Page 1

Use, Care, and

Installation Guide

Guide

d’utilisation,

d’entretien et

d’installation

Guía de

instalación, uso y

mantenimiento

Models: ECV630S3

ECV636S3

READ AND SAVE THESE

INSTRUCTIONS

LISEZ CES

INSTRUCTIONS ET

CONSERVEZ-LES

LEA Y CONSERVE

ESTAS INSTRUCCIONES

LIB0140473

Printed in Mexico

10/17

1

Page 2

ENGLISH

Contents

Important safety notice................................................................................................................................................................................................. 3

Electrical & installation requirements ................................................................................................................................................................ 4

Before installing the hood ...................................................................................................................................................................................... 4

Dimensions and clearances......................................................................................................................................................................................... 4

List of materials................................................................................................................................................................................................................. 5

Parts supplied .............................................................................................................................................................................................................. 5

Parts not supplied ...................................................................................................................................................................................................... 5

Ducting options and examples.................................................................................................................................................................................. 6

Installation ......................................................................................................................................................................................................................... 6

Electrical connection................................................................................................................................................................................................ 8

Complete the installation........................................................................................................................................................................................ 9

Description of the hood................................................................................................................................................................................................. 9

Control.................................................................................................................................................................................................................................. 9

Maintenance ...................................................................................................................................................................................................................... 10

Warranty ........................................................................................................................................................................................................................... 11

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn o power circuit at service panel and lock out panel, before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit.

2

Page 3

IMPORTANT SAFETY NOTICE

I

I CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS OR

VAPOURS.

I WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

B.

at service panel and lock service panel disconnecting

means to prevent power from being switched on

accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

C. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes & standards, including fire-rated construction.

D.

exhausting of gases through the flue (Chimney) of fuel

burning equipment to prevent back- drafting.

Follow the heating equipment manufacturers guideline

and safety standards such as those published by the

national fire protection association (NFPA), the american

society for heating, refrigeration and air conditioning

engineers (ASHRAE), and the local code authorities.

E. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

F. Ducted fans must always be vented to the outdoor.

I CAUTION

To reduce risk of fire and to properly exhaust air, be sure to

duct air outside - do not vent exhaust air into spaces within

walls, ceilings, attics, crawl spaces, or garages.

I WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT

WORK.

I WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE.

a) Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

flambeing food (I.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambe’).

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate

for the size of the surface element.

I WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

a) SMOTHER FLAMES with a close-fitting lid, cookie sheet,

electric element. BE CAREFUL TO PREVENT BURNS. If the

flames do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - you may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a class ABC extinguisher, and

you already know how to operate it.

2) The fire is small and contained in the area where it

started.

3) The fire department is being called.

4) You can fight the fire with your back to an exit.

a

Based on “Kitchen Fire Safety Tips” published by NFPA.

a

the

I CAUTION

Automatically Operated Device - To Reduce The Risk Of

Injury Disconnect From Power Supply Before Servicing.

Install this hood in accordance with all requirements specified.

I WARNING

To reduce the risk of fire or electric shock, do not use this

hood with any external solid state speed control device.

3

Page 4

ELECTRICAL & INSTALLATION REQUIREMENTS

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsibility:

• To contact a qualified electrical installer.

• To assure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70

— latest edition*, or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No.0-M91-latest edition**

and all local codes and ordinances.

• If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

• Do not ground to a gas pipe.

• Check with a qualified electrician if you are not sure range

hood is properly grounded.

• Do not have a fuse in the neutral or ground circuit.

IMPORTANT

• Save Installation Instructions for electrical inspector’s use.

• The range hood must be connected with copper wire only.

• The range hood should be connected directly to the fused

disconnect (Or circuit breaker) box through metal

electrical conduit.

• Wire sizes must conform to the requirements of the

National Electrical Code ANSI/NFPA 70 — latest edition*,

or CSA Standards C22.1-94, Canadian Electrical Code Part

1 and C22.2 No. 0-M91 - latest edition** and all local codes

and ordinances.

• A U.L.- or C.S.A.-listed conduit connector must be

provided at each end of the power supply conduit (at the

range hood and at the junction box).

BEFORE INSTALLING THE HOOD

1 For the most ecient air flow exhaust, use a straight run

or as few elbows as possible.

CAUTION: Vent unit to outside of building, only.

2 At least two people are necessary for installation.

3 Fittings material is provided to secure the hood to most

types of walls/ceilings, consult a Qualified Installer,

check if they perfectly fit with your cabinet/wall.

4 Do not use flex ducting.

5 COLD WEATHER installations should have an additional

backdraft damper installed to minimize backward cold air

flow and a nonmetallic thermal break to minimize

conduction of outside temperatures as part of the

ductwork. The damper should be on the cold air side of

the thermal break.

The break should be as close as possible to where the

ducting enters the heated portion of the house.

6 Make up air: Local building codes may require the use of

Make-Up Air Systems when using Ducted Ventilation

Systems greater than specified CFM of air movement.

The specified CFM varies from locale to locale. Consult

your HVAC professional for specific requirements in your

area.

Copies of the standards listed may be obtained from:

* National Fire Protection Association Batterymarch Park Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575

PRODUCT DIMENSIONS

H

G

I

F

E

A

B

C

D

Models

ECV630S3 ECV636S3

A 30” (76 cm) 36” (91.54 cm)

B 23” (58.4 cm)

C 111⁄32” (27.9 cm)

D 1111⁄16” (29.7 cm)

E 219⁄32” (6.6 cm)

F 29” (73.3 cm) 35” (88.9 cm)

G 71⁄2” (19 cm)

H 29⁄16” (6.5 cm)

I

3

⁄8” (1 cm)

4

Page 5

LIST OF MATERIALS

Removing the packaging.

I CAUTION

Remove carton carefully, wear gloves to protect against sharp edges.

I WARNING

Remove the protective film covering the product before putting into operation.

Supplied Part Pieces Supplied Part Pieces

1

Hood assembly and

LED lamps already installed

Tools/Materials required

• Level

• Drill with 11⁄4” (3.0 cm), 1⁄8” (3.0 mm), 1⁄16” (4.8 mm) drill bits

• Pencil

• Wire stripper or utility knife

• Tape measure or ruler

• Pliers

• Caulking gun and weatherproof caulking compound

• Vent clamps

• Saber or keyhole saw

• Metal snips

• Screwdrivers:

- Phillips

- Flat-blade

5x45 mm

4.5x13 mm

4x8 mm

4

6

4

Parts no supplied

Rectangular duct 31⁄4” x 10” (8.3 x 25.4 cm)

with back draft dampers

Torx 20 adapter

10x50 mm wall anchors

Optional accessories and consumable parts

KIT # Part

Duct Cover

Extension Kit 6”

Duct Cover

Extension Kit 12”

Stainless Back

Splash and Warm

Racks Kit

30” (76 cm) 36” (91.54 cm)

KIT02159 KIT02158

KIT02160 KIT02161

KIT02162 KIT02163

1

1

4

5

Page 6

Ducting Options

Closely follow the instructions set out in this manual.

All responsability, for any eventual inconveniences, damages or fires caused by not complying with the instructions in this

manual, is declined.

