Elka KOMET 280, KOMET 282, KOMET 400, KOMET 202, KOMET 200 Installation And Operating Instructions Manual

...Page 1

Installation and operating instructions

Swing Gate Opener

KOMET 200 - 600

Translation of original installation and operating instructions

D-ID: V2_3 – 01.14

ELKA-Torantriebe GmbH u. Co. Betriebs KG

Phone: +49-(0) 48 61 - 96 90-0

Dithmarscher Str. 9 Fax: +49-(0) 48 61 - 96 90-90

25832 Tönning E-mail: info@ELKA-Torantriebe.de

Germany Internet: www.ELKA-Torantriebe.de

Page 2

KOMET 200 - 60

0

Contents

1 Preface 3

1.1 General notes 3

1.2 Copyright 4

1.3 Information regarding installation instruction 4

2 Safety 5

2.1 General notes on safety 5

2.2 Notes on safety for the operation 5

2.3 Safety notes for the operation with radio remote control 5

2.4 Intended use 5

2.5 Danger, which could emanate from the site of operation 5

3 Transportation and storing 7

3.1 Transportation inspection 7

3.2 Storing 7

4 Declaration of incorporation 8

4.1 Installation information for partly completed machinery 9

4.2 Declaration of conformity 9

4.3 Name plate 9

5 Usage 10

6 Technical Data 11

7 Installation example 13

8 Installation 14

8.1 Installation dimensions (pivot point) 14

8.2 Installation dimensions (elevation) 17

8.3 Installation at the gate and gate post 18

8.4 Adjusting of the internal stops (KOMET 200 and 280) 19

9 Emergency release 22

9.1 Emergency releasing 22

9.2 Engaging of emergency release 22

10 Controller MO 36 23

10.1 Electrical installation 23

10.2 Connections 24

10.3 Programming MO36 27

10.4 Safety contact profiles for gate open (SLA) and close (SLZ) 40

10.5 Additional modules 41

10.6 Power failure 42

1

Page 3

KOMET 200 - 60

0

2

10.7 Fault diagnosis 42

10.8 Emergency mode 43

10.9 Parameter and Original settings 44

Page 4

KOMET 200 - 60

0

1 Preface

1.1 General notes

These operating instructions must be available on site at all times. It should be

read thoroughly by all persons who use, or service the appliances. Improper

usage or servicing or ignoring the operating instructions can be a source of

danger for persons, or result in material damage. If the meaning of any part of

these instructions isn’t clear, then please contact ELKA-Torantriebe GmbH u.

Co. Betriebs KG before you use the appliance.

This applies to all setup procedures, fault finding, disposal of material, care

and servicing of the appliance. The accident prevention regulations and

applicable technical regulations (e.g. safety or electrical) and environment

protection regulations of the country in which the appliance is used also apply.

All repairs on the appliances must be carried out by qualified persons. ELKATorantriebe GmbH u. Co. Betriebs KG accepts no liability for damage which is

caused by using the appliance for purposes other than those for which it is

built.

ELKA-Torantriebe GmbH u. Co. Betriebs KG cannot recognise every possible

source of danger in advance. If the appliance is used other than in the

recommended manner, the user must ascertain that no danger for himself or

others will result from this use. He should also ascertain that the planned use

will have no detrimental effect on the appliance itself. The appliance should

only be used when all safety equipment is available and in working order. All

faults which could be a source of danger to the user or to third persons must

be eliminated immediately. All warning and safety notices on the appliances

must be kept legible.

All electrical periphery equipment which is connected to the appliance must

have a CE Mark, which ensures that it conforms to the relevant EEC

regulations. Neither mechanical nor electrical alterations to the appliance,

without explicit agreement of the manufacturer, are allowed. All alterations or

extensions to the appliance must be carried out with parts which ELKATorantriebe GmbH u. Co. Betriebs KG have defined as suitable for such

alterations, and be carried out by qualified personnel. Please note that with

any alteration of the product, no matter whether mechanical or electrical, the

warranty expires and the conformity is revoked. Only the use of ELKA

accessories and original ELKA spare parts is allowed. In case of any

contravention ELKA disclaims liability of any kind.

INFORMATION!

The operation of the system within CEN countries must also be conformant

with the European safety-relevant directives and standards.

We reserve the right to make technical improvements without prior notice.

3

Page 5

KOMET 200 - 60

0

4

1.1.1 Symbol explanation

Remarks regarding the safety of persons and the gate opener itself are

marked by special symbols. These remarks have to be absolutely observed in

order to avoid accidents and material damage.

DANGER!

…points to an imminent dangerous situation, which can cause death or

serious injuries if it is not avoided.

WARNING!

…points to a potentially dangerous situation, which can cause death or

serious injuries if it is not avoided.

ATTENTION!

…points to a potentially dangerous situation, which can cause minor or

slight injuries if it is not avoided.

ATTENTION!

…points to a potentially dangerous situation, which can cause property

damage if it is not avoided.

REMARK!

Important notice for installation or functioning.

1.2 Copyright

The operating manual and the contained text, drawings, pictures, and other

depictions are protected by copyright. Reproduction of any kind – even in

extracts – as well as the utilization and/or communication of the content

without written release certificate are prohibited. Violators will be held liable for

damages. We reserve the right to make further claims.

1.3 Information regarding installation instruction

This document is to be used as installation instruction for partly completed

machinery (according to machinery directive 2006/42/EG, article 13, (2)).

Page 6

KOMET 200 - 60

0

2 Safety

2.1 General notes on safety

The valid regulations and standards have to be observed during installation

and operation, e.g. DIN EN 13241-1, DIN EN 12445, DIN EN 12453 etc.

Only the use of spare parts made by the original manufacturer is allowed. Do

not put a defective gate opener / barrier into operation.

After set-up (installation) every user of the equipment has to be instructed

about the operation and function of the gate opener / barrier.

2.2 Notes on safety for the operation

Children and not instructed persons are not allowed to operate the gate

system / barrier.

No persons, objects, or animals are allowed within the range of the gate

movement / barrier movement during opening or closing.

Never reach into moving parts of the gate operator, gate or barrier.

Drive through the gate system /barrier only after complete opening.

The gate system / barrier has to be secured depending on the type of usage,

corresponding to the valid standards and regulations (e.g. safety at the main

and secondary closing edges).

The safety devices have to be checked regularly for functioning according to

the standards and regulations, at least once a year.

2.3 Safety notes for the operation with radio remote control

The radio remote control should only be used, if the area of movement of the

gate / barrier is always completely visible by the operator and thus it is

assured, that no person, object, or animal is present within this range of

movement.

The radio remote control transmitters have to be carefully kept, so that an

unintentional use is impossible.

Radio remote controls should not be operated at radio-technical sensitive

locations, like airports or hospitals.

Interferences by other (properly operated) radio communication installations,

which are used within the same frequency range, cannot be ruled out.

2.4 Intended use

The operating safety is only guaranteed with the intended use of the gate

opener.

After the installation, the swing gate opener of this serve the purpose of traffic

flow control of vehicle paths (vehicle traffic only).

The controller MO 36 is a component part and controls the swing gate opener.

Any usage beyond this and/or any different application of the equipment

is prohibited and is considered as not according to regulations.

2.5 Danger, which could emanate from the site of operation

The swing gate opener operates with movable parts.

5

Page 7

KOMET 200 - 60

0

WARNING!

Rotating and/or linear movable components can cause serious injuries.

Do not reach into moving parts or handle any moving components during

operation.

Turn the appliance off before any maintenance work, repair work or other

work and secure it against unintentional restarting.

6

Page 8

KOMET 200 - 60

0

3 Transportation and storing

3.1 Transportation inspection

The shipment has to be inspected for transportation damage immediately after

receipt. In case of any damage record the type and extent on the delivery

receipt or refuse acceptance.

Inform ELKA-Torantriebe immediately in the event of damage.

