Page 1

ELK-BLT Battery LifeTester

Application

The ELK-BLT Battery Life Tester or “Mhos Meter” is a

compact, easy to use service tool for testing 12 Volt

rechargeable batteries. The BLT measures internal

conductivity (Mhos), which is the best indicator of a

battery’s health and life expectancy. Mhos happens to

be the inverse of Ohms (conductance as opposed to

resistance). The BLT operates as follows: For each

battery brand and size installed you should start by

measuring and recording a “baseline” Mhos reading.

Then, during any service call or inspection simply

measure and record the current (most recent) Mhos

reading. Always compare the current Mhos reading with

the original reading. Self-adhesive test data labels may

be used for recording each inspection. When the

current Mhos reading has reached at or around 71% of

the original baseline then it is time to consider changing

the battery. The BLT includes a reference chart on the

back with numbers equating to Mhos readings for

common security industry battery sizes.

a.k.a Battery Mhos Meter ver 3.0

The BLT receives its operating power from the battery

under test and automatically warns when the battery

voltage is too low for testing.

Features

• Does not discharge or damage the battery.

• Tests 12 Volt Rechargeable Batteries.

• Display Shows Battery Voltage and Mhos.

• Warns if battery voltage is too low.

• Replaceable test leads.

• Includes padded carrying case.

• Includes self-adhesive test data labels. **

• Lifetime Limited Warranty.

Specifications

• Operating Voltage: 10.0V - 14 Volts D.C.

• Current Draw: 1.1 Amps Max., 0.0016 Ah for full test.

• Battery Leads: ~12 Inches.

• Size: 4.4” W x 3”H x 1.15”D w/o carrying case.

** To reorder a pack of 100 test data labels specify: ELK-BLT LABELS.

PO Box 100 • Hildebran, NC 28637 • 800-797-9355 • 828-397-4200

Fax 828-397-4415 • www.elkproducts.com • info@elkproducts.com

03/1/08

ELK

PRODUCTS, INC.

Page 2

Instructions

BLT measurements should be taken and recorded periodically. The popular method is to record the information onto self-adhesive

labels placed directly onto the battery. A supply of these labels is included with the tester. Additional labels may be ordered in

packs of 100 by specifying part number ELK-BLT LABELS. This information will be valuable in future tests for trending analysis.

The recorded data should include:

A. The Date of the test.

B. The Battery Voltage reading. (optional)

C. The Mhos reading.

1. Disconnect the battery from it’s equipment.

2. Connect the BLACK test clip to the Negative (-) battery terminal, and the RED to the Positive (+) terminal. (For accurate

readings, the test clips must be tightly clipped directly to the battery posts, not to the battery bolts).

“Err” or blank indicates battery voltage is too low for testing or a test clip connection is loose.

Try charging the battery or reconnecting the test clips.

3. The Voltage of the Battery will display briefly. A new battery, out of the box, will generally read around 12.6 Volts. A fullycharged battery should read between 12.6 Volts and 13.5 Volts.

“- - -” indicates test in process, please wait.

ELK - BLT

4. The Mhos (internal conductance) reading of the battery will display within 6 seconds.

ON NEW INSTALLATIONS:

4a. Record the Mhos reading and the date of test on the test data labels or on the battery housing using a permanent marker.

ON SERVICE CALLS OR INSPECTIONS:

