Elica ETT136SS Instruction handbook

Use, Care, and Installation Guide

Guide d’utilisation, d’entretien et d’installation

Guía de instalación, uso y mantenimiento

READ AND SAVE THESE INSTRUCTIONS

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

LEA Y GUARDE ESTAS INSTRUCCIONES

LI32WA

09/14

EN

Contents

page

2

FR

ES

Sommaire

Contenido

page

página

12

22

English

Contents

Important safety Notice................................................................................. 3

Electrical & Installation requirements ........................................................... 4

List of Materials............................................................................................. 5

Parts supplied .............................................................................................. 5

Parts not supplied ........................................................................................ 5

Product Dimensions...................................................................................... 5

Location Requirements................................................................................. 6

Venting Requirements................................................................................... 6

Installation .................................................................................................... 7

Make electrical connection........................................................................... 8

Complete Installation and check operation....................................................9

Range hood use............................................................................................ 9

Range hood care........................................................................................... 10

Warranty ....................................................................................................... 11

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE

PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local

Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit

for the owner.

OWNER: Please retain these instructions for future

reference.

Safety Warning: Turn off power circuit at service panel and

lock out panel, before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit

2

READ AND SAVE THESE INSTRUCTIONS

Important Safety Notice

CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS OR

VAPOURS.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer.

B. Before servicing or cleaning the unit, switch power off at service

panel and lock service panel disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

C. Installation work and electrical wiring must be done by qualied

person(s) in accordance with all applicable codes & standards,

including re-rated construction.

D. Sufcient air is needed for proper combustion and exhausting of

gases through the ue (Chimney) of fuel burning equipment to

prevent back- drafting. Follow the heating equipment

manufacturers guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), the

American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

E. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

F. Ducted systems must always be vented to the outdoors.

CAUTION

To reduce risk of re and to properly exhaust air, be sure to duct

air outside - do not vent exhaust air into spaces within walls,

ceilings, attics, crawl spaces, or garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT WORK.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:

a) SMOTHER FLAMES with a close-tting lid, cookie sheet, or other

metal tray, then turn off the gas burner or the electric element. BE

CAREFUL TO PREVENT BURNS. If the ames do not go ou

immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - you may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a class ABC extinguisher, and you already

know how to operate it.

2) The re is small and contained in the area where it started.

3) The re department is being called.

4) You can ght the re with your back to an exit.

a

Based on “Kitchen Fire Safety Tips” published by NFPA.

OPERATION

a. Always leave safety grills and lters in place. Without these components, operating blowers could catch onto hair, ngers and loose

clothing.

The manufacturer declines all responsibility in the event of failure to

observe the instructions given here for installation, maintenance and

suitable use of the product. The manufacturer further declines all

responsibility for injury due to negligence and the warranty of the unit

automatically expires due to improper maintenance.

a

Install this hood in accordance with all requirements specied.

WARNING

To reduce the risk of re or electric shock, do not use this hood

with any external solid state speed control device.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE.

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

ambeing food (i.E. Crepes suzette, cherries jubilee, peppercorn

beef ambe’).

c) Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or lter.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

3

Electrical & Installation requirements

Electrical requirements

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsibility:

• To contact a qualied electrical installer.

• To assure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70 —

latest edition*, or CSA Standards C22.1-94, Canadian Electrical

Code, Part 1 and C22.2 No.0-M91 - latest edition** and all local

codes and ordinances.

• If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

• Do not ground to a gas pipe.

• Check with a qualied electrician if you are not sure range hood is

properly grounded.

• Do not have a fuse in the neutral or ground circuit.

IMPORTANT

• Save Installation Instructions for electrical inspector’s use.

• The range hood must be connected with copper wire only.

• The range hood should be connected directly to the fused

disconnect (Or circuit breaker) box through metal electrical

conduit.

• Wire sizes must conform to the requirements of the National

Electrical Code ANSI/NFPA 70 — latest edition*, or CSA

Standards C22.1-94, Canadian Electrical Code Part 1 and C22.2

No. 0-M91 - latest edition** and all local codes and ordinances.

• A U.L.- or C.S.A.-listed conduit connector must be provided at

each end of the power supply conduit (at the range hood and at

the junction box).

Before installing the hood

1. For the most efcient air ow exhaust, use a straight run or as few

elbows as possible.

CAUTION: Vent unit to outside of building, only.

2. At least two people are necessary for installation.

3. Fittings material is provided to secure the hood to most types of

walls/ceilings, consult a Qualied Installer, check if they perfectly

t with your cabinet/wall.

4. Do not use ex ducting.

5. COLD WEATHER installations should have an additional back

draft damper installed to minimize backward cold air ow and a

nonmetallic thermal break to minimize conduction of outside

temperatures as part of the ductwork. The damper should be

on the cold air side of the thermal break. The break should be as

close as possible to where the ducting enters the heated portion of

the house.

6. Make-Up air: Local building codes may require the use of

make-up air systems when using ducted ventilation systems

greater than specied CFM of air movement. The specied CFM

varies from locale to locale. Consult your HVAC professional for

specic requirements in your area.

