Page 1

Made in Ge r m a ny

Operation Manual

MULTIMIG 200

MIG / MAG - Welding machine

Item-No: 327 973

Revision: 1.0 - Original

Version: 31.01.2013

Be sure you have read and understood this operating

manual before you carry out any works on and/or with this

equipment!

Page 2

© BlitzRotary GmbH

Branch Bremen

Hinterm Sielhof 22

D-28277 Bremen

Germany

Phone: +49 (0)421 / 54 90 6 - 906

Fax: +49 (0)421 / 54 90 6 - 19

E-Mail: vertrieb@elektron-bremen.de

Internet: www.elektron-bremen.de

Release:

BlitzRotary GmbH Branch Bremen

2

Page 3

MULTIMIG 200

Table of contents

1

Machine elements 4

2

Explanation of symbols 5

2.1

Meaning of the symbols in the operation

manual 5

2.2

Meaning of the symbols on the machine 5

3

Safety precautions 5

4

General regulation of use 6

5

Unit protection 6

6

Noise emission 6

7

Ambient conditions 7

8

UVV inspection 7

9

Electromagnetic compatibility

(EMC) 7

10

Setup and transport 8

13

Start-up 14

13.1 Control console MULTIMIG 200 14

13.2 Start-up 15

13.3 Current / voltage display 16

13.4 Torch with remote control 16

13.5 Deactivate operation mode 16

13.6 Characteristic line 17

13.7 Mode Manual 17

13.8 Secondary parameters 17

13.9 Tiptronic 18

13.10 Special functions 21

13.11 Reset setting 21

Table of contents

14

Menu structure 23

15

Messages 25

16

Troubleshooting 26

17

Repair and maintenance 28

17.1 Check regularly 28

17.2 Torch care 28

11

Brief operating instructions 9

12

Before start-up 10

12.1 Connecting the torch 10

12.2 Connecting the ground cable 10

12.3 Fastening the ground clamp 10

12.4 Insert the welding wire spool 11

12.5 Thread the wire electrode in 11

12.6 Connecting the inert gas cylinder 12

12.7 Changing the wire electrode 12

18

Technical data 29

19

Options and accessories 30

19.1 torch holder 30

20

Disposal 30

21

22

Service 30

Schematic 31

3

Page 4

MULTIMIG 200

sories are not included in the scope

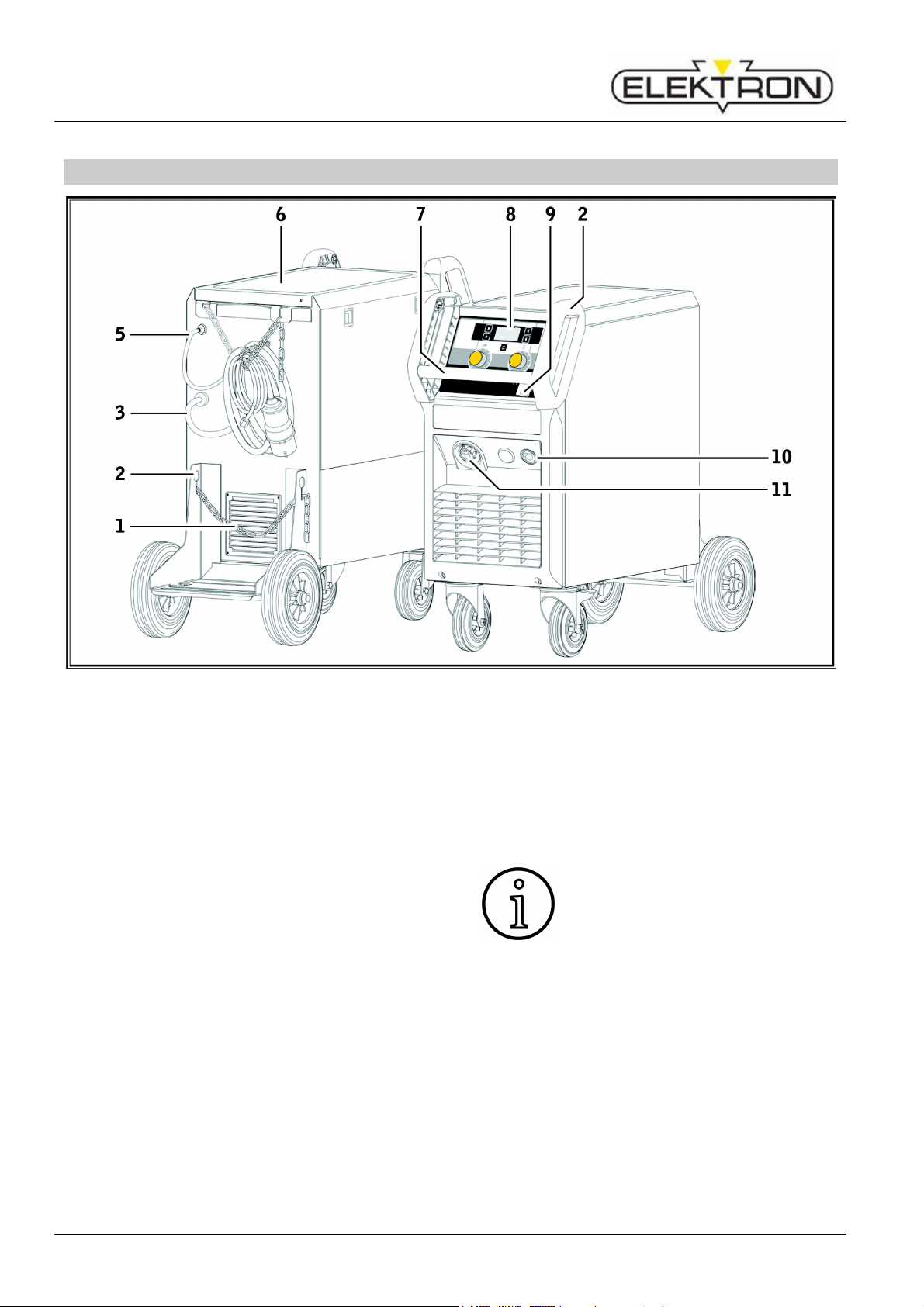

Machine elements

1 Machine elements

Fig. 1: Machine elements

1 Safety chain for gas

2 Hoisting points

3 Mains cable

5 Gas hose

6 Tray area

7 Handle

8 Control panel

9 Main switch

10 Socket for ground cable

11 Central socket

Some depicted or described acces-

of delivery.

