Page 1

POWER SUPPLY KIT

MODEL XP-15K

Instruction & Assembly Manual

Copyright © 2012, 1991 by ELENCO®All rights reserved. Revised 2012 REV-P 753015

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

ELENCO

®

Page 2

INTRODUCTION

Assembly of your XP-15K Regulated Variable Power Supply Kit will prove to be an exciting project and give much

satisfaction and personal achievement. If you have experience in soldering and wiring technique, you should have no

problem in the assembly of this kit. Care must be given to identifying the proper components and in good soldering habits.

Above all, take your time and follow the easy step-by-step instructions. Remember, “An ounce of prevention is worth a

pound of cure”. Avoid making mistakes and no problems will occur.

USE SAFETY GOGGLES WHEN ASSEMBLING THIS KIT!!

SPECIFICATIONS FOR XP-15K POWER SUPPLY

Output Voltage 0 - 15VDC

Output Current

0.3A @ 12V, 0.2A @ 15V

Load Regulation 0.1V

Line Regulation 0.1V

Ripple Max. 0.01V rms

Short Protection IC THERMO

Output Impedance 0.3Ω

-1-

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore. If you purchased

this kit from a distributor, catalog, etc., please contact ELENCO

®

(address/phone/e-mail is at the back of this manual)

for additional assistance, if needed. DO NOT contact your place of purchase as they will not be able to help you.

