Page 1

EN Instruction on mounting and use

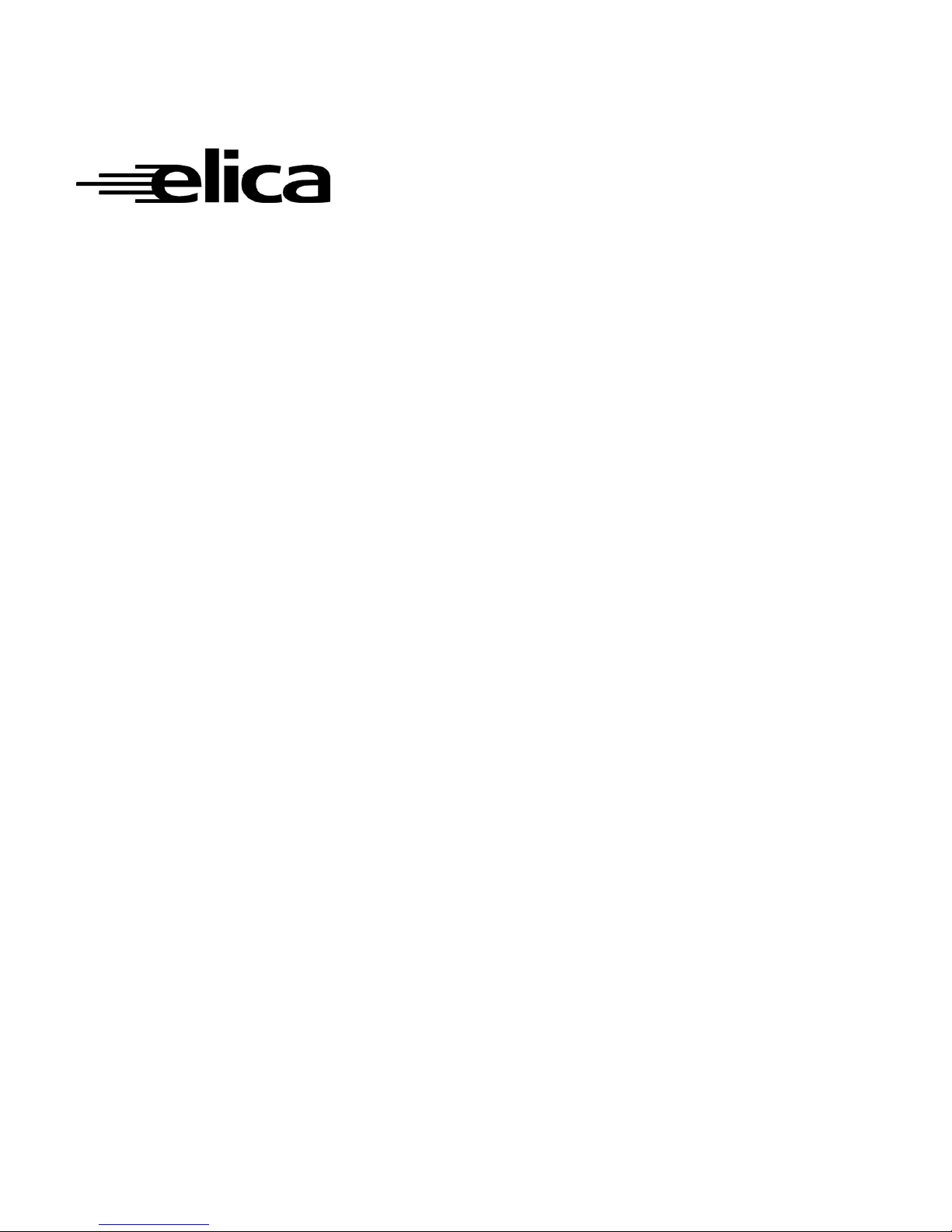

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

EN - Instruction on mounting and use

Closely follow the instructions set out in this manual. All

responsibility, for any eventual inconveniences, damages or

fires caused by not complying with the instructions in this

manual, is declined.

The hood can look different to that illustrated in the

drawings in this booklet. The instructions for use,

maintenance and installation, however, remain the same.