NOTE:

Use the Range Hood models ETT136SS, ETT142SS and ETT148SS

(Dual Blower Motor=1200CFM) above cooktops rated higher than

65,000 BTU and less than 108.000 BTU.

Copies of the standards listed may be obtained from:

* National Fire Protection Association Batterymarch Park Quincy, Massachu

setts 02269

** CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-

5575

-

4

List of Materials

Removing the packaging

CAUTION!

Remove carton carefully, wear gloves to protect against sharp edges.

WARNING!

Remove the protective lm covering the product before putting into

operation.

Parts supplied

• Hood assembly with blower & light bulb already installed.

• Metal grease lter.

• Hardware bag with:

• Use, care and installation guide

• 2 - d5.3 x 20 mm metal washers

• 4 - 6 x 80 mm screws

• 4 - 3.5 x 9.5 mm mounting screws

• 4 - 4.2 x 19 mm mounting screws

• 2 - 10 x 50 mm wall anchors

Parts needed

• Home power supply cable

• ½” (12.7 mm) UL listed or CSA approved strain relief

• 3 UL listed wire connectors

• 1 wall or roof cap

• 10” round metal vent system

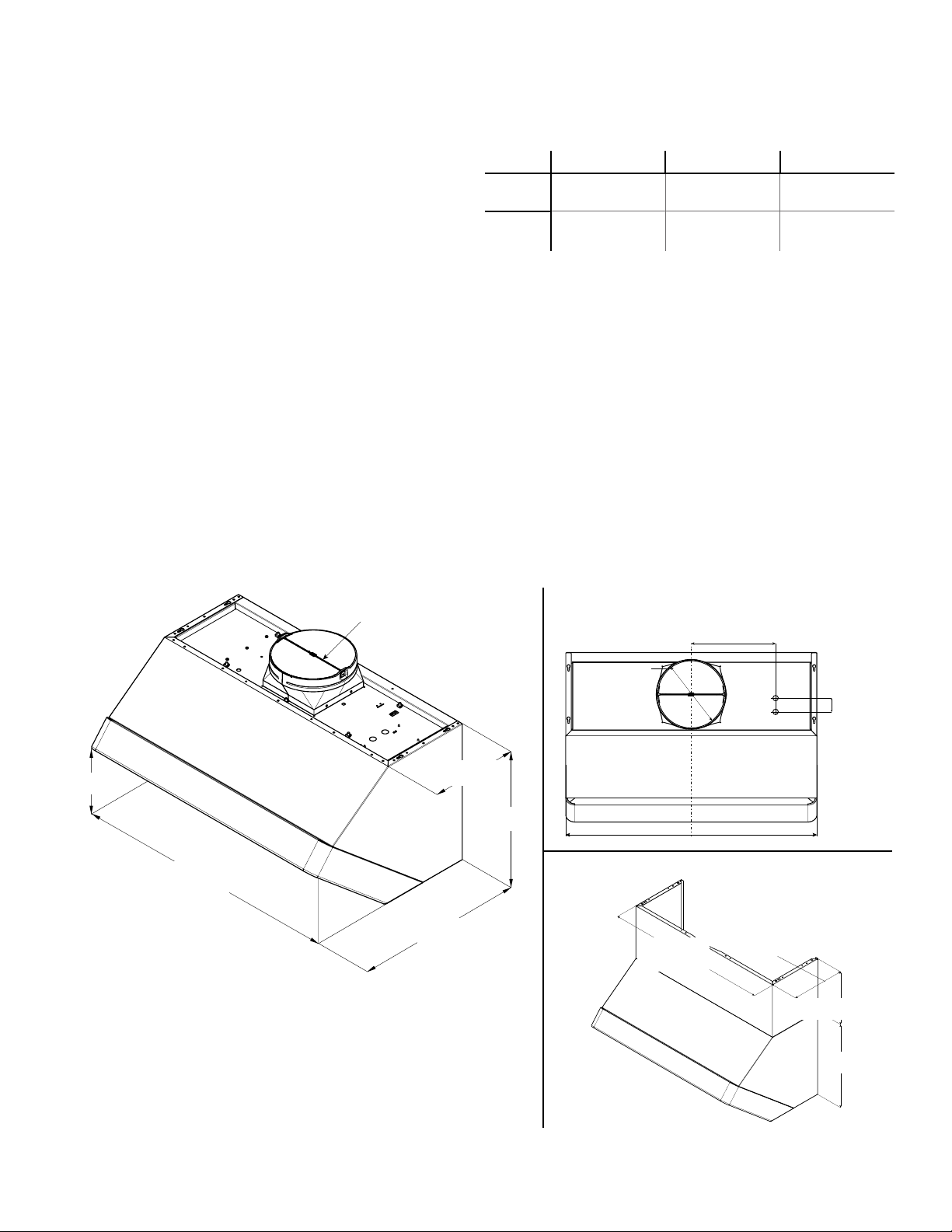

Product Dimensions

Parts not supplied

Optional Accessories

1. Duct Cover Kits

36” 42” 48”