In case the above points are not observed claims will be denied due to

insurance regulations.

3.2 Storing

The swing gate opener has to be stored as follows:

Do not expose the gate opener to aggressive substances.

Do not expose the gate opener to heat sources.

Storage temperature -20°C to +70°C.

7

Page 9

KOMET 200 - 60

0

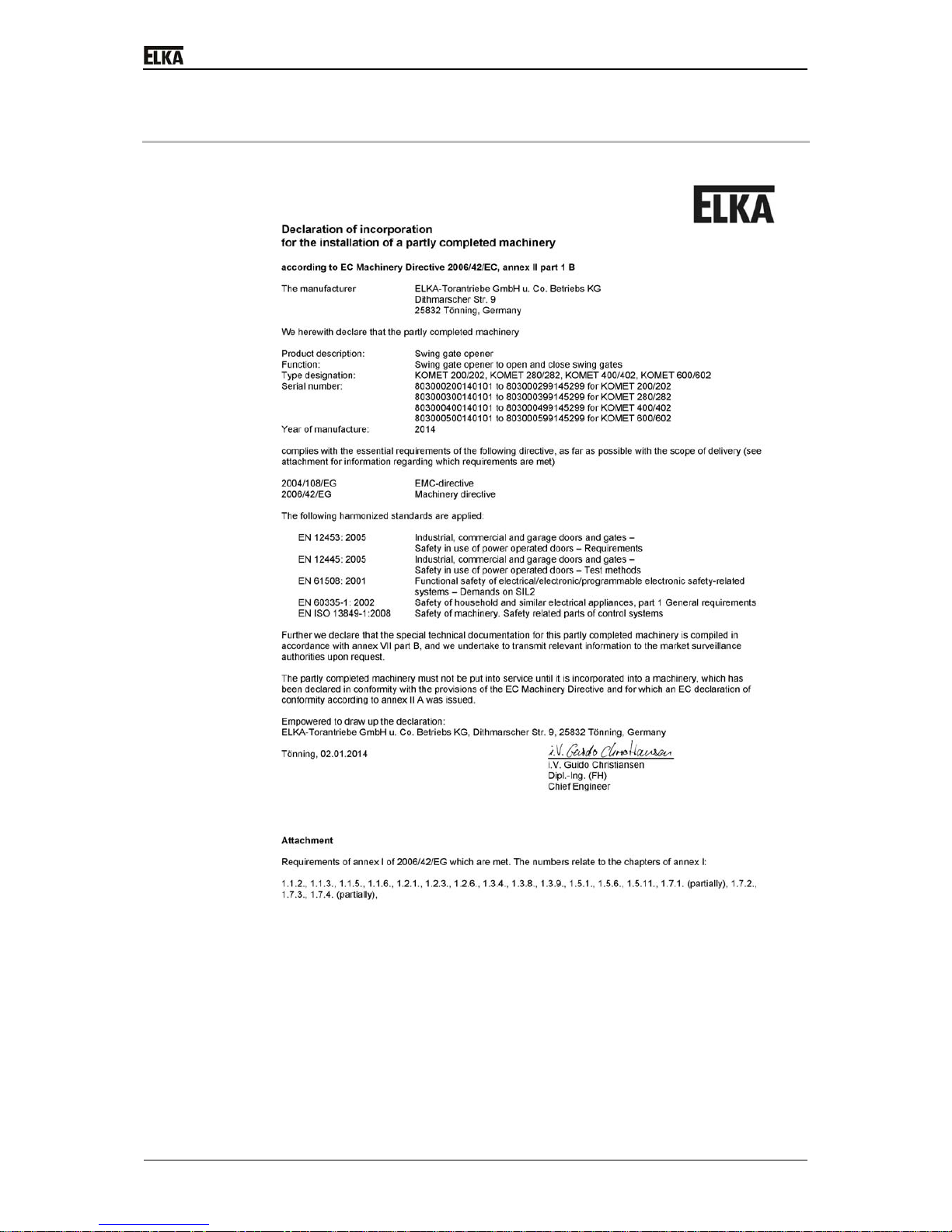

4 Declaration of incorporation

Drawing 1

8

Page 10

KOMET 200 - 60

0

4.1 Installation information for partly completed machinery

The partly completed machinery must not be put into service until the

final machinery into which it has to be incorporated has been declared

inconformity with the provisions of the machinery directive.

The safety functions of the controller comply with EN ISO 13849-1:2008

Kat.2PLc/d.

According to EC Directive 2006/42/EG the mains supply has to be equipped

with an all-pole circuit breaker.

WARNING!

Danger through voltage!

Danger of an electric shock.

Only certified electricians (VDE 0100) should connect the controller to the

mains supply.

According to DIN EN 12453, for an application with passenger traffic,

depending on the type of use and type of activation, suitable safety devices

have to be installed additionally, in order to provide the minimum level of

protection.

4.2 Declaration of conformity

After the installation an EG- declaration of conformity according to ECmachinery directive 2006/42/EG for the complete system has to be issued by

the person responsible for the integration (according to product standard DIN

EN 13241-1).

4.3 Name plate

The name plate of the swing gate opener is mounted inside the housing

(interior area close to the motor) or at the motor support.

9

Page 11

KOMET 200 - 60

0

5 Usage

The swing gate openers of series KOMET 200 - 600 are designed for gates

moving horizontally and having low wind resistance. For max. width and

weight of gate wing see table and diagram below.

When usage is different from the above samples, please contact your supplier.