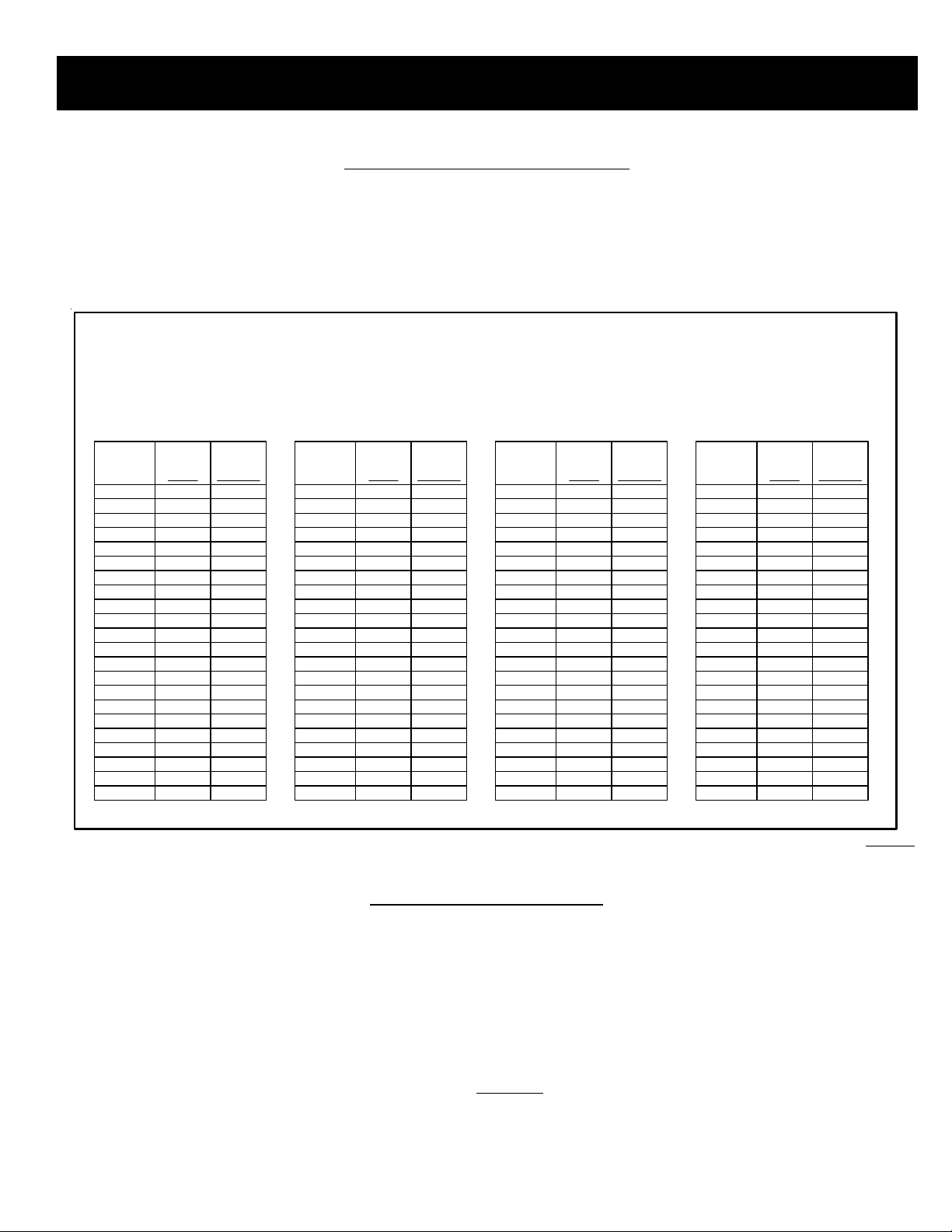

4b. Compare the latest current Mhos reading to the original baseline Mhos reading previously recorded. Then calculate the

percentage difference between the baseline and the current Mhos reading (the decline). If the Mhos has declined to 71% or

lower from the baseline Mhos reading the battery should be replaced. NOTE: If a calculator is not convenient then use the

Battery Mhos Reference Chart on the back of the BLT to locate the value closest to the baseline recorded on this battery. The

middle and right hand columns represent the value at 81% (weak) and 71% (replace) respectively.

E.G. Baseline - 180 Mhos Weak - 180 Mhos X .81 = 145.8 Mhos Replace - 180 Mhos X .71 = 127.8 Mhos

NOTE: No standard Mhos values exist for any battery size or brand. In some cases, different production batches of

the same brand battery will produce different readings. RARELY will any “similarly rated” batteries from different

manufacturers have the same baseline. Therefore, to accurately judge the remaining life of a battery it is absolutely

critical to have a recorded baseline for each battery that you use.

