Page 1

DISTAR

t

ELENBERG 2910F, CAMERON STV-2937

SERVICE MANUAL

1. Caution……………………………………………………………2

2. Specification………………………………………………………6

3. BOM List ……………………… …………………………………9

4. Alignment Procedure………………………………………….…35

5. Block Diagram……………………………………………………39

6. Schematic Diagram………………………………………………40

7. PCB Layout………….……………………………………………41

8. Explode View Diagram……………………………………………43

DT-2977

This manual is the latest at the time of printing, and does no

include the modification which may be made after the printing, by

the constant improvement of product.

Page 2

CAUTION:

Use of controls, adjustments or procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION: T O REDUCE THE RISK OF

CAUTION

RISK RISK OF OF ELECTRIELECTRICC

SHOCK SHOCK DO DO NOT NOT OPEN.OPEN.

The lighting flash with arrowhead symbol, with an equilateral triangle is intended to

alert the user to the presence of uninsulated voltage within the products

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

the person.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

ELECTRICAL SHOCK, DO NOT REMOVE

COVER (OR BACK). NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

dangerous

WARNING: TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

CAUTION:

Read all of these instructions. Save these instructions for later use . Follow all Warnings and

Instructions marked on the audio equipment.

1. Read Instructions- All the safety and operating instructions should be read before the product is operated.

2. Retain Instructions- The safety and operating instructions should be retained for future reference.

3. Heed Warnings- All warnings on the product and in the operating instructions should be adhered to.

4. Follow Instructions- All operating and use instructions should be followed.

FOR YOUR PERSONAL SAFETY

1. When the power cord or plug is damaged or frayed, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

2. Do not overload wall outlets and extension cords as this can result in fire or electric shock.

3. Do not allow anything to rest on or roll over the power cord, and do not place the TV where power cord is subject to

traffic or abuse. This may result in a shock or fire hazard.

4. Do not attempt to service this television set yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

5. Never push objects of any kind into this television set through cabinet slots as they may touch dangerous voltage

points or shor t out parts that could result in a fire or electric shock. Never spill liquid of any kind on the television set.

6. If the television set has been dropped or the cabinet has been damaged, unplug this television set from the wall outlet

and refer servicing to qualified service personnel.

7. If liquid has been spilled into the television set, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

8. Do not subject your television set to impact of any kind. Be particularly careful not to damage the picture tube surface.

9. Unplug this television set from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

10.1. Do not place this television set on an unstable cart, stand, or table. The television set may fall, causing serious injury

to a child or an adult, and serious damage to the appliance. Use only with a cart or stand recommended by the

manufacturer, or sold with the television set. Wall or shelf mounting should follow the manufacturer s instructions, and

should use a mounting kit approved by the manufacturer.

10.2. An appliance and car t combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

3

Page 4

PROTECTION AND LOCATION OF YOUR SET

11. Do not use this television set near water ... for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a

wet basement, or near a swimming pool, etc.

Never expose the set to rain or water. If the set has been exposed to rain or water, unplug the set from the wall

outlet and refer servicing to qualified service personnel.

12. Choose a place where light (artificial or sunlight) does not shine directly on the screen.

13. Avoid dusty places, since piling up of dust inside TV chassis may cause failure of the set when high humidity persists.

14. The set has slots, or openings in the cabinet for ventilation purposes, to provide reliable operation of the receiver, to

protect it from overheating. These openings must not be blocked or covered.

Never cover the slots or openings with cloth or other material.

Never block the bottom ventilation slots of the set by placing it on a bed, sofa, rug, etc.

Never place the set near or over a radiator or heat register.

Never place the set in enclosure, unless proper ventilation is provided.

a built-in

PROTECTION AND LOCATION OF YOUR SET

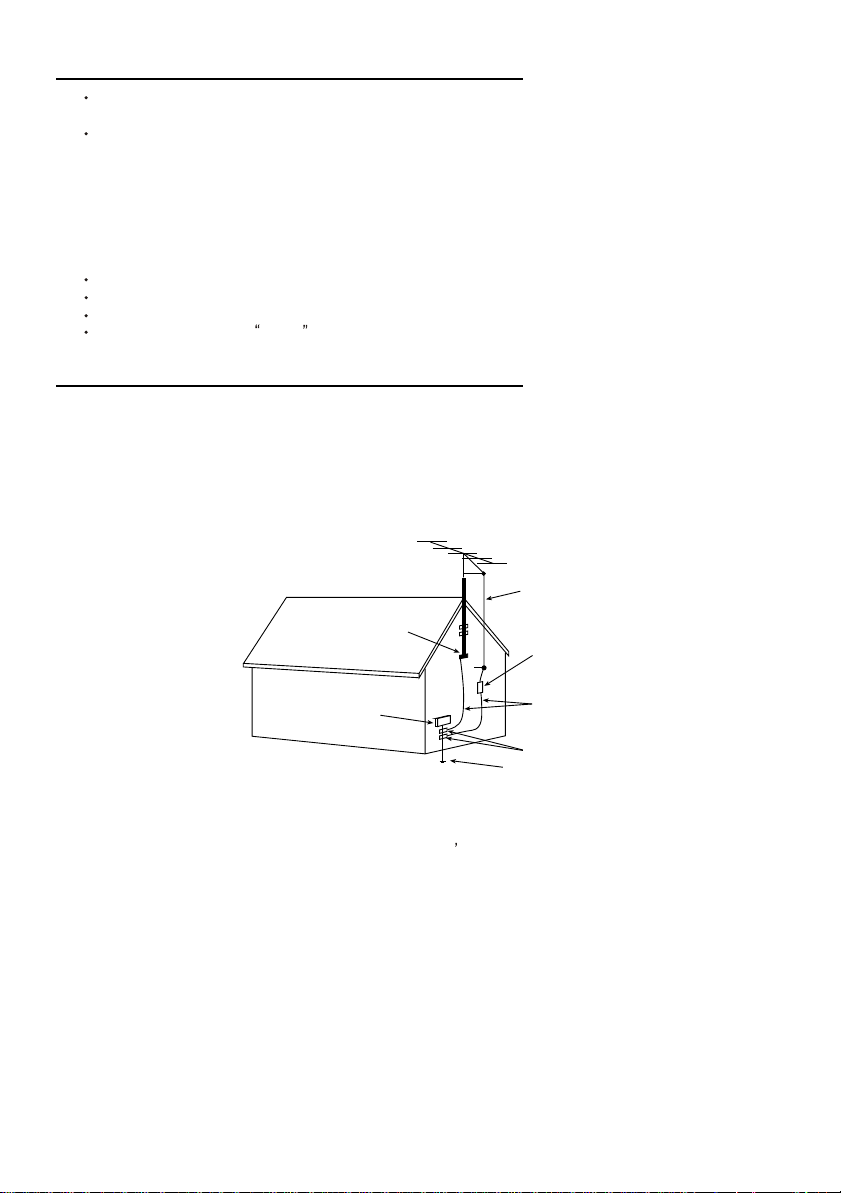

15.1. If an outside antenna is connected to the television set, be sure the antenna system is grounded so as to provide some

protection against voltage surges and built up static charges, Section 810 of the National Electrical Code, NFPA No.

70-1975, provides information with respect to proper grounding of the mast and supporting structure, grounding of the

lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection

to grounding electrode, and requirements for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER NATIONAL ELECTRICAL CODE INSTRUCTIONS

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONALELECTRICAL CODE

ANTENNA

LEAD- INWIRE

GROUND CLAMP

ELECTRIC SERVICE

EQUIPMENT

NEC-NATIONALELECTRICAL CODE

ANTENNA DISCHARGE

UNIT (NEC SECTION

810-20)

GROUNDING

CONDUCTORS

(NECSECTION 810-21)

GROUND CLAMPS

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250. PARTH)

15.2. Note to CATV system installer : (Only for the television set with CATV reception)

This reminder is provided to call the CATV system attention to Article 820-40 of the NEC that pro vides

installer s

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entry as practical.

16. An outside antenna system should not be located in the vicinity of overhead power lines or other electric lights or power

circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power lines or circuits as contact with them might be fatal.

17. For added protection for this television set during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect the antenna. This will prevent damage due to lightning

and power-line surges.

4

Page 5

OPERATION OF YOUR SET

18.

This television set should be operated only from the type of power source indicated on the marking label. If you are not

sure of the type of power supply at your home, consult your television dealer or local power company. For television

sets designed to operate from batter y power, refer to the operating instructions.

19. If the television set does not operate normally by following the operating instructions, unplug this television set from the

wall outlet and refer servicing to qualified service personnel. Adjust only those controls that are covered in the operating

instructions as improper adjustment of other controls may result in damage and will often require extensive work by a

qualified technician to restore the television set to normal operation.

20. When going on a holiday : If your television set is to remain unused for a period of time, for instance, when you go on

a holiday, turn the television set and unplug the television set from the wall outlet.

off

IF THE SET DOES NOT OPERATE PROPERLY

21. If you are unable to restore normal operation by following the detailed procedure in your operating instructions,

do not attempt any further adjustment. Unplug the set and call your dealer or service technician.

22. Whenever the television set is damaged or fails, or a distinct change in performance indicates a need for

service, unplug the set and have it checked by a professional service technician.

23. It is normal for some TV sets to make occasional snapping or popping sounds, particular ly when being

turned on or off. If the snapping or popping is continuous or frequent, unplug the set and consult your

dealer or service technician.

FOR SERVICE AND MODIFICATION

24. Do not use attachments not recommended by the television set manufacturer as they may cause hazards.

25. When replacement parts are required, be sure the service technician has used replacement parts specified

by the manufacturer that have the same characteristics as the original part. Unauthorized substitutions

may result in fire, electric shock, or other hazards.

26. Upon completion of any service or repairs to the television set, ask the ser vice technician to perform

routine safety checks to determine that the television is in safe operating condition.

5

Page 6

PFS2 FORMAT-1 Report

p

p

g

g

gy

g

q

y

r

y

y

g

g

play

ype

(

y

y)

y)

g

g (

)

p

p

p

p

guag

p

Date:2004-7-6 17:19

ProductView......:

Re

ort by............:

Specs / Products

MasterData

Customer Id

Version

Status

Brand

EAN

UPC

tion

Rece

+Tunin

+Tunin

+Tunin

+Fre

+Channels

+IF Freq

+TV S

+Add Systems Ext In

+TV S

+Sound S

Picture - Processin

+Scan

+Scan Modes

+Wide Screen Switchin

+Combfilter

+Picture Control

+Pict Enhancement

+Pict Noise Reduction

Picture - Dis

+Display T

+Screen Format

+Size

+Deflection S

+Tube Technology (CRT onl

+CRT Defl

+CRT Gun

+CRT Ma

+Resolution

+Coatin

+White Point

Sound

+RMS Power Intern

+RMS Power Extern

+Surround Sound

+Sound Features

+Sound Control

Sound - S

+S

+S

+S

User Interface

+Interface Name

+Voice Control

+Menu

+Menu Colours

+Menu Lan

+Special Features

+O

+PP Features

+Tuning/Install Features

+Clock/Timer Functions

- presets/channels

- technolo

- Indication

Bands

stems Off Ai

stems Multi

stems

Visual)" - size/vis. cm

stem (CRT onl

n field

only for D.V. sets

eakers

eaker configuration

eakers used

eaker Size

es

erational Features

Product:

DT-2977

Distar

0.1

New

\

\

100

PLL

FS TUNER

CATV 470MHz

PICTURE 38.

NTSC 3.58, NTSC 4.43, NTSC Play

Back, PAL 60 IN AV mode

AV Stereo

Brightness, Colour, Contrast, Color

Temperature, Hue, Sharpness Cont

Var, Smart Pict. 4 Modes

Three kinds Color

Temperatures:Normal, Cool, Warm

Black Stretch

DV - CRT - RF

4:3

25"

Black Matrix, Iron

Stand Gun

Mute

Volume, super woofer

L01- Full Interface

Cursor Control

Program preengage/soft start/

Calendar/ Notebook

/Favorite channel/ Build-in Game /

Hotel Lock / Surround System/

Channel Edit List

Alternate Channel

Auto Store, Factory Mode, Fine

Tuning, Manual Search/Store,

Manual Sort, Service Mode

Clock, On/off timer, Sleep timer

9 MHz

PAL B/G

PAL

Standard

4;3

2

Normal

Thai

2004-7-6 17:33 29228PFS 1 of 3

Page 7

Date:2004-7-6 17:19

p

p

(

)

(

)

(

)

r

p

(

)

)

)

)

)

(

)

)

(

)

y

g

p

t

)

(

)

)

(

)

(

)

)

p

)

p

p

y

g

g

p

p

y

g

y

g

q

y

yp

p

ProductView......:

Re

ort by............:

Specs / Products

+Local Controls Front

+Local Controls To

+Indicators - screen

+Indicators - front

+Numb of Loc Cont

+Number of Ind.

