Page 1

Installation and operating instructions

Barriers

ES 25 – ES 25HS – ES 30HS – ES 30

ES 40 – ES 50 – ES 60 – ES 80

1.

1.1. Dimensions ES 25 – ES 40 2

1.2. Installation ES 25 – ES 40 3

2.

2.1. Dimensions ES 50 – ES 80 4

2.2. Installation ES 50 – ES 80 5

3.

3.1 Connections 6

3.2. Further connections 7

3.3 Visual indication 7

4. Operating mode MO 63 8

5. Photo-cell test 9

6. Programming 9

6.1. Running time and automatic closure 9

6.2. Setting personal code for radio remote 10

7. External connections 10

8. Layout in the barrier 11

9. Fault finding 12

10. Examples for use of loop detectors 14

11. Maintenance 16

12. Radio remote control 16

13. Extra equipment (swinging support, folding boom) 17

14. General notes to safety 19

Contents page

Technical data ES 25 - ES 40

Technical data ES 50 - ES 80

Controller MO 63

2

4

6

© 03.10.2001 ELKA-Torantriebe GmbH & Co. Betriebs KG Seite 1

ES 25 – ES 40 mit MO63

Page 2

1. Technical data ES 25- ES 40

Operative range

Application

for ...

Drive pulse

from ...

Safety - Reversing on obstacle

- Parking area, parking garage

- Company entrance

- Safety area

- Toll-station

- Push-button, card reader, key swit ch,

remote control, desk top panel etc.

- Handsfree data-capture

- Induction loop

- Best protection against vandalism

- Ergonomic emergency release

General Data

Mains supply 230V / 50Hz

Max. current 2,5A

Duty cycle 100%

Temperature range -20°C to +70°C

Controller MO 63

Measurements (w/l/h) 350x300x1100 mm

Foundation (frost-proof) 550x500x800 mm

Boom connector left or right

Housing aluminium

Mechanical parts steel, zinc coated

Typical Data ES 25 * ES 25 HS * ES 30 HS * ES 30 ES 40

Drawn power 0.37 kW 0.37 kW 0.37 kW 0.25 kW 0.26 kW

Running time ca. 1.4 s ca. 0.9 s ca. 1.4 s ca. 2.3 s ca. 3.2 s

Maximum boom length 2500 mm 2500 mm 3000 mm 3000 mm 4000 mm

Effective length 2280 mm 2280 mm 2780 mm 2780 mm 3780 mm

Reversing on obstacle switchable switchable switchable switchable switchable

Boom weight /{ 4 / 2 kg 4 / 2 kg 4.7 / 2.3 kg 4.7 / 2.3 kg 6 / 3 kg

Barrier weight 47.5 kg 47.5 kg 47.5 kg 47.5 kg 50 kg

* Vehicle traffic only

The accident prevention regulations and the approved safety rules have to be observed.

Moving parts inside the barrier can cause accidents.

Do not operate the barrier when housing is open.