1

0

Page 12

KOMET 200 - 60

0

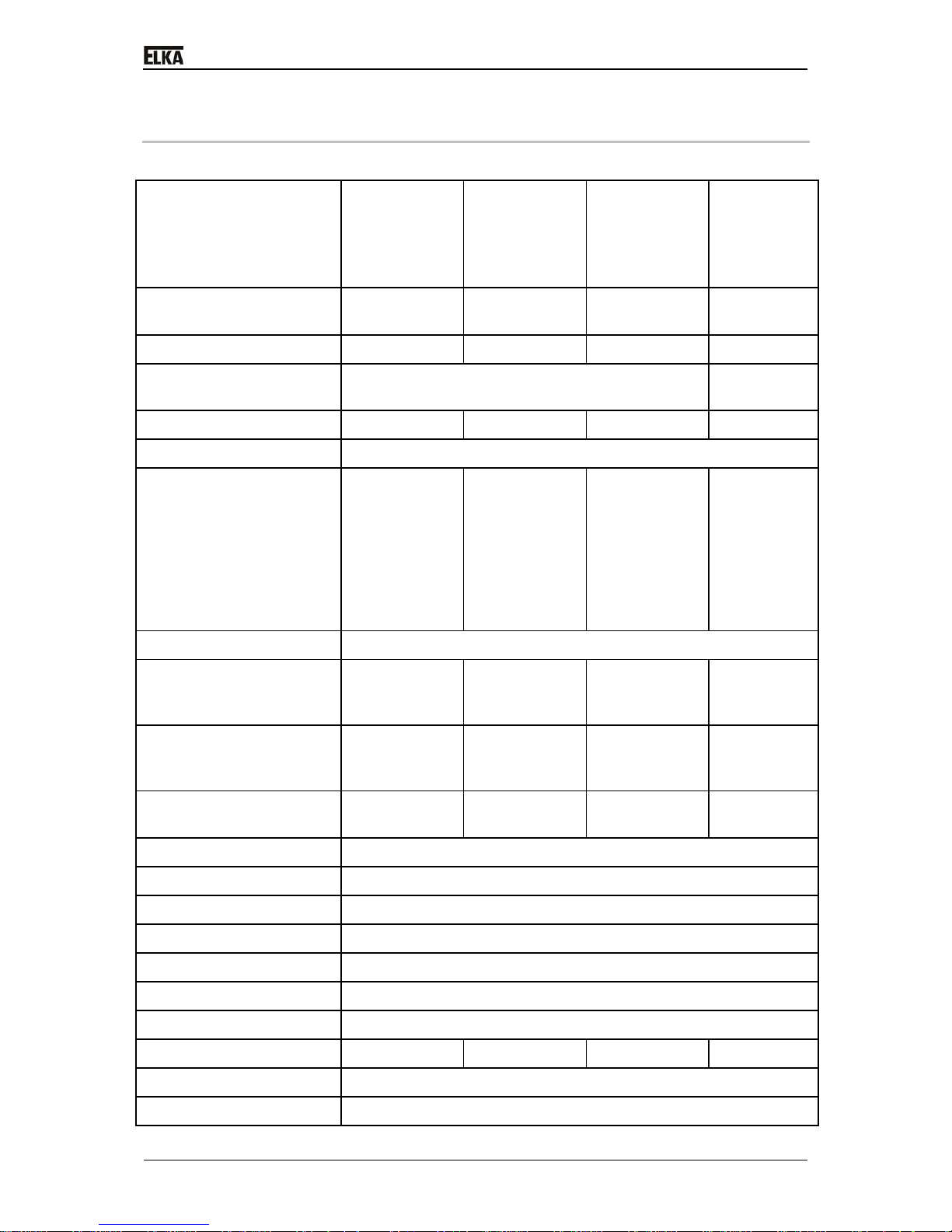

6 Technical Data

KOMET

200/202

one winged

gate/two

winged gate

KOMET

280/282

one winged

gate/two

winged gate

KOMET

400/402

one winged

gate/two

winged gate

KOMET

600/602

one winged

gate/two

winged gate

Maximum width of wing * 2.000mm /

wing

2.800mm /

wing

4.000mm /

wing

6.000mm /

wing

Maximum weight of wing 200kg 300kg 400kg 500kg

Maximum movement

(stroke)

370mm 500mm

Electromagnetic bolt no no yes yes

Emergency release from top and bottom

Running time (opening

angle 90°)

(each wing) **

stroke 280mm

= approx. 12s

stroke 350mm

= approx. 16s

stroke 300mm

= approx. 13s

stroke 350mm

= approx. 16s

stroke 320mm

= approx. 14s

stroke 350mm

= approx. 16s

stroke

440mm

= approx.

21s

stroke

500mm

= approx.

24s

Opening angle max. *** 120°

External limit stoppers at

opened positions required

****

yes no yes yes

External limit stoppers at

closed positions required

****

yes no yes yes

Limit stoppers at opened

and closed positions

optional yes no no

Power supply 230V, 50Hz

Operating voltage 24Vdc

Duty cycle 50%

Soft-Start and Soft-Stop yes, with ramp function

Controller, separately MO 36 (175x260x100mm, WxHxL)

Traffic light Module (optional)

Safety contact profile Separately for OPEN and CLOSE

Weight 19kg / 34kg 20kg / 35kg 19kg / 34kg 24kg / 44kg

Degree of protection IP 44

Temperature range -20°C up to +70°C

11

Page 13

KOMET 200 - 60

0

1

2

Maintenance The maintenance intervals must be decided individually as they

are dependent on the frequency of use. We recommend

maintenance at least once every 12 months.

Table1

* gates with low wind resistance

** depending on the installation dimensions (stroke) and the speed level

*** depending on the installation dimensions

**** A perfect fixation of the gate in position OPEN and CLOSED is only

possible with external stops!

Page 14

KOMET 200 - 60

0

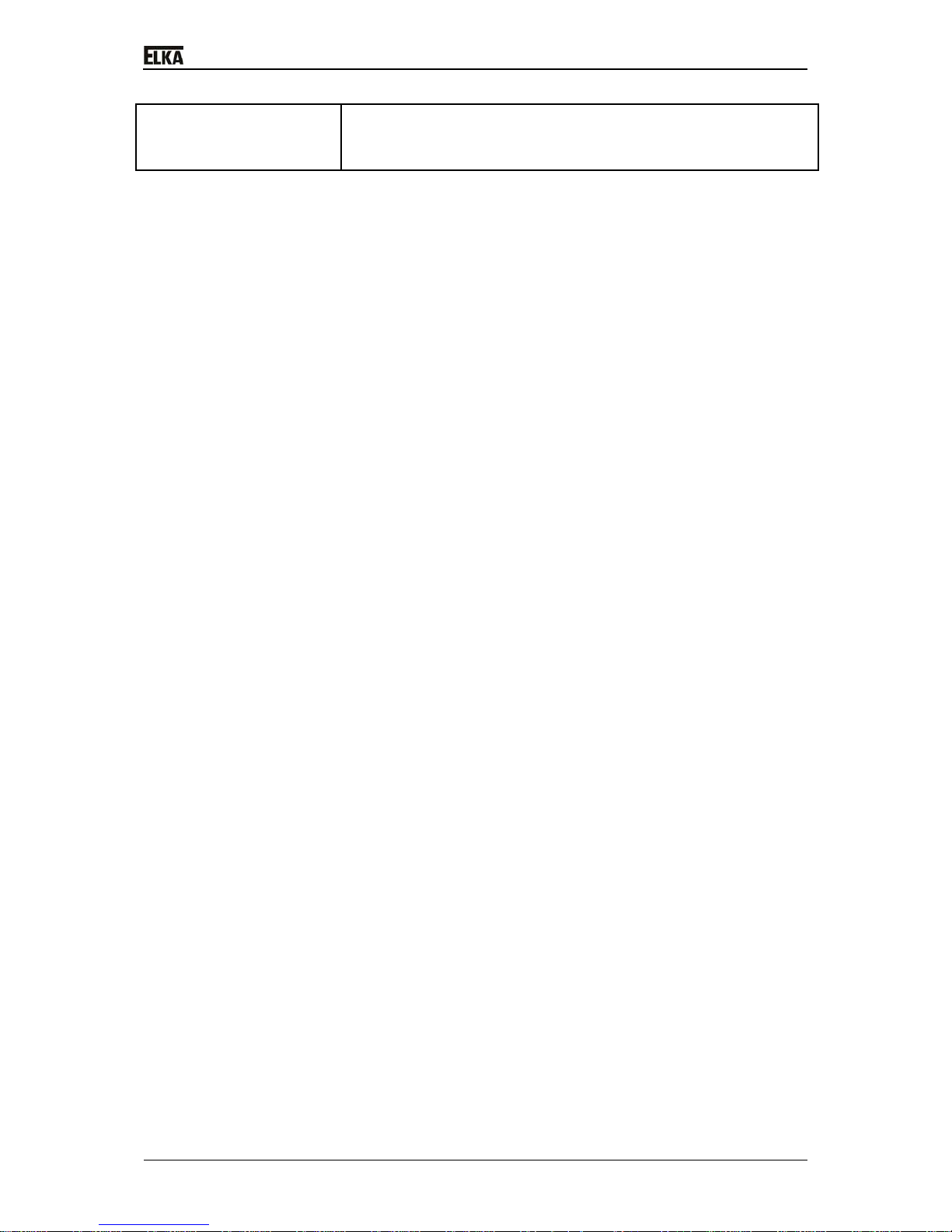

7 Installation example

Drawing 2

1

3

Page 15

KOMET 200 - 60

0

8 Installation

8.1 Installation dimensions (pivot point)

All measurements are quoted in millimetre.

The opener KOMET is for usage left and right.

Drawing 3

14

Page 16

KOMET 200 - 60

0

KOMET 200/280/400

C = approx. 100mm

D = approx. 80mm

E = 1010mm

Drawing4

KOMET 600

C = approx. 100mm

D = approx. 120mm

E = 1245mm

Drawing 5

1

5

Page 17

KOMET 200 - 60

0

Mounting dimensions – Opening angles:

Table of opening angels KOMET 200

depending on measurements A and

B.