! It is important to conserve this booklet for consultation at

any moment. In the case of sale, cession or move, make

sure it is together with the product.

! Read the instructions carefully: there is important

information about installation, use and safety.

! Do not carry out electrical or mechanical variations on the

product or on the discharge conduits.

Note: the elements marked with the symbol “(*)” are optional

accessories supplied only with some models or elements to

purchase, not supplied.

Caution

WARNING! Do not connect the appliance to the mains until

the installation is fully complete.

Before any cleaning or maintenance operation, disconnect

hood from the mains by removing the plug or disconnecting

the mains electrical supply.

Always wear work gloves for all installation and maintenance

operations.

The appliance is not intended for use by children or persons

with impaired physical, sensorial or mental faculties, or if

lacking in experience or knowledge, unless they are under

supervision or have been trained in the use of the appliance

by a person responsible for their safety.

This appliance is designed to be operated by adults, children

should be monitored to ensure that they do not play with the

appliance.

This appliance is designed to be operated by adults. Children

should not be allowed to tamper with the controls or play with

the appliance.

Never use the hood without effectively mounted grating!

The hood must NEVER be used as a support surface unless

specifically indicated.

The premises where the appliance is installed must be

sufficiently ventilated, when the kitchen hood is used together

with other gas combustion devices or other fuels.

The ducting system for this appliance must not be connected

to any existing ventilation system which is being used for any

other purpose such as discharging exhaust fumes from

appliances burning gas or other fuels.

The flaming of foods beneath the hood itself is severely

prohibited.

The use of exposed flames is detrimental to the filters and

may cause a fire risk, and must therefore be avoided in all

circumstances.

Any frying must be done with care in order to make sure that

the oil does not overheat and ignite.

Accessible parts may become hot when used with cooking

appliances.

With regards to the technical and safety measures to be

adopted for fume discharging it is important to closely follow

the regulations provided by the authorised authorities.

The hood must be regularly cleaned on both the inside and

outside (AT LEAST ONCE A MONTH).

This must be completed in accordance with the maintenance

instructions provided in this manual). Failure to follow the

instructions provided in this user guide regarding the cleaning

of the hood and filters will lead to the risk of fires.

Do not use or leave the hood without the lamp correctly

mounted due to the possible risk of electric shocks.

We will not accept any responsibility for any faults, damage or

fires caused to the appliance as a result of the nonobservance of the instructions included in this manual.

When handling the hood do not put hands within the range of

action of the pull-out suction panel (trolley)

The hood is equipped with safety switches which inhibit

operation when the front filter panel is unhooked.

With the intention of constantly improving our products, we

reserve the right to make all the changes in their technical,

functional or design characteristics, deriving from their

evolution. In case of the version with external motor, the

normal operation of the hood requires the use of a suction unit

(external motor) of the same manufacturer.

This appliance is marked according to the European directive

2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE). By ensuring this product is disposed of correctly, you

will help prevent potential negative consequences for the

environment and human health, which could otherwise be

caused by inappropriate waste handling of this product.

The symbol

on the product, or on the documents

accompanying the product, indicates that this appliance may

not be treated as household waste. Instead it should be taken

to the appropriate collection point for the recycling of electrical

and electronic equipment. Disposal must be carried out in

accordance with local environmental regulations for waste

disposal.

Page 8

Use

The hood is designed to be used either for exhausting or filter

version.

Ducting version

In this case the fumes are conveyed outside by means of a

special pipe connected with the connection ring located on top

of the hood.

Attention! The exhausting pipe is not supplied and must be

purchased apart.

Diameter of the exhausting pipe must be equal to that of the

connection ring = 150mm.

In the horizontal runs the exhausting pipe must be slightly

slanted (about 10°) and directed upwards to vent the air easily

from the room to the outside.

Attention! If the hood is supplied with active charcoal filter,

then it must be removed.

Filter version

One active charcoal filter is needed for this and can be

obtained from your usual retailer.

The filter removes the grease and smells from the extracted

air before sending it back into the room through the upper

outlet grid.

Note: The recycled air in the charcoal filter is sent back to the

kitchen through a duct which conveys air on a side of the

cabinet (Fig. 11).

