Page 1

Version:

Made in G e r many

Operating Manual

MULTISPOT MI-100control

Resistance welder

Item no.: 328 010

Revision: 0.9 – Translation

31. July 2013

Be sure you have read and understood this operating

manual before you carry out any works on and / or with

this equipment.

Page 2

© BlitzRotary GmbH

Branch Bremen

Hinterm Sielhof 22

D-28277 Bremen

Germany

Phone: +49 (0)421 / 54 90 6 - 906

Fax: +49 (0)421 / 54 90 6 - 19

E-Mail: vertrieb@elektron-bremen.de

Internet: www.elektron-bremen.de

Release:

BlitzRotary GmbH Branch Bremen

2

Page 3

Resistance welder MULTISPOT MI-100control

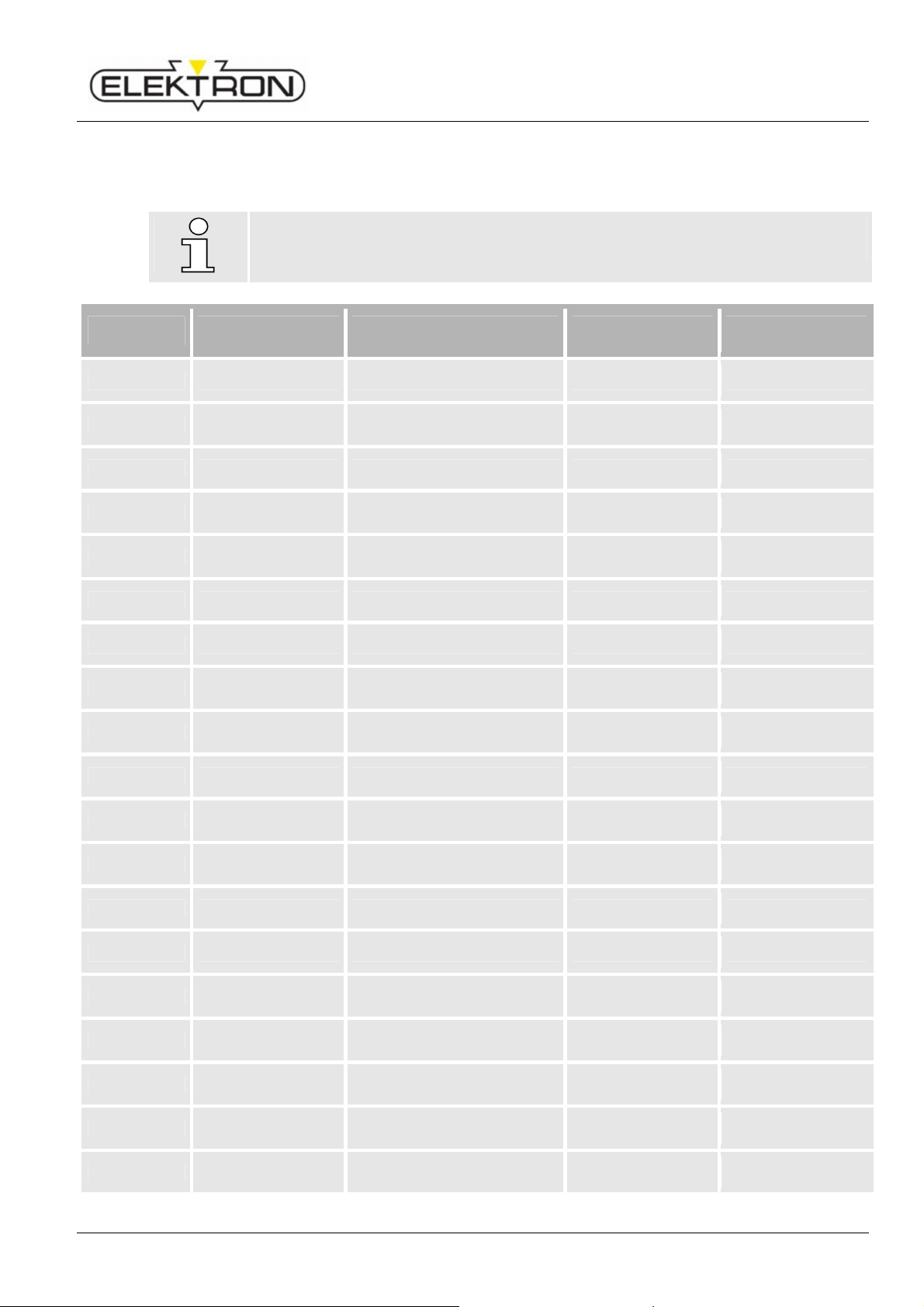

Table of contents

1

General Information .............................................................................................. 6

1.1 Information concerning the operating manual .......................................................................... 6

1.2 Copyright ................................................................................................................................... 6

1.3 Disclaimer ................................................................................................................................. 6

1.4 Symbols .................................................................................................................................... 7

1.5 Warranty and guarantee ........................................................................................................... 9

1.6 Customer service ...................................................................................................................... 9

2

Health and safety ................................................................................................ 10

2.1 Intended purpose .................................................................................................................... 10

2.2 Responsibilities of the operating company ............................................................................. 10

2.2.1

2.2.2

2.2.3

2.3 Particular dangers ................................................................................................................... 14

2.3.1

2.3.2

2.3.3

2.4 Correct behaviour in accidents and dangerous situations ...................................................... 17

2.5 Measures to be taken in case of work at the device ............................................................... 17

2.6 Safety devices ......................................................................................................................... 18

2.7 Safety labels and markings on this equipment ....................................................................... 19

2.7.1

2.7.2

2.7.3

2.7.4

2.8 Spare and wear parts.............................................................................................................. 20

2.9 Waste management and environmental protection ................................................................ 21

General responsibilities ........................................................................................... 10

Requirements to personnel ..................................................................................... 12

Personal protective equipment (PPE) ..................................................................... 13

Dangers due to the equipment ................................................................................ 14

Dangers due to the work environment .................................................................... 16

Dangers to this equipment and other property ........................................................ 16

On the flap cover ..................................................................................................... 19

Signs on the backside ............................................................................................. 19

On the balancer ....................................................................................................... 20

On the control board ................................................................................................ 20

Table of contents

3

Transport, packaging, storage ........................................................................... 22

3.1 Safety during transport............................................................................................................ 22

3.2 Symbols on packaging ............................................................................................................ 22

3.3 Unpacking ............................................................................................................................... 22

3.4 Acceptance after shipping ...................................................................................................... 23

3.5 Handling .................................................................................................................................. 23

3.5.1

Forklift truck ............................................................................................................. 23

3.5.2

Moving equipment to the site .................................................................................. 24

3.6 In case of return of goods / further transport needs ............................................................... 25

3.7 Storage ................................................................................................................................... 25

4

Design and functionality .................................................................................... 26

4.1 Overview ................................................................................................................................. 26

4.2 Description .............................................................................................................................. 26

4.3 Display and control elements .................................................................................................. 27

4.3.1

On the display and control panel ............................................................................. 27

4.3.2

On the inverter control unit ...................................................................................... 28

4.4 Connections ............................................................................................................................ 28

3

Page 4

Resistance welder MULTISPOT MI-100control

Table of contents

4.4.1

Connections on the front side .................................................................................. 28

4.4.2

Connections on the backside .................................................................................. 29

4.5 Accessories ............................................................................................................................. 30

4.5.1

Optional accessories ............................................................................................... 30

4.5.2

Tools required .......................................................................................................... 30

5

Installation ........................................................................................................... 31

5.1 Before installation ................................................................................................................... 31

5.1.1

Preliminary works .................................................................................................... 31

5.2 Filling up cooling water tank.................................................................................................... 31

5.3 Ventin coolant circuit ............................................................................................................... 32

5.4 Assembling the balancer ......................................................................................................... 33

5.5 Electrical connections ............................................................................................................. 34

5.6 Connecting the pneumatics .................................................................................................... 35

5.7 Connecting the pliers .............................................................................................................. 36

5.8 Connecting the welding gun .................................................................................................... 37

6

Operation ............................................................................................................. 38

6.1 Preliminary works before welding ........................................................................................... 38

6.1.1

Preparing the sheets ............................................................................................... 38

6.1.2

Preparing welding pliers .......................................................................................... 38

6.1.3

Checks before switching on ..................................................................................... 41

6.2 Switching on ............................................................................................................................ 42

6.3 Basic settings .......................................................................................................................... 43

6.3.1

Set languages .......................................................................................................... 43

6.3.2

Register welder ........................................................................................................ 44

6.4 Recurring settings ................................................................................................................... 45

6.4.1

Maintaining electrode caps ...................................................................................... 45

6.4.2

Selecting control mode ........................................................................................... 45

6.4.2.1 Keyboard operation .................................................................................. 46

6.4.2.2 Setting welder in mode “Keyboard operation”.......................................... 47

6.4.2.3 OEM programs ......................................................................................... 48

6.4.2.4 Free mode ................................................................................................ 49

6.4.3

Electrode recognition ............................................................................................... 51

6.4.4

Manual tool selection ............................................................................................... 52

6.4.5

Switching off the cooling water pump ...................................................................... 53

6.5 Important information concerning welding .............................................................................. 53

6.6 Calling up welding parameters................................................................................................ 57

6.7 Settings in the service menu ................................................................................................... 57

6.7.1

Service menu settings (page 1) ............................................................................... 58

6.7.1.1 Enter order data ....................................................................................... 58

6.7.1.2 Concluding an order ................................................................................. 58

6.7.1.3 Administering programs ........................................................................... 59

6.7.1.4 Emptying cooling system ......................................................................... 59

6.7.1.5 Registering welder ................................................................................... 59

6.7.1.6 Activating fuse protection ......................................................................... 59

6.7.1.7 Setting languages .................................................................................... 60

6.7.1.8 Setting time and date ............................................................................... 60

6.7.2

Service menu: settings (page 2) .............................................................................. 60

6.7.2.1 Calling up electrode-cap service mode .................................................... 60

4

Page 5

Resistance welder MULTISPOT MI-100control

6.7.2.2 Changing configuration ............................................................................ 61

6.7.2.3 Loading most recent configuration ........................................................... 61

6.7.2.4 Storing all welding jobs ............................................................................ 62

6.7.2.5 Switching off weld rules ........................................................................... 63

6.7.2.6 Calling up status and error messages ..................................................... 63

6.7.2.7 Calling up the software version ................................................................ 64

6.7.2.8 Calling up current and voltage values ...................................................... 64

6.7.2.9 Modifying service address ....................................................................... 65

6.8 Updating software ................................................................................................................... 65

6.9 Operating the welding gun ...................................................................................................... 67

6.9.1

Push spot welding ................................................................................................... 67

6.9.2

Pulling-out dents with washer .................................................................................. 68

6.9.3

High-speed planishing hammer “SAH” (special accessory) .................................... 69

6.9.4

Pushing-in dents ...................................................................................................... 70

6.9.5

Shrinking sheet ........................................................................................................ 70

6.9.6

Welding-on threaded studs ..................................................................................... 71

6.9.7

Welding-on T-pins ................................................................................................... 72

6.9.8

Fixing sheet metal parts (tacking) ........................................................................... 73

6.9.9

Water-cooled spot welding gun (special accessory) ............................................... 73

6.9.10 Connection of Airpuller/ Dentpuller .......................................................................... 73

Table of contents

7

Troubleshooting .................................................................................................. 74

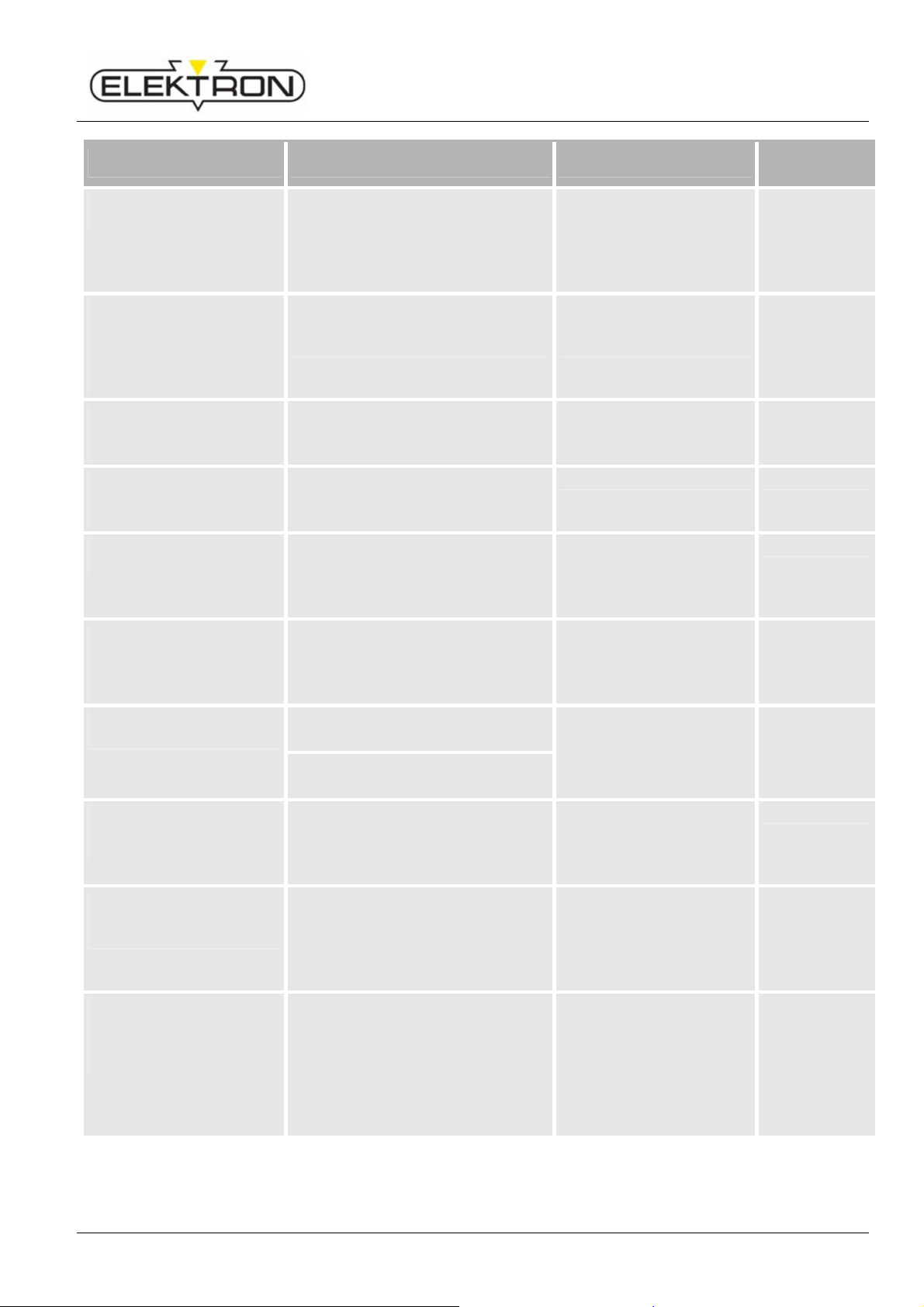

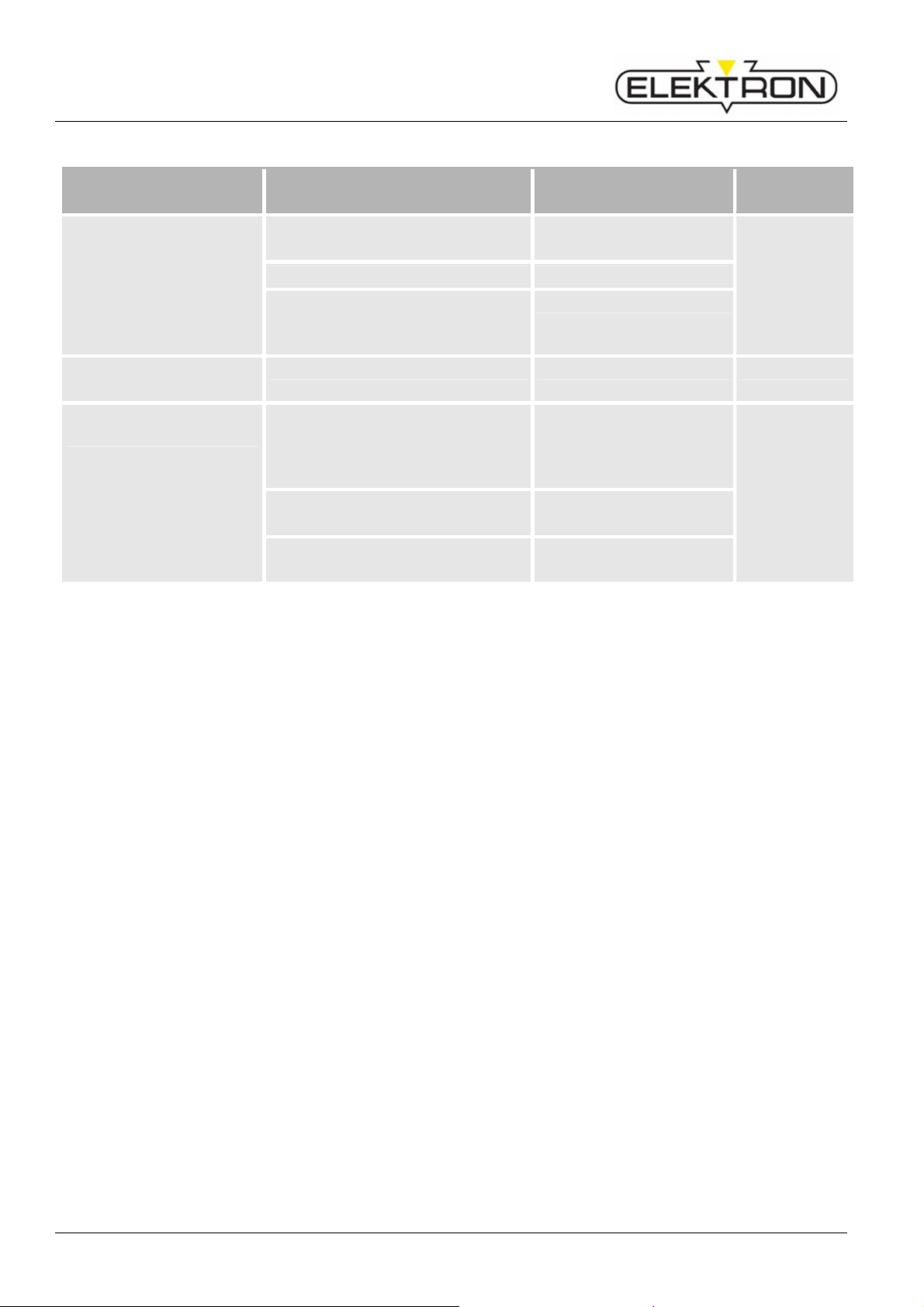

7.1 Health and safety during troubleshooting ............................................................................... 74

7.2 Error messages and troubleshooting tables .......................................................................... 74

7.2.1

Problems displayed on the control panel ............................................................... 74

7.2.2

Problems NOT displayed on the control panel ....................................................... 78

7.2.3

Possible causes and remedies in case of unsatisfactory welding results ............... 79

8

Maintenance ........................................................................................................ 80