RESISTORS

Qty. Symbol Description Color Code Part #

r 1 R2 150Ω 5% 1/4W brown-green-brown-gold 131500

r 2 R1, R4 2.2kΩ 5% 1/4W red-red-red-gold 142200

r 1R3 2kΩ Potentiometer 192421

CAPACITORS

Qty. Symbol Description Part #

r 1C2 4.7μF 50V Electrolytic 264747

r 1 C4 220μF 16V Electrolytic 282244

r 1 C3 470μF 35V Electrolytic 284746

r 1 C1 2,200μF 35V Electrolytic 292226

SEMICONDUCTORS

Qty. Symbol Description Part #

r 8 D1-8 1N4001 Diode 314001

r 1 U1 LM317 Regulator 330317

r 1 D9 LED Red 350002

MISCELLANEOUS

Qty. Description Part #

r 1 Transformer YD-1485 440111

r 1 PC board 510002

r 1 Heat sink 615009

r 1 Knob 622009

r 1 Case top 623061

r 1 Case bottom 623062

r 1 Strain relief 2-wire 624002

r 1 Binding post black 625031

r 2 Nut binding post 625031HN

r 2 Lockwasher binding post 625031LW

r 1 Binding post red 625032

r 4 Screw 2.8 x 8mm 641102

r 1 Screw 4-40 x 1/4” 641430

Qty. Description Part #

r 2 Screw 6-32 x 3/8” Blk 641652

r 1 Nut 7mm 644101

r 1 Nut 4-40 644400

r 2 Nut 6-32 644600

r 1 Washer flat 8 x 14mm 645101

r 4 Washer fiber #6 645602

r 2 Lockwasher #6 646600

r 4 Rubber foot 662015

r 1 Label top 723071

r 1 Line cord 2 wire 862100

r 2” Shrink tubing 890120

r 1 Solder lead-free 9LF99

Page 3

-2-

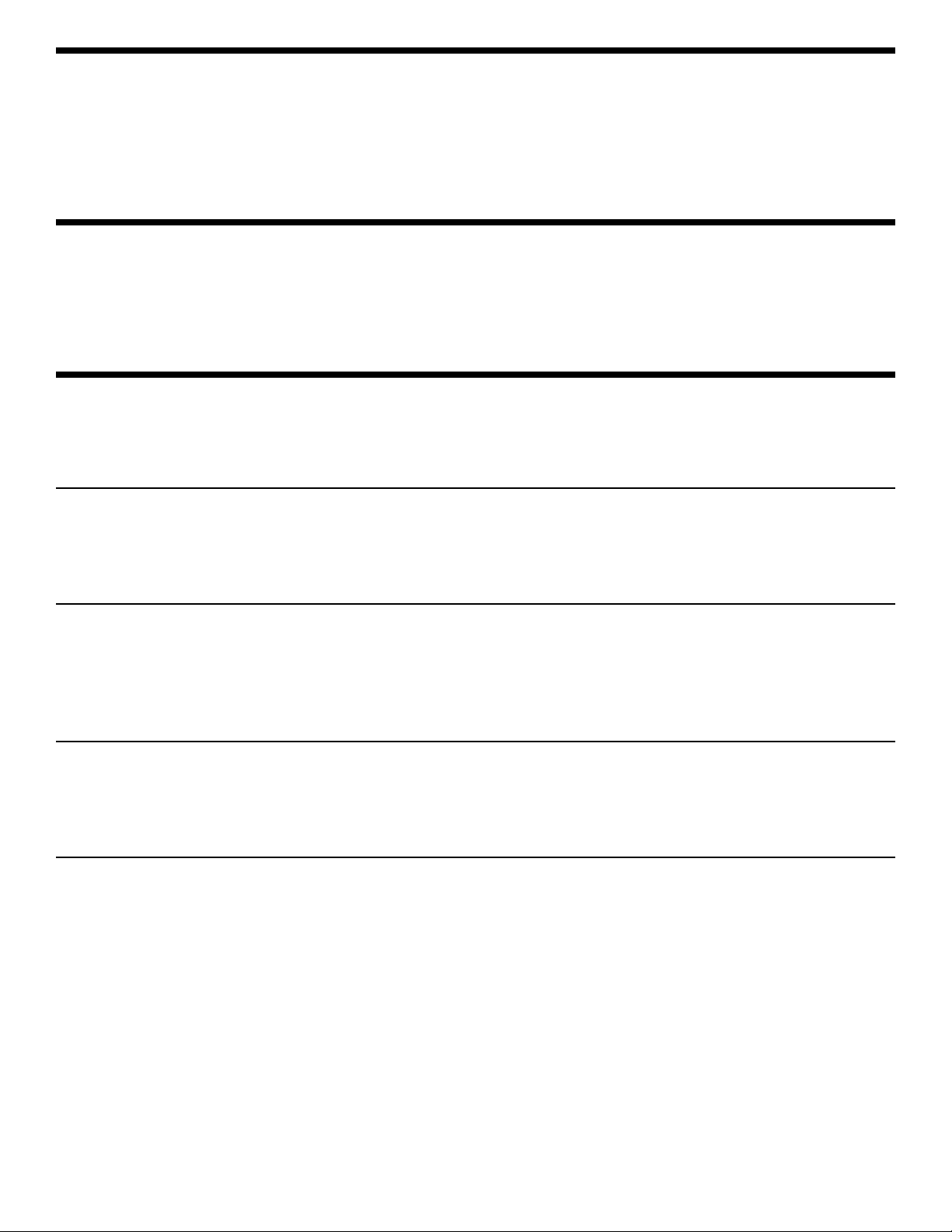

PARTS VERIFICATION

Before beginning the assembly process, familiarize yourself with the components and this instruction book.

Verify that all of the parts are present. This is best done by checking off the parts in the parts list.

RESISTORS CAPACITOR SEMICONDUCTORS

Electrolytic (radial)

Diode

2kΩ Potentiometer

LM317 Regulator LED

Knob

Transformer YD-1485

MISCELLANEOUS

Strain relief 2-wire

Heat sink

Carbon film

PC Board

Case top

Case bottom

Binding posts

Black Red

Binding post nut

Binding post

lockwasher

Screws

2.8 x 8mm

4-40 x 1/4”

6-32 x 3/8”