Subject to change.

4

Page 5

MULTIMIG 200

garded, this can cause slight or

Disregarding danger warnings can

cause damage to work pieces,

Designates useful information

Read the user information in the

Pull out the mains plug before

chine is only possible if you read

fore using the machine for the first

Before starting any welding work,

clear away any solvents,

degreasing agents, and other

flammable materials from the

working area. Cover flammable

materials which can not be moved.

Only weld if the ambient air

centrations of

t, acid vapours, gases or

flammable substances. Special

care must be taken during repair

work on pipe systems and tanks

tained

Never touch live parts inside or

outside of the housing. Never

ding electrodes or live

welding current parts in a machine

Do not expose the machine to

rain, do not spray water on it or

Always use a welding shield. Warn

other persons in the welding area

2 Explanation of symbols

2.1 Meaning of the symbols in the

operation manual

Danger to life and limb!

If the danger warnings are disre-

severe injuries or even death.

Danger of property damage!

tools, and equipment.

General note!

about the product and equipment.

Explantion of symbols – Safety precautions

2.2 Meaning of the symbols on the

machine

Danger!

operation manual.

Disconnect the mains plug!

opening the housing.

3 Safety precautions

Hazard-free working with the ma-

the operating and safety instructions completely and strictly observe them.

Please obtain practical training be-

time. Follow the accident prevention regulations (UVV 1)).

contains no high con

dus

which contain or have con

flammable liquids or gases.

touch wel

that is on.

steam blast it.

about arc-rays.

Please use a suitable extraction

system for gases and cutting

fumes. Always wear breathing

apparatus whenever there is a

risk of inhaling welding or cutting

vapours.

5

Page 6

MULTIMIG 200

The machine must be transported

or set up only on firm, level

surfaces. The maximum

admissible angle of inclination for

General regulation of use

If the mains cable is damaged or

severed in use, do not touch the

cable but unplug the mains plug

immediately. Never use a

machine if the mains cable is

damaged.

Keep a fire extinguisher near the

welding area.

Check the welding area for fire af-

ter welding (see UVV 1)).

Never try to disassemble the pressure reducer. Replace the defective one.

setting up or transporting is 10°.

Service and repair work may only be carried

out by a trained electrician.

Ensure that the ground cable has good and

direct contact near the welding location. Do

not allow welding current to pass through

chains, ball bearings, steel cables or

grounding equipment; this may melt them.

Secure yourself and the welding machine

when working in elevated or inclined areas.

The machine may only be connected to a

properly grounded mains supply. (Threephase four-wire system with grounded

neutral conductor or single phase-three-wire

system with grounded neutral conductor)

socket and extension cable must have a

functional protective conductor.

Wear correct protective clothing, leather

gloves and leather apron.

Protect the welding area with curtains or

mobile screens.

Do not use this machine to thaw frozen

water pipes or cables.

In closed containers, under cramped conditions, and in high electrical risk areas, only

use machines with the S sign.

Switch off the machine during breaks and

close the valve of the gas cylinder.

Secure the gas cylinder with a chain to

prevent it falling over.

Disconnect the mains plug from the mains

before changing the place of installation or

making repairs to the machine.

Please heed the safety regulations which apply

to your country.

Subject to change.

4 General regulation of use

This unit is for welding of steel, aluminium and

their alloys as well as for brazing with CuSi

wires for commercial as well as for industrial

use.

5 Unit protection

This machine is protected electronically

against overloading. Do not use fuses of higher

amperage than printed on the identification

plate.

Close the side cover before starting any

welding work.

6 Noise emission

The noise level of the unit is less than

70 dB(A), measured under standard load in accordance with EN 60974-1 in the maximum

working point.

6

Page 7

MULTIMIG 200

tion, storage and transport

may only be carries out within the

ranges indicated! Use outside of

this range is considered not used

with its intended purpose. The

Improper UVV inspections can

7 Ambient conditions

Temperature range of ambient air:

In operation:

-10 °C … +40 °C (+14 °F … +104 °F)

Transport and storage:

-25 °C … +55 °C (-13 °F … +131 °F)

Relative humidity:

up to 50 % at 40 °C (104 °F)

up to 90 % at 20 °C (68 °F)

-25 °C … +55 °C (-13 °F … +131 °F)

Opera

Electromagnetic compatibility (EMC)

9 Electromagnetic compatibility

(EMC)

This product is manufactured in conformance

with the current EMC standard. Please note

the following:

The machine is intended for welding in both

commercial and industrial applications

(CISPR 11 class A). Use in other

surroundings (for example in residential

areas) may disturb other electronic devices.

Electromagnetic problems during start-up

can arise in:

• Mains cables, control cables, signal and

telecommunication lines near the welding or

cutting area

• TVs / radios

manufacturer is not liable for damages cause by misuse.

Ambient air must be free of dust, acids, corrosive gases or other damaging substances!

8 UVV inspection

Operators of commercially-operated welding

systems are obliged to have safety inspections

of the equipment carried out regularly in

accordance with VDE 0544-4. ELEKTRON

recommends inspection intervals of 12 months.

A safety inspection must also be carried out

after alterations or repair of the system.

destroy the system.

• Computers and other control equipment

• Protection equipment such as alarm

systems

• Pacemakers and hearing aids

• Equipment for measurement and calibration

• Equipment with too little protection against

disturbances

If other equipment is disturbed it may be

necessary to provide additional shielding.

The affected area can be bigger than your

premises/property. This depends on the

building, etc.

Please use the machine in compliance with the

manufacturer's instructions. The machine

operator is responsible for installation and use

of the machine. Furthermore, the owner is

responsible for eliminating the disturbances

caused by electromagnetic fields.