The Battery Mhos Reference Chart chart on the back of the BLT displays numbers equating to Mhos readings for

common security industry battery sizes. It is also based on a battery’s ambient temperature being at 72 degrees

fahrenheit. This temperature assumption covers many environmental situations, including cold basements or

unoccupied buildings, since the battery will be kept warm by the recharging and by being inside the electronics

enclosure. However, because cooler temperatures can significantly lower the Mhos reading of a battery, this

instruction manual has a more extensive Mhos chart with columns for evaluating batteries that are being adversely

affected by 62F, 52F, and 42F degree environments. Also see How Temperature affects a Battery

Automatic Shutdown

If the BLT is left connected to a battery for more than 30 seconds after the test is complete, it will automatically shutdown to

conserve battery power. Disconnecting and reconnecting a test lead will restart the test procedure.

Page 3

Instructions

ELK - BLT

How Temperature affects a Battery

Generally speaking, temperatures below 72F degrees tend to slow down a battery’s internal activity, causing a significant decrease

in the Mhos (conductivity) reading as the temperature falls. Therefore, cool temperatures (not below freezing) will tend to prolong a

battery’s life. Temperatures above 72F cause a battery’s internal activity to accelerate, but with only a slight increase in the Mhos

reading. Warm temperatures will tend to dry out and degrade a battery much faster than normal.

72 F degrees = 0% no adjustment 52 F degrees = 87% (13% degrade) of normal Mhos

62 F degrees = 92% (8% degrade) of normal Mhos 42 F degrees = 82% (18% degrade) of normal Mhos

Battery Mhos Chart

for various Temperature Environments

72 Degree F Environment

Ideal Conditions

Baseline

Mhos

20 16

25 20 18

30 24 21

40 32 28

50 41 36

60 49 43

70 57 50

80 65 57

90 73 64

100 81 71

125 101 89

150 122 107

175 142 124

200 162 142

225 182 160

250 203 178

275 223 195

300 243 213

350 284 249

400 324 284

450 365 320

500 405 355

81%

Mhos

Weak

71%

Mhos

Replace

14

62 Degree F Environment

-8% degrade

Baseline

Mhos

20 15

25 19 16

30 22 20

40 30 26

50 37 33

60 45 39

70 52 46

80 60 52

90 67 59

100 75 65

125 93 82

150 112 98

175 130 114

200 149 131

225 168 147

250 186 163

275 205 180

300 224 196

350 261 229

400 298 261

450 335 294

500 373 327

81%

Mhos

Weak

71%

Mhos

Replace

13

52 Degree F Environment

-13% degrade

Baseline

Mhos

20 14

25 18 15

30 21 19

40 28 25

50 35 31

60 42 37

70 49 43

80 56 49

90 63 56

100 70 62

125 88 77

150 106 93

175 123 108

200 141 124

225 159 139

250 176 154

275 194 170

300 211 185

350 247 216

400 282 247

450 317 278

500 352 309

81%

Mhos

Weak

71%

Mhos

Replace

12

42 Degree F Environment

-18% degrade

Baseline

Mhos

20 13

25 17 15

30 20 17

40 27 23

50 33 29

60 40 35

70 46 41

80 53 47

90 60 52

100 66 58

125 83 73

150 100 87

175 116 102

200 133 116

225 149 131

250 166 146

275 183 160

300 199 175

350 232 204

400 266 233

450 299 262

500 332 291

81%

Mhos

Weak

71%

Mhos

Replace

12

ELK Products is not responsible for misprints or errors. The Mhos baseline values are benchmarks created from fresh samples of batteries. Be aware that if you find consistent,

minor variations in readings from multiple samples of a battery, it’s likely due to manufacturing differences.

Recording Battery Readings

The baseline Mhos reading of a new “fresh out of the box” battery may not be as high as the same battery after it has been sitting

on charge for at least 24 hours. If the reading is considerably lower than what you would expect then try charging the battery for at

least 24 hours, then retest.

Battery performance degrades over time due to use and abuse, and may be impacted by many factors like depth and frequency of

discharge. The higher the Mhos value the more current the battery can deliver. Therefore, a new 7 amp-hour battery will have a

higher Mhos value than a new 4 amp-hour battery of the similar construction.