6”

height

12”

height

Tools/Materials required

• Level

• Drill with 1¼” (3.2 cm),⅛” (3.2 mm), and

drill bits

• Pencil

• Wire stripper or utility knife

• Tape measure or ruler

• Pliers

• Caulking gun and weatherproof caulking compound

• Vent clamps

• Jigsaw or keyhole saw

• Flat-blade screwdriver

• Metal snips

EXXCEK02 ECLCEK07 ECLCEK05

EXXCEK04 ECLCEK08 EXXCEK06

5

⁄16” (7.9 mm)

97⁄8”

(25cm)

36” (91.4cm)

42” (106.7cm)

48” (121.9cm)

10”

(25.4cm)

241⁄4”

(61.6cm)

1113⁄16”

(30.2cm)

187⁄8”

(48cm)

Top view

10” (25.4 cm)

= =

Duct cover view

36” (91.4cm)

42” (106.7cm)

48” (121.9cm)

36”: 12” (30.6 cm)

42”: 15” (38.3 cm)

48”: 18” (45.9 cm)

117⁄8” (30cm)

21⁄3”

(5.9 cm)

6” (15.24cm) or

12” (30.48cm)

187⁄8”

(48cm)

5

Location Requirements

IMPORTANT: Observe all governing codes and ordinances. Have a

qualied technician install the range hood. It is the installer’s responsibility to comply with installation clearances specied on the model/

serial rating plate. The model/serial rating plate is located behind the

left lter on the rear wall of the vent hood.

Canopy hood location should be away from strong draft areas, such

as windows, doors and strong heating vents.

Cabinet opening dimensions that are shown must be used. Given

dimensions provide minimum clearance.

Grounded electrical outlet is required. See “Electrical

Requirements” section.

The canopy hood is factory set for venting through the roof or

wall. For non-vented (recirculating) installation see the installation

instructions in this guide. Recirculation Kit is available from your dealer or an authorized parts distributor. All openings in ceiling and wall

where canopy hood will be installed must be sealed.

For Mobile Home Installations

The installation of this range hood must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home Con-

struction and Safety, Title 24, HUD, Part 280) or when such standard

is not applicable, the standard for Manufactured Home Installation

1982 (Manufactured Home Sites, Communities and Setups) ANSI

A225.1/NFPA 501A, or latest edition, or with local codes.