+Local Controls

Remote Control

Connectors Rea

+Scart RGB+Y/C+CVBS

+Scart RGB+CVBS

+Scart CVBS+Y/C

+Com

+In Y/C+Cinch

+In Y/C+Cinch(CVBS+Mo

+In Y/C+Cinch(St

+In BNC (CVBS

+In Cinch(CVBS+St

+In Cinch

+Out Cinch(CVBS+St

+Out Cinch

+Out Cinch Audio Stereo

+Out Cinch Audio Mono

+Out Cinch Dolb

+Out Cinch Subwoofer

+Di

+Louds

+Control Busses

+Feature Slot

+ITV Smart Port

+Terr. Antenna in

Guide + IR Blaster Jack

Connectors Fron

+In Y/C + Cinch(CVBS+St + Mo

+In Y/C + Cinch Stereo

+In Cinch

+In Cinch (CVBS+Mo +St

+Headphone Out

+Feature Slot

Connectors Side

+In Y/C + Cinch

+In Y/C + Cinch Stereo

+In Cinch

+IN Cinch (CVBS + Mo

+Headphone Out

Connectors To

+In Cinch (CVBS + St

+Headphone Out

Connectors Mechanical

+Head

+Cinch A/V in/out

+Cinch Com

+Cinch Y/C

St

+Cabinet Name

+Confi

+Gra

-Cabinet Colour and Finish

Silver Frost

+Mechanics

+S

General

+Se

+Chassis

+Software Deliver

+Software Version

+Mains Volta

+Mains Fre

+T

Power Consum

onent In (Y/U/V) Cinch

CVBS+Mo

CVBS+Mo

Audio Out

eakers

CVBS + St

CVBS + St+ Mo

hone

lin

uration

hics/Logo's

eaker Visibilit

ment

uenc

e Mains Cord

incl Mains

incl Mains

Old

CVBS+St

Surround

CVBS+St+ Mo

onent

Mode

e

tion (P)TV in On

Product:

DT-2977

Channel +-, Volume +-,

TV/AV,MENU,

Power Switch,

RC Recvd LED, SB LED

7

1

X

X

X

75 Ohms (IEC type)

x

29228

Standard

Standard 4:3

M113A

180-240V

50Hz/60Hz

2004-7-6 17:33 29228PFS 2 of 3

Page 8

Date:2004-7-6 17:19

p

p

y

g

g)

)

g

R

quip

ging

guag

pp

pp

pp

quip

ging

ging

ging

pp

g

V

ype

g

y

(

g

gy

g

ype

ype

y

yp

yp

k

y

g

t

)

y

)

ProductView......:

Re

ort by............:

Specs / Products

Power Consumption SB in Watts

Power Consum

+Power in "ON" for

+Power in Standb

+Power in "OFF" for

Wei

Weight (P)TV (excl. Package

Weight AVUnit excl Packagin

+INDICATION on BACKCOVE

+Channel

Final E

+Packa

+Documents and manuals

+Lan

+Cables Su

+Antenna Su

+Stand Su

+Aux E

Packa

Packa

Packa

Miscellaneous

+EAN Indication

+A

+Tests

+Local Inte

+Service Call-Rate

PIP/POP

+T

+Features

Di

+Transmission

Built-in Data S

+Text Standard

+

+Nbr bck

+Text Technolo

+Digital Data handlin

+Program Guide

Built-in Clock/Timer

+T

+Features

Built-in Radio

+T

Built-in PC displa

+PC Synch

+PC Control

Built-in DVD drive

+T

+T

+Version of Deck

Phased Out Items

+Tuner/Frontend

+Sensitivit

+CRT EHT

+Li

+Accoun

+XX(Radio Antenna in

+Non Volatile Memor

+In Y/C + Cinch(CVBS+Mo

Version of deck

ht (P)TV (incl. Packagin

ment

robation

arious Perf. Param.

ital Reception

Tele)text Features

e of Medium

e of Dec

htning Protection

tion Semi SB in W

for

- methods

es DFU

lied

lied

lied

m Supplied

- width cm

- height cm

- depth cm

ration

stem

rnd page / Mem Size

Product:

DT-2977

Less than 10W

2004-7-6 17:33 29228PFS 3 of 3

Page 9

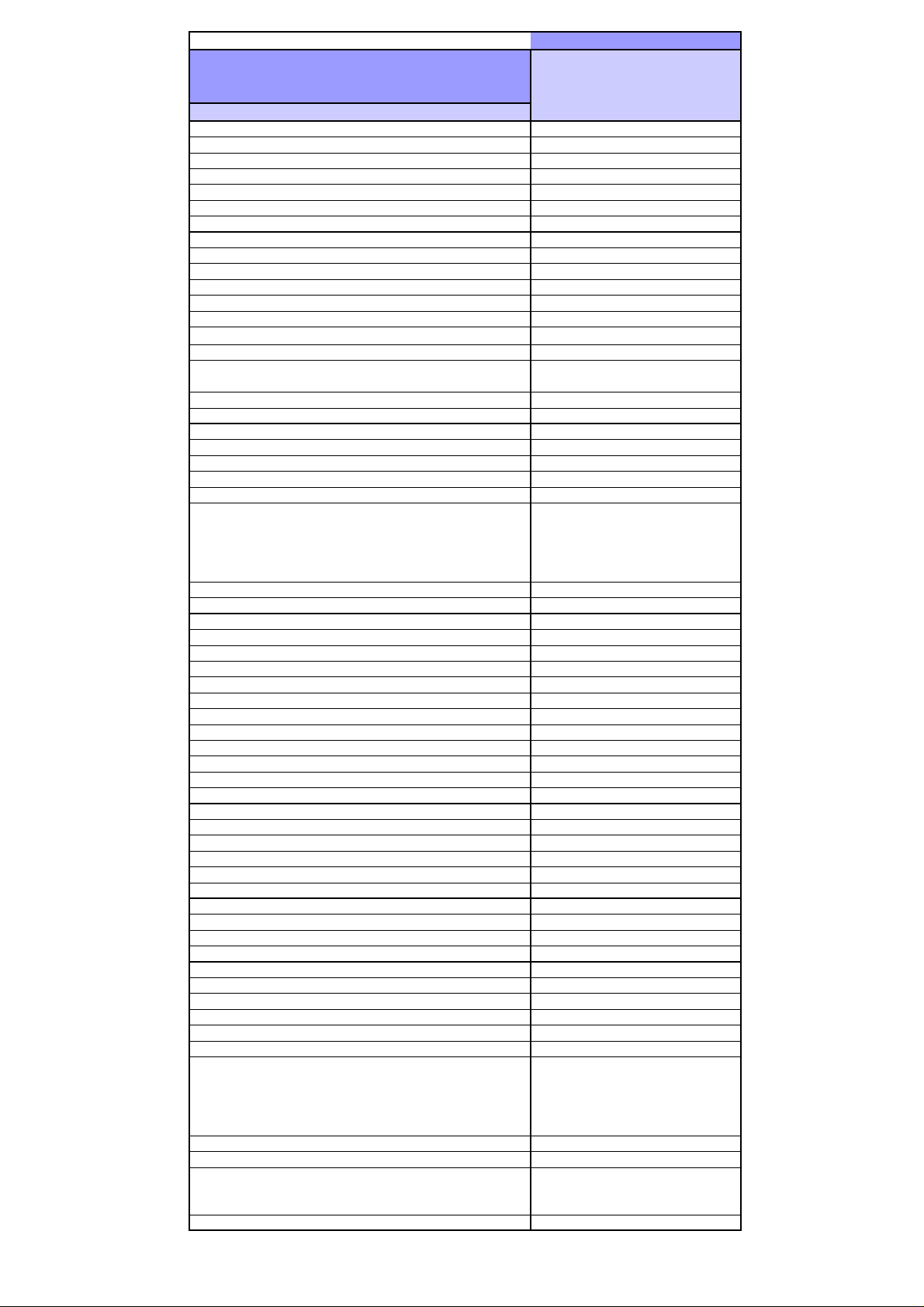

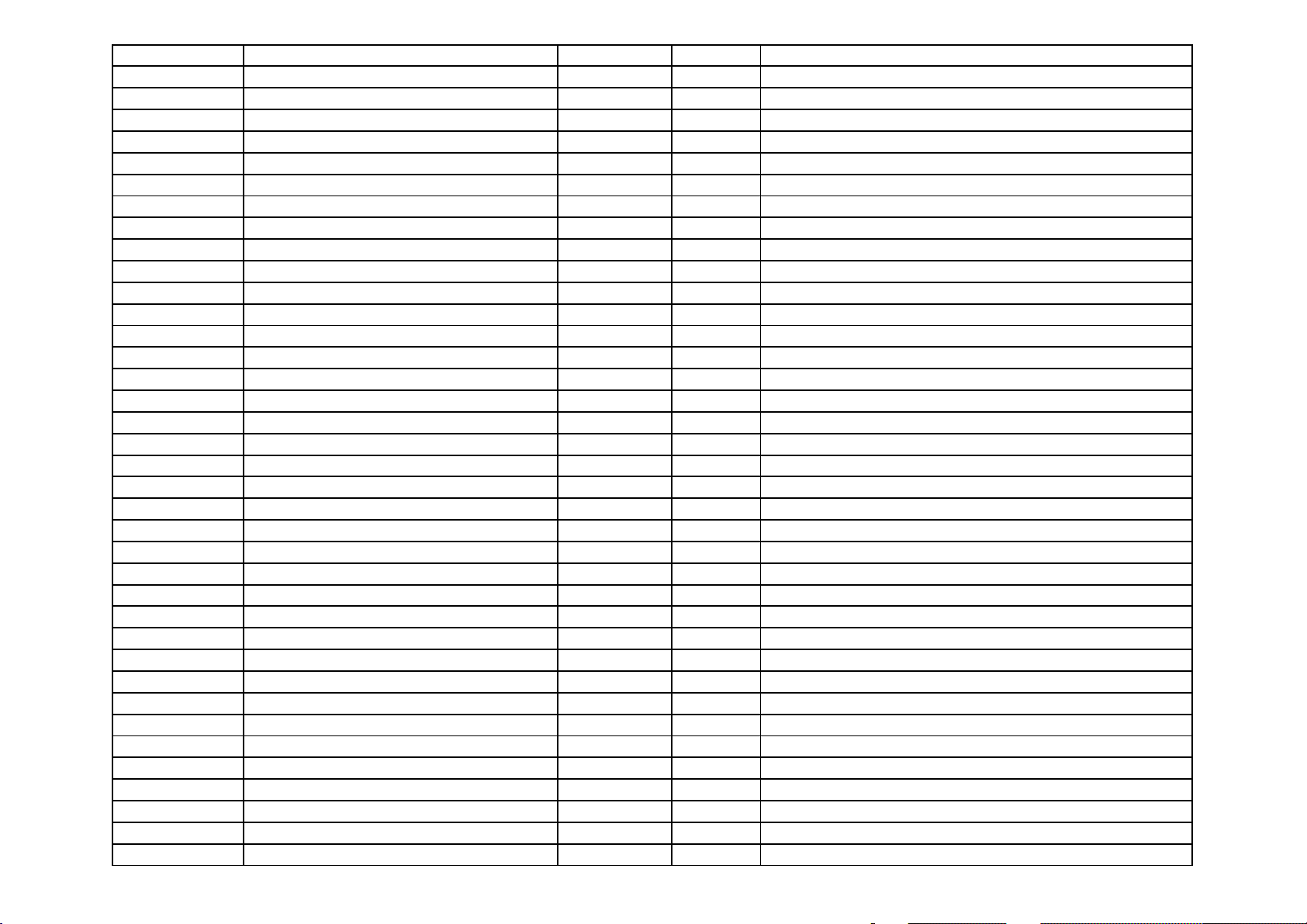

Item No. Description Quantity Req. Designator Remarks

08-00034E-WOY 1

10-0RU4YX-F0X DIODE RU4YX (FAST RECOVERY) 1 D827

13-TDA894-5SS IC TDA8945S 1 IC603

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R623

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R603

18-CD0829-JNX RES. C.F. 8.2 OHM 1/4W +/-5% 1 R621

18-RG0109-JHX RES. WIRE ROUND 1 OHM 2W +/-5% 1 R622

25-BDA102-M1X CAP. ELEC 1000 UF 25V +/-20% 1 C636

25-BDA102-M1X CAP. ELEC 1000 UF 25V +/-20% 1 C829

25-BDB100-M1X CAP. ELEC 10 UF 25V +/-20% 1 C642

25-BFB229-M1X CAP. ELEC 2.2 UF 50V +/-20% 1 C606

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C637

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C638

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C828

26-AIC221-KBX CAP. CER 220 PF 500V +/-10% B 1 C827

27-MBC224-J0X CAP. M.P.E 0.22UF 63V +/-5% 1 C640

27-MBC224-J0X CAP. M.P.E 0.22UF 63V +/-5% 1 C641

27-MBC333-J0X CAP. M.P.E 0.033UF 63V +/-5% 1 C639

35-237250-00X FERR. BEAD HF70 4.5X5.0 2 FOR D827

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J622

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J816

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J607

41-WJ0095-B00 WIRE BARE JUMPER 9.5MM 1 J611

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J614

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J814

64-B30100-104 M/C SCREW B 3 X 10 2 FOR IC603

67-H34423-5A0 HEAT SINK (A=50 C=17.5MM) 1 FOR IC603

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR IC603

26-ABC102-KBX CAP. CER 1000 PF 50V +/-10% B 1 C609

08-029ABE-CR1 1

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D501

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D502

11-A562TM-0BX TRANSISTOR 2SA562TM-0 1 Q507

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q502

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q504

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q506

11-SC4544-0AX TRANSISTOR 2SC4544 1 Q501

9

Page 10

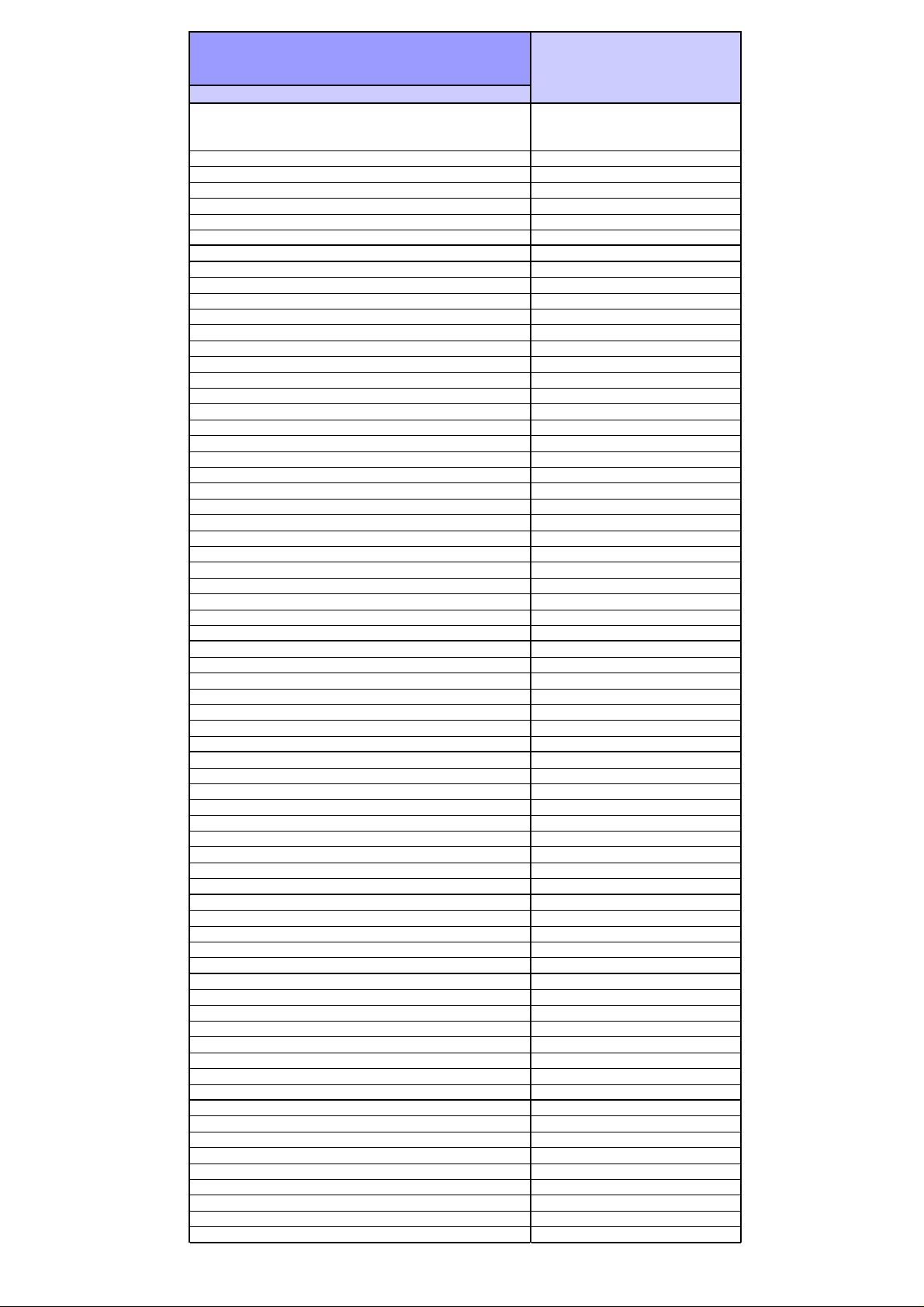

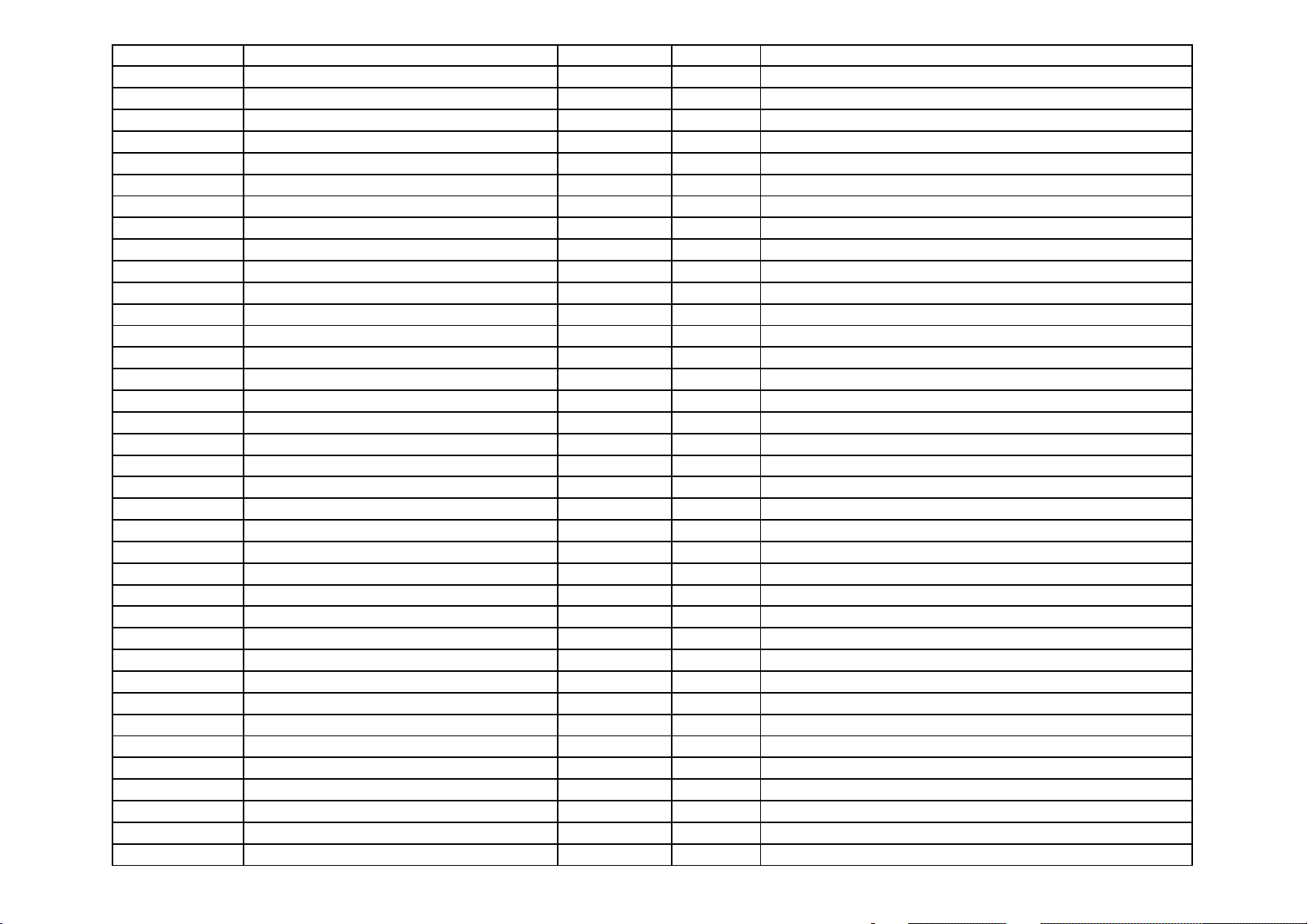

Item No. Description Quantity Req. Designator Remarks

11-SC4544-0AX TRANSISTOR 2SC4544 1 Q503

11-SC4544-0AX TRANSISTOR 2SC4544 1 Q505

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R515

18-CB0272-JNX RES. C.F. 2.7k OHM 1/6W +/-5% 1 R514

18-CB0561-JNX RES. C.F. 560 OHM 1/6W +/-5% 1 R501

18-CB0561-JNX RES. C.F. 560 OHM 1/6W +/-5% 1 R505

18-CB0561-JNX RES. C.F. 560 OHM 1/6W +/-5% 1 R510

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R502

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R506

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R509

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R522

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R503

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R508

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R513

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R511

18-FE0272-JNX RES. M.O. 2.7K OHM 1/2W +/-5% 1 R519

18-FE0272-JNX RES. M.O. 2.7K OHM 1/2W +/-5% 1 R520

18-FE0272-JNX RES. M.O. 2.7K OHM 1/2W +/-5% 1 R521

18-FG0183-JHX RES. M.O. 18K OHM 2W +/-5% 1 R516

18-FG0183-JHX RES. M.O. 18K OHM 2W +/-5% 1 R517

18-FG0183-JHX RES. M.O. 18K OHM 2W +/-5% 1 R518

25-BCB471-M1X CAP. ELEC 470 UF 16V +/-20% 1 C506

26-AMK182-KRX CAP. CER 1800PF 2KV +/-10% R 1 C505

27-MBC474-J0X CAP. M.P.E 0.47UF 63V +/-5% 1 C508

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C509

26-EBP391-JCX CAP. CER. 390PF 50V +/-5% CH 1 C502

26-EBP391-JCX CAP. CER. 390PF 50V +/-5% CH 1 C501

26-EBP471-JCX CAP. CER 470PF 50V +/-5% CH 1 C503

34-R100K2-1BX COIL CHOKE 10 UH +/-10% 1 L503

40-02501C-CRH1X P.C.B CRT BD 1

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 L504

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R504

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R507

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R512

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J503

46-10967W-01X PIN BASE *1 TJC1-1A 1 P501 FOR CRT GROUNDING HOUS.

46-30615H-04X HS 4P24 460 F/W TJC3-4Y/SCN-4 1 P502 FOR M.BD P421

10

Page 11

Item No. Description Quantity Req. Designator Remarks

46-37030H-05X HS 5P 2468#24 450 TJC3-5Y/SCN 1 P503 FOR M.BD P201

47-CRT004-XX0 CRT SOCKET GZS10-2-AC2 1 S501

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 L501 ("+" TO P503"1")