7

Page 8

MULTIMIG 200

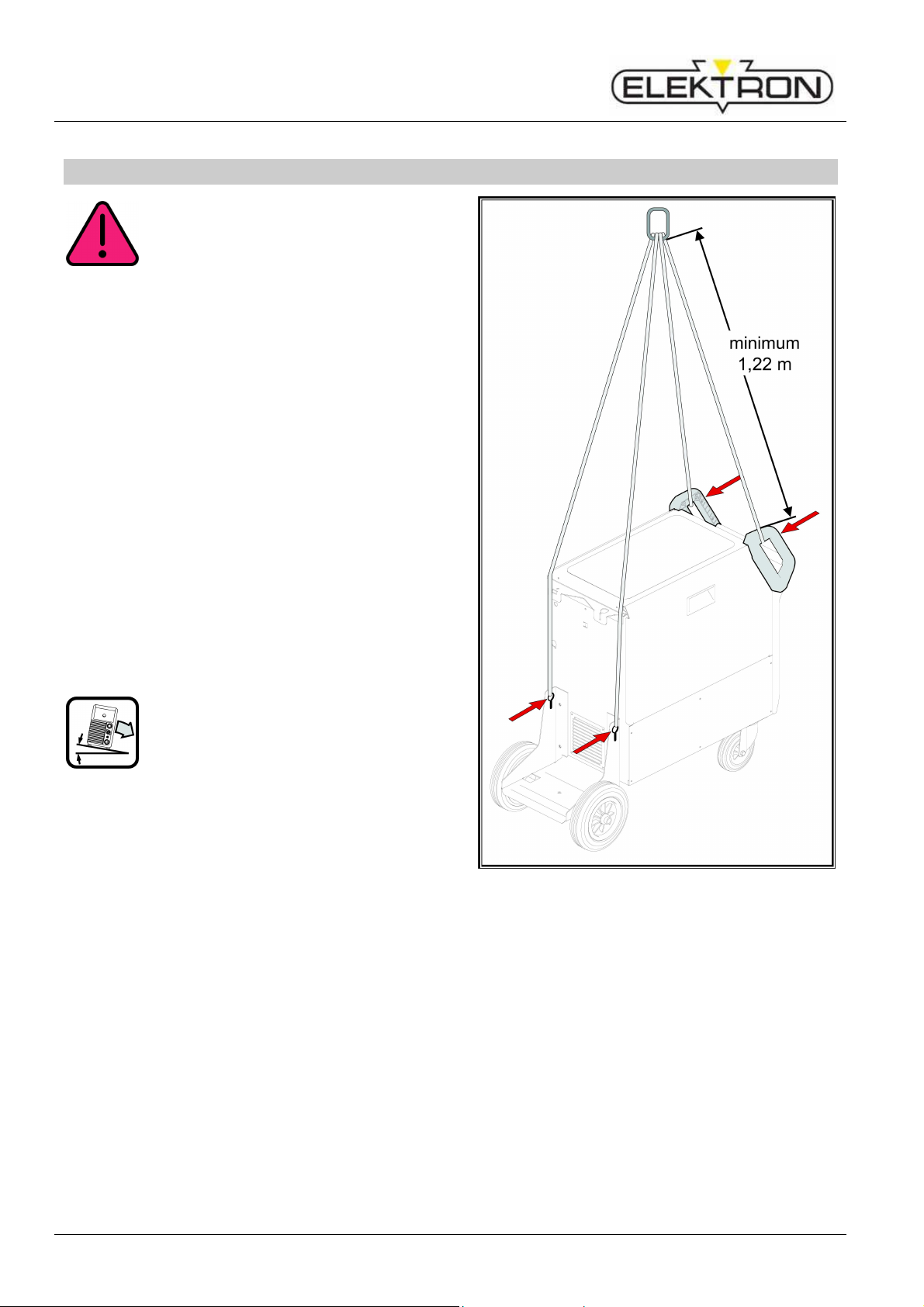

cal lifting equipment (e.g. crane,

etc.), only the hoisting points shown

here may be used. Use suitable

Each lifting point must be loaded

for example

put one load strap through both

handles, as this could lead them to

be pulled together and cause

lar

device to lift the machine by its

Remove the gas cylinder from the

The machine must be transported

faces. The maximum admissible

setting up or

Setup and transport

10 Set-up and transport

Danger of injury due to the device falling over and crashing!

When transporting using mechani-

load-carrying equipment.

separately. Do NOT,

breakage!

Do not use a fork-lift truck or simi

housing.

welding machine before transportation.

or set up only on firm, level sur-

angle of inclination for

transporting is 10°.

Fig. 2: Lifting point for 4-point hoisting

8

Page 9

MULTIMIG 200

A detailed description can be found

up“ Page

11 Brief operating instructions

in chapter. „Before start10 and chapter. „Start-up“ Page 14.

Place the inert gas cylinder on the unit and

secure it with the chain 1.

Remove the screw cap from the inert gas

cylinder and open the valve 32 briefly (blowout).

Connect the pressure reducer 13 to the inert

gas cylinder.

Connect the insert gas hose 5 from the unit

to the pressure reducer and open the

cylinder valve.

Insert the mains plug in the socket.

Connect welding return cable to connector

10 and the clamp to the workpiece.

Insert wire feed rollers 25 into wire feed unit

in accordance with the type of welding wire

selected, set contact pressure to 2.

Connect the torch to central connector 11

and insert the relevant contact tip to selected welding wire.

Insert welding wire.

Keep torch switch pressed and set main

switch 9 ON. Magnetic valve will be activated!

Adjust gas quantity at pressure reducer.

(Rule: wire diameter x 10 = gas quantity).

Hold down the wire feed switch 29 until the

welding wire projects from the torch neck to

the gas nozzle by approx. 20 mm.

Brief operating instructions

Mode key 47 for selection of 2-stroke mode.

Key characteristics 50 and operation knob

52 for adjusting the selected characteristic

line (material-gas-wire-combination).

Turn knob 45 to set material thickness of

the weldable material.

Torch switch pressed and held = welding.

Release the torch switch = welding process

completed.