black

4-40

7mm

Nuts

6-32

Washers

Flat

8 x 14mm

Fiber #6

Lockwasher #6

Rubber foot

Shrink tubing

Label

Lead-free solder

Page 4

-3-

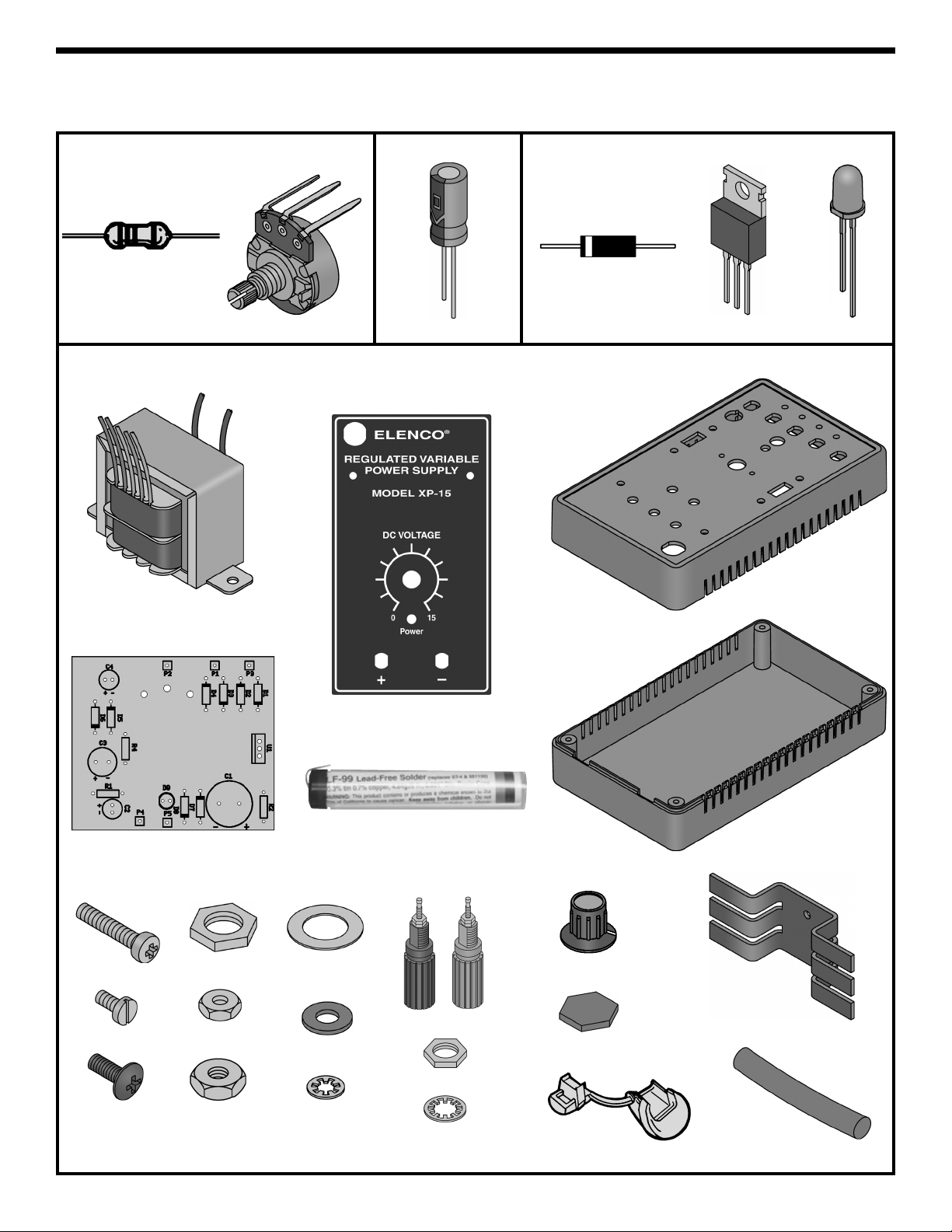

CONSTRUCTION

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to

the iron tip. This allows the heat to

leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the

heated component and the circuit

foil to melt the solder.

1. Insufficient heat - the solder will

not flow onto the lead as shown.

3. Allow the solder to flow around

the connection. Then, remove

the solder and the iron and let the

connection cool. The solder

should have flowed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the connection

until it is covered.

Use just enough solder to cover

the connection.

3. Excessive solder - could make

connections that you did not

intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when

solder runs between circuit paths

and creates a short circuit. This is

usually caused by using too much

solder.

To correct this, simply drag your

soldering iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and uniformly

flowed over all surfaces.

Types of Poor Soldering Connections

Introduction

The most important factor in assembling your XP-15K Regulated

Variable Power Supply Kit is good soldering techniques. Using the

proper soldering iron is of prime importance. A small pencil type

soldering iron of 25 - 40 watts is recommended. The tip of the iron

must be kept clean at all times and well-tinned.

Solder

For many years leaded solder was the most common type of solder

used by the electronics industry, but it is now being replaced by leadfree solder for health reasons. This kit contains lead-free solder, which

contains 99.3% tin, 0.7% copper, and has a rosin-flux core.

Lead-free solder is different from lead solder: It has a higher melting

point than lead solder, so you need higher temperature for the solder to

flow properly. Recommended tip temperature is approximately 700

O

F;

higher temperatures improve solder flow but accelerate tip decay. An

increase in soldering time may be required to achieve good results.