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 L502

25-BLA100-M1X CAP. ELEC 10 UF 250V +/-20% 1 C504

08-02970E-MAY 1

10-0BY228-F0X DIODE BY228 1 D411

10-0FR104-FBX DIODE FR104 (FAST RECTIFIER) 1 D412

10-0FR104-FBX DIODE FR104 (FAST RECTIFIER) 1 D421

10-0FR104-FBX DIODE FR104 (FAST RECTIFIER) 1 D441

10-0FR104-FBX DIODE FR104 (FAST RECTIFIER) 1 D431

10-0FR104-FBX DIODE FR104 (FAST RECTIFIER) 1 D432

10-1N4001-EBX DIODE 1N4001 (RECTIFIER) 1 D301

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D201

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D202

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D203

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D204

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D205

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D602

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D603

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D002

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D003

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D310

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D604

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D305B

10-79C5V1-DBX DIODE ZENER 5V1 1/2W 5% 1 D001

10-79C8V2-DBX DIODE ZENER 8V2 1/2W 5% 1 D303

10-CW574C-DJX DIODE CW574CD 1 D101

11-630MFP-0AX TRANSISTOR IRF630MFP 1 Q414

11-C124ES-0BX TRANSISTOR PDTC124ES (NPN) 1 Q001

11-C124ES-0BX TRANSISTOR PDTC124ES (NPN) 1 Q002

11-SA1015-YBX TRANSISTOR 2SA1015Y 1 Q008

11-SA1015-YBX TRANSISTOR 2SA1015Y 1 Q215

11-SA1015-YBX TRANSISTOR 2SA1015Y 1 Q412

11-SA1015-YBX TRANSISTOR 2SA1015Y 1 Q413

11-SA1015-YBX TRANSISTOR 2SA1015Y 1 Q601

11-SA1015-YBX TRANSISTOR 2SA1015Y 1 Q912

11

Page 12

Item No. Description Quantity Req. Designator Remarks

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q007

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q202

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q909

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q910

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q911

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q913

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q914

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q214

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q630

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q631

11-SC2482-0BX TRANSISTOR 2SC2482 1 Q401

11-SC3779-DBX TRANSISTOR 2SC3779D (RF AMPL) 1 Q101

13-000040-52P IC 4052 1 IC901

13-000040-52P IC 4052 1 IC902

13-0TDA81-77S IC TDA8177 1 IC301

13-NJW113-6LP IC NJW1136L 1 IC601

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R203

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R213

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R101

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R100

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R003

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R004

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R031

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R032

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R453

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R904

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R906

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R923

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R924

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R925

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R926

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R931

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R950

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R950A

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R951

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R951A

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R910

12

Page 13

Item No. Description Quantity Req. Designator Remarks

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R912

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R001A

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R033

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R035

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R012

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R224

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R227

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R246

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R013

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R607

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R247

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R248

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R252

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R314

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R617

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R034

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R210

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R943

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R235

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R236

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R907

18-CB0122-JNX RES. C.F. 1.2k OHM 1/6W +/-5% 1 R253

18-CB0123-JNX RES. C.F. 12k OHM 1/6W +/-5% 1 R310

18-CB0151-JNX RES. C.F. 150 OHM 1/6W +/-5% 1 R102

18-CB0151-JNX RES. C.F. 150 OHM 1/6W +/-5% 1 R108

18-CB0151-JNX RES. C.F. 150 OHM 1/6W +/-5% 1 R228

18-CB0151-JNX RES. C.F. 150 OHM 1/6W +/-5% 1 R928

18-CB0151-JNX RES. C.F. 150 OHM 1/6W +/-5% 1 R929

18-CB0183-JNX RES. C.F. 18k OHM 1/6W +/-5% 1 R225

18-CB0183-JNX RES. C.F. 18k OHM 1/6W +/-5% 1 R933

18-CB0202-JNX RES. C.F. 2K OHM 1/6W +/-5% 1 R412

18-CB0220-JNX RES. C.F. 22 OHM 1/6W +/-5% 1 R027

18-CB0220-JNX RES. C.F. 22 OHM 1/6W +/-5% 1 R028

18-CB0220-JNX RES. C.F. 22 OHM 1/6W +/-5% 1 R104

18-CB0221-JNX RES. C.F. 220 OHM 1/6W +/-5% 1 R401

18-CB0221-JNX RES. C.F. 220 OHM 1/6W +/-5% 1 R015

18-CB0221-JNX RES. C.F. 220 OHM 1/6W +/-5% 1 R016

13

Page 14

Item No. Description Quantity Req. Designator Remarks

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R615

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R903

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R946

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R946A

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R417

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R423

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R420A

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R909

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R905

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R932

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R938

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R939

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R942

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R940

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R941

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R911

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R913

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R220

18-CB0223-JNX RES. C.F. 22k OHM 1/6W +/-5% 1 R616

18-CB0224-JNX RES. C.F. 220k OHM 1/6W +/-5% 1 R240

18-CB0271-JNX RES. C.F. 270 OHM 1/6W +/-5% 1 R243

18-CB0271-JNX RES. C.F. 270 OHM 1/6W +/-5% 1 R244

18-CB0271-JNX RES. C.F. 270 OHM 1/6W +/-5% 1 R245

18-CB0303-JNX RES. C.F. 30K OHM 1/6W +/-5% 1 R241

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R214

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R608

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R609

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R201

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R944

18-CB0332-JNX RES. C.F. 3.3k OHM 1/6W +/-5% 1 R212

18-CB0332-JNX RES. C.F. 3.3k OHM 1/6W +/-5% 1 R216

18-CB0470-JNX RES. C.F. 47 OHM 1/6W +/-5% 1 R927

18-CB0471-JNX RES. C.F. 470 OHM 1/6W +/-5% 1 R036

18-CB0471-JNX RES. C.F. 470 OHM 1/6W +/-5% 1 R103

18-CB0471-JNX RES. C.F. 470 OHM 1/6W +/-5% 1 R211

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R315

18-CB0473-JNX RES. C.F. 47K OHM 1/6W +/-5% 1 R226

14

Page 15

Item No. Description Quantity Req. Designator Remarks

18-CB0473-JNX RES. C.F. 47K OHM 1/6W +/-5% 1 R610

18-CB0512-JNX RES. C.F. 5.1k OHM 1/6W +/-5% 1 R219

18-CB0560-JNX RES. C.F. 56 OHM 1/6W +/-5% 1 R107

18-CB0681-JNX RES. C.F. 680 OHM 1/6W +/-5% 1 R106

18-CB0683-JNX RES. C.F. 68K OHM 1/6W +/-5% 1 R418

18-CB0750-JNX RES. C.F. 75 OHM 1/6W +/-5% 1 R922

18-CB0752-JNX RES. C.F. 7.5K OHM 1/6W +/-5% 1 R256

18-CB0820-JNX RES. C.F. 82 OHM 1/6W +/-5% 1 R908

18-CB0820-JNX RES. C.F. 82 OHM 1/6W +/-5% 1 R902

18-CB0822-JNX RES. C.F. 8.2K OHM 1/6W +/-5% 1 R202

18-CD0479-JNX RES. C.F. 4.7 OHM 1/4W +/-5% 1 R030

18-CD0829-JNX RES. C.F. 8.2 OHM 1/4W +/-5% 1 R620

18-CD0829-JNX RES. C.F. 8.2 OHM 1/4W +/-5% 1 R613

18-CE0271-JNX RES. C.F. 270 OHM 1/2W +/-5% 1 R209

18-CE0472-JNX RES. C.F. 4.7k OHM 1/2W +/-5% 1 R316

18-DB0103-FNX RES. M.F. 10K OHM 1/6W +/-1% 1 R302

18-DB0104-FNX RES. M.F. 100K OHM 1/6W +/-1% 1 R303

18-DB0123-FNX RES. M.F. 12K OHM 1/6W +/-1% 1 R312

18-DB0912-FNX RES. M.F. 9.1K OHM 1/6W +/-1% 1 R311

18-EG0109-JHX RES. FUS. 1 OHM 2W +/-5% 1 R422

18-FF0242-JGX RES. M.O. 2.4K OHM 1W +/-5% 1 R402

18-FF0681-JGX RES. M.O. 680 OHM 1W +/-5% 1 R419

18-FG0103-JHX RES. M.O. 10K OHM 2W +/-5% 1 R421

18-FG0399-JHX RES. M.O. 3.9 OHM 2W +/-5% 1 R415

18-GM0302-KUX1 RES.C.C.7W 3KOHM +/-10% 1 R404

25-264610-M1X CAP. ELEC 4.7UF 50V +/-20% NP 1 C415

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C021

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C033

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C228

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C235

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C902

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C903

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C911

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C912

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C917

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C905

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C906

15

Page 16

Item No. Description Quantity Req. Designator Remarks

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C219

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C233

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C914

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C930

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C930A

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C028

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C612

25-BCB221-M1X CAP. ELEC 220 UF 16V +/-20% 1 C910

25-BCB331-M1X CAP. ELEC 330 UF 16V +/-20% 1 C630

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C213

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C901

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C920

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C229

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C631

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C904

25-BDA102-M1X CAP. ELEC 1000 UF 25V +/-20% 1 C623

25-BDB101-M1X CAP. ELEC 100 UF 25V +/-20% 1 C308

25-BDB470-M1X CAP. ELEC 47 UF 25V +/-20% 1 C632

25-BEA102-M1X CAP. ELEC 1000 UF 35V +/-20% 1 C432

25-BEA221-M1X CAP. ELEC 220 UF 35V +/-20% 1 C301

25-BEB101-M1X CAP. ELEC 100 UF 35V +/-20% 1 C302

25-BFB101-M1X CAP. ELEC 100 UF 50V +/-20% 1 C224

25-BFB101-M1X CAP. ELEC 100 UF 50V +/-20% 1 C105

25-BFB101-M1X CAP. ELEC 100 UF 50V +/-20% 1 C237

25-BFB101-M1X CAP. ELEC 100 UF 50V +/-20% 1 C104

25-BFB109-M1X CAP. ELEC 1 UF 50V +/-20% 1 C218

25-BFB109-M1X CAP. ELEC 1 UF 50V +/-20% 1 C221

25-BFB229-M1X CAP. ELEC 2.2 UF 50V +/-20% 1 C601

25-BFB229-M1X CAP. ELEC 2.2 UF 50V +/-20% 1 C607

25-BFB229-M1X CAP. ELEC 2.2 UF 50V +/-20% 1 C650

25-BFB229-M1X CAP. ELEC 2.2 UF 50V +/-20% 1 C657

25-BFB478-M1X CAP. ELEC 0.47 UF 50V +/-20% 1 C227

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C223

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C304

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C614

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C615

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C616

16

Page 17

Item No. Description Quantity Req. Designator Remarks

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C617

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C618

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C619

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C620

25-BFB479-M1X CAP. ELEC 4.7 UF 50V +/-20% 1 C101

25-BKA100-M1X CAP. ELEC 10 UF 200V +/-20% 1 C421

25-BLF100-M1X CAP. ELEC 10 UF 250V +/-20% 1 C442

25-GFB228-K1X CAP. ELEC 0.22 UF 50V +/-10% 1 C216

25-GFB478-K1X CAP. ELEC 0.47 UF 50V 10%CEC-K 1 C246

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C624

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C611

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C622

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C643

26-AIC221-KBX CAP. CER 220 PF 500V +/-10% B 1 C431

26-AIC221-KBX CAP. CER 220 PF 500V +/-10% B 1 C441

26-AIC221-KBX CAP. CER 220 PF 500V +/-10% B 1 C433

26-AIC332-KBX CAP. CER 3300 PF 500V +/-10% B 1 C402

26-AIC391-KBX CAP. CER 390 PF 500V +/-10% B 1 C403

26-EBP102-KBX CAP. CER 1000 PF 50V +/-10% B 1 C109