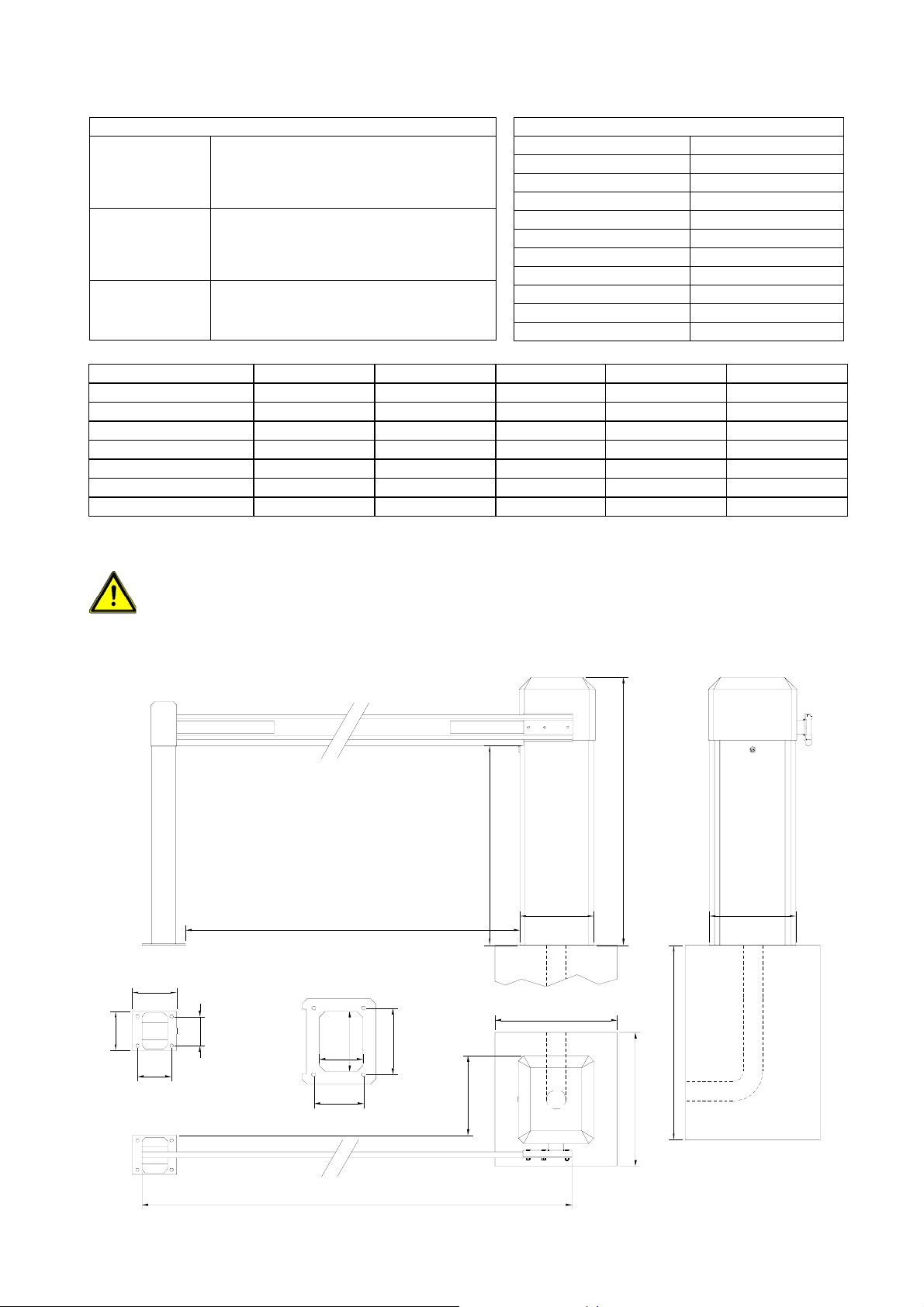

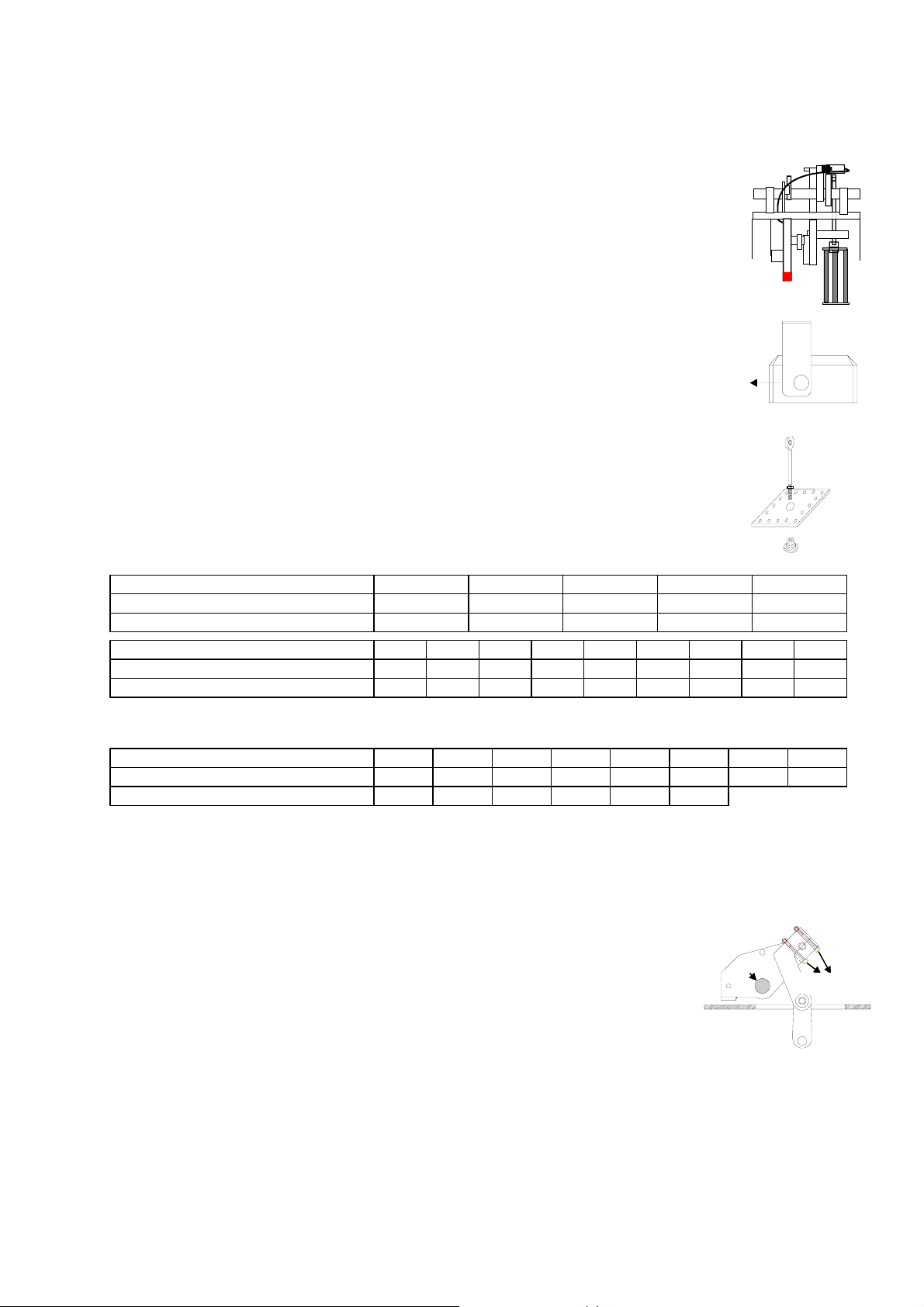

1.1. Measurements ES 25 – ES 40

1100

820

Boom length mi nus 360m m

160

140

130

Fixed suppo rt

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 2 ES 25 – ES 80 (MO63)

110

Drilling template

barr i er housing

247

179

Panel/Roadway

203

2500/3000/4000

273

320

300 350

500

800

550

Foundation

500x550x800

Page 3

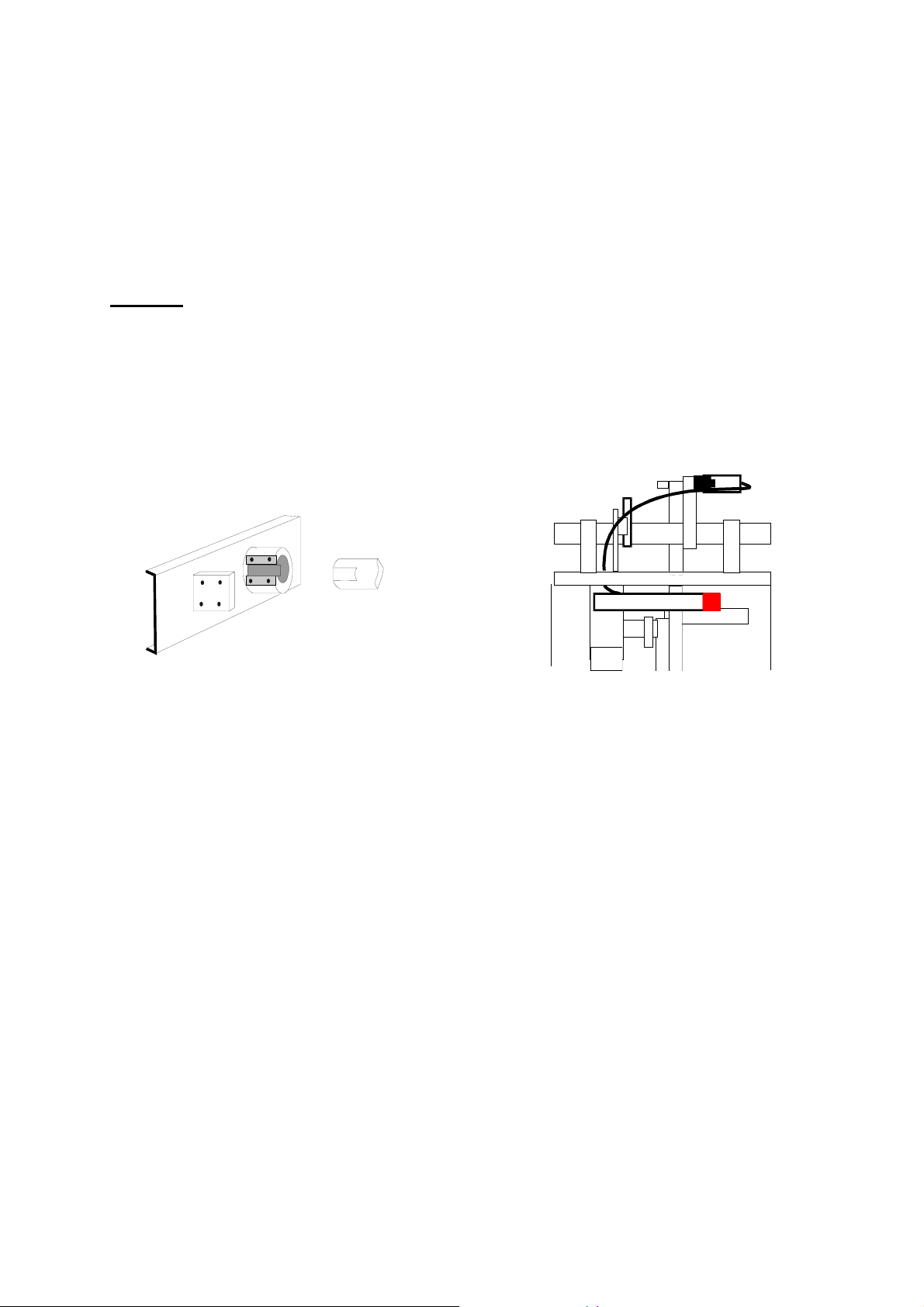

1.2. Installation ES 25 – ES 40

a) When you prepare the concrete foundation lay enough cable or a plastic duct for the cable you need.

The foundation must be at least 800 mm deep with a horizontal surface 500 x 550 mm.

b) Using the template you can, either incorporate bolts in the foundation, or drill holes in the hardened

concrete for heavy-duty fixings. The door side of the template must face towards the road on which the

barrier will be closing.

c) As an alternative 2 "U"-profile clamping-irons are delivered with the barrier. This gives more flexibility in

positioning the fastening points and allows the barrier to be aligned exactly as required.

Attention: The barrier is closed when shipped.

The door faces towards the road.

d) Secure the barrier on the foundation.

e) Connect the boom holder to the shaft. Tighten all screws, the top ones first with 35 Nm. The enclosed

nuts and bolts are a predetermined breaking point and should only be replaced with the same.

(Bolt M 8 x 45 ISO 4762 12.9, Nut hexagonal M 8 ISO 4032 5-2)

Boom holder

f) Emergency release during current failure etc. Pull the lever with the red end which is behind the access

panel. The boom can then be raised manually. To engage the boom again pull the lever and pull the

boom down, the release bolt will then lock at the appropriate position.

The controller is switched off until the boom is locked at the operating position.

g) Mount the boom before doing a test run. If necessary adjust the limit switches and the stoppers.