Opening angle A / B * A / B * A / B * A / B * A / B *

90° 140 / 140 150 /150 160 / 160 170 / 170 180 / 180

95° 140 / 130 150 / 140 160 / 150 170 / 160 180 /170

100° 150 / 130 160 / 140 170 / 150 180 / 160 -

105° 160 / 130 170 / 140 180 / 150 - -

110° 170 / 130 180 / 140 - - -

115° 180 / 130 - - - -

120° 180 / 120 - - - -

Table 2 - (*All measurements are quoted in millimetre.)

Table of opening angels KOMET 280depending on measurements A and

B.

Opening angle A / B * A / B * A / B * A / B *

90° 150 / 150 160 /160 170 / 170 180 / 180

95° 150 / 140 160 / 150 170 / 160 180 / 170

100° 160 / 140 170 / 150 180 / 160

105° 160 / 130 170 / 140 180 / 150 -

110° 170 / 130 180 / 140 - -

115° 180 / 130 - - -

120° 180 / 120 - - -

Table 3 - (*All measurements are quoted in millimetre.)

Table of opening angels KOMET 400depending on measurements A and

B.

Opening angle A / B * A / B * A / B *

90° 160 / 160 170 /170 180 / 180

95° 160 / 150 170 / 160 180 / 170

100° 170 / 150 180 / 160 -

105° 170 / 140 180 / 150 -

110° 180 / 140 - -

115° 180 / 130 - -

120° 180 / 120 - -

Table 4 - (*All measurements are quoted in millimetre.)

1

6

Page 18

KOMET 200 - 60

0

Table of opening angels KOMET 600depending on measurements A and

B.

Opening angle A / B * A / B *

90° 225 / 225 240 / 240

95° 225 / 210 240 / 225

100° 225 / 195 240 / 210

105° 225 / 180 240 / 195

110° 240 / 180 -

115° 240 / 165 -

120° 240 / 150 -

Table 5 - (*All measurements are quoted in millimetre.)

The measurement E for KOMET 200 / KOMET 280 / KOMET 400 is

1,010mm each, for the KOMET 600 it is 1,245mm. To exceed these

measurements may result in a disruption of operation. To go below

these measurements, reduces the opening angle.

Please strictly observe the approved measurements. This is necessary

for an optimal operation. In case these measurements cannot be

observed, please send us your dimensional drawing for checking.

External stops for gate OPEN and gate CLOSED are mandatory for the

gate openers KOMET200, KOMET 400, and KOMET 600.

8.2 Installation dimensions (elevation)

Drawing6

1 Mounting support P

2 Mounting support T 24mm higher than mounting support P

Please make sure, that the gate wings can be moved easily and that the axis

of rotation is in a completely vertical position. Check that there is enough room

for the opener behind the opened gate.

1

7

Page 19

KOMET 200 - 60

0

WARNING! The controller needs to be disconnected while welding is

performed on the gate.

8.3 Installation at the gate and gate post

Drawing 7

1 Mounting support P

2 Mounting support P with base plate (on side)

1. Secure the mounting support P on the gatepost at a height above the

ground in which the mounting support T can also be secured properly on

the gate. Welding seams have to be matched to the metal sheet thickness

of the mounting support P.

2. Close the gate so that it presses against the end stopper. Determine the

connection point of the mounting support T at the gate. Make sure that the

distance to the gate is sufficient, so that the gate opener does not touch

the gate later during movement. Using a water level determine the correct

height. Keep the necessary distance “E“ between the mounting supports P

and T.

Drawing 8

1 Mounting support T

2 Mounting support T with base plate (on side)

3. For steel gates: connect the mounting support T to the gate using tack

welding. If neccessary weld the mounting support to a reinforcement plate

(on site) and connect the reinforcement plate to the gate using tack

welding. For other gates: weld the mounting support to a support plate (on

site, approx.120x80x15mm) and connect the support plate to the gate (e.g.

using screws).

1

8

Page 20

KOMET 200 - 60

0

Drawing 9

4. Fit the gate opener with the joint bolts into the mounting supports P and T

at gatepost and gate. Release the opener as described under 9. page 22

Now open and close the

gate manually. Check if the gate can be moved

the complete distance between the end positions easily. Remove the gate

opener. Complete the final connection of the mounting supports P and T.

Grease the drill hole of the mounting support P slightly. Fit the gate opener

to the gate again. Tighten the screw at the gatepost, but not too tight.

Secure the fixing nut using the stop nut. Connect the joint bolt (gate) to the

mounting support T using the Screw.

5. All electrical connections should be according to the description for the MO

36control box 10 - Controller MO 36.

6.

Now close the gate and engage the gate opener. Continue with 10.3 Programming MO36.).

7.

Install now the periphery equipment like key switches, photo-cells etc. and

lay the electrical cabling according to the installation example on page 13.

Make sure that the cable cannot be

tensed or damaged by the gate or the

moving gate opener.

8.4 Adjusting of the internal stops (KOMET 200 and 280)

If external stops are installed, make sure that the gate wing pushes

against the external stop with slight force only.

1. Disengage the emergency release as described under 9 - Emergency

release .

2.

Move the gate wing/s to an opening angle of approx. 45°.

3. Reengage the emergency release.

4. Loosen the screw at the mounting support T.

5. Lift the narrow end of the gate opener out of the mounting support T.

6. Three counter sunk screws at the end of the arm and another three

between the aluminium arm and the push rod can now be seen from below

(these are the internal stops). Loosen these six screws. Move the internal

stops closer to the driver (joint bolt) using the socket wrench. Tighten the

screws slightly, so that the internal stops cannot shift accidentally on their

own.

1

9

Page 21

KOMET 200 - 60

0

Drawing 10

1 Internal stops

7. Replace and refit the opener to the mounting support T. Now connect the

opener/s to the terminals of the controller MO 36. Connect the main wing

to the terminal FAHR and the pedestrian wing to the terminal GEH. For

one winged gates connect the wing to the terminal FAHR.

8. Connect to the mains.

ATTENTION! During the next steps the gate wing will be moved electrically.

Make sure the range of movement is free from obstacles. During learning the

safety devices can react differently from the normal operation.

9. Press the button LERN on the controller for approx. 2 seconds. The

display shows p1.Press the button LERN again. The display now shows

1f.

10. Now select the number of gate wings. Push button BT until it displays 2f.

Confirm the displayed 2f (for two wings) with the button LERN. The

display shows ha (manual operation).

11. Now you can move each gate wing separately into the end positions in

slow mode (dead man´s function). The main wing moves into direction

OPEN only as long as button BT is pressed. When button BT is pushed

again, the wing moves into direction CLOSED. The pedestrian wing moves

into direction OPEN only as long as button BTG is pressed. When button

BTG is pushed again, the wing moves into direction CLOSED.

12. Now move the main wing with button BT into the end postitions OPEN and

CLOSED. Now move the pedestrian wing with button BTG into the end

positions OPEN and CLOSED. The internal end stops are now adjusted

but not fixed.

13. Move the gate wings with button BT and BTG into position „half OPEN“.

ATTENTION! Do not give any further commands to the controller now.

14. Remove the plug from the 5-pin connection FAHR and GEH.

15. Loosen the screw at the mounting support T. Lift the narrow end of the

gate opener out of the mounting support T.

16. The three counter sunk screws from the internal stop must be tightened

by allen key.

17. Replace and refit the opener to the mounting support T.

18. Now connect the gate opener to the controller MO36.

2

0

Page 22

KOMET 200 - 60

0

21

ATTENTION! The gate moves automatically during the next installation step.

19. During the following step the controller learns the running distance of the

(one or two) gate wings. Push the button LERN. The controller sends the

wing/wings into direction OPEN to the end stop and then into direction

CLOSED to the end stop. The display shows P2.