26-EBP102-KBX CAP. CER 1000 PF 50V +/-10% B 1 C226

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C022

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C029

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C234

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C238

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C244

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C250

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C921

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C931A

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C922

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C923

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C034

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C106

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C107

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C108

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C214

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C220

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C225

17

Page 18

Item No. Description Quantity Req. Designator Remarks

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C418

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C913

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C103

26-EBP220-JCX CAP. CER 22PF 50V +/-5% CH 1 C252

26-EBP221-JCX CAP. CER 220PF 50V +/-5% CH 1 C907

26-EBP221-JCX CAP. CER 220PF 50V +/-5% CH 1 C027

26-EBP221-JCX CAP. CER 220PF 50V +/-5% CH 1 C030

26-EBP221-JCX CAP. CER 220PF 50V +/-5% CH 1 C015

26-EBP221-JCX CAP. CER 220PF 50V +/-5% CH 1 C016

26-EBP222-KBX CAP. CER 2200PF 50V +/-10% B 1 C217

26-EBP222-KBX CAP. CER 2200PF 50V +/-10% B 1 C231

26-EBP222-KBX CAP. CER 2200PF 50V +/-10% B 1 C306

26-EBP330-JCX CAP. CER 33PF 50V +/-5% CH 1 C916

26-EBP390-JCX CAP. CER 39PF 50V +/-5% CH 1 C031

26-EBP390-JCX CAP. CER 39PF 50V +/-5% CH 1 C032

26-EBP471-JCX CAP. CER 470PF 50V +/-5% CH 1 C239

27-MBC103-J0X CAP. M.P.E 0.01UF 63V+/-5% 1 C626

27-MBC103-J0X CAP. M.P.E 0.01UF 63V+/-5% 1 C628

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C241

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C243

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C625

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C633

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C251

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C242

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C602

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C603

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C605

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C652

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C253

27-MBC222-J0X CAP. M.P.E 0.0022UF 63V +/-5% 1 C653

27-MBC222-J0X CAP. M.P.E 0.0022UF 63V +/-5% 1 C604

27-MBC222-J0X CAP. M.P.E 0.0022UF 63V +/-5% 1 C654

27-MBC333-J0X CAP. M.P.E 0.033UF 63V +/-5% 1 C656

27-MBC334-J0X CAP. M.P.E 0.33UF 63V +/-5% 1 C608

27-MBC334-J0X CAP. M.P.E 0.33UF 63V +/-5% 1 C305

27-MBC473-J0X CAP. M.P.E 0.047 UF 63V +/-5% 1 C655

27-MBC474-J0X CAP. M.P.E 0.47UF 63V +/-5% 1 C248

18

Page 19

Item No. Description Quantity Req. Designator Remarks

27-MCC563-J0X CAP M.P.E 0.056UF 100V +/-5% 1 C451

27-PBC822-J0X CAP. P.E 0.0082UF 63V +/-5% 1 C247

34-A109K0-1IX COIL CHOKE 1 UH +/-10% 1 L102

34-R100J2-0EX COIL PL - 10 UH +/-5% 1 L002

34-R100J2-0EX COIL PL - 10 UH +/-5% 1 L208

34-R220J2-0EX COIL PL - 22 UH +/-5% 1 L206

34-R220J2-0EX COIL PL - 22 UH +/-5% 1 L202

34-R270J2-0EX COIL PL - 27 UH +/-5% 1 L207

34-R470J2-0EX COIL PL - 47 UH +/-5% 1 L101

35-237250-00X FERR. BEAD HF70 4.5X5.0 2 FOR D421

36-HDR001-AX1 TRANSFOR HOR. DRIVE (MAGNETIC CORE) 1 T401

41-WJ0055-B00 WIRE BARE JUMPER 5.5 MM 1 J915

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J018

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J218

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J229

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J624

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J307

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J924

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J909

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J910

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J911

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R001

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R002

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J014A

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J310

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J311

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J403

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J1111

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J1112

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J410

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R930

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J004

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J005

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J235

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J201

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J202

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J236

19

Page 20

Item No. Description Quantity Req. Designator Remarks

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J603

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J605

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J608A

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J625

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J627

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J923

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J925

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J926

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J002

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J007

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J008

41-WJ0070-B00 WIRE BARE JUMPER 7MM 1 J922

41-WJ0070-B00 WIRE BARE JUMPER 7MM 1 J404

41-WJ0070-B00 WIRE BARE JUMPER 7MM 1 J015B

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 D410

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J308

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J208

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J221

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J222

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J226

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J608

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J917

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J626

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J102

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J014B

41-WJ0080-B00 WIRE BARE JUMPER 8 MM 1 J013

41-WJ0080-B00 WIRE BARE JUMPER 8 MM 1 J620

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J313

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J223

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J902

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J907

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J010

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J305

41-WJ0095-B00 WIRE BARE JUMPER 9.5MM 1 J610

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J211

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J901

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J912

20

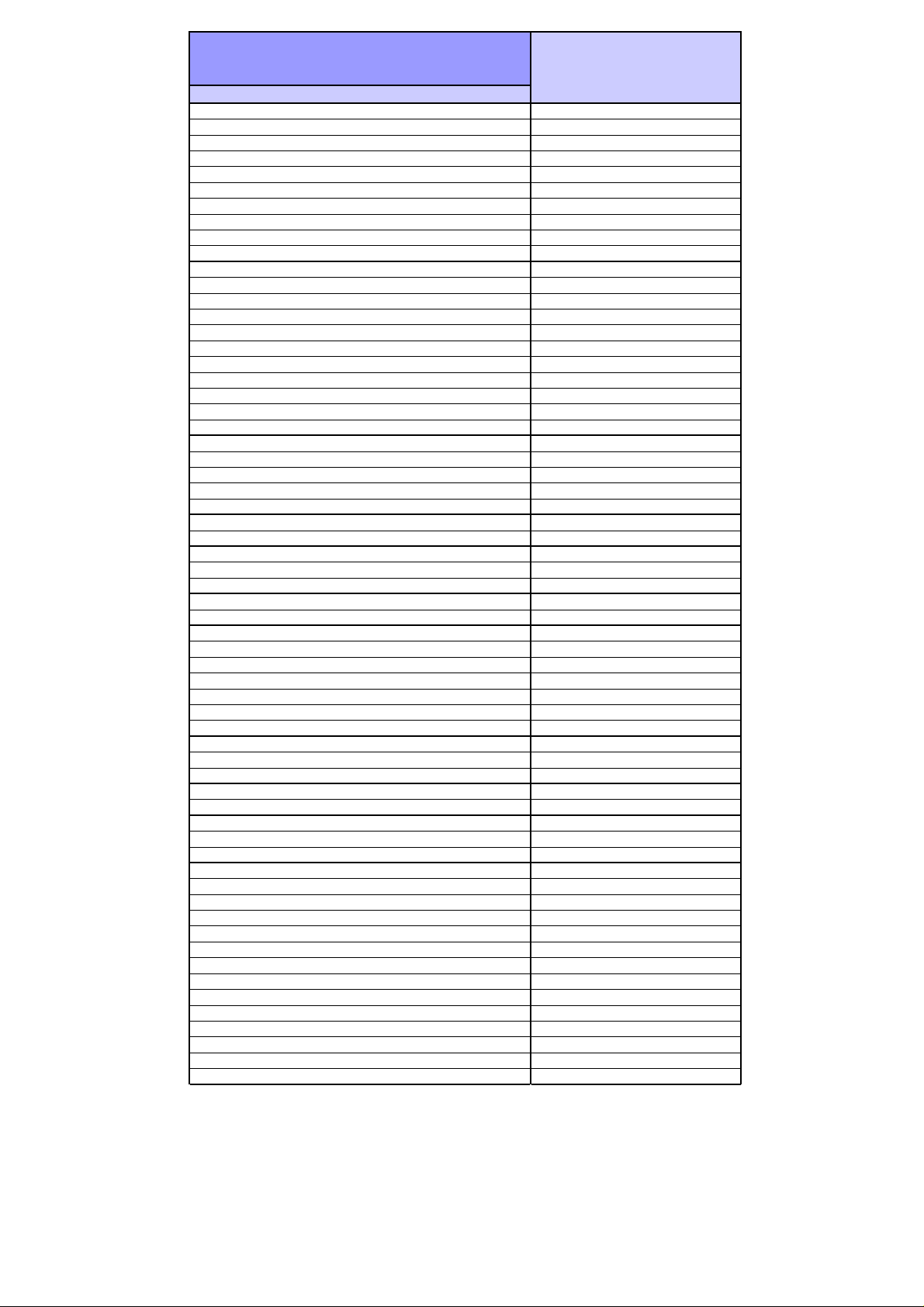

Page 21

Item No. Description Quantity Req. Designator Remarks

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J914

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J916

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J921

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J602

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J618

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J619

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J931

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J932

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J312

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J1230

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J1231

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J1232

41-WJ0100-B00 WIRE BARE JUMPER 10MM 1 J022

41-WJ0105-B00 WIRE BARE JUMPER 10.5MM 1 J230

41-WJ0105-B00 WIRE BARE JUMPER 10.5MM 1 J027

41-WJ0105-B00 WIRE BARE JUMPER 10.5MM 1 J1218

41-WJ0110-B00 WIRE BARE JUMPER 11MM 1 J609

41-WJ0110-B00 WIRE BARE JUMPER 11MM 1 J012

41-WJ0110-B00 WIRE BARE JUMPER 11MM 1 J601

41-WJ0110-B00 WIRE BARE JUMPER 11MM 1 J918

41-WJ0110-B00 WIRE BARE JUMPER 11MM 1 J026

41-WJ0120-B00 WIRE BARE JUMPER 12MM 1 J009

41-WJ0120-B00 WIRE BARE JUMPER 12MM 1 J216

41-WJ0120-B00 WIRE BARE JUMPER 12MM 1 J217

41-WJ0120-B00 WIRE BARE JUMPER 12MM 1 J302

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J206

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J011

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J227

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J306

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J402

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J405

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J406

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J927

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 R308

41-WJ0130-B00 WIRE BARE JUMPER 13MM 1 J613

41-WJ0130-B00 WIRE BARE JUMPER 13MM 1 J220

41-WJ0130-B00 WIRE BARE JUMPER 13MM 1 J207

21

Page 22

Item No. Description Quantity Req. Designator Remarks

41-WJ0130-B00 WIRE BARE JUMPER 13MM 1 J612

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J205

41-WJ0140-B00 WIRE BARE JUMPER 14MM 1 J224

41-WJ0145-B00 WIRE BARE JUMPER 14.5MM 1 J621

41-WJ0145-B00 WIRE BARE JUMPER 14.5MM 1 J904

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J101

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J303

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J920

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 L412

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 R614

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J609A

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J304

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 L411

41-WJ0165-B00 WIRE BARE JUMPER 16.5MM 1 J225

41-WJ0175-B00 WIRE BARE JUMPER 17.5MM 1 J105

41-WJ0175-B00 WIRE BARE JUMPER 17.5MM 1 J212

41-WJ0180-B00 WIRE BARE JUMPER 18MM 1 J213

41-WJ0180-B00 WIRE BARE JUMPER 18MM 1 J616A

41-WJ0180-B00 WIRE BARE JUMPER 18MM 1 J617A

41-WJ0185-B00 WIRE BARE JUMPER 18.5MM 1 J228

41-WJ0185-B00 WIRE BARE JUMPER 18.5MM 1 J028

41-WJ0185-B00 WIRE BARE JUMPER 18.5MM 1 J210

41-WJ0190-B00 WIRE BARE JUMPER 19MM 1 J908

41-WJ0190-B00 WIRE BARE JUMPER 19MM 1 J023

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J017

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J215

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J209

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J214

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J021

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J1217

41-WJ0200-B00 WIRE BARE JUMPER 20MM 1 J016

41-WJ0200-B00 WIRE BARE JUMPER 20MM 1 J905

41-WJ0200-B00 WIRE BARE JUMPER 20MM 1 J913

41-WJ0200-B00 WIRE BARE JUMPER 20MM 1 J604

41-WJ0200-B00 WIRE BARE JUMPER 20MM 1 J024

41-WJ0200-B00 WIRE BARE JUMPER 20MM 1 J025

45-OSC8M0-0Y0 CRYSTAL 8.0MHZ 1 X001

22

Page 23

Item No. Description Quantity Req. Designator Remarks

46-20598W-04X PIN BASE *4 TJC1-4A 1 P411 FOR D.Y CONNECTOR

46-33079W-03X PIN BASE *3 TJC3-3A 1 P002 P2 - P4 FOR W. BAL . ADJUST

46-33079W-04X PIN BASE *4 TJC3-4A 1 P421 FOR CRT BD P502

46-33079W-05X PIN BASE *5 TJC3-5A 1 P201 FOR CRT BD P503

46-33079W-05X PIN BASE *5 TJC3-5A 1 P001 FOR F. CTL BD

62-227680-0UA BRACKET ABS-KINGFA 606 (UO) 1

64-P30080-104 M/C SCREW P 3 X 8 1 FOR Q411

64-P30080-104 M/C SCREW P 3 X 8 1 FOR IC301

64-P30080-104 M/C SCREW P 3 X 8 1 FOR Q414

64-P30100-104 M/C SCREW P 3 X 10 2 FOR IC602

65-Z30050-23M NUT M 3 2 FOR IC301 & Q411

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 10 FOR T402

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 3 FOR Q411

67-H27292-1A0 HEAT SINK 1 FOR Q414

67-H30147-0A0 HEAT SINK FOR HORIZ (2501/2909 1 FOR Q411

67-H30179-5A0 HEAT SINK 1 FOR IC301

57-10654X-00F

cable ties(2.5mmX95mm) 3

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 J411

34-R100J2-0EX COIL PL - 10 UH +/-5% 1 L005

25-BDG222-M1X CAP. ELEC 2200 UF 25V +/-20% 1 C435

25-KJG101-M1X CAP. ELEC 100 UF 160V +/-20% 1 C422

26-AIM103-KBX CAP. CER 0.01UF 500V +/-10% B 1 C401

13-0AT24C-16P IC EEPROM 16K AT24C16A (WRITE) 1 IC001

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R025

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R026

18-CB0471-JNX RES. C.F. 470 OHM 1/6W +/-5% 1 R024

26-EBP330-JCX CAP. CER 33PF 50V +/-5% CH 1 C314

46-10967W-01X PIN BASE *1 TJC1-1A 1 G1

41-WJ0070-B00 WIRE BARE JUMPER 7MM 1 J919

18-CB0229-JNX RES. C.F. 2.2 OHM 1/6W +/-5% 1 R204

26-EBP104-ZFX CAP. CER 0.1UF 50V +80%/-20% 1 C230

26-EBP104-ZFX CAP. CER 0.1UF 50V +80%/-20% 1 C232

26-EBP104-ZFX CAP. CER 0.1UF 50V +80%/-20% 1 C236

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C613

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR R404

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 14 FOR C412,C414,C411,C413,C419,L414,L413