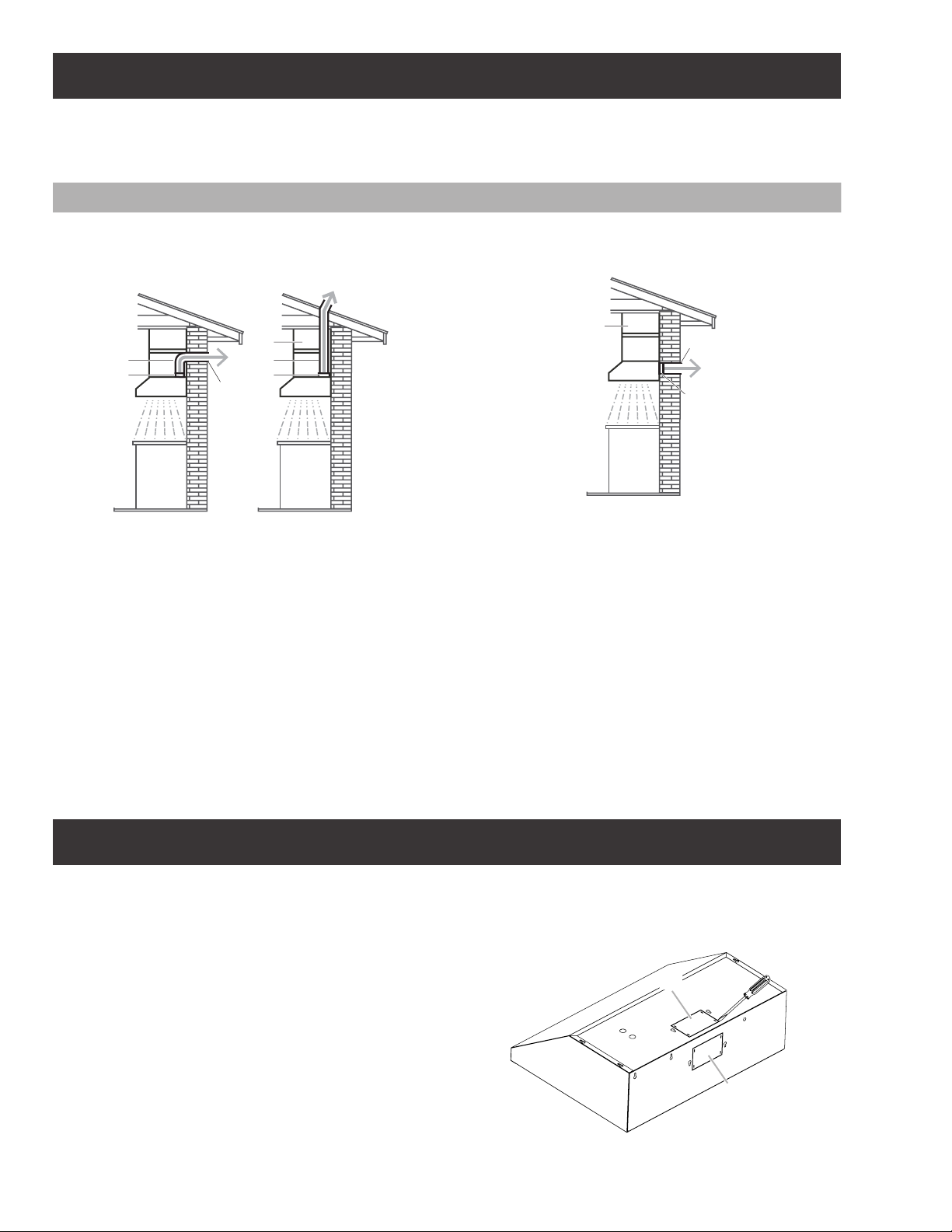

Vertical Discharge Horizontal Discharge

Use a rectangular duct 31⁄4” x 10” (8.3 x 25.4 cm) and a 31⁄4”

x 10” (8.3 x 25.4 cm) rectangular transition for discharge of

fumes to the outside.

C

D

A

A. 31⁄4” x 10” (8.3 x 25.4 cm)

rectangular transition

B. 31⁄4” x 10” (8.3 x 25.4 cm) duct

B

A

B

C. Cabinet

D. 90° elbow

Preparation

Do not cut a joist or stud unless absolutely necessary. If a joist

or stud must be cut, then a supporting frame must be

constructed.

Fittings material is provided to secure the hood to most types

of walls/ceilings.

However, a qualified technician must verify suitability of the

materials in accordance with the type of wall/ceiling.

Before making cutouts, make sure there is proper clearance

within the ceiling or wall for exhaust vent.

I CAUTION

For gas cooktop & range installations: Mount the hood so the

bottom is at least 30” (76.2 cm) above the cooking surface.

For electric/induction cooktop & range installations:

Use a rectangular duct 31⁄4”x10” (8.3x25.4 cm) for discharge

of fumes to the outside.

C

A. 31⁄4” x 10” (8.3 x 25.4 cm) rectangular transition

B. 31⁄4” x 10” (8.3 x 25.4 cm) duct

C. Cabinet

B

A

Mount the hood so the bottom is at least 24” (61 cm) above the

cooking surface.

There is no maximum mounting height, however, we recommend

mounting the hood no greater than 36” (91.4 cm) above the

cooking surface. For every inch (2.54 cm) above 36” (91.4 cm),

fume and moisture capture eciency diminishes at an increasing rate and may not deliver an acceptable level of ventilating

performance.

This hood is intended for household use.

PLEASE READ THE INSTALLATION MANUAL FOR SPECIFIC

APPLICATION. Check your ceiling height and hood height

before selecting your hood.

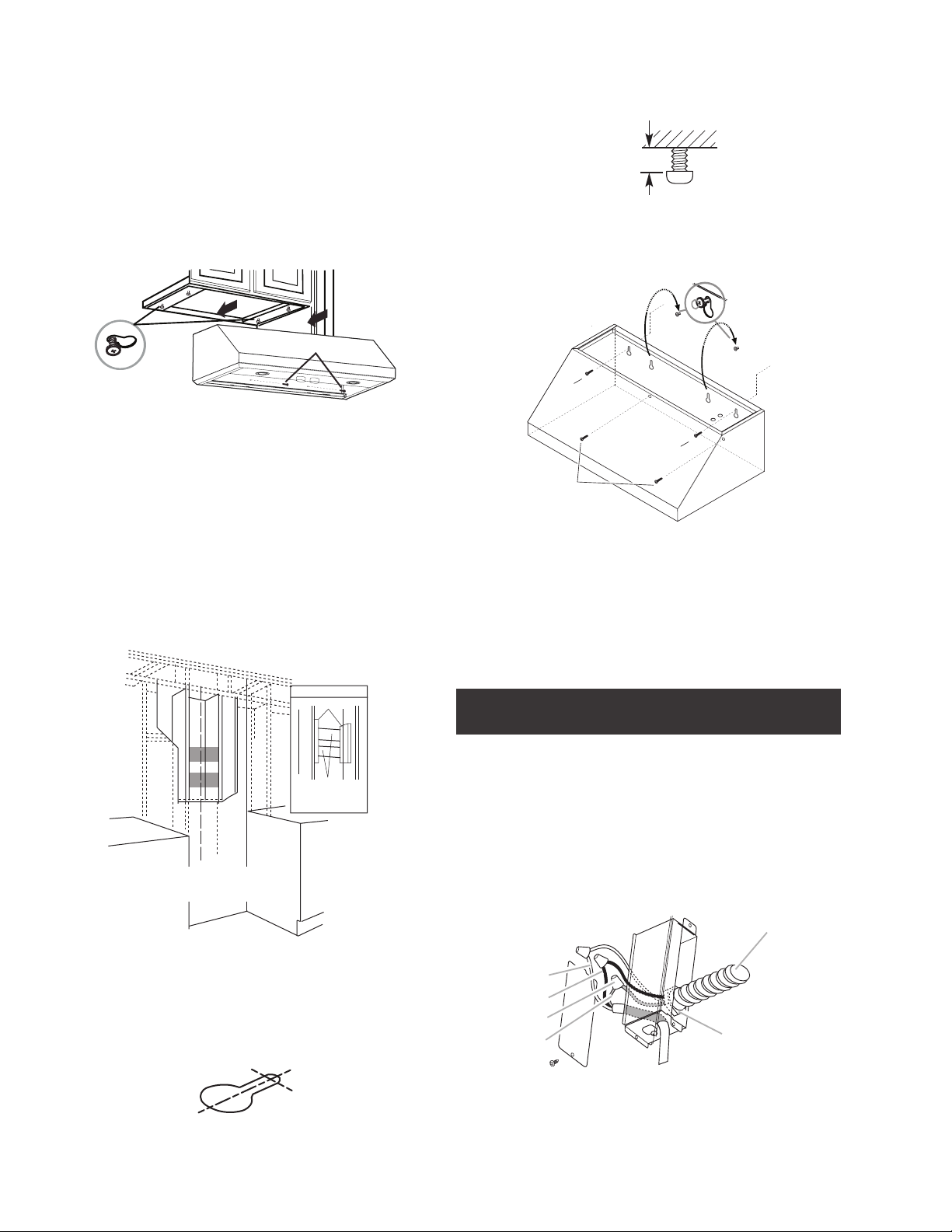

Installation- Ducting Version

After having chosen the vent option, proceed as follows:

• Prepare duct and conduit cut outs as needed.

• If possible, disconnect and move freestanding or slide-in

range from cabinet opening to provide easier access to

rear wall.

Otherwise put a thick, protective covering over countertop,

cooktop or range to protect from damage and debris.

Select a flat surface for assembling the unit. Cover that

surface with a protective covering and place all canopy

hood parts and hardware in it.

• Determine and mark the centerline on the wall where the

canopy hood will be installed. Select a mounting height

comfortable for the user and mark on wall.

• Prepare duct and conduit cut outs as needed.

• Remove the duct knockouts using a flat blade screwdriver

and a small hammer.

6

• Use the screwdriver by knocking out the pannel in similar

fashion to a scalpel.

• Take care of sharp edges.

A

B

A. Vertical discharge

B. Horizontal discharge

Page 7

• Attach air exhaust transition over knockout opening with

4 - 4x8 mm screws.

A

A

NOTE:

The exhaust adaptor/damper can be installed up to 1 inch on

either side of the hood center to accommodate ocenter ductwork. In extreme ocenter installations, one end of the duct

connector may need to be trimmed to clear the electrical cable

clamp.

Mark holes

Select the vent option that your installation will require and

proceed to that section:

Outside rear exhaust

(Horizontal duct– 31⁄4”x 10” Rectangular)

Use the diagram or the hood as a template and mark the

locations on the wall for ductwork, electrical wiring and keyhole

screw slots.

39

⁄64” (1.5 cm)

Mounting hole

37

⁄64” (34.5 cm)

30”: 13

36”: 1611⁄16” (42,4 cm)

6

421⁄64”

(11 cm)

61

⁄64”

2

(7.5 cm)

Permanent

10

13

⁄16”(17.4 cm)

51⁄2”

(14 cm)

5

⁄8” (27 cm)

CENTER LINE

WALL

13

6

⁄16”(17.4 cm)

51⁄2”

(14 cm)

5

10

⁄8” (27 cm)

30”: 1337⁄64” (34.5 cm)

36”: 1611⁄16” (42,4 cm)

39

⁄64” (1.5 cm)

Permanent

Mounting hole

1 Remove the grease filters.

2 Remove the blower mounting screws. Put the screws in a

safe place in order to use them again.

Outside top exhaust

(Vertical duct– 31⁄4”x 10” Rectangular)

Use the diagram or the hood as a template and mark the locations on the cabinet for ductwork, electrical wiring and keyhole

screw slots. It is recommended to make the marks before the

cabinet’s installation.