Non-return valve locking

Attention, before connecting the flexible air outlet pipe make

sure that the non-return valves of the suction unit can freely

rotate (Fig. 12).

The models with no suction motor only operate in ducting

mode, and must be connected to an external suction device

(not supplied).

The connecting instructions are supplied with the peripheral

suction unit.

Installation

When installing the product, it is recommended to keep a

minimum distance of 400mm between the worktop and any

components laid on top of the hood.

This is to let the suction panel move upwards (opening) and

downwards (closing) without any obstacles, and to facilitate

access to the hood controls on the panel.

WARNING: Put the metal box containing the electronic

components at a distance not shorter than 65 cm from the gas

hob or 65 cm from the hood suction point.

RECOMMENDATION: We recommend you to install the

metal box containing the electronic components at a distance

of at least 10 cm from the ground and sufficiently from all the

sources of heat (e.g.: side of an oven or hob).

If the instructions for installation for the gas hob specify a

greater distance, this must be adhered to.

Electrical connection

The hood must be connected to the mains supply by qualified

and trained technicians.

The mains power supply must correspond to the rating

indicated on the plate situated inside the hood. If provided with

a plug connect the hood to a socket in compliance with current

regulations and positioned in an accessible area. If it not fitted

with a plug (direct mains connection) or if the plug is not

located in an accessible area apply a double pole switch in

accordance with standards which assures the complete

disconnection of the mains under conditions relating to overcurrent category III, in accordance with installation

instructions.

Warning! Before re-connecting the hood circuit to the mains

supply and checking the efficient function, always check that

the mains cable is correctly assembled.

Warning! Power cable replacement must be undertaken by

the authorised service assistance centre or similar qualified

person.

Page 9

Mounting

Before starting to mount the appliance, make sure that no

component is damaged, otherwise contact the dealer and stop

mounting. In addition, read all the instructions below carefully.

• Use an air outlet pipe no longer than 5 metres.

• Limit the number of curves in the duct since each curve

reduces the suction effectiveness equivalent to 1 linear

metre. (E.g.: if two 90° curves are used, the duct should

be no longer than 3 metres).

• Avoid drastic changes of direction.

• Use a duct with 150mm diameter constant for the whole

length.

• Use a duct made of standard complying material.