9

Page 10

MULTIMIG 200

Before start-up

12 Before start-up

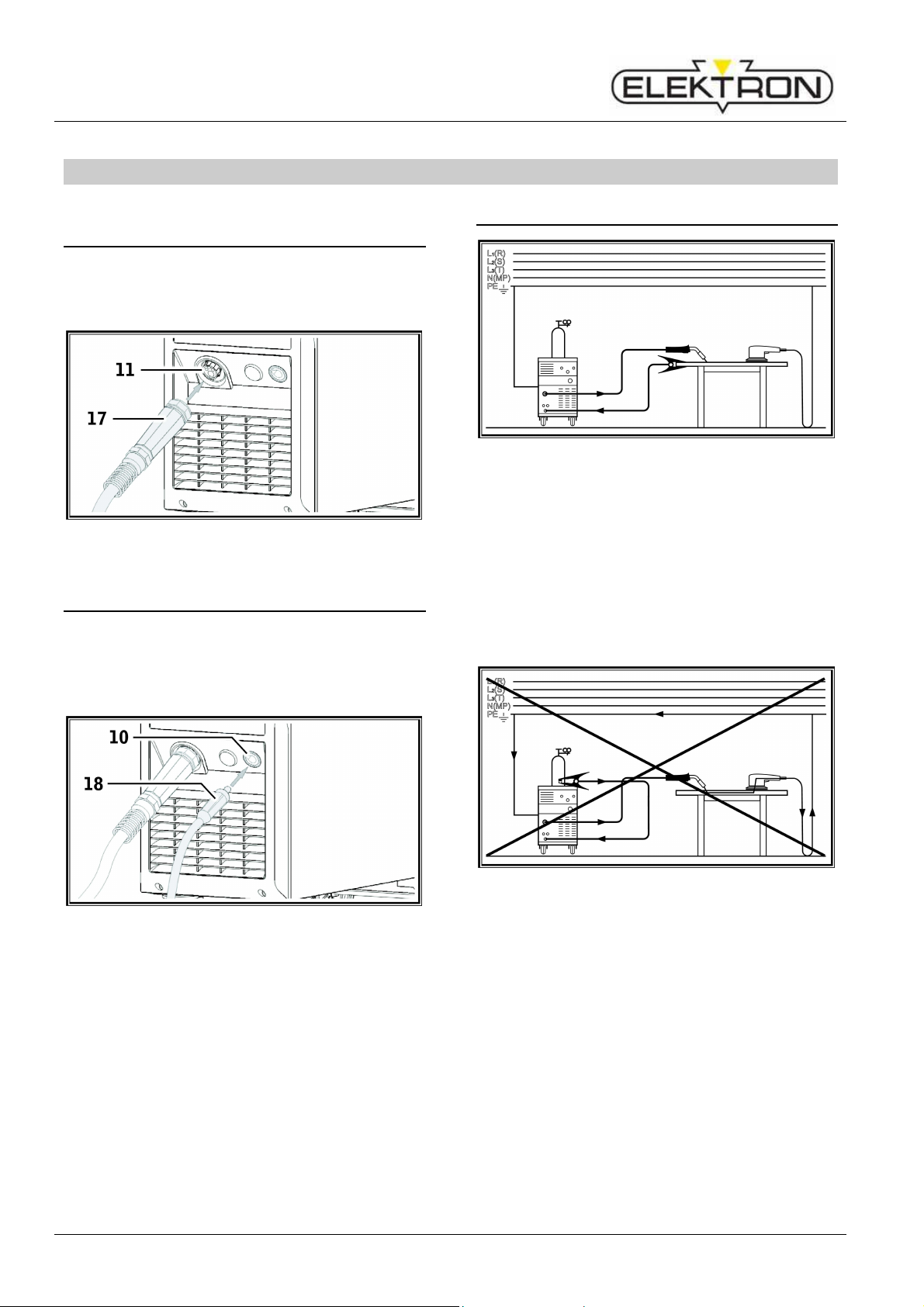

12.1 Connecting the torch

Connect the central connector 17 of the

torch to the central socket 11.

Fig. 3: Connecting the torch

12.2 Connecting the ground cable

Connect welding return cable 18 to con-

nector 10 and secure it by turning it clockwise.

12.3 Fastening the ground clamp

Fig. 5: Correct

Attach the ground clamp immediately be-

side the welding point so that the welding

current will not try to find its own return path

through machine parts, ball bearings or

electric circuits.

Connect the ground clamp firmly to the

welding bench or the workpiece.

Fig. 4: Connecting the ground cable

10

Fig. 6: Incorrect

Do not place the ground clamp on the

welding machine or the gas cylinder; otherwise the welding current will be carried via

the protective conductors and it will destroy

these.

Page 11

MULTIMIG 200

A protruding piece of wire out of the

pool can cause short circuits

to the side panel or bottom of the

When inserting the welding wire

spool, please pay attention to the

correct winding and make sure that

there are no protruding pieces of

Set the wire brake in such a way

tinue

running when releasing the torch

12.4 Insert the welding wire spool

Danger to life and limb and fire

hazard due to glowing welding

wire or parts!

wire s

unit.

wire.

that the wire spool doesn’t con

key.

Open side panel and turn the retaining nut

20 off from the wire spool holder 22.

Place the welding wire reel on the decoiler

mandrel and ensure that the carrier mandrel

23 locks in position.

For small welding wire reels, use an adaptor

(order number: 420 922).

Set the wire brake 21 so that, when the

torch switch is released, the welding wire

spool just does not run on.

Before start-up

Unscrew the contact tip of the torch.

Open side panel.

The diameter of the wire electrode must

agree with the legible embossed figure on

the wire feed rollers 25.

Swing the tilt levers 27 to the side and

thread the wire electrode through the inlet

nozzle 26 and central socket 11.

Fig. 8: open 4-roll wire feed

Swing the lever back 28 and secure in po-

sition with the tilt levers 27.

Fig. 7: Decoiler mandrel

12.5 Thread the wire electrode in

Fig. 9: close 4-roll feed

Turn on the machine at mains switch 9.

11

Page 12

MULTIMIG 200

Before start-up

Fig. 10: Wire feed button

Press wire feed button 29.

Adjust the contact pressure using the reg-

ulation screws 27 so that wire feed rollers

25 just slip when the welding wire spool is

stopped. The wire must not be jammed or

deformed.

A B C

Correct

Fig. 11: Wire feed rollers

Contact pressure

too high

Note for wire feed unit with 4 rollers:

Adjust the contact pressure of the wire feed

rollers 25 on the side of the inlet nozzle 26

to be less than on the side of the central

socket 11 in order to keep the wire

electrode under tension in the wire feed

unit.

Push the wire feed button 29 until the wire

protrudes from the torch neck by about

20 mm.

Screw the contact tip matching the wire

thickness into the torch and cut off the

protruding end of the wire.

12.6 Connecting the inert gas cylinder

Wrong wire feed

roller

Set the insert gas cylinder 14 down on the

carrier plate and secure it with the chain 1.