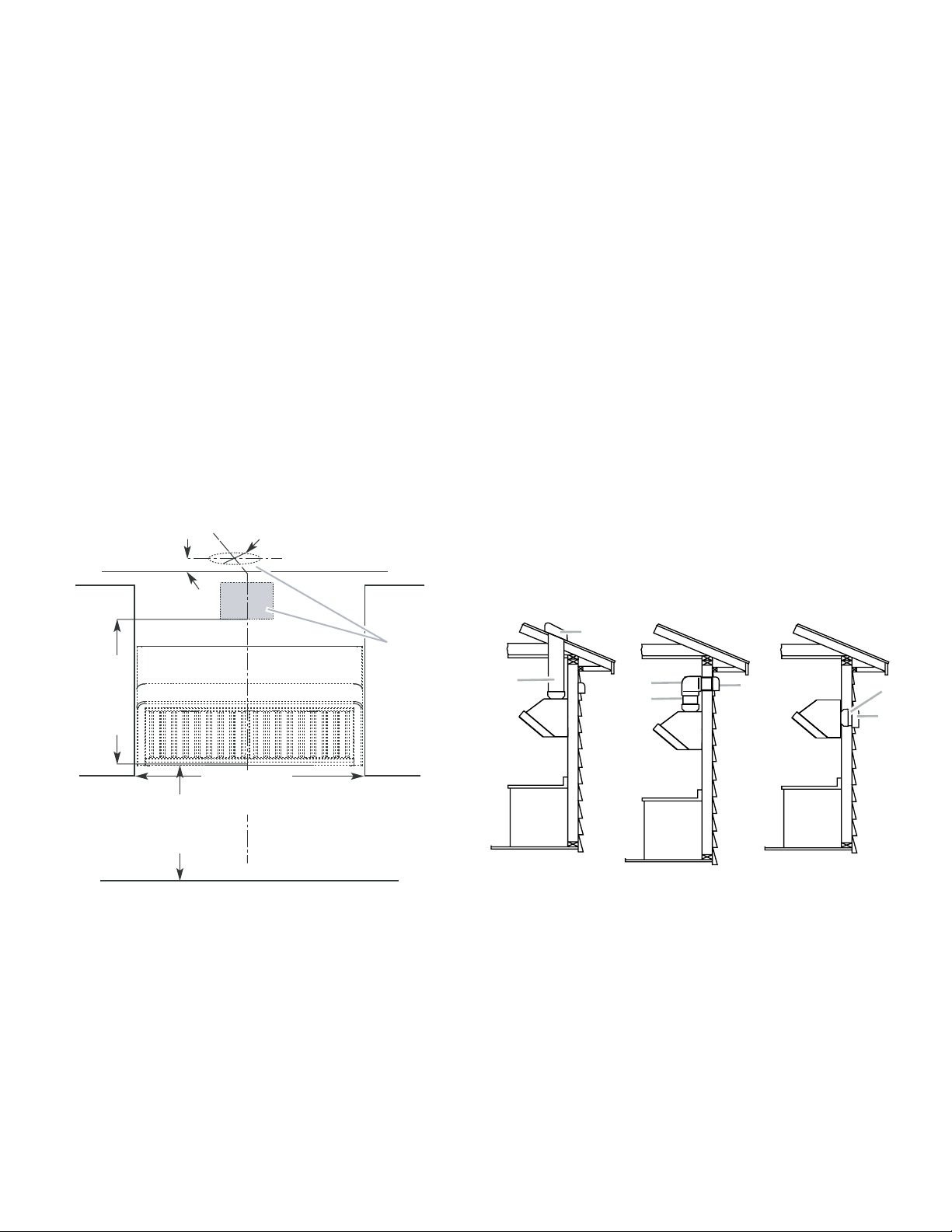

Cabinet Dimensions

10½” (26.67 cm)

6” (15.3 cm)

Vent and

power

supply cable

entry location

22” (58 cm)

side

cabinet

36” (91.4 cm)

42”(106.7 cm)

“A”: bottom of

canopy to cooking

surface

48” (121.9 cm)

centerline

cooking surface

IMPORTANT:

Minimum distance “A”: 18” (45.72 cm) from cooking surface.

Suggested maximum distance “A”: 24” (61 cm) from cooking surface.

cabinet

side

Venting Requirements

(Ducted models only)

• Vent system must terminate to the outdoors, except for nonvented

(recirculating) installations.

• Do not terminate the vent system in an attic or other enclosed

area.

• Do not use 6” (15.2 cm) laundry-type wall cap.

• Use metal vent only. Rigid metal vent is recommended.

Plastic or metal foil vent is not recommended.

• The length of vent system and number of elbows should be kept

to a minimum to provide efcient performance.

For the most efcient and quiet operation:

• Use no more than three 90° elbows.

• Make sure there is a minimum of 24” (61 cm) of straight vent

between the elbows if more than 1 elbow is used.

• Do not install 2 elbows together.

• Use clamps to seal all joints in the vent system.

• The vent system must have a damper. If the roof or wall cap has a

damper, do not use the damper supplied with the range hood.

• Use caulking to seal exterior wall or roof opening around the cap.

• The size of the vent should be uniform.

Venting Methods

This canopy hood is factory set for venting through the roof or wall. A

10” (25.4 cm) round vent system is needed for installation (not included). The hood exhaust opening is 10” (25.4 cm) round.

NOTE: Flexible vent is not recommended. Flexible vent creates back

pressure and air turbulence that greatly reduce performance. Vent

system can terminate either through the roof or wall.

