Page 1

Installation manual (EN/UK)

Modore 75H

Leave these instructions as manual with the device

Warning:

The combustion chamber of this stove should only be opened and serviced

by a registered gas installer.

Page 2

Page 3

InstallatIon manual

3

1 CE declaration ����������������������������������������������������������������������������������� 4

1�1 Ceramic parts ���������������������������������������������������������������������������������� 4

1�2 Renovation/construction ����������������������������������������������������������������� 4

2 Important safety information �������������������������������������������������������������4

2.1 Using the replace the rst time ����������������������������������������������������� 4

3 Remote control with full electronic ignition ������������������������������������ 5

3�1 Adjusting the communication code �������������������������������������������������5

3�1�1 Igniting the pilot light ������������������������������������������������������������������5

3�1�2 Igniting the main burner� ��������������������������������������������������������������5

3.1.3 Switching off the replace �����������������������������������������������������������5

4 Installation requirements ������������������������������������������������������������������� 6

4�1 Distance between combustible materials ���������������������������������������� 6

4.2 Important points - replace ������������������������������������������������������������� 6

4�3 Important points gas connection ����������������������������������������������������� 6

4�4 Important points casing ������������������������������������������������������������������� 6

4�5 Requirements for exhaust and outlets ��������������������������������������������� 6

5 Preparation and installation instructions �������������������������������������������� 6

5�1 Gas connection ������������������������������������������������������������������������������� 6

5�2 Fireplace ������������������������������������������������������������������������������������������ 6

5�3 Assembly and placement of discharge material �����������������������������7

5�4 False chimney breast ����������������������������������������������������������������������� 7

5�4�1 Fireproof setup ���������������������������������������������������������������������������� 7

5.5 Mounting and nishing ������������������������������������������������������������������ 7

6 Electric connection �����������������������������������������������������������������������������7

6�1 Automation ������������������������������������������������������������������������������������� 7

6�2 Element4 ProControl App� �������������������������������������������������������������7

7 Glass removal �������������������������������������������������������������������������������������8

8 Installing the decorative material ������������������������������������������������������� 9

9 Check installation and rst use ���������������������������������������������������������� 9

10 Important points installation ���������������������������������������������������������� 10

10.1 Installing ue ������������������������������������������������������������������������������10

10�1�1 Adapting the length of the chimney �����������������������������������������10

11 Calculate chimney ��������������������������������������������������������������������������10

11�1 Power-Fan �����������������������������������������������������������������������������������10

11�2 Main chimney rules� ��������������������������������������������������������������������10

11�2�1 Determining the chimney diameter ������������������������������������������10

11�2�2 Determining the maximum vertical length ������������������������������10

11�2�3 Determining the maximum horizontal length ��������������������������10

11�2�4 Calculating Total Vertical Part (TVP) ������������������������������������� 10

11�2�5 Calculating Total Horizontal Part (THP) ��������������������������������� 10

11�2�6 Flue gas restrictor ��������������������������������������������������������������������� 11

11�2�7 Calculation table horizontal outlet pipe diameter 200/130 ������12

11�2�8 Calculation table vertical outlet pipe diameter 200/130 ����������13

12 Outlet location �������������������������������������������������������������������������������� 14

12�1 Location at roof outlet ����������������������������������������������������������������� 15

13 Technical data �������������������������������������������������������������������������������16

14 Instructions for use ������������������������������������������������������������������������� 17

14�1 Handover to customer ����������������������������������������������������������������� 17

14�2 Maintenance instructions for installer ���������������������������������������� 17

14.3 Anti-reective glass ��������������������������������������������������������������������17

14�4 Replacement of parts ������������������������������������������������������������������17

15 Emergency repairs �������������������������������������������������������������������������18

16 Packaging materials ����������������������������������������������������������������������� 20

17 Dimensional drawings ������������������������������������������������������������������20

17�1 Control hatch, BDLE4 ���������������������������������������������������������������� 20

17�2 Modore 75H �������������������������������������������������������������������������������� 21

18 Parts Ontop ue material ���������������������������������������������������������������22

19 Warranty conditions ����������������������������������������������������������������������� 28

Table of content

Page 4

InstallatIon manual

4

1 CE declaration

We hereby declare that the design and construction of the

gas decorative heating appliance by Element4 complies

with the requirements of the Gas appliances directive�

Product: gas decorative heating appliance

Models: Modore 75H E4-19

Applicable EC-directives: 90/396/EEC

Applied harmonised standards: NEN-EN-613

NEN-EN-613/A1

1.1 Ceramic parts

This device is equipped with a ceramic re bed with heatresistant ceramic bres, being articial vitreous silicate

bres. Excessive exposure to this material can irritate

the eyes, skin and airways� Therefore, when dealing with

these materials, we recommend that dust emissions be

minimised as much as possible�

1.2 Renovation/construction

Discoloration of walls is a annoying problem and is

difcult to solve. As a replace is a heat source, air

circulation is created� Due to natural air circulation,

moisture, cigarette smoke and not yet cured volatile

components from paint, building materials and carpeted

oors and such are sucked in. These things can settle on

cold surfaces as soot�

With a newly plastered replace or after renovation, it is

recommended to wait at least 6 weeks before ring. The

building moisture must be totally evaporated from walls,

oor and ceiling.

2 Important safety information

The replace may only be installed by a qualied

installer/dealer� Follow the installation manual� We

urgently advise you to read the

installation directions properly�

Check the replace for transport damage, report

any damage immediately to your supplier�

Check if the details on the name plate

correspond with the local gas type and pressure�

The name plate is xed to the replace.

Make sure this is reachable at all times�

The replace must never be used without a window or

with a broken window, ue gases can then freely enter

the installation area�

The settings and the construction of the replace

may not be changed!

Parts, if required, should only be replaced with original

parts from the manufacturer�

Do not place additional imitation wood or glowing

material on the burner or in the combustion chamber�

This unit is designed for use with natural gas or LPG�

However, each unit is only suitable for the type of gas

that is specied at the time of the purchase.

Please note: once a kind of gas is specied, the replace

cannot burn on another gas� The type of gas your

replace requires, is indicated on the name plate.