Briefly open the gas cylinder valve 32

several times in order to blow out any dirt

particles present.

Connect the pressure reducer 13 to the inert

gas cylinder 14.

Screw the inert gas hose 5 to the pressure

reducer.

Open valve 32 of shielding gas bottle 14.

Turn the machine off at main switch 9.

Press torch key and keep it pressed.

Turn on the machine at mains switch 9.

Solenoid valve will be switched on for 10

seconds.

Set the gas quantity using adjusting screw

35 of the pressure reducer 13. The gas

quantity will be displayed on the flowmeter

34.

Rule of thumb:

Gas volume = wire diameter x 10 l/min.

The cylinder content is indicated on the

content manometer 33.

Fig. 12: Connecting the inert gas cylinder

12.7 Changing the wire electrode

12

Page 13

MULTIMIG 200

ment parts depend upon the type of

torch used and the diameter of the

the

Change the wire feed rollers. Select the

most suitable rollers for the application.

Fig. 13: Wire feed rollers

A Steel feed roller

B Aluminium feed roller

C Knurled feed roller (for flux-cored wire)

Before start-up

Shorten the protruding plastic core so that it

is tight up against the wire feed roller, and

slide the appropriately shortened support

tube over the protruding plastic core for

stabilisation.

All:

Tighten the torch and thread the wire elec-

trode in.

The order numbers of the replace-

wire, and can be obtained from

torch spares lists.

Fig. 14: Marking of wire feed rollers

Replace the steel torch with an appropriate

torch, or change the wire feed spiral.

Wire feed spiral: (for steel or flux-cored

wire)

Remove the existing wire feed spiral or

plastic core and insert the new wire feed

spiral. (Refer to the operating manual for the

torch)

Insert the guide tube 85 into the central

connection.

Plastic core: (for aluminium, stainless steel

or CuSi wire)

Remove the existing wire feed spiral or

plastic core and insert the new plastic core.

(Refer to the operating manual for the torch)

Remove the guide tube 85 from the central

connection.

Fig. 15: Wire feed

7 Central socket

17 Central connection (torch)

25 Wire feed roller

38 Retaining nipple (=clamp) of the plastic

liner for 4.0 mm and 4.7 mm outside

diameter

39 O-ring

40 Union nut

41 Plastic liner

42 Support tube for plastic cores with 4 mm

OD Support tube not required with OD of

4.7 mm.

43 Guide tube

44 Wire feed spiral

13

Page 14

MULTIMIG 200

Start-up

13 Start-up

13.1 Control console MULTIMIG 200

Fig. 16: Control console MULTIMIG 200

Fig. 17: Graphic display

14

Page 15

MULTIMIG 200

9 Main switch for turning the welding

machine ON and OFF.

45 Turning knob for setting material

thickness/welding voltage/welding step.

46 Key button secondary parameter to

access the secondary parameter menu.

When within this menu this key serves to

end it.

47 Trigger Mode to select 2-stroke, 4-stroke,

spot welding or interval mode.

48 Key button menu to access the main

menu. Pressing this key will move one

level back.

49 Graphic display displays all information in

clear text.

50 Key Tiptronic/characteristics direct access

to the Tiptronic menu alt. characteristics

menu (if Tiptronic is switched off).

51 Key Secondary parameter access the

secondary parameter directly. Within the

menu press this key to end menu.

52 Operation knob Menu Turning knob wire

feed serves to:

• select menu (turn)

• confirm menu option (press)

• setting wire feed

• setting secondary parameter

55 Display mode displays the selected mode

by symbol.

56 Display characteristics displays the set

characteristic line.

57 Display Tiptronic-Job if the job no. is

followed by an asterisk (*) on the display,

a min. parameter of a saved job has been

changed.

58 Display wire feed correction displays the

wire feed as correction value differing from

the characteristic line in %.

59 Display wire feed displays the actual wire

feed speed in m/min.

Start-up

60 Display welding step displays the selected

welding step.

61 Display material thickness displays the

selected material thickness of the

workpiece in mm.

62 Display welding voltage displays the

selected welding voltage in Volt.

13.2 Start-up

Select with mode key 47 the 2-stroke mode.

Press key characteristics 50 to enter menu

characteristics.

Set matching characteristic line (material-

gas-wire combination) by turning operation

knob 52.

Confirm the characteristic line by pressing

operation knob 52.

Press operation knob 52 again to end menu

and return to standard display.

Set the required material thickness alt.

welding step by using turning knob 45.

The machine is ready for welding.

Use operation knob 52 to correct the wire

feed if needed.

15

Page 16

MULTIMIG 200

Start-up

13.3 Current / voltage display

The actual values of welding voltage and

welding current are displayed during and after

welding (hold function).

These values can be displayed individually or

together on the graphic display.

Possible display:

Welding voltage and welding current

Welding voltage

Welding current

Fig. 18: Display mode

Change of display modern

Fig. 19: Torch PowerMaster

65

Torch display displays the actual welding

step or wire feed speed in Tiptronic mode.

The current job will be displayed.

66 Torch rocker switch Change welding step

and wire feed speed. Between active jobs

can switched over whilst being in Tiptronic

mode.

67 Torch key „Mode“ By pressing (for at least

2 seconds) changeover between Tiptronic

and regular mode will take place. A quick

press in regular mode change between

wire feed, welding step and material

thickness (at selected characteristics).

Press menu key 48.

Select menu option „Display mode“ by

pressing operation knob 52.

Confirm menu option „Display mode“ by

pressing operation knob 52.

Set the desired display mode by turning

operation knob 52.

Confirm the desired display by pressing

operation knob 52.

For about 2 seconds a preview of the dis-

play will be shown if the display mode has

been changed.

13.5 Deactivate operation mode

The operation mode spot welding and interval

can be deactivated in the menu and will no

longer be accessable with mode key 47.

Press key menu 48.

Set menu to „options“ by turning operation

knob 52.

Confirm menu „options“ by pressing op-

eration knob 52.

Set the menu option „interval welding“ or

„spot welding“ by turning operation knob 52

for deactivation.

Confirm the menu option by pressing opera-

tion knob 52.

Select and confirm the menu option „off“ by

using operation knob 52.

13.4 Torch with remote control

16

Page 17

MULTIMIG 200

Fig. 20: Interval-welding deactivated

Press key 46, 50 or 51 to end menu and

return to standard display.