3

⁄4” (7 cm)

2

screws (4)

61⁄16”

(15.4 cm)

Wiring access knockout

(cabinet bottom side)

Mounting

Vent

shims

13

(1 cm)

71⁄2”

(19 cm)

23

2

⁄64”

(6 cm)

Cabinet

bottom side

5

(14 cm)

system hole

front side

Cabinet

1

⁄2”

(14 cm)

Vent

CENTER

LINE

1

⁄2”

5

⁄32”

431⁄64”

(11 cm)

For recessed bottom cabinet only

If the cabinets have front, side or back trim, make 2 wood shims

the width of the trim and attach them to the cabinet bottom

recess on both sides.

Wood shims

A

B

A. Blower

B. Blower screws

3 Set free the two blower springs from the top of the range

hood housing.

4 Flip the blower base to the rear face of the range hood.

5 Insert the two blower springs to the top of the range hood

housing, secure it with the four mounting screws previously

released.

7

Page 8

Cabinet Installation

NOTE: Your cabinet must be able to support at least 88 lb (40kg).

1 Drive a mounting screw (from the hardware package)

partway into each center of the narrow neck of the keyhole

slots marked on the cabinet bottom.

2 Install the 4 - 4 x 8 mm mounting screws. Leave a 1⁄4” (6.4 mm)

gap between the wall and the back of the screw head to

slide range hood into place 1⁄4” (6.4 mm).

3 Fix the wiring conduit of the hood.

4 Slide the hood back against the cabinet. Tighten the

mounting screws. Be sure the screw heads are in the narrow

neck of the keyhole slot.

5 Drive 2 pieces of the selected screws in the security holes

(See the image below).

2 Install the 2 pieces of the selected screws on the mountings

screws location (see the image). Leave a 1⁄4” (6.4 mm) gap

between the wall and the back of the screw head to slide

range hood into place.

1

⁄4”

(6.4 mm)

3 Fix the wiring conduit of the hood.

4 Slide the hood back against the wall. Tighten the mounting

screws. Be sure the screw heads are in the narrow neck of

the keyhole slot.

A

B

A. 4- 4x8 mm mounting screws

B. Security screws

Wall Installation

Install framing for hood support

1 Mark the screw hole locations indicated in the “Outside

rear exhaust” figure.

2 If drywall is present, cut away enough drywall to expose

2 vertical studs at the indicated holes location. Install two

horizontal supports between two wall studs at the bottom

and upper mounting holes installation location.

3 The horizontal support must be flush with the room side

of the studs. Use cleats behind both sides of the support

to secure wall studs.

4 Reinstall drywall and refinish.

IMPORTANT: Framing must be capable

of supporting 100 lbs.

View from rear

Cleats

A

B

B

C

B. Upper security screws (Wall Installation)

C. Lower security screws (Wall Installation)

A. Mounting screws

5 Drive 2 pieces of the selected screws in the upper security

screws location (see the image above).

6 Drive 2 pieces of the selected screws in the lower security

screws location (see the image above).

7 Connect Ductwork to hood.

Electrical connection

Mounting

Support

Centerline of

Installation

Space

5 Cut holes at marked locations for duct and electrical wiring.

Mounting the hood

1 Drive a mounting screw (from the hardware package)

partway into each center of the narrow neck of the keyhole

slots marked on the wall’s support frame.

8

I WARNING

ELECTRICAL SHOCK HAZARD.

I WARNING

DISCONNECT POWER BEFORE SERVICING.

REPLACE ALL PARTS AND PANELS BEFORE OPERATING.

FAILURE TO DO SO CAN RESULT IN DEATH OR ELECTRICAL

SHOCK.

• Remove the knockout and the Junction box cover and

install the conduit connector (cULus listed) in junction box.

E

A

B

C

D

A. White wires

B. Black wires

C. UL listed wire connector

D. Green (or bare) and yellow-green

ground wire

E. Home power supply cable

F. UL listed or CSA approved ½” strain relief

F

Page 9

• Run 3 wires; black, white and green ,according to the

National Electrical Code and local codes and ordinances,

in 1⁄2” conduit from service panel to junction box.

I WARNING

ELECTRICAL SHOCK HAZARD.

I WARNING

ELECTRICALLY GROUND BLOWER.

CONNECT GROUND WIRE TO GREEN AND YELLOW GROUND

WIRE IN TERMINAL BOX. FAILURE TO DO SO CAN RESULT IN

DEATH OR ELECTRICAL SHOCK.

• Connect black wire from service panel to black or red in

junction box, white to white and green to green-yellow.

• Close and secure junction box cover.

Complete installation

Replace filters.

Check operation of the hood.

Control

The range hood is designed to remove smoke, cooking vapors

and odors from the cooktop area. For best results, start the

hood before cooking and allow it to operate several minutes

after the cooking is complete to clear all smoke and odors

from the kitchen.

The hood controls are located on the center side of the hood.

Recessing Knobs

• You can hide control knobs by depressing them until flush

with the hood body.

If range hood does not operate:

• Check that the circuit breaker is not tripped or the house

fuse blown.

• Disconnect power supply. Check that wiring is correct.

To get the most ecient use from your new range hood, read

the “Maintenance” section.

Keep your Installation Instructions and Use and Care Guide

close to range hood for easy reference.

Description of the hood

1

2

3

1. Blower and light controls

2. LED lamps

3. Grease filter handle

4. Grease filter

3

4

• Pressing the knobs again will lower the knobs, and enable

the user to operate the lights and blower.

Controls

A

A. Lamps knob B. Blower knob

Operating the lamps

1. Turn the light switch to the “ON” position to turn the

range hood lights On.

2. Turn the light switch to the “OFF” position to turn the

range hood lights O.

Operating the blower

1. Turn the blower switch at “1” to turn the range hood on.

2. Turn the blower switch to the desired speed position.

3. Turn the blower switch to the “MAX” position to turn the

range hood on High.

4. Turn the blower switch to the “OFF” position to turn the

range hood blower O.

Auto On blower

The range hood is equipped with a sensor to automatically turn

on the blower when excessive heat is detected in the control

area. When the blower switch is in the “Off” position, this sensor

will turn the blower to high speed when necessary. When the

heat decreases, the blower will turn off. When the blower

switch is in the On position, the heat sensor is not active and

the range hood functions normally.

B

9

Page 10

Maintenance

Cleaning

Exterior surfaces:

To avoid damage to the exterior surface, do not use steel wool

or soap-filled scouring pads. Rub in direction of the grain line

to avoid scratching the surface.

Always wipe dry to avoid water marks.

• Stainless Steel Cleaner and Polish.

• Mild liquid detergent and water.

• Wipe with damp soft cloth or nonabrasive sponge, then

rinse with clean water and wipe dry.

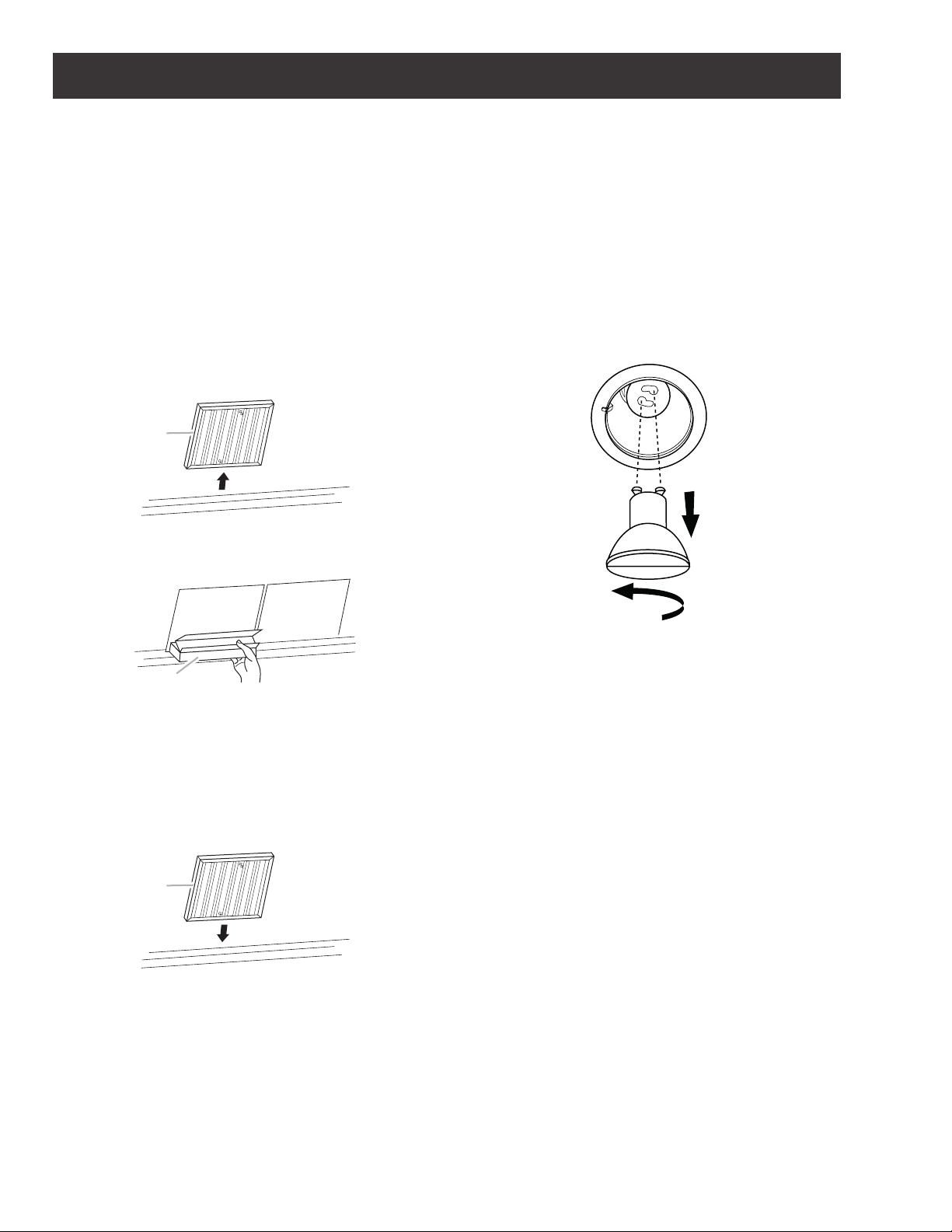

Metal filters and drip trays:

1. Use 2 hands to remove filters.

2. Grasp filter handles, pull toward the front of range hood

and pull down on the rear handle to remove. Repeat for

each filter.