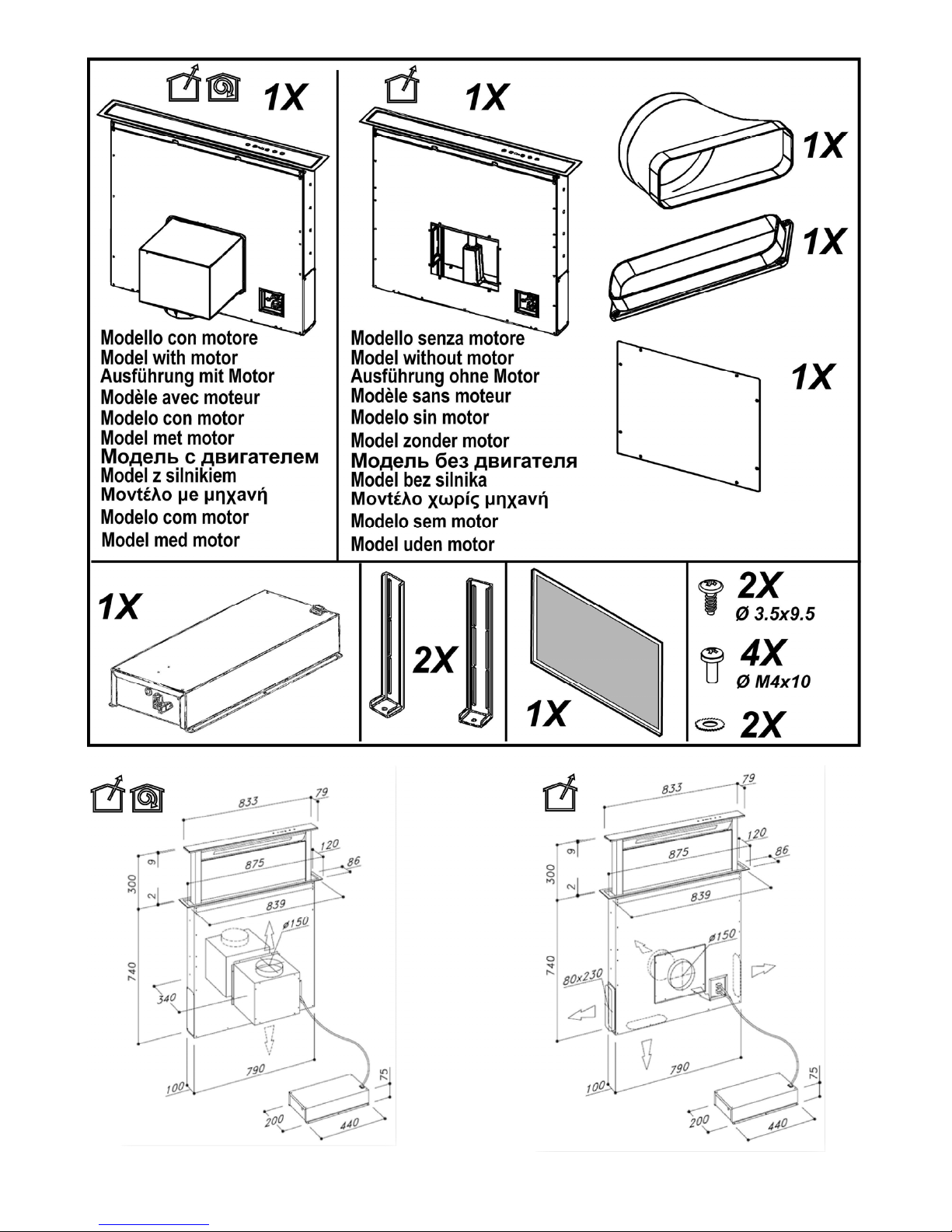

• Remove the safety shim highlighted in the picture (Fig. 1-

2) at the end of the installation.

• In case of failure to observe the instructions above, the

supplier can not be held responsible for capacity or noise

problems and no warranty will be granted.

• Before making the hole, make sure that the inside of the

cabinet, near the hood housing area, does not have the

structure of the cabinet or other particulars which may

cause problems for the proper installation. Make sure

that the overall dimensions of the hood and the hob ae

compatible with the cabinet and therefore the installation

is feasible.

• Make a 848x100mm rectangular hole on the back of the

hob.

• In case of version with motor already mounted, remove

the screws and the suction unit to insert the hood into the

hole made.

• Install the hood in the hole made, inserting it from above,

as shown (Fig. 3). In case of version with motor on

board, it is necessary to remove the suction unit before

inserting the product into the cabinet.

• Fix the hood inside the cainet using the special brackets

supplied (Fig. 4). Start mounting the brackets in the lower

part of the hood (Fig. 5a) making sure that there is a

distance of 2 mm between the lower part of the bracket

and the cabinet bottom (Fig. 5b). This distance allows

the traction of the product downwards on fixing, (Fig. 5c),

so that the stainless steel frame adheres perfectly on the

worktop.

• Before inserting the screws into the cabinet, make sure

that the product is perfectly perpendicular to the worktop.

• After completing the installation and connecting the

product to the power supply, lift the hood and remove the

door lock (Fig. 6).