This unit has been developed as a heating device and all

its parts, including the glass are therefore very hot during

use. (exceeding 100 degrees) never touch the replace

during use�

The heat coming from this unit, can affect materials in

the immediate vicinity� Curtains should hang at least 50

centimetre away�

Floors, walls and covers (ceilings) should be non-

combustible in the area where a re hazard is present due

to heat radiation of the appliance and/or chimney�

2.1 Using the replace the rst time

Stoke the re the rst time for a few hours on the highest

setting, so the paint gets a chance to harden� Provide

adequate ventilation, so any fumes being released can

be discharged� We recommend being as little as possible

present in the space during this process�

For information:

Combustible materials such as wood can catch re from

a temperature of 85 C� This can be within a few minutes

(at high temperatures > 200 C) to within a few weeks (at

low temperatures > 85 C)� An atmospheric unit can have

a temperature on the outside that can be up to 150 C�

If you use insulation material in the construction, use

white unbounded insulation wool, which is heat-resistant

up to 1000 degrees C� Never use glass or mineral wool�

These can release unpleasant odours with heat�

Page 5

InstallatIon manual

5

3.1.3 Switching off the replace

You switch off the replace by pressing the on/off button,

this also turns off the pilot light!

For a detailed description of the E-save remote control,

please refer to the E-save manual which is included with

the replace.