Roof Venting

A

B

A. Roof cap

B. 10” (25.4 cm)

round vent

Wall Venting

C

B

A. Wall cap

B. 10” (25.4 cm)

round vent

C. 90° elbow

A

Wall Venting

rear discharge

A. Wall cap

B. 10” (25.4 cm)

round vent

B

A

6

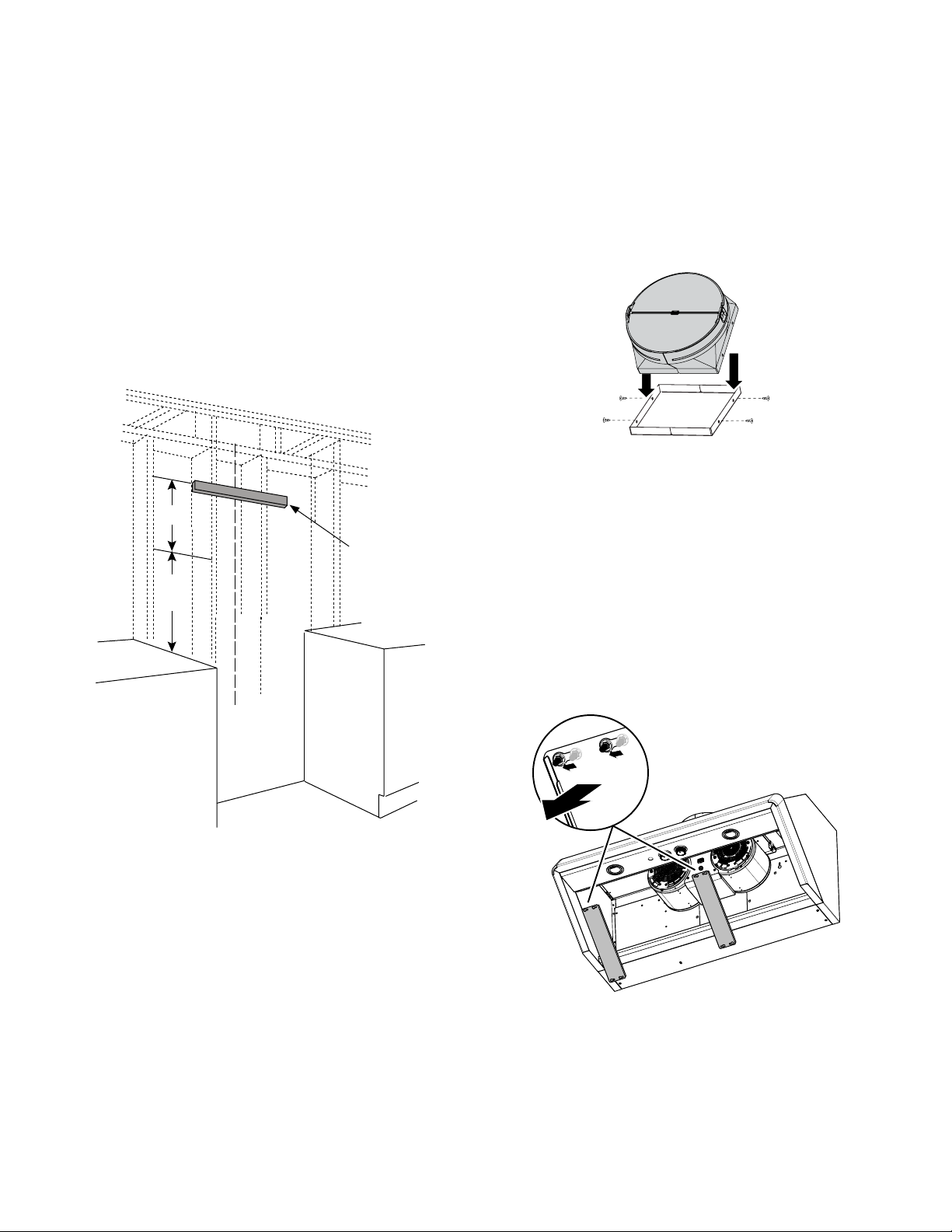

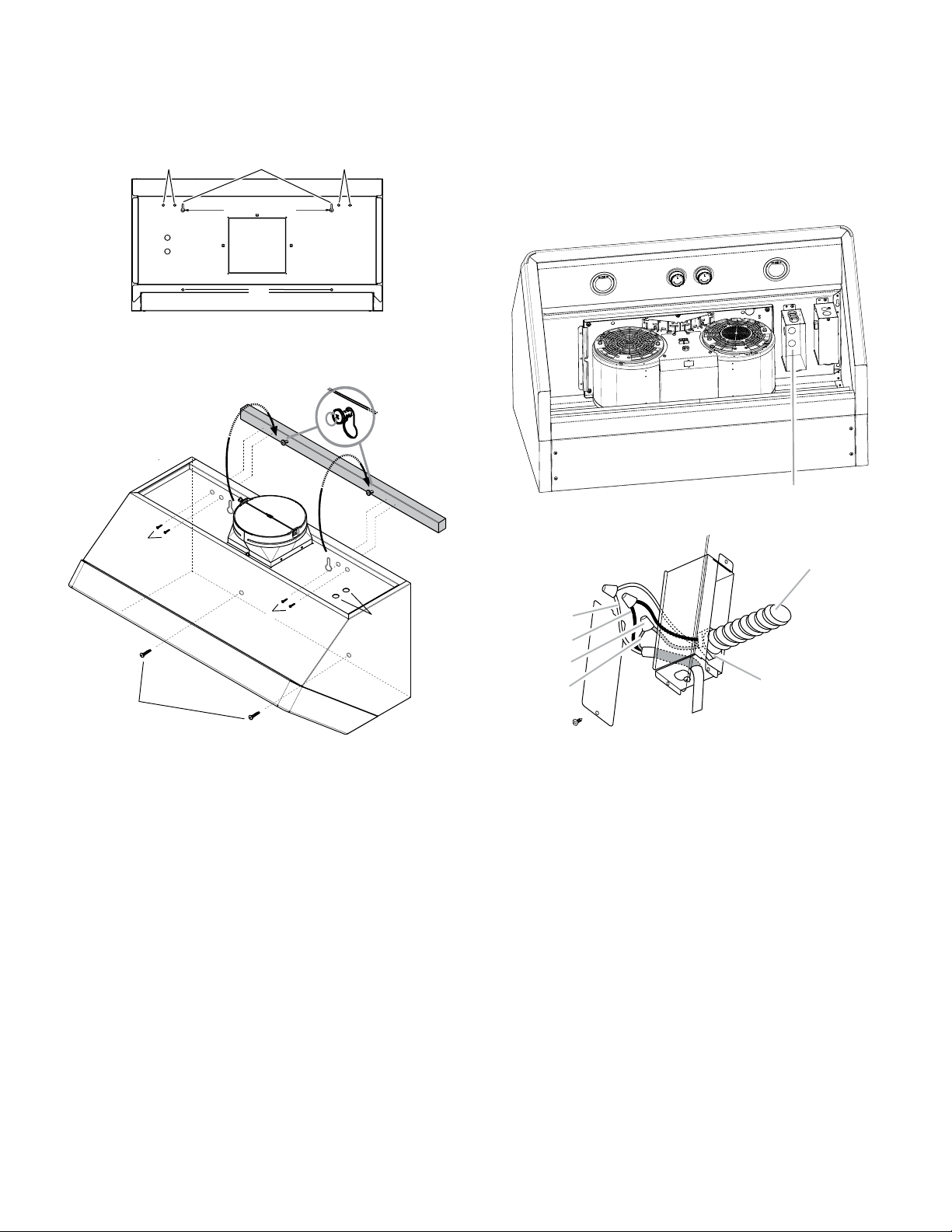

Installation

• If possible, disconnect and move freestanding or slide-in range

from cabinet opening to provide easier access to rear wall.