Release bolt

Shaft

Release lever

h) Start the programming mode (6.1 – Running time and automatic closure).

The logic board MO 63 is connected to the terminals (X1) in the barrier and to the microswitches in the head.

All electrical connections should be carried out at the front of the terminals (X1). The barrier is ready for use

when delivered. The running time and a ‘stay open’ time of 5 seconds are stored in an EEPROM.

You only need the programming mode if the time to stay open (when automatic closure is being used) is to

be altered, the photo-cell test is activated or when a controller is replaced.

Switch off the mains supply before altering the operating mode dip switches!

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 3 ES 25 – ES 80 (MO63)

Page 4

2. Technical data ES 50- ES 80

Operative range

Application

for ...

Drive pulse

from ...

Safety - Reversing on obstacle

- Parking area,

- Parking garage

- Company entrance

- Safety area

- Push button, card reader, key swit ch,

remote control, desk top panel etc.

- Handsfree data-capture

- Induction loop

- Best protecting against vandalism

- Ergonomic emergency release

General data

Mains supply 230V / 50Hz

Max. current 2.5A (max.)

Duty cycle 100%

Temperature range -20°C to +70°C

Controller MO 63

Measurements (w/l/h) 400x450x1100 mm

Foundation (frost-proofed) 600x650x800 mm

Boom connector central

Housing aluminium

Mechanical parts steel, zinc coated

Typical Data ES 50 ES 60 ES 80

Drawn power 0.26 kW 0.26 kW 0.26 kW

Running time ca. 4.0 s ca. 5.5 s ca. 8.5 s

Maximum boom length 5000 mm 6000 mm 8000 mm

Effective length 5140 mm 6140 mm 8140 mm

Fixed- / swinging support required required required

Reversing on obstacle switchable switchable switchable

Boom weight /{ 10 / 9 kg 16.5 / 11 kg 23 / 14 kg

Barrier weight 110 kg 115 kg 118 kg

The accident prevention regulations and the approved safety rules have to be observed.

Moving parts inside the barrier can cause accidents.

Do not operate the barrier when housing is open.

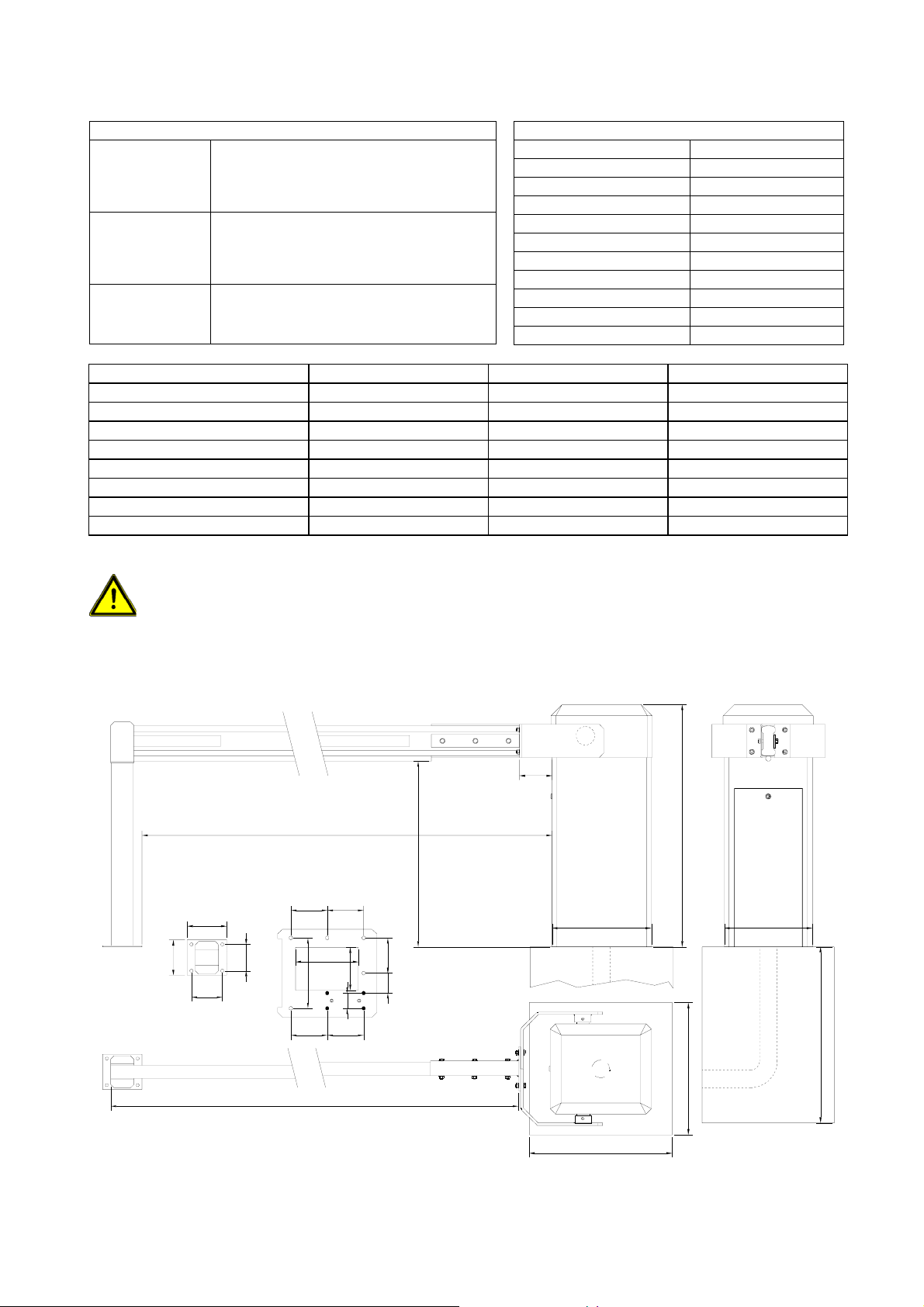

2.1. Measurements ES 50 – ES 80

160

140

130

Fixed support

Length of boom

110

Panel/Roadway

5000/6000/8000

Drilli ng temp late

barrie r ho us ing

165165

286

194

320

70

165165

M

1

1

M

1

3

1

2

x

6

5

843

160

90

13

M 12

M

3

3

1

1

2

2

x

x

6

6

5

5

145

1100

450 400

1313

13

13

M 12

M 12

1313

650

600

13

13

M 12

13

13

Foundation

600x650x800

800

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 4 ES 25 – ES 80 (MO63)

Page 5

2.2. Installation ES 50 – ES 80

a) When you prepare the concrete foundation lay enough cable or a plastic duct for the cable you need. The

foundation must be at least 800 mm deep with a horizontal surface 600 x 650 mm.

b) Emergency release during current failure etc. Pull the lever with the red end which is

behind the access panel. The boom can then be raised manually. To engage the boom

again pull the lever and pull the boom down, the release bolt will then lock at the

appropriate position. The controller is switched off until the boom is locked at the

operating position.

c) Using the template you can, either incorporate bolts in the foundation, or drill holes in the

hardened concrete for heavy-duty fixings. The door side of the template must face

towards the road on which the barrier will be closing. Secure the barrier on its foundation.

Ensure that the housing is vertical. The screws or bolts at the thickly marked points

(drawing on page 4) also secure the foot of the spring assembly.

d) The left and right parts of the boom assembly aren’t identical. The greater distance

between the edge and the hub must be towards the access panel. Secure the boom

assembly on both ends of the shaft. The barrier is delivered in the open position, which

means the assembly must be vertical. Secure the boom holder on the assembly. The two

parts are then joined together.

e) Remove the adjusting nut from the spring assembly. If the boom is to be shortened

reduce the number of springs. The following table shows approximate values, check that

the balance is as described under f). The springs must be divided equally between the

back and the front. One spring alone may not be used. The springs should be inspected

regularly and be tightened or replaced, if necessary.