1

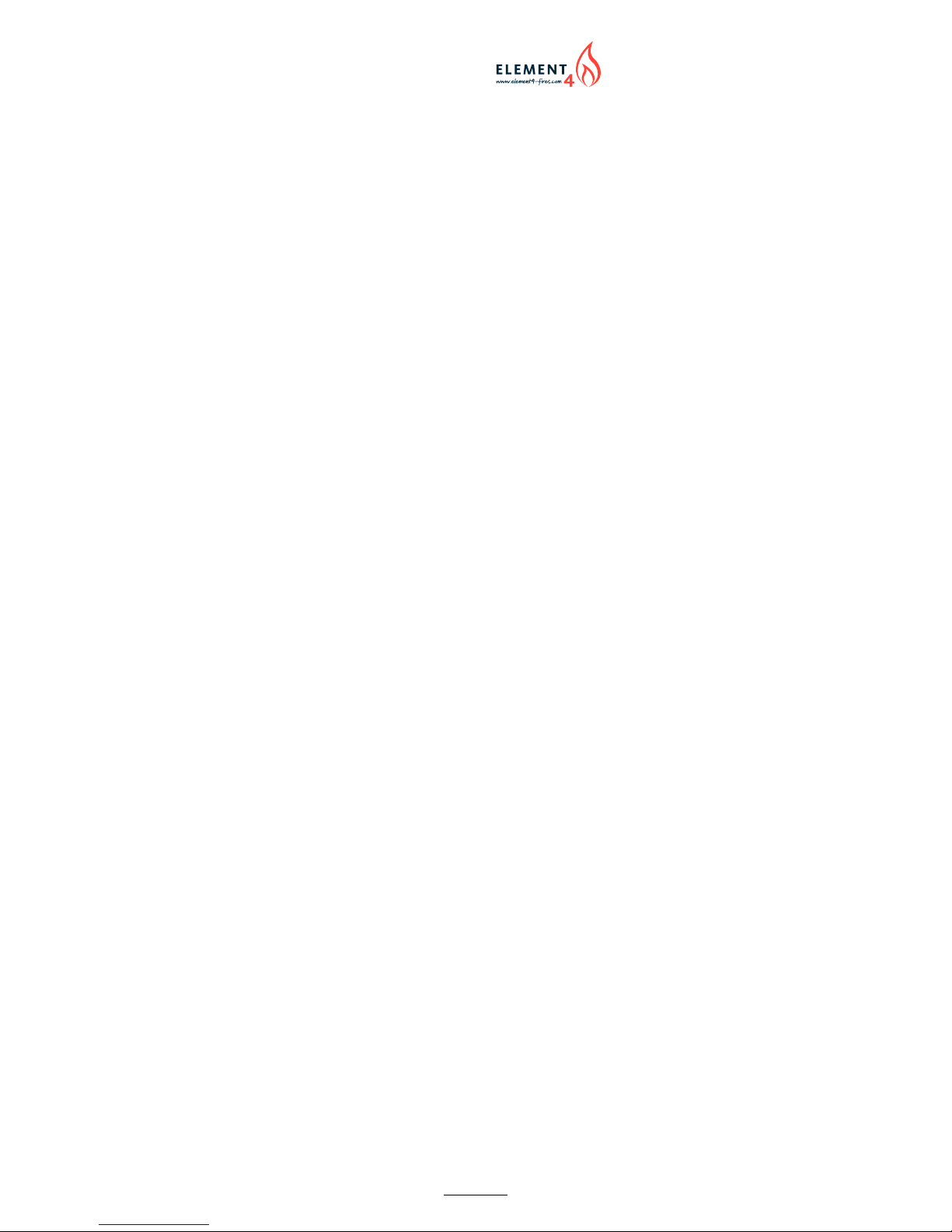

3 Remote control with full electronic ignition

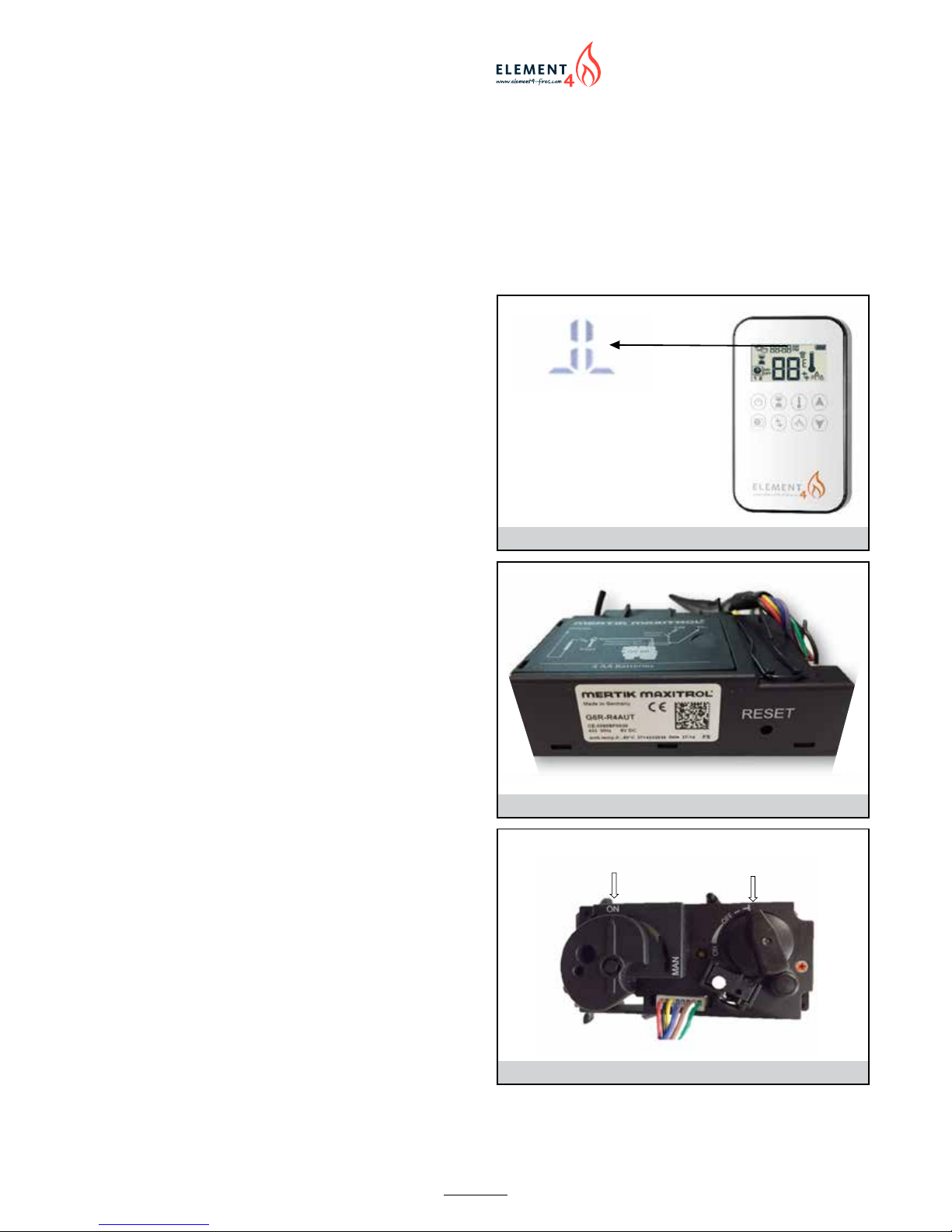

The unit is operated using a remote control (g. 1). The

ignition, regulating the ame height and switching off is

done using the remote control, operating a receiver (g.

2) in the control box�

The receiver and the remote control is powered by

batteries� 4 pen lite (type AA) batteries are required for

the receiver; 2 penlight batteries (type AAA) for the

remote control� The life of the batteries is about a year

with normal use�

3.1 Adjusting the communication code

Before taking the appliance in use, a communication code

must be set between the remote control and the receiver�

The code is chosen at random from the 65000 available

codes� Therefore the chances are small that other remotes

in your area use the same code�

You must work as follows:

Press the reset button on the receiver until you hear two

beeps in succession� After the second, longer signal, let

go of the reset button� Fig� 2 Within 20 seconds, press

on the down arrow on the remote control until you

hear a sound signal. This is conrmation of the proper

communication�

3.1.1 Igniting the pilot light

Check that the control knob (A) is in the ON position� Fig

3� Press the button on/off button of your remote control

and continue to hold down (3 to 5 sec�) until you hear two

short peep tones� Flashing lines appear at the top of the

screen (g. 1) now release the button. The start procedure

is started�

NB:

If the pilot light doesn't remain lit after 3 attempts you

must turn off the gas tap and warn your installer.

3.1.2 Igniting the main burner.

After starting the pilot light, button B automatically

switches counter clockwise and the main burner will start

burning� Fig 3

Always wait 5 minutes after killing the pilot light before

you start the pilot ame again.

NB:

The pilot light must ignite the main burner, evenly and

without a thud, if it does thud, close the gas tap and

warn your installer.

2

3

A

B

Page 6

InstallatIon manual

6

4 Installation requirements

This device was developed, tested and approved in

accordance with the applicable standards for use, the

performance and safety of the product� The installation

of your device must comply with current building codes�

We therefore recommend you appoint an accredited

gas installer for the installation� He can give you all

the information about the safety limitations of the

installation�

The installation must be carried out in accordance with

the following regulations:

The Building Regulations issued by the department of

the environment, the Building Standards (Scotland),

regulations issued by the Scottish Development

Department�

BS 5440 part 1, BS 5871 part 2 and BS 6891

In the Republic of Ireland the installation must also

conform to the relevant standards, particularly in regard

to ue sizing and ventilation. Refer to documents IS813,

ICP3, IS327 and any other rules in force�

4.1 Distance between combustible materials

It is important to work carefully according to the

installation requirements� If the installation instructions

do not, or insufciently provide in the aspects of re

safety, than the instructions according to NPR 337820:2010 shall apply�

4.2 Important points - replace

This unit can be placed in a new or existing situation�

This unit can be installed in a fully enclosed or

mechanically ventilated room without extra ventilation�

4.3 Important points gas connection

The gas connection must comply with the applicable

local standards�

4.4 Important points casing

The casing should be of non-combustible material� The

casing ventilation shall comply with the applicable local

Standards� The casing structure should not rest on the

mounting frame of the replace

4.5 Requirements for exhaust and outlets

The European CE mark for this unit applies exclusively

to the ue system specied by the supplier. The unit must

therefore be installed with the stainless steel ue system

US of Metaloterm/On Top� The use of other concentric

stainless steel systems is only permitted if it has the same

technical specications as the aforementioned system US.