Soldering iron tips wear out faster since lead-free solders are more

corrosive and the higher soldering temperatures accelerate corrosion,

so proper tip care is important. The solder joint finish will look slightly

duller with lead-free solders.

Use these procedures to increase the life of your soldering iron tip when

using lead-free solder:

• Keep the iron tinned at all times.

• Use the correct tip size for best heat transfer. The conical tip is the

most commonly used.

• Turn off iron when not in use or reduce temperature setting when

using a soldering station.

•

Tips should be cleaned frequently to remove oxidation before it becomes

impossible to remove. Use Dry Tip Cleaner (Elenco

®

#SH-1025) or Tip

Cleaner (Elenco®#TTC1). If you use a sponge to clean your tip, then use

distilled water (tap water has impurities that accelerate corrosion).

Safety Procedures

• Always wear safety glasses or safety goggles to

protect your eyes when working with tools or

soldering iron, and during all phases of testing.

• Be sure there is adequate ventilation when soldering.

•

Locate soldering iron in an area where you do not have to go around

it or reach over it. Keep it in a safe area away from the reach of

children.

• Do not hold solder in your mouth. Solder is a toxic substance.

Wash hands thoroughly after handling solder.

Assemble Components

In all of the following assembly steps, the components must be installed

on the top side of the PC board unless otherwise indicated. The top

legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

'

Page 5

MOUNTING THE TRANSFORMER & BINDING POSTS

r Peel the backing off of the label

and place it onto the case top,

while carefully lining up the

holes as shown in Figure A.

The label should fit snug within

the indentation in the case.

r Install the binding posts with

the colors in the order as

shown in Figure B. Insert the

post into the hole and fasten it

with the nut and lockwasher.

Tighten down the nut with

pliers.

r

Install the transformer as shown

in Figure B. Use a 6-32 x 3/8”

screw, #6 lockwasher, 6-32 nut,

and two #6 fiber washers on

each side to fasten in place as

shown.

r Cut the red wires on the

transformer off close to the

transformer.

These wires will be used on

the PC board.

Figure B

#6 Lockwasher

6-32 Nut

6-32 x 3/8”

Screws

#6 Lockwasher

#6 Fiber washer

#6 Fiber washer

Transformer

#6 Fiber washer

#6 Fiber washer

Case top

Binding post

lockwashers

Binding

post nuts

Black binding post

Red binding post

Cut these two

wires (red)

Figure A

-4-

Page 6

Figure F

-5-

D4 - 1N4001 Diode

D3 - 1N4001 Diode

D2 - 1N4001 Diode

D1 - 1N4001 Diode

(see Figure C)

D8 - 1N4001 Diode

D7 - 1N4001 Diode

(see Figure C)

C1 - 2,200μF Electrolytic Cap.

(see Figure D)

R2 - 150Ω 5% 1/4W Res.

(brown-green-brown-gold)

U1 - LM317 Regulator

(see Figure E)

ASSEMBLE COMPONENTS TO THE PC BOARD

Place a check mark in the box provided next to each step to indicate that the step is completed.

C4 - 220μF Electrolytic

(see Figure D)

D5 - 1N4001 Diode

D6 - 1N4001 Diode

(see Figure C)

R4 - 2.2kΩ 5% 1/4W Res.

(red-red-red-gold)

C3 - 470μF Electrolytic

(see Figure D)

R1 - 2.2kΩ 5% 1/4W Res.

(red-red-red-gold)

C2 - 4.7μF Electrolytic

(see Figure D)

P4 - 3” Red wire

P5 - 3” Red wire

Cut two 3” wires from the cutoff red transformer wires and

strip 1/4” of insulation off of

each side.

Figure D

These capacitors are polarized. Be sure

to mount them with the “+” lead in the

correct hole as marked on the PC

board. Also, the negative lead of a radial

electrolytic is shorter than the positive

one.

Warning: If the capacitor is connected

with incorrect polarity it may heat up and

either leak or cause the capacitor to

explode.

Figure C

Diodes have polarity. Be sure to

mount them with the band going

in the same direction as marked

on the PC board.

Band

Polarity

marking

(–) (+)

Figure E

Mount the regulator as shown, with the metal backing in

the same direction as the marking on the PC board. Attach

the heat sink using a 4-40 x ¼” screw and 4-40 nut.