Otherwise put a thick, protective covering over countertop,

cooktop or range to protect from damage and debris. Select a at

surface for assembling the unit. Cover that surface with a

protective covering and place all canopy hood parts and hardware in it.

• Determine and mark the centerline on the wall where the canopy

hood will be installed.

• Select a mounting height between a minimum of 18” (45.72 cm)

and a suggested maximum of 24” (61 cm), above the cooking

surface and the bottom of the range hood and mark a horizontal

reference line on the wall.

• Remove the wood support from the back of the range hood

by loosening the 2 screws from the inside. Locate and level

the top of the wood support 15

horizontal line and centered on the vertical centerline.

Using 2 - 6 x 80 mm screws, install wood support so that it is

screwed into at least 2 vertical studs.

153⁄8”

18”

to

24”

3

⁄8” (39.1 cm) above the marked

Wood

support

Complete preparation

1. Determine and make all necessary cuts in the wall for the vent

system. Install the vent system before installing the range hood.

See the “Venting Requirements” section.

2. Determine the location where the power supply cable will be run

through the wall.

3. Drill a 1¼” (3.2 cm) hole at this location.

4. Pull enough power supply cable through the wall to allow for easy

connection to the terminal box.

5. Install the 10” (25.4 cm) square x 10” (25.4 cm) round vent

transition with damper to top of the range hood using

4 - 3.5 x 9.5 mm screws.

6. Remove terminal box cover and set aside.

7. Remove knockout from the top of the vent hood and install a UL

listed or CSA approved ½” strain relief. See “Make Electrical

Connection” section.

8. Place the range hood near its mounting position and run the

power supply cable through the strain relief into terminal box

(enough to make connection).

9. Tighten the strain relief screws.

Install Range Hood

The hood attaches to the wall by the 2 mounting screws in the

wood support mounted to the wall.

1. Remove metal grease lters. See the “Range Hood Care”

section.

NOTE: Only for the ETT142SS model, remove the lateral

panels as shown the picture below.

Centerline

of installation

space

NOTE: The screws provided for mounting this hood must be

fastened into solid wood, do not fasten into sheet rock only.

Installing the Duct Cover Kits

Attach the full-width duct cover to the top of the range hood with the

screws provided with duct covers. The duct cover must be attached to

the top of the range hood before mounting the range hood to the wall.

For information on ordering the optional duct cover, see “Optional

Accessories” section.

7

2. Using 2 or more people, hang the range hood on the the wall

by placing the slotted holes in the range hood back over the 2

screws mounted to the wood support mounted to the wall.

NOTE: If your installation uses the optional duct cover, the vent system needs to be connected to the hood and the duct cover mounted

to the top of the range hood before tightening the mounting screws.

AC C

Make Electrical Connection

WARNING: Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

21¼” (54cm)

B

Rear View

A. Key hole slots

B. Security lower key holes (2 - 6 x 80 mm)

C. Security key holes (4 - 4.2 x 19 mm)

D. Knockouts

C

C

B

1. Disconnect power.

2. Locate junction box inside of the range hood.

A

A

A. Knockout in canopy back into terminal box

E

D

A

B

C

D

F

3. Adjust depth of original mounting screws in the wood support until

they protrude

1

⁄4” forward. This 1⁄4” gap will provide clearance to

hang the hood (A).

4. Push the range hood up into the narrow slots, align the bottom of

the hood to the horizontal line, level the hood, and tighten the 2

mounting screws.

5. Mark 2 lower mounting hole locations. Drill

holes are located into wood. If holes are not located into wood,

remove the hood and drill two

3

⁄8” pilot holes and insert 10 x 50

1

⁄8” pilot holes if the

mm wall anchors. Remount the hood, level, and tighten the upper

screws. Install 2 - 6 x 80 mm screws and 2 - at washers into the

lower mounting anchors and tighten (B).

6. Install 4 - 4.2 x 19 mm screws through the back of the hood

into the wood support and tighten (C).

7. Connect vent system to hood. Seal all joints with clamps.

8. If your installation uses the optional duct cover, mount it to

the top of the range hood following the instructions supplied

with the duct cover.

A.White wires

B. Black wires

C. UL listed wire connectors

D. Green, Bare or Yellow/Green wires

E. Home power supply

F. UL listed or CSA approved ½” strain

relief

3. Use UL listed wire connectors and connect black wires (B)

together.

4. Use UL listed wire connectors and connect white wires (A)

together.

5. Connect green (or bare) ground wire from home power supply

to the green/yellow ground wire (D) in terminal box using UL

listed wire connectors.