Only when using these materials can

Element4 guarantee a safe and proper working�

This warranty is void if the apparatus is installed (fully

or partly) with other materials than with the described

above�

5 Preparation and installation instructions

5.1 Gas connection

Calculate the diameter of the gas pipe in such a way that

there is no pressure loss in the pipe�

Place a shut-off valve in the proximity of the unit,

position the gas connection so that it is easily accessible

for service purposes�

Place the control block and the receiver in the appropriate

openings of the control hatch�

Make sure the regulator and the receiver is properly

accessible for service purposes�

Fig� 4

5.2 Fireplace

Place the replace on a sufciently strong oor, for

example concrete, so that no ammable materials are

present around the device or ue.

There must always be at least 50 mm space between the

appliance and the casing for convection�

see g. 6 for the minimum distances

A = 50 mm

D = 500 mm

5

4

Minimale afstand boezem

D

Page 7

InstallatIon manual

7

5.3 Assembly and placement of discharge material

The combined supply and discharge can go both

through the sides (C11) and the roof (C31)�

Verify that the desired outlet position complies with local

regulations regarding pollution and ventilation openings�

(see page 12 and 13)

For the proper functioning, the mouth must be at least 0�5

m away from:

• Corners of the building�

• Roof overhangs and balconies�

• Roof edges� (except the roof ridge)

A screen may be required if the mouth is within two

metres above the ground�

5.4 False chimney breast

Before the breast is tted, we advise you to carry out

a functional test with the gas replace.

Good ventilation prevents too high a temperature of

the gas regulator and its electronics and also limit the

temperature of the convection air� That's why grills must

be tted and have a ventilating control hatch. Ventilation

should be so that the outowing air remains under the

80grd�

To do this, use for instance the ventilation grills CVRE4

and the control hatch (BDLE4) of Element4, see

dimensional drawing page 22�

Place the ventilation grills 300 mm below the ceiling�

Place a screen plate made of non-combustible material in

the casing directly above the grates�

5.4.1 Fireproof setup

Construct the casing of non-combustible material and use

metal proles. When you use masonry bricks/concrete

bricks always use a lintel or grid iron� The structure may

not be positioned on the replace.

5.5 Mounting and nishing

Never attach the replace to the installation frame

because it will expand during heating up� This allows

cracks to form in the casing material�

NB:

make sure that the window and the mouldings can be

removed after installation in the casing.

Make sure the recess is sufciently large.

Take care with the choice of materials and the radiant

heat in zone D g. 6

6 Electric connection

The standard replace is battery-controlled. As an option,

a special mains power adapter can be supplied� Type

G60-ZMA

6.1 Automation

The receiver offers the possibility to be connected on a

home automation system� A special connection cable can

be supplied for this purpose�

Type: G60- ZCE

6.2 Element4 ProControl App.

It is possible to operate your appliance via Smartphone

or Tablet. Fit the replace with a dedicated receiver and

control box�

Your dealer will provide you with all the information the

App and the electric connections�

6

Page 8

InstallatIon manual

8

7 Glass removal

Before you start:

Prepare a safe place to store the glass plate and use the

suction cup to remove the glass�

Take the following steps to remove the glass:

Remove the edge strips 1, 2 and 3. g. 7.1, Position the

suction cup on the glass sheet. g. 7.2, Remove the glass

cords from the grooves g 7.3, Move the glass up to

the bottom of the groove� Then remove the glass in one

smooth movement from below forward� Fig� 7�4

Replacing the glass and the mouldings are in reverse

order�

NB:

Thoroughly clean the glass before you replace it!

Fingerprints will burn into the glass and can't be

removed again.