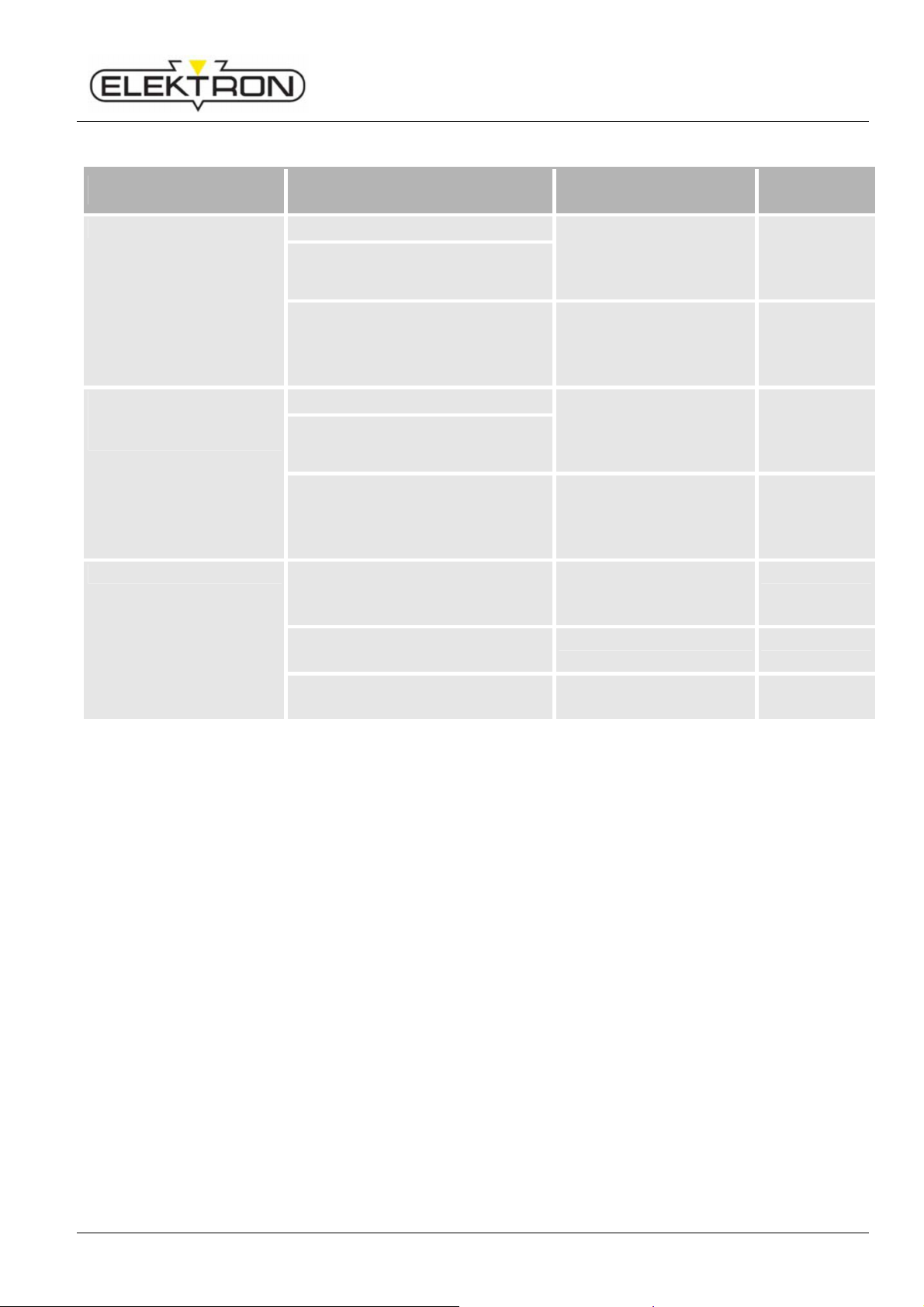

8.1 Maintenance schedule ............................................................................................................ 80

8.2 Carrying out maintenance jobs ............................................................................................... 80

8.2.1

Cleaning .................................................................................................................. 81

8.2.2

Maintaining the pneumatic unit ................................................................................ 81

8.2.3

Replacing water filter ............................................................................................... 82

8.2.4

Empty cooling water tank ........................................................................................ 83

8.3 Measures to be taken after maintenance ............................................................................... 84

9

Specifications ...................................................................................................... 85

9.1 Dimensions and weights ......................................................................................................... 85

9.2 Power requirements ................................................................................................................ 85

9.3 Supplies .................................................................................................................................. 86

9.4 Working conditions .................................................................................................................. 86

9.5 Exposure limit values .............................................................................................................. 86

9.6 Type plates ............................................................................................................................. 86

10 Index .................................................................................................................... 87

11 Appendix.............................................................................................................. 89

11.1 Training Report ....................................................................................................................... 89

5

Page 6

Resistance welder MULTISPOT MI-100control

General Information

1 General Information

1.1 Information concerning the operating manual

This operating manual will enable you to work efficiently and safely with this equipment.

The manual is an essential part of this product and must be stored ready at hand not far from the

equipment so that people can use it at any time without any problems. Operators must read and

understand the manual before they carry out any works. Compliance with any and all information

contained herein concerning health, safety and safe behaviour and procedures is a prerequisite for

safe work.

Shall apply in addition: Any and all local accident prevention regulations, any and all general safety

regulations that may apply to the scope of application of this equipment.

Pictures, drawings etc. contained in this operating manual are supposed to convey a general

understanding of facts. In details, they may deviate from the reality you encounter.

Besides this operating manual, there may be specific instructions for units, components etc.

They shall apply accordingly.

1.2 Copyright

This operating manual is protected by copyright. It may be used for internal purposes, exclusively.

The manual and / or its contents may not be relinquished to third parties and / or communicated,

processed, used and / or reproduced in any way or form whatsoever (not even in excerpts and / or for

internal purposes) without the prior written consent of the manufacturer.

Contravention shall entail damage claims.

All other rights reserved.

1.3 Disclaimer

Any and all information contained in this operating manual has been written on the basis of pertinent

standards and regulations, the state of the art, and the long-standing insights and experience of our

staff.

The manufacturer cannot be made liable for damage due to:

Non-compliance with this operating manual

Non-compliance with the purpose and intent of this equipment

Deployment of unskilled personnel

Unauthorised constructional changes, alterations etc.

Unauthorised changes, modifications etc. to design and engineering etc.

Use of unauthorised spare and wear parts

The scope of the delivery you actually receive may deviate from explanations and / or representations

in this manual - if and when you ordered special options, your equipment is a special design and / or

technical progress facilitates improvements.

Shall apply: any and all obligations and stipulations of the Delivery Contract, the General Terms of

Business and Terms of Supply and Delivery of the manufacturer as well as any and all legal

stipulations and regulations in force on the day the Contract was concluded.

We constantly strive to further develop and improve our products and their functionality. We, therefore,

reserve the right to implement technical changes without notice.

6

Page 7

Resistance welder MULTISPOT MI-100control

DANGER!

WARNING!

CAUTION!

CAUTION!

Electric current!

Electromagnetic fields!

Crushing!

Hot surfaces!

Hot liquids!

1.4 Symbols

Safety information

This manual uses symbols to highlight important safety information. In addition, there is always a

signal word heading the information indicating the severity of the danger or hazard that may be

encountered.

Be sure to comply with any and all safety information. Proceed with care and circumspection.

Prevent accidents and damage to people and property.

Warnings

General Information

… indicates a situation that is imminently dangerous and will entail the death of people

and severe injuries unless it is properly avoided and prevented.

... indicates a situation that may become dangerous and may entail the death of people

and severe injuries unless it is properly avoided and prevented.

... indicates a situation that may become dangerous and may entail medium and small

injuries unless it is properly avoided and prevented.

… indicates a situation that may become critical and may entail damage to property

unless properly avoided and prevented.

Electricity constitutes a danger to life and limb.

Life hazard for persons with heart pacemakers, or other magnetically influenced

implants. Damage to equipment.

As long as the unit is in operation, risk of injury.

Risk of burns from hot surfaces.

Danger of scalding from escaping hot coolant!

7

Page 8

Resistance welder MULTISPOT MI-100control

Harmful substances!

Risk of stumbling!

Slip hazard!

Electromagnetic fields!

Electromagnetic fields!

Electromagnetic fields!

S

afety clothing

Safety shoes

Face screen

Welder's gloves

General Information

Danger of toxic, harmful vapours at least.

Risk of injury due to falls.

Risk of slipping due to leaking water.

Prohibitions

Hazard to persons with pacemakers.

Persons who may suffer health risks due to the influence of electromagnetic fields must

not approach this equipment.

Mandatorys

Hazard to persons with magnetisable implants.

Persons who may suffer health risks due to the influence of electromagnetic fields must

not approach this equipment.

Hazard to magnetisable objects

Magnetisable data carriers and similar objects that may suffer from magnetism must not

be brought close to this equipment.

…is a tight-fitting sort of special clothing that is not inflammable, covers arms and legs

completely and tears easily (instead of getting pulled in). Its main purpose is to protect

against burns.

…protects the wearer's feet against falling objects, slippery surfaces and being run over

by vehicles.

…protects the face and eyes against splashes, flying sparks and other hot particles.

8

…protect the hands against splashes, flying sparks and other hot particles, and prevent

contact with hot surfaces.

Never use wet welder's gloves.

Page 9

Resistance welder MULTISPOT MI-100control

Tips, tricks and recommendations

NOTE!

... highlights information that may be helpful to maintain efficient and trouble-free

operation.

1.5 Warranty and guarantee

The guarantee conditions shall be as stipulated in the General Terms of Business of the manufacturer.

1.6 Customer service

Our customer service will be happy to provide technical support.

For contact information, see page 2 of this manual or the service menu on the control panel.

Please note: Our staff is always eager to learn about new information, insights and / or experience our

customers may derive from the work with our products that may be helpful for their future

improvement.

General Information

9

Page 10

Resistance welder MULTISPOT MI-100control

MULTISPOT MI

-

100control

WARNING!

Misuse may entail danger

!

Health and safety

2 Health and safety

This section contains an overview of the most important health and safety at work aspects in order to

protect employees and to guarantee safe and trouble-free operation.

Non-compliance with any and all of the information, safe behaviour and procedures etc. contained

herein may entail severe health and safety risks.

2.1 Intended purpose

This equipment has been designed and built for the following purpose(s), exclusively, and shall be

used accordingly:

The

maintenance work on car bodies, for stock of up to 3 mm sheet gauge and combinations of up to three

sheets within its specifications and limits of use ( see “Specifications”).

“Intended use” and “intended purpose” shall include proper compliance with any and all information

contained in this operating manual.

Any and all use diverting from and / or going beyond the limits as set by the equipment's intended

purpose and use shall be deemed misuse and may entail dangerous situations.

Misuse of this equipment may entail dangerous situations.

Therefore:

Do not operate this equipment unless clearly within its specs and limits of use

( see “Specifications”).

Be sure to use this equipment for welding sheet metal up to 3 mm, galvanised stock

and sheets made of super speed steel (HSS), exclusively.

Do not misuse this equipment for heating, thawing or perhaps even igniting objects.

Do not use this equipment in explosive atmospheres.

Do not open, alter, modify and / or manipulate etc. this equipment.

The manufacturer shall not be held liable for any and all damage due to misuse of this equipment.

resistance welder serves the sole purpose of spot welding during

2.2 Responsibilities of the operating company

2.2.1 General responsibilities

This equipment has been designed for professional use. The owner / operator or operating company

therefore being a businessman or commercial company, they are subject to any and all legal

obligations concerning health and safety at work.

That means, in addition to this operating manual, any and all accident prevention, health and safety at

work and environmental regulations pertaining to this equipment's scope of application shall apply as

well.

This means in particular:

The operating company must be informed about any and all pertinent health and safety at

10

work regulations and must carry out a risk assessment in order to determine additional

hazards existing under the specific conditions in the specific work environment at the place

of operation. Any and all findings from such a risk assessment must then be used to draw up

additional operating instructions for the operation of this equipment.

Page 11

Resistance welder MULTISPOT MI-100control

Electromagnetic fields!

Electromagnetic fields!

Electromagnetic fields!

Health and safety

During the entire lifetime of this equipment, the operating company must check in regular

intervals whether such additional operating instructions are still up to date and must update

them when necessary.

The operating company must unambiguously determine and communicate responsibilities

concerning the installation, operation, maintenance and cleaning of this equipment.

The operating company must make sure that any person handling this equipment has read

and understood this operating manual. Operating personnel, in addition, must be trained in

regular intervals and must be informed about the dangers existing in connection with this

equipment. (For a draft of a training report form, see “Appendix”)

The operating company must equip operating personnel with suitable personal protective

equipment (PPE) and check it for proper working condition in regular intervals.

Defective PPE must be replaced with new ones.

The operating company must take appropriate and suitable fire protection measures and

make available fire extinguishers and first aid kits.

The operating company is responsible that the equipment is in proper working order at all times.

Therefore:

The operating company must make sure that any and all maintenance jobs described in this

manual are really carried out.

The operating company must have any and all safety labels, markings etc. on the equipment

checked for integrity and readability in regular intervals.

Symbols the operating company must install on access ways and doors

Symbol Meaning

Hazard to persons with pacemakers.

Persons who may suffer health risks due to the influence of electromagnetic fields must

not approach this equipment.

Hazard to persons with magnetisable implants.

Persons who may suffer health risks due to the influence of electromagnetic fields must

not approach this equipment.

Symbols the operating company must install in the immediate vicinity of the equipment

Symbol Meaning

Hazard to magnetisable objects

Magnetisable data carriers and similar objects that may suffer from magnetism must not

be brought close to this equipment.

11

Page 12

Resistance welder MULTISPOT MI-100control

WARNING!

People with insuffic

ient skills may suffer injuries!

Health and safety

2.2.2 Requirements to personnel

Inexpert handling may entail severe damage to persons and property.

Therefore:

Make sure that any and all activities are carried out by skilled personnel, only.

This equipment may be operated only by persons who can be relied on to do their work

properly.

Persons whose capability of reaction is impaired, e. g. by drugs, alcohol or medication, must

not be allowed to handle this equipment.

When selecting suitable operating personnel, be sure to respect occupational regulations

and legislation concerning skills, age etc.

This operating manual specifically names the following types of personnel who must have the

following skills:

Operator / welder

has extensive skills and experience in the field of resistance welding and with the

corresponding preliminary and finishing jobs. The welder / operator has been coached /

trained by employees of ELEKTRON and / or an authorised representative / dealer of

ELEKTRON concerning his tasks and duties and possible hazards in connection with

inappropriate behaviour and confirms this with his signature (see draft of training report form,

“Appendix”).

Service personnel

refer to manufacturer's own service personnel and / or that of his representative / dealer.

Such service personnel have the professional training, skills and experience as well as

knowledge of pertinent regulations to carry out the jobs they accept and to identify, avoid

and prevent hazards on their own and without additional support.

Skilled electrician

has the professional training, skills and experience as well as knowledge of pertinent

regulations to carry out jobs on electrical equipment and to identify, avoid and prevent

hazards on his own and without additional support. A skilled electrician is needed, for

instance, if the conductor cross-section and fuse protection of the operating company's

power grid must be adapted to the special requirements of resistance welding.

12

Page 13

Resistance welder MULTISPOT MI-100control

CAUTION!

Insufficient protection

against injuries

!

S

afety clothing

Safety shoes

Face screen

Welder's gloves

Furthermore

2.2.3 Personal protective equipment (PPE)

Defective safety clothing may not constitute a proper protection against injuries.

Therefore:

Be sure to check PPE for integrity and good working condition before you start any

works.

Replace defective PPE.

Consider manufacturer's instructions and expiration dates, when and where

applicable.

Wearing PPE during work is essential to minimise health and safety risks.

Be sure to be always wearing the appropriate PPE for the job at hand.

Be sure to take note of and comply with warning signs concerning PPE that may be installed

at the workplace.

When working, always wear:

Health and safety

…is a tight-fitting sort of special clothing that is not inflammable, covers arms and legs

completely and tears easily (instead of getting pulled in).

Its main purpose is to protect against burns.

…protect the wearer's feet against falling objects, slippery surfaces and being run over

by vehicles.

In case of special work wear:

…protects the face and eyes against splashes, flying sparks and other hot particles.

…protect the hands against splashes, flying sparks and other hot particles, and prevent

contact with hot surfaces.

Never use wet welder's gloves.

…no long hair, rings, necklaces, watches and / or other sorts of jewellery. Do not carry

easily inflammable objects in your pockets (matches, lighters etc.).

13

Page 14

Resistance welder MULTISPOT MI-100control

DANGER!

Electricity consti

tutes a danger to

life and limb!

DANGER!

Electromagnetic fields pose a potentially fatal hazard to people with

Health and safety

2.3 Particular dangers

2.3.1 Dangers due to the equipment

Electricity

Touching live components can result in a fatal electrical shock.

Therefore:

As soon as you notice any damage to insulation, disconnect the power supply and

have the damage repaired.

Do not open this equipment yourself. Have all repairs carried out by service

personnel, exclusively. Have works on electrical equipment carried out by skilled

electricians, exclusively.

Before any and all electrical works: disconnect power, earth and short. Check

whether equipment is really dead.

Keep live components away from liquids and humidity. They may cause short

circuits.

Protect cables against running over, contact with oils, aggressive substances, tools,

pointed and / or hot objects.

When pulling from a socket: Never pull on the cable. Pull on the plug.

Do not use the cable to trail or drag equipment over the floor.

Always grab equipment by the handles provided for that purpose.

Use strain relief clamps to protect cables.

Make sure protective ground conductors have been connected properly.

After disconnecting the welder from the mains the welder still contains residual

current for approx. 15 minutes.

Electromagnetic fields

pacemakers or other magnetisable implants!

Electromagnetic fields affect the functionality of pacemakers and other magnetisable

implants. Electromagnetic fields can irritate human sense organs, nerve and muscle

cells.

Therefore:

Persons with pacemakers or other magnetisable implants must not approach the

work area.

Be sure to put up suitable warning signs.

Be sure to put warning signs on access ways and doors leading to the work area.

Do not guide welding cables along people's heads or spines. (To comply safely with

permissible exposure limits, keep distances ≥ 20 cm. Keep a distance of at least

2 cm between cable assemblies and people's heads / spines.)

14

Page 15

Resistance welder MULTISPOT MI-100control

WARNING!

Splashes and flying sparks constitute a danger of fire and

CAUTION!

Hot surfaces pose a ris

k of burns!

DANGER!

Scalding may occur due to hot water coming out!

DANGER!

Slip hazard due to water coming out!

Health and safety

Splashes, flying sparks

explosion. Splashes and flying sparks pose a risk of injuries!

Welding generates sparks and - hot spatter. They can ignite combustible materials and

generate explosions. Contact with body parts may entail injuries.

Therefore:

Before you tackle any welding jobs, make sure there are no combustible and / or

explosive materials in the work area.

Do not carry out welding jobs in the vicinity of pressure vessels, tanks, oil barrels,

paint cans and / or in a work area with an explosive atmosphere.

Have fire extinguishing gear ready at hand.

Make sure access and escape routes are not blocked.

During any and all welding jobs: be sure to be wearing a face screen, non-

inflammable safety clothing and welder's gloves.

Do not carry easily inflammable objects in your pockets (matches, lighters etc.).

Hot surfaces

Electrodes may heat up to 80 degrees centigrade approx. Stock may have up to

100 degrees right after welding. So there is an acute risk of burning yourself.

Therefore:

Never work without proper safety clothes and gloves near hot components.

Let freshly welded parts cool down to ambient temperature before you go on to

work with them.

Scald hazard

While pulling out the cooling water hoses hot water may come out.

Therefore:

Wear gloves.

Pull out water hoses carefully.

Slip hazard

While pulling out the cooling water hoses water may come out.

Therefore:

Remove water from the floor.

15

Page 16

Resistance welder MULTISPOT MI-100control

WARNING!

Vapours may constitute a dange

r to your health!

WARNING!

Possibility of injuri

es due to stumbling and falling!

