Elektra Beckum mig mag 232 ep, mig mag 302 ep, mig mag 502 ep, mig mag 402 ep Operating Instructions Manual

Page 1

S0021IVZ.fm

A

V

MIG MAG 232 EP

MIG MAG 302 EP

MIG MAG 402 EP

MIG MAG 502 EP

Betriebsanleitung. . . . . . . . . . . . . . . . . . . . .3

Operating Instruction . . . . . . . . . . . . . . . . .12

Instructions d’utilisation . . . . . . . . . . . . . . .20

Handleiding . . . . . . . . . . . . . . . . . . . . . . . .29

Manuale d’istruzioni. . . . . . . . . . . . . . . . . .38

Manual de uso. . . . . . . . . . . . . . . . . . . . . .47

115 167 6789 / 1701 - 1.1

Page 2

Ê

ÖRSÄ

U2S0021.fm

D DEUTSCH ENG ENGLISH

KONFORMITÄTSERKLÄRUNG DECLARATION OF CONFORMITY

Wir erklären in alleiniger Verantwortlichkeit, dass dieses Produkt mit

den folgenden Normen übereinstimmt* gemäß den Bestimmungen der

Richtlinien**

F FRANÇAIS NL NEDERLANDS

DECLARATION DE CONFORMITE CONFORMITEITSVERKLARING

Nous déclarons, sous notre seule responsabilité, que ce produit est en

conformité avec les normes ou documents normatifs suivants* en vertu

des dispositions des directives **

IT ITALIANO ES ESPAÑOL

DICHIARAZIONE DI CONFORMITÀ DECLARACION DE CONFORMIDAD

Noi dichiariamo sotto la nostra esclusiva responsabilità che il presente

prodotto è conforme alle seguenti norme* in conformità con le

disposizioni delle normative **

We herewith declare in our sole repsonsibility that this product

complies with the following standards* in accordance with the

regulations of the undermentioned Directives**

Wij verklaren als enige verantwoordelijke, dat dit product in

overeenstemming is met de volgende normen*

conform de bepalingen van de richtlijnen**

Declaramos bajo nuestra exclusiva responsabilidad, que el presente

producto cumple con las siguientes normas* de acuerdo a lo dispuesto

en las directrices**

PT PORTUGU

DECLARAÇÃO DE CONFORMIDADE

Declaramos sob nossa responsabilidade que este produto está de

acordo com as seguintes normas* de acordo com as directrizes dos

regulamentos **

FIN SUOMI NO NORGE

VAATIMUKSENMUKAISUUSVAKUUTUS SAMSVARSERKLÆRING

Vakuutamme, että tämä tuote vastaa seuraavia normeja* on

direktiivien määräysten mukainen**

DA DANSK POL POLSKI

OVERENSSTEMMELSESATTEST OŚWIADCZENIE O ZGODNOŚCI

Hermed erklærer vi på eget ansvar, at dette produkt stemmer overens

ed følgende standarder* iht bestemmelserne i direktiverne**

EL ΕΛΛHNIKA HU MAGYAR

∆ΗΛΩΣΗ ΑΝΤΙΣΤΟΙΧΕΙΑΣ MEGEGYEZŐSÉGI NYILATKOZAT

∆ηλώνουµε µε ιδία ευθύνη ότι το προϊόν αυτό αντιστοιχεί στις

ακόλουθες προδιαγραφές*

σύµφωνα µε τις διατάξεις των οδηγιών**

S SV SVENSKA

KRAN OM ÖVERENSSTÄMMELSE

F

Vi försäkrar på eget ansvar att denna produkt överensstämmer med

följande standarder* enligt bestämmelserna i direktiven**

Vi erklærer under eget ansvar at dette produkt samsvarer med

følgende normer* henhold til bestemmelsene i direktiv**

Oświadczamy z pełną odpowiedzialnością, że niniejszy produkt

odpowiada wymogom następujących norm* według ustaleń

wytycznych **

Kizárólagos felelősségünk tudatában ezennel igazoljuk, hogy ez a

termék kielégíti az alábbi szabványokban lefektetett követelményeket*

megfelel az alábbi irányelvek előírásainak**

MIG MAG 232 EP, MIG MAG 302 EP, MIG MAG 402 EP, MIG MAG 502 EP

* EN 60974-1

** 98/37/EG, 73/23/EWG, 89/336/EWG, 93/68/EWG

Jürgen Kusserow

Vorstand

ELEKTRA BECKUM AG – Daimlerstraße 1 – 49716 Meppen

1001004/ 01

2

Page 3

Xs0014e.fm Operating Instruction ENGLISH

ENGLISH

Table of Contents

1. Please Read First!.....................12

2. Safety .........................................12

2.1 Specified conditions of use .........12

3. Operating Elements..................13

3.1 Powerbox

(welding power source)...............13

3.2 SDV (separate wire feed unit).....13

3.3 SWK

(separate watercooling unit)........13

3.4 Control unit..................................13

3.5 Control unit for default

machine settings.........................14

4. Installation.................................14

5. Transport ...................................14

5.1 Crane hoisting.............................14

6. Preparing for Operation............14

6.1 Manual arc welding.....................14

6.2 Gas-shielded arc welding............14

6.3 Threading the electrode

wire in.............................. ... .........15

6.4 Connect the gas cylinder.............16

7. Default Machine Settings .........16

7.1 Control unit for default

machine settings.........................16

7.2 Charateristics curves...................16

7.3 Gas type......................................16

7.4 Pulsed MIG/MAG........................16

7.5 MIG/MAG....................................16

7.6 Manual arc welding.....................16

7.7 FBZ Burnback time .....................16

8. Operation...................................17

8.1 Control unit..................................17

8.2 Gas-shielded arc welding............17

8.3 Manual arc welding.....................17

8.4 Shutting down .............................17

9. Maintenance ..............................17

10. Available Accessories..............17

11. Repairs.......................................18

12. Environmental Protection ........18

13. Troubles.....................................18

13.1 Error messages...........................18

13.2 General faults..............................18

14. Technical Specifications..........19

15. Available Accessories..............59

1. Please Read First!

• Read these instructions before use.