20. The gate is now in position CLOSED. Should the gate now be in position

OPEN, the wires 4 and 5 of the motor connection cable at the 5-pin

connection have to be switched. Then repeat by pressing button BTG

once (1x - display p1) and pressing button LERN three times (3x - display

1f, ha and au).

21. Push the button BT until pp is displayed. Confirm with button LERN.

22. Continue with paragraph - Programming MO36.

Shall the end position of one or both gate openers be changed, proceed us

described under 8.4 - Adjusting of the internal stops (KOMET 200 and 280).

You may also loosen the end stops separately and thus adjust them.

Page 23

KOMET 200 - 60

0

9 Emergency release

9.1 Emergency releasing

Depending on the accessibility remove either the plastic cap on top or the one

at the bottom of the gate opener. Place the wrench into the opening until it

engages into the locking device (hexagon socket).

Drawing 11

1 release

2 engage

When using the top emergency release, turn the wrench approx. ½ turn

anticlockwise. When using the bottom emergency release, turn the wrench

approx. ½ turn clockwise. The gate wing can now be moved freely.

The display in the controller shows ef (EF = message from the controller MO

36 that at least one opener is disengaged).

9.2 Engaging of emergency release

Insert the wrench into the emergency release. Turn the wrench approx. ½ turn

clockwise. The overcoming of the dead point must be clearly noticeable (when

engaging the emergency release at the bottom, turn the wrench

anticlockwise). In case the wrench can only be moved slightly out of its original

position, move the gate wing until the teeth of the gear interconnect and the

wrench can be moved approx. ½ turn.

When the emergency release is correctly engaged, the display on the

controller stops showing ef.

At the next use of BT the gate wing moves into position OPEN for

synchronizing. At the following use of BT the opener moves in normal mode.

2

2

Page 24

KOMET 200 - 60

0

10 Controller MO 36

10.1 Electrical installation

The leads must be inserted from below. For gates with two wings a minimum

cross section [mm²] of the lead is necessary, which is determined by the

length of the lead between the 2.opener and the controller.

Cross sections selected too small will have adverse effect on the motor

performance.

For the gate openers (with controller MO 36) the following lead dimensions are

required:

Cross section: 5 x 1,5mm² up to 15m distance

Cross section: 5 x 2,5mm² up to 20m distance

Power supply for the controller: 230Vac, 50Hz, single Phase

Connection: By fixed wiring and main switch (on site) or flexible wiring with

cable stress relief device according to the European standards.

The provided motor cable is only suitable for the short way to the connection

box; a mechanical protection should be used where applicable. For the longer

connection distance between gate opener and controller please use a suitable

cable. Here also use a mechanical protection (conduit) if applicable.

REMARK! For the connection of the motor lead to the controller MO 36 use

solely leads with flexible conductors, like e.g. ÖLFLEX ROBUST 210.

Cable configuration:

Mark Contacts on the MO 36

1 GND

2 IMP

3 I+

4 M-

5 M+

Table 6

2

3

Page 25

KOMET 200 - 60

0

10.2 Connections

10.2.1 Connection plan of the controller MO36

Each safety contact strip terminal which is not used has to be linked to an

8.2kΩ resistor.

Each photo-cell and stop terminal which is not used has to be linked to a

j

umper.

Drawing 12

24

Page 26

KOMET 200 - 60

0

10.2.2 Input terminals

Input Description Connection Function

BT n.o. contact 1 pin Push button (serial

switching)

BTG n.o. contact 1 pin Push button for pedestrian

opening

BA n.o. contact 1 pin Push button OPEN

BZ n.o. contact 1 pin Push button CLOSE

Ground - 1 pin Mutual ground BT, BTG, BA

and BZ

BS n.c. contact 1 pin Push button STOP

Ground - 1 pin Ground for STOP

LSA

LSI

Each max. 6 photocells with n.c. contact

and terminating

resistor 1kΩ

2 pin Photo-cells for installation

outside (LSA) and inside

(LSI)

(according to EN954-1

category 2)

Ground - 1 pin Mutual ground LSA and LSI

SLA

SLZ

Safety contact profile:

resistor detection n.c.

contact with 8.2kΩ

resistor (serial or

parallel with n.o.

contact with 8.2 kΩ)

2 pin Integrated detectors with

testing function (according

to EN954-1 category 2) for

safety contact profile for

gate OPEN (SLA) and

CLOSE (SLZ)

Ground - 1 pin Mutual ground SLA and SLZ

IMPg pulser See motor Pulser for pedestrian wing

IMPf See motor Pulser for main wing

SU Plug socket Connection for timer module

ASU2

Funk Plug socket

for receiver

EKX1OF or

receiver

with

decoder

Integrated receiver for BT,

BTG and MULTI

Netz

(L1, N

and

PE)

- 3 pin Power supply

230Vac – L1, N and PE

Table7

10.2.3 Buttons on the controller

Mark Function

2

5

Page 27

KOMET 200 - 60

0

BT Same function as external button BT

BTG Same function as external button BTG

LERN Starting the learning mode

Table 8

10.2.4 LEDs on the controller

Mark Colour Function Desired value

Vp Yellow Lights when connected to main

power

ON

SLA Red Lights when safety contact

profile SLA active

OFF

SLZ Red Lights when safety contact

profile SLZ active

OFF

BT Green Lights when the contact is closed OFF, when

pushing button =

ON

BTG Green Lights when the contact is closed OFF, when

pushing button =

ON

BA Green Lights when the contact is closed OFF, when

pushing button =

ON

BZ Green Lights when the contact is closed OFF, when

pushing button =

ON

BS Green Lights when the contact BS is

closed

ON

LSA Green Lights when LSA is interrupted OFF

LSI Green Lights when LSI is interrupted OFF

Display Red 2 x 7-segment-display OFF

Table 9

2

6

Page 28

KOMET 200 - 60

0

10.2.5 Output terminals

Output Connection Corresponds to:

Motor

pedestrian

wing

and IMP

g

5 pin Connection for 24Vdc motor and pulser for

the pedestrian wing

Motor main

wing

and IMP

f

5 pin Connection for 24Vdc Motor and pulser for

the main wing or for one-winged gates

SCHLOSS 3 pin Connection for electromagnetic bolt or

magnetic lock with 24Vdc (max. 1A)

WARN 2 pin Potential-free contact for warning light

230Vac /max. 60W

MULTI 2 pin Potential-free contact for multi-functional

relays(230Vac / max. 60W)

Uext 3 pin 24Vdc and 12Vdc, mutual ground terminal,

stabilised direct voltage, together max.

300mA, ground terminal is connected with

controller ground

LS-TEST 1 pin 24Vdc for photo-cell transmitter

PE 1 pin Earth

AMPEL 2 pin Socket for traffic light module AMO34A red /

green

Table 10

10.3 Programming MO36

For programming and to set operating parameters, use the two-digit 7segment display and the buttons BT, BTG and LERN.

At least the following sequences have to be learned as basic

configuration:

P1 - Learning of running distance

P2 - Selecting of force and speed

PC - Pressure relief of electromechanical bolt (mandatory when

using optional internal blocking)

10.3.1 Learning sequence

During normal operation the display is off. The learning sequence is

activated by pushing the button LERN for approx. 2s. The display shows

P1. The sequence 1 is pre-set. With the button BT you can move on to the

next sequence P2, P3 etc. With the button BTG you can move back to the

last sequence. When the required sequence is displayed it has to be activated

with the button LERN.