13.6 Characteristic line

Select characteristic line

Press key menu 48.

Set menu option „characteristic line“ by

turning operation knob 52.

Confirm menu option „characteristic line“ by

pressing operation knob 52.

Set required characteristic line by turning

operation knob 52.

Confirm characteristic line by pressing op-

eration knob 52.

Start-up

Fig. 22: „noP“ (no program)

Select a suitable welding step with turning

knob 45.

13.7 Mode Manual

Manual welding mode allows welding independent of characteristic lines.

Press key menu 48.

Select menu option „characteristics“ by

turning operation knob 52.

Confirm menu option „characteristics“ by

pressing operation knob 52.

Select menu option „manual“ by turning

operation knob 52.

Confirm menu option „manual“ by pressing

operation knob 52.

Press key 46, 50 or 51 to exit menu and

return to standard display.

Fig. 21: Characteristics

Press key 46, 50 or 51 to exit menu and

return to standard display.

If the graphic display shows „noP“ (no pro-

gram) for material thickness, the set welding

step is inapplicable for the selected

characteristic line.

Fig. 23: Manual mode

13.8 Secondary parameters

17

Page 18

MULTIMIG 200

Start-up

Press key secondary parameter 46 or 51 to

open the secondary parameter menu.

Select the required secondary parameter by

turning operation knob 52.

Confirm set secondary parameter by

pressing operation knob 52.

Set parameter value 72 as required by

turning operation knob 52.

Activate Tiptronic

Press key menu 48.

Select menu option „Tiptronic“ by turning

operation knob 52.

Confirm menu option „Tiptronic“ by pressing

operation knob 52.

Set menu option „Tiptronic on/off“ by turning

operation knob 52.

Confirm menu option „Tiptronic on/off“ by

pressing operation 52.

Set and confirm option „on“ with operation

knob 52.

Fig. 24: Secondary parameters

70 Symbol secondary parameter

71 Factory setting

72 Parameter value

Confirm parameter value 72 by pressing

operation knob 52.

Press key 46, 50 or 51 to exit menu and

return to standard display.

13.9 Tiptronic

The Tiptronic function provides 10 separate

jobs. All settings and adjustments made on the

control panel are stored in each job.

The Tiptronic function also gives the user

certain advantages, e.g. frequently recurring

welding jobs can be assigned to specific job

numbers, or different welders can save their

individual settings in „their“ job.

Factory setting for Tiptronic function is deactivated.

Fig. 25: activate Tiptronic

Press key 46, 50 or 51 to exit menu and

return to standard display.

Save job

Press key Tiptronic 50.

Set menu option „Job save“ by turning op-

eration knob 52.

Confirm menu option „Job save“ by pressing

operation knob 52.

Select the required saving position

(J00 … J09) by turning operation knob 52.

Confirm the job by pressing operation knob

52.

If the job to be saved is already existent / allocated; a safety question before overwriting

appears.

18

Page 19

MULTIMIG 200

Fig. 26: safety question

Select „YES“ for overwriting the job by

turning operation knob 52.

Confirm „YES“ by pressing operation knob

52.

Fig. 27: Save job

If required the job name can be changed.

(see „edit job ext).

Save the job by pressing key 51.

Press key 46, 50 or 51 to exit menu and

return to standard display.

Edit Job-text

Press key Tiptronic 50.

Set menu option „edit job text“ by turning

operation knob 52.

Confirm menu option „edit job text“ by

pressing operation knob 52.

Select the job no. where text must be edited

by turning operation knob 52.

Confirm the job no. by pressing operation

knob 52.

Start-up

Fig. 28: edit job text

Press key mode 47 to edit numbers.

Press key secondary parameter 46 to edit

letters.

Repress key secondary parameter to

change between capital and small letters.

Set the required number or letter by turning

operation knob 52.

Confirm number or letter by pressing op-

eration knob 52.

Repeat above procedure for each character.

Use key Tiptronic 50 to go back stepwise in

order to correct a character.

Press key secondary parameter 51 to fi-

nalize the saving process.

Press key 46, 50 or 51 to exit menu and

return to standard display.

Select job

Press key Tiptronic 50.

Set menu option „select job“ by turning

operation knob 52.

Confirm menu option „select job“ by press-

ing operation knob 52.

A listing of all existing jobs will be displayed

in the menu. The currently selected job is

marked with a tick (√) on the right side.

19

Page 20

MULTIMIG 200

Start-up

Fig. 29: select job

Set the required job by turning operation

knob 52.

Confirm the job by pressing operation knob

52.

Active job summary

Tiptronic-Jobs can be set either active or inactive.

When PowerMaster torch is connected and

Tiptronic function is active, use rocker switch to

switch between active jobs.

Press key Tiptronic 50.

Select menu option „Active Jobs“ by turning

operation knob 52.

Confirm menu option „Active Jobs“ by

pressing operation knob 52.

A listing of all existing jobs will be displayed

in the menu. All active jobs are marked with

a tick (√) on the right side.

Press key 46, 50 or 51 to exit menu and

return to standard display.

Copying a job

Press key Tiptronic 50.

Select menu option „copy job“ by turning

operation knob 52.

Confirm menu option „copy job“ by pressing

operation knob 52.

Select the job to be copied by turning op-

eration knob 52.

Fig. 31: Copy job: source

Confirm the job by pressing operation knob

52.

Select the job to be overwritten by turning

operation knob 52.

Fig. 30: Active job summary

Select the job to be activated or deactivated

by using operation knob turning knob 52.

Activate or deactivate the job by pressing

operation knob 52.

20

Fig. 32: Copy job: target

Confirm the job by pressing operation knob

52.

Safety question „copy job?“ appears.

Select „YES“ to copy by turning operation

knob.

Page 21

MULTIMIG 200

Fig. 33: Copy job: safety question

Confirm „YES“ by pressing operation knob

52.

Press key 46, 50 or 51 to exit menu and

return to standard display.

Delete job

Press key Tiptronic 50.

Select menu option „delete job“ by turning

operation knob 52.

Confirm menu option „delete job“ by press-

ing operation knob 52.

Select the job to be deleted by turning op-

eration knob 52.

Confirm this job by pressing operation knob

52.

Safety question „delete job?“ appears.

Select „YES“ to delete this job by turning

operation knob 52.

Start-up

13.10 Special functions

Gas test

Turn the unit OFF using main switch 9.