A

A. Grease filter

3. Remove grease drip tray.

Replacing a LED Lamp

Turn off the range hood and allow the LED lamp to cool.

To avoid damage or decreasing the life of the new lamp, do

not touch lamp with bare fingers. Replace lamp, using tissue

or wearing cotton gloves to handle lamp.

If new lamps do not operate, make sure the lamps are inserted

correctly before calling service.

1 Disconnect power.

2 Push up on the lens and turn it counterclockwise.

3 Remove the lamp and replace it with a 120-volt, 7.5 W watt

maximum halogen lamp with a GU10 base. Turn it clockwise

to lock it into place.

4 Repeat steps 2-3 for the other lamps if needed.

5 Reconnect power.

A

A. Drip tray

4. Wash metal filters and grease trays as needed in

dishwasher or hot detergent solution to clean.

5. Replace grease drip tray.

6. Reinstall filters, grasp filter handles and place front edge

of filter into the hood.

7. Push up on the back handle and set rear of filter into the

drip tray to secure. Repeat for each filter.

A

A. Grease filter

10

Page 11

Register your product in

elica.com

ELICA North America

TWO-YEAR LIMITED WARRANTY

and earn a 3

warranty, covering all parts

rd

year of factory

plus in-home labor.

TO OBTAIN SERVICE UNDER WARRANTY

Owner must present proof of original purchase date. Please keep a copy of your dated proof of purchase (sales slip) in

order to obtain service under warranty.

PARTS AND SERVICE WARRANTY

For the period of two (2) years from the date of the original purchase, Elica will provide free of charge, non consumable

parts or components that failed due to manufacturing defects. During these two (2) years limited warranty, Elica will also

provide free of charge, all labor and in-home service to replace any defective parts.

WHAT IS NOT COVERED

đƫ Damage or failure to the product caused by accident or act of God, such as, flood, fire or earthquake.

đƫ Damage or failure caused by modification of the product or use of non-genuine parts.

đƫ Damage or failure to the product caused during delivery, handling or installation.

đƫ Damage or failure to the product caused by operator abuse.

đƫ Damage or failure to the product caused by dwelling fuse replacement or resetting of circuit breakers.

đƫ Damage or failure caused by use of product in a commercial application.

đƫ Service trips to dwelling to provide use or installation guidance.

đƫ Light bulbs, metal or carbon filters and any other consumable part.

đƫ Normal wear of finish.

đ Wear to finish due to operator abuse, improper maintenance, use of corrosive or abrasive cleaning products/pads and

oven cleaner products.

WHO IS COVERED

This warranty is extended to the original purchaser for products purchased for ordinary residential use in North America

(Including the United States, Guam, Puerto Rico, US Virgin Islands & Canada).

This warranty is non-transferable and applies only to the original purchaser and does not extend to subsequent owners of

the product. This warranty is made expressly in lieu of all other warranties, expressed or implied, including, but not limited

to any implied warranty of merchantability or fitness for a particular purpose and all other obligations on the part of Elica

North America, provided, however, that if the disclaimer of implied warranties is ineective under applicable law, the dura

tion of any implied warranty arising by operation of law shall be limited to two (2) years from the date of original purchase

at retail or such longer period as may be required by applicable law.

Th

is warranty does not cover any special, incidental and/or consequential damages, nor loss of profits, suered by the

original purchaser, its customers and/or the users of the Products.

WHO TO CONTACT

To obtain service under warranty or for any service related question:

đƫ Elica North America Service, call at 1 888 732 8018

đƫ For Eastern Canada, call AGI Services at 1 888 651 2534 Ask for the service department

đƫ elica@servicepower.com

-

Page 12

FRANÇAIS

Table des matières

Avis de sécurité important ......................................................................................................................................................................................... 13

Exigences électriques et d’installation ............................................................................................................................................................. 14

Avant d’installer la hotte ........................................................................................................................................................................................ 14

Dimensions du produit ................................................................................................................................................................................................. 14

Liste des pièces ............................................................................................................................................................................................................... 15

Pièces fournies ........................................................................................................................................................................................................... 15

Pièces non fournies .................................................................................................................................................................................................. 15

Méthodes d’evacuation ................................................................................................................................................................................................ 16

Installation ......................................................................................................................................................................................................................... 16

Electrical connection................................................................................................................................................................................................ 19

Achever l’installation ................................................................................................................................................................................................ 19

Description de la hotte ................................................................................................................................................................................................ 19

Commandes ..................................................................................................................................................................................................................... 19

Entretien ............................................................................................................................................................................................................................ 20

Garantie ............................................................................................................................................................................................................................ 21

APPROUVÉ POUR LES APPAREILS DE TYPE RÉSIDENTIEL

POUR UNE UTILISATION RÉSIDENTIELLE SEULEMENT

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

VEUILLEZ LIRE CES INSTRUCTIONS AU COMPLET AVANT DE COMMENCER.

L’INSTALLATION DE L’APPAREIL DOIT RESPECTER TOUS LES CODES EN VIGUEUR.

IMPORTANT : Conservez ces instructions afin de pouvoir les remettre à l’inspecteur-électricien de votre région.

INSTALLATEUR : Veuillez laisser ces instructions avec l’appareil pour le propriétaire.

PROPRIÉTAIRE : Veuillez conserver ces instructions pour pouvoir vous y référer plus tard.

Avertissement de sécurité : Coupez l’alimentation du circuit dans le panneau électrique et verrouillez le

panneau avant de raccorder les fils de cet appareil.

Exigence : 120 V c.a., 60 Hz circuit de dérivation de 15 V c.a., 20 Hz, de 15 ou 20 A.

12

Page 13

AVIS DE SÉCURITÉ IMPORTANT

I

I ATTENTION

UTILISER CET APPAREIL À DES FINS DE VENTILATION

GÉNÉRALE SEULEMENT. NE PAS UTILISER CET APPAREIL

POUR ÉVACUER DES MATÉRIAUX OU DES VAPEURS

DANGEREUX OU EXPLOSIFS.

I AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE ET DE BLESSURE, RESPECTER LES DIRECTIVES

SUIVANTES:

A. Utiliser cet appareil uniquement aux fins prévues par le

fabricant. Si vous avez des questions à propos de l’appareil,

communiquez avec le fabricant.

B. Avant de faire l’entretien de l’appareil ou de le nettoyer,

coupez l’alimentation dans le panneau électrique et

verrouillez le panneau en bloquant le dispositif permettant

d’empêcher d’activer l’alimentation accidentellement. S’il

n’est pas possible de verrouiller l’accès au panneau, fixez

une étiquette très voyante au panneau électrique.

C.

câblage des fils électriques en conformité avec tous les

codes et toutes les normes, y compris la cote de résistance

au feu.

D.

et l’évacuation adéquates des gaz par le conduit de cheminé afin de prévenir les refoulements d’air. Respectez

les directives et les normes de sécurité des fabricants de

National Fire Protection Association (NFPA), la American

Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) et le code des autorités de votre région.

E. Au moment de couper ou de percer un mur ou un plafond,

assurez-vous de ne pas endommager la filerie électrique

ou tout autre accès à un service publique.

F. Les ventilateurs conduits doivent toujours être évacués

vers l’extérieur.

I ATTENTION

Pour réduire les risques d’incendie et évacuer l’air correctement,

assurez-vous que le conduit mène à l’extérieur; il ne faut pas

évacuer l’air dans l’espace entre les murs, dans les plafonds, dans

les greniers, les vides sanitaires ou les garages.

I AVERTISSEMENT

POUR RÉDUIRE DES RISQUES D’INCENDIE, UTILISEZ

UNIQUEMENT DES CONDUITS EN MÉTAL.

Installez cette hotte en respectant toutes les exigences

mentionnées.

I AVERTISSEMENT

Pour réduire les risques d’incendie et de choc électrique,

n’utilisez pas cette hotte avec un

conducteurs.

contrôleur de vitesse à semi-

I ATTENTION

Dispositif à commande automatique - pour réduire le risque

de Blessure Débrancher de l’alimentation électrique avant la

maintenance.

I AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE DE GRAISSE SUR

LES CUISINIÈRES.

a) Ne laissez jamais la cuisinière sans surveillance lorsqu’elle

est réglée à une haute température. Les débordements par

bouillonnement causent de la fumée et des débordements

lentement, à une température basse ou moyenne.

b) Faites toujours fonctionner la hotte lorsque vous utilisez

la cuisinière à une haute température ou que vous faites

flamber des aliments (P. ex.: crêpes Suzette, cerises

jubilées, boeuf au poivre flambé).

c) Nettoyez les hélices de ventilation fréquemment. Il ne faut

pas que la graisse s’accumule sur les filres ou les hélices.

d) Utilisez le bon format de casserole. Utilisez toujours un

chaudron de taille approprié à l’élément de la cuisinière.

e) Convient pour utilisation dans la zone de cuisson domestique.