Pay special attention to the safety

information.

• If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the

machine!

• Dispose of the packing in an environmentally friendly manner. Take

to a proper collecting point.

• Keep these instructions for reference on any issues you may be

uncertain about.

• If you lend or sell this machine be

sure to have the instructions go with

it.

2. Safety

All legal regulations pertaining to the

operation of electric arc welding

machines must be observed.

The following information should be

observed as well for a safe and risk-free

handling of the welding machine!

Danger! Electric potential!

− Use the machine indoors and in dry

environment only.

− Connect the machine only to an

properly earthed out.

If in doubt check with a qualified

electrician!

Danger! Electric potential!

Service and repairs to the machines

must only be made by qualified electricians.

Unplug before removing the machine’s

cover.

Danger!

Wear sufficient protective clothing when

welding.

Always use a welding visor and welder’s

gloves to protect against flying sparks

and arc radiation.

Danger!

All metal fumes are detrimental to

health!

When working indoors ensure sufficient

ventilation and extraction in order to not

exceed the max. permissible workplace

pollutant concentration.

Fumes of lead, cadmium, copper, zinc

and beryllium are especially harmful!

Caution!

Never weld earthed metal.

Welding earthed metal may cause possible damage to the protective earth conductors by stray currents.

Caution!

Always attach the earth cable directly to

the weld metal and as close as possible

to the welding spot.

Caution!

Special care is required when working

near computers, electronically controlled

equipment or in the proximity of magnetic data media (sound recording

tapes, floppy disks, data recording

tapes, credit cards, etc.).

The arc start can cause misfunction of

this type of equipment or data loss.

2.1 Specified conditions of

use

The following components

− Powerbox (welding power source)

− SDV (separate wire feed unit)

− SWK (separate watercooling unit,

optional available for models 232/

302 EP at extra cost)

together constitute are complete welding

machine for professional and industrial

use.

Note:

The componenents, connected to

each other and ready to run are referred

to as "welding machine" in these instructions.

Their most important features:

− Secondary-switched inverter for

gas-shielded arc welding

− Integrated manual arc welding mode

− Gas-shielded arc welding with pre-

programmed charateristics curves

− Integrated charateristics curve for

MIG brazing

− 4-roller drive with tachometer-controlled motor for precise and reliable

wire feed

− Integrated softstart for operating

modes MIG/MAG and pulsed MIG/

MAG

− Water cooling for high shielding gas

welding power.

This welding machine is intended for

welding FE-metals, alloyed steels, nonferrous heavy metals and aluminium.

It conforms to all relevant regulations at

the time of delivery.

This welding machine is intended for

operation by professional arc weldors or

specialists with similar qualification.

Permissible welding processes:

− MIG and pulsed MIG (Metal-InertGas),

for aluminium and aluminium alloys

− MAG and pulsed MAG (MetalActive-Gas)

for steel or stainless steel

− Manual arc welding

for steel

− MIG brazing

for electro-galvanized steel plates.

For TIG welding it must be ensured that

the shielding gas cover is not blown

away by air draft.

12

Page 4

ENGLISH

A

V

For machine performance see "Technical Specifications".

Any other use is not as specified and

prohibited.

The manufacturer is not liable for any

damage caused by unspecified use.