See chapter 15 for maintenance�

7�1

7�2

7�3

7�4

Page 9

InstallatIon manual

9

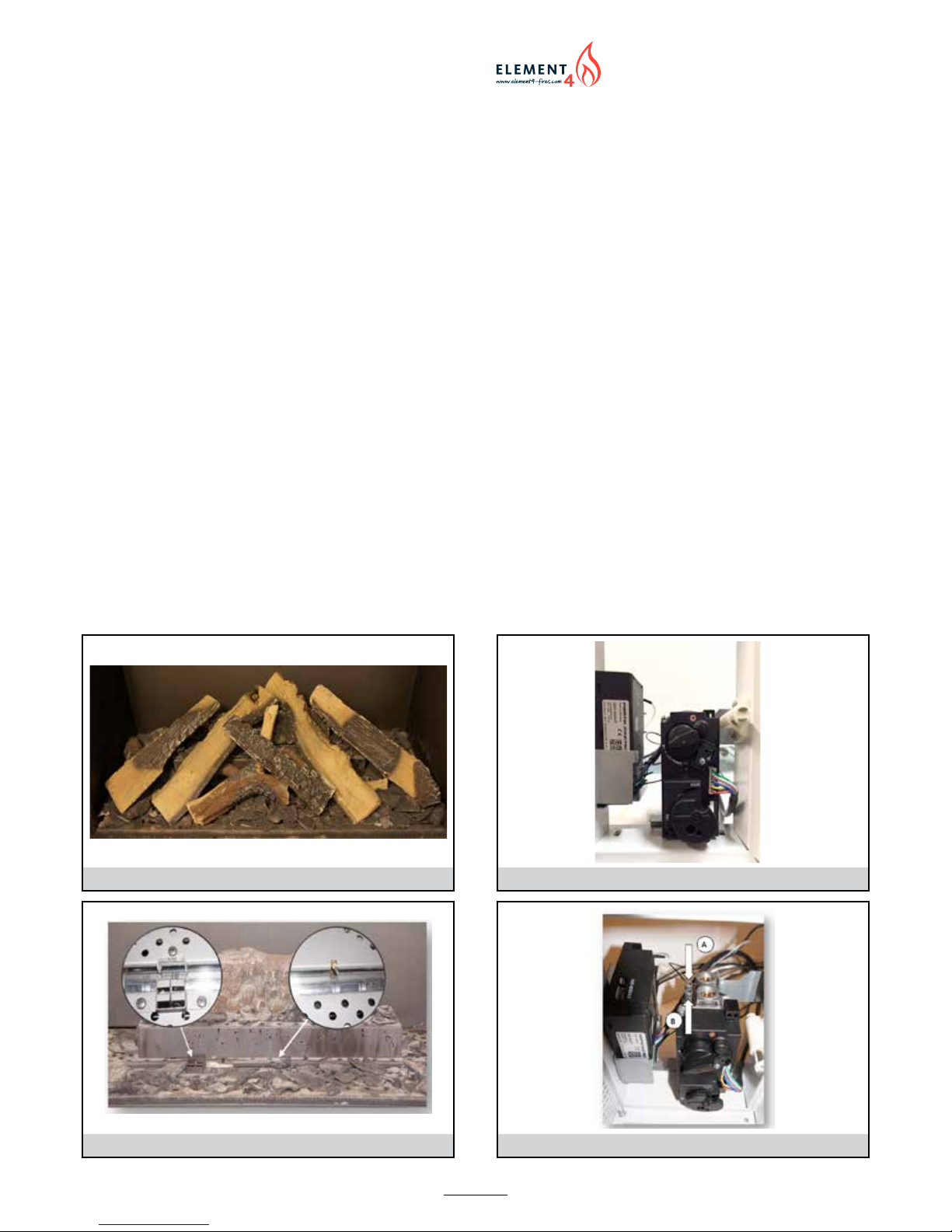

8 Installing the decorative material

Make sure that the grid is placed rmly at the bottom

of the burner chamber and that the long groove in the

middle of the grid lies in one line parallel with the burner

pipe�

The pilot light must be visible through the grid and the

cut-out in the ame protection.

Replace the decorative material according to drawing 8�1

or use the instruction card included�

Take note of the following:

Make sure gaps remain open in different places of the

grid. That the pilot light and thermocouple is away from

decorative material. Fig. 8.2

Sprinkle the included ash on the wood blocks and black

chips. Check that the pilot ame is free and the ignition

works before the window is replaced�

Too many chips or decorative material not inserted

properly will negatively affect the re effect and the

replace can ignite with a "thud"!

9 Check installation and rst use

Remove the glass sheet from the appliance if necessary

and use the pre-pressure measuring nipple on the gas

regulator to bleed the gas pipe! g 9.1 and 9.2.

A= Burner pressure

B= Pre-pressure

• Make sure the ignition cables hang loosely below the

device, this is necessary for proper ignition�

• Remove the cable ties�

• Make sure the pilot light and thermo couple (g. 8.2 )

are free of decorative material�

• Start the pilot light and check the proper ignition of

the main burner�

• Check seals of all gas connections on the device�

8�1 9�1

8�2 9�2

Page 10

InstallatIon manual

10

10 Important points installation

To guarantee re safety around ue material, a casing is

necessary� Use heat resistant sheet materials�

Do not insulate a vent shaft, it must be ventilated! so that

hot air can be removed�

Make the transit of the ue gas system by a partitioning,

wall, ceiling, oor or roof sheathing, so thermal

insulation and re resistance is guaranteed according to

the building Act�

10.1 Installing ue

• Drill a hole of 160 mm for the wall or roof transit

with a 150 mm diameter ue connection, and 210

mm with a ue with a diameter of 200 m.

• Keep a distance of at least 50 mm between the

outside of the concentric pipes and the wall or

ceiling. - Provide a (re) safe transit construction in

wall, oor or roof sheeting

• Build the system from the replace.

• Assemble pipes in the correct direction! The inner

pipe goes into and the outer pipe goes over the

replace connection.

• Make sure the tubes are sufciently braced, so the

weight of the tubes are not supported on the hearth�

• The concentric pipes could come loose due to

expansion and cooling down� It is recommended that

a chuck parker be used in places that are inaccessible

after installation�

• The horizontal drain portion must be tted sloping to

the hearth�

10.1.1 Adapting the length of the chimney

Not all parts can be adjusted!

• To t the drainage system correctly, you are to use an

adjustable tting.

• You can use an adjustable concentric pipe, wall or

roof tting. To get a sealed ue gas connection, the

inner pipe must always be 2 cm longer than the outer

pipe�

• Always attach adjustable parts with a chuck�

11 Calculate chimney

For proper operation of the replace it is important that

the ue pipe meets the requirements. Do determine this,

we prepared a calculation chart� (See page� 13)

11.1 Power-Fan

For chimney congurations that are not functioning on a

natural draught, the Power Fan can be used, a maximum

chimney length of 36 metres horizontally and vertically

combined is then possible�

For detailed installation instructions and operation of the

Power Fan we refer to the Power Fan manual�

11.2 Main chimney rules.

11.2.1 Determining the chimney diameter

The main rule is that the chimney must always be

200/130 in diameter�

Exception is:

• If your chimney only moves upward, then you may

change the replace to a diameter 150/100.

11.2.2 Determining the maximum vertical length

If you have changed your chimney according to the

above exception scheme to a diameter of 150/100, the

total maximum vertical length of your chimney is 11

meters� If you use a diameter of 200/130, your maximum

total vertical length is 22 meters�

11.2.3 Determining the maximum horizontal length

To see if your intended chimney will work properly,

check the calculation models in the annex�

Every annex has two Tables

1� A table for 200/130mm horizontal outlet�

2� A table for 200/130mm vertical outlet�

You use the table that applies to you� You calculate your

total vertical part� (TVP) and your total horizontal part

(THP)� In the table you can read the advice where TVP

lies on the vertical axis, and THP on the horizontal axis�

11.2.4 Calculating Total Vertical Part (TVP)

You calculate the Total Vertical Part by adding all vertical

rises in the chimney pipe�

11.2.5 Calculating Total Horizontal Part (THP)

You calculate the Total Horizontal Part by adding all

horizontal rises in the chimney pipe�

Page 11

InstallatIon manual

11

Take care with curves!

Curves give extra resistance in the system and should

therefore be included in the TVP and THP.

We have two kinds of curves, being:

• Curves 45

o

and 90o from vertical to horizontal and

vice versa� (Type N)

• Curves 45o and 90o from horizontal to horizontal

(Type Q)

The curves type N (from vertical to horizontal) do not

need to be calculated� The maximum number of curves

are 3

The following applies for a curve type Q ( horizontal to

horizontal):

• 90o curve in the horizontal part equals

2 horizontal meters in THP�

• 45o curve in the horizontal part equals

1 horizontal meter in THP�

Chimney parts in a 45o rising pipe:

• 45o rising parts calculated both vertical

and horizontal�

Statement results table:

*The Power-Fan may just be the solution.