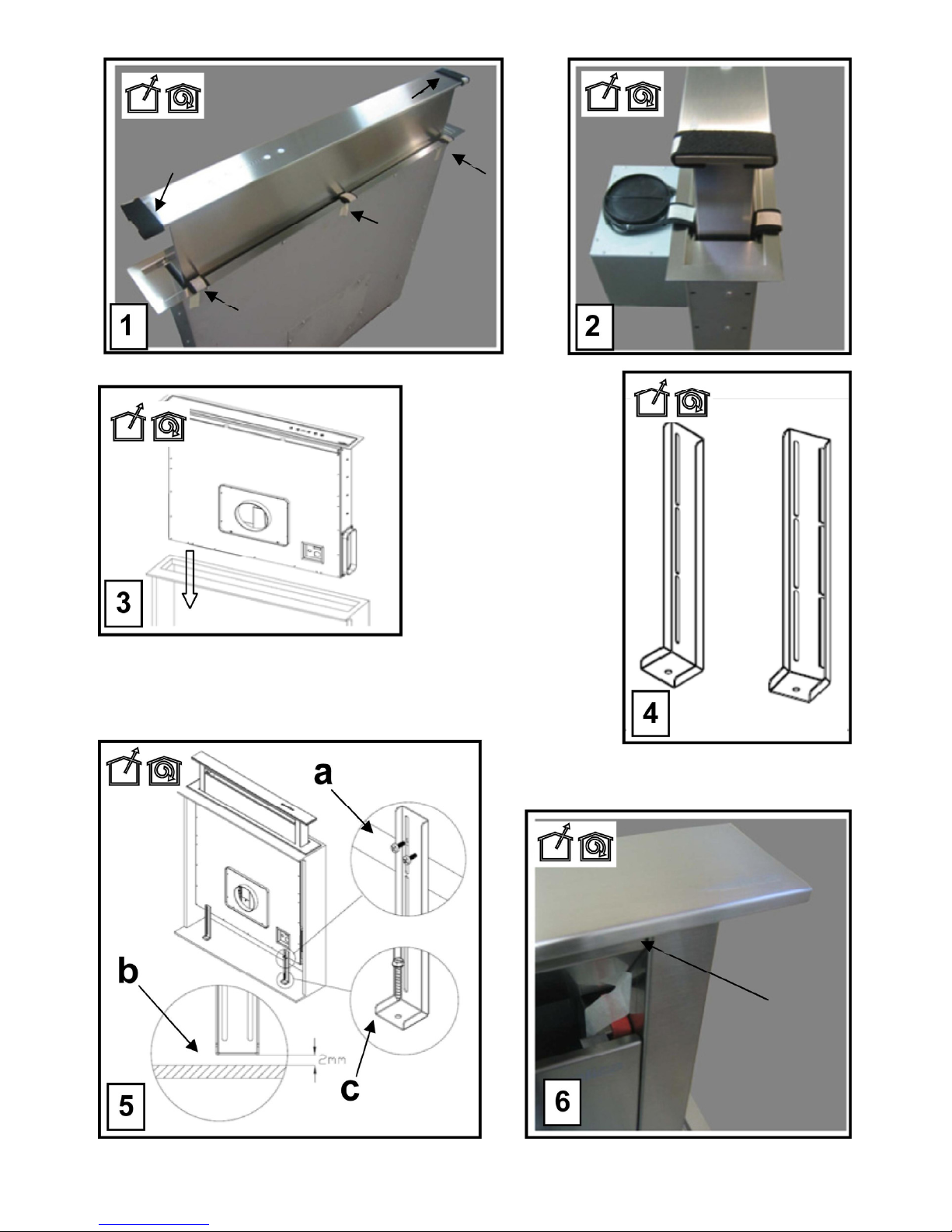

• In case of version with motor on board start mounting the

motor unit directing the air outlet to the chosen position

downwards or upwards (Fig. 7b). The motor can be

installed on both the front side and the back one of the

hood. Once the installationof the motor has been

comleted, start mounting the duct for the air outlet.

• In case of version with external motor put the suction unit

(external motor) in a suitable area and arrange the air

outlet duct. Start mounting the air outlet duct between the

external motor and the hood. Select the air outlet among

the five possibilities (Fig. 7a) and install the union

supplied.

• Put the metal box containing the electronic components

in an easily accessible area for any assistance

operations (Fig. 8), connecting the electric connectors of

the same to the hood: pushbutton panel connector (Fig.

9a), 9-pole connector (Fig. 9b), neon connector (Fig. 9c)

• In applications with external motor, connect the cable of

the motor unit to the special connector on the electronic

component box (Fig. 10a) in case an external control unit

SEM7 is used connect the 2-pole connector as well (Fig.

10b)

• Connect the product to the power supply

Page 10

Operation

Use the high suction speed in cases of concentrated kitchen

vapours. It is recommended that the cooker hood suction is

switched on for 5 minutes prior to cooking and to leave in

operation during cooking and for another 15 minutes

approximately after terminating cooking.