Press the torch key and keep it pressed.

Turn the unit ON using main switch 9.

The solenoid valve of the unit will go on and

the gas supply can be tested / adjusted. The

function is active for 30 seconds and will be

automatically stopped. Re-pressing the

torch key can interrupt the gas test.

Fan test

Turn the unit ON using main switch 9.

The fan will start for function purposes.

Operation panel test

Press the mode key 47 for at least 2 sec-

onds.

The complete display panel of the graphic

display will flash.

Press the key operation mode 47 again.

Another display test follows.

Press the key operation mode 47 again.

The operation panel test will be initiated.

Press and turn the keys as shown in the

graphic display.

If there is no input for 20 seconds, the operation panel test will be cancelled automatically.

13.11 Reset setting

Factory settings

Press key menu 48.

Select menu option „options“ by turning

Fig. 34: Delete job

Confirm „YES“ by pressing operation knob

52.

Press key 46, 50 or 51 to exit menu and

return to standard display.

operation knob 52.

Confirm menu option „options“ by pressing

operation knob 52.

Select menu option „Factory settings“ by

turning operation knob 52.

Confirm menu option „Factory Settings“ by

pressing operation knob 52.

Safety question „ ...reset?“ appears.

21

Page 22

MULTIMIG 200

All welding and secondary

ry

Start-up

Attention! All personal settings

will be lost.

parameters are reset to their facto

set-tings.

Fig. 35: Factory settings

Select „YES“ by turning operation knob 52

to reset all values to factory settings.

Confirm „YES“ by pressing operation knob

52.

Safety question „delete all jobs?“ appears.

Attention! All Tiptronic-jobs will

be deleted.

Fig. 36: Delete all jobs

Select „YES“ by turning operation knob 52

to delete all jobs.

Confirm „YES“ by pressing operation knob

52.

22

Page 23

MULTIMIG 200

14 Menu structure

Menu structure

23

Page 24

MULTIMIG 200

Menu structure

Main menu Level 1 Level 2 Note

Sprache /

Language

Characteristics

Display Mode

Tiptronic

Options

Deutsch

English

Select menu language

…

Manual

SG 2/3 0,8 mm 82/18

All settings can be performed independently

from a characteristic line.

Depending on type of model are various

characteristics set in the menu

…

(material-gas-wire combination)

Current and Voltage

Welding voltage

Different display settings can be selected

Welding current

see chapter „Tiptronic“ page 18

EU

Characteristic type

AWS

Display in accordance to EU (European)

classification

Display in accordance to AWS

(American Welding Society) classification.

Interval-Welding On Off To switch interval welding on/off

Spot Welding On Off To switch spot welding on/off

Diagnosis

… reset

Factory Settings

No Yes

Delete all jobs?

No Yes

Firmware Version Displays Firmware Version

Master reset to reset all settings back to factory

settings

To delete all jobs

Serial Number Displays serial no

Configuration Displays machine configuration

Operating Hour

Counter

Displays welding time in hours and minutes

Op. voltages 60/24V Displays voltages in Volt

Transf. Temperature Displays temperature in °C

Main menu Level 1 Factory settings Range

Parameters

Spot welding time 1,0 s 0,1…10,0 s

Interval time-Welding 1,0 s 0,1…10,0 s

Interval time-Wait 0,2 s 0,1…1,0 s

Note

Only available in spot

welding mode

Only available in interval

mode

Gas pre-flow 0,1 s 0,0…10,0 s

Wire creep speed 2,0 m/min 1,0…15,0 m/min

Wire burn back time 100 % 0…300 %

Gas post-flow 0,5 s 0,1…20,0 s

24

Page 25

MULTIMIG 200

As long as there is an error code on

15 Messages

In case of failure, a failure code is displayed in

graphical display 49.

Code

noP no program

E01 Excessive temperature The equipment has been overheated

E02 Mains overvoltage Mains input voltage too high Check mains voltage

Error description Note Rectification

Instead of material thickness „noP“ is

displayed. Welding is not possible at

activated characteristic line and set

welding step

display welding is not possible.

Select a different welding step

Allow the system to cool down in

standby, check the ventilation system

Messages

E03 Overcurrent

E06 Overvoltage Output voltage too high Inform Service

E07

E08 Wire feed

E09 Voltage-measuring Voltage measuring system defective Inform Service

E10 Torch connector/- cable

E13 Temp. sensor error

E14 Supply voltage

E15 Power measuring Fault at power measuring Inform Service

E16

EEProm checksum

error

Supply voltage motor

and main contactor

Output current is too high / Permanent short circuit

Setting data faulty or missing Switch the equipment off and on again

Too high power intake from wire

feed motor (Motor Over-Current)

Welding potential on torch control

cable

Thermal sensor not ready for operation

internal supply voltage too low

(18V~ / 24V-)

Internal supply voltage is too little

(42V~ / 60V-) /

PE conductor monitoring input

(Fault current to protective earth

conductor)