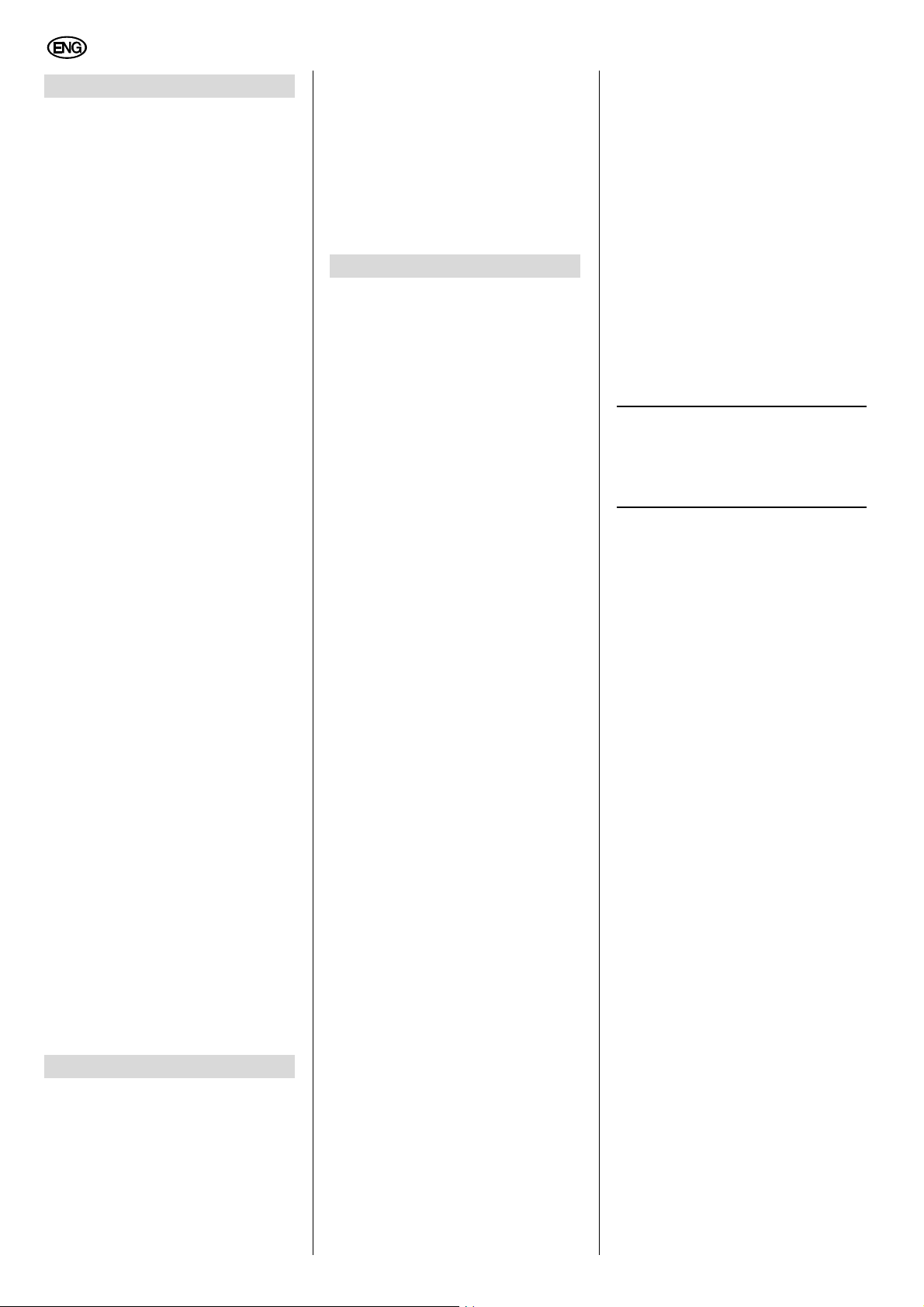

3. Operating Elements

3.1 Powerbox

(welding power source)

6 Power cable

SDV motor. When using a SWK the

power supply cable is connected to

the SWK. The SDV then automatically controls the water cooling

when welding.

7 Welding cable

with cable connector (+ pole).

8 Connection (rear) for earth cable

(- pole).

9 Power supply cable

with CEE plug.

3.2 SDV (separate wire feed

unit)

14

15 Connection for shielding gas

line

16 Connector socket for exteral

programming

17 Connector socket for power sup-

ply

18 Connector plug for welding cur-

rent supply

19 Connection for coolant runback

into SWK.

20 Connection for coolant feed from

SWK.

21 Connector socket for pilot lead

3.3 SWK (separate watercooling unit)

1

2

1 Connection (front) for earth

cable (- Pole).

2 Main switch

switches the Powerbox and all

devices connected to it ON or OFF.

3

4

13

12

11

10

The SWK is automatically controlled by

the Powerbox.

10 Euro connector socket for weld-

ing gun

for connection of all commercially

available welding guns.

11 Connection for coolant runback

from welding gun.

Note:

Instructions on how to connect

and operate the SWK are given in the

separate instructions supplied with the

device.

12 Connection for coolant feed to

5

welding gun.

13 Connector socket for pilot lead

of external devices.

14 Control unit.

6

7

Selection, display and setting of the

operating parameters.

The control unit for the machine’s

default settings is located inside the

SDV.