The hood is equipped with a “TOUCH” device to control the

lights and speed.

For the correct use please carefully read the intructions below.

The cooker hood can be controlled through a remote control

available as accessory kit (see the paragraph relating to the

functioning of the remote control).

• Key T1: delays hood switching off timing the speed set

for some minutes.

By such function, when the timing is elapsed, the hood

switches off.

The timing is divided as follows:

• suction speed (power) 1: 20 minutes

• suction speed (power) 2: 15 minutes

• suction speed (power) 3: 10 minutes

• suction speed (power) 4: 5 minutes

When keys T2 and T3 are pressed, the hood leaves the

timed function and the suction speed (power) increases

or decreases according to the key pressed. During the

timing phase the LED related to the corresponding speed

flashes.

• Key T2: Decreases the active suction speed (power)

(4→3→2→1→OFF).

The speed is displayed through the LED related to the

corresponding speed.

Key T2 has no effect on the opening/closure of the

suction panel.

• Key T3: Increases the active suction speed (power)

(1→2→3→4).

The speed is displayed through the LED related to the

corresponding speed.

Note: If the panel is closed (hood is off) key T3 activates

the opening of the suction panel first and then sets the

hood to the suction speed (power) 1.

• Key T4: Switches on the light

Note: If the suction panel is closed (hood is off) key T4

activates the opening of the suction panel first and then

switches on the light.

• Key T5: Opens (Lifts) and closes (lowers) the suction

panel.

With the hood switched off and the panel closed, key T5

opens the suction panel first and then sets the hood to

the suction speed (power) 1.

With the hood switched on (at any speed) and the panel

open, key T5 switches off the hood first (and, if they are

on, it switches off the lights as well) and then closes the

suction panel.

Additional operating information

During the removal of the front panel due to cleaning and

maintenance operations, all the electronic functions of suction

and movement are locked.

Anti-pinch safety: if an obstacle obstructs the closure of the

Downdraft, the closure is stopped and the trolley goes up.

Grease Filter saturation signal.

Every 40 hours of use the hood signals the need for

maintenance of the grease filter.

The signal is by making all the suction speed LEDs (powers)

flash contemporaneously.

Reset of the grease filter signal

After carrying out the maintenance of the grease filter, press

key T1 for more than 3" in order to reset the signal.

Note: The signal is not displayed with hood switched off

(OFF), regardless of the position of the suction panel.

Page 11

Use of the remote control

the remote control can control all the functions of the hood:

Selection of the suction speeds (powers)

Control of the light

Key without functions

Reset and configuration of the filter saturation signal

Selection of the suction speeds (powers):

Press key "◄" or "►" until the following symbol is displayed

on the remote control: ”

Press key “+” or “-” or "■" respectively to increase or reduce or

switch off the suction speed (power).

When the hood is off and the suction panel closed, by

pressing key "■" or “+”, the hood activates the opening of the

suction panel first and then sets the hood to the suction speed

(power) 1.

When the hood is on and the suction panel open press key

"■" once to switch off the hood, press again to close the

suction panel (if it is on, the light is switched off as well).

Light control:

Press key "◄" or "►" until the remote control displays the

symbol

The central light can be switched on and off in two ways:

1. Press key “+” or “-” respectively to switch on (ON) or off

(OFF) the central light.

2. Press key "■" to change the light state from off (OFF) to

on (ON) or viceversa.

Note 1: if the suction panel is closed, the key switching on the

light opens the panel first.

Note 2: With the light switched on, press key "■" once to

switch off the hood, if no suction speed (power) is selected,

the suction panel is closed by pressing again.

Reset and configuration of the filter saturation signal

Switch on the hood at any speed (see paragraph above

“Selection of the suction speeds (powers)”)

Press key "◄" or "►" until the remote control displays the

symbol

Press keys “+” and “-“ contemporaneously for more than 3

seconds, all the suction speed LEDs (powers) stop flashing,

showing that the reset of the signal has been carried out.

Maintenance of the remote control

Cleaning the remote control:

Clean the remote control with a damp cloth and a neutral

solution of detergent without abrasive substances.