Generating an Average Baseline

Start with 2 or 3 fresh new batteries out of the box. The battery voltage should be around 12.6 Volts or higher. Place the batteries

in service (on charge) for 24 hours. Remove them from charge and measure the Mhos reading of each one. Average the readings

together. This will be the baseline number that you can use for estimating battery decline. However, there is no substitute or

shortcut that can match the accuracy of actually measuring a baseline for each individual installed battery.

Page 4

Instructions

ELK - BLT

Accumulating Trend Analysis over a Period of Years

Trending of periodic Mhos measurements can yield valuable insights for estimating the remaining life of the battery. Suppose that

a battery has been in service for three years, and that the BLT measurements after the first year was 90 Mhos, 85 Mhos after the

second year, and 80 Mhos after the third year. Since the battery is still at 80 Mhos and is dropping an average of 5 Mhos per year,

it is highly likely that this battery will not need replacing before the end of the fourth year. On the other hand, suppose that the

readings were 90 Mhos after the first year, 82 Mhos after the second year, and 70 Mhos after the third year. The rate of decay has

increased from 8 Mhos to 12 Mhos per year. This indicates that although the battery is still serviceable, it is degrading more and

more rapidly. It is unlikely that this battery will be serviceable for another year. Under these circumstances, either the battery

should be replaced early or the service interval should be shortened to catch this battery before a system failure.

Why Mhos instead of Amp Hour

The BLT measures the Mhos (conductance) of a battery using an AC impedance measurement algorithm. Every battery manufacturing

process produces a slightly different conductance value for a given battery size. Elk Products elected to display consistent,

accurate Mhos (conductance) values, rather than just estimated Amp Hour values. The only accurate method for measuring a

battery’s Amp-hour capacity is with a long discharge test, which actually decreases the life of the battery. Estimation of Amp-hour

capacity without a discharge test is a complex error-prone process involving the conductance value, the battery state-of-charge, the

voltage, the temperature, and the many varying design and production variables for each battery type. Ordinary testers which

measure static criteria or Amp-hour are inherently inaccurate across varying battery designs. In contrast, extensive testing has

proven that when the conductance of a charged battery is tested and has declined to approximately 71% of its full-capacity

reference, the battery is unlikely to deliver its rated capacity and should be replaced.

Is Mhos relational to Cold Cranking Amps?

No, the BLT is designed to measure the conductance of a battery at frequencies indicative of the capacity of a battery in Amp-hour.

Conductance measurements for estimating the Cold Cranking Amps for starter type batteries are at a much higher frequency.

Although the measurement techniques are similar, there is little correlation between the Cold Cranking Amps measurement of a

battery and the Mhos reading of the BLT, or vice-versa.

Using Mhos to Estimate Battery Life

The Mhos reading of a new battery out of the box will generally not be the same as that of a fully charged battery. This is due to

the plates not being totally formed during manufacturing. Once the battery has been on charge for some time the plates will finish

forming and the peak Mhos reading will normalize. For standby batteries, peak capacity is normally reached after about three

months on a float charging system. For cyclic use batteries, full capacity may not be reached until after ten to thirty cycles,

depending upon the depth of discharge and the charging method.

If a new battery has been in storage for an extended period, say over six months without being charged, plate oxidation from selfdischarge will occur, causing a decrease in the Mhos reading. Plate oxidation also occurs in standby batteries during a power

failure, particularly if a battery remains in a highly discharged state for an extended time period. Plate oxidation is unhealthy and

can destroy a battery’s capacity. Once a battery is weakened by plate oxidation, it is difficult to recover full capacity without special

charging or conditioning methods. In some cases a battery will recover and pass a test after being recharged. However, a second

test should be performed a few days later after recovery to accurately assess the overall life of the battery.

The average life cycle of a sealed lead-acid battery in standby use on a float charge is 3 to 5 years. At this point in its service life

the battery Mhos reading has generally reached a point of 71% or lower of its original baseline reading. The battery should therefore

be replaced since it is no longer considered serviceable.

Loading...

Loading...