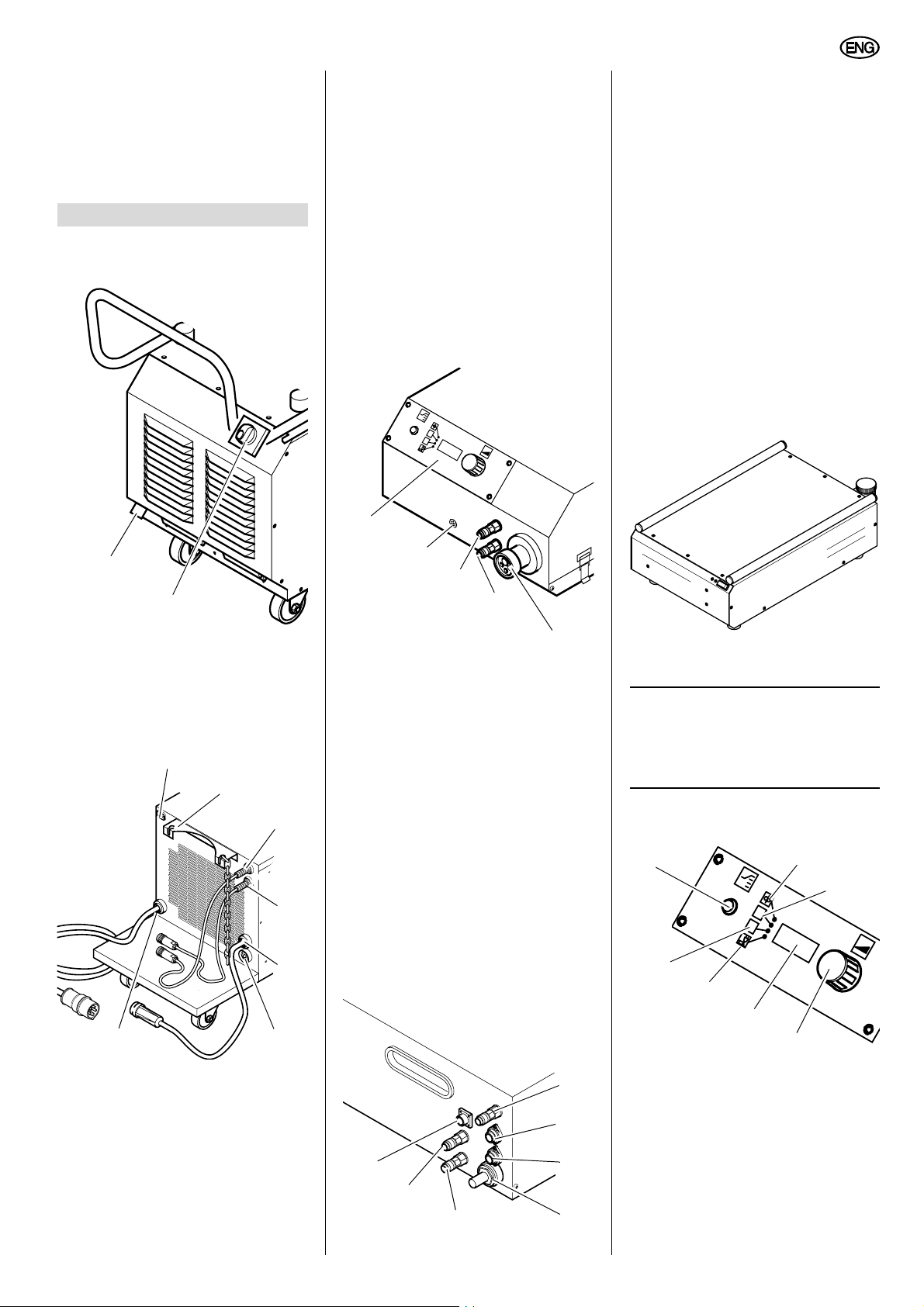

3.4 Control unit

22

A

V

25

23

24

26

98

3 Power supply outlet for addi-

tional devices

Rating: 10 A / 230 V.

4 Bracket with chain

secures the gas cylinder against

turning over.

5 Pilot lead

for SDV.

21

20

19

15

16

17

18

27

28

22 Parameter selection (momen-

tary contact switch)

for selection of the parameter to be

displayed and/or adjusted.

The LEDs [

selected parameter.

23-26] indicate the

23 LED wire feed [m/min]

24 LED welding current [A]

13

Page 5

ENGLISH

LED welding voltage [V]

25

26 LED arc length [%]

27 7-segment display (3 digits)

The display shows:

− the value of the selected

parameter or

− an error message.

28

Parameter adjustment

to adjust the selected parameter.

3.5 Control unit for default

machine settings

29 30

34

33

31

32

4. Connect the cables as illustrated

below.

1. Fit the hoisting straps as illustrated

below.

A

V

Caution!

At the workplace, secure the

machine against rolling away.

29 Wire thread-in button

(Manual Wire Feed Drive)

30 Operating mode selector switch

(Mode Selection)

31 Burnback time selector switch

(Wire burnback control)

32 Gas type selector switch

(Gas Type)

33 Wire diameter selector switchr

(Wire Diameter)

34 Wire type selector switch

(Wire Type)

4. Installation

The individual components need to be

connected to each other before being

connected to the mains and before inital

operation. By default the components as

set for gas-shielded arc welding:

1. With the help of another person lift

the SWK (water cooling unit) and

place it on the Powerbox, to that its

feet stand between the pipes on the

rubber mat.

2. With the help of another person lift

the SDV (wire feed unit) and place it

onto the water cooling unit.

3. Connect the coolant hoses as illustrated below (see also the SWK

instructions).

14

5. Transport

The Powerbox is mounted on a wheel

set. With fitted SDV and SWK the complete welding machine is conveniently

moved to the workplace.

Danger!

Close the cylinder’s valve

before relocating.

Danger!

Note the hight weight of the

welding machine. It may get out of

control, especially on sloping

ground!

Walk along the intended way, before

you set off with the welding machine.

Ask another person for assistance, if

necessary!

5.1 Crane hoisting

The welding machine can be hoisted by

crane.

Danger!

Remove the gas cylinder

before hoisting.

Hoisting with the gas cylinder is forbidden!

6. Preparing for Operation

6.1 Manual arc welding

When setting the machine for manual

arc welding, you must:

1. Check all connections.

Disconnect earth cable (- pole) and

welding current supply cable

(+ pole).

2. Connect earth cable to the Powerbox - pole).

3. Connect welding cable to the welding current supply cable (+ pole).

6.2 Gas-shielded arc welding

1. Check all connections. Disconnect

earth cable (- pole).

The welding current supply cable

(Powerbox) must be connected to

the connector plug of the welding

current supply (SDV).