I AVERTISSEMENT

POUR ÉVITER DE BLESSER QUELQU’UN LORS D’UN

INCENDIE DE GRAISSE SUR LA CUISINIÈRE, SUIVRE LES

CONSEILS SUIVANTS:

a) ÉTOUFFER LES FLAMMES avec un couvercle aux

dimensions de la taque de cuisson, une tôle à biscuit ou

tout autre plateau métallique, puis couper le gaz ou

l’alimentation électrique de la cuisinière. FAIRE ATTENTION

A NE PAS SE BRÛLER. Si les flammes ne s’éteignent pas

immédiatement, QUITTER LA PIÈCE ET APPELER LES

POMPIERS.

b) NE JAMAIS PRENDRE EN MAIN UNE CASSEROLE N FEU,

vous pourriez vous blesser.

c) NE PAS UTILISER D’EAU, y compris les essuies de vaisselle

ou les serviettes humides – une violente explosion due à la

vapeur formée pourrait survenir.

d)

Utiliser un extincteur SEULEMENT si:

1) Vous êtes sûr d’avoir un extincteur de classe ABC que

vous savez utiliser.

2) Le feu est petit et confiné à la zone où il s’est formé.

3) Les pompiers ont été appelés.

4) Vous pouvez lutter contre le feu avec une sortie

derrière vous.

a

Recommandations tirées des conseils de sécurité en cas d’incendie de cuisine

publiés par la NFPA.

a

.

MODE OPÉRATOIRE

Toujours laisser les grilles de sécurité et les filtres à leurv

place. Sans la présence de ces derniers, les parties aspirantes

pourraient attirer les cheveux, les doigts ou les vêtements.

Le fabricant décline toute responsabilité si les informations

détaillées dans ce manuel pour l’installation, l’entretien et

l’utilisation adéquate du produit ne sont pas observées. Le

fabriquant décline en outre toute responsabilité pour

d’éventuelles blessures dues à des négligences; en outre, la

garantie de l’appareil sera annulée suite à des conditions

d’entretien inappropriées. Cet appareil est fabriqué pour un

usage interne. Ne pas utiliser cet appareil à l’extérieur.

13

Page 14

EXIGENCES ÉLECTRIQUES ET D’INSTALLATION

IMPORTANT

Respectez tous les codes et les ordonnances en vigueur.

Le client a la responsabilité de :

• Contacter un électricien-installateur.

• Vérifier que l’installation électrique est adéquate et confor me avec le Code national de l’électricité, ANSI/ NFPA

70 (la plus récente édition*), ou les normes C22.1-94, Code

canadien de l’électricité, Partie 1 et C22.2 No.0-M91

(La plus récente édition**) de la CSA, ainsi que tous les

codes et les ordonnances de votre région.

• Si le code le permet et que vous utilisez un fil de mise

à la terre distinct, il est recommandé de faire vérifier le

chemin du fil par un électricien.

• Ne pas mettre l’appareil à la terre sur une conduite de gaz.

• Consultez un électricien qualifié si vous n’êtes pas

certain que la hotte est mise à la terre correctement.

• N’installez pas un fusible dans le circuit neutre ou le

circuit de mise à la terre.

IMPORTANT

• Conservez ces instructions afin de pouvoir les remettre à

l’inspecteur-électricien.

• La hotte doit être câblée uniquement à l’aide de fils de

cuivre.

• Il faut raccorder la hotte directement à une boîte à

fusible ou à un disjoncteur par l’entremise d’une

canalisation électrique en métal.

• Le calibre de fil doit être conforme aux exigences du

Code national de l’électricité, ANSI/NFPA 70 (La plus

récente édition*), ou les normes C22.1-94, Code

canadien de l’électricité, Partie 1 et C22.2 0-M91 (La

plus récente édition**) de la CSA, ainsi que tous les

codes et les ordonnances de votre région.

• Il faut prévoir un connecteur de canalisation approuvé

par l’UL ou la CSA à chaque extrémité de la canalisation

d’alimentation (À la hotte et à la boîte de jonction).

AVANT D’INSTALLER LA HOTTE

1 Pour assurer la ventilation la plus ecace possible,

installez la conduite en ligne droite ou avec le moins de

coudes possibles.

ATTENTION : La sortie de la conduite de ventilation

doit donner sur l’extérieur.

2 Deux personnes sont nécessaires pour eectuer

l’installation.

3 La quincaillerie fournie permet de fixer la hotte à la

plupart des murs et des plafonds; consultez un

installateur qualifié pour vous assurer que la

quincaillerie fournie est adaptée à votre type de mur

ou d’armoire.

4 N’utilisez pas de conduit flexible.

5 Dans le cas des endroits sujets aux TEMPÉRATURES

FROIDES, il faut installer un clapet de contre-tirage

supplémentaire afin de minimiser le retour d’air froid et

un isolant thermique non métallique afin de minimiser

la conduction de la température extérieur dans le

conduit. Il faut placer le clapet du côté de l’air froid de

l’isolant thermique.

L’isolant doit être placé le plus près possible de

l’endroit où le conduit entre dans la partie chauée de

la maison.

Air d’appoint : Le code du bâtiment de votre région

peut exiger l’utilisation d’un système d’air d’appoint si

vous utilisez un système de ventilation à conduit dont

le mouvement d’air dépasse un certain nombre de

CFM. Le nombre de pi3/min varie d’une région à

l’autre. Consultez un professionnel de CVC pour

connaître les exigences précises de votre région.

Vous pouvez obtenir un exemplaire des normes indiquées en vous adressant à:

* La National Fire Protection Association, Batterymarch Park Quincy, Massachusetts, 02269

** La CSA International, 8501 East Pleasant Valley Road, Cleveland, Ohio, 44131-5575

DIMENSIONS DU PRODUIT

F

E

A

14

H

G

I

ECV630S3 ECV636S3

Modèles

A 30” (76 cm) 36” (91,54 cm)

B 23” (58,4 cm)

C 111⁄32” (27,9 cm)

D 1111⁄16” (29,7 cm)

E 219⁄32” (6,6 cm)

F 29” (73,3 cm) 35” (88,9 cm)

C

D

G 71⁄2” (19 cm)

H 29⁄16” (6,5 cm)

B

I

3

⁄8” (1 cm)

Page 15

LISTE DES PIÈCES

Retirer les pièces de leur emballage.

I ATTENTION

Enlever délicatement le carton, porter des gants pour se protéger des bords coupants.

I AVERTISSEMENT

Enlever le film de protection recouvrant le produit avant de commencer l’opération.

Pièces Fournies Quantité Pièces Fournies Quantité

1

Assemblage hotte avec lampes DEL

Outils nécessaires

• Perceuse

• Foret de 11⁄4” (3,0 cm)

• Foret de 1⁄8” (3,0 mm) pour avant-trous

• Crayon

• Pince à dénuder ou couteau utilitaire

• Ruban á mesurer ou règle

• Pistolet à calfeutrage et composé de calfeutrage résistant

aux intempéries

• Tournevis à lame plate

• Tournevis Philips

• Scie sauteuse ou scie à guichet

• Cisaille de ferblantier

5x45 mm

4,5x13 mm

4x8 mm

4

6

4

Pièces non fournies

Module connecteur de conduit

rectangulaire de 31⁄4” x 10” (8,3 x 25,4 cm)

Adaptateur Torx 20

Accessoires optionnel

KIT # Pièce

Couverture

du conduit 6”

Couverture

du conduit 12”

Kit de dosseret

en acier

inoxydable et de

supports chauds

10x50 mm

30” (76 cm) 36” (91,54 cm)

KIT02159 KIT02158

KIT02160 KIT02161

KIT02162 KIT02163

1

1

4

15

Page 16

Méthodes d’évacuation

Suivez à la lettre les directives présentées dans ce manuel.

Le fabricant refuse toute responsabilité en ce qui a trait à tout préjudice, dommage ou incendie causé par la non observation

des directives contenues dans le présent manuel.

Évacuation verticale Évacuation horizontale

Utiliser un conduit et transition rectangulaires de

31⁄4” x 10” (8,3 x 25,4 cm).

C

D

A

B

A

B

A. Transition de 31⁄4” x 10” (8,3 x 25,4 cm)

B. Conduit de 31⁄4” x 10” (8,3 x 25,4 cm)

Préparation

Ne coupez pas une solive ou un montant à moins qu’il soit

absolument nécessaire de le faire. Si vous devez couper une

solive ou un montant, vous devez construire un cadre de soutien.

La quincaillerie fournie permet de fixer la hotte à la plupart des

murs et des plafonds.

Vous devez cependant demander à un technicien qualifié de

vérifier la solidité des matériaux selon le type de mur ou de

plafond.

Avant de couper, assurez-vous qu’il y a un dégagement susant

dans le plafond ou le mur pour passer la conduite de sortie.

C. Placard

D. 90° coude

Utiliser un conduit et transition rectangulaires de

31⁄4” x 10” (8,3 x 25,4 cm).

C

A. Transition de 31⁄4” x 10” (8,3 x 25,4 cm)

B. Conduit de 31⁄4” x 10” (8,3 x 25,4 cm)

C. Placard

B

A

I ATTENTION

Pour l’installation des cuisinieres à gaz: Installer cette hotte de

sorte que le rebord inférieur est à 30” (76,2 cm) au-dessus de la

surface de cuisson.