Changing the battery:

• Open the battery casing using a small screwdriver with a

flat point.

• Change the finished battery with a new one of 12 V type

MN21/23

In inserting the new battery respect the polarity indicated

on the battery casing!

• Close the battery casing up again.

Disposal of the batteries

Ultimate disposal of the batteries should be handled according

to all national laws and regulations. Do not place used

batteries in your regular waste.

Ultimate disposal of the batteries must be done safely.

Contact your local waste management officials for other

information regarding the environmentally sound collection,

recycling, and disposal of the batteries.

Operation anomalies

The hood does not work

Make sure that:

• There is no current blackout

• A speed has been effectively selected.

• The panel is correctly hooked.

• The 9-pole connection is well inserted (Picture 9b).

• The red reset key above the electric system box is

pressed.

• The wires in the 9-pole connection are well inserted into

the connector. (During connection, exerting an

overpressure may cause the contacts to bend).

The hood has low efficiency

Make sure that:

• The motor speed selected is sufficient for the quantity of

fumes present

• The kitchen is aired enough to allow an air intake and the

charcoal filter is not worn out (filter version hood).

• The air outlet pipe is not clogged.

• The suction unit non-return valves can rotate freely.

The hood stops during operation

Make sure that:

• There is no current blackout

• The differential magnetothermal switch (automatic circuit

breaker) has not been released.

Page 12

Maintenance

Attention! Before any cleaning or maintenance operation,

disconnect the hood from the power supply removing the

plug or switching off the master switch of the house or

pressing the red button in the control box (Fig. 13c).

At the end of the clearing or maintenance operations on

the hood or the filters, put the front panel and the filters

back to their place following the instructions, checking

the correct installation and hooking, otherwise the hood

will not switch on.

Cleaning

The cooker hood should be cleaned regularly (at least with the

same frequency with which you carry out maintenance of the

fat filters) internally and externally. Clean using the cloth

dampened with neutral liquid detergent. Do not use abrasive

products. DO NOT USE ALCOHOL!

WARNING: Failure to carry out the basic cleaning

recommendations of the cooker hood and replacement of the

filters may cause fire risks.

Therefore, we recommend oserving these instructions.

The manufacturer declines all responsibility for any damage to

the motor or any fire damage linked to inappropriate

maintenance or failure to observe the above safety

recommendations.

Grease filter

Traps cooking grease particles.

This must be cleaned once a month (or when the filter

saturation indication system – if envisaged on the model in

possession – indicates this necessity) using non aggressive

detergents, either by hand or in the dishwasher, which must

be set to a low temperature and a short cycle.

When washed in a dishwasher, the grease filter may discolour

slightly, but this does not affect its filtering capacity.

Mounting and dismounting of the grease filters and charcoal

filters must be carried out with the pul-out drawer of the hood

in open position. For this, press key ON/1. Then remove the

front panel pushing at the same time on the upper part of each

side (Fig. 13). The panel rotates forward, letting the grease

filters enter (Fig. 14).

Charcoal filter (filter version only)

It absorbs unpleasant odours caused by cooking.

The saturation of the activated charcoal occurs after more or

less prolonged use, depending on the type of cooking and the

regularity of cleaning of the grease filter.

In any case it is necessary to replace the cartridge at least

every four mounths.

The carbon filter may NOT be washed or regenerated.

After removing the grease filter, it is possible to insert the

charcoal filters (Fig. 15) (not supplied).

Replacing lamps

Disconnect the hood from the electricity.

Warning! Prior to touching the light bulbs ensure they are

cooled down.

To replace the neon proceed as follows:

1. Lift the trolley.

2. Disconnect from power supply. (this operation can be

carried out by disconnecting the plug, if accessible, or

open the switch if envisaged during installation or press

the red button in the control box (Fig. 10c)

3. Remove the screws which fix the upper front as shown in

(Fig. 16)

4. Lift the upper front (Fig. 17)

5. Remove the damaged neon (Fig. 18) and replace it with

one having the same characteristics (Mod.T5 14W 860).

If the lights do not work, make sure that the lamps are fitted

properly into their housings before you call for technical

assistance.

Loading...

Loading...