Length of boom [mm] ES 50 3000 3500 4000 4500 5000

Springs without folding skirt 2 2 2 3 3

Spring with folding skirt 2 3 3 4 5

Length of boom [mm] ES60/80 4000 4500 5000 5500 6000 6500 7000 7500 8000

Springs without folding skirt 4 4 5 6 8 8 10 11 12

Spring with folding skirt 5 6 7 8 10 12 14 16 18

The following values are only for the round boom

Length of boom [mm] ES50/60/80 3000 4000 4500 5000 5500 6000 7000 8000

Spring without folding skirt 2 2 3 3 4 5 8 10

Spring with folding skirt 2 3 4 5 7 8/9

f) When all electrical connections are completed, ensure that the spring assembly is not yet connected to

the drive shaft. Close the barrier with the motor and then mount the boom. Pull the emergency release

lever and push the boom into the vertical position. Screw the adjusting nut onto the connecting rod and

tighten the springs. Pull the release lever again and push the boom down, if the spring tension is correct,

it should move easily to about 45°. After that the boom has to be pushed down.

g) The connecting rod of the ES 50 to ES 80 consists of two parts which are screwed

together and form a predetermined breaking point in case of vertical force on the

boom. The boom is then disconnected from the shaft and is pulled to about 45° by

the springs. If a break occurs here the nut and the bolts must be replaced with the

original ELKA vandalism set. The nuts must be secured with thread lock.

The nuts may only be replaceed with those supplied by ELKA.

h) Start the programming mode (6.1 – Running time and automatic closure).

The logic board MO 63 is connected to the terminals (X1) in the barrier and to the microswitches in the

head. All electrical connections should be carried out at the front of the terminals (X1). The barrier is

ready for use when delivered. The running time and a ‘stay open’ time of 5 seconds are stored in an

EEPROM.

You only require the programming mode if the time to stay open (when automatic closure is being used)

is to be altered, the photo-cell test is activated or when a controller is replaced.

Release bolt

Release lever

Panel

Shaft

Boom

assembly

Counter nut

Adjusting

nut

Pre-determined

breaking point

Switch off the mains supply before altering the operating mode dip switches!

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 5 ES 25 – ES 80 (MO63)

Spring assembly

Page 6

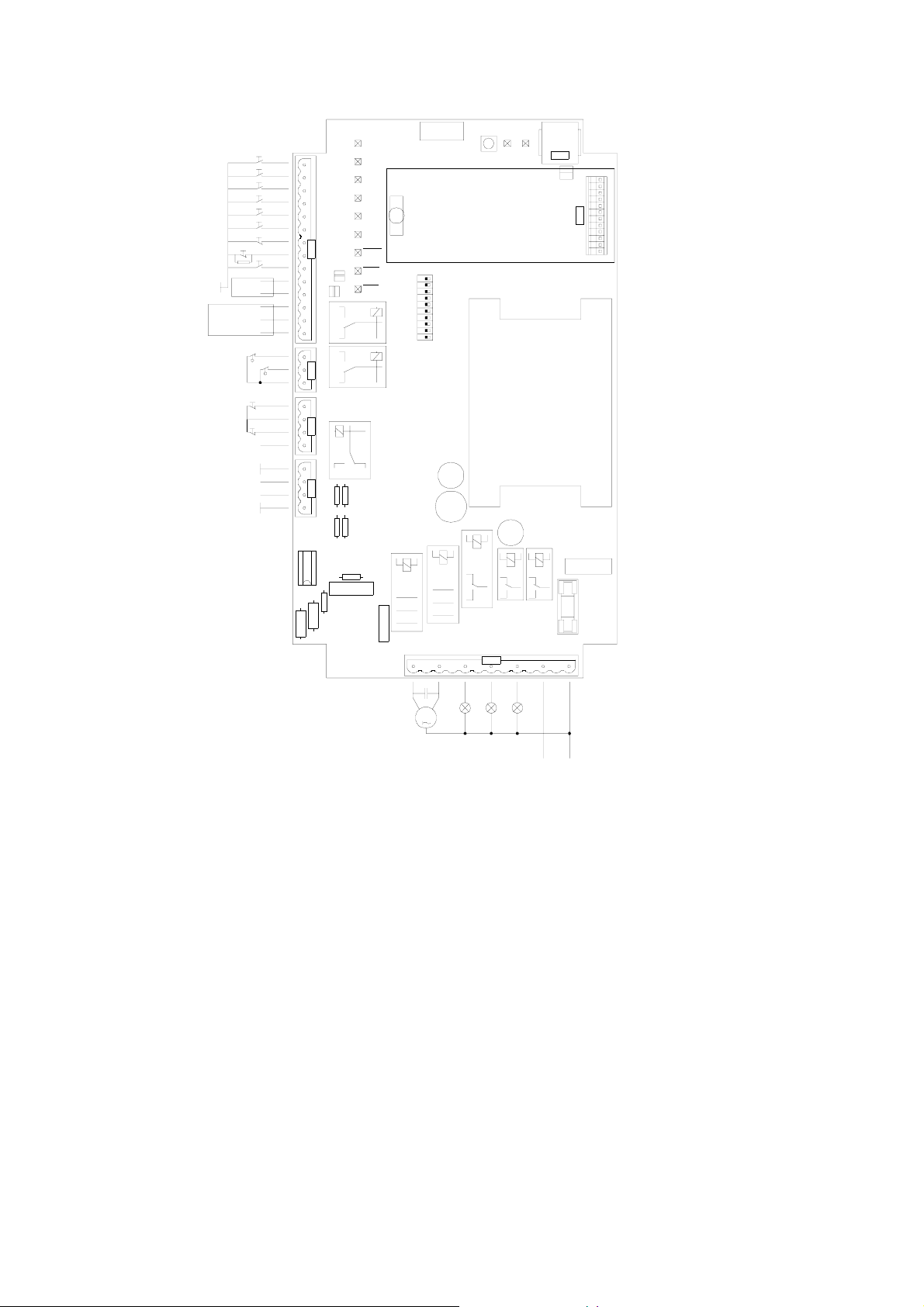

3. Controller MO 63

BT

BTA1

BTA2

BTZ1A

BTZ2

BTS1

BTS2

LS

BTZ1B

Barrier open

Barrier closed

common

SEA

SEZ

No boom

No boom

Stop

Photo-cell test 24V

24Vdc max. 500mA

12Vdc max. 500mA

3.1. Connections

BT

BTA1

BTA2

BTZ1A

BTZ2

Single push button (n.o. – V15.1 – X1/5t)

With the serial switching BT the barrier can be opened and closed. Additional functions of BT

depend on setting of the dip switches for automatic closure (S4) and the counter settings (S6).

When the automatic closure is activated, or the counter is deactivated, then the barrier can be

closed by BT – otherwise the barrier will be opened. When the automatic closure is blocked (e.g.

by a stop signal), and the counter is activated, then BT can only open the barrier. Which means

that closing by BT is not possible.

Push button ‘open’ 1 and 2 (n.o. – V15.2 – X1/6t and V15.3 – X1/6b)

When one of the contacts BTA1 or BTA2 is open and the other is closing, the barrier opens.

When the barrier is open and BTA1 or BTA2 is being closed, then the barrier cannot be closed

(constant open).

Push button ‘close’ 1A and 1B (n.o. – V15.4 – X1/7t and V15.9 – X1/10b)

When BTZ1A closes while BTZ1B is open, or BTZ1B closes while BTZ1A is open, the barrier

closes. When the barrier is closed and at least one contact is cl osed, the barrier cannot be

opened (constant closed).

Push button ‘close’ 2 (n.o. – V15.5 – X1/7b)

When the contact BTZ2 is opening, the order ‘close’ is given.

V15

V6

V4

V12

1

2

3

4876510914131211 1 2

3

3

412

3

412

BT

BTA

BTZ1

BTZ2

LS

BTS1

BTS2

SEA

SEZ

Operating mode

MO63

1

B1

ON

123456 987

VWA1

VWA2

VWZ

ZLA

REV.

ZAHL

SZ

LSA

10

LSTST

RES.

2

M

Motor Red light

Barrier closed

LERN

VpDiag.