CAUTION!

Tipping and toppli

ng may cause damage to property!

CAUTION!

Equipment rolling aw

ay may cause damage to property!

Health and safety

2.3.2 Dangers due to the work environment

Vapours

Stock that has not been properly ground and cleaned before welding may be

contaminated with residues of glues, paints, undercoating products etc. that may

generate harmful or even toxic vapours during welding.

Therefore:

Before you tackle any welding jobs, make sure the sheets you want to weld have

been properly ground and cleaned and are free of residues.

Be sure to be wearing a face screen. Respiratory equipment may be

recommendable in case of doubt.

Stumbling hazards

The work environment may pose stumbling risks. Stumbling and falling may lead to

severe injuries.

Therefore:

Before you tackle any welding jobs, make sure the work area is tidy and free of

clutter and offers enough freedom to move.

Install cables and supply lines in such a way that they do not constitute a stumbling

trap.

When welding, assume a safe and stable working position.

2.3.3 Dangers to this equipment and other property

Tipping and toppling hazards due to high centre of gravity and obstacles during travel

This equipment's centre of gravity is relatively high. In the event the wheels jam and / or

block (due to an obstacle or transverse pull, for instance), there is a danger the

equipment tips over.

Therefore:

Move this equipment always using the handles.

Keep potential obstacles out of the work area.

Install cables and supply lines in such a way that they do not constitute a stumbling

trap.

There is a danger the equipment rolls away because the wheels must not be blocked due to the

tipping and toppling hazard

The wheels of the equipment must not be blocked because this would cause a tipping

and toppling hazard. On the other side, though, this detail causes and increases the

danger the equipment rolls away.

Therefore:

Be sure to operate this equipment only on a flat and even floor.

Proceed with care when moving this equipment.

16

Page 17

Resistance welder MULTISPOT MI-100control

CAUTION!

Display and c

ontrol panel may sustain damage!

Dangers to display and control panel

The display and control panel may sustain damage when being closed if negligent

employees leave objects lingering on the accessory box beneath.

Therefore:

Never put objects on the accessory box beneath the display and control panel.

Proceed with care when closing the flap cover with integrated display and control

panel.

2.4 Correct behaviour in accidents and dangerous situations

Preventive measures

Be prepared to confront accidents and fires.

Be sure to have first aid equipment (kits, blankets etc.) and fire extinguishers ready at hand.

All personnel must know about accident signalling systems, first aid, rescue and escape

equipment.

Keep access ways for ambulances clear and open.

Health and safety

Measures to be taken in case of accidents

Actuate emergency stop. ( see “2.6”.)

Initiate first aid.

Evacuate people from danger zone.

Alert persons in charge.

Alert fire brigade and ambulance service.

Keep access ways for ambulances clear and open.

2.5 Measures to be taken in case of work at the device

De-energise.

Secure against restarting (e. g. pull out mains plug).

Unstressedness determines.

Ground and short circuit.

Neighbouring energized parts cover or provide with gates.

17

Page 18

Resistance welder MULTISPOT MI-100control

WARNING!

Danger! Due to insufficient protection against residual current!

WARNING!

Danger

of life and limb

! Equip

ment may still be under voltage!

Health and safety

2.6 Safety devices

Connection to electrical socket: the device may only be plugged into a socket with a

residual current device and an operable earthing device.

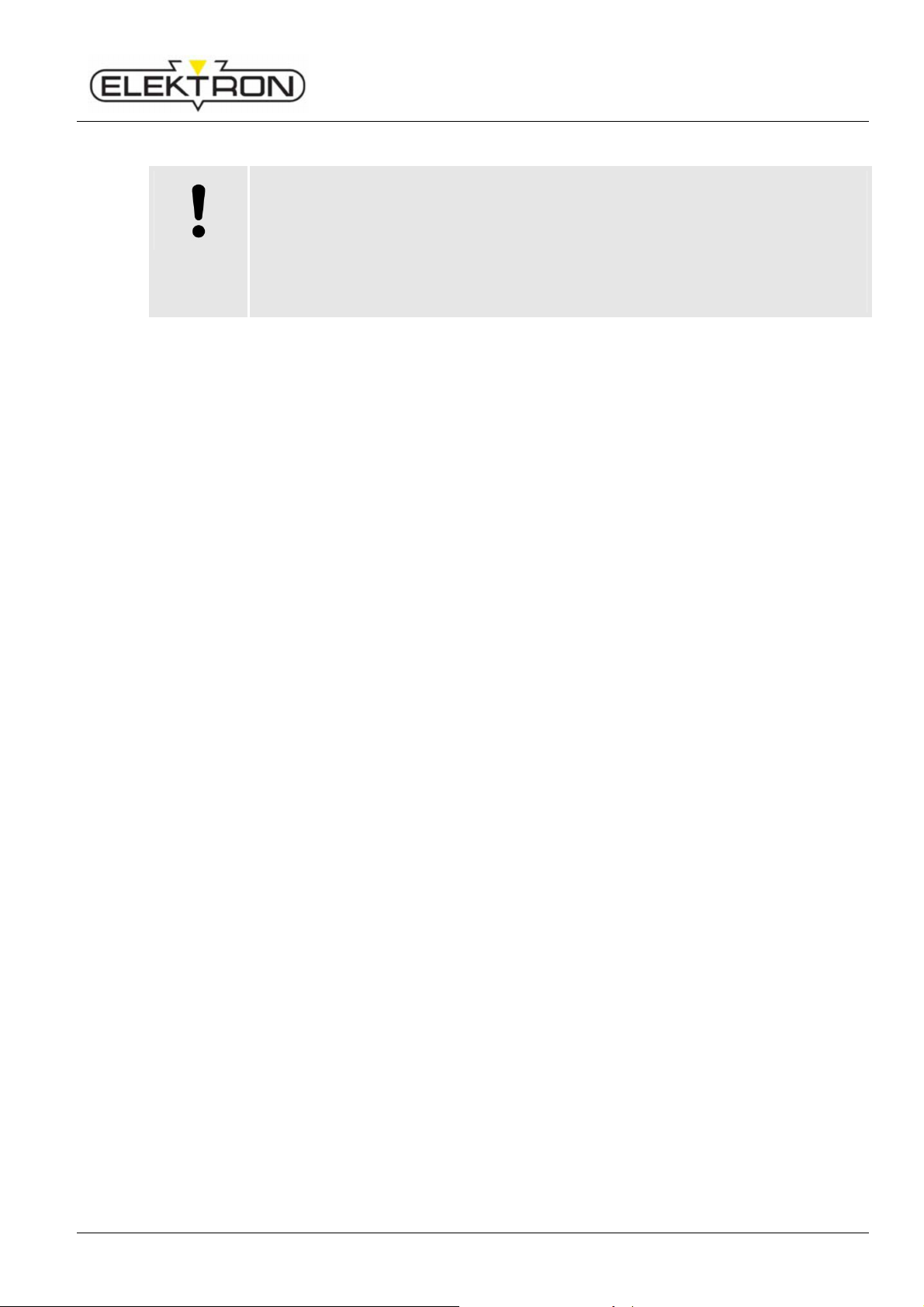

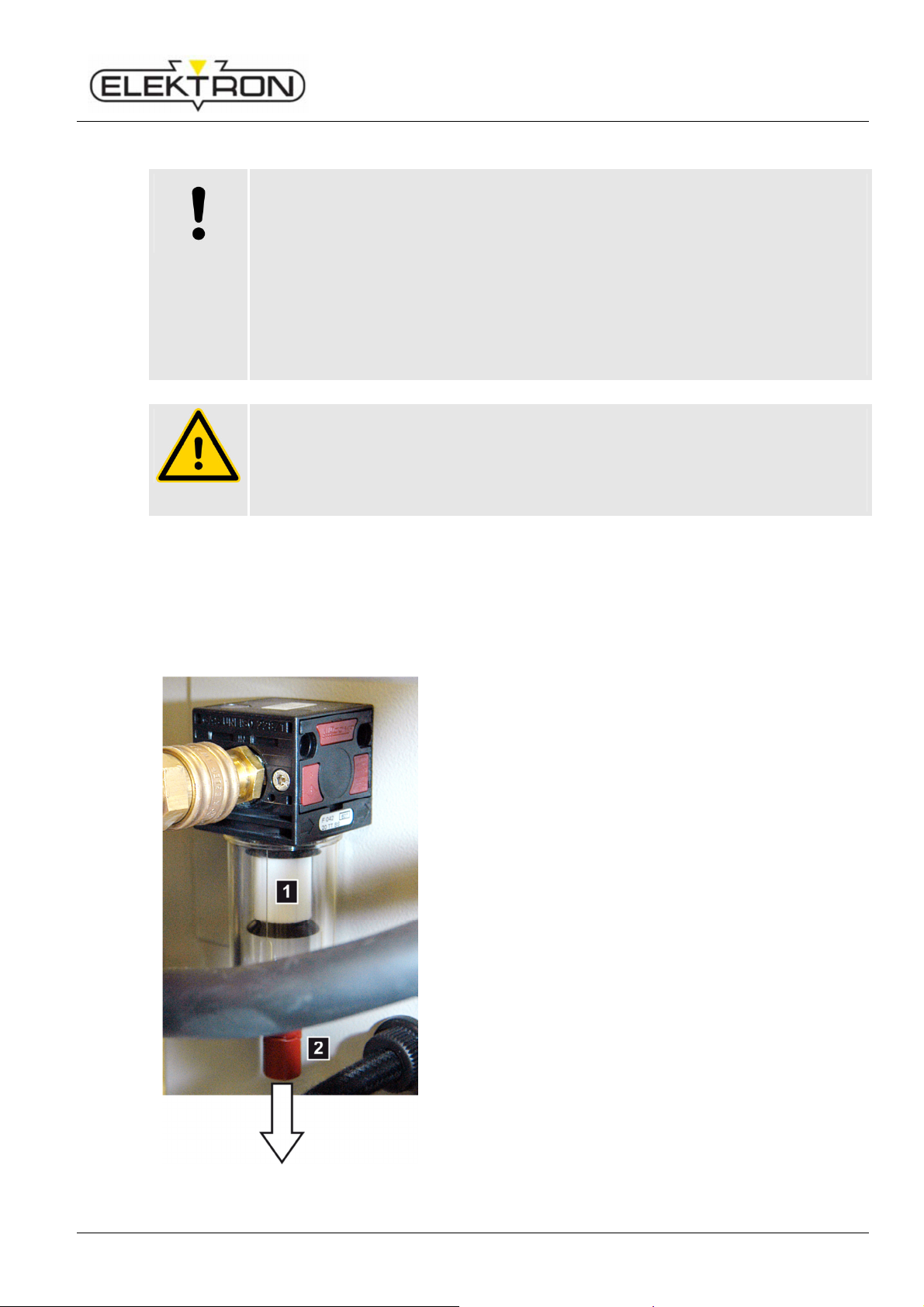

Fig. 1: Emergency stop pushbutton

Emergency stop pushbutton

Hitting the emergency stop pushbutton will shut down the

equipment immediately. After the emergency stop has been

actuated, it must be turned clockwise (cw) to unlock before

the equipment can be switched on again.

Fig. 2: Power switch on the backside

The emergency stop will shut down the equipment, but will not disconnect the power

supply. To accomplish that, push the power switch on the backside of the equipment.

Even then, there may still be components inside that are still under voltage.

Therefore:

In order to disconnect this equipment from the power supply, switch off using the

power switch. Earth components, short circuit and check for residual electricity.

Do not unlock the emergency stop pushbutton before danger has been completely

removed.

Power switch

Turning the power switch to position “0” will disconnect the

power supply immediately (which, basically, has the same

effect as an emergency stop).

18

Page 19

Resistance welder MULTISPOT MI-100control

DANGER!

Electromagnetic fields pose a mortal da

nger to persons with

CAUTION!

Pump damage due to dry running!

2.7 Safety labels and markings on this equipment

2.7.1 On the flap cover

Meaning

Welding generates electromagnetic fields.

Electromagnetic fields pose a potentially fatal hazard to

Fig. 3: Warning sign “Electromagnetic fields” on

the flap cover

pacemakers!

Electromagnetic fields affect the functionality of pacemakers and other magnetisable

implants. Electromagnetic fields can irritate human sense organs, nerve and muscle

cells.

Therefore:

Persons with pacemakers or other magnetisable implants must not approach the

working area.

Be sure to put up suitable warning signs.

Be sure to put warning signs on access ways and doors leading to the work area.

Do not guide welding cables along people's heads or spines. Keep a distance of at

least 2 cm.

people with pacemakers or other magnetisable implants.

Electromagnetic fields also affect magnetisable objects, like

e. g. watches, smart cards etc.

Health and safety

2.7.2 Signs on the backside

Fig. 4: Warning sign on the backside

Pump may sustain damage when running dry.

Pump running dry may sustain damage.

Therefore:

Before starting up, check cooling water level at the level gauge.

If necessary (i. e. if you can't see water in the level gauge), fill up. ( see “5.2”.)

Meaning

Do not operate pump without cooling water.

Pump running dry may sustain damage.

19

Page 20

Resistance welder MULTISPOT MI-100control

CAUTION!

Tipping and toppli

ng may cause damage to property!

WARNING!

Wrong spare and

wear parts constitute a hazard!

Health and safety

2.7.3 On the balancer

Fig. 5: Warning sign on balancer

Danger of tipping by relatively high centre of gravity and any obstacles in the path

This equipment's centre of gravity is relatively high. In the event the wheels jam and / or

block (due to an obstacle or transverse pull, for instance), there is a danger the

equipment tips over.

Therefore:

Move this equipment always using the handles.

Keep potential obstacles out of the work area.

Install cables and supply lines in such a way that they do not constitute a stumbling

trap.

Meaning

Always pull in the direction the guiding wheels are pointing.

In the event of lateral and / or transverse pull, there is a

danger the wheels jam / block and the equipment tips over.

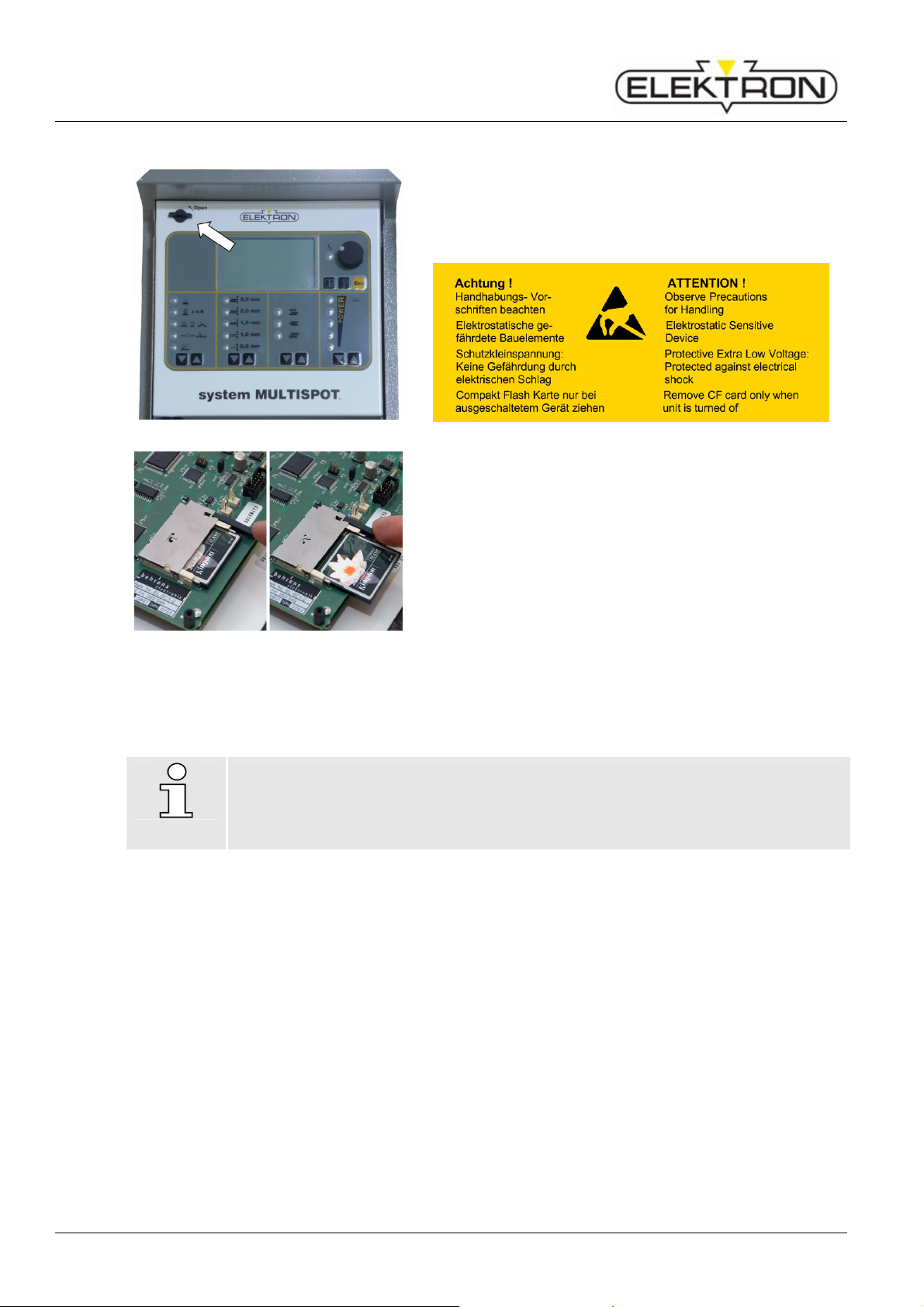

2.7.4 On the control board

Fig. 6: Warning sign on the control board

2.8 Spare and wear parts

Wrong and / or defective spare and wear parts may constitute a safety hazard and may

entail errors, damage and even total destruction.

Therefore:

Always use genuine spare and wear parts made by the manufacturer.

Be sure to buy your spare and wear parts directly from the manufacturer or an authorised dealer.

For contact information see page 2 of this manual or the service menu on the control panel.

Meaning

Do not pull compact flash card unless equipment has been

properly switched off.

Compact flash card might be destroyed otherwise.

20

Page 21

Resistance welder MULTISPOT MI-100control

CAUTION!

Inexpert handling may consti

tute an

environmental hazard!

2.9 Waste management and environmental protection

Inexpert handling of environmentally harmful substances, especially wrong disposal,

may constitute a hazard to the environment.

Therefore:

Be sure to take appropriate measures whenever harmful substances get (or

threaten to get) into the environment. In case of doubt, inform competent local

authorities about the hazard or damage.

Local authorities and specialised waste management companies will be happy to

advise you with your disposal issues.

Please also consider the following information.

Batteries

Batteries contain toxic heavy metals. Batteries are subject to hazardous waste management and must

be collected by specialised companies or taken to special collection centres.

Electronic components

Electronic components and scrap are subject to hazardous waste management and must be collected

by authorised companies.

Health and safety

Other components

Unless you have concluded a return and / or disposal agreement with the manufacturer, please

disassemble and recycle components.

Scrap metals.

Recycle plastic parts.

Other components must be sorted by materials and disposed of accordingly.

21

Page 22

Resistance welder MULTISPOT MI-100control

CAUTION!

Improper transpo

rt may cause damage to property!

CAUTION!

Improper waste disposal

may cause environmental hazards!

Transport, packaging, storage

3 Transport, packaging, storage

3.1 Safety during transport

Inexpert transport

Improper transport may cause damage to property.

Therefore:

When you unload packing units and move them across your premises, proceed with

care. Consider symbols and information on packaging.

Be sure to transport equipment as described hereinafter. ( see “3.5”.)