Page 6

ENGLISH

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

2. Connect earth cable to the Powerbox - pole).

3. Check coolant level of the SWK.

Note:

Refer to separate instructions

supplied with the device.

4. Connect the welding gun to the

SDV’s Euro connector socket.

5. Connect coolant hoses according to

their colour coding.

A

V

6. Install electrode wire spool:

− Open SDV cover.

− Remove the arbor cap from the

spool carrier arbor and place the

electrode wire spool on the spool

carrier arbor.

− The driving pin (35) must fit into

the wire roll’s driving hole.

− Put the arbor cap back on.

Check setting of brake, correct

with screw (36) if necessary. The

brake prevents post-running of

the wire roll when the welding

process stops.

36

6.3 Threading the electrode

wire in

1,0/1,2 mm oder 0,6/0,8 mm.The feed

rolls are grooved for 1.0/1.2 mm or 0.6/

0.8 mm wire diameter. In operation the

electrode wire runs through the rear

groove (on the motor side). The wire

feed drive is factory-set for 1.0 mm electrode wire.

If 1.2 mm electrode wire is to be used

the feed rolls must be reversed, for 0.6/

0.8 mm electrode wire the correspond-

ing feed rolls must be fitted.

38

37

− Loosen retaining screws (37).

− Pull the feed rolls (38), complete

with gearwheels, off the floating

axles.

− Lift the feed roll off the gearwheel

and put it back on in a reversed

position, or replace with a feed

roll of appropriate groove size.

− Put both parts back onto the

floating axle and secure with the

retaining screw.

3. Deburr the electrode wire and run it

− through the spiral guide,

− over the rear feed roll,

− through the guide tube,

− over the front feed roll

− into the Euro connector socket.

4. Close pressure roll brackets and

swing handles up.

Set the contact pressure of the front

feed roll a little higher than that of

the rear feed roll.

5. Remove gas shroud and contact tip

from the welding gun’s swan neck.

39

6. Switch all devices ON keep the wire

1. Swing handles outwards. The pressure roll brackets will swing up.

2. Check position of the feed rolls,

reverse rolls if necessary:

thread-in button on the SDV (39)

pressed down, until the electrode

wire projects approx. 2 cm at the

swan neck.

7. Replace contact tip and gas shroud.

8. Close the SDV cover.

35

15

Page 7

ENGLISH

6.4 Connect the gas cylinder

1. Place gas cylinder on Powerbox and

secure with chain against turning

over.

40

2. Connect gas hose to the SDV (40).

Note:

The SDV is fitted with a solenoid

valve. Gas flows only during the welding

process.

3. Connect gas hose to pressure regu-

lator.

7. Default Machine Settings

7.1 Control unit for default

machine settings

1. Open SDV cover.

2. Stipulate the welding process set-

tings with the selector switches:

− the type of electrode wire (Wire

Type)

− the wire diameter (Wire Diameter)

− the type of shielding gas (Gas

Type)

− the operating mode (Mode Selection)

− the burnback timer (Wire burnback control).

7.2 Charateristics curves

The default charateristics curves, supplied with the machine, are selected by

the settings made at the control unit for

the default machine settings.

Example: Charateristics curve for

MIG brazing

MIG brazing is suitable for brazing galvanized sheet metal. To select this charateristics curve, the following settings

must be made.

Wire type: Cu/CuZn

Gas type: I1 (Argon) or

M12 (0-5% CO2,

balance Argon)

Operating mode: MIG/MAG or

pulsed MIG/MAG.

Note:

The allocation of settings and

corresponding charateristics curves is

shown on the label affixed to the inside

of the cover.

As an option, any charateristics curve

can be changed by a PC via the connector socket for programming.

Note:

Detailed information about programming of characteristic curves is

available from the service centre in your

country (see address listing on back

cover of the spare parts list).

The operating mode PROGRAMM is

reserved for charateristics curve programming.

7.3 Gas type

I1 = 100% Argon

M13 = 0-3% O2, balance Argon

M12 = 0-5% CO2, balance Argon

M21 = 0-25% CO2, balance Argon

7.4 Pulsed MIG/MAG

2-step = manual welding operation:

1. Actuate the torch trigger

The welding process starts.

2. Release the torch trigger

The welding process ends.

4-step = continuous welding operation:

1. Actuate and release the torch trigger

The welding process starts.

2. Actuate and release the torch trigger

again

The welding process ends.

4-step+H = continuous welding operation +

High-Start:

1. Actuate the torch trigger

Welding current and wire feed

speed are increased by 25% over

the set values.

2. Release the torch trigger

The welding process runs at the set

values.

3. Actuate the torch trigger again

The welding process will then run at

a reduced welding current (rated

current reduction).

4. Release the torch trigger

The welding process ends.

ABS (reduced value for end crater filling)

With the ABS function the parameters of

the charateristics curve are reduced for

the pulsed MIG/MAG welding process

for best welding results. The end of the

weld is welded with reduced power and

end craters are prevented.

The ABS function is dependent on the

selected wire type.

7.5 MIG/MAG

2-step = manual welding operation:

1. Actuate the torch trigger

The welding process starts.

2. Release the torch trigger

The welding process ends.

4-step = continuous welding operation:

1. Actuate and release the torch trigger

The welding process starts.

2. Actuate and release the torch trigger

again

The welding process ends.