Rece iver radio

remote control

Transformer

4567

3

V2

Green light

Barrier open

Amber or

flashing light

max. 120W

V9

10A

L1

230VN50Hz

V14

Fuse

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 6 ES 25 – ES 80 (MO63)

Page 7

BTS1

Push button ‘stop’ 1 (n.o. – V15.6 – X1/4t)

When the contact BTS1 is closed the barrier stops. Stored signals are erased. Automatic cl osure

is blocked until the next signal.

BTS2

Push button ‘stop’ 2 (n.c. – V15.7 – X1/8b)

When the contact BTS2 is open the barrier stops. Stored signals are erased. Automatic closure is

blocked until the next signal.

LS

Photo-cell (n.c. – V15.8 – X1/9b)

When the photo-cell reports an obstacle the barrier cannot be closed. During the opening of the

barrier an existing obstacle is not report. When an obstacle is reported during closing, the barri er

stops and reverses. Additional functions of the photo-cell depend on operating mode, photo-cell

closing automatic, and photo-cell test.

3.2. Further connections

Photo-cell +24V V4.4 X1/26b Power supply for photo-cell transmitter +24V (only for photo-cell test).

(transmitter) 0V V12.1 X1/26t Ground for photo-cell transmitter 0V (only for photo-cell test).

Uext +24V V12.2 X1/1b + 24Vdc stabilised, for external equipment.

Max. 500 mA (for V12.1 + V12.2)

Uext +12V V12.3 X1/3b + 14Vdc stabilised, for external equipment.

Max. 500 mA

Gnd V12.4 X1/2b Ground for Uext – external equipment

Display

‘barrier open’

V15.12 X1/11t Display ‘barrier open’. The contact V15.12 is connected with the

contact V15.14 when the barrier is open. The contact will be closed

when the green light is lit. Maximum permissable: 24V / 1A.

Display

‘barrier closed’

V15.13 X1/12t Display ‘barrier closed’. The contact V15.13 is connected with the

contact V15.14 when the barrier is open. The contact will be closed

when the red light is lit. Maximal admissible: 24V / 1A.

V15.14 X1/11b Common terminal for display ‘barrier open’ and ‘barrier closed’.

Motor V2.1 X1/20 Motor open

Motor V2.2 X1/22 Motor close

Red traffic

light

V2.3 X1/13t The red traffic light is on when the barrier is closed. The red traffic light

is also on during the time ‘warning prior to opening’.

(max. 230V/120W)

Amber or

flashing light

V2.4 X1/14t The contact for the Amber or the flashing light is closed when the

barrier is moving and during the time ‘warning prior movement’.

(max. 230V/120W)

Green traffic

light

V2.5 X1/15t The green traffic light is on when the barrier is open. During the time

‘warning before closing’ the green traffic light is out.

(max. 230V/120W)

L1 V2.6 X1/17b L1, power supply 230V 50Hz

further connections : X1/ 16t, 16b, 17t, 17b

N V2.7 X1/19b N, power supply 230V 50Hz

further connections: X1/ 13b, 14b, 15b, 18t, 18b, 19t, 19b

3.3. Visual indication

LED Colour Function

BT green LED is lit when contact BT is closed or the receiver of the radio

remote control receives a signal.

BTA green LED is lit when contact BTA1 or BTA2 is closed.

BTZ1 green LED is lit when contact BTZ1A or BTZ1B is closed.

BTZ2 green LED is lit when contact BTZ2 is closed.

BTS1 green LED is lit when contact BTS1 is clo sed.

BTS2 green LED is lit when contact BTS2 is clo sed.

LS green LED is lit when the photo-cell is activated.

SEA green LED is lit when contact SEA is closed.

SEZ green LED is lit when contact SEZ is closed.

Vp yellow LED is lit when the main power is on.

Diag red Error code and display for radio remote control.

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 7 ES 25 – ES 80 (MO63)

Page 8

4. Operating mode MO63

Switch off the mains supply before altering the operating mode dip switches 1 - 9!

4.1. Pre-warning before opening (S1 und S2=VWA)

The warning light (flashing or amber light) illuminates right after a signal to open, if pre-warning time before

opening is activated.The barrier opens after the pre-warning time has elapsed.

S1 off and S2 off: No pre-warning time.

S1 off and S2 on: 1.5 s pre-warning time before opening.

S1 on and S2 off: 4.0 s pre-warning time before opening.

4.2. Pre-warning before closing (S3=VWZ)

The warning light (flashing or amber light) goes on right after a signal to close, if pre-warning time before

closing is activated.The barrier closes after the pre-warning time has elapsed.

S3 off: No pre-warning time before closing.

S3 on: 4.0 s pre-warning time before closing.

4.3. Automatic closure (S4=ZLA)

The open barrier closes automatically after the programmed ‘stay open time’ has elapsed. An earlier closing

of the barrier is possible by BT or BTZ. Is a stop signal given during the stay open time, then the automatc

closure is blocked and is only released again by a new signal. BTA1, BZA2, or LS keep the barrier in the

end-position ‘open’ even after the stay open time has elapsed. The barrier closes immediately when a signal

BTA1, BTA2, or LS is removed.

S4 off: No automatic closure.

S4 on: The barrier closes after the time which was saved during the setup (0 s up to 300 s).

4.4. Reversal on hitting obstacles (S5=REV)

When learning the running time during the setup the torque power for the reversing on obstruction is

determined. When the barrier boom hits an obstacle during closing and blocks, the controller stops the

movement or gives an ‘open’ signal.

S5 off: The closing boom stops when it hits an obstacle and re-opens immediately.

S5 on: The closing boom stops when it hits an obstacle and only moves when a new signal

is received.

4.5. Counting (S6=ZÄHL)

The signals ‘open’ and ‘close’ are counted by the controller.

S6 off: No counting. The barrier closes after one signal to close, even after two signals to

open.

S6 on: Counting is activated. The barrier closes after two signals to close if there were two

consecutive opening signals.

4.6. Reversal during opening (S7=SZ)

When a ‘close’ signal is received during opening, the barrier will either open completely and then close or the

barrier closes immediately.

S7 off: The barrier always opens completely before reacting to a signal to close.

S7 on: The opening barrier reverses immediately when it receives a signal to close.

4.7. Automatic closure by photo-cell (S8=LSA)

The photo-cell always gives a signal to close, when the obstacle is not longer present.

S8 off: Automatic closure by photo-cell is not activated.

The closing function by loop B3/2 is not applicable.

S8 on: When an obstacle is not longer present the barrier closes.

4.8. Photo-cell test (S9=LSTST)

Before each closing of the barrier, the photo-cells may be tested.

S9 off: Photo-cell test is not activated.

S9 on: A photo-cell test occurs before each closing.

Attention: The photo-cell test has to be learnt when programmimg the cont roller.

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 8 ES 25 – ES 80 (MO63)

Page 9

5. Photo-cell test

Before the closing of the barrier, the photo-cells may be tested. The photo-cell test consists of two parts.

Part one: The transmitter is taken off the power supply and then the receiver has to report an obstacle (within

max. 2.5 seconds).

Part two:

obstacle is present.

If during part one the receiver does not report an obstacle, the photo-cell is faulty and an error code is shown

on the Diag.-LED (flashes 6 times). If during part two the obstacle is still being reported (the controller

assumes a real obstacle being present), the barrier will not close. No error code is shown.

Max. 6 photo-cells can be connected to the controller MO63 and be tested. For the testing of more than one

photo-cell the relay connections of the receivers have to be connected in series. Parallel to the relay

connections a resistor of 1kΩ each has to be connected.

6. Programming

The controller has to learn the following parameters:

- Running time for opening and closing

- Torque power for reversal on hitting an obstruction.

- Quantity of photo-cells when the photo-cell test is activated

- Time to stay open for automatic closure

- Personal code for radio remote control

On delivery 5 seconds open before automatic closure and the running time for the barrier are already

saved.