3.2 Symbols on packaging

Top

The arrows point towards the ‘roof’ of the packing unit. This

side up. The arrows must always point up; otherwise the

Fig. 7: Top

contents of the packing unit could be damaged.

Fig. 8: Do not stack

3.3 Unpacking

1. Do not remove packaging until immediately before installation.

During unpacking, do not use pointed tools.

2. Keep the original pallet (Fig. 9) in case of any further transport needs (return of goods,

further transport).

3. Recycle packing materials.

What to do with packing materials

Do not stack

Fragile goods. Do not stack; otherwise the contents of the

packing unit could be damaged.

Packing materials are valuable raw materials. In many cases, they can be recycled,

i. e. used again for packaging or in some other way or they can be further processed or

treated in some way.

Therefore:

Be sure to dispose of packing materials in sustainable manner and / or according to

local laws and regulations.

Observe local waste management legislation. In case of doubt, contact a

specialised company.

22

Page 23

Resistance welder MULTISPOT MI-100control

3.4 Acceptance after shipping

Check packing units immediately after delivery. Check for integrity, missing pieces and damage.

If you detect any external shipping damage, proceed as follows:

Do not accept delivery; or accept under reserve.

Report damage on carrier's shipping papers or delivery ticket.

Initiate complaint procedure.

NOTE!

Be sure to register a complaint as soon as a defect has been detected. Claims for

damages may be brought forward only within the deadlines set for complaints.

3.5 Handling

3.5.1 Forklift truck

Transport, packaging, storage

Fig. 9: Using a forklift truck

NOTE!

Keep the original pallet in case of any further transport needs (return of goods, further

transport).

Packing units on pallets may be handled with a forklift truck,

as long as the following conditions are fulfilled:

The forklift truck must be certified for the weight of the

packing unit at hand.

The operator must have a licence to drive forklift trucks.

Packing units may have very high centres of gravity.

Make absolutely sure they cannot tip over.

23

Page 24

Resistance welder MULTISPOT MI-100control

CAUTION!

Tipping and toppli

ng may cause damage to property!

CAUTION!

Equipment rolling aw

ay may cause damage to property!

Transport, packaging, storage

3.5.2 Moving equipment to the site

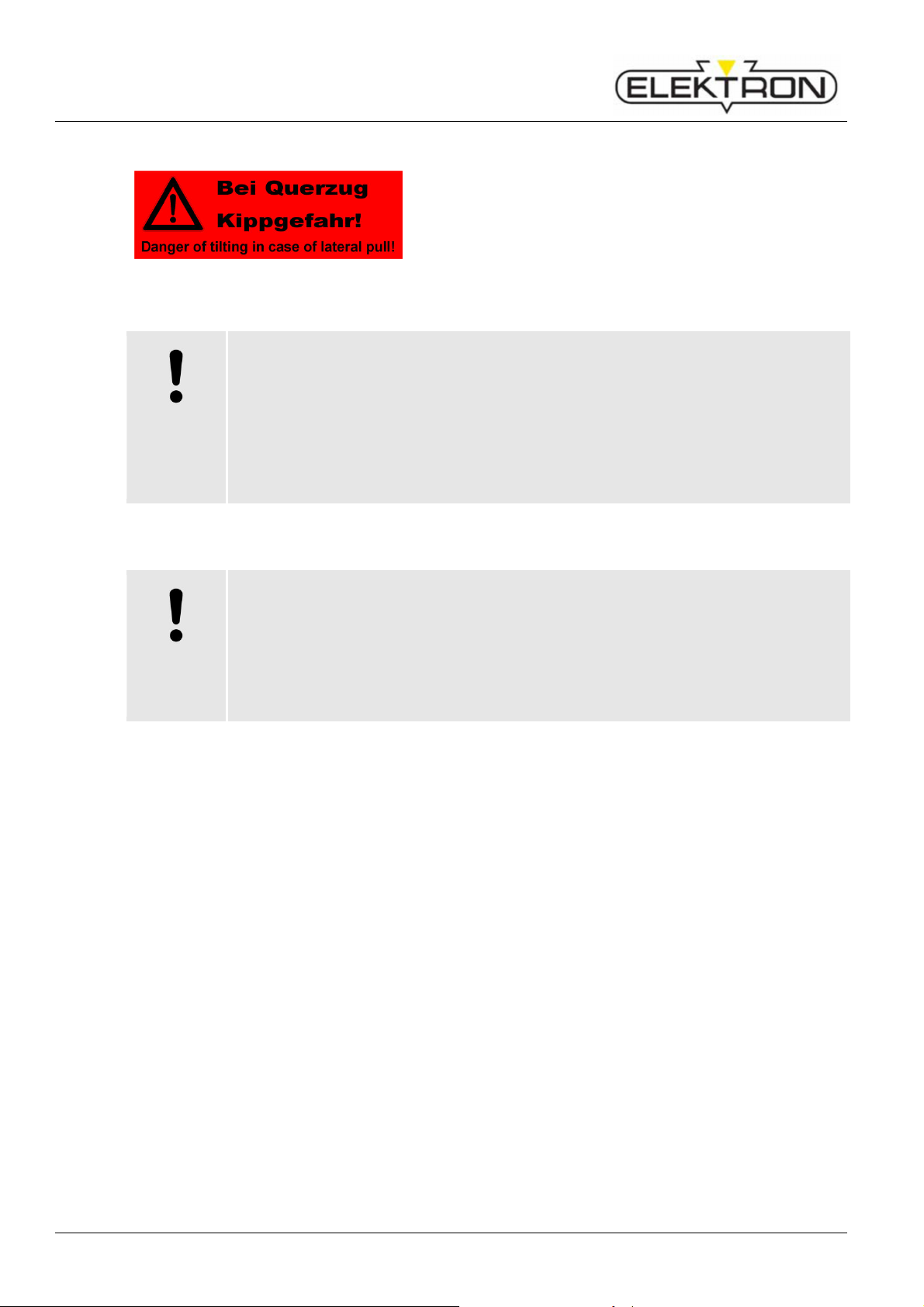

Fig. 10: Warning sign on balancer

There is a danger of tilting

This equipment’s centre of gravity is relatively high. In the event the wheels jam and / or

block (due to an obstacle or transverse pull, for instance), there is a danger the

equipment tips over.

Therefore:

Move this equipment always using the handles.

Keep potential obstacles out of the work area.

Securely stow cables and wires.

When moving around, always grip equipment by the handle

provided for that purpose.

There is a danger the equipment rolls away because the wheels must not be blocked due to the

tipping and toppling hazard.

The wheels of the equipment must not be blocked because this would cause a tipping

and toppling hazard. On the other side, though, this detail causes and increases the

danger the equipment rolls away.

Therefore:

Be sure to operate this equipment only on a flat and even floor.

Proceed with care when moving this equipment.

24

Page 25

Resistance welder MULTISPOT MI-100control

CAUTION!

Improper transport conditio

ns may cause damage to property!

Transport, packaging, storage

3.6 In case of return of goods / further transport needs

1. Drain cooling water tank completely. see “8.2.4”.

2. Use original transport pallet. (see Fig. 9)

3. Use packing materials that correspond to original packing materials.

4. Mark packing materials with symbols as shown in “3.2”.

Packaging with inappropriate dimensions, quality or weight, or cooling water left in

coolant tank may cause damage during transport.

Therefore:

Be sure to completely drain coolant tank before transport.

Use packaging of appropriate size and quality.

3.7 Storage

Storage conditions:

Do not store packing units outdoors.

Provide for dry and dust-free storage.

Protect against aggressive media.

Protect against direct sun exposure.

Protect against mechanical shocks and vibrations.

Storage temperature: -10 to 50 degrees centigrade.-50 to 122 degrees Fahrenheit.

Rel. humidity: 85 % max.; no dew.

When storing equipment longer than three months, check general conditions of all parts and

packaging in regular intervals. If and when necessary, refresh or renew corrosion protection.

25

Page 26

Resistance welder MULTISPOT MI-100control

Design and functionality

4 Design and functionality

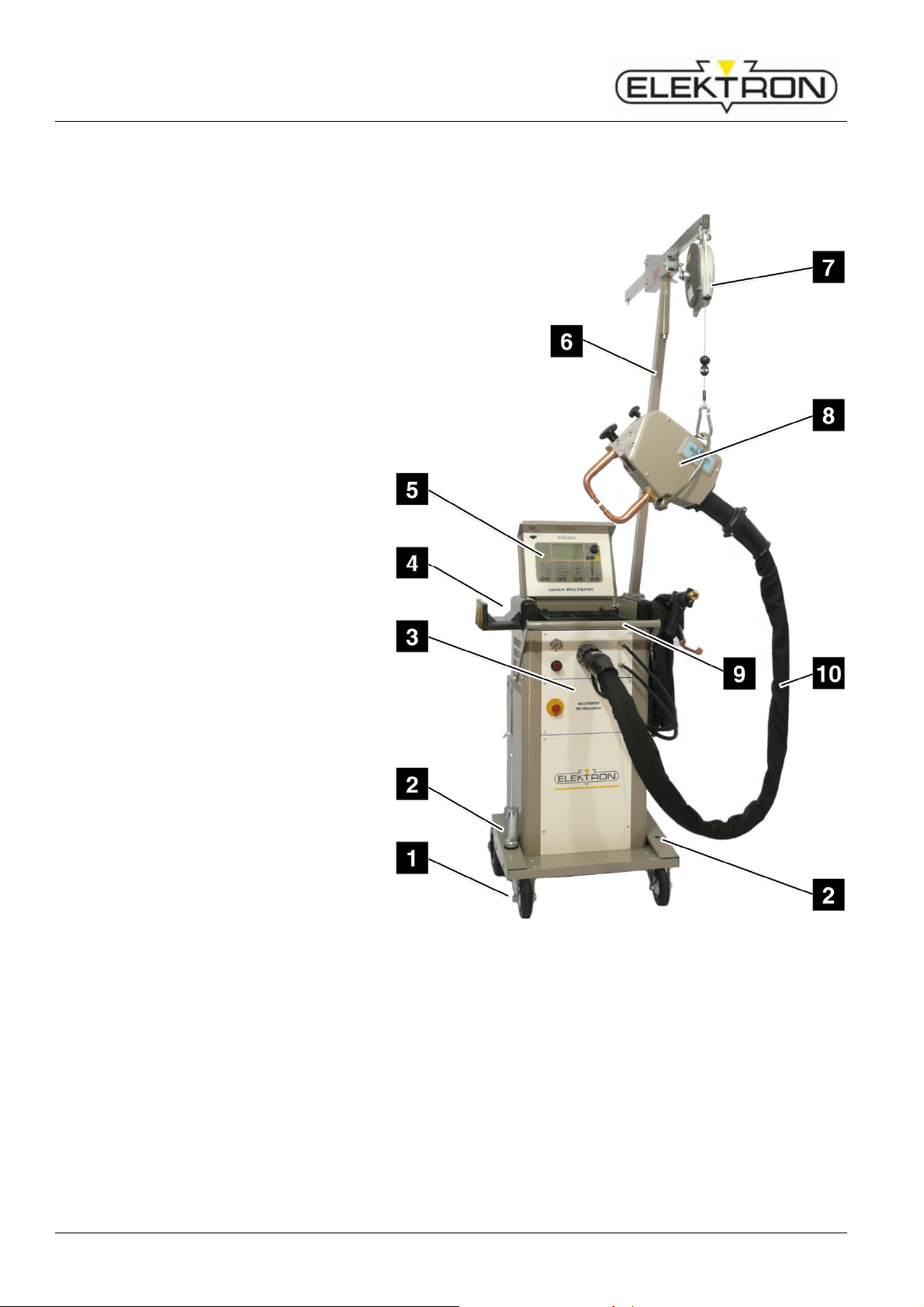

4.1 Overview

1 Running gear

2 Support for tools

3 Inverter control unit

4 Cable or welding pliers support

5 Display and control panel

6 Balancer support

7 Balancer

8 Welding pliers

9 Handle

10 Welding pliers supply lines

Fig. 11: MULTISPOT system (standard)

4.2 Description

The MULTISPOT MI-100control resistance welder has been designed and built with the special

requirements of body makers and maintenance in mind.

The inverter, which provides the power for welding, is controlled by a microprocessor. That way, weld

current and weld time will be adjusted automatically on the basis of the selected operating mode,

sheet gauge and welding job.

The automatic current adjustment facilitates a perfect reproducibility of welding results.

The additional power needed for adjustment is taken from the mains.

26

Page 27

Resistance welder MULTISPOT MI-100control

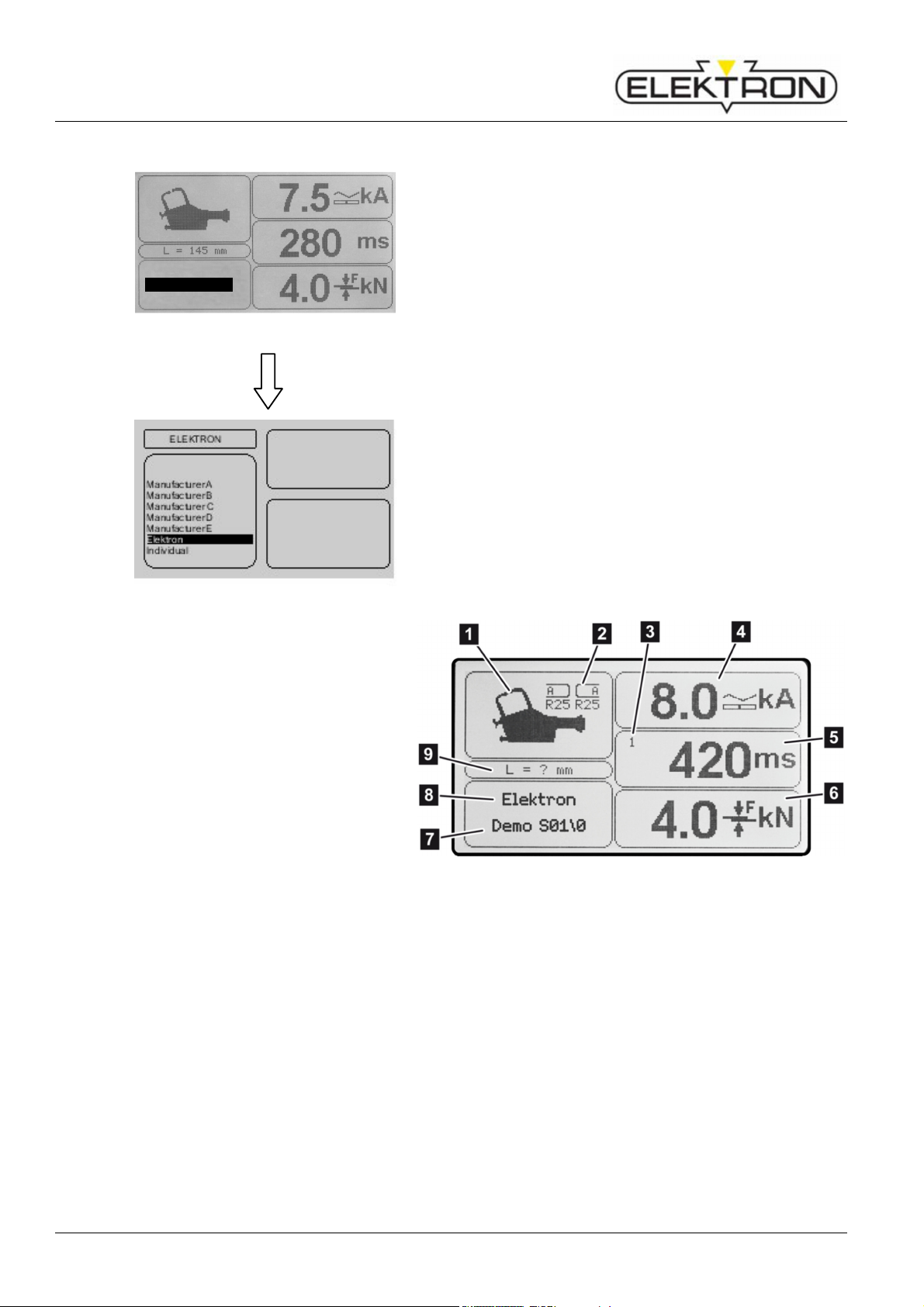

1

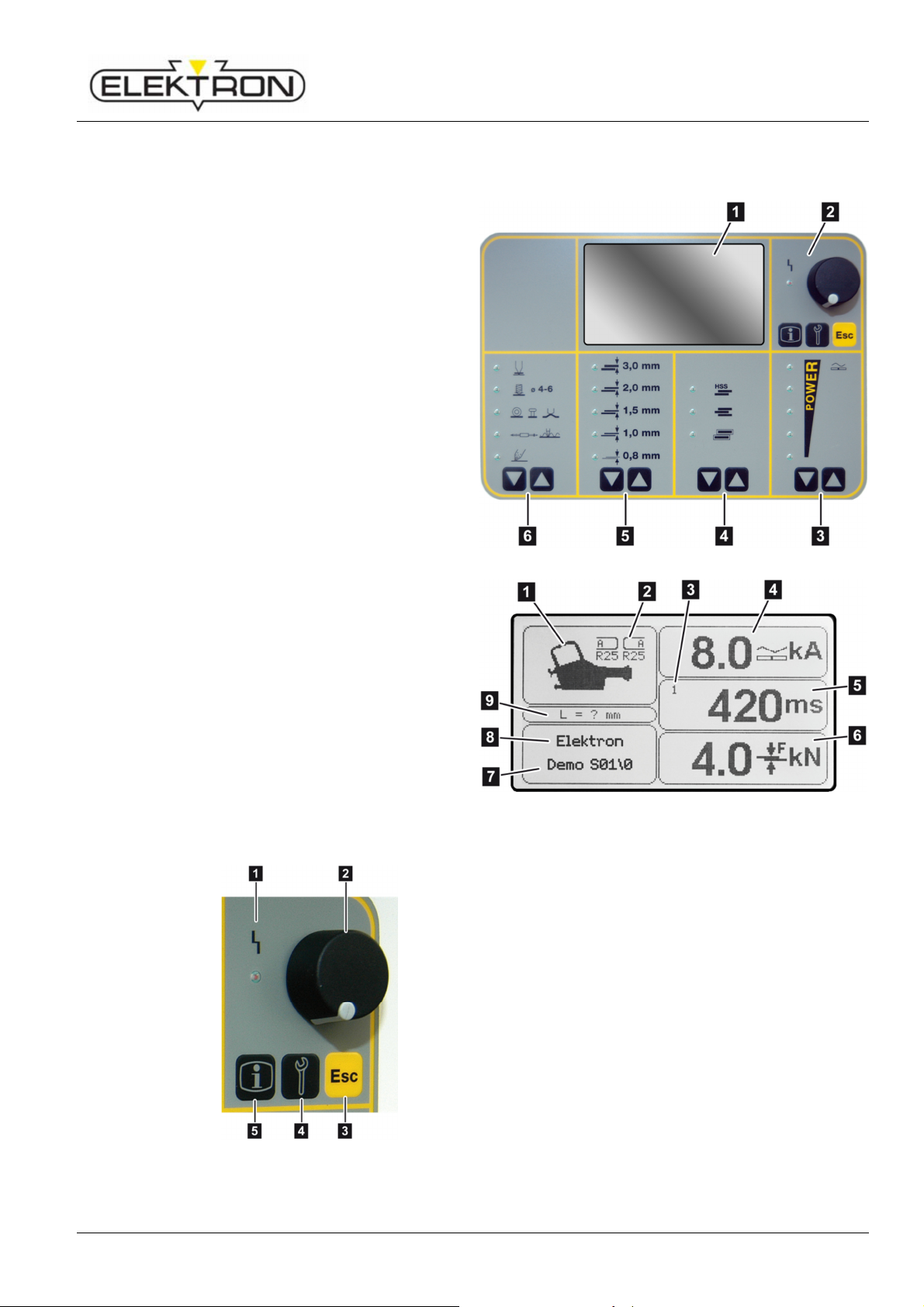

4.3 Display and control elements

4.3.1 On the display and control panel

1 Display

see also Fig. 13

2 Selection elements

see also Fig. 14

3 Touch key for power selection

4 Touch key for selecting welding jobs

(from top to bottom):

high strength steel (HSS)

3 layer sheets

galvanised sheets

5 Touch key for selecting sheet gauges

6 Touch key for selecting a welding gun

Design and functionality

Tools detected automatically

2 Electrode caps required for welding

program

3 No. of pulses (1 – 36)

4 Weld current set

5 Weld time set

(Total of all current times)

6 Contact pressure set

7 Program name

8 Operating mode

9 Projection of electrodes

(i. e. actual length minus engaging area)

Fig. 14: Detail from Fig. 12

Fig. 12: Display and control panel

Fig. 13: Detail from Fig. 12

1 LED “Malfunction”,

see “7.2.2”, work cannot continue as long as the

LED is on.