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR D411

23

Page 24

Item No. Description Quantity Req. Designator Remarks

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR Q414

26-ABC102-KBX CAP. CER 1000 PF 50V +/-10% B 1 C416

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D601

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D604A

18-CB0203-JNX RES. C.F. 20k OHM 1/6W +/-5% 1 R619

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R604

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R611

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R630

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R632

18-CB0182-JNX RES. C.F. 1.8K OHM 1/6W +/-5% 1 J614A

18-CB0182-JNX RES. C.F. 1.8K OHM 1/6W +/-5% 1 J615

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C627

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C629

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R631

18-CB0104-JNX RES. C.F. 100K OHM 1/6W +/-5% 1 R633

08-02970E-PWY 1

10-0001H8-FBX DIODE 1H8 (FAST RECOVERY) 1 D851

10-0FR104-FBX DIODE FR104 (FAST RECTIFIER) 1 D832

10-0RU4AM-F0X DIODE RU4AM (FAST RECOVERY) 1 D831

10-0RU4YX-F0X DIODE RU4YX (FAST RECOVERY) 1 D833

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D807

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D808

10-1N4148-ABX DIODE 1N4148 (SWITCHING) 1 D826

10-79C5V6-DBX DIODE ZENER 5V6 1/2W 5% 1 D810

10-79C8V2-DBX DIODE ZENER 8V2 1/2W 5% 1 D825

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q805

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q802

11-SK3451-0CX TRANSISTOR 2SK3451-01MR 1 Q801

13-L7805C-VAP IC L7805CV 1.5A (REGULATOR) 1 IC805

13-DA1684-62P IC TDA16846-2(Q67040-S4494) 1 IC801

13-SFH615-A3P PHOTO COUPLER SFH615A3 1 IC802

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R838

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R813

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R807

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R835

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R837

18-CB0123-JNX RES. C.F. 12k OHM 1/6W +/-5% 1 R805

24

Page 25

Item No. Description Quantity Req. Designator Remarks

18-CB0221-JNX RES. C.F. 220 OHM 1/6W +/-5% 1 R809

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R836

18-CB0303-JNX RES. C.F. 30K OHM 1/6W +/-5% 1 R808

18-CB0332-JNX RES. C.F. 3.3k OHM 1/6W +/-5% 1 R825

18-CB0333-JNX RES. C.F. 33K OHM 1/6W +/-5% 1 R806

18-CB0683-JNX RES. C.F. 68K OHM 1/6W +/-5% 1 R804

18-CD0103-JNX RES. C.F. 10K OHM 1/4W +/-5% 1 R822

18-CD0362-JNX RES. C.F. 3.6K OHM 1/4W +/-5% 1 R823

18-CD0470-JNX RES. C.F. 47 OHM 1/4W +/-5% 1 R810

18-CE0823-JNX RES. C.F. 82K OHM 1/2W +/-5% 1 R820

18-DD0102-FNX RES. M.F. 1K OHM 1/4W +/-1% 1 R811

18-DD0102-FNX RES. M.F. 1K OHM 1/4W +/-1% 1 R821

18-DD0102-FNX RES. M.F. 1K OHM 1/4W +/-1% 1 R833

18-EG0479-JHX RES. FUS. 4.7 OHM 2W +/-5% 1 R834

18-EG0479-JHX RES. FUS. 4.7 OHM 2W +/-5% 1 R834A

18-FG0183-JHX RES. M.O. 18K OHM 2W +/-5% 1 R842

18-FG0330-JHX RES. M.O. 33 OHM 2W +/-5% 1 R832

18-FG0563-JHX RES. M.O. 56K OHM 2W +/-5% 1 R851

18-FH0153-JLX RES. M.O. 15K OHM 3W +/-5% 1 R831

18-KE0105-JN3 RES. H.VOLT. CC 1M OHM 1/2W +/-5% 1 R802

18-KE0105-JN3 RES. H.VOLT. CC 1M OHM 1/2W +/-5% 1 R803A

18-KE0475-JNX RES. H. VOLT. CC 4.7M OHM 1/2W 1 R803

18-KF0825-JH3 RES. H.VOLT.CC 8.2M OHM 1W +/-5% 1 R812

20-TR102H-5CX TRIMMER B1K HORIZ TYPE 1 VR824

22-NTC479-XX0 NTC 4.7 OHM +/-18% NTC4.7D2-14 1 RT802

22-PTC200-XX0 POSISTOR 20 OHM (25-34) 1 RT801

25-BCB100-M1X CAP. ELEC 10 UF 16V +/-20% 1 C836A

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C845A

25-BCB221-M1X CAP. ELEC 220 UF 16V +/-20% 1 C840

25-BDA102-M1X CAP. ELEC 1000 UF 25V +/-20% 1 C839

25-BJG221-M1X CAP. ELEC 220 UF 160V +/-20% 1 C835

25-GCA222-M1X CAP. ELEC 2200 UF 16V +/-20% 1 C838

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C838A

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C839A

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C843

26-ABC104-ZFX CAP. CER 0.1 UF 50V +80-20% F 1 C846A

26-ABC333-ZFX CAP. CER 0.033UF 50V +80-20% F 1 C811

25

Page 26

Item No. Description Quantity Req. Designator Remarks

26-ABC681-JZX CAP. CER 680 PF 50V +/-5% SL 1 C815

26-AIC221-KBX CAP. CER 220 PF 500V +/-10% B 1 C832

26-AIC221-KBX CAP. CER 220 PF 500V +/-10% B 1 C833

26-AIM103-KBX CAP. CER 0.01UF 500V +/-10% B 1 C825A

26-AMK221-KZX CAP. CER 220 PF 2KV +/-10% SL 1 C831

26-AMK331-JZX CAP. CER 330 pF 2KV +/-5% SL 1 C834

26-AMK561-KBX CAP. CER 560 pF 2KV +/-10% 1 C817

26-APK222-ME4 CAP. CER 2200PF 400VAC+/-20% E 1 C817A

26-APK471-KB4 CAP. CER 470 pF 400VAC +/-10% 1 C804

26-APK471-KB4 CAP. CER 470 pF 400VAC +/-10% 1 C805

26-AQK472-ZFX CAP. CER 4700PF 250VAC+80-20%F 1 C804A

26-AQK472-ZFX CAP. CER 4700PF 250VAC+80-20%F 1 C805A

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C812

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C844

26-EBP331-JCX CAP. CER 330PF 50V +/-5% CH 1 C813

26-EBP560-JCX CAP. CER 56PF 50V +/-5% 1 C814

27-AQQ683-K0X CAP. M.PP 0.068 UF 250VAC +/-10% 1 C851

27-MBC104-J0X CAP. M.P.E 0.1 UF 63V +/-5% 1 C823

27-MBC224-J0X CAP. M.P.E 0.22UF 63V +/-5% 1 C821

27-MBC224-J0X CAP. M.P.E 0.22UF 63V +/-5% 1 C822

27-MHM104-K0X CAP. METAL P.E. 0.1UF 400V 10% 1 C803

34-R101K2-1BX COIL CHOKE 100 UH +/-10% 1 L824

34-R220K2-1BX COIL CHOKE 22 UH +/-10% 1 L825

35-139730-00X FERR. BEAD BF60 2 FOR L801

35-237250-00X FERR. BEAD HF70 4.5X5.0 2 FOR D832

35-237250-00X FERR. BEAD HF70 4.5X5.0 2 FOR D833

35-237250-00X FERR. BEAD HF70 4.5X5.0 2 FOR D831

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J830

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J809

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J821

41-WJ0065-B00 WIRE BARE JUMPER 6.5MM 1 J817

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J818

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J802A

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J822

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J811

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J812

41-WJ0125-B00 WIRE BARE JUMPER 12.5MM 1 J819

26

Page 27

Item No. Description Quantity Req. Designator Remarks

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J825

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J826

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J805

41-WJ0145-B00 WIRE BARE JUMPER 14.5MM 1 J824

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J807

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J813

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J820

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 L801

41-WJ0180-B00 WIRE BARE JUMPER 18MM 1 J806

41-WJ0185-B00 WIRE BARE JUMPER 18.5MM 1 J808

41-WJ0185-B00 WIRE BARE JUMPER 18.5MM 1 J815

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 J810

46-10962W-02X PIN BASE *2 TJC2-2A 1 P803 FOR DEGAUSSING COIL

64-P30060-104 M/C SCREW 3 X 6 (ZINC) 1 FOR Q803

64-P30080-104 M/C SCREW P 3 X 8 1 FOR Q801

64-P30080-104 M/C SCREW P 3 X 8 1 FOR IC805

66-20516X-0B0 FUSE HOLDER 2 FOR F801

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 2 FOR C835

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 2 FOR D832

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 3 FOR RT801

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 2 FOR C839

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 2 FOR C801

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 6 FOR T803

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 4 FOR DB801

67-H24249-1M2 HEAT SINK 1 FOR Q803

67-H27292-3A0 HEAT SINK 1 FOR IC805

67-H35984-2A0 HEAT SINK 1 FOR Q801

71-DYP000-WX1 LABEL 1 STICK ON HEAT SINK

11-3DA882-YAX TRANSISTOR 3DA882-Y NPN 1 Q803

26-AMK471-JZX CAP.CER 470PH 2KV +/-5% 1 C852

36-LIF001-XX0 LINE FILTER LCL1602 1 T802

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 4 FOR T802

27-AQT474-MVH CAP. M.PP 0.47UF 250VAC +/-20% 1 C801

26-AIM103-KBX CAP. CER 0.01UF 500V +/-10% B 1 C807A

36-LIF005-XX0 LINE FILTER LCL-2826 1 T801

66-343730-0B0 HOLLOW RIVET 1.6X3.0XL3.2 3 FOR T801

26-ABC821-KBX CAP. CER 820 PF 50V +/-10% B 1 C810

27

Page 28

Item No. Description Quantity Req. Designator Remarks

26-APK471-KB4 CAP. CER 470 pF 400VAC +/-10% 1 C817B

10-RS405M-H7X DIODE ZENER RS405M (4.0A/600V) 1 DB801

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR C806

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR P803

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR D831

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR D833

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR IC805

36-TRF127-AX2 TRANSFORMER CONV. BCK-4922 1 T803

18-CD0470-JNX RES. C.F. 47 OHM 1/4W +/-5% 1 R808A

25-BDB101-M1X CAP. ELEC 100 UF 25V +/-20% 1 C816

08-0B181E-AVY 1

40-B181ME-SIA P.C.B. SIDE AV BD 1

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 FOR Q962 (B - E)

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 C955

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 C954

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 C951

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R953

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 JM13B

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R952

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 R966

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J951

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 C962

46-39136H-07X 7P 2468#24/1185#26 550 TJC3-7Y/SCN-7Y 1 P902 FOR M.BD P921

47-RCA002-XX0 RCA SOCKET AV-8.4-6 (WHITE) 1 P941L

47-RCA003-XX0 RCA SOCKET AV-8.4-6 (YELLOW) 1 P941V

47-RCA017-XX0 RCA JACK RED (RCA-101P) (THREE FEET) 1 P941R

47-SVI001-XX0 SOCKET 1 P951

08-0B228E-KEY ASS'Y - KEY BD 1

18-CB0152-JNX RES. C.F. 1.5k OHM 1/6W +/-5% 1 R1027

18-CB0182-JNX RES. C.F. 1.8K OHM 1/6W +/-5% 1 R1026

18-CB0272-JNX RES. C.F. 2.7k OHM 1/6W +/-5% 1 R1025

18-CB0432-JNX RES. C.F. 4.3K OHM 1/6W +/-5% 1 R1024

18-CB0622-JNX RES. C.F. 6.2k OHM 1/6W +/-5% 1 R1023

40-29128E-KEA1X P.C.B. KEY BD 1

46-CE040T-02J HS 2P 2468#24 400MM TJC3-2Y 1 P1005 FOR M.BD P005A

48-TAC001-XX0 TACT SWITCH 1 S1001

48-TAC001-XX0 TACT SWITCH 1 S1002

28

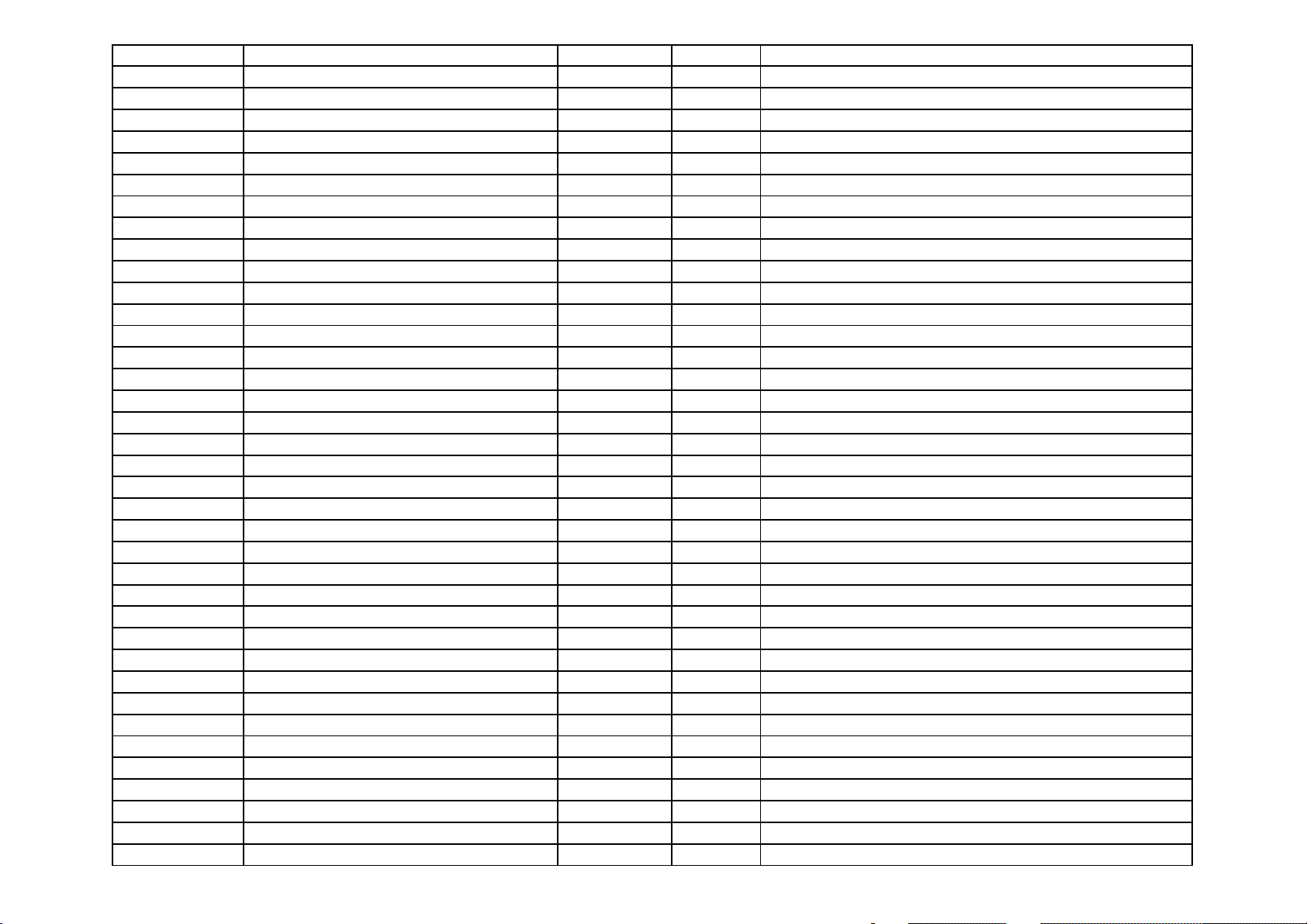

Page 29

Item No. Description Quantity Req. Designator Remarks

48-TAC001-XX0 TACT SWITCH 1 S1003

48-TAC001-XX0 TACT SWITCH 1 S1004

48-TAC001-XX0 TACT SWITCH 1 S1005

48-TAC001-XX0 TACT SWITCH 1 S1006

08-0B228E-SWN ASS'Y - SWITCH BD 1

14-LED05B-XX2 LED BT-504BUW-31-470E-B6 1 D080

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R090

18-CB0470-JNX RES. C.F. 47 OHM 1/6W +/-5% 1 R089

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C080

41-WJ0085-B00 WIRE BARE JUMPER 8.5MM 1 J081

46-28559W-02X PIN BASE *2 TJC1-2A 1 S1002

46-35184W-03X PIN BASE *3 TJC1-3A 1 S1001 FOR POWER CORD

46-35049H-02X HS 2P 1617#22 350 TJC1-2Y/TJC1-2Y 1 FOR PWR SW. BD(S1002) & PWR PARTS

48-POW001-AX0 SWITCH POWER 1 SW1001

51-DC0230-0LG06 POWER CORD L=2.3M 1

62-226920-0HA LED HOLDER ABS-LG H121 (HB) 1

40-B228SM-SWA1X P.C.B. SWITCH BD 1

46-37030H-05X HS 5P 2468#24 450 TJC3-5Y/SCN 1 P005 FOR M.BD P001

11-C124ES-0BX TRANSISTOR PDTC124ES (NPN) 1 Q082

02-IRR001-XX1 IR RECEIVER MODULE HRM380017 1 IR001

62-265160-0HA POWER SW. ADAPTOR 1

08-A1864E-SYY ASS'-SYY BD 1

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q204

18-CB0121-JNX RES. C.F. 120 OHM 1/6W +/-5% 1 R217

18-CB0121-JNX RES. C.F. 120 OHM 1/6W +/-5% 1 R218

18-CB0271-JNX RES. C.F. 270 OHM 1/6W +/-5% 1 R250

34-R829J2-0EX COIL PL - 8.2 UH +/-5% 1 L204

40-3418ME-SYA P.C.B. SYSTEM BD 1

41-WJ0025-B00 WIRE BARE JUMPER 2.5mm 1 FOR Q205 (C - E)