Pour l’installation des cuisinieres électriques/induction: Installer

cette hotte de sorte que le rebord inférieur est pas moins de

24” (61 cm) sur la surface de cuisson.

Il est recommandé d’installer cette hotte plus de 36” (91,4 cm)

au-dessus de la surface de cuisson. Par pouce (2,54 cm)

supérieure à 36 (91,4 cm) diminuera l’ecacité de la capture

de la fumée et de l’humidité, et la performance de ventilation.

S’IL VOUS PLAÎT LIRE L’INSTALLATION POUR UNE

INSTALLATION SPÉCIFIQUE. Avant de choisir la hotte, vérifiez

la hauteur du plafond et la hauteur maximale de la hotte.

Installation- Version à conduit

Après avoir choisi le type d’évacuation, procéder comme suit:

• Préparer le conduit et les découpes nécessaires.

• Si possible, débranchez la cuisinière et déplacez la afin

d’avoir un meilleur accès au mur arrière. Sinon, placez

une couverture épaisse sur le comptoir et la surface de

cuisson afin de les prot ger des dommages et des saletés.

Sélectionnez une surface plane pour assembler l’appareil.

Placez une couverture protectrice sur cette surface, puis

disposez les pièces de l’auvent de la hotte et la quincaillerie.

• Déterminez et marquez la ligne centrale sur le mur où sera

installé l’auvent de la hotte. Déterminez une hauteur confortable pour l’utilisateur et marquez la sur le mur derrière

la surface de cuisson.

• Préparer le conduit et les découpes nécessaires.

• Enlever les parties prédécoupées pour les conduits en

utilisant un fin tournevis et un petit marteau.

16

• Utiliser le tournevis à la façon d‘un biseau.

• Faire attention aux parties blessants.

A

A. Décharge vertical

B. Décharge horizontal

B

Page 17

• Installer le raccord de transition de la hotte avec 4 vis de

4x8 mm screws.

A

A

A. Transition rectangulaire

REMARQUE:

Le joint/soupape d’évacuation peut être installé jusqu’à 2,5 cm

(1 inch) de part et d’autre du centre de la hotte pour permettre

le décentrage des conduits.

Emplacement des trous

Sélectionner le type d’évacuation choisi pour votre hotte et

procéder:

Évacuation extérieure par l’arrière de la hotte

(Conduit horizontal rectangulaire de 31⁄4”x 10”)

Utiliser le schéma ou la hotte comme patron et indiquer sur

l’armoire l’emplacement des conduits, des fils électriques et les

fentes réglables pour les vis.

39

⁄64” (1,5 cm)

37

⁄64” (34,5 cm)

30”: 13

11

36”: 16

⁄16” (42,4 cm)

6

421⁄64”

(11 cm)

61

⁄64”

2

(7,5 cm)

5

Trou de

montage

permanent

10

MUR

13

⁄16”(17,4 cm)

(14 cm)

⁄8” (27 cm)

LIGNE DU CENTRE

51⁄2”

13

6

⁄16”(17,4 cm)

(14 cm)

10

30”: 13

36”: 16

51⁄2”

5

⁄8” (27 cm)

37

⁄64” (34,5 cm)

11

⁄16” (42,4 cm)

39

⁄64” (1,5 cm)

Trou de

montage

permanent

1 Retirer les filtres à graisse.

2 Retirez les vis du moteur.

Évacuation extérieure par le dessus de la hotte

(Conduit verticale rectangulaire de 31⁄4”x 10”)

Utiliser le schéma ou la hotte comme patron et indiquer sur

l’armoire l’emplacement des conduits, des fils électriques et les

fentes réglables pour les vis.

3

⁄4” (7 cm)

2

fixation de la

Morceaux

61⁄16”

(15,4 cm)

Accés au circuit eléctrique

(á l’arriere du gabinet)

Vis de

hotte (4)

en bois

13

(1 cm)

71⁄2”

(19 cm)

23

2

⁄64”

(6 cm)

Face avant

⁄32”

431⁄64”

(11 cm)

de l’armoire

Fond de

l’armoire

51⁄2”

(14 cm)

(14 cm)

Trou pour le

passege du conduit

LIGNE DU

CENTRE

1

⁄2”

5

Pour armoires encastrées uniquement

Si les armoires ont une garniture à l’avant, sur le côté ou à

l’arrière, réaliser 2 morceaux de bois de la largeur des garnitures

et les attacher à l’armoire encastrée sur les 2 côtés.

Morceaux de bois

A

B

A. Moteur

B. Vis du moteur

3 Libérer les deux clips de moteur de la partie supérieure du

hotte.

4 Tournez la base du moteur à l’arrière de la hotte.

5 Insérez les deux clips de moteur vers la face arrière

de la hotte. Fixer avec les quatre vis du montage avec

précédemment publiée.

17

Page 18

Cabinet Installation

REMARQUE: Votre armoire doit pouvoir supporter au moins 40

kg (88 lb).

Soulever la hotte sous le placard ou el gabinet et déterminer sa

position d’installation finale en la centrant sous le placard. Sur la

face inférieure du placard, marquer l’emplacement des 4 trous

de montage sur la hotte.

6 Installez les 4 - montage mm vis 4 x 8. Laisser un espace d’en-

viron 1⁄4” (6,4 cm) entre les têtes des vis et le placard pour faire

glisser la hotte et la mettre en place.

7 Fixer le conduit de câblage de la hotte.

8 Positionner les trous allongés de la hotte par-dessus la tête

des vis de montage. Puis pousser la hotte vers le mur pour

engager la partie étroite des trous sur les vis de fixation.

Serrer les vis de montage en s’assurant que les vis sont dans

la partie étroite des trous de fixation des vis.

9 Conduisez 2 pièces des vis sélectionnées dans les trous de

sécurité (Voir l’image ci-dessous).

A

Installation de la hotte

1 Soulever la hotte sous le placard ou el gabinet et déterminer

sa position d’installation finale en la centrant sous le placard.

Sur la face inférieure du placard, marquer l’emplacement des

4 trous de montage sur la hotte.

2 Installer les 2 vis de montage dans les avanttrous (voir

l’image). Laisser un espace d’environ 1⁄4” (6,4 cm) entre les

têtes des vis et le placard pour faire glisser la hotte et la

mettre en place.

1

⁄4”

(6,4 mm)

B

A. 4 Vis de montage

B. Vis de sécurité

Installation al mur

Installer la structure de support de la hotte

1 Indiquer les emplacements des trous des vis des la figure

“évacuation arrière extérieur.

2 Si une paroi est présente, Couper susamment de paroi

pour placer 2 crampons sur les trous indiqués. Installer 2

supports horizontaux entre les deux crampons muraux

aux emplacements des trous de montage inférieurs et

supérieurs.

3 Le support horizontal doit être de niveau avec le côté

pièce des crampons. Utiliser des tasseaux de deux côtés

du support pour sécuriser aux crampons du mur.

4 Replacer la paroi et faire les finitions.

IMPORTANT: La paroi doit être capable

de supporter 100 lbs.

Vue arriere

Tasseaux

Support

de

montage

3 Fixer le conduit de câblage de la hotte.

4 Faites glisser le capot arrière contre le mur. Serrer les vis de

montage. Assurez-vous que les têtes de vis sont dans le col

étroit de la fente de trou de serrure.

A

B

B

C

B. Vis supérieurs de sécurité (montage mural)

C. Vis inférieures de sécurité (montage mural)

A. Vis de montage

5 Conduisez 2 morceaux de vis sélectionnés à l’emplacement

des vis de sécurité supérieur (voir l’image ci-dessus).

6 Conduisez 2 morceaux de vis sélectionnés à l’emplacement

des vis de sécurité inférieure (voir l’image ci-dessus).

7 Raccorder le circuit d’évacuation à la hotte.

Ligne du

centre de

l’espace

d’installation

5 Réaliser les trous pour les conduits et les fils électriques

aux emplacements indiqués.

18

Page 19

Connexion Électrique

IAVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE.

IAVERTISSEMENT

DÉCONNECTER LA SOURCE DE COURANT ÉLECTRIQUE

AVANT L’ENTRETIEN. REPLACER PIÈCES ET PANNEAUX

AVANT DE FAIRE LA REMISE EN MARCHE. LE NON-RESPECT

DE CES INSTRUCTIONS PEUT CAUSER UN DÉCÈS OU UN

CHOC ÉLECTRIQUE.

• Remove the knockout and the Junction box cover and

install the conduit connector (cULus listed) in junction box.

Description de la hotte

1

2

3

E

A

B

C

D

F

A. White wires

B. Black wires

C. UL listed wire connector

D. Green (or bare) and yellow-green

ground wire

E. Home power supply cable

F. UL listed or CSA approved ½” strain relief

• Run 3 wires; black, white and green ,according to the

National Electrical Code and local codes and ordinances,

in 1⁄2” conduit from service panel to junction box.

I AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE.

I AVERTISSEMENT

DÉCONNECTER LA SOURCE DE COURANT ÉLECTRIQUE

AVANT L’ENTRETIEN. REPLACER PIÈCES ET PANNEAUX

AVANT DE FAIRE LA REMISE EN MARCHE.

LE NON-RESPECT DE CES INSTRUCTIONS PEUT CAUSER UN

DÉCÈS OU UN CHOC ÉLECTRIQUE.

• À l’aide des connecteurs de fils (homologation UL), connecter le conducteur de liaison à la terre (vert ou nu) du

câble d’alimentation du domicile au conducteur vertjaune

de liaison à la terre (D) dans le boîtier de connexion.