11.2.6 Flue gas restrictor

A limiter of 35 mm is mounted as standard in the

combustion chamber� This is mounted in addition to the

ue gas opening.

The calculation table shows you when you need to t a

ue gas limiter

NB:

By unscrewing the screws, the limiter can be twisted

over the ue gas opening and xed. (g. 10.1)

10

Result Action

35 Fitting the limiter

0 No limiter

x No proper function

guaranteed *

10�1

Page 12

InstallatIon manual

12

11.2.7 Calculation table horizontal outlet pipe diameter 200/130

11 35 35 35 35 35 35 35 0 0 x

9 35 35 35 35 35 35 35 0 0 x

8 35 35 35 35 35 35 35 0 0 x

7 35 35 35 35 35 35 35 0 0 x

6 35 35 35 35 35 35 35 0 0 x

5 35 35 35 35 35 35 35 0 0 x

4 35 35 35 35 35 35 35 0 0 x

3,5 35 35 35 35 35 35 35 0 0 x

3 0 0 0 0 0 0 0 0 0 x

2,5 0 0 0 0 0 0 0 0 x x

2 0 0 0 0 0 0 x x x x

1,5 0 0 0 0 0 0 x x x x

1 0 0 0 0 0 x x x x x

0,5 x 0 0 x x x x x x x

TVG 0 0,5 1 2 2,5 3,5 4 4,5 5 THG

Page 13

InstallatIon manual

13

11.2.8 Calculation table vertical outlet pipe diameter 200/130

23 x x x x x x x x x x

22 35 x x x x x x x x x

21 35 35 0 x x x x x x x

20 35 35 0 0 x x x x x x

19 35 35 35 35 0 x x x x x

18 35 35 35 35 35 0 0 x x x

17 35 35 35 35 35 35 35 0 0 x

16 35 35 35 35 35 35 35 35 0 x

15 35 35 35 35 35 35 35 35 0 x

14 35 35 35 35 35 35 35 35 0 x

13 35 35 35 35 35 35 35 35 0 x

12 35 35 35 35 35 35 35 35 0 x

11 35 35 35 35 35 35 35 35 0 x

10 35 35 35 35 35 35 35 35 0 x

9 35 35 35 35 35 35 35 0 x x

8 35 35 35 35 35 35 0 x x x

7 35 35 35 35 35 0 x x x x

6 35 35 35 35 0 x x x x x

5 35 35 35 35 0 x x x x x

4 35 35 35 0 x x x x x x

3,5 35 35 0 x x x x x x x

3 0 0 0 x x x x x x x

2,5 0 0 0 x x x x x x x

2 0 0 0 x x x x x x x

1,5 0 0 x x x x x x x x

1 0 0 x x x x x x x x

0,5 0 x x x x x x x x x

TVG 0 0,5 1 2 2,5 3,5 4 4,5 5 THG

Page 14

InstallatIon manual

14

12 Outlet location

Dimensions Position at end Distance (mm)

A* Directly beneath an opening, ventilation brick, open window etc� 600

B Above an opening, ventilation brick, open window etc� 300

C Next to an opening, ventilation brick, open window etc� 400

D Under gutters or drainage pipes 300

E Under roof edges 300

F Under balconies or roofs of open garages 600

G From a vertical drainage pipe 300

H From an inner or outer curve 600

I Above ground roof or balcony level 300

J From a surface opposite to the outlet 600

K From an outlet opposite to the outlet 600

L From an opening in the open garage (i�e� door, window in the home) 1200

M Vertical from an outlet in the same wall 1500

N Horizontal from an outlet in the same wall 300

P From a vertical structure on the roof 600

Q Above the intersection with the roof 150

Page 15

InstallatIon manual

15

12.1 Location at roof outlet

“Distance” = minimum distance required to position the outlet to prevent negative effects involving:

A� A ventilation opening of a used room, toilet or bathroom

B. Hot air supply, like the supply owing through a room in use.

C� A window that can be opened and located in the vicinity of a room, toilet or bathroom�

(*) If the required distance is not achievable, the rules pertaining to the outlet position comes rst.

(**) If the outlet is positioned at least a meter higher than the inlet opening, or a window can be opened�

(***) If the required distance is not achievable, the outlet must be placed at least a meter above the highest wall/the

highest roof�

12�2 Minimum vertical length�

Roof outlets may be installed from a minimum height of 1�0 metres� (See calculation model)

To prevent negative effects

Distance: outlet

A,B or C

At the same roof level >6 m (*)

At another roof level >3 m (*) (**)

On a wall located lower >2 m (**)

At a higher sloped surface >6 m (***)

calculation model

Page 16

InstallatIon manual

16

13 Technical data

The model tag indicates for which gas type, gas pressure and for which country this unit is intended� The model tag is

attached to a chain� It must stay attached to the chain

NB: Check to ensure the device is suitable for the local gas type and gas pressure.

Natural gas:

GB United Kingdom : 12HG20@20 mbar

IE Ireland : 12HG20@20mbar

LPG:

GB United Kingdom : 13B/P G30/G31@30mbar, 13+G30/G31@28-30/37mbar

IE Ireland : 13+ G30/G32@28-30/37mbar

PIN: 0359CN1268

LPG

I2H I3B/P I3+

20 30 28-30/37

13,5 13,0 13,0

(Gross kW)

Efficiency Class 2 2 2

G30-ZP2-312 G30-ZP2-271 G30-ZP2-271

1,25 0,36 0,36

13,1 28,1 28,1

220 (x2) 220 (x2)

NOX Class 5 5 5

M o d o r e 7 5 H E 4 - 1 9

N atu ral G as

Gas Category

Supply Pressure (mbar)

Nominal Input

Pilot Burner

Gas Rate

(max.m3/hr)

Burner Pressure

(mbar-hot)

Injector Marking 650 (front) 560 (Rear)