6.1. Running time and automatic closure

a) Push the learn button approx. 3 seconds – the red Diag.-LED starts flashing.

b) Push the learn button again. When the photo-cell test is activated (S9=on) the controller learns how many

c) The Diag.-LED is lit during the learning of the running time. The barrier closes if it is not closed already. If

d) After the required stay open time push the learn button again. The barrier closes automatically and learns

The transmitter is connected to the power supply again and then the receiver has to report that no

1

T1

2

1

T2

2

1

T3

2

3

R1

4

1

2

3

R2

4

1

2

3

R3

4

1

2

For the photo-cell test the controller MO63 has to

learn the quantity of photo-cells which are

connected, by activating the dip switch S9=on and

1

T6

2

3

R6

4

1

2

X1/9o

X1/9u

X1/2uX1/1uX1/26o X1/26u

learning the running time again.

Terminal X1

photo-cells are connected. During learning the Diag.-LED flashes at 1 second intervals, then the learning

of the running time starts automatically.

When the photo-cell test is not activated (S9=off) the learning of the running time starts immediately.

it is closed then it opens and learns the running time for opening. Then the Diag.-LED flashes at 1 second

intervals and the controller learns the stay open time.

the running time for closing and the torque power for the reversing on obstruction. The learnt values are

stored even if power failure occurs and the Diag.-LED turns off.

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 9 ES 25 – ES 80 (MO63)

Page 10

6.2. Setting personal code for radio remote

Push the learn button approx. 3 seconds – the red Diag.-LED starts flashing.

Push the corresponding button on your transmitter. The contoller learns the code - the red Di ag.-LED is lit

while a signal is received. Release the button.

The code is stored even if power failure occurs and the Diag.-LED turns off.

Cancel personal code

Push the learn button approx. 3 seconds – the red Diag.-LED starts flashing. Keep the learn button pushed

for approx. 10 seconds. The red Diag.-LED lights for 2 seconds – the personal code is erased and the

learning is finished.

7. External connections

For the power supply of the external equipment (e.g. photo-cells, induction-loops....) the controller provides

stabilised 24 Vdc and 12 Vdc. Max. 500 mA can be drawn from the 12 V source and the 24 V source, but

together max. 700 mA.

The supply of the photo-cell transmitter during photo-cell test comes from the 24 V source and has to be

considered.

red jumper

(B2)

loop 3

loop 1

(B3/1)

loop 2

(B3/2)

ON / OFF

Serial switching

Barrier open

Barrier close

No boom (option)

Boom open

Boom closed

Barrier open (green light)

Barrier moving, or about to move (amber, or f lashing light)

Barrier closed (red light)

Photo-cell

X1/9t

X1/9b

Stop

X1/8t

X1/8b

Important instructions when using loops for safety and closing

When using a loop-detector for safety remove the red junper between contects 6 and 10 on the socket B3.

The socket B3 is always for the loop under the barrier boom, and is prewired for safety and for closing when

leaving the loop. When B3 is equipped with a 2-channel-detector, the second channel may be used for an

opening loop or a loop detecting that a vehicle is present.

The socket B2 is prewired for an opening loop in connection with a 1-channel-detector. Please see chapte r

10 “Examples for use of loop detectors”.

When all connections are completed and the barrier is closed, only the following LEDs should be lit:

the yellow LED Vp for main power, the green LED SEA and the green LED BTS2.

If is not the case then see chapter 9 “Fault finding”.

Warning: Please check the direction of rotation of the transmission lever of the gearbox. The reversal by

obstruction can only work when the rod always moves to the rear of the housing, never to the door.

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 10 ES 25 – ES 80 (MO63)

Page 11

8. Layout in the barrier

B1: receiver radio remote control

S1: limit switch OPEN

S2: limit switch CLOSED

S5: push button OPEN / CLOSE

If a detector is used, remove the red jumper.

S6: switch "no boom" (optional)

S0: switch "STOP"

B3: socket for 1- or 2-channel detector

set operating mode switch 8 ON.

loop 1: 1-channel detector for safety and closing

loop 1: 2-channel detector for safety and closing

Set push button between 27b and 6b.

loop 2: 2-channel detector for opening

If a 1-channel detector is used, remove the jumper between 27b-6b.

If a 2-channel detector is used, remove the jumper between 25b-25t and

B2: socket for 1-channel detctor

loop 3: 1-channel detector for opening

If loop 2 is used for presence, do not remove the jumper between 25b-25t.

: upper and lower terminals connected internally

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 11 ES 25 – ES 80 (MO63)

Page 12

9. Fault finding

9.1. The closed barrier doesn’t react to a signal to open

Symptom Possible cause Possible solution

The yellow power LED is out. No mains supply. Check the mains lead and the

The red diagnostic LED flashes

non-stop.

The green LED BTS1 is lit. The controller is switched off. a) Operating mode switch 1 off.

Programming is started. Carry it out to the end.

The green LED BTS2 is out. a) The stop button is pressed. Release the button (X1/8 top and

The green LED SEA is out and the

red Diag.-LED flashes 4 times –

then a break.

b) Emergency release in use. Lock the shaft.

c) Wiring fault. Check the wiring.

a) Faulty limit switch ’open‘. Replace the limit switch.

b) Wiring faulty Check the wiring to the limit switch

The green LED BTZ1 is lit. There is a permanent signal to

When the controller gives an error code through the red Diag.-LED see the chap ter 9.4.

close.

fuses.

b) Switch On/Off switch (X1/4 top

and X1/4 bottom off).

bottom).

and plug V6 on the controller.

Check the button (X1/2 bottom/top

and 7 top).

9.2. The open barrier doesn’t react to signals to close

Symptom Possible cause Possible solution

The yellow power LED is out. No mains supply. Check the mains lead and the

The red diagnostic LED flashes

non-stop

The green LED LS is lit. a) Loop detector is activated. Check the detector in socket B3.

The green LED LS is lit when the

photo-cell is free, and not lit when

an obstacle is present

The green LED BTA is lit. There is a permanent signal to

The green LED SEZ is out and the

red diagnostic LED flashes 4 times

– then a break.

The green LED BTZ2 is lit. There is a permanent signal to the

When the controller gives an error code through the red Diag.-LED see the chap ter 9.4.

Programming is started. Carry it out to the end.

b) The red jumper is removed from

the terminals 6 and 10 in socket

B3, but the loop detector hasn’t

been inserted.

c) The photo-cell is activated. Check it (X1/9 top and X1/9

The photo-cell is connected as

normally open.

open.

a) Faulty limit switch ’closed‘. Replace the limit switch.

b) Wiring fault. Check the wiring and plug V6 in

terminals BTZ2.

fuses.

Plug the detector into the socket

B3 or replace the red jumper.

bottom).

Connect the photo-cell as normally

closed.

a) Check the ’open‘ button (X1/2

bottom and X1/6 top)

b) Check the loop detector in

socket B2

the control box.

Check the button (X1/7 bottom and

X1/2 bottom/top)

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 12 ES 25 – ES 80 (MO63)

Page 13

9.3. Fault finding continued

Symptom Possible cause Possible solution

Delay before opening. Warning is active. Operating mode switch 1+2 off.

Delay before closing. Warning is active. Operating mode switch 3 off.

The barrier does the following when it hits an obstacle ...

...switches off. Reversing is not activated. Operating mode switch 5 off.

...tries to carry on closing. Torque setting is wrong. Adjust it.

The boom isn’t vertical when the barrier is open ...

The green LED SEA is out. Limit switch ‘open’ maladjusted,

The green LED SEA is lit. The red

diagnostic LED flashes twice then

a break.

The boom isn’t horizontal when the barrier is closed...

The green LED SEZ is out. Limit switch ’closed‘ maladjusted,

The green LED SEZ is lit. The red

diagnostic LED flashes three

times – then a break.

Re-adjust it and the corrsponding

but still switches.

a) Faulty limit switch ‘open’. Replace it.

b) The limit switch ‘open‘ is

maladjusted and doesn’t switch.

but still switches.

a) Faulty limit switch ’closed‘. Replace the limit switch.

b) The limit switch ’closed‘ is

maladjusted and doesn’t switch.

mechanical stopper.