Integrated softstart

The machine features an integrated softstart for the MIG/MAG and pulsed MIG/

MAG welding modes.

As long as there is no welding current

flow, the electrode wire is fed very

slowly. This prevents to much wire emergence. As soon as the arc starts the wire

is fed at the preset speed.

Note:

In position EXT (MIG/MAG and

pulsed MIG/MAG) an external control

can be connected.

If this operating mode is selected and no

external control connected, the machine

operates in 2-step mode.

7.6 Manual arc welding

ELECTRODE:

After arc start the welding process

run for a brief period with an

increased welding current (integrated Hot-Start).

The welding current increase for the

intergrated Hot-Start is 25% of the

set welding current.

Example:

Welding current = 100 A

Current increase = 25%

=> Hot-Start current = 125 A.

7.7 FBZ Burnback time

If set correctly, the burnback timer keeps

the electrode wire from sticking to the

weld pool. Adjustment is made with the

selector switch Burnback Time. The

scale values of 1-10 correspond to a

burnback time range of 0…0.4 s.

16

Page 8

ENGLISH

8. Operation

Caution!

Check all connections and

supply lines before switching ON.

Caution!

At the workplace, secure the

machine against rolling away.

8.1 Control unit

The operating parameters are set and

displayed at the control unit.

With the pushbutton for parameter

selection, the parameter to be displayed

or adjusted is selected.

The following parameters can be

selected and displayed:

− Wire feed [m/min]

− Welding current [A]

− Welding voltage [V]

− Arc length [%]

The selected parameter is indicated by

the LEDs and its value is displayed on

the 7-segment display.

Using the parameter adjustment the

desired value, except the welding voltage, is set.

Wire feed

Via the parameter wire feed the feed

speed of the wire feed drive is set. The

best value for welding voltage and welding current is computed by the machine,

dependent on the selected charateristics

curve.

wire feed value range:

− 1.5 ... 19 m/min.

The value range available for adjustment

is dependent on the selected electrode

wire and the operating mode.

For manual arc welding the display is

disabled.

Welding current

The best current strength is determined

by the machine. During MIG/MAG welding the welding current can not be

adjusted. The set value can be adjusted

prior to welding via the parameter adjustment.

For manual arc welding it is possible to

adjust the set value of the welding current before the welding starts and also

during the welding process (actual

value).

Welding voltage

The welding voltage is displayed only. It

can not be adjusted.

Arc length

In MIG/MAG and pulsed MIG/MAG operating mode, the value set affects welding

voltage.

The adjustment range is from 50%

through 150%. 100% is the best operating point.

Note:

When using interconnecting torch

lead extensions, the occuring voltage

drop can be compensated by the parameter. In this case adjust to values of

110% ... 120%.

8.2 Gas-shielded arc welding

Caution!

Check before starting any

work:

− Correct electrode wire installed?

− Correct shielding gas connected?

− Welding gun correctly fitted

(liner, spiral liner, contact tip, gas

shroud, support tube)?

1. Attach earth cable at suitable loca-

tion of workpiece.

2. Open cylinder valve and set desired

gas flow rate.

Change gas shroud, if necessary.

Shielding gas amount in l/min

Gas shroud diameter

in mm

3. Set main switch at Powerbox and

mains switch of SWK to ON.

4. Adjust the machine’s default setting.

Selet charateristics curve.

5. Change parameters, if required.

The welding machine is now operable.

Aluminium

Welding current in A

Steel

8.3 Manual arc welding

1. Attach earth cable at suitable loca-

tion of workpiece.

2. Set main switch of Powerbox to ON.

3. Select welding process ELE-

KTRODE.

The welding machine is now operable.

8.4 Shutting down

1. Close gas cylinder valve.

2. Set main switch to "0".

3. Disconnect earth cable from the

workpiece.

4. Unplug power cable.

9. Maintenance

This welding machine contains no userserviceable parts.

Depending on dust accumulation, the

Powerbox and the SDV should be blown

out with condensate-free compressed

air.

Periodically check all components for

visible damage.

Contact a qualified electrician if any of

the cables are damaged.

10. Available Accessories

For models 232/ 302/ 402/ 502 EP the

accessories mentioned below are recommended. These accessories have

been tested with the machine and

ensure operation without any problem.

A Welding guns for 232 EP

1) SB 24/3

2) SB 24/4

3) SB 24/5

B Welding guns for 302 EP

1) SB 36/3

2) SB 36/4

3) SB 36/5

C Welding gun for 402 EP and

232/302 EP with water cooling

1) SB 41/W3

2) SB 41/W4

3) SB 41/W5

D Welding guns for 502 EP

1) SB 51/W3

2) SB 51/W4

3) SB 51/W5

E Earth cable

1) 5 m, 25 mm

2) 5 m, 50 mm

for 302/ 402 EP

3) 5 m, 70 mm2 (copper jaws)

for 502 EP

F Interconnecting torch lead exten-

sion

for 232/302 EP

1) 5 m, 50 mm

2) 10 m, 50 mm

G Interconnecting torch lead exten-

sion for 232/302/402 EP with water

cooling

1) 5 m, 50 mm

2) 10 m, 50 mm

H Interconnecting torch lead exten-

sion

for 402/502 EP

1) 5 m, 70 mm

2) 10 m, 70 mm

I Pressure gauge with 2 gauges and

stop valve.