Page 17

InstallatIon manual

17

14 Instructions for use

We advise you to have it checked annually by a qualied

specialist in order to guarantee safe use and a long service

life,

garanderen,

14.1 Handover to customer

• User Manual

• Installation manual

• Instruction chart decorative material

• Suction cups

• Remote Control

14.2 Maintenance instructions for installer

The following is an overview of the minimum

maintenance that should take place annually

• Remove the glass sheet and remove all ceramic parts�

• Remove possible dirt on top of the burner using a

vacuum cleaner and brush�

• Inspect the burner�

• Do an ignition check�

• Make sure the pilot light ignites the main burner

freely and unhampered by the ceramic material�

• Do a ame-failure check

• Maintenance to the burner should not be required� If

this is necessary, check the pressure adjustment at the

inlet of the burner� The correct pressure is listed at the

back of this manual�

Wood assembly

• Brush off the imitation wooden logs and replace any

broken or damaged parts (see earlier in this manual)�

• Pebbles or /grey stone:

• Never put more than one layer over the burner

• More layers will negatively affect the re effect

Check

• The ceramic cord on the glass sheet and

• replace the glass sheet�

• Check the installation for gas leaks�

• Check if the wall / roof outlets are free of obstacles�

14.3 Anti-reective glass

Anti-reective glass is polished ceramic glass to which

10 layers of metal oxide coating was applied� The

thickness of the coating is checked to the nanometre to

master the reection factor perfectly.

Thanks to the new antiglare coating technology, anti-

reective glass, when you view this right from the front,

is almost invisible�

By burning in the layers of lacquer and through

condensation, a grey haze may develop on the inside of

the glass sheet�

We therefore recommend the cleaning of the glass panel

according to the following instructions�

Cleaning anti-reective glass:

TAKE NOTE:

Anti-reective glass requires extra careful handling!

Never use abrasive cleaning products�

Use a Microber Cleaning cloth.

Most deposits can be removed with a dry cloth, should

this not be sufcient use a neutral cleaning product like

for instance “Instaned�”

Check to ensure no ngerprints remain on the glass sheet,

this will burn-in and will no longer be removable�

Once you have replaced the glass, the outside must also

be cleaned�

14.4 Replacement of parts

If parts need to be replaced, use only original parts from

the manufacturer� When using non-standard parts, the

warranty will expire� They may also be hazardous�

Page 18

InstallatIon manual

18

15 Emergency repairs

You will nd an overview of the possible cause and solutions below.

Problem Possible Cause Solution

A� No transmission 1� The (new) communication 1� Hold the reset button of the receiver

(motor not running) code between receiver and pushed in until you hear 2 beeps�

remote control still need After the second, longer sound signal,

to be conrmed. let go of the reset button and press within 20 sec. on the

button (small ame) on the remote control, until you hear a

sound signal, conrming the setting of the new code.

2� Empty batteries� 2� Replace the batteries�

3. Damaged receiver. 3. Replace the receiver and conrm the code

4 Damaged remote control. 4. Replace the remote control and conrm the

code

5� Motor cable at the valve / receiver 5� Replace motor cable�

broken�

6� Bent pins of the 8-wire 6� Ensure the pins of the 8-wire connector

connector� are straight

7� If the receiver is surrounded 7� Change the position of the antenna�

by metal, it can reduce the sender

range�

B. No ignition (spark) 1. Button A in MAN position. 1. Set button A on gas regulator to ON (g. 3, page 5)

2� Ignition cable lies about and/ 2 Do not lay the ignition cable over and/or along

or along metal parts� metal parts� This weakens the spark�

Replace the ignition cable if necessary�

3� Ignition pin corroded� 3� Replace the ignition pin�

4� Waiting period of 60 seconds for 4� Consider the required waiting period�

complete restart not passed

B ignition stops after rst spark 1 bad mass connection 1. .. remove mass screw of the valve and clean

and replace again�

C. No sound signal 1. Damaged receiver. 1. Replace the receiver and conrm the code

2� Waiting period of 60 seconds for 2� Consider the required waiting period�

complete restart not passed�

D� A single continuous sound 1� Loose wiring between receiver 1� Connect the wiring properly�

signal of 5 sec� (Maybe and gas regulator�

7 short beeps before 5 sec. 2. Damaged receiver. 2. Replace the receiver and conrm the code

sound signal) 3� Bent pins of the 3� Ensure the pins of the 8-wire connector are

8-wire connector� straight�

4� Damaged magnet valve 4� Replace the gas regulator�

E� No pilot light 1� Air in the pilot light pipe� 1� Vent the pipe or start the ignition process

a number of times�

2� Change thermo couple wires of 2� Check the polarity of the thermo couple wiring�

thermo couple�

Connect the thermocouple wires properly�

3� No spark with the pilot light burner� 3�1 Check of the ignition cable is (away from

metal parts; Reposition if necessary�

3�2 Replace the ignition cable if necessary�

3�3 Replace the ignition pin if necessary�

4� Blocked nozzle� 4�1 Clean the nozzle�

4�2 Replace nozzle if necessary�

Page 19

InstallatIon manual

19

Problem Possible Cause Solution

F� Electronics continue to spark 1. Damaged receiver. 1. Replace the receiver and conrm the code

while pilot light is burning

G� Pilot light is burning but 1� Thermocouple is not working� 1�1 Measure the voltage, using a digital multi-meter

solenoid valve closes after app� 10 set to mV range, by connecting the cables to

seconds or when the appliance the cable sheave� The cable sheave

heats up is located on the outside, directly next to the

magnetic nut on the back of the gas regulator;

The voltage within 20 seconds must be at least

5mV� This must not be less when the appliance is heated�

If the voltage is low:

-the thermocouple must be positioned properly in the ame

or - the thermocouple must be replaced�

1�2 Check the size of the pilot light�

Check too small a pilot light�

1�3 Check the wiring of the thermocouple

to the receiver� Replace the wiring if necessary�

2� Batteries (almost) empty� 2� Replace the batteries in the receiver�

H There are short sound- 1� Batteries (almost) empty� 1� Replace the batteries in the receiver�

signals but no spark and

there is no sound / ticking audible

of the magnet opening the valve

I. The pilot light is burning but there is 1. Button A in MAN position. 1. Turn button A on gas regulator to ON (g.3, page 5)

no gas ow to the

(ame) main burner 2. Appliance on pilot light position. 2. Increase the ame size by pressing the button (big one of

the remote control� UT2}

3� Gas pre-pressure too low� 3� Check pre-pressure�

If necessary, connect the energy supply�

4� Damaged magnet valve� 4� Damaged magnet valve�

J� Main burner ignites, 1� Loose wiring thermocouple� 2* 1� Connect the wiring properly�

but dies after app� 22 seconds 2� Thermocouple wiring 2*incorrectly 2� Connect the wiring properly�

wired�

3� Short-circuit in wiring of thermo- 3� Replace the wiring�

coupling 2*�

4� Broken wire in wiring to thermo- 4� Replace the wiring�

coupling 2*

5� 2nd Thermocouple is dirty�* 5� Clean thermocouple�

6. 2nd Thermocouple is not placed properly in 6. Place thermocouple properly in ame.

ame *

7� 2nd Thermocouple is defective�* 7� Check voltage of thermocouple just

before the main burner dies�

If the voltage is less than 1,8 mV, replace the

thermocouple�

8� Receiver defective� 8� Check voltage of thermocouple just

before the main burner dies�

If the voltage is more than 1,8 mV, replace the

receiver�

Page 20

InstallatIon manual

20

16 Packaging materials

The packaging of the appliance is recyclable�

The following can be used:

• Cardboard

• CFC-free foam (soft)

• Wood

• Plastic

• Paper

These materials must be disposed of in a responsible

manner and in accordance with the ofcial regulations

Batteries should be disposed of as chemical waste�

Batteries must be disposed of in a responsible manner

and in accordance with the ofcial regulations. First

remove the batteries before you dispose of the remote

control�

The government can also inform you about the

responsible disposal of end-of-life devices�

17 Dimensional drawings

17.1 Control hatch, BDLE4

Page 21

InstallatIon manual

21

17.2 Modore 75H

Page 22

InstallatIon manual

22

18 Parts Ontop ue material

On the following pages you will nd a description of the components that can be used with the installation with the closed

combustion system of this unit�

The part number in the table refers to the number of the part on the following pages� This number is also the number that

is used to designate components in the proposed installation schedules�

Description pipe diameter.

Ø150/100 Ø200/130

A Device

B Connecting the device

C Chimney Adapter

D Chimney, gas-proof Ø150 minimum

E Chimney, gas-proof Ø160 minimum

F Stainless steel exible chimney lining Ø100

G Stainless steel exible chimney lining Ø150

1 Pipe concentric chimney pipe length 250mm US 25 100 US 25 130

2 Pipe concentric chimney pipe length 500mm US 50 100 US 50 130

3 Pipe concentric chimney pipe length 1000mm US 100 100 US 100 130

4 Clamp USKB 100 USKB 130

5 Cover band USAB 100 USAB 130

6 Adjustable pipe tting 50 - 300mm USPP 100 USPP 130

7 Roof transit USDVC2 100

8 Wall transit Ø100 USDHCE 100

9 Assembly bracket USEB 100 USEB 130

10 Adjustable wall bracket USMB 100 USMB 130

11 Concentric curve 90° USB 90 100 USB 90 130

12 Concentric curve 45° USB 45 100 USB 45 130

13 Concentric curve 15° USB 15 100 USB 15 130

14 Storm collar USSR 100 USSR 130

15 Roof sheeting at roof (aluminium) USDPAL 100 USDPAL 130

16 Roof sheeting at roof (aluminium) USDP 100 USDP 130

18 Roof sheeting sloping 5° - 30° USDH 100 USDH 130

19 Roof sheeting sloping lead slab pane 20° - 45° USLS 100 USLS 130

20 Adjustable roof sheeting (supplied per pair) USCP 100 USCP 130

21 Wall sheeting USMPG 100 USMPG 130

22 Reducer Ø130 - Ø100 USVK 10 130

23 Wall transit Ø130 USDHC 130

Page 23

InstallatIon manual

23

Page 24

InstallatIon manual

24

Page 25

InstallatIon manual

25

Page 26

InstallatIon manual

26

Page 27

InstallatIon manual

27

Page 28

InstallatIon manual

28

19 Warranty conditions

If there are malfunctions that you cannot solve using the

fault nder on pag 20, please contact your installer or

your dealer�

The Element4 products that are covered by this warranty

card are carefully manufactured from high quality

materials� If errors or defects still occur, then the

following warranty coverage apply:

1) The installer will, before continuing with the

installation, rst check the proper quality and the smooth

operation of the chimney system� The gas appliances

should always be built in by a competent installer in

accordance with the national and any regional standards

and according to the installation instructions supplied

with the unit�

2) The warranty period on the E4 gas appliances is 2

years counting from the date of purchase that must be

mentioned clearly on the purchase invoice�

3) Not covered under warranty are the ceramic glass as

well as external physical and chemical action during

transport, storage or assembly�

4) If a malfunction should occur within the warranty

period resulting from a manufacturing defect or material

defect, Element4 will send the installer a free spare part

to replace the defective part, without compensation for

the mounting and dismounting

5) If the installer cannot resolve the fault itself, he may

request Element4 BV to do so, if this is within the limits

of the Benelux�

6) Only after prior consultation can the entire device

or parts of it be sent in for inspection or repair� These

goods must be accompanied by this completed warranty

document along with the dated proof of purchase�

7) In case of a service at home by Element4 BV (only

within Benelux) during the warranty period, the warranty

documents (this page together with the dated proof of

purchase) must be submitted�

8) With service at home out of the warranty period, the

following fee will be charged: material costs, work hours

and travel costs�

The warranty is not applicable in the following cases:

1) If the above points have not been met or where only

partially met�

2) If unknown to E4 to, any changes were made to the

appliance�

3) If the device was not built in according to the

installation instructions, or not used according to the

operating manual�

4) If there are any material other than the prescribed

articial wooden logs, ceramic material or stones on the

burner bed�

Page 29

Page 30

Page 31

Page 32

Element4 B.V.

Paxtonstraat 23

8013 RP Zwolle

The Netherlands

December 2015

Loading...

Loading...