page 52

0

P 2500 - P 500

Drawing 39

51

Page 53

0

2

P 2500 - P 500

40

The module with 8 supplementary multifunctional relays for MO 24 is available

as an option. Please note for the corresponding installation and operating

instructions!

5

Page 54

0

3

9 Barrier maintenance

Rotating and/or linear movable components can cause

serious injuries.

Do not reach into moving parts or handle any moving

components during operation.

Turn the appliance off before any maintenance work,

repair work or other work and secure it against

Maintenance P 2500-5000

The maintenance intervals must be decided individually as they are dependent

on the application and the frequency of use. We recommend maintenance at

least once every six months.

1. Check the balancing springs. In case of a faulty spring, all springs must be

replaced simultaneously.

2. Check that the boom is perfectly balanced by the springs (see page 28).

3. Check barrier housing and boom for accidents and damage and replace

where necessary.

4. Ensure that the potential earthing cable is still connected to the housing

and to the door.

5. Check that the operating instructions are complete.

6. Check that all safety equipment works properly (induction loops,

photoelectric barriers, power reversal,...).

7. Check that the barrier is still secure on the foundation.

8. Check the plastic screws (M8x45) or steel screws (M8x70) at the boom

connector.

9. Check the emergency release for correct functioning (by activation).

10. Perform a visual inspection and tighten screws where necessary.

11. Grease the guide bars using multi-purpose grease (temperature range 30°C to +70°C / -22°F to +158°F). Remove excess grease.

unintentional restarting.

P 2500 - P 500

WARNING!

5

Page 55

0

10 Layout (exploded drawing)

P 2500 - P 500

Drawing 41

54

Page 56

0

5

P 2500 - P 500

Pos. Qty. Part name

1 1 Hood

2 2 Pillow block

3 2 Plain bearing, main shaft

4 1 Main plate

5 1 Drive lever M

6 1 Drive lever F

7 1 Tension lever - holder T1

8 1 Tension lever - holder T2

9 2 Plain bearing, spring holder

10 1 Distance ring

11 1 Main shaft

12 2 Connecting lever

13 1 Gearbox shaft

14 2 Cylinder bolt, mechanics

15 4 Plain bearing, mechanics

16 1 Bearing plate

17 1 BLDC-Motor / planetary gear

18 1 Eccentric tappet, releasing device

19 1 Spring, releasing device

20 1 Plain bearing, eccentric tappet (releasing device)

21 1 Plain bearing, gearbox

22 1 Lever, emergency release

23 1 Bracket, emergency release

24 2 Rod, emergency release

25 2 Guide bar

26 2 Spring plate

27 2 Spring guide

28 2 Spring holder

29 1 Pressure spring (F1.1 / F1.2)

30 2 Support plate P

31 1 Pull plate P

32 1 Plain bearing, flange bearing

33 1 Joint head 12R

34 1 Tension lever

35 1 Housing

36 1 Base plate

37 1 Controller MO 24, board

5

Page 57

0

6

P 2500 - P 500

Pos. Qty. Part name

38 1 Mounting plate

39 1 Top had rail with on-off switch and terminals

40 1 Controller MO 24, housing

41 1 Power-supply unit

42 1 Bracket, mounting plate

43 1 Access panel

44 1 Lock cylinder with nut and lock bolt

45 1 Boom holder

46 1 Boom

47 1 Mounting kit boom with boom reinforcement

48 1 Supporting plate for seal or sealing cap

49 1 Sealing cap, housing

50 1 Felt seal

51 2 Boom end cap

52 1 Bracket, spring assembly

53 1 Hood sheet, housing, right

54 1 Hood sheet, housing, left

55 1 Battery support

Table 12

5

Page 58

0

7

P 2500 - P 500

Index

module with 8 supplementary

B

Balancing springs ....................... 28

multifunctional relays for MO 24 . 52

Mounting dimensions .................. 19

C

Circuit diagram ........................... 46

E

Emergency release .................... 38

F

Fixed support ............................. 34

Fixed support with electromagnet

................................................... 35

Foundation ................................. 20

Function description ................... 15

G

General notes on safety ............... 5

H

Hazard warnings .......................... 8

I

Installation .................................. 18

Instructed person ......................... 7

L

Layout (exploded drawing) ......... 54

LED boom lighting ...................... 37

N

Notes on safety for the operation .. 5

O

Opening and closing times ......... 32

P

Personal protective equipment ..... 7

plastic screws ............................. 53

Preface ......................................... 3

R

radio remote control ...................... 5

S

Specialist ...................................... 7

Storing ........................................ 12

Swinging support ........................ 33

Symbol explanation ...................... 4

T

Technical data P 2500-5000 ....... 16

Terminal row ............................... 41

Tools ........................................... 18

Transportation and storing .......... 11

Transportation inspection ........... 11

M

Maintenance ............................... 53

5

V

Vandalism ................................... 38

Loading...

Loading...