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J250

45-TRA5M5-0Y0 CER TRAP TPS 5.5MHZ 1 X203

46-21550W-05X HEADER *5 TS3B-SQ-1 1 S205 FOR M. BD P205

08-325000-SKY ASS'Y - ACCESSORY PACKING(SKD) 1

76-002091-0AT CARTON BOX LWH 624X384X556MM 0.0036

76-326350-01A CARTON SHEET 61X37X0.3CM 0.0619

08-B2284E-OT2 ASS'Y -OTHER PARTS OF MAIN BD 1

07-389FI5-NB1 TUNER 1 TU101

29

Page 30

Item No. Description Quantity Req. Designator Remarks

11-DD3402-0AX TRANSISTOR 3DD3402 1 Q411

13-A25V04-TOP IC TCL-A25V04-TO 1 IC101

13-TDA894-4JS IC TDA8944J 1 IC602

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R045

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R009

18-CB0103-JNX RES. C.F. 10K OHM 1/6W +/-5% 1 R037

18-CB0123-JNX RES. C.F. 12k OHM 1/6W +/-5% 1 R432

18-CB0123-JNX RES. C.F. 12k OHM 1/6W +/-5% 1 R413

18-CB0471-JNX RES. C.F. 470 OHM 1/6W +/-5% 1 R044

18-CB0123-JNX RES. C.F. 12k OHM 1/6W +/-5% 1 R417A

18-CB0563-JNX RES. C.F. 56K OHM 1/6W +/-5% 1 R414

18-CB0753-JNX RES. C.F. 75K OHM 1/6W +/-5% 1 C211

18-CB0820-JNX RES. C.F. 82 OHM 1/6W +/-5% 1 R901

18-CB0912-JNX RES. C.F. 9.1K OHM 1/6W +/-5% 1 R416

18-EG0109-JHX RES. FUS. 1 OHM 2W +/-5% 1 R431

18-EG0229-JHX RES. FUS. 2.2 OHM 2W +/-5% 1 R461

18-FF0159-JGX RES. M.O. 1.5 OHM 1W +/-5% 1 R304

18-FG0129-JHX RES. M.O. 1.2 OHM 2W +/-5% 1 R313

18-RF0109-JGX RES. WIRE ROUND 1 OHM 1W +/-5% 1 R433

25-BCB221-M1X CAP. ELEC 220 UF 16V +/-20% 1 C245

25-BCB221-M1X CAP. ELEC 220 UF 16V +/-20% 1 C210

25-BMJ221-M1X CAP. ELEC 220 UF 400V +/-20% 1 C806

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C001

26-EBP331-JCX CAP. CER 330PF 50V +/-5% CH 1 C035

27-ALQ392-J0X CAP. M.PP 3900PF 1.6KV +/-5% 1 C411

27-ALR512-J0X CAP. M.PP 5100 pF 1.6KV +/-5% 1 C414

27-ALR822-J0X CAP. M.PP 8200 PF 1.6KV +/-5% 1 C412

27-MBC472-J0X CAP. M.P.E. 0.0047UF 63V +/-5% 1 C645

27-MBC472-J0X CAP. M.P.E. 0.0047UF 63V +/-5% 1 C646

27-MCC102-J0X CAP. M.P.E 1000PF 100V +/-5% 1 C311

27-RHQ223-J0X CAP. PP 0.022 UF 400V +/-5% 1 C413

36-LIN180-XX1 COIL LINEARITY 18 UH 1 L414

37-FCA001-EAA0C FBT JF0501-21130 1 T402

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 JP901

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 JP902

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 JP904

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 D209

30

Page 31

Item No. Description Quantity Req. Designator Remarks

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J401

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J204A

45-SAW296-6M00G SAW FILTER K2966M 1 Z101

46-28559W-02X PIN BASE *2 TJC1-2A 1 P801

46-12866W-02X PIN BASE *2 S11-02Y 1 P601 FOR P601H

46-33079W-02X PIN BASE *2 TJC3-2A 1 P602 FOR P602H

46-33079W-07X PIN BASE *7 TJC3-7A 1 P921 FOR SIDE AV BD

47-RCA023-XX1 RCA JACK 3PV YEL WHI RED/SW 1 P904

47-RCA023-XX1 RCA JACK 3PV YEL WHI RED/SW 1 P906

50-03150D-1GS1 FUSE 3.15AT 250VAC 5mmX20mm 1 F801

62-B159MB-3UN MAIN BD BRACKET 1

63-W30100-AB4 S/T SCREW W 3 X 10 AB 8 MTG M.BD & M.BD BKT

67-H34423-4A0 HEAT SINK 1 FOR IC602

71-270870-0A9 LABEL 2

90-209770-SR1 SILICONE GREASE G-746 0.0015 FOR Q411,Q414,IC602,IC301,Q801

90-269080-ZU0 CLEAN COATING TC-131L 14KG/BARREL 0.0001

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R010

26-ABC100-JCX CAP. CER 10 PF 50V +/-5% NPO 1 C052

26-ABC360-JCX CAP. CER 36 PF 50V +/-5% NPO 1 C054

27-MBC334-J0X CAP. M.P.E 0.33UF 63V +/-5% 1 C309

18-FF0181-JGX RES. M.O. 180 OHM 1W +/-5% 1 R309

36-WID601-XX1 COIL CHOKE 600 UH 1 L413

26-EBP181-JCX CAP. CER 180PF 50V +/-5% CH 1 C008

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R006

18-CB0472-JNX RES. C.F. 4.7k OHM 1/6W +/-5% 1 R005

27-AGQ394-JSX CAP. M.PP 0.39UF 250VAC +/-5% 1 C419

57-10654X-00F

cable ties(2.5mmX95mm) 5

41-WJ0060-B00 WIRE BARE JUMPER 6mm 1 J315

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R237

40-3418ME-MAI1X P.C.B. MAIN PCB BD 1

66-343740-0B0 HOLLOW RIVET (2.3mmx4.0mmx3.5mm) 2 FOR IC602

41-WJ0150-B00 WIRE BARE JUMPER 15MM 1 J227A

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R602

18-CB0222-JNX RES. C.F. 2.2k OHM 1/6W +/-5% 1 R612

26-EBP103-ZFX CAP. CER 0.01UF 50V +80/-20% F 1 C222

25-BCB470-M1X CAP. ELEC 47 UF 16V +/-20% 1 C241A

18-CB0332-JNX RES. C.F. 3.3k OHM 1/6W +/-5% 1 J219

31

Page 32

Item No. Description Quantity Req. Designator Remarks

41-WJ0090-B00 WIRE BARE JUMPER 9MM 1 J906

11-SC1815-YBX TRANSISTOR 2SC1815Y 1 Q212

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R231

18-CB0331-JNX RES. C.F. 330 OHM 1/6W +/-5% 1 R232

18-CB0102-JNX RES. C.F. 1K OHM 1/6W +/-5% 1 R233

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 JP903

41-WJ0050-B00 WIRE BARE JUMPER 5MM 1 JP1201

41-WJ0195-B00 WIRE BARE JUMPER 19.5MM 1 JP1202

46-37204H-02X HS 2P 1185#26 220 SCN-2Y/SCN-2Y 1 FOR P603 TO P605

47-SPK003-XX0 JACK SUPER WOOFER (2128SZ) 1 P606

26-EBP104-ZFX CAP. CER 0.1UF 50V +80%/-20% 1 C816A

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J203

41-WJ0135-B00 WIRE BARE JUMPER 13.5MM 1 J204

46-33079W-02X PIN BASE *2 TJC3-2A 1 P005A FOR KEY BD

08-HS46F0-A113C 1

11-0BC337-0BX TRANSISTOR (NPN) BC337-40 1 Q1501

13-00AS12-13B IC AS1213B 1 IC1501

14-IRE05B-XX0 IR EMITTING DIODE TSAL6200 1 D1501

18-CB0221-JNX RES. C.F. 220 OHM 1/6W +/-5% 1 R1503

18-CB0229-JNX RES. C.F. 2.2 OHM 1/6W +/-5% 1 R1501

25-BCB101-M1X CAP. ELEC 100 UF 16V +/-20% 1 C1504

26-EBP101-JCX CAP. CER 100PF 50V +/-5% CH 1 C1501

26-EBP101-JCX CAP. CER 100PF 50V +/-5% CH 1 C1502

26-EBP104-ZFX CAP. CER 0.1UF 50V +80%/-20% 1 C1503

40-UOCASF-RMA P.C.B. REMOTE HANDSET BD 1

45-COS455-KY1 CERAMIC RESONATOR 455KHz 1 X1501

49-HS46F0-00X RUBBER PAD KEYS 1

55-HS46FB-0HA CASE LOWER - REMOTE HANDSET 1

55-HS46FD-0HA DOOR BATT. - REMOTE HANDSET 1

55-HS46FT-0HA CASE UPPER - REMOTE HANDSET 1

58-HS46F4-8UI INLAY REMOTE HANDSET 1

63-B26060-BT2 S/T SCREW B 2.6 X 6 BT 1

67-X26968-0E2 BATT. TERMINAL (+/-) 1

67-X31028-0E2 SPRING - BATTERY (-) 1

67-X31029-0E2 SPRING - BATTERY (+) 1

74-009022-60C POLYBAG HANDSET (9CMX22CM) 1

08-HS46F0-PAY ASS'Y - PACKING OF IR HANDSET 1

32

Page 33

Item No. Description Quantity Req. Designator Remarks

76-002091-0AT CARTON BOX LWH 624X384X556MM 0.0031

76-326350-01A CARTON SHEET 61X37X0.3CM 0.062

08-0B228E-FCN ASS'Y - FRONT CABINET 1

02-GND029-XX3 ASS"Y-CRT GND WIRE&HOUSE 1

36-DEG290-XX1 DEGAUSSING COIL 3100MM 1

42-61308F-XX2 SPEAKER 8 OHM 8W 1 SP601

42-61308F-XX2 SPEAKER 8 OHM 8W 1 SP602

44-29SFLN-BP1A CRT M68LWF088X50 1 CRT01

46-14026H-02X HS 2P 2468#22 570mm S11-2Y/7mm 1 P601H FOR M.BD P601

46-26514H-04X HS 4P A/B 500/13 RBGW TJC1-4Y 1 P411H FOR D.Y COIL

46-27580H-02X HS 2P22 600/7 TJC3-2Y 1 P602H FOR M.BD P602

54-113970-0U0 PVC TUBE #5 L=ROLL 0.32 FOR SPK HOUSING

54-205140-000 SPACER CRT MOUNTING T=2MM 4 MTG CRT & F. CAB.

54-310140-000 SPONGE 50 X 20MM (BKK) 2 FOR HI-SPK

54-314740-0X0 CRT FIBRE SHEET (22mmX22mmX0.8mm) 8 FOR CRT & F. CAB.

55-B228FC-0CN FRONT CABINET 1

56-B228FB-0HA PUSH BUTTON 1

56-B228LS-0HC DISPLAY LENS 1

56-B228PK-0HA POWER KNOB 1

54-114000-00X FELT TAPE (150mmX19mmX0.3mm) 9 STICK ON F.CAB

59-130460-00X RUBBER PAD (25mmX7mm) 2 STICK ON F.CAB. (FOOTING)

59-312160-000 SPEAKER RUBBER CUSHION 8 FOR SPK

62-389500-1CN CRT SUPPORT 2

63-Z60300-AB4 S/T SCREW HA 6X30 4 MTG CRT & F. CAB.

63-W30100-AB4 S/T SCREW W 3 X 10 AB 5 MTG PUSH BUTTON AND KEY BD & F. CAB.

63-W30100-AB4 S/T SCREW W 3 X 10 AB 1 MTG LENS TO F.CAB.

63-W30100-AB4 S/T SCREW W 3 X 10 AB 2 MTG SWITCH BD & F. CAB.

63-W30140-HS4 S/T SCREW W 3 X 14 HS 8 MTG SPK TO F.CAB.

65-A35150-12E WASHER 3.5mmX15.0mmX1.2mm 2 FOR SWITCH BD

67-X21679-0E0 SPRING CRT 6mmX50mmX0.6mm 2

67-X25045-0E0 SPRING KNOB 1

54-237930-0X0 HEAT SHRINKABLE TUBE 5*0.25 0.03

57-10654X-00F

cable ties(2.5mmX95mm) 8

08-0B228E-RCY ASS'Y - REAR CABINET 1

54-114000-00X FELT TAPE (150mmX19mmX0.3mm) 10 STICK ON R.CAB

55-B189RC-4EN REAR CABINET 1

58-B189RI-QUI INLAY REAR AV 1

33

Page 34

Item No. Description Quantity Req. Designator Remarks

58-B228MP-0UI PLATE MODEL NO. 1

58-D106SI-0UI INLAY SIDE AV 1

59-130460-00X RUBBER PAD (25mmX7mm) 2 STICK ON REAR CAB.(FOOTING)

62-389620-0UD POWER LINE BLOCK 1

63-B40200-AB3 S/T SCREW B 4 X 20 AB 10 MTG FRONT & REAR CABINET

63-F30100-BT3 S/T SCREW F 3 X 10 BT (BLACK) 3 MTG RCA JACK & REAR CABINET

63-W30100-AB4 S/T SCREW W 3 X 10 AB 2 MTG SIDE AV BD & REAR CAB.