Inform Service

Blow down torch package with

pressured air and check pressure on

wire feed rolls

Check torch / exchange

Inform Service

Check mains voltages

Check power supply voltage / Check

connection of the workpiece cable and

ground clip, check for short-circuits

between welding wire and housing

E17

E18 Error configuration

Tab. 1: Massages

Peripheral devices

overload/ short circuit

Short circuit in torch or hose package, gas valve or feed line, wire run

key or line

Faulty or wrong pc-board, wrong

software system played

Test alt. exchange the connected torch

Inform Service

25

Page 26

MULTIMIG 200

Troubleshooting

16 Troubleshooting

Fault Possible cause Rectification

Torch becomes too hot Contact tip not tightened properly check

Torch switch has no function

when actuated

Open circuit in control cable in the torch

Thermal protection has triggered Allow the equipment to cool

Wire sticking or burnt onto

contact tip

Burr at start of wire Trim the end of the wire

Wire feed irregular or failed

completely

Torch faulty Check and replace if necessary

Union nut from torch hose pack to central

Tighten the union nut

socket is not correctly tightened

Check and replace if necessary

hose pack

down at no-load

Wire electrode jammed on the reel Check and replace if necessary

Incorrect contact pressure on wire feed unit Set as described in the operat-

ing instructions

Guide tube in the central socket is missing

Insert the guide tube or clean it

or dirty

Welding wire reel badly wound Check and replace if necessary

Surface rust on wire electrode Check and replace if necessary

Torch internal coil clogged with abrasion

dust

Unscrew the torch from the

equipment, remove contact tip

from torch and blow out the coil

with compressed air

Torch internal coil flexed Check and replace if necessary

Wire brake setting too hard Set as described in the operat-

ing instructions

Equipment switches off Duty cycle exceeded Allow the equipment to cool

down at no-load

Insufficient cooling of components Check air inlet and outlet on the

equipment

Arc or short circuit between

contact tip and gas nozzle

Unstable arc Contact tip does not match the wire diameter

A spatter bridge has formed between the

contact tip and the gas nozzle

Remove using suitable special

pliers

Check and replace if necessary

or contact tip is worn

Control panel is completely

dark

Phase missing Check the equipment at a dif-

ferent power socket. Check the

supply cable and mains fuse

Inert gas missing Gas cylinder empty Replace

Torch faulty Check and replace if necessary

Pressure reducer dirty or faulty Check and replace if necessary

Gas cylinder valve faulty Replace gas cylinder

26

Page 27

MULTIMIG 200

Troubleshooting

Fault Possible cause Rectification

Inert gas does not switch off Gas valve dirty or sticking Remove torch and pressure

reducer, blow out the gas valve

in the opposite flow direction

with compressed air

Inert gas feed insufficient Inert gas quantity set incorrectly at the

pressure reducer

Pressure reducer dirty Check the pressure reducing

Torch or gas hose blocked or leaking Check and replace if necessary

Inert gas blown away by draughts Eliminate the draughts

Welding power is reduced Phase missing Check the equipment using a

Set the inert gas quantity as

described in the operating

instructions

nozzle

different power socket; check

the supply cable and the mains

fuses

Insufficient ground contact at workpiece Create a good clear ground

connection

Ground cable not correctly inserted at the

equipment

Lock the ground connector at

the equipment by turning clockwise

Torch faulty Repair or replacement

Ground cable connector

becomes hot

Wire feed unit has increased

wire abrasion

The connector was not locked by turning

clockwise

The wire feed rollers do not match the wire

diameter

Check

Fit the correct feed rollers

Incorrect contact pressure on wire feed unit Set as described in the operat-

ing instructions

Tab. 2: Troubleshooting

27

Page 28

MULTIMIG 200

In this case the manufacturer’s

r

Repair and maintenance

17 Repair and maintenance

Please heed the current safety

and accident prevention regulations during all maintenance

and repair work.

17.1 Check regularly

Check the following points for damage

before starting up the welding machine:

• Mains plug and cable

• Welding torch and connections

• Ground cable and connection

Blow out the welding machine every two

months.

Switch the machine off.

Disconnect the mains plug.

Unscrew both side panels of the unit.

Blow out the welding machine with dry, low

pressure compressed air. Avoid blowing

directly on the electronic components from a

short distance, to prevent damage.

Screw the two side panels onto the machine

back again.

Never make repairs or technical

changes yourself.

warranty is no longer valid.

If you experience problems o

need repairs, contact a dealer authorised by ELEKTRON.

17.2 Torch care

Remove the weld spatter from inside the

gas nozzle using suitable tongs.

Spray the inside surface of the gas nozzle

with a releasing agent, or use nozzle

protection paste.

This will prevent weld spatter from being

burnt on.

28

Page 29

MULTIMIG 200

18 Technical data

Technical Data

Welding range (I2

Welding range (U2

No-load voltage V

Voltage setting Steps

Slope characteristic constant voltage characteristic line

ED 100 % A

ED 60 % A

ED at max. current %

Usable wires steel Ø mm

Usable wires aluminium Ø mm

Usable wires CrNi Ø mm

Usable wires CuSi Ø mm

Wire feed rate m/min

Mains

Mains voltage 3~ (50/60 Hz) V

Positive mains voltage tolerance %

Negative mains voltage tolerance %

Input power S1 (100 %) kVA

Input power S1 (60 %) kVA

Input power S1 (max. Strom) kVA

Current input I1 (100 %) A

Current input I1 (60 %) A

Current input I1 (max. Strom) A

Maximum effective mains current (I1

Power factor (at I2

Mains fuse (slow-response) A

Mains plug

Machine

Protection class

(in accordance with EN 60529)

Insulation class

Cooling method

Noise emission dB(A)

Dimensions and weights

Dimensions mm 880 x 400 x 755

Weight kg

Standard equipment

Feed unit Rolls

Tab. 3: Technical Data

1

) measured at 40° C environmental temperature

2

) reduced performance at 1~ 230 V operation mode

1)

min

max

…I2

min

)

max

…U2

) V

max

)

eff

) cos ф

MULTIMIG 200

A

A

IP

15…200

14,8…24,0

14,4…32,5

21

100

130

20

0,6…1,0

1,0…1,2

0,8…1,0

0,8…1,0

0,5…25

3~ 400

15

25

2,7

4,0

7,3

3,9

5,4

10,6

4,7

0,89

16

CEE 16

23S

F

F

< 70

74

4

Technical data

29

Page 30

MULTIMIG 200

Options and accessories

19 Options and accessories

19.1 Torch holder

Fig. 37: Torch holder assembly left

Order number: 420 958

20 Disposal

Fig. 38: Torch holder assembly right

Order number: 420 959

Only for EU countries.

Do not dispose of electric tools together with household waste material!

In accordance with European Council Directive

2002/96/EC on electrical and electronic

equipment waste and its implementation in

accordance with national law, electric tools that

have reached the end of their service life must

be collected separately and returned to an

environmentally compatible recycling facility.

21 Service

ELEKTRON Bremen GmbH Hinterm Sielhof 22 D-28277 Bremen Germany

Phone.: +49 (0)421 54 90 6-906 Fax: +49 (0)421 54 90 6-19

Web: www.elektron-bremen.de Mail: service @ elektron-bremen.de

30

Page 31

MULTIMIG 200

22 Schematic

Schematic

31

Page 32

Bl it zR o t ar y G m b H

Phone +49 / (0)421 / 54 90 6-906 Fax +49 / (0)421 / 54 90 6-19 vertrieb@elektron-bremen.de www.elektron-bremen.de

B r a n c h B r e m en

H i n t e r m Si e l h o f 22

D - 28 2 7 7 Br em e n

Loading...

Loading...