• Installer le couvercle du boîtier de connexion.

• Reconnecter la source de courant électrique.

3

4

1. Commandes du ventilateur et lampes

2. Lampes DEL

3. Poignée du filtre à graisse

4. Filtre à graisse

Commandes

La hotte de cuisinière est conçue pour extraire fumée, vapeurs

de cuisson et odeurs de la zone de la table de cuisson.

Pour obtenir les meilleurs résultats, mettre le ventilateur de la

hotte en marche avant d’entreprendre une cuisson, et laisser

le ventilateur fonctionner pendant plusieurs minutes après

l’achèvement d’une cuisson pour pouvoir évacuer de la cuisine

toute trace d’odeur de cuisson, vapeur ou fumée.

Les commandes de la hotte sont situées sur le côté central de

la hotte.

Cache les boutons

• Vous pouvez masquer les boutons de contrôle en les

poussant vers le bas.

Achever l’installation

Mettez en place le filtre à graisse.

Vérifier le fonctionnement de la hotte.

Si la hotte ne fonctionne pas:

• Vérifiez que le disjoncteur ne s’est pas déclenché ou que le

fusible n’est pas grillé.

• Débranchez l’alimentation. Vérifiez que les raccords électriques

ont été eectués correctement.

Pour utiliser votre nouvelle hotte de façon optimale, lisez la

section intitulée “Entretien”.

Gardez vos instructions d’installations et d’utilisation près de

la hotte pour pouvoir vous y référer facilement.

• Appuyez à nouveau pour acher à nouveau les boutons

de commande et activer les fonctions des lumières et du

ventilateur.

19

Page 20

Commandes

A

A. Commutateur de lampe

B. Commutateur de ventilateur

B

Pour faire fonctionner les lampes

1. Tournez le commutateur d’éclairage sur la position “ON”

pour allumer les lumières.

2. Placer le commutateur d’éclairage à la position “OFF”

(arrêt) pour éteindre les lumières.

Entretien

Nettoyage

Surfaces externes:

Afin d’éviter d’endommager la surface externe, ne pas utiliser

de tampons en laine d’acier ou de tampons à récurer savonneux.

Frotter dans la direction des lignes du grain pour ne pas

détériorer la surface.

Toujours essuyer pour éviter de laisser des marques d’eau.

• Nettoyant et poli pour acier inoxydable.

• Détergent liquide doux et eau.

• Frotter avec un chion doux humide ou une éponge non

abrasive, puis rincer avec de l’eau propre et essuyer.

Filtres métalliques et plateaux d’égouttement:

1 Utiliser les 2 mains pour retirer les filtres.

2 Saisir les poignées du filtre, tirer vers l’avant de la hotte et

tirer sur la poignée arrière pour retirer le filtre. Répéter

pour chaque filtre.

A

A. Filtre à graisse

3 Retirer le plateau d’égouttement à graisse.

Utilisation du ventilateur

1. Tournez le bouton du ventilateur à “1” pour allumer la hotte.

2. Tournez le commutateur du ventilateur à la position de

vitesse désiré.

3. Tournez le commutateur du ventilateur à la position “MAX”

pour mettre la hotte Haut.

4. Tournez le commutateur du ventilateur à la position “OFF”

pour éteindre le ventilateur de la hotte.

Activation automatique du ventilateur

La hotte de cuisine est équipée d’un capteur qui met le

ventilateur automatiquement en marche lorsqu’un niveau

de chaleur excessif est détecté dans la zone de commande.

Lorsque le commutateur du ventilateur est à la position “Off”,

ce capteur met en marche le ventilateur à la vitesse élevée

lorsque c’est nécessaire. Lorsque le niveau de chaleur diminue,

le ventilateur s’éteint. Lorsque l’interrupteur du ventilateur est

à la position “On”, le capteur de chaleur est inactif et la hotte

fonctionne normalement.

A

A. Filtre à graisse

Remplacement de la lampe à DEL

Interrompre l’alimentation de la hotte; attendre le refroidissement

de la lampe à DEL. Pour éviter d’endommager ou de réduire la

longévité de l’ampoule neuve, ne pas toucher l’ampoule avec

les doigts nus. Remplacer l’ampoule en la manipulant avec un

mouchoir de papier ou des gants de coton.

Si les nouvelles lampes ne fonctionnent pas, vérifier que chaque

lampe est correctement insérée dans sa douille avant de

demander l’intervention d’un dépanneur.

1 Déconnecter la source de courant électrique.

2 Pousser la plaque de verre vers le haut et la tourner dans le

sens antihoraire.

3 Retirer l’ampoule et la remplacer par une ampoule DEL de

120 volts, 7,5 watt maximum avec culot GU10. La tourner

dans le sens horaire pour l’emboîter.

4 Répéter les étapes 2 à 3 pour les autres ampoules, si

nécessaire.

5 Reconnecter la source de courant électrique.

A

A. Plateau d’égouttement

4 Laver les filtre métalliques et les plateaux à graisse selon le

besoin au lave-vaisselle ou avec une solution de détergent

chaude.

5 Réinstaller le plateau d’égouttement à graisse.

6 Réinstaller les filtres: saisir les poignées du filtre et placer le

rebord avant du filtre dans la hotte.

7 Pour bien fixer le filtre, pousser vers le haut sur la poigné

arrière et installer l’arrière du filtre dans la plateau

d’égouttement. Répéter pour chaque filtre.

20

Page 21

Enregistrez votre produit sur

elica.com

ELICA North America

GARANTIE DE DEUX ANS

et obtenez une

garantie, qui couvre toutes les

pièces en plus de la main-d'œuvre.

º

3

année de

POUR OBTENIR UN DEPANNAGE SOUS GARANTIE

Le propriétaire doit présenter une preuve de la date d’achat. Garder une copie de votre preuve d’achat datée (ticket de caisse)

de façon à pouvoir bénéficier du service après-vente sous garantie.

GARANTIE PIECES DE RECHANGE ET MAIN D’OEUVRE

Pendant une période de deux (2) ans à partir de la date d’achat, Elica s’engage à fournir gratuitement les pièces de rechange ou

les composants autres que les recharges ayant des défauts de fabrication.

Durant cette garantie de deux (2) ans, Elica fournira également gratuitement, toute la main d’oeuvre et le service à domicile

pour remplacer d’éventuelles pièces défectueuses.

CE QUE LA GARANTIE NE COUVRE PAS

• Dégât ou panne du produit causé par un accident ou un cas de force majeure tels que inondation, incendie ou tremblement

de terre.

• Dégât ou panne du produit causé par modification du produit ou utilisation de pièces pas d’origine.

• Dégât ou panne du produit causé lors de la livraison, de la manipulation ou de l’installation.

• Dégât ou panne du produit causé par une mauvaise utilisation.

• Dégât ou panne du produit causé par un remplacement des fusibles ou une remise en fonction des disjoncteurs par le

propriétaire.

• Dégât ou panne du produit causé par une utilisation du produit pour raison commerciale.

• Déplacement à domicile pour explication d’utilisation ou d’entretien.

• Ampoules, filtres métalliques ou au charbon et toute autre pièce consommable.

• Usure normale.

• Usure due à une mauvaise utilisation du propriétaire, un entretien incorrect, une utilisation de substances nettoyantes

QUI EST COUVERT

Cette garantie s’étend à l’acheteur original de produits achetés pour un usage domestique habituel en Amérique du Nord

(Y compris Etats Unis, Guam, Porto Rico, les Iles virgin Américaines & le Canada).

Cette garantie n’est pas transférable et vaut uniquement pour l’acheteur original et ne s’étend pas aux propriétaires successifs du

produit. Cette garantie vaut expressément en lieu et place de toute autre garantie, expresse ou sous- entendue, mais ne limite pas

toute autre garantie sous-entendue de marchandage ou adaptation dans un but particulier et toute autre obligation de la part de

Elica North America, étant entendu, cependant, que si la réclamation pour garanties sous-entendues n’est pas applicable aux yeux

de la loi en vigueur, la durée de toute garantie sous-entendue émanant de la loi doit être limitée à deux (2) ans à partir de la date

d’achat du produit ou à une période plus longue selon ce que dit la loi en vigueur.

Cette garantie ne couvre pas tout dégât particulier, accidentel et/ou consécutif, ni les pertes et profits, à charge du propriétaire,

des ses clients et/ou des utilisateurs Des produits.

QUI CONTACTER

Pour obtenir un Service Après-vente durant la Garantie ou pour toute autre Question liée au Service Après-vente:

Appeler:

• Service Après-vente autorisé Elica North America au (888) 732-8018

• Pour l’Est du Canada, composez le 1-888 651 2534 Demandez le service après-vente

Page 22

ESPAÑOL

Contenido

Aviso de seguridad importante ................................................................................................................................................................................. 23

Requisitos eléctricos y de instalación ............................................................................................................................................................... 24

Antes de instalar la campana ................................................................................................................................................................................ 24

Dimensiones del producto .......................................................................................................................................................................................... 24

Lista de materiales ......................................................................................................................................................................................................... 25

Piezas suministradas ................................................................................................................................................................................................ 25

Piezas no suministradas .......................................................................................................................................................................................... 25

Métodos de ventilación ................................................................................................................................................................................................ 26

Instalación .......................................................................................................................................................................................................................... 26

Conexión eléctrica ..................................................................................................................................................................................................... 28

Complete la instalación ........................................................................................................................................................................................... 29

Descripción de la campana ......................................................................................................................................................................................... 29

Control ................................................................................................................................................................................................................................ 29

Mantenimiento ................................................................................................................................................................................................................. 30

Garantía .............................................................................................................................................................................................................................. 31

APROBADO PARA APARATOS DE USO DOMÉSTICO

SÓLO PARA USO DOMÉSTICO

LEA Y GUARDE ESTAS INSTRUCCIONES

ANTES DE CONTINUAR, LEA LAS INSTRUCCIONES POR COMPLETO.