Re-adjust it and the corrsponding

mechanical stopper.

Re-adjust it and the corrsponding

mechanical stopper.

Re-adjust the limit switch and the

corresponding mechanical stopper.

9.4. Error code

The red Diag.-LED serves as a status indicator. During regular, fault free operation the LED is only lit, when

a radio remote signal is received.

An error code is given, when the controller detects a fault. the Diag.-LED flashes max. 12 times, then a

break, then repeats the flashing code.

Error code Cause/solution

2 x flashing Limit switch “OPEN” did not open after the learnt running time. The limit switch has a short

circuit.

3 x flashing Limit switch “CLOSE” did not open after the learnt running time. The limit switch has a short

circuit.

4 x flashing Both limit switches signal at the same time. While SEA and SEZ signal at the same time, the

controller is blocked.

5 x flashing The power supply limit for the external equipment 12 V and/or 24 v has been reached. The

power source load is too high. The controller is blocked. Check the connected equipment.

6 x flashing Photo-cell error. The following error occurred during the photo-cell test. The transmitter is

inactive but the receiver does not signal an obstacle.

7 x flashing An error occurred during learning of the torque power for the reversing on obstacle. Either

the controller, the motor, or the capacitor of the motor are faulty.

Check the above and repeat the learning of the running time. If the error still exists the

controller is faulty.

8 x flashing The EEPROM has lost the data. Repeat the learning of the running time. If the error still

exists the controller is faulty.

9 x flashing The EEPROM is faulty.

10 x flashing The controller has detected a fault in the redundant detection of the “stop” contact. The

controller is faulty.

11 x flashing One of the motor relays has not switched off. The controller is faulty.

12 x flashing The controller detects that the “Triac” has not switched off. The controller is faulty.

Attention: You may use the service device ZS701 to read the error memory of the controller.

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 13 ES 25 – ES 80 (MO63)

Page 14

10. Examples for use of loop detectors

B3/2 This loop may be used for opnening or for detecting that a vehicle is present (connected to socket B3

by contacts X1/24 top und X1/24 bottom).

B3/1 This loop is for the safety only and is placed under the barrier boom (connected to socket B3 by

contacts X1/23 top und X1/23 bottom).

B2 This loop is for opening only (connected directly to socket B2 – contacts 7 and 8).

Push button, key switch, card reader, coin selecto r, etc.

Photo-cell

Example 1 (for 1-channel loop detector on socket B3)

Entrance and Exit – opening with push button. Safety and closing with loop detector on socket B3/1 (all

jumpers at default settings).

Remove red jumper of socket B3 and jumper between the terminals 27 bottom and 6 bottom.

252627 123 45678910

IN

OUT

B3/1

Example 2

Entrance – opening with a key switch. Safety and closing with both loops B3/1 and B3/2.

Exit - opening with loop B3/2. Safety and closing with both loops (all jumpers at default settings).

Remove red jumper of socket B3 and jumper between the terminals 25 top and 25 bottom. DIP S8 = ’on’.

(for 2-channel loop detector on socket B3)

252627 1 2 3 4 5 6 7 8 9 10

IN

min. 1000 mm

max. 1500 mm

B3/1 B3/2

OUT

Example 3 (for 1-channel loop detector on socket B3)

Entrance and Exit – opening with a coin selector. Safety with photo-cells and loop B3/1. Automatic closure

when the time to stay open has elapsed. Remove the jumper between 9 top and 9 bottom and connect the

safety contact of the photo-cells to them (all jumpers at default settings). Remove red jumper of socket B3

and jumper between the terminals 27 bottom and 6 bottom.

.

252627 1 2 3 4 5 6 7 8 9 10

IN

B3/1

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 14 ES 25 – ES 80 (MO63)

OUT

Page 15

Example 4 (for 2-channel loop detector on socket B3)

Entrance and Exit - with card reader. The loop B3/2 allows use of the card reader only when a vehicle is on

the loop. The loop B3/1 is for safety, and closing when a vehicle leaves the loop. The jumpers are at the

default settings. Remove the jumper between terminals 6 bottom and 27 bottom and connect the contact

from the card reader here. The red jumper on socket B3 between terminals 6 and 10 must remain in place.

min. 1000 mm

max. 1500 mm

OUT

B3/1

B3/2

252627 1 2 3 4 5 6 7 8 9 10

IN

B3/2

min. 1000 mm

max. 1500 mm

B3/1

Example 5 (for 1-channel loop detector on socket B2 and 2-channel loop detector on so cket B3)

Entrance – with card reader. The loop B3/2 allows use of the card reader only when a vehicle is on the loop.

Remove the jumper between terminals 6 bottom and 27 bottom and connect the contact from the card

reader here. Safety with loop B3/1, closing with B3/1 or B2. Remove the red jumper of socket B3 and set

DIP-switch S8 ’on’.

252627 1 2 3 4 5 6 7 8 9 10

IN

min. 1000 mm

max. 1500 mm

min. 1000 mm

max. 1500 mm

OUT

B3/2

B3/1

B2

Example 6 (for 2 x 1-channel loop detector on socket B2 and socket B3)

Entrance – opening with key switch. Safety with loop B3/1, closing with both loops B3/1 or B2.

Exit – opening with loop B2, safety and closing with B3/1.

Remove red jumper of socket B3 and jumper between the terminals 27 bottom and 6 bottom.

252627 1 2 3 4 5 6 7 8 9 10

IN

min. 1000 mm

max. 1500 mm

OUT

B2B3/1

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 15 ES 25 – ES 80 (MO63)

Page 16

11. Maintenance

11.1. Maintenance ES 25 – ES 40

The maintenance intervals must be decided individually as they are depen dent on the

frequency of use. We recommend maintenance at least once every six months.

- Check everything for mechanical damage and replace where necesary.

- Check that the barrier is still secure on the foundation.

- Tighten screws where necessary.

- Check the plastic screws at the boom holder.

- Using a grease gun, grease the bearings of the main shaft (grease must be suitable

for –25°C to +125°C).

- Check that the boom reaches the horizontal and vertical positions. If necessary re-

adjust the limit switches and the mechanical stoppers.

- Ensure that the potential earthing cable is still connected to the housing and to the

door.

- Check that all safety equipment works properly (Loops, photo-cells, and the

reversal on obstruction).

- Oil the emergency release bolt and check the function.

- Check that the pre-determined breaking point has the correct nuts and bolts (bolts

M8x45 ISO 4762 12.9 and nuts M8 ISO 4032 5-2).

- Check that the operating instructions are complete.

11.2. Maintenance ES 50 – ES 80

The maintenance intervals must be decided individually as they are depen dent on the

frequency of use. We recommend maintenance at least once every six months. The

springs are designed for 250,000 openings.

- Check the spring assembly. In case of faulty springs all springs must be replaced at

once.

- Check the spring tension as explained in 2.2.

- Check everything for mechanical damage and replace where necesary.

- Check that the barrier is still secure on the foundation.

- Tighten screws where necessary.

- Using a grease gun, grease the bearings of the main shaft. (grease must be

suitable for –25°C to +125°C.)

- Check that the boom reaches the horizontal and vertical positions. If necessary re-

adjust the limit switches and the mechanical stoppers.

- Ensure that the potential earthing cable is still connected to the housing and to the

door.

- Check that all safety equipment works correctly. (Loops, photo-cells, and the

reversal on obstruction.)

- Oil the emergency release bolt and check the function.

- Check that the pre-determined breaking point has the correct nuts and bolts (use

ELKA vandalism set only).

- Check that the operating instructions are complete.

12. Radio remote control

Example A)

or MO 542 or receiver with code switches in conjunction with the boards : MO 32,

MO 35, MO 42, MO 52Z2, MO 60 or MO 62

Follow the example in the diagram below:

Transmitter SK, SKX and SKI in conjunction with K Type receivers using code

switches.

The switches 1 to 7 in transmitter and receiver must have the same settings. The

switches 8 and 9 of the receiver allocate a channel appropriate to the button of the

transmitter. The switches 8 and 9 in multi - channel must be set at 0.