4-40 x ¼”

Screw

4-40 Nut

Heat sink

Metal backing

PC board marking

1/4”

D9 - LED

r Mount the

LED to the

copper side

of the PC

board, spaced 3/8” off the

board, with the flat side in

the same direction as

shown in Figure F.

R3 - 2kΩ Potentiometer

r Mount the potentiometer

to the copper side of the

PC board as shown in

Figure F. Insert the the

pins through the holes so

the body sits flat against

the PC board, then solder

in place.

2kΩ Potentiometer

LED

Flat side

3/8”

Flat side

Copper side of PC board

Long lead (+)

Short lead (–)

(–) (+)

Flat

side

Page 7

-6-

Install the following wires as shown in Figure G.

r Cut the blue and both yellow transformer

wires so that they are 4”. Strip 1/4”

insulation off the ends.

r Solder one of the yellow wires from the

transformer to PC Board P1 and the

other to P3.

r Solder the blue wire from the transformer

to the PC board hole P2.

r Solder the red wire from the P5 to the

end of the the red binding post.

r Solder the red wire from the P4 to the

end of the the black binding post.

r Install the PC Board into case by lining

up the shaft of the pot and the LED with

the holes in the case, and then pressing

PC board into place. Flip the case around

and install the 8 x 14mm flat washer and

7mm nut as shown in Figure H.

r Turn the shaft on the pot fully counter-

clockwise. Push the knob onto the shaft

so that the line on the knob lines up with

the end of the circle on the front panel as

shown in Figure I. If the knob is loose on

the pot shaft, insert a screwdriver in to

the slot and expand the slot slightly. If the

knob has a set screw, tighten the set

screw located on the side of the knob.

WIRING

Figure G

Figure IFigure H

Yellow wires

Red wires

Blue wire

Red binding post

Black binding post

7mm Nut

8 x 14mm

Flat washer

Knob

Line on

knob

Flat head

screwdriver

blade

Pot shaft

Page 8

r Cut the two black wires from the transformer to

1½”. Strip ¼” of insulation off of each wire.

r Feed 2” of line cord into the hole of the chassis.

Place the line cord in the slot of the strain relief and

squeeze the two sections together with pliers.

Then, insert the strain relief into the hole, as

shown in Figure J.

r Separate the two line cord wires. Place 1” of shrink

tubing over each black transformer wire. Twist and

solder the line cord wires to the black transformer

wires as shown in Figure K.

r Slide the shrink tubing up to cover the solder joints.

Shrink the tubing with the heat from your soldering

iron. BE CAREFUL NOT TO TOUCH THE SHRINK

TUBING OR WIRES WITH THE IRON.

LINE CORD ASSEMBLY

Install the following wires as shown in Figure K.

Figure J

Shrink tubing

Twist and solder

wires together

Strain relief

Pliers

Case top in this direction

FINAL ASSEMBLY

r Remove the backing from each rubber foot and

place them in the locations shown in Figure L.

r Assemble the top and bottom case sections and

fasten with four 2.8 x 8mm self-tapping screws as

shown in Figure L. Make sure the slots on the side

line up with one another.

Figure L

2.8 x 8mm Screws

2.8 x 8mm

Screws

Rubber feet

Rubber feet

Slot

Figure K

Soldering

iron

-7-

Bend wires

over as shown

Slide tubing

Page 9

TESTING THE XP-15K POWER SUPPLY

Figure 1

Simplified diagram of positive power supply

120VAC

Input

18VAC 20VDC 0 - 15V

Regulated

Output

Transformer

120V to 18V

AC to DC

Converter

Voltage

Regulator

Figure 2

Voltage Waveform for Supply

A) Transformer

Winding AB

B) Transformer

Winding BC

C) Output of

diode D1.

D) Output of

diode D3.

E) Total of diodes

D1 & D3.

20V

F) Output of capacitor C1

Ripple depends on load

current (expanded).

-8-

Testing the XP-15K Power Supply is very simple.

Before applying power to the unit, be sure that all of

the wiring and soldering is firm. If so, obtain a digital

voltmeter. Apply power to the XP-15K and vary the

voltage control knob.

Next, short the output of the supply. It should turn off

and recover when the short is removed. If you have

a 4.7Ω 1 watt resistor, set the voltage to 1.4 volts

and place is across the output terminals. The output

of the supply should not change more than 0.1 volts.