2 Control knob,

for selecting and confirming menu items.

3 “ESC”,

can have different functions: “Cancel” or “Pump

OFF”, depending on menu.

4 “Service”,

for selecting the service menu.

see “6.7.1” and “6.7.2”.

5 “Info”,

calls up welding parameters; see “6.6”.

27

Page 28

Resistance welder MULTISPOT MI-100control

Design and functionality

4.3.2 On the inverter control unit

Fig. 15: Power switch (in „OFF” position)

4.4 Connections

4.4.1 Connections on the front side

The power switch (Fig. 15) is for switching the

power supply on and off.

Fig. 16: Connections on the front side

1 Pressure gauge

displays input pressure.

2 Pressure reducer

continuous adjustment of input pressure

3 Central connection point for weld current,

compressed air and control voltage of the

welding pliers

4 Coolant outlet

5 Coolant return

6 Connection for sensors

7 Emergency stop pushbutton

shuts down equipment immediately.

28

Page 29

Resistance welder MULTISPOT MI-100control

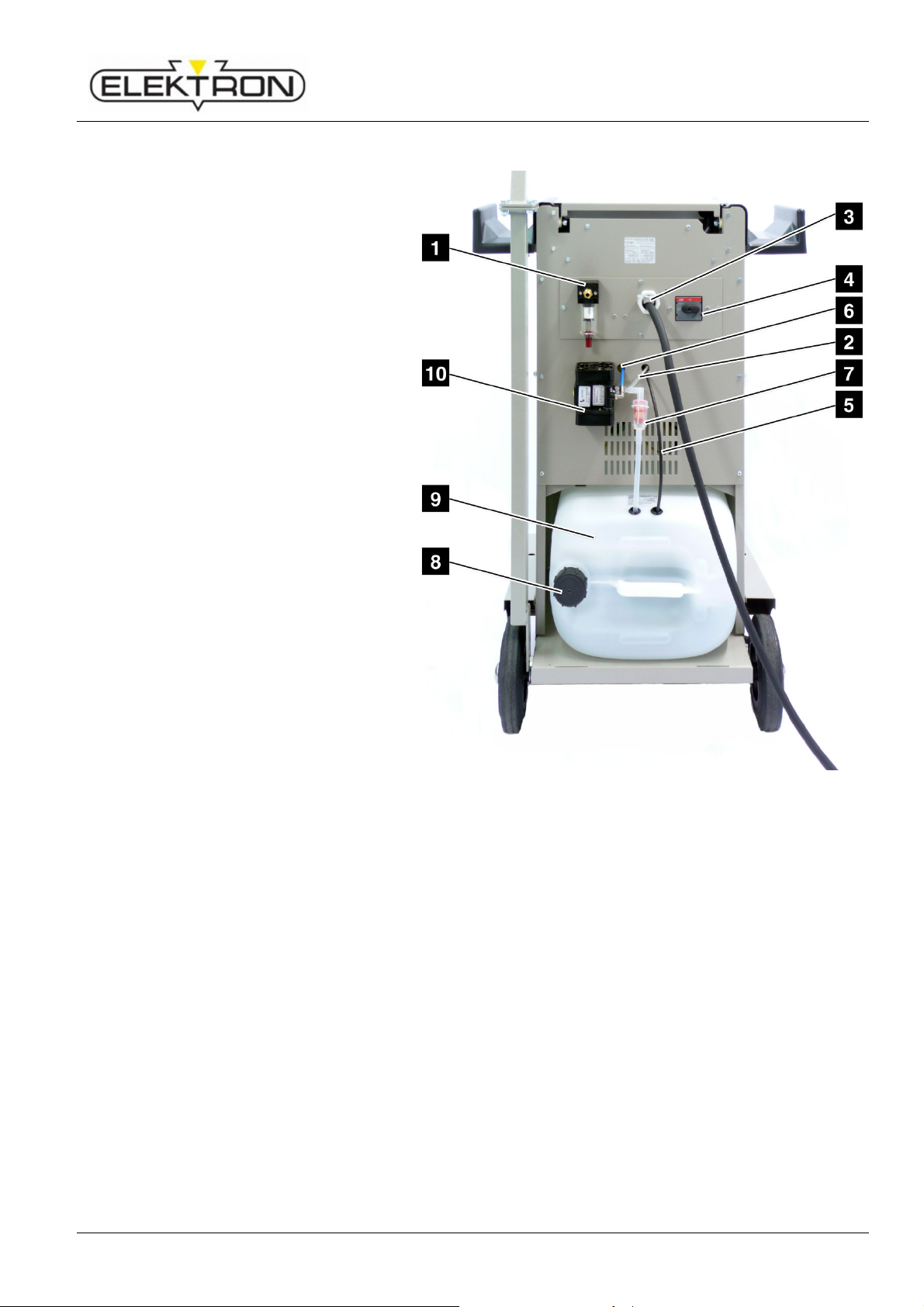

4.4.2 Connections on the backside

1 Compressed-air filter unit

2 Coolant-pump air supply

3 Power cord

4 Power switch

5 Coolant outlet towards pump

6 Coolant return

7 Water filter

8 Cooling-water tank cap

9 Cooling-water tank

Design and functionality

Fig. 17: Connections on the backside

29

Page 30

Resistance welder MULTISPOT MI-100control

Design and functionality

4.5 Accessories

4.5.1 Optional accessories

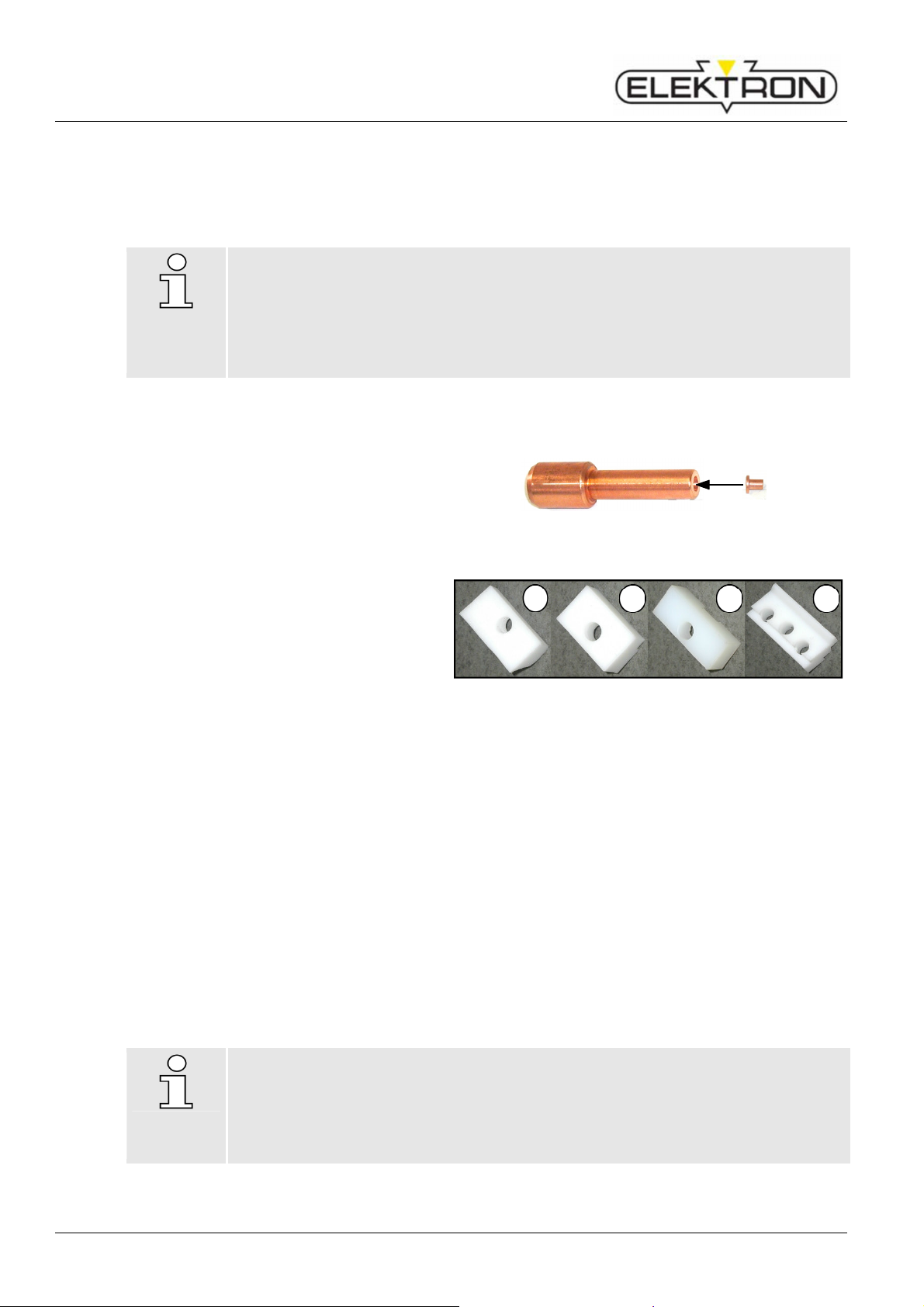

Additional cooler (Fig. 18),

to increase service life of welder

Electrode arms / hoops

Electrode caps

Fig. 18: Optional cooler

4.5.2 Tools required

Fig. 19: Key for electrode caps

Key for electrode caps (Fig. 19)

NOTE!

Find our complete range of products and order information at www.elektron-bremen.de.

30

Page 31

Resistance welder MULTISPOT MI-100control

1.

5 Installation

5.1 Before installation

5.1.1 Preliminary works

Check operating conditions according to specifications.

( see “9.4”.)

If necessary, allow equipment time to adapt to ambient temperature SLOWLY.

Make sure that operating company’s supply systems comply with specifications.

( see “9.2”.)

Before you start any works, make sure the work area is tidy, clean and free of clutter and

offers enough room to move.

Make sure your tools are complete and in good working order.

Do wear safety shoes.

5.2 Filling up cooling water tank

Installation

Fig. 20: Filling up the cooling water tank

Remove the cover on the rear side, the coolant outlet and coolants return.

2. Remove cooling water tank raise and turn off cooling water tank cap.

3. Fill about 30 litres / 7.9 gallons of cold, clean drinking water into the tank.

4. Add chlorine-free disinfectant to prevent growth of algae and bacteria.

5. Replace cap properly. Check for tightness.

6. Move the cooling water tank back. Put in the coolant outlet and coolant return into the tank; put on

the rear cover.

7. Before you switch on the welder, check the coolant level before each use and, if necessary, top up

coolant.

NOTE!

For draining the tank, see “8.2.4”

31

Page 32

Resistance welder MULTISPOT MI-100control

CAUTION!

Property damage due to heat build!

Installation

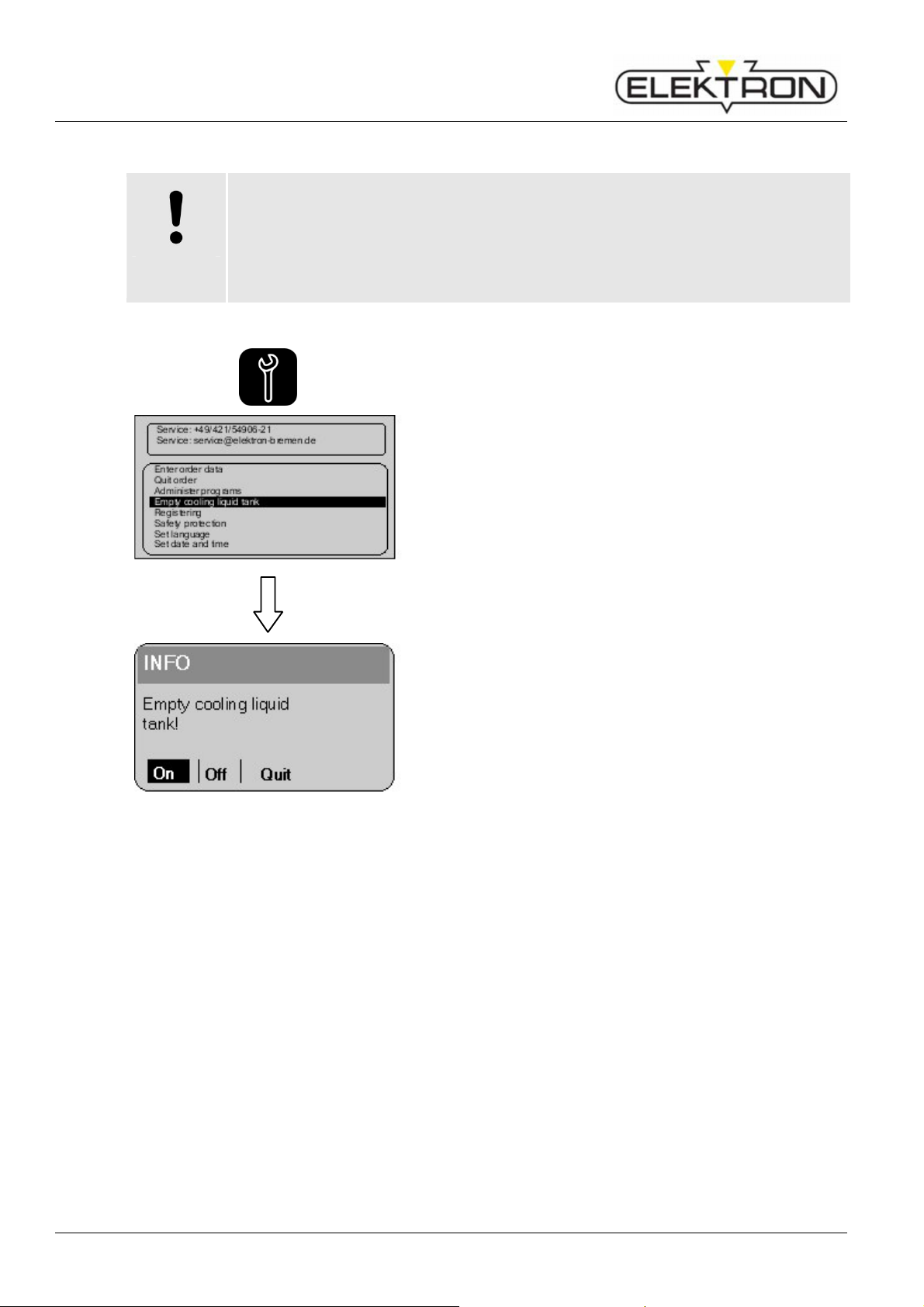

5.3 Venting coolant circuit

The power unit of the MULTISPOT MI-100control is partially connected to the cooling

circuit.

Therefore:

Before initial operation and after each filling of the coolant tank, the cooling circuit

must be vented.

1. Press service button on the control panel – once.

This will call up the “Service” menu (page 1).

2. Use the control knob to select “Empty cooling liquid

tank”. Press to confirm.

Fig. 21: Draining the cooling system

3. To vent select “ON” and confirm.

———— To stop, select “OFF” and confirm.

———— To go back to the menu, select “Cancel” and confirm.

4. To vent the cooling water pump leave running until the

pump frequency audible significantly reduced.

32

Page 33

Resistance welder MULTISPOT MI-100control

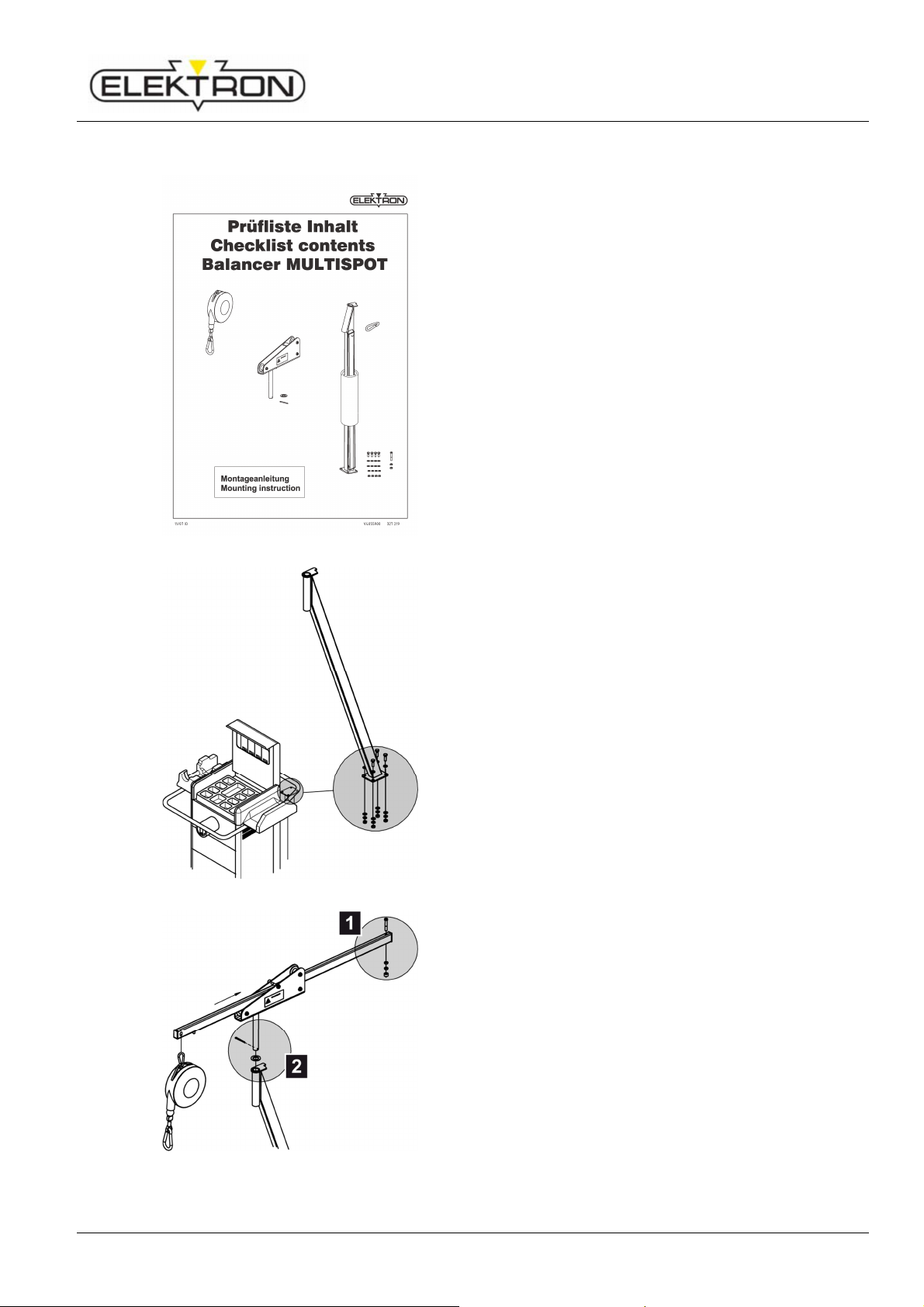

5.4 Assembling the balancer

Fig. 22: Balancer checklist

Installation

1. Unpack the balancer.

2. Check balancer components for damage. Use the

checklist provided (Fig. 22) to check whether you have all

the parts.