LA INSTALACIÓN DEBE CUMPLIR TODA LA NORMATIVA LOCAL.

IMPORTANTE: Guarde estas instrucciones para su uso por parte del inspector de electricidad local.

INSTALADOR: Entregue al propietario estas instrucciones junto con la unidad.

PROPIETARIO: Conserve estas instrucciones para futuras consultas.

Advertencia de seguridad: Antes de realizar el cableado de este aparato, desactive el circuito de energía eléctrica en el panel

de servicio y desbloquee el panel.

Requisito: Circuito auxiliar de 120 V AC, 60 Hz. 15 ó 20 A.

CAMPANA PURIFICADORA

Marca: ELICA

Modelos: ECV630S3, ECV636S3

Contenido: 1 pza

Hecho en México

Fabricado por: ELICAMEX S.A. de C.V.

Dirección: Av. La Noria No. 102 int. S/N Col.

Parque Industrial Querétaro

Del. Santiago de Querétaro, C.P. 76220 Querétaro,

R.F.C. EII060102RK8

22

Page 23

AVISO DE SEGURIDAD IMPORTANTE

I

I PRECAUCIÓN

SÓLO PARA USO DE VENTILACIÓN GENERAL. NO UTILIZAR PARA

EXPULSAR VAPORES O MATERIALES PELIGROSOS O EXPLOSIVOS.

I ADVERTENCIA

PARA REDUCIR EL RIESGO DE FUEGO, DESCARGA ELÉCTRICA O

LESIONES PERSONALES, RESPETE LO SIGUIENTE:

A. Utilice esta unidad solamente en el modo que indica el fabricante. En

caso de duda, póngase en contacto con el fabricante.

B. Antes de reparar o limpiar la unidad, desconecte la alimentación en el

panel de servicio y bloquee los medios de desconexión del panel de

servicio para evitar la conexión accidental de la alimentación. Si no

es posible bloquear los medios de desconexión del panel de servicio,

coloque un dispositivo de advertencia que destaque como, por ejemplo,

una etiqueta, en el panel de servicio.

C. La instalación y el cableado eléctrico deben realizarlos personas cua-

lificadas de acuerdo con las normativas y los estándares aplicables,

incluida la construcción ignífuga.

D. Es necesaria una ventilación suficiente para la correcta combustión

y expulsión de gases por la salida de humos (Chimenea) del equipo

de combustión de carburante para evitar el contratiro. Siga las directrices de fabricantes de equipos de calefacción y los estándares de

seguridad como los publicados por la National Fire Protection

Association (NFPA), American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE) y las normativas locales.

E. Al efectuar orificios en una pared o techo, no dañe el cableado

eléctrico y otras instalaciones ocultas.

F. Los sistemas instalados mediante conducto deben tener ventilación

con salida al exterior.

I PRECAUCIÓN

Para reducir el riesgo de fuego y conseguir una salida del aire correcta,

asegúrese de conducir el aire hacia el exterior.

No permita que el aire se expulse en espacios situados en el interior

de muros, techos, desvanes, sótanos de pequeña altura o garajes.

I ADVERTENCIA

PARA REDUCIR EL RIESGO DE FUEGO, UTILICE SOLAMENTE TUBOS

METÁLICOS.

Instale esta campana de acuerdo con los requisitos especificados.

I ADVERTENCIA

Para reducir el riesgo de fuego o descarga eléctrica, no utilice esta

campana con ningún dispositivo externo en estado sólido para el control de la velocidad.

I ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO OCASIONADO POR GRASA:

a) No deje nunca ninguna unidad externa desatendida y con valores de

fuego altos. La cocción puede causar humo o reboses de grasa que

pueden prender fuego. Caliente el aceite a fuego lento o medio.

b) Encienda siempre la campana cuando cocine a una temperatura alta

o cuando realice flameados (por ejemplo, Crepas Suzette, cerezas

flameadas, ternera a la pimienta flameada).

c) Limpie con frecuencia los ventiladores. No permita que la grasa se

acumule en el ventilador o filtro.

d) Utilice un tamaño de sartén adecuado. Utilice siempre piezas de

batería de cocina adecuadas al tamaño.

I ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES PERSONALES, EN CASO DE

FUEGO OCASIONADO POR GRASA, TENGA EN

CUENTA LO SIGUIENTE:

a) EXTINGA LAS LLAMAS con una tapa ajustada, una lámina para

hacer galletas u otro tipo de bandeja metálica y apague el quemador de gas o elemento eléctrico. TENGA CUIDADO PARA EVITAR

QUEMADURAS. Si las llamas no se extinguen inmediatamente,

DESALOJE EL LUGAR Y LLAME A LOS BOMBEROS.

b) NUNCA TOME UNA SARTÉN EN LLAMAS, podría sufrir quemaduras.

c) NO UTILICE AGUA, incluidas bayetas o toallas húmedas ya que se

produciría una violenta explosión de vapor.

d) Utilice un extintor SÓLO si:

1) Sabe que dispone de un extintor de la clase ABC y conoce su

funcionamiento.

2) El fuego es pequeño y se encuentra en la misma zona donde

se inició.

3) Ha llamado a los bomberos.

4) Puede luchar contra el fuego teniendo una salida a su espalda.

a

Basado en “Consejos de seguridad para fuegos se cocina” publicado por NFPA.

FUNCIONAMIENTO

Coloque siempre las rejillas y los filtros de seguridad en su lugar correspondiente. Sin estos componentes, los ventiladores en funcionamiento

podrían atrapar su pelo, sus dedos o su ropa.

El fabricante declina toda responsabilidad en caso de fallo

de cumplimiento de las instrucciones aquí facilitadas para la instalación, el mantenimiento y el uso adecuado del producto. El fabricante

declina además toda responsabilidad por daños ocasionados por negligencia y la garantía de la unidad queda cancelada automáticamente

como consecuencia de un mantenimiento incorrecto.

I PRECAUCIÓN

Equipo operado automaticamente - para reducir el riesgo de lastimarse desconecte de la linea antes de dar servicio.

• Use esta unidad de la manera para la que fue diseñada por el fabricante. Si tiene preguntas, póngase en contacto con el fabricante.

• Electrodoméstico diseñado exclusivamente para su uso en interiores.

• Antes de dar servicio o limpiar la unidad, apague el suministro de

energía en el panel de servicio y bloquee los medios de desconexión

del servicio para evitar que se encienda accidentalmente el

suministro de energía. Cuando el medio de desconexión del servicio

no se pueda bloquear, sujete de manera segura un dispositivo de

advertencia prominente, como podría ser una etiqueta, al panel de

servicio.

• Limpie la unidad de acuerdo a las instrucciones descritas en este

manual para evitar riesgo de incendio.

• El trabajo de instalación y cableado se debe llevar a cabo por una

persona(s) calificada(s), en conformidad con todos los códigos y

estándares aplicables, incluyendo construcciones clasificadas como

resistentes al fuego.

• En caso de que su cordón de alimentación llegase a sufrir un daño

parcial o total no trate de repararlo acuda al centro de servicio marcado en su garantía o bien con un técnico especialista para su sustitución.

• Es necesario que haya suficiente aire para la adecuada combustión y

ventilación de gases a través del conducto (la chimenea) del equipo

que consume combustible, para evitar que ocurra contratiro. Siga

la guía y los estándares de seguridad del fabricante del equipo de

calefacción.

• Cuando corte o taladre en una pared o techo, no dañe el cableado

ni otros servicios públicos.

• Los ventiladores con conductos siempre deben dar salida al aire

hacia el exterior. N OTA: Sólo para versión Aspirante.

• Para usarse solamente en ventilación común. No lo utilice para

ventilar materiales y vapores peligrosos o explosivos.

• Sólo use conductos metálicos.

RECOMENDACIONES GENERALES

• Nunca deje las unidades de superficie sin vigilancia cuando estén en

ajustes altos. Los derrames por hervor causan salpicaduras

grasosas y humeantes, las cuales pueden encenderse. Caliente los

aceites lentamente y con ajustes bajos o medios.

• Siempre ENCIENDA LA CAMPANA cuando cocine.

• Limpie los filtros anti-grasa con frecuencia (al menos cada 2 meses). No permita que se acumule la grasa en el filtro. Aplica para

filtros de aluminio.

• Se recomienda cambiar los filtros de carbón cada 6 meses.

• No flamear alimentos bajo la campana de cocina.

• Use cacerolas del tamaño adecuado. Siempre use utensilios de

cocción que sean los adecuados para el tamaño del elemento de

la superficie.

• Este aparato no se destina para utilizarse por personas (incluyendo

niños) cuyas capacidades físicas, sensoriales o mentales sean diferentes o estén reducidas o carezcan de experiencia o conocimiento

a menos que dichas personas reciban supervisión o capacitación

del funcionamiento del aparato por una persona responsable de su

seguridad.

• Los niños deben supervisarse para asegurar que ellos no empleen

los aparatos como juguete.

• No use el ventilador de la campana con ningún dispositivo semiconductor para el control de la velocidad.

23

Page 24

REQUISITOS ELÉCTRICOS Y DE INSTALACIÓN

IMPORTANTE