The examples on the right in the diagram above show the allocation of a chan nel with a

one - channel transmitter using the switches 8 and 9 as in the receiver.

Example B)

These receivers learn the code from the transmitter as described in the paragraph

‘Learning personal code’ in these installation instructions.

Example C)

A garage door opener with MO 55 and a swing gate opener with either MO 32, MO 33.

1.) Set the code of the transmitter and receiver for the swing gate opener as described

above. Switches 1 to 7 have the same settings in both transmitter and receiver. The

switches 8 and 9 set at 0.

The swing gate opener now receives signals from the first button of the transmitter.

2.) You can now allocate the second button to the garage door opener by going

the procedure described in the installation instructions for the

the paragraph ‘Learning personal code’.

Receiver using the code switches on the logic b oard : MO 33, MO 43

1 2 3 4 5 6 7 8 9

+

-

Receiver

channel 1

1 2 3 4 5 6 7 8 9

+

-

channel 2

1 2 3 4 5 6 7 8 9

+

-

channel 3

1 2 3 4 5 6 7 8 9

+

-

channel 4

1 2 3 4 5 6 7 8 9

+

-

Transmitter

1 2 3 4 5 6 7 8 9

+

-

1 2 3 4 5 6 7 8 9

+

-

1 2 3 4 5 6 7 8 9

+

-

1 2 3 4 5 6 7 8 9

+

-

Receivers without code switches : Logic boards MO 34, MO 44, MO 55

Combination of examples A and B

1 2 3 4 5 6 7 8 9

+

-

garage door opener in

through

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 16 ES 25 – ES 40 mit MO63

Page 17

13. Extra equipment

13.1. Folding boom for ES 25 – ES 40

All numbers refer to the following drawing.

Determine the length of the vertical part of the boom (1). The length (L3) should not be

longer than the distance from the deck to the ceiling (L1) minus 945 mm. The maximum

vehicle height (L2) is the ceiling height (L1) minus 160 mm. L3 max. 1500 mm.

a) Screw the support (6) with the internal reinforcing plate (7) onto the barrier casing.

b) Cut the boom into two pieces with the appropriate length.

c) Cut off 60 mm from the rubber tube from the vertical part of the boom.

d) For the connection of the side plates to the horizontal boom, drill 2 x 2 holes ø 6,5

mm in the cut end of the boom (find the drawing on page 11).Using the four M 6 x 45

bolts, secure the side plates (3) on the boom. Place a washer M6 between side

plate and boom to maintain clearance.

e) Screw the pivot bolt (13) onto the support (6).

f) Push the short brass bush (14) and the bearing (8) onto the pivot bolt M8x50 and

secure them.

g) Push the bearing (9) into the cut off end of the vertical part of the boom. Drill 2 holes

ø 5,0 mm from the bottom side in the boom (15 and 40 mm from the cut end) and

secure the bearing with two M5x60 hex. socket screws.

h) Fit the bearing (9) between the side plates (3) with a long brass bush and an M8 x

50 bolt.

j) F it the connecting rod (5) with a long brass bush between the side plates (3).

k) Mount the boom on the barrier.

l) Push the connecting rod into the bearing (8).

m) Hold the second part of the boom horizontal and cl amp the connecting rod with the

grub screws (15).

n) Pull out the emergency release bolt and push the boom into the vertical.

o) Align the horizontal part by moving the pivot screw (13) up or down.

p) Check that all screws are tight.

q) Cut off the superfluous part of the connecting rod.

Folding boom for ES 50 – ES 80 upon inquiry.

side plates

support

connecting rod

brass bush (s hort)

13

7

bearing

bearing

6

8

14

15

ø8.5

ø8.5

45

830

side plates

Housing

55

105

horizo ntal boom

brass bush (long)

connecting ro d

11

4

1

9

110

10

L2

2

3

3

10

12

12

5

horizo ntal boom

62.5

L3 (max. 150 0 m m)

L1

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 17 ES 25 – ES 80 (MO63)

Page 18

13.2. Swinging support for ES 40 – ES 80

a) Close the barrier.

b) Using the screws ‘B’, conn ect the upper and lower parts in the approximate length.

c) Remove about 500 mm of the rubber tubing under the boom and push the securing

piece ‘A’ into the slot. Secure it with the two hex. socket screws.

d) Push the rubber tube into the slot and cut off the protruding part.

e) A fine adjustment of the length can no w be made on the foot ’D’.

f) Screw a 4 mm screw into the hole ‘E’.

g) The foot can now be screwed to the appropriate position.

13.3. Fixed support with electromagnet

a) Connect the flexible lead from the magnet to the cable from the barrier. There is

enough room in the lower part of the support for a junction box.

b) Fit the forked part onto the foot and secure it in the required height.

c) Remove the rubber tube from the boom at the point at which the anchor plate is to

be secured.

d) Push one of the securing pieces, followed by the

anchor plate, into the slot of the boom until the

plate is immediately above the magnet.

e) Push the second securing piece up to the magnet.

f) Push the securing pieces from both sides against

the anchor plate and secure them with the screws.

Connecting the magnet in the barrier

a) The 4 seconds warning before opening must be activated.

Switch 2 on the logic board.

b) The coil of the relay must be connected to the terminals ‘14 top’ and ‘14 bottom’ in

the terminal block.

c) Connect contact 11 of the relay to ‘1 bottom’ in the terminal block.

d) Connect contact 21 of the relay to ‘2 top’ in the terminal block.

e) The leads to the magnet come from the contacts 12 and 22 of the relay.

OPERATION:

1) The relay switches off on receipt of a signal to open. The magnet loses it’s residual

magnetism during the 4 seconds warning time.

2) The barrier opens after the 4 seconds.

3) The magnet switches on again when

the barrier reaches the limit switch at

the closed position.

12 22

A1

14

top

A2

14

bottom

11

1

bottom

top

21

2

Magnet

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 18 ES 25 – ES 80 (MO63)

Page 19

14. General notes of safety

These operating instructions must be available on site at all times. It should be read

thoroughly by all persons who use, or service the appliances. Improper usage or

servicing or ignoring the operating instructions can be a source of danger for perso ns, or

result in material damage. If the meaning of any part of these instructions isn’t clear,

then please contact ELKA Torantriebe GmbH & Co. Betriebs KG before you use the

appliance.

This applies to all setup procedures, fault finding, disposal of material, care and

servicing of the appliance.

The accident prevention regulations and applicable tec hnical regulations (e.g. safety or

electrical) and environment protection regulations of the countr y in which the appliance

is used also apply.

All repairs on the appliances must be carried out by qualifi ed persons. ELKA Torantriebe

GmbH & Co. Betriebs KG accepts no liability for damage which is ca used by using the

appliance for purposes other than those for which it is built.

ELKA Torantriebe GmbH & Co. Betriebs KG cannot recognise every po ssible source of

danger in advance. If the appliance is used other than in th e recommended manner, the

user must ascertain that no danger for himself or others will result from this use. He

should also ascertain that the planned use will have no detrimental effect on the

appliance itself. The appliance should only be used when all safety equipment is

available and in working order. All faults which could be a source of danger to the user

or to third persons must be eliminated immediately. All warning and safety notices on

the appliances must be kept legible.

All electrical periphery equipment which is connected to t he appliance must have a CE

Mark, which ensures that it conforms to the relevant EEC regulations. Neither

mechanical nor electrical alterations to the appliance, without explicit agreement of the

manufacturer, are allowed. All alterations or extensions to the a ppliance must be carried

out with parts which ELKA Torantriebe GmbH & Co. Betriebs KG have defined as

suitable for such alterations, and be carried out by qualified personnel.

Any contravention of these conditions revokes the ma nufacturer’s guarantee and also

the CE Mark and the user is alone responsible for the consequences.

Our service department is available to answer all queries about these con ditions and, of

course, about our appliances.

The operation of the system within CEN countries must also be conformant with the

European safety-relevant directives and standards.

We reserve the right to make technical improvements without prior notice.

© 26.07.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 19 ES 25 – ES 80 (MO63)

Loading...

Loading...