———— Balancer

———— Guide rollers with locking pin and ring

———— Vertical pipe and crossbar pipe

———— Replacement carabine hook

———— Four M8 bolts with two nuts and washers each

———— Mounting instructions

Fig. 23: Vertical pipe

Fig. 24: Crossbar pipe

3. Mount the vertical pipe using four M8 bolts

(Fig. 23, see separate operating and mounting

instructions).

4. Mount the crossbar (Fig. 24,

see separate mounting instructions).

Proceed as follows:

———— Mount and screw down stopper (Fig. 24/1).

———— Insert crossbar pipe into guiding element.

Secure with locking pin (Fig. 24/2).

———— Hang up spring balancer and secure (see operating

instructions for spring balancer).

33

Page 34

Resistance welder MULTISPOT MI-100control

CAUTION!

WARNING!

Stumbling hazards

!

Installation

5.5 Electrical connections

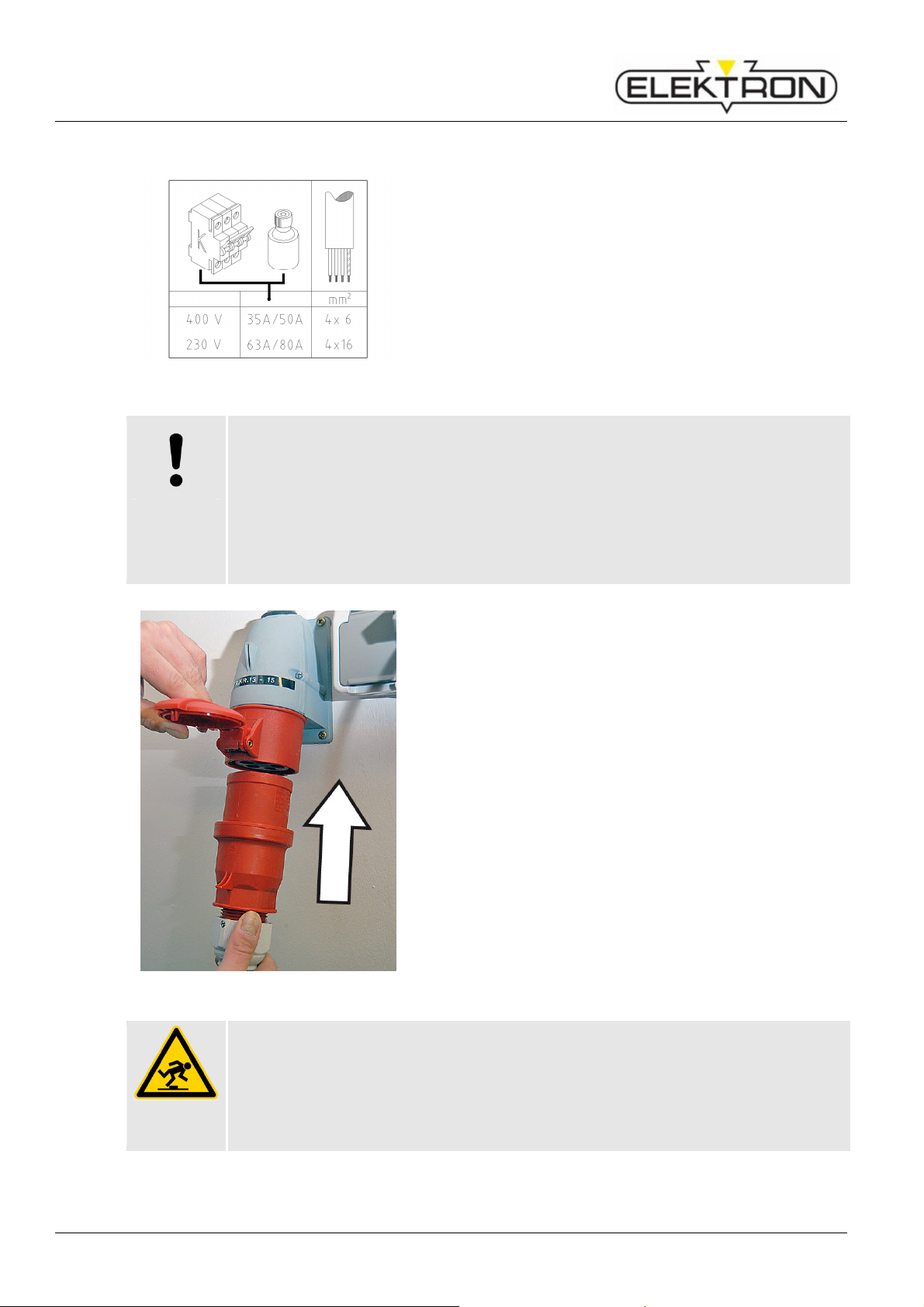

Fig. 25: Power grid specifications

Insufficient conductor cross-sections and fuse protection may make the grid collapse

and / or trigger the fuses and make efficient welding impossible.

Therefore:

Before you connect the welder to the mains, make sure conductor cross-sections

are sufficient (at least 6 mm² per 10 metres / AWG 10 per 33 ft of cable length).

Before you connect the welder to the mains, make sure the grid is properly

protected by fuses (at 32 A).

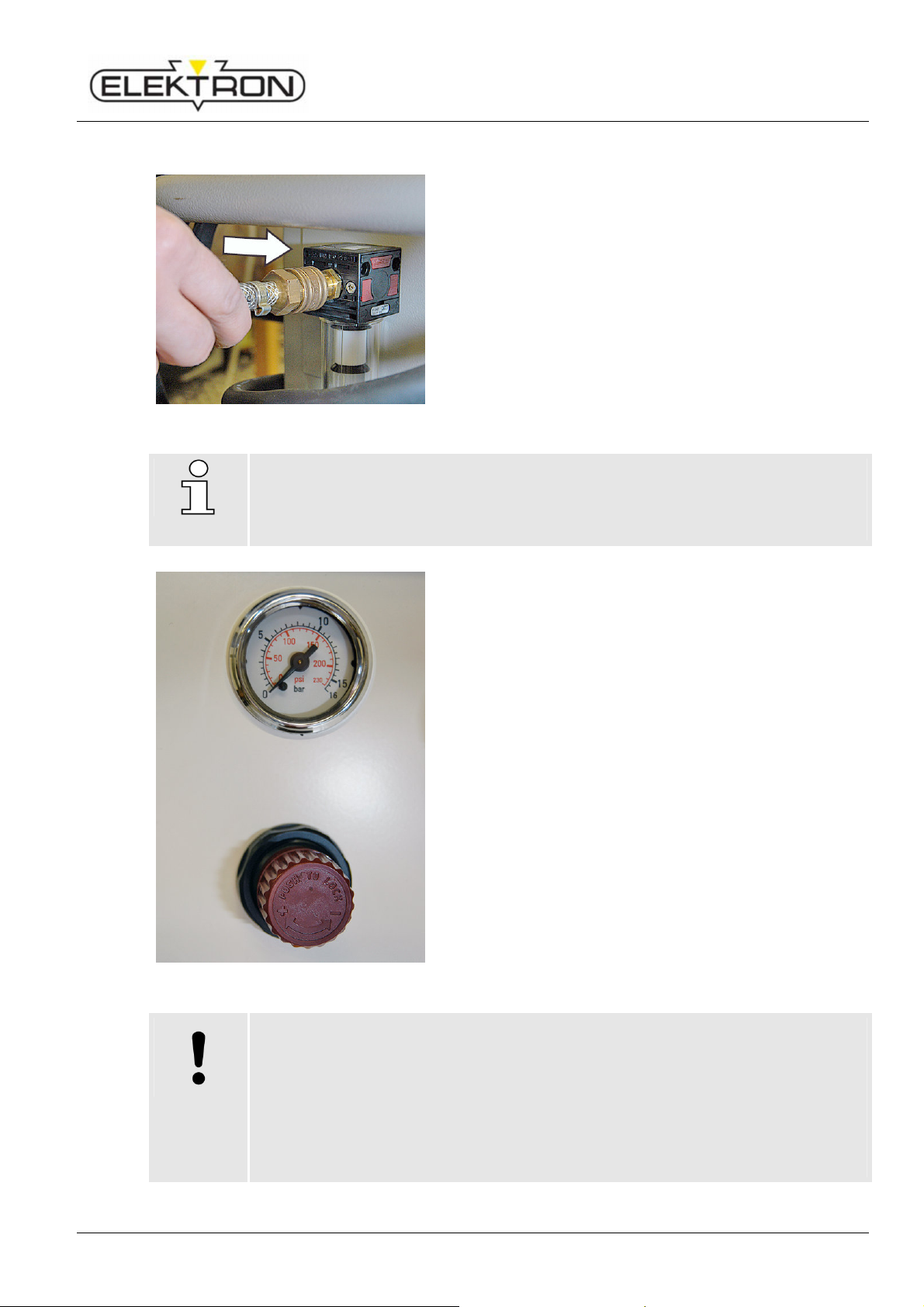

Fig. 26: Connecting welder to power supply

1. Take the power cord from its support.

2. Run the power cord along a safe route.

3. Connect the power cord to the mains.

4. Use strain relief clamps to protect cables.

34

Power cords may constitute a stumbling hazard when improperly laid or installed and

may cause people to fall and hurt themselves. In this particular case, the cable could

block the wheels of the welder and make it tip over.

Therefore:

Run the power cord along a safe route.

Page 35

Resistance welder MULTISPOT MI-100control

CAUTION!

Improper pressure of com

pressed air may damage property!

5.6 Connecting the pneumatics

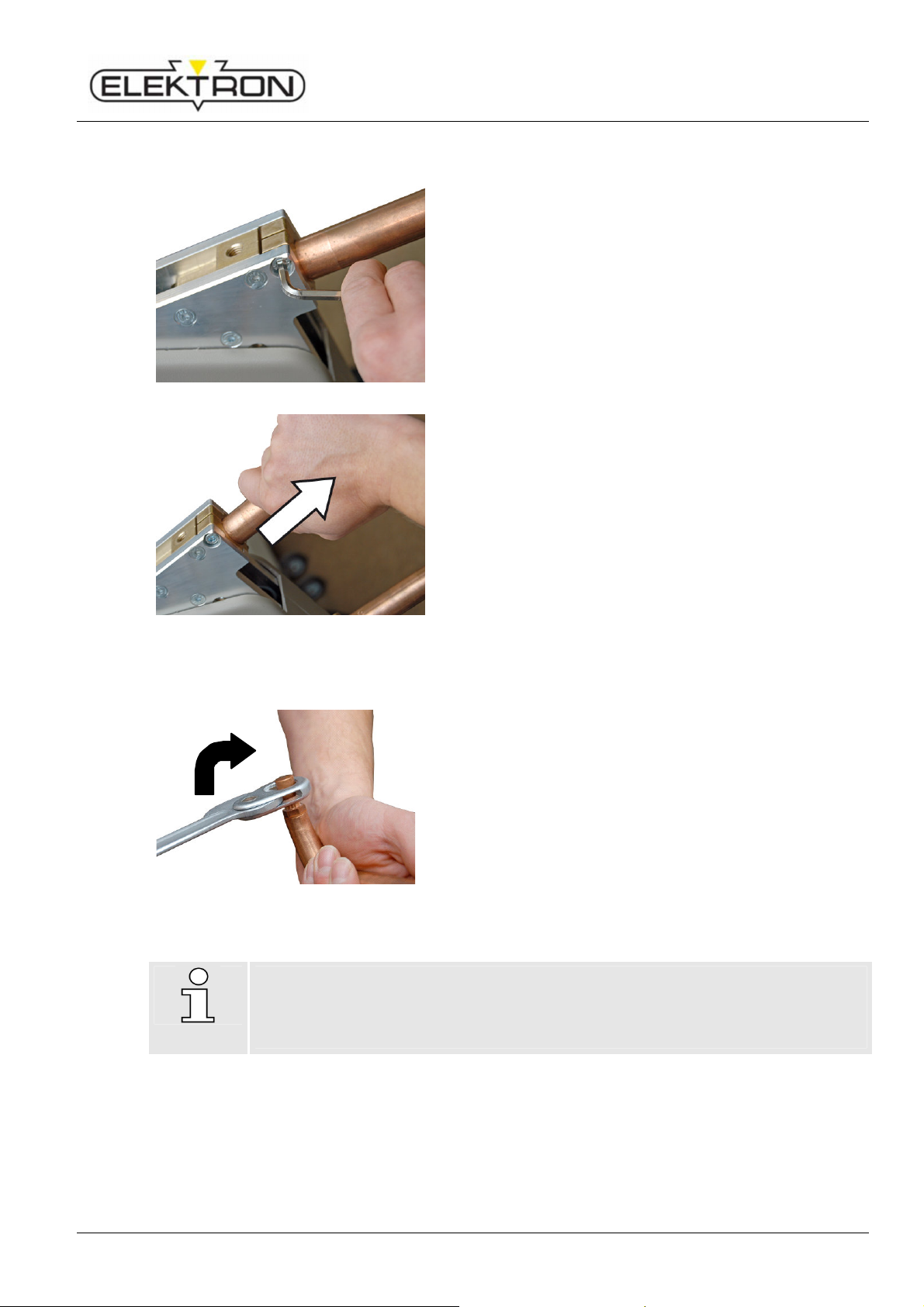

Fig. 27: Connecting compressed-air supply

NOTE!

6 bar (87 Psi) input pressure generate a contact force of the electrodes of 360 daN

(809 lb f) approx.

To adjust the contact force of the electrodes, proceed as described below.

Installation

1. Take the supply line from the pneumatic grid of the plant

and plug it on to the welder (Fig. 27).

2. The plant’s pneumatic mains must provide about 8 bar

(116 Psi) input pressure to the welder.

Fig. 28: Pressure gauge and pressure regulator

3. Check the pressure supplied at the pressure gauge

(Fig. 28).

If necessary, use the pressure regulator (Fig. 28) to set

the pressure as required (depending on welding program

and manufacturer’s specs).

Turn the regulator in the “+” direction to increase the

input pressure.

(max. admissible: 10 bar / 145 Psi)

Turn the regulator in the “–” direction to decrease the

input pressure.

(min. admissible: 6 bar / 87 Psi)

4. When decreasing the input pressure, actuate the pliers

from time to time to let the air escape.

5. Push in the regulator to set and lock the selected value.

Low pressure reduces the contact force of the electrodes which, in turn, increases wear

of the electrodes. High pressure, on the other hand, may damage the spot welding

pliers.

Therefore:

Check the pressure gauge before you switch on the welder. Compare to the

parameters of the welding program selected.

Maintain the pressure between 6 and 10 bar (87 and 145 Psi).

35

Page 36

Resistance welder MULTISPOT MI-100control

Installation

5.7 Connecting the pliers

1.

2.

Fig. 29: Connecting the pliers

1. Push the main plug of the welding pliers into the main

socket of the equipment (Fig. 29/1.).

2. Turn the retainer nut clockwise (Fig. 29/2.) to lock the

connection.

Fig. 30: Water cooling system for the pliers

Fig. 31: Connecting sensors of the pliers

3. Connect the water cooling system of the pliers.

4. Connect the sensors of the pliers.

36

Page 37

Resistance welder MULTISPOT MI-100control

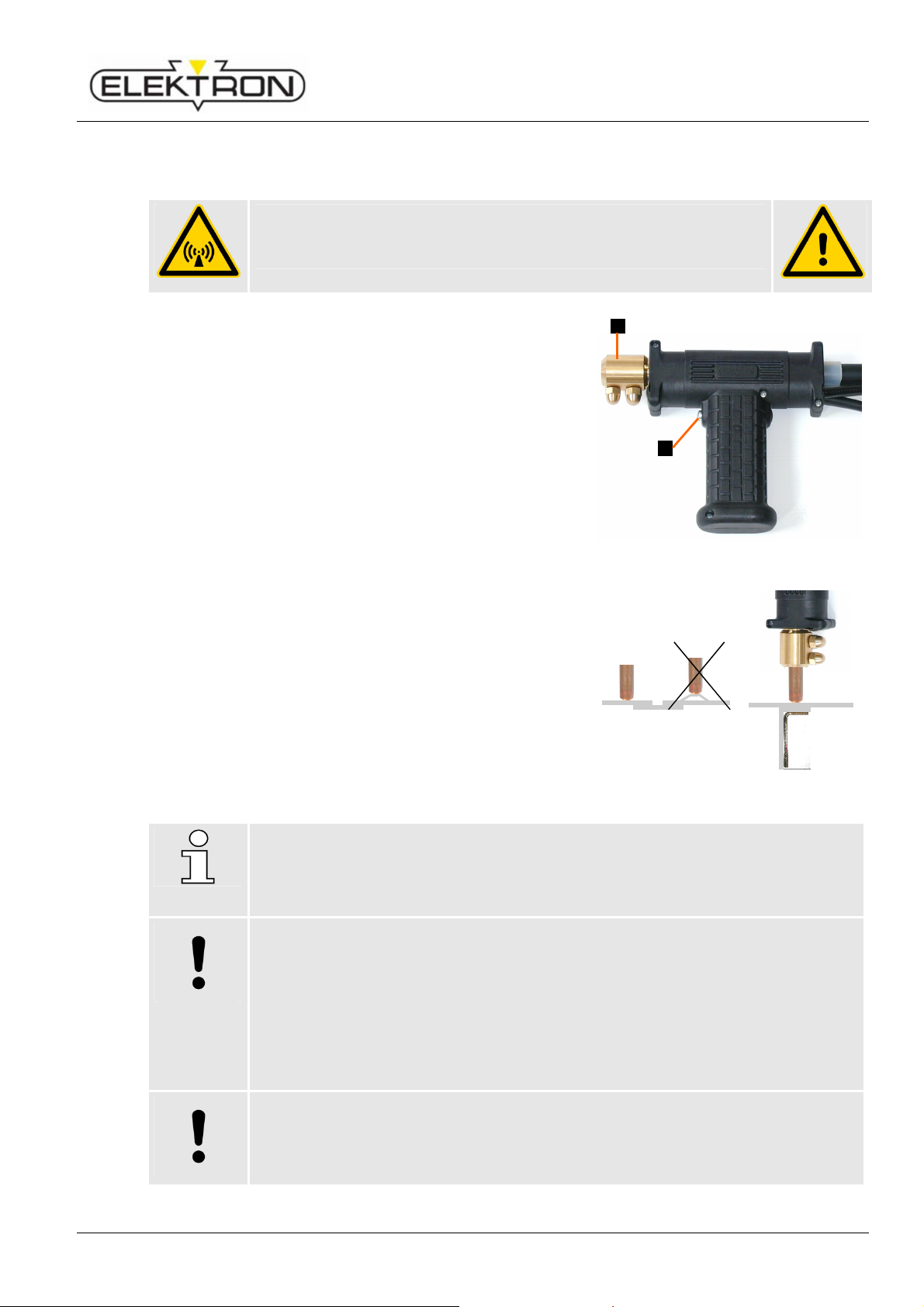

Attention!

5.8 Connecting the welding gun

1.

2.