Set the output voltage to 15 volts and place a 75Ω 5

watt resistor across the output terminals. Again, the

output should not change by more than 0.1 volts. In

making these tests, the voltmeter leads should be

clipped directly to the output terminals and not to

the load leads. This is to prevent errors due to

voltage drop in the load leads.

Should any of these tests fail, refer to the

troubleshooting guide.

CIRCUIT DESCRIPTION

INTRODUCTION

The XP-15K Power Supply features an output

voltage variable from 0 to 15V at 0.3 ampere

maximum current. The voltage is regulated to within

0.1V when going from no load to full load. Varying

the input AC voltage from 110 to 130V will have

practically no effect on the output voltage. This is

because of the specially designed IC circuit used in

the XP-15K. Severe overloading or even short

circuiting the output will not damage the supply.

Special turn-off circuits in the IC sense the overload

and turn off the output.

Figure 1 shows a simplified circuit diagram of the

power supply. It consists of a power transformer, a

DC rectifier stage and the regulator stage.

TRANSFORMER

The transformer T1 serves two purposes. First, it reduces the 120VAC input to

18VAC to allow the proper voltage to enter the rectifier stage. Second, it isolates

the power supply output from the 120VAC line. This prevents the user from

dangerous voltage shock should they be standing in a grounded area.

AC to DC CONVERTER

The AC to DC converter consists of diodes D1 and D3 and capacitor C1.

Transformer T1 has two secondary windings which are 180 degrees out of phase.

The AC output of each winding is shown in Figure 2A and 2B.

Diodes are semiconductor devices that allow current to flow in one direction. The

arrow in Figure 3 points to the direction that the current will flow. Only when the

transformer voltage is positive will current flow through the diodes. Figure 3 shows

the simplest possible rectifier circuit. This circuit is known as a half wave rectifier.

Here, the diode conducts only half the time when the AC wave is positive as shown

in Figure 2C. Use of this circuit is simple but inefficient. The big gap between cycles

requires much more filtering to obtain a smooth DC voltage.

By the addition of a second diode and transformer winding, we can fill in the gap

between cycles as shown in Figure 4. This circuit is called full wave rectification.

Page 10

-9-

The regulator circuit in the Model XP-15K Power

Supply consists of a LM317 integrated circuit. This

IC is specially designed to perform the regulation

function. Figure 6 shows a simplified circuit of how

the LM317 IC works.

Transistors Q1 and Q2 form a circuit known as a

differential amplifier. Transistor Q1’s base is

connected to a stable 1.5V reference voltage. The

base of Q2 is connected to the regulator output

circuit through a voltage divider network. The

collector of transistor Q2 is connected to a current

source. This basically is a PNP transistor biased to

draw about 1mA current. Transistor Q2 sees the

current source as a very high resistor of about 1

meg ohms. Thus, the gain of transistor Q2 is very

high.

Transistor Q5 is called the pass transistor. It controls

the current reaching the output. Transistors Q3 and

Q4 are emitter followers. Their function is to raise

the impedance of the pass transistor. Note that

transistor Q2, Q3, Q4, Q5 and resistor R1 form a

closed loop. Also, note that the feedback to the base

of Q2 is negative, that is, the output at emitter Q5

goes negative. Now, if the 1.25V output voltage

goes down because of current drain at the output,

the base of Q2 will drop, forcing the collector voltage

of Q2 to go higher. This will bring the output voltage

back to 1.25V. This is the basis of all negative

feedback regulators.

Another feature of the LM317 regulator is to protect

the IC against overload and output shorts. If the IC

is overloaded, the junction will overheat. A transistor

will sense this overheating and shut down transistor

Q5.

The LM317 IC is basically a 1.25V regulator. To be

able to vary the output 0 - 15V, we stack the IC on

the negative 1.25VDC voltage as shown in Figure 7.

When R3 equals 0, the output voltage is 0 volts.

REGULATOR CIRCUIT

Each diode conducts when the voltage is positive.

By adding the two outputs, the voltage presented to

capacitor C1 is more complete, thus, easier to filter,

as shown in Figure 2F. When used in 60 cycles AC

input power, the output of a full wave rectifier will be

120 cycles.

Capacitor C1 is used to store the current charges,

thus smoothing the DC voltage. The larger the

capacitor, the more current is stored. In this design,

a 2,200μF capacitor is used, which allows about 2

volts of AC ripple when one half amp is drawn.