08-B2284E-PAN ASS'Y - PACKING PARTS 1

02-WDF020-XX4 CARTON BOX OF WOOFER (BIG/SMALL) 1

49-382550-BAT BATTERY R06P AA 1.5V 5# 2

74-022032-6WE POLYBAG (23cmX34cmX0.06mm) 1

74-130130-80HAA POLYBAG W/SUFFOCATION WARNING 1

75-B228LL-CC0 POLYFOAM "LL" 1

75-B228LR-CC0 POLYFOAM "LR" 1

75-B228UL-CC0 POLYFOAM "UL" 1

75-B228UR-CC0 POLYFOAM "UR" 1

76-A29228-0AT CARTON BOX 1

74-010050-40C POLYBAG FOR POWER (10CMX50CM) 1

72-B2284E-E04 OPERATION MANUAL 1

08-029276-FRY 1

74-120120-8CD POLYBAG (120CMX120CM) 1 FOR FRONT CABINET

74-145120-8CD POLYBAG (145CMX120CM) 1 FOR REAR CABINET

74-344740-50C EPE BOARD ((750MMX580MMX5MM) 0.25 FOR FRONT CABINET

76-001497-0AF CARTON BOX LWH 640X460X360MM 0.0416 FOR OTHER

76-002913-0AR CARTON BOX 0.3333 FOR REAR CABINET

76-002935-0AF CARTON BOX 0.25 FOR FRONT CABINET

76-346740-01A CARTON SHEET LWH 440X620X3MM 0.037 FOR OTHER

77-120120-6WC BUBBLE BAG (120cmX120cm) 0.5 FOR FRONT CABINET

08-0B276E-YUY 1

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R206

18-CB0101-JNX RES. C.F. 100 OHM 1/6W +/-5% 1 R207

18-CB0820-JNX RES. C.F. 82 OHM 1/6W +/-5% 1 R206A

18-CB0820-JNX RES. C.F. 82 OHM 1/6W +/-5% 1 R207A

47-RCA089-XX0 RCA SOCKET AV-3.2-3LK-N2 1 P903

41-WJ0075-B00 WIRE BARE JUMPER 7.5MM 1 J903

34

Page 35

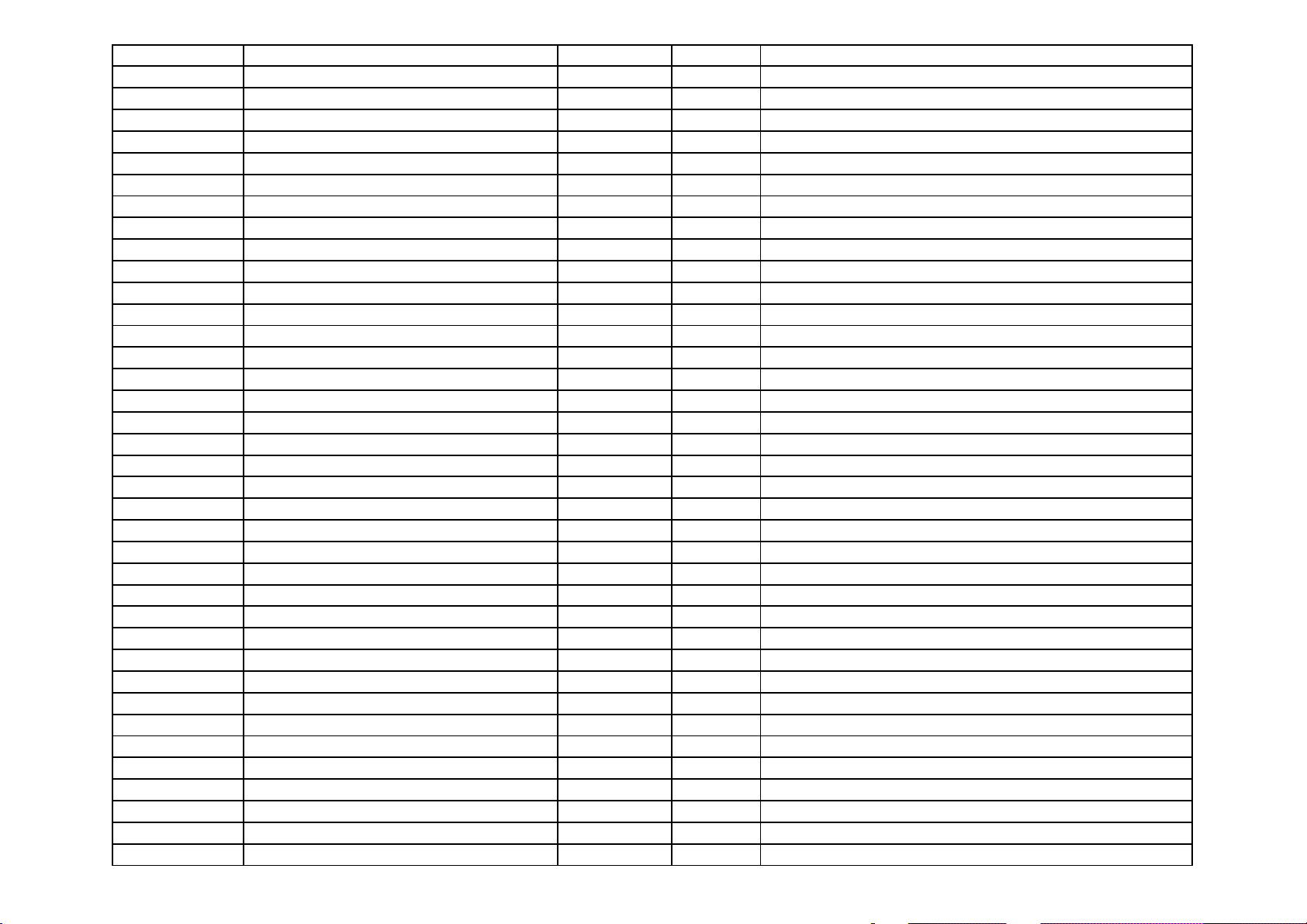

TCL M113A chassis alignment instruction

Enter factory mode in production line

Simply press the D-mode key on the factory remote handset.

Enter service mode

Press and hold the VOLUME DOWN key tightly on the unit until minimum level and don’t release the

VOLUMN DOWN key, then press the DISPLAY key on the remote handset.

“D” letter on the screen indicated that the factory mode was entered. Now you can use the shortcut key

to access the factory menu. All change in factory data will save in EEPROM automatically

Note:

1. You can disable the D-Mode key (on factory remote handset) by change “BIT-0” of “OPT” to “0”.

If the D-Mode key was disabled, you can’t enter D-Mode by the D-mode key on the factory remote

(but you can still enter service mode). It is suggested to disable the D-Mode key before the set

leave the factory.

2. On the factory remote handset, you can find the “I²C” key. It can cut off the I2C control from the

CPU to other IC. This is only useful when automatic adjustment of white balance.

3. All system data in menu of “key 6” must keep unchanged when servicing. Otherwise, the set may

not work properly.

Setting method:

No Adjustment

Items

1 Screen

voltage

2 Focus voltage ------------ Cross hatch

3 Vertical

geometry for

PAL system

(Key 1)

Data Name (default

value inside blanket)

------------ “IRGB cut off”

HIT(11)

VP50(04)

VLIN(0B)

VSC(09)

VBLK(00)

VCEN(1B)

OSDH(1F)

DPC43(00)

Conditions and

input signal

must set to 80 (all

Input a PAL cross

hatch pattern.

pattern)

pattern.

Setting method (need enter D-mode)

Press “MUTE” key on the remote handset

and the screen will become a horizontal

line. Then adjust the “screen” VR on the

flyback until the horizontal line can just

be seen (minimum visible intensity).

Adjust the “focus” VR on the flyback

until the screen becomes clear.

Adjust HIT for vertical amplitude.

Adjust VP50 for vertical position.

Adjust VLIN for vertical linearity.

Adjust VSC for vertical S-correction

(Normally use default value)

Adjust VCEN for vertical position

Adjust OSDH for OSD position

Same as DPC, adjust it on EXPAND 4:3

mode.

Page 36

4 Vertical

p

geometry for

NTSC system

(Key 1)

5 Horizontal

geometry for

PAL system

(Key 2)

6 Horizontal

geometry for

NTSC system

(Key 2)

HITS(11)

VP60(02)

VLIS(0A)

VSS(08)

VBLK(00)

VCEN(1C)

OSDHS(1D)

DPC43S(00)

HPOS(0C)

DPC(23)

KEY(20)

WID(22)

ECCT(09)

ECCB(0A)

VEHT(04)

HEHT(04)

HPS (10)

DPCS(1F)

KEYS(1F)

WIDS(22)

ECCTS(0E)

ECCBS(10)

VEHTS(04)

HEHTS(04)

Input a NTSC

cross hatch

pattern.

Input a PAL cross

hatch pattern with

black and white

background.

Input a NTSC

cross hatch

attern with black

and white

background.

Adjust HITS for vertical amplitude.

Adjust VP60 for vertical position.

Adjust VLINS for vertical linearity.

Adjust VSS for vertical S-correction

(normally use default value)

Adjust VCEN for vertical position.

Adjust OSDHS for OSD position

Same as DPC, adjust it on EXPAND 4:3

mode.

Adjust HPOS for horizontal position.

Adjust DPC, KEY, ECCT and ECCB until

the vertical line at left and right side of the

picture become straight.

Adjust WID for horizontal width.

VEHT and HENT is for the picture size

stability when changing the brightness of

the screen. Receive pattern of cross hatch

with black background and then change to

white background, then compare the

vertical and horizontal size between black

and white background. Adjust VEHT and

HEHT until you get the minimum

difference of screen size. After you adjust

VEHT and HEHT, you must re-adjust

vertical and horizontal amplitude.

Adjust HPS for horizontal position.

Adjust DPCS, KEYS, ECCTS and

ECCBS until the vertical line at left and

right side of the picture become straight.

Adjust WIDS for horizontal width.

Adjust VEHTS and HEHTS using same

method of PAL system. Also need

re-adjustment of vertical and horizontal

amplitude.

7 Key 3

(Status

adjustment)

8 Key 4

(Status

adjustment)

CNTX (5A)

CNTN (07)

BRTX (20)

BRTN (1D)

COLX (3F)

COLN (00)

TNTX (42)

TNTN (28)

BRTC (30)

COLC (57)

COLS (47)

COLP (F0)

SCOL(04)

SCNT (0F)

CNTC (40)

TNTC (48)

---------- (all use default value)

---------- (all use default value)

Page 37

9 Key 5

(sharpness

adjustment)

10 Key 7

(Status

adjustment)

11 Key 8

(curve of

volume

control,

curve of

B.E./WOO-

FER)

12 Key 9

(curve of

B.E./WOO-

FER)

ST3 (20)

SV3 (20)

ST4 (20)

SV4 (20)

SVD(15)

ASSH(04)

SHPX (3F)

SHPN (1A)

RFAGC (1A)

SBY (08)

SRY (08)

BRTS (0D)

TXCX (1F)

RGCN (00)

SECD(08)

MUTT(20)

STAT(60)

V01(3A)

V25(B0)

V50(DC)

V100(FF)

BASC(40)

BASX(72)

TREC(40)

WOFC(39)

AV C ( 0 E )

NEWS(14)

SPACES(5A)

NEWT(14)

SPACET(5A)

WOFF(00)

B01(4F)

B25(68)

B50(7F)

---------- (all use default value)

Receive a 60dB

grey scale +

color bar signal

---------- (all use default value)

---------- (all use default value)

Adjust RFAGC until the picture noises

disappear exactly.

Adjust SBY and SRY to get the optimal

color for SECAM system.

For the adjustment of BRTS, receive an 8

step grey scale pattern and adjust all

picture settings to 50%. Then adjust BRTS

until the first and second step on the

screen can just be distinguished.

(the other use default value)

13 Key calendar

(other

adjustment)

14 Key note

(other

adjustment)

SVM(05)

SVM1(05)

SVM2(05)

SVM3(05)

PYNX(28)

PYNN(15)

PYXS(22)

PYNS(04)

CLTO(4B)

CLTM(4C)

CLVO(4D)

CLVD(48)

ABL(27)

DCBS(33)

DEF(01)

---------- (all use default value)

---------- (all use default value)

Page 38

15 Key game

(other

adjustment)

16 Key 0

(White

balance

adjustment)

System data:

Item Adjust item Default value

OSD1(2B)

OSDF1(63)

OSD2(1C)

OSDF2(63)

HAFC(09)

NOIS(01)

UCOM(00)

R CUT (80)

G CUT (80)

B CUT (80)

G DRV (40)

B DRV (40)

---------- (all use default value)

Black and white

pattern (PAL)

1. Measure the dark side of the picture with

a color analyzer and set RCUT to 80.

Then adjust BCUT and GCUT until the

data on the analyzer become x = 284, y =

299.

2. Measure the bright side of the picture,

Then adjust BDRV and GDRV until the

data on the analyzer become x = 284, y =

299.

3. Repeat step 1 and 2 until you get right

color on both dark and bright side of the

screen.

Key6 OPT

FLG0

FLG1

STBY

HD-DELAY

MODE0