2

for 232 EP

2

(copper jaws)

2

, gas-cooled

2

, gas-cooled

2

, water-cooled

2

, water-cooled

2

, water-cooled

2

, water-cooled

17

Page 9

ENGLISH

11. Repairs

Danger!

Repairs to electric tools must

be carried out by qualified electricians only!

Welding machines in need of repair can

be sent to the service centre of your

country. Refer to the spare parts list for

the address.

Please attach a description of the fault to

the power tool.

12. Environmental Protection

The machine’s packaging can be 100 %

recycled.

Worn out power tools and accessories

contain considerable amounts of valuable raw and rubber materials, which can

be recycled.

These instructions are printed on chlorine-free bleached paper.

13. Troubles

The Powerbox is protected against overloads with multiple, independent of each

other working protective devices.

These protective devices also comprise

the fine-wire fuses, fitted on the PCBs.

Should any of these fuses blow, it is an

indication of some serious machine fault.

Danger! High voltage!

Never replace a fine-wire fuse

inside the machine on your own.

Contact a qualified electrician!

Before fitting a fresh fuse, the

machine must be completely checked

and the cause for the fault removed!

13.1 Error messages

Error message 333

General internal fault:

− Switch the machine OFF for 5 seconds, then ON again.

Error message 444

The control has detected a fault in the water

cooling (to hot, not switched on, faulty):

− Check water cooling unit.

Error message 555

Temperature and/or phase failure.

When the permissible duty cycle or temperature is exceeded, the machine switches OFF:

− In such case do not switch the

machine off.

The fan can no longer run, which

extents the cooling down time.

Error message 666

Communication error between SDV and Powerbox:

− Check all connections.

Error message 775 and 776

No match between SDV and Powerbox. Different revison numbers (software):

− Contact customer service.

Error message 777

No suitable charateristics curve selected:

− Select a suitable charateristics

curve.

Status message 888

The operating mode PROGRAMM is

selected. Programming of characteristics

curves (optional) possible:

− Select different operating mode.

Note:

If the error can not be corrected:

− Switch the machine OFF for 5 seconds, then ON again.

− If the error messages appear again,

switch OFF and contact a qualified

electrician!

13.2 General faults

Irregular wire feed

Contact pressure of pressure rolls?

− Correct contact pressure.

Wire guide on wire feed motor not

aligned?

− Align feed roll and wire guide.

Spiral guide blocked or not suitable for

wire size?

− Check, replace if necessary.

Poorly coiled wire or wire crossovers?

− Replace wire roll.

Rusty wire or of inferior quality?

− Replace wire roll, clean or replace

spiral guide.

Spool arbor brake tightened too much?

− Loosen spool arbor brake.

Feed rolls dirty, worn, or not suitable for

wire size?

− Clean or replace feed rolls.

No wire feed

Torch trigger or pilot lead in torch lead

faulty?

− Have torch trigger checked by a

qualified electrician.

Control module faulty?

− Replace control module

No welding current with working wire

feed

Earth cable making poor contact?

− Check earth cable for proper contact.

Control module faulty?

− Replace control module

Brittle or porous weld seam

Gas line connection not tight?

− Check connections.

Gas cylinder empty?

− Replace.

Gas valve closed?

− Open gas valve.

Pressure regulator faulty?

− Check pressure regulator.

Solenoid valve faulty?

− Have solenoid valve checked by a

qualified electrician.

Gas shroud on torch or torch leads

blocked?

− Clean gas shroud.

Air draft at welding spot?

− Screen off welding spot or increase

gas flow rate.

Workpiece not clean?

− Remove rust, grease or paint coating.

Inferior wire quality or unsuitable shielding gas?

− Use fresh electrode wire or suitable

shielding gas.

Steady gas flow

Solenoid valve faulty?

− Replace solenoid valve.

Foreign matter in solenoid valve?

− Clean solenoid valve.

Arcing when gas shrouds contacts

workpiece

Short between contact tip and gas

shroud?

− Clean gas shroud and neck, spray

with anti-spatter spray.

Torch is getting too hot

Contact tip too large or loose?

− Fit contact tip matching the wire

diameter, tighten contact tip.

Coolant circulation interrupted?

− Have pump checked by a qualified

electrician,

top up coolant.

No function of machine

Supply circuit fuse blown or cut-out?

− Replace or switch ON again.

Overload protection of pump tripped?

− Top up coolant

− Have pump checked by a qualified

electrician.

18

Page 10

14. Technical Specifications

Model 232 EP 302 EP 402 EP 502 EP

ENGLISH

Supply voltage

Open-circuit voltage

Working voltage MIG/MAG:

Working voltage, manual arc

Current setting range: Manual arc

MIG/MAG, pulsed MIG/MAG

Power input max.:

Max. input current:

R.M.S. current:

Max. duty cycle MIG/MAG (25°C)

100% duty cycle

Max. duty cycle MIG/MAG (40°C)

100% duty cycle

Max. duty cycle manual arc (25°C)

100% duty cycle

Max. duty cycle manual arc (40°C)