Sequence Function

p1

Selection one wing / two wings

2

7

Page 29

KOMET 200 - 60

0

Adjusting of end stops

Learning of safety contact profiles and photo-cells

connected

Learning of running distance

p2

Adjusting of force and speed

p3

Adjusting of time lag of the pedestrian wing during closing

p4

Adjusting of time lag of main wing during opening

p5

Learning of radio remote control codes for BT, BTG and

MULTI

Deleting of radio remote control codes for BT, BTGand

MULTI

p6

Automatic closure for complete opening (for both wings)

activating / deactivating

change stay-open time

p7

Automatic closure for pedestrian wing

activating / deactivating

change stay-open time

p8

Selecting of warning prior to opening and closing

p9

Selecting of photo-cell function

pa

Activating / deactivating photo-cell testing

pb

Activating / deactivating lockage function for photo-cells

pc

Selecting pressure relief of electromagnetic bolt

pd

Selecting wind blast suppression

pe

Selecting mode of multi-functional relay

pf

Return to original settings

pp

Saving of data and returning to regular mode

Table 11

10.3.1.1 Sequence P1: Learning of the running distance

When sequence P1 has been activated, it has to be selected first between

gates with one (1F) or with two (2F) wings using button BT. Then confirm the

selection with button LERN.

Display Effect / Function

1f

To operate gates with one wing

2f

To operate gates with two wings

Table 12

Then ha is displayed. The gate wings now can be operated by dead man’s

motion using buttons BT or BTG to adjust the internal mechanical end. BT

is used for the main wing and BTG for the pedestrian wing. The first

direction is always OPEN.

2

8

Page 30

KOMET 200 - 60

0

ATTENTION! During learning the safety devices may act different from the

regular operation. Please ensure that no people are in the danger area during

learning.

After adjusting the end stoppers, push the button LERN to continue: The

controller tests the safety contact strips and the photo-cells. It learns the type

of the safety contact strips (8.2 kΩ) and the number of connected photo-cells.

Only when this photo-cell testing was successful, additional photo-cell tests

can be carried out during future operation.

Gates with

one wing:

During learning of the running distance the wing opens first

and then closes.

Gates with

two wings:

During learning of the running distance the pedestrian wing

opens, the main wing opens, the main wing closes and

pedestrian wing closes.

In both cases the wings move until they hit the stoppers at the closed position.

During the learning of the running distance the pressure relief of the

electromechanical bolt is not in function. The electromechanical bolt is being

activated during each wing movement. After the learning of the running

distance, returning to the main sequence follows automatically.

Remark: After adjustment of the end stoppers, the wings should not be in

either end position but at least 50cm before. The first movement is into

direction open.

10.3.1.2 Sequence P2: Adjusting of force and speed

The force and speed can be adjusted for each wing separately, and for

opening and closing separately.

When sequence P2 is activated by button LERN an additional selection menu

for force and speed opens. With button BT you may move to different

points of the selection menu.

Subsequence Function

f1

Force for opening of main wing (2-winged gates) / the wing

(1-winged gates)

f2

Force for closing of main wing (2-winged gates) / the wing

(1-winged gates)

f3

Force for opening of pedestrian wing. No function with 1winged gates.

f4

Force for closing of pedestrian wing. No function with 1winged gates.

s1

Speed for opening of main wing (2-winged gates) / the wing

(1-winged gates)

s2

Speed for closing of main wing (2-winged gates) / the wing

(1-winged gates)

s3

Speed for opening of pedestrian wing. No function with 1winged gates.

s4

Speed for closing of pedestrian wing. No function with 1winged gates.

2

9

Page 31

KOMET 200 - 60

0

13

With the button LERN the selected point can be activated. The present value

for force (F = force) or speed (S = speed) is displayed. Possible values are

01 (for minimum force) up to 99 (for maximum force) or 01 (for minimum

speed) up to 08 (for maximum speed). With button LERN the values may be

increased, with the button BTG they can be decreased. Return to the learning

sequence using button LERN.

ATTENTION! The maximum force (F1 - F4) has to be adjusted according to

the relevant gate opener using the learning sequence. If a force higher than

shown below is adjusted, the motor will not be able to reverse on obstacle.

Swing gate opener Adjustment range

KOMET 200/202 F1 – F4 = max. 35

KOMET 280/282 F1 – F4 = max. 35

KOMET 400/402 F1 – F4 = max. 45

KOMET 600/602 F1 – F4 = max. 55

Table 14

10.3.1.3 Sequence P3: Time lag of the pedestrian wing (closing)

When sequence P3 is activated by button LERN, the present value for the

time lag of the pedestrian wing during closing is displayed. Possible values are

00 (for 0s) up to 09 (for 9s). The value can be increased using button BT

and decreased using button BTG. Return to the learning sequence using

button LERN.

Remark: When a time lag is selected for gates with one wing, it will not be in

effect.

10.3.1.4 Sequence P4: Time lag of the main wing (opening)

When sequence P4 is activated by button LERN, the present value for the

time lag of the pedestrian wing during closing is displayed. Possible values are

00 (for 0s) up to 09 (for 9s). The value can be increased using button BT

and decreased using button BTG. Return to the learning sequence using

button LERN.

Remark: When a time lag is selected for gates with one wing, it will not be in

effect.

10.3.1.5 Sequence P5: Learning and deleting of code for radio remote control

To learn a code the transmitter has to be operated. The code will then be

stored. When sequence P5 is activated with the button LERN, an additional

selection menu is displayed for selecting the code. Move to the next point

using button BT.

Sub-sequence Function

c1

Radio remote control code for BT can be learned or deleted

c2

Radio remote control code for BTG can be learned or

deleted

3

0

Page 32

KOMET 200 - 60

0

c3

Radio remote control code for MULTI can be learned or

deleted

Next Return to main sequence

Table 15

Sub-sequence is activated with button LERN. The display shows:

Display Corresponds to:

--

The selected radio remote control code is deleted and

another can be learned.

xx

The selected radio remote control code is already stored and

can be overwritten or deleted.

Table 16

To erase the radio remote control code, press and hold the button BT and

additionally push the button LERN. The radio remote control code is erased.

Return to the subsequence follows automatically. If only the button LERN is

pushed, then return to the subsequence follows immediately without erasing

the code.

Radio remote control signal: Receiving of a learned radio remote control

signal is displayed through lighting of the right display dot.

31

Page 33

KOMET 200 - 60

0

10.3.1.6 Sequence P6: Automatic closure for complete opening

When sequence P6 is activated by button LERN, the present value for stayopen time for complete opening is displayed. Possible values are -- (not

activated), 01 up to 299 (for 1s -299s). The value can be increased using

button BT and decreased using button BTG. The decimal dots of the

display are each equal to 100 (one lit dot = 100 / two lit dots = 200).

Display(example) Corresponds to:

--

Automatic closure is deactivated.

23

Automatic closure is activated. Stay-open time 23

seconds.

2.3

Automatic closure is activated. Stay-open time 123

seconds.

2.3.

Automatic closure is activated. Stay-open time 223

seconds.

Table 17

Return to the learning sequence using button LERN.

When using automatic closure both wings close automatically after the learned

stay-open time has elapsed. The stay-open time starts elapsing when the last

wing has reached the position OPEN.

When contact BS is opened, the automatic closure function is blocked.

When the stay-open time has elapsed and the safety contact profile for

direction CLOSE (SLZ) is currently activated, the gate remains open. The

elapsed stay-open time will not be repeated. When the SLZ is not

activated anymore and the stay-open time has elapsed, the warning time

prior to closing starts.

When the automatic closure function is blocked it will be reactivated with a

new signal (BA or BT).

When the lockage function for the photo-cells is activated, the automatic

closure function is blocked, as long as an obstacle is present between the

photo-cells (see sequence PB).

When the gate hits an obstacle during closing and reversing is activated

through SLZ, the gate opens. When automatic closure is activated and the

obstacle is not removed, the gate will try to close twice. After hitting the

obstacle for the second time the gate will reverse for a short distance and

stop.- The counting will be erased when using BT, BA, or BZ.

3

2

Page 34

KOMET 200 - 60

0

10.3.1.7 Sequence P7: Automatic closure for pedestrian wing

When sequence P7 is activated by button LERN, the present value for stayopen time for the pedestrian wing is displayed. Possible values are -- (not

activated), 01 up to 299 (for1s - 299s). The value can be increased using

button BT and decreased using button BTG. The decimal dots of the

display are each equal to 100 (one lit dot = 100 / two lit dots =200).