Fig. 32. Connecting the gun

Installation

1. Push the main plug of the welding pliers into the main

socket of the equipment (Fig. 32/1.).

2. Turn the retainer nut clockwise (Fig. 32/2.) to lock the

connection.

3. Unit will switch automatically and shows the “gun” symbol

in the display.

4. Connect the copper shoe of the grounding cable to a bare

point on the bodywork to be welded. Use lever clamp

provided or a mole wrench.

Before using the lever clamp, you have to weld on

two 8 mm washers as close to the point of weld as

possible, (see 6.9.2)!

In this case, press the copper shoe of the grounding

cable firmly onto the metal sheet. This is the only way

to obtain a good current transfer.

Fig. 33: Copper shoe and lever clamp

The copper shoe must always be connected to the metal sheet below the metal part of

the body to be worked on.

In any case avoid current transfer via hinges, door and bonnet locks, as these might

otherwise be damaged! (see 6.9)

37

Page 38

Resistance welder MULTISPOT MI-100control

WARNING!

Do no

t hurt yourself during grinding!

WARNING!

Unintentional

start

-up

of welder may

constitute a hazard of injuries!

CAUTION!

Operation

6 Operation

6.1 Preliminary works before welding

6.1.1 Preparing the sheets

Always connect the earth connection to the lower sheet. Otherwise the electricity cannot

flow.

When using insulating layers (e.g. spot welding primer), you must first establish an auxiliary

connection (using a vise-grip wrench, for instance) in order to establish the electrical contact.

Contact faces must be ground down to the bare metal on all sides.

Grinding sheets may constitute a hazard of injuries.

Therefore:

Be sure to deploy employees who are experienced in this type of jobs.

Strictly observe any manuals etc. that come with the grinding tools.

Galvanised sheets should not be damaged, if possible.

Make sure the sheets are always stacked with their faces parallel to each other.

Otherwise, it will not be possible to apply clean spot welds.

6.1.2 Preparing welding pliers

If the new tool is switched on during retooling, the weld current and / or unintentional

movements of the pliers may be actuated. There is a danger of pinching and crushing.

Therefore:

Be sure to tool up first, and only then switch on the welder.

If retooling is unavoidable during the work, be sure to switch OFF before you do

anything.

NOTE!

For more detailed information on preparing / tooling up the welding pliers,

see separate operating instructions.

Therefore:

Switch off cooling first before changing electrodes!

38

Page 39

Resistance welder MULTISPOT MI-100control

Operation

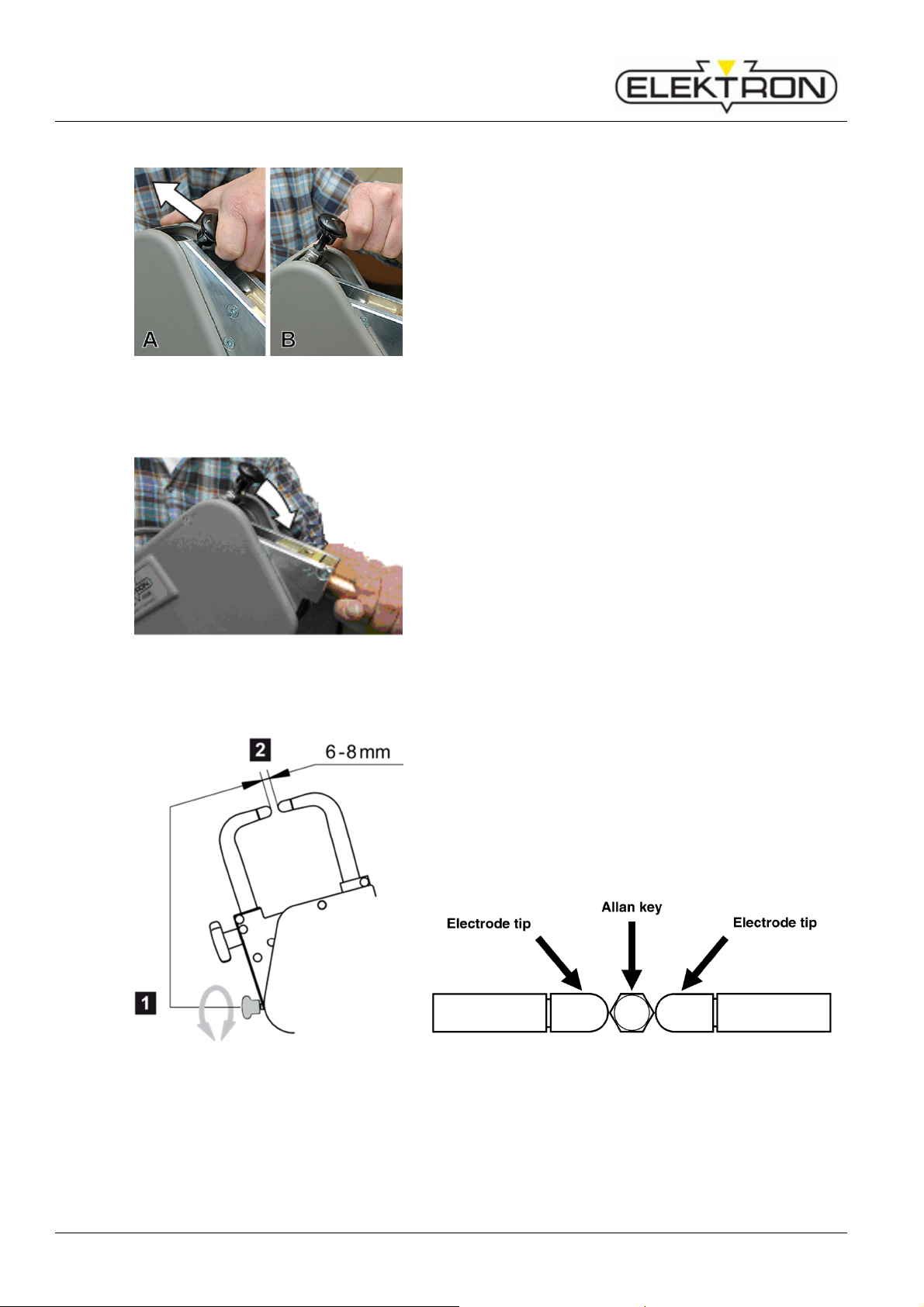

Exchanging electrode arms

1. To unbolt the electrode arm, use the Allen key provided

for that purpose (Fig. 34).

Fig. 34: Unbolting electrode arm

2. Remove the electrode arm simply by pulling it out.

(Fig. 35).

3. Insert the new electrode arm and bolt down.

Fig. 35: Removing the electrode arm

Exchanging electrode caps

Fig. 36: Exchanging electrode caps

NOTE!

The perfectly sound condition of the caps is essential for good welding results.

Electrode caps must be milled (or replaced) latest after 50 welding jobs, especially

when working with super speed and / or galvanised steel.

1. To loosen the electrode caps, use the special key

provided for that purpose (or some equivalent tool)

(Fig. 36).

2. Turn clockwise, otherwise the cone comes loose.

3. Put the new caps on the electrode head and press in

position.

39

Page 40

Resistance welder MULTISPOT MI-100control

Operation

Deploying the electrode arm

Fig. 37: Unlocking the arm / hoop

Locking the electrode arm

1. Switch the locking device of the electrode arm / hoop from

position “locked” (Fig. 37/A) to position “open” (Fig. 37/B)

as shown in the picture.

2. Push the electrode arm / hoop without much force into the

Fig. 38: Locking the arm / hoop

Adjusting the distance between electrodes

Make sure the distance between the electrodes is 6 to

Carry out the first welds, and then check the distance

Use an Allen key SW 5 as gauge in between the tips:

locking device until you feel and hear it engage (Fig. 38).

8 mm.

again. Re-adjust, if necessary.

Fig. 39: Adjusting the distance between

electrodes

Fig. 40: Measure the distance between electrode tips

40

Page 41

Resistance welder MULTISPOT MI-100control

WARNING!

Unskilled

employees may hurt themselves and others. Inexpert

Aligning electrodes

Fig. 41: “Electrode must be in true alignment”

Additional explanation on the welding plier, see separate operating manual.

6.1.3 Checks before switching on

Inexpert and / or negligent handling of this equipment and / or ignorance of hazards and

dangers may entail the most severe injuries.

Therefore:

Make sure this equipment is put to use by skilled welding operators with sufficient

training and experience in spot welding, exclusively.

Before operation, consult the manual and make sure any and all preconditions are

fulfilled; any and all checks and preliminary works etc. have been carried out.

Work place must be clean and tidy – no clutter. Make sure you have enough room

to move.

Operation

Be sure to look from different angles. Electrodes must

align no matter how you look.

operation constitutes a hazard of injuries!

Be sure to be wearing adequate PPE. ( see “2.2.3”.)

Check any and all connections. ( see “5”.)

Check input pressure. ( see “5.6”.)

Check cooling water level. ( see “5.2”.)

Check your tools / welding pliers). Re-tool now, if necessary.

( see “6.1.2” and / or separate operating instructions for welding pliers.)

Check status of the emergency stop pushbutton. ( see “2.6”.)

If you find the emergency stop button locked, check the welder and make sure it is

operational before you unlock the pushbutton. Turn clockwise (cw) to unlock.

41

Page 42

Resistance welder MULTISPOT MI-100control

3

.

Operation

6.2 Switching on

Fig. 42: Power switch

1. Once the welder has been installed and prepared

according to instructions, you may switch it on by turning

the power switch (Fig. 42).

If switching on has been successful, the display will show the

following message: S07 “Powering up, please wait.”

This will be followed by the message shown here on the left

(Fig. 43).

Fig. 43: Prompting operator to service caps

Fig. 44: Control knob

2. Visually check caps.

Clean, mill and / or replace the electrode caps, as

required.

Turn the control knob (Fig. 44) clockwise (cw) to position

“OK”. Confirm by pressing.

The display shows:

S12 “Calibrate tool”

“Please weld without sheets”

4. Press the welding button on the welding pliers.

If calibration was successful, the display will show:

S13 “Calibration successful”

> “OK”

5. Acknowledge by pressing the control knob.

If calibration was not successful, the display will show:

S13 “Error at calibration”

> “Repeat / Abort”

The reason may be that the electrode caps are dirty or worn.

If that should be the case, clean the electrode caps again.

If necessary, mill or replace. ( see “6.1.2”).

Repeat calibration.

42

Page 43

Resistance welder MULTISPOT MI-100control

6.3 Basic settings

6.3.1 Set languages

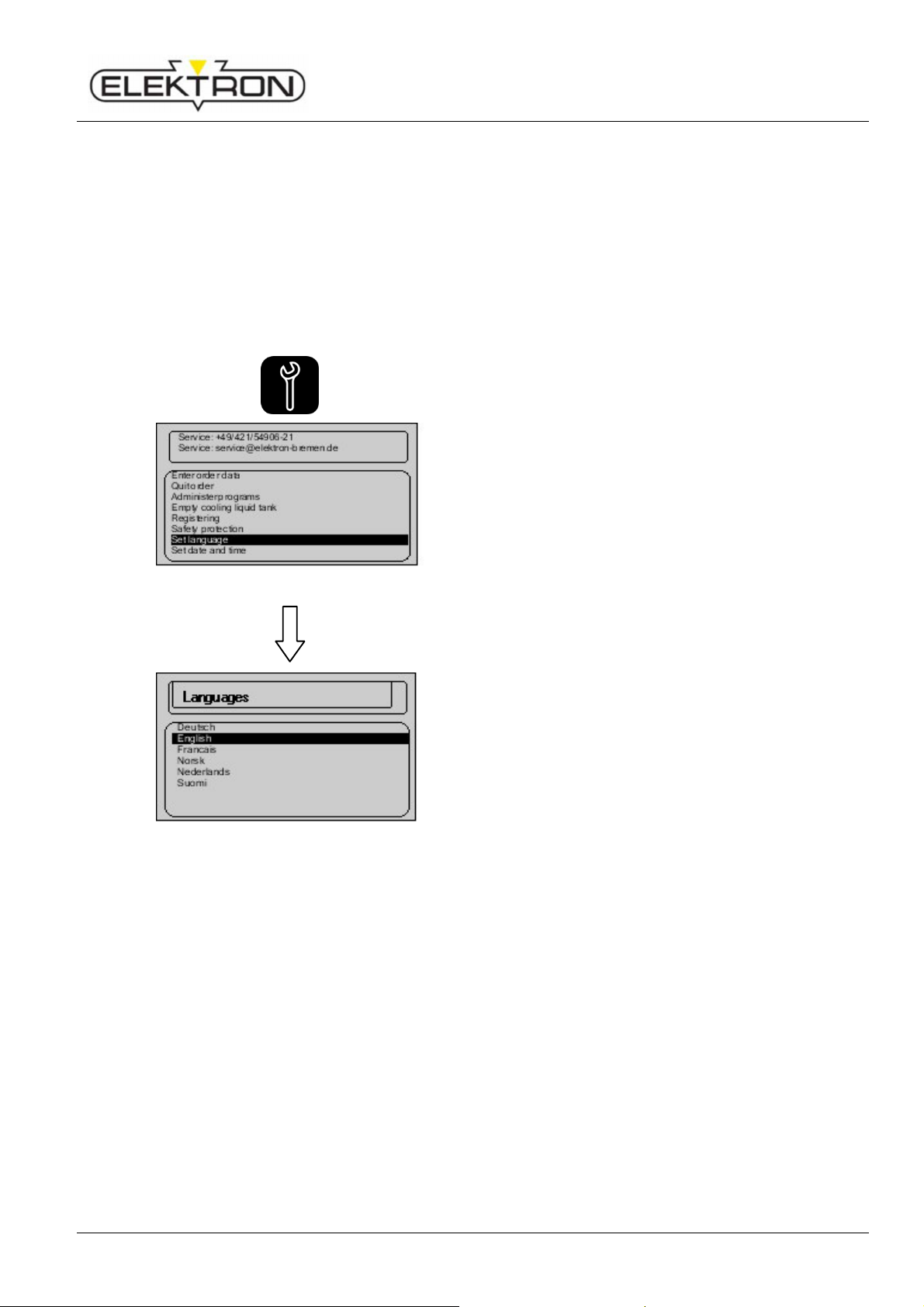

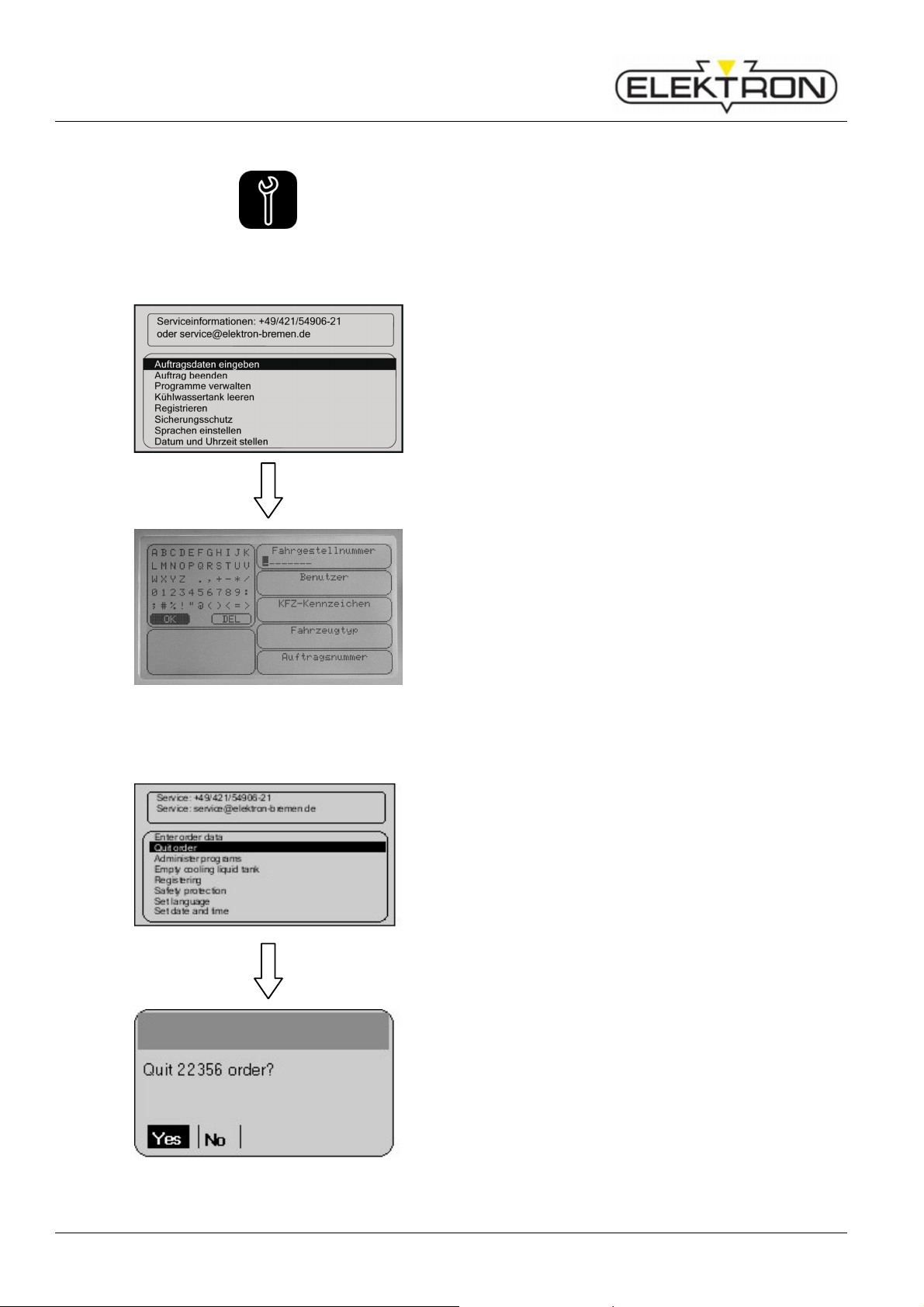

To set the display language, proceed as follows:

Operation

1. Switch off the welder.

2. Pull the plug of the welding pliers.

3. Switch on again.

The display will show message “F35”.

4. Acknowledge by pressing the control knob.

5. Press the service button (wrench icon).

6. Use the control knob to select menu item

“Set languages” (Fig. 45). Confirm.

Fig. 45: Service menu (page 1)

Fig. 46: Languages menu

Next, the display will show a list of languages from which to

choose (Fig. 46).

7. Use the control knob to select a language. Confirm.

43

Page 44

Resistance welder MULTISPOT MI-100control

Operation

6.3.2 Register welder

Fig. 47: Menu item „Registering”

Fig. 48: Registering the welder

Menu item “Registering” displays the equipment info.

The equipment may be registered.

Registering is required, if you want to use the “Free mode”

and “Program mode”.

1. Use the control knob to select menu item “Registering”.

Confirm.

The display shows the equipment info (Fig. 48).

2. Write down equipment ID and software version.

3. Go to the ELEKTRON website: www.elektronbremen.de.

Call up the “Product registration” page. Enter your data.

4. Fill in all the information in the online form in order to

obtain the best possible service.

As soon as we have received your registration data, we send

you an email with your registration number.

NOTE!

Make sure your data is correct. Otherwise, your welder will not be cleared.

Registration must be carried out within 120 days after delivery.

5. Enter the registration no. in menu item “Registering” of

the service menu.

44

Page 45

Resistance welder MULTISPOT MI-100control

CAUTION!

Improper settin

gs may

lead to improper welding!

1.