6. Install terminal box cover.

7. Check that all light bulbs are secure in their sockets.

8. Reconnect power.

8

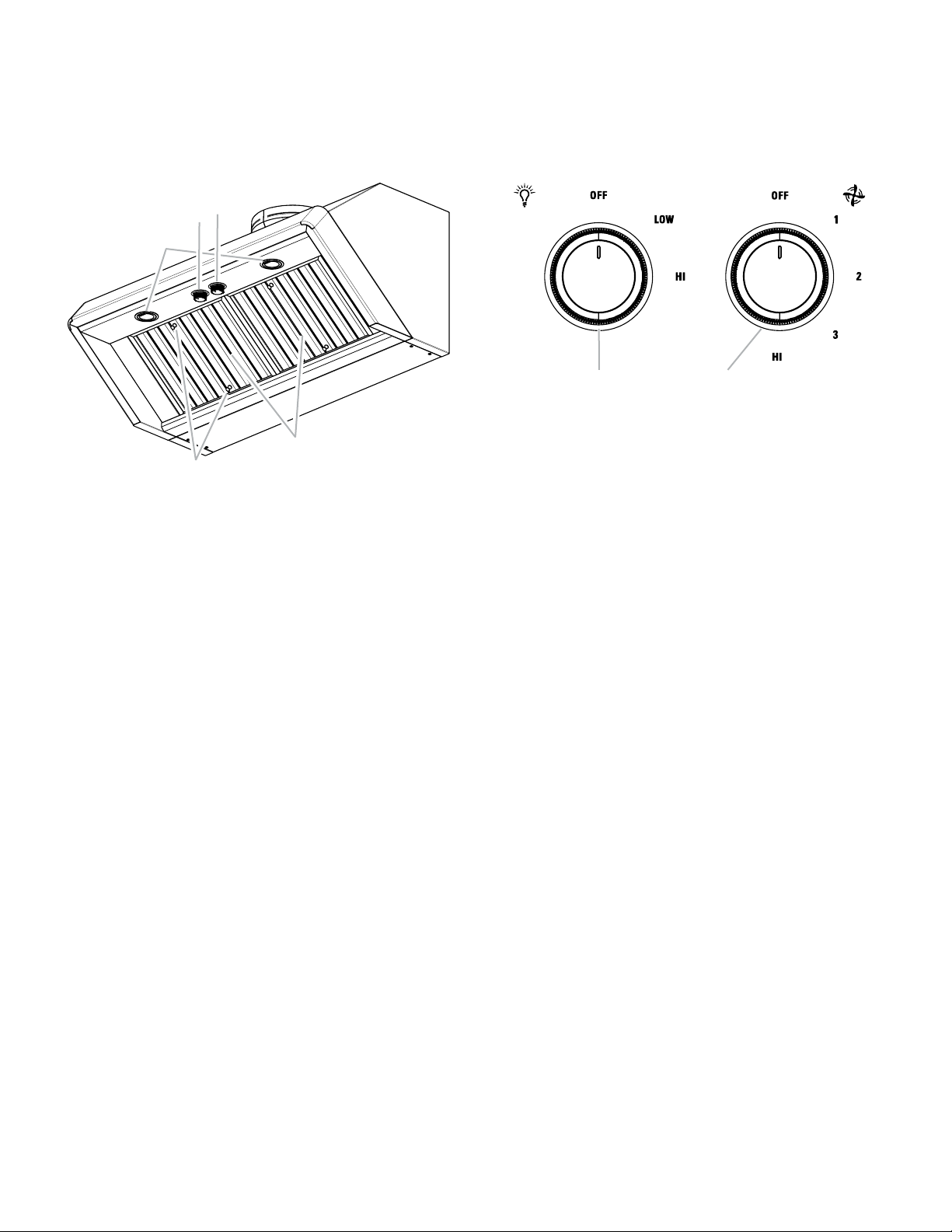

Complete Installation and

Range hood use

Check Operation

1. Install grease lters. See the “Range Hood Care” section.

2. Check operation of the range hood blower and lights. See the

“Range Hood Use” section.

C

B

A

E

D

A. Halogen lamps

B. Lamps knob

C. Blower knob

D. Filter handles

E. Grease lter

The range hood is designed to remove smoke, cooking vapors and

odors from the cooktop area. For best results, start the hood before

cooking and allow it to operate several minutes after the cooking is

complete to clear all smoke and odors from the kitchen.

The hood controls are located on the center side of the range hood.

A B

A. Lamps knob

B. Blower knob

Operating the lights

1. Turn the light switch to the “LOW” position to turn the range hood

lights On.

2. Turn the light switch to the “HI” position to turn the range hood

lights at its higher intensity.

3. Turn the light switch to the “OFF” position to turn the range hood

lights Off.

3. If range hood does not operate, check to see whether a circuit

breaker has tripped or a household fuse has blown.

Disconnect power supply and check that the wiring is correct.

NOTE: To get the most efcient use from your new range hood, read

the “Range Hood Use” section.

Operating the blower

1. Turn the blower switch at “1” to turn the range hood on.

2. Turn the blower switch to the desired speed position.

3. Turn the blower switch to the “HI” position to turn the range hood

on High.

4. Turn the blower switch to the “OFF” position to turn the range

hood blower Off.