Display(example) Corresponds to:

--

Automatic closure is deactivated.

23

Automatic closure is activated. Stay-open time 23

seconds.

2.3

Automatic closure is activated. Stay-open time 123

seconds.

2.3.

Automatic closure is activated. Stay-open time 223

seconds.

Table 18

Return to learning sequence using button LERN.

When using automatic closure the pedestrian wing closes automatically after

the learned stay-open time has elapsed. The stay-open time starts elapsing

when the wing has reached the position OPEN.

When contact BS is opened, the automatic closure function is blocked.

When the stay-open time has elapsed and the safety contact profile for

direction CLOSE (SLZ) is currently activated, the gate remains open. The

elapsed stay-open time will not be repeated. When the SLZ is not

activated anymore and the stay open time has elapsed, the warning time

prior to closing starts.

When the automatic closure function is blocked it will be reactivated with a

new signal (BA or BT).

When the lockage function for the photo-cells is activated, the automatic

closure function is blocked, as long as an obstacle is present between the

photo-cells (see sequence PB).

When the gate hits an obstacle during closing and reversing is activated

through SLZ, the gate opens. When automatic closure is activated and the

obstacle is not removed, the gate will try to close twice. After hitting the

obstacle for the second time the gate will reverse for a short distance and

stop. The counting will be erased when using BT, BA, or BZ.

3

3

Page 35

KOMET 200 - 60

0

10.3.1.8 Sequence P8: Warning prior to opening and closing

When sequence P8 is activated by button LERN, the present value for

warning time (opening and closing) is displayed. With the button BT the value

can be selected (see table).Return to the learning sequence using button

LERN. The warning light is only active, when a gate wing is moving and during

warning prior to opening and closing.

Display Warning time before

opening

Warning time before

closing

oo

No warning time No warning time

o4

No warning time 4 seconds warning time

4o

4 seconds warning time No warning time

44

4 seconds warning time 4 seconds warning time

Table 19

10.3.1.9 Sequence P9: Photo-cell function

When sequence P9 is activated by button LERN, the present selection for the

photo-cell function is displayed. With the button BT the value can be selected

(see table). Return to the learning sequence using button LERN.

Drawing 13

Function Photocell Gate not

moving

Gate opens Gate closes

l1

LSI Remains not

moving

Stops when

interrupted,

opens when

free again

Stops when

interrupted,

opens when

free again

LSA Remains not

moving

Stops when

interrupted,

opens when

free again

Stops when

interrupted,

opens when

free again

34

Page 36

KOMET 200 - 60

0

l2

LSI Remains not

moving

Stops when

interrupted,

opens when

free again

Stops when

interrupted,

closes when

free again

LSA Remains not

moving

Stops when

interrupted,

opens when

free again

Stops when

interrupted,

closes when

free again

l3

LSI Only closing

allowed

Stops when

interrupted,

opens when

free again

No effect

LSA Only opening

allowed

No effect Stops and

opens

immediately

Table 20

3

5

Page 37

KOMET 200 - 60

0

10.3.1.10 Sequence PA: Photo-cell testing

Prior to every gate movement a photocell test may be performed. The test

consists of two phases. During the first phase the supply of the transmitters is

switched off. The controller expects within the next 2.5 s that the receiver

reports an obstacle. During the second phase the supply of the transmitter is

switched on again. The controller expects the receiver to report no obstacle

any more. Only after this procedure the gate can move. If an error occurs in

the first phase, the photocell (receiver) is damaged. The gate will not move.

An error message is given through the display. If an error occurs in the second

phase, the controller interprets this as a real obstacle. The gate will not move.

No error message is given. You may connect and test each (LSI and LSA)

maximum 6 pairs of photocells with the controller MO 36. Therefore add all

n.c. relay contacts of the receivers in serial. Parallel to each relay contact you

must add a 1kOhm resistor (resistors are needed only when photocell test is

used).

Drawing 14

ATTENTION! The MO 36 must learn how many photocells are connected to it.

Activate the test by setting PA = ON and run the learning of the running

distance P1.

After this please check every single photocell for proper function.

REMARK: When a faulty photo-cell is detected during photo-cell testing or

when an obstacle is present within the photo-cell, the gate can be opened and

closed in emergency mode (dead man’s function).

When sequence PA is activated by button LERN, the present selection for

the photo-cell testing is displayed. With the button BT the value can be

selected (see table).Return to the learning sequence using button LERN.

Display Corresponds to:

xf

Photo-cell testing deactivated

xn

Photo-cells, which have past the LS-Test during sequence

P1, will execute photo-cell testing also in regular mode.

3

6

Page 38

KOMET 200 - 60

0

Table 21

10.3.1.11 Sequence PB: Lockage function for the photo-cells

Drawing 15

When using photo-cells in connection with the automatic closure for both

wings, a lockage function is possible. To activate this function use the learning

sequence.

The lockage function is only activated when the gate is opened.

When the gate reaches the end position OPEN, the lockage function is

initialised. This means: when a vehicle passes through the gate from the

outside, a signal from LSA (photo-cell outside) blocks the automatic

closure function. Only the signal from LSI (photo-cell inside) removes the

blocking and starts the stay-open time.

When a vehicle passes through the gate from the inside, a signal from LSI

blocks the automatic closure function. Only the signal from LSA removes

the blocking and starts the stay-open time.

When sequence PB is activated by button LERN, the present selection is

displayed. With the button BT the value can be selected (see table).Return to

the learning sequence using button LERN.

Display Corresponds to:

xf

Lockage function is deactivated.

xn

Lockage function is activated (only working when automatic

closure is selected.) When the photo-cell is interrupted,

closing of the gate wing / wings is only possible, when the

vehicle / person has passed both (LSA and LSI) photo-cells.

Table 22

10.3.1.12 Sequence PC: Pressure relief of electromechanical bolt

When sequence PC is activated by button LERN, the present selection is

displayed. With the button BT the value can be selected (see table). Return to

the learning sequence using button LERN.

3

7

Page 39

KOMET 200 - 60

0

Display Corresponds to:

S1

Pressure relief for electromagnetic bolt is deactivated.

S2

The gate wing pushes slowly (500ms min., but 1000ms max.)

against the end stopper until the selected force is reached.

S3

The gate wing pushes slowly (500ms min., but 2000ms max.)

against the end stopper until the selected force is reached.

S4

The gate wing pushes slowly (500ms min., but 90s max.)

against the end stopper until the selected force is reached.

Table 23

10.3.1.13 Sequence PD: Wind blast suppression

It can be chosen to either reverse on obstacle immediately, or to reverse after

a preset time. When setting a time, a short wind blast or an oscillating gate

wing do not result in a stop (and reversal).

ATTENTION! Only use the wind blast suppression, when additional

safety devices like photo-cells and safety contact profiles are installed at

the gate.

When sequence PD is activated by button LERN, the present selection is

displayed. With the button BT the value can be selected (see table). Return to

the learning sequence using button LERN.

Display Corresponds to:

u-

No wind blast suppression. The controller immediately reacts

on obstacle/wind blast.

u1 bis u9 The wind blast suppression equals 1s (for U1) up to 9s (for

U9). The controller reacts on obstacle / wind blast only after

the selected time1s (for U1) up to 9s (for U9).

Table 24

10.3.1.14 Sequence PE: Multi-functional relay

The multi-functional relay on the controller is suitable for four different modes.

During learning function the relay is inactive.

When sequence PE is activated by button LERN, the present selection is

displayed. With the button BT the value can be selected (see table).

Return to the learning sequence using button LERN.