In practice, the current through the diodes is not as

shown in Figure 2E. Because capacitor C1 has a

charge after the first cycle, the diode will not

conduct until the positive AC voltage exceeds the

positive voltage in the capacitor. Figure 5 shows a

better picture of what the current flow looks like,

assuming no loss in the diode.

It takes a few cycles for the voltage to build up on

the capacitor. This depends on the resistance of the

winding and diode. After the initial start-up, there will

be a charge and discharge on the capacitor

depending on the current drawn

by the output load. Remember,

current only flows through the

diode when the anode is more

positive than the cathode. Thus,

current will flow in short bursts

as shown in Figure 5C.

The DC load current may be

one ampere, but the peak diode

current may be three times that.

Therefore, the diode rating must

be sufficient to handle the peak

current. The 1N4001 has a peak

current rating of 10 amps.

Figure 5

A) Transformer

Winding

B) Voltage C1

C) Current

through diodes

20V

Peak

20V

Figure 4

Full Wave Rectifier

Figure 3

Half Wave Rectifier

Figure 6

1.25V

Output

R1

R2

Divider

Q1

Q2

1.5V

Q3

Q4

Q5

Current

Source

Equalized

to 1 Meg.

C1

D1

D1

D3

C1

0V - 15V

R2

R3

LM-317

–DC

Figure 7

Page 11

-10-

1.

AC voltage is supplied to the rectifier stages by the . . .

r A. step up transformer.

r B. step down transformer.

r C. 1 to 1 transformer.

r D. AC to DC transformer.

2. The secondary windings of the transformer are . . .

r A. 90

O

out of phase.

r B. 180Oout of phase.

r C. 270Oout of phase.

r D. 320Oout of phase.

3. Diodes allow current to flow . . .

r A. when the anode is more negative than the

cathode.

r B. when the cathode is more positive than the

anode.

r C. in one direction.

r D. when a negative or positive voltage is on the

anode.

4.

What circuit is more efficient for rectifying AC to DC?

r A. Hartley oscillator.

r B. Half wave.

r C. Schmitt trigger.

r D. Full wave.

5. The DC voltage is smoothed by using a . . .

r A. half-wave rectification circuit.

r B. small value capacitor with a high voltage value.

r C. Large value capacitor.

r D. 90Oout of phase rectification circuit.

6. An inefficient rectification circuit usually contains . . .

r A. large gaps between cycles.

r B. twice the AC voltage needed.

r C. more diodes.

r D. all of the above.

7. The maximum current that a diode can handle is

determined by . . .

r A. the transformer’s current rating.

r B. the amount of AC ripple.

r C. three times the diode rating.

r D. peak current rating.

8. The LM317 will shut down when . . .

r A. the output voltage is too high.

r B. no current is being drawn.

r C. the junction overheats.

r D. the output voltage drops to 1.25V.

9. The LM317 regulator contains . . .

r A. a pass transistor.

r B. a constant current source.

r C. a differential amplifier.

r D. all of the above.

10. The LM317 is . . .

r A. a positive voltage regulator.

r B. a 6.25V regulator.

r C. a 2.5V regulator.

r D. a negative voltage regulator.

LED Not Lit

1) Check transformer and line cord.

2) Check for 20VDC at the cathode of D1.

3) LED in backwards or defective.

No Output Voltage

1) Check AC voltage across points P1 & P2 or

P2 & P3. It should read about 18VAC.

2) Measure voltage at the output of D1 and D3.

It should read about 20VDC. If not, then

check D1, D3, C1, U1, R2, R3, D7, and D8.

Poor Regulation

1) Check AC ripple at the input of the regulator.

It should be less than 2.5V.

2) If ripple is higher, check diodes D1, D3, and

the filter of capacitor C1.

QUIZ

TROUBLESHOOTING GUIDE

Consult your instructor or contact ELENCO®if you have any problems. DO NOT contact your place of purchase

as they will not be able to help you.

Copper Side of PC Board

Page 12

ELENCO

®

150 Carpenter Avenue • Wheeling, IL 60090

(847) 541-3800 • Website: www.elenco.com • e-mail: elenco@elenco.com

SCHEMATIC DIAGRAM

Answers: 1. B, 2. B, 3. C, 4. D, 5. C,

6. D, 7. D, 8. C, 9. D, 10. A

REV-A

Loading...

Loading...