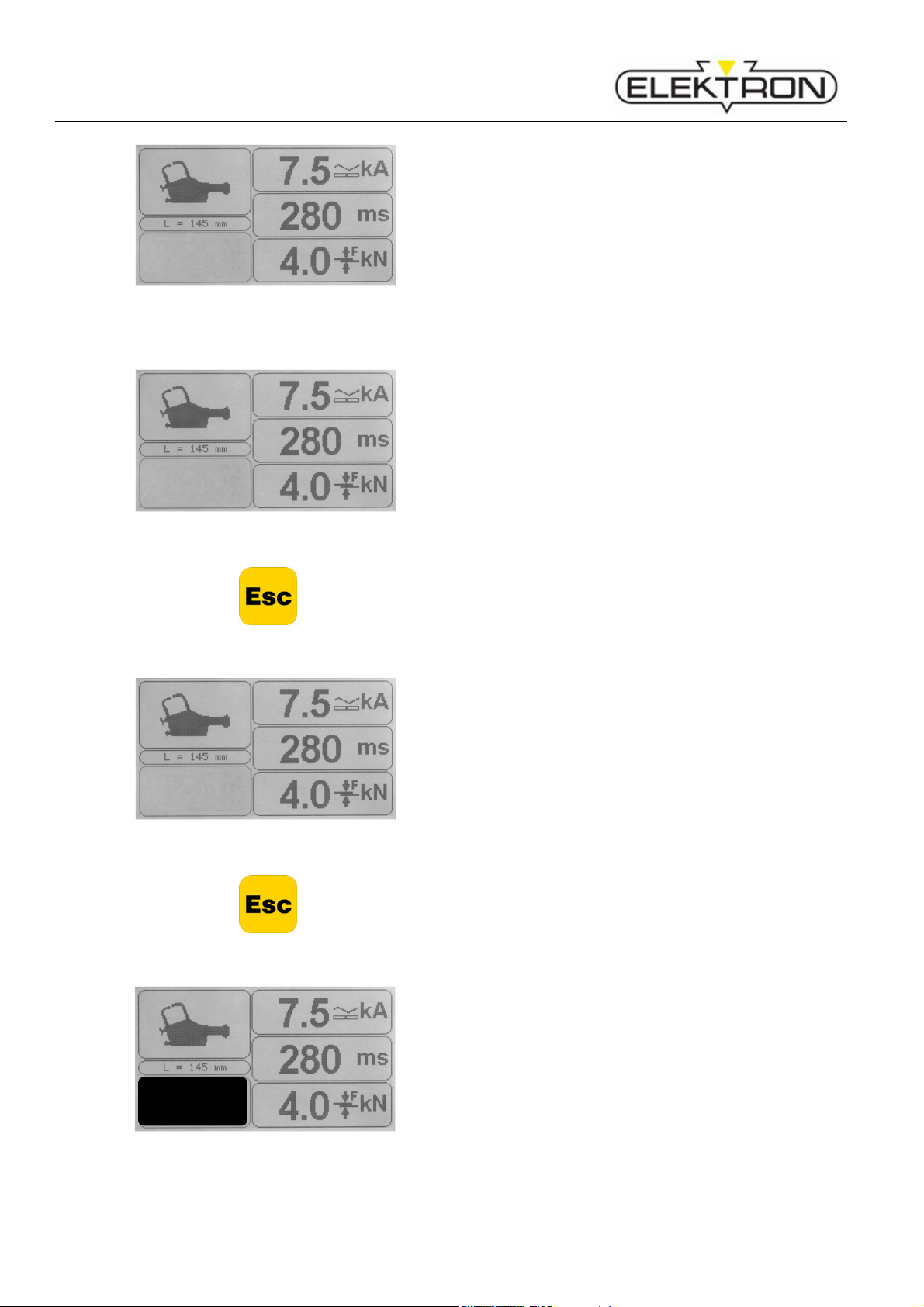

6.4 Recurring settings

6.4.1 Maintaining electrode caps

Fig. 49: Prompting operator to service caps

6.4.2 Selecting control mode

Failure to properly set the risk of faulty welds.

Therefore:

Welding parameters in the “Free mode” must be set by skilled welding operators,

exclusively.

Operation

Whenever you switch on the welder and in regular intervals

during operation, you will be reminded to take care of the

electrode caps (Fig. 49).

What to do:

1. Check the caps. If necessary, clean, mill or replace the

caps.

2. Only then confirm by switching control knob to “OK”.

Fig. 50: Main menu

Press the control knob twice, quickly.

2. Use the control knob to select one of the three following

control modes.

“Keyboard operation”

For the welding job at hand, the following parameters

may be set manually;

see “6.4.2.2”.

“OEM programs“

To select programs provided by the OEMs;

see “6.4.2.3”.

“Free mode”

This mode is suitable for skilled operators who have

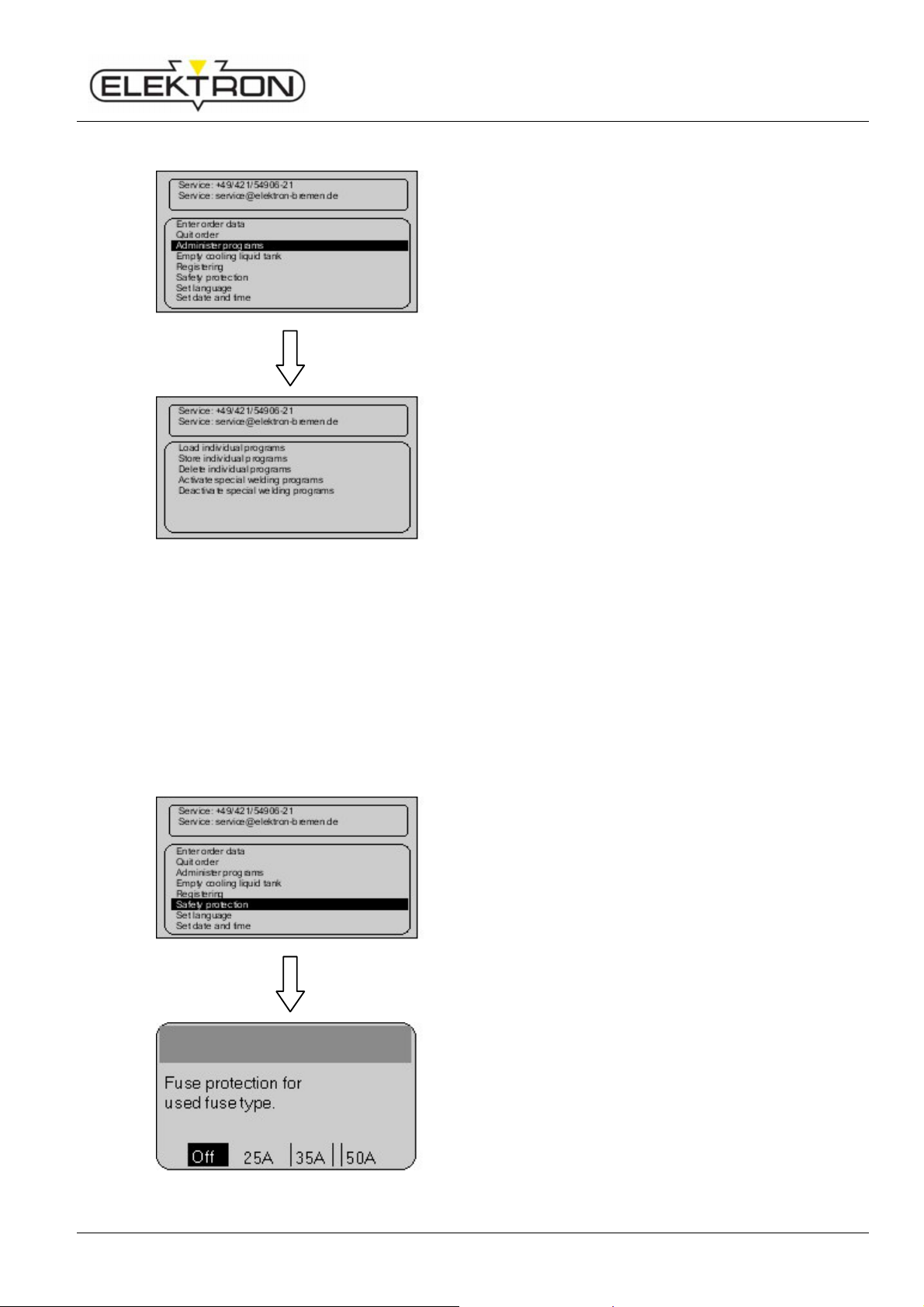

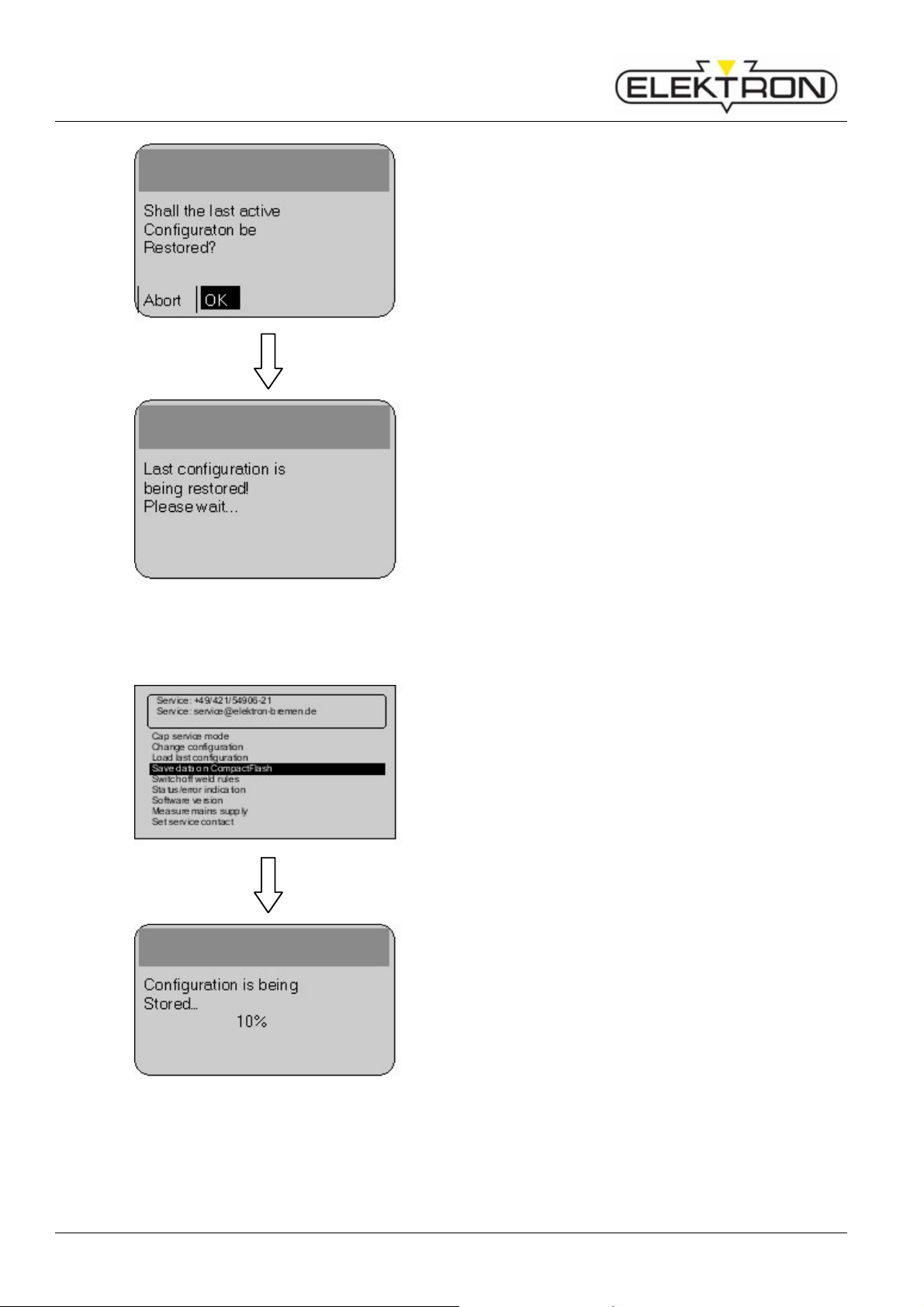

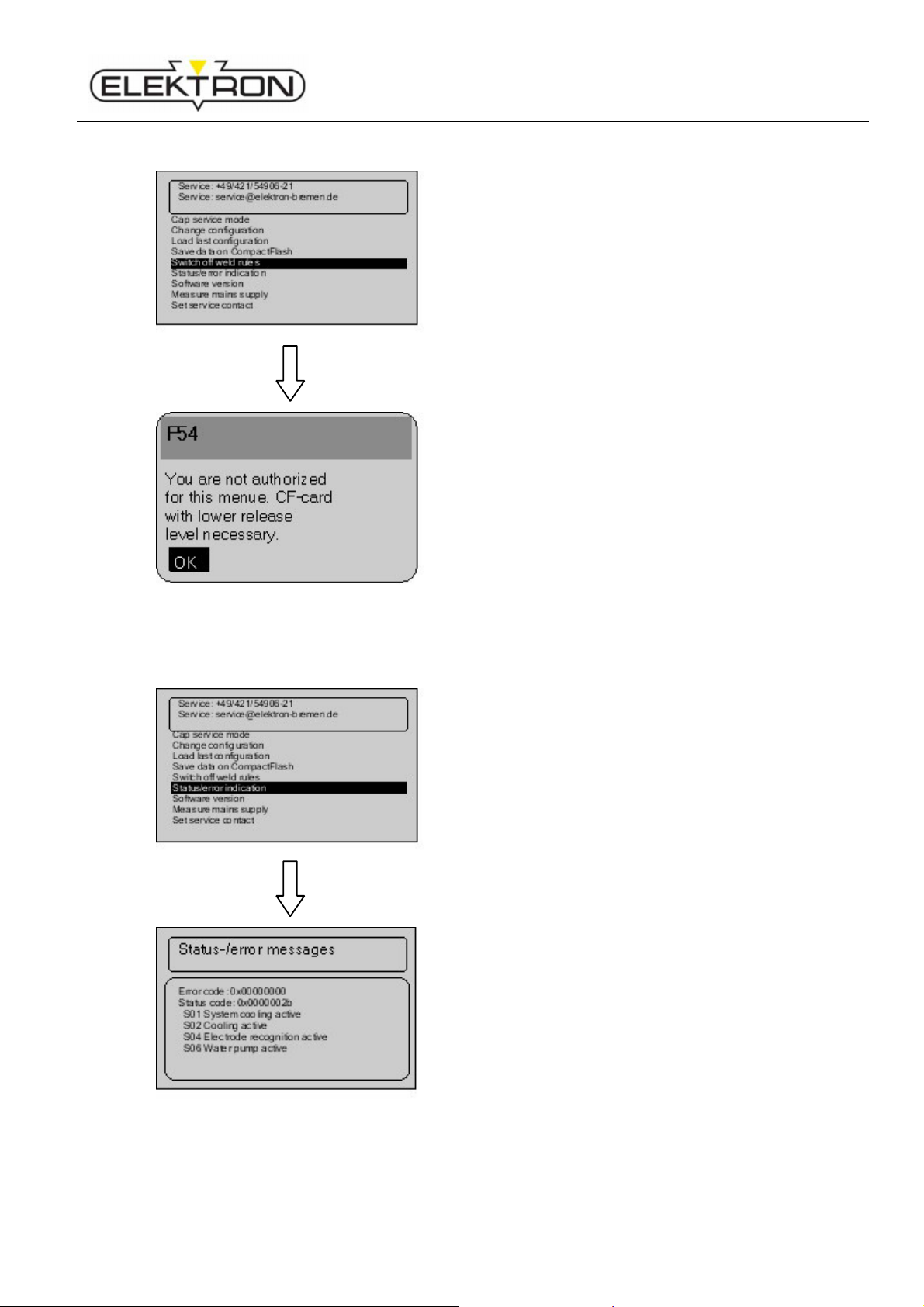

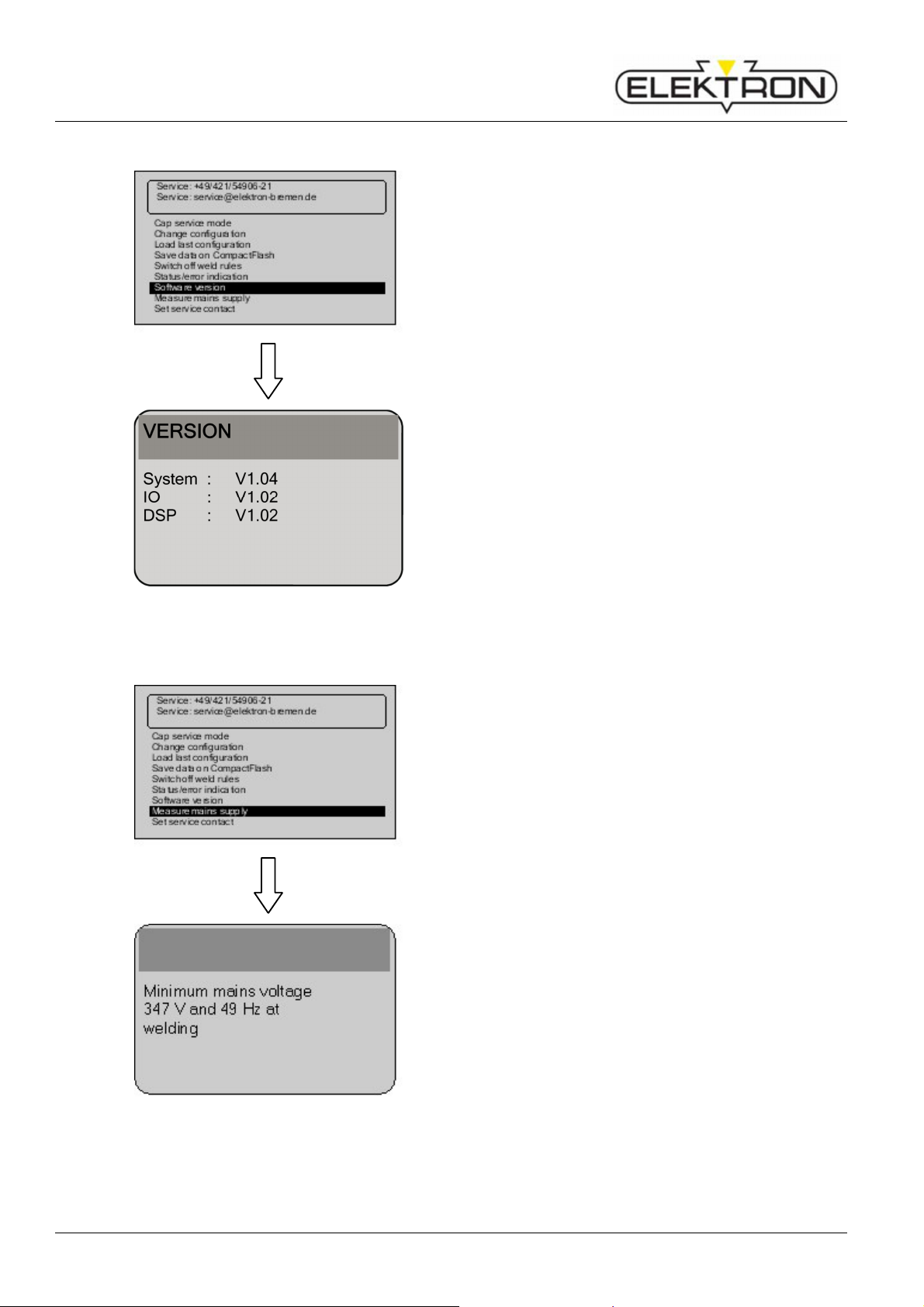

experience in setting welding program parameters and