Display Corresponds to:

r1

Push button mode: The relay is active as long as the

controller receives the radio remote control code MULTI.

r2

Toggle mode: The relay alternates between active and

deactive with each radio remote control code MULTI.

r3

Light pulse mode: The relay is active for 1 second, when BT,

FunkBT, BTG, Funk BTG, BA or BZ are pushed.

r4

3-minute light: The relay is active for 180 seconds, when BT,

FunkBT, BTG, Funk BTG, BA or BZ are pushed.

Table 25

3

8

Page 40

KOMET 200 - 60

0

10.3.1.15 Sequence PF: Return to original settings

When sequence PF is activated by button LERN, re is displayed. To return

to original settings, press and hold button BT and push button LERN.

When only button LERN ispushed, you return to learning sequence without

changing any values. After returning to original settings, the running distance

has to be relearned.

3

9

Page 41

KOMET 200 - 60

0

10.4 Safety contact profiles for gate open (SLA) and close

(SLZ)

Gates with two wings: When a safety contact profile is activated, both motors

react.

The controller has two integrated detectors with testing function (according to

EN954-1 category 2 for safety contact profiles with 8.2kOhm resistor) for gate

OPEN and CLOSE. The status of the safety contact profiles is displayed by

red LEDs (SLA and SLZ). When the safety contact profile is activated, the

matching LED lights.

Direction of

movement

Function of SLA Function of SLZ

From stop to open Only possible in

emergency mode

-

From stop to

closing

- Only possible in

emergency mode

Opening Stop and movement for a

short distance into

direction closed

-

Closing - Stop and re-opening

Table 26

Automatic closure: When the gate hits an obstacle during closing and

reversing is activated through SLZ, the gate opens. When automatic closure is

activated and the obstacle is not removed, the gate will try to close twice. After

hitting the obstacle for the second time the gate will reverse for a short

distance and stop.- The counting will be erased when using BT, BA, or BZ.

The connection of the n.o. contact with 8.2kΩ ±5% resistor (parallel) or the n.c.

contact with 8.2kΩ ±5% resistor (serial) is possible. In case no safety contact

profiles are connected, an 8.2kΩ ±5% resistor has to be connected. When

using more than one safety contact profile, they can be connected in

sequence (see drawing below).

Drawing 16

4

0

Page 42

KOMET 200 - 60

0

10.5 Additional modules

10.5.1 Timer module ASU2 (optional)

The timer module can be plugged onto the controller. Function: When the

timer has reached the set time for open, it sends an OPEN command to the

controller. The gate cannot be closed as long as the timer is activated. After

the open time has elapsed, the timer sends a CLOSE command to the

controller. Note: When the timer sends the CLOSE command, the gate is

closed immediately, even when automatic closure is activated.

10.5.2 Traffic light module AMO34A (optional)

Red and/or green traffic lights can be connected to the traffic light module.

Drawing 17

Gate position Red traffic light Green traffic light

Gate is

completely

open

Off On

Gate is not

open (it is

moving,

partially open,

orclosed)

On Off

Table 27

41

Page 43

KOMET 200 - 60

0

10.6 Power failure

After power failure or disconnecting from mains the position of the wing/wings

is unknown to the controller. The controller first works in a starting mode. The

wings are moving slowly. A pressure relief of electromagnetic bolt occurs

before every movement. The wings close one after the other. When stopping

at the end position (closed), the controller recognises this position. The

controller continues in its regular mode. Note: Emergency mode is possible

during the starting mode.

10.7 Fault diagnosis

An error is shown on the display as a code, when detected by the controller.

The following errors are recognised and displayed.

Display Error

e1

Photo-cell testing LSI failed.

e2

Photo-cell testing LSA failed.

e3

Testing safety contact profile SLA failed.

e4

Testing safety contact profile SLZ failed.

e5

Running distance exceeded (gate was stopped). Check end

stoppers and re-learn the running distance.

e6

The power supply limit for the external equipment 12V has

been reached. The power source load is too high. The

controller is blocked.

e7

The power supply limit for the external equipment 24V has

been reached. The power source load is too high. The

controller is blocked.

e8

The memory data has been lost / is faulty. The controller has

to be relearned.

e9

Error in storing of data on memory. Controller is faulty. Return

for repairs.

ea

Error in the redundant detection of BS. Controller is faulty.

Return for repairs.

eb

The controller detects one of the motor relays is faulty. Return

for repairs.

ec

Measuring amplifier faulty. Return for repairs.

ed

The main wing pulser is faulty. Check the wiring between the

opener and controller.

ee

The pedestrian wing pulser is faulty. Check the wiring

between the opener and controller.

ef

Power supply Uext has a short cut. OR At least one wing is

released. Check the emergency release.

Table 28

4

2

Page 44

KOMET 200 - 60

0

10.8 Emergency mode

In case a safety device (LSA, LSI, SLA or SLZ) is faulty, emergency mode is

possible. After a warning time of 10 seconds, the gate can be moved in an

emergency mode by using BA or BZ (dead man’s function). During the

warning time as well as during the emergency mode the warning light is

flashing. Emergency mode by radio remote control BT or BTG) is not possible

due to safety reasons.

WARNING!

Even when a safety device is faulty, the gate can be moved by BA and

BZ. The buttons BA and BZ therefore have to be installed in such a way,

that the gate can be seen during movement.

WARNING!

Are external devices -giving a constant signal (e.g. timer) - connected to

BA or BZ, these devices can activate the emergency mode and move the

gate when a safety feature is faulty or active.

WARNING!

In case the multi-functional relay is used for an additional radio remote

channel, which is connected to BA or BZ, the emergency mode can be

started by radio remote control. In this case only fixed transmitters

should be used in such away, that the gate can be seen during

movement.

4

3

Page 45

KOMET 200 - 60

0

10.9 Parameter and Original settings

Constant, not changeable values

Parameter Original

settings

Time-lag before reactivating motor 500ms

Reversing for a short distance on obstacle 500ms

Time-lag before reversing 200ms

Max. running time limit 500s

Running time reserve during regular mode 10s

Warning time prior to emergency mode 10s

Table 29

Changeable values

Parameter Selection

range

Original

settings

Running distance Max. 32.000

Impulse

3.000

Impulse

Force 1 - 99 30

Speed 1 / 8 8

Time lag during opening 0s - 9s 2s

Time lag during closing 0s - 9s 5s

Stay-open time for both wings 1s - 299s /

OFF

OFF

Stay-open-time for pedestrian wing 1s - 299s /

OFF

OFF

Wind blast suppression 0s - 9s 0s

Warning prior to opening 0s / 4s 0s

Warning prior to closing 0s / 4s 0s

Pressure relief of electromagnetic bolt 0s / 1s / 2s /

90s

0s

Multi-functional relay Push button

mode /

Togglemode

/ Light pulse

/ 3-minute

light

Push

button

LS lockage function ON / OFF OFF

Photo-cell function L1 / L2 / L3 L1

Number of wings 1 / 2 1

Photo-cell testing ON / OFF OFF

44

Page 46

KOMET 200 - 60

0

4

5

Radio remote control code BT X-Code - + - + -

+ - + -

All other radio remote control codes X-Code deleted

Table 30

Page 47

KOMET 200 - 60

0

Index

C

Connections ............................... 24

Controller MO 36 .................. 19, 23

D

Declaration of incorporation ......... 8

E

Emergency mode ....................... 43

Emergency release .............. 19, 22

F

Fault diagnosis ........................... 42

G

General notes on safety ............... 5

I

Installation example ................... 13

Intended use ................................ 5

L

learning sequence ...................... 27

N

Name plate ................................... 9

O

Original settings .......................... 44

P

Parameter ................................... 44

Power failure ............................... 42

R

radio remote control ...................... 5

S

Storing .......................................... 7

Symbol explanation ...................... 4

T

Technical Data ............................ 11

Transportation and storing ............ 7

Transportation inspection ............. 7

U

Usage ......................................... 10

4

6

Loading...

Loading...