9

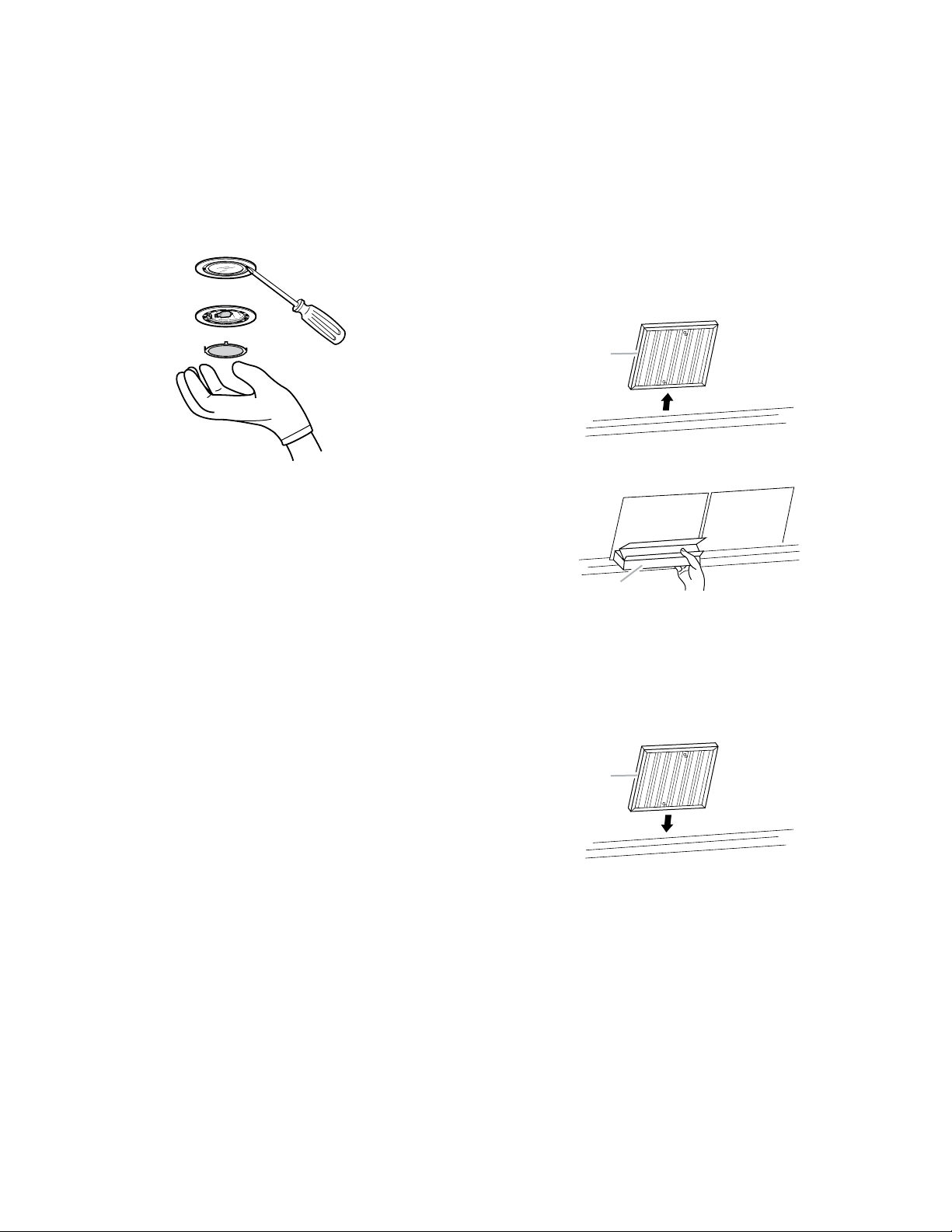

Range hood care

Replacing an Halogen Lamp

Turn off the range hood and allow the halogen lamp to cool. To avoid

damage or decreasing the life of the new lamp, do not touch lamp

with bare ngers. Replace lamp, using tissue or wearing cotton gloves

to handle lamp.

If new lights do not operate, make sure the lamps are inserted

correctly before calling service.

1. Disconnect power.

2. Use a at-blade screwdriver and gently pry the light cover loose.

3. Remove the lamp and replace with a 120-volt, 40-watt

maximum, halogen lamp made for a G-9 base.

4. Replace the light cover.

5. Reconnect power.

Cleaning

Exterior surfaces:

To avoid damage to the exterior surface, do not use steel wool or

soap-lled scouring pads. Rub in direction of the grain line to avoid

scratching the surface.

Always wipe dry to avoid water marks.

■ Stainless Steel Cleaner and Polish.

■ Mild liquid detergent and water.

■ Wipe with damp soft cloth or nonabrasive sponge, then rinse

with clean water and wipe dry.

Metal Filters and Drip Trays:

1. Use 2 hands to remove lters.

2. Grasp lter handles, pull toward the front of range hood and pull

down on the rear handle to remove. Repeat for each lter.

A

A. Grease lter

3. Remove grease drip tray.

A

A. Drip tray

4. Wash metal lters and grease trays as needed in dishwasher or

hot detergent solution to clean.

5. Replace grease drip tray.

6. Reinstall lters, grasp lter handles and place front edge of lter

into the hood.

7. Push up on the back handle and set rear of lter into the drip tray

to secure. Repeat for each lter.

A

A. Grease lter

10

Loading...

Loading...