100% duty cycle

Control with control unit, external

Weldable wire diameter MIG/MAG

3 x 400 V 50-60 Hz

54 V

15.5...25.5 V 15.5...29 V 15.5...34 V

20.4...29.2 V 20.4...32 V 20.4...36 V

10…230 A

30…230 A

10…300 A

30…300 A

10…400 A

30…400 A

15.5...39 V

20.4...40 V

10…500 A

30…500 A

6.4 kVA 12.6 kVA 17.8 kVA 23.5 kVA

13 A

10 A

230 A / 60%

180 A

230 A / 50%

160 A

230 A / 50%

160 A

230 A / 40%

145 A

19 A

15 A

300 A / 60%

230 A

300 A / 50%

210 A

300 A / 50%

210 A

300 A / 40%

190 A

26 A

20 A

400 A / 60%

310 A

400 A / 50%

280 A

400 A / 50%

285 A

400 A / 40%

255 A

39 A

30 A

500 A / 60%

390 A

500 A / 30%

350 A

500 A / 50%

355 A

500 A / 25%

315 A

stepless

0.8…1.6 mm

Protection class

Degree of protection

Cooling

Insulation class

Dimensions L x W x H (mm):

Weight

1080 x 423 x 533 1080 x 455 x 635

105 kg 120 kg 191 kg

SK I

IP 21

F

F

Model SDV EP

Weldable wire diameter MIG/MAG 0.8…1.6 mm

Feed drive MIG/MAG 4-roll drive

Degree of protection IP 21

Insulation class F

Dimensions L x W x H (mm): 760 x 420 x 290

Weight 22 kg

Complete system 232 EP 302 EP 402 EP 502 EP

201 kg

Dimensions L x W x H (mm): 1080 x 423 x 823 1080 x 455 x 1030

Weight 127 kg 142 kg 241.5 kg 251.5 kg

19

Page 11

Xs0014f.fm Instructions d’utilisation FRANÇAIS

FRANÇAIS

Table des matières 1. A lire impérativement !

1. A lire impérativement ! .............20

2. Sécurité......................................20

2.1 Utilisation conforme aux

prescriptions................................20

3. Eléments de commande...........21

3.1 Powerbox

(source de courant de soudage) .21

3.2 SDV (dispositif d’avance

de fil séparé) ...............................21

3.3 Système de refroidissement

à eau séparé...............................22

3.4 Organe de commande ................22

3.5 Organe de commande pour

le paramétrage de base des

appareils......................................22

4. Montage .....................................22

5. Transport ...................................22

5.1 Transport par grue ......................22

6. Mise en ordre de marche ..........23

6.1 Soudage à électrodes.................23

6.2 Soudage sous protection

gazeuse...................................... .23

6.3 Introduction du fil d'apport...........23

6.4 Raccordement de la

bouteille de gaz...........................24

7. Paramétrage de base des

appareils ....................................24

7.1 Organe de commande pour

le paramétrage de base des

appareils......................................24

7.2 Courbes caractéristiques ............24

7.3 Type de gaz ................................24

7.4 MIG/MAG à arc pulsé..................25

7.5 MIG/MAG....................................25

7.6 Soudage à électrodes.................25

7.7 Temps de latence FBZ................25

8. Manipulation de l’appareil........25

8.1 Organe de commande ................25

8.2 Soudage sous protection

gazeuse...................................... .26

8.3 Soudage à électrodes.................26

8.4 Mise hors service........................26

9. Maintenance ..............................26

10. Accessoires disponibles..........26

11. Réparations ...............................26

12. Protection de

l'environnement.........................26

13. Dérangements...........................26

13.1 Messages d’erreurs.....................26

13.2 Défaillances d'ordre général........27

14. Caractéristiques techniques....28

15. Accessoires disponibles..........59

• Avant la mise en marche, lire attentivement ces instructions d’utilisation. Observer en particulier les con-

signes de sécurité.

• Au cas où, lors du déballage, un

dommage dû au transport serait

constaté, en informer immédiatement le revendeur. Ne pas mettre

l'appareil en service !

• Eliminer l'emballage en respectant

l'environnement. L'amener à la station de collecte correspondante.

• Conserver ces instructions de

manière à pouvoir s'y référer à tout

instant en cas d'incertitude.

• En cas de vente ou de location de

cet appareil, remettre également

ces instructions.

2. Sécurité

D'une façon générale, les dispositions

légales relatives à la manipulation

d'appareils de soudage à l'arc sont à

respecter.

Pour une utilisation sans danger et en

toute sécurité de l'appareil de soudage,

respecter également les indications suivantes !

Danger ! Tension électrique.

− N’installer l’appareil que dans une

pièce close et dans un environnement sec.

− Ne raccorder l'appareil qu'à une

source de courant dont les dispositifs de sécurité fonctionnent parfaitement.

S'adresser à un électricien en cas

de doute !

Danger ! Tension électrique.

Toute réparation ou modification de

l'appareil ne peut être effectuée que par

un électricien qualifié.

Débrancher l'appareil du secteur avant

d'ouvrir l'appareil.

Danger !

Porter impérativement des vêtements

protecteurs adaptés pour les travaux de

soudage.

Utiliser obligatoirement un bouclier et

des gants de protection.

Ces dispositifs protègent des projections

d'étincelles et du rayonnement de l'arc

électrique.

Danger !

Toutes les vapeurs métalliques sont

toxiques !

Veiller à un renouvellement d'air suffisant et constant pendant les travaux de

soudure en intérieur afin que les concentrations maximales tolérées de produits

toxiques ne soient pas dépassées sur le

lieu de travail.

Les vapeurs de plomb, de cadmium, de

cuivre, de zinc et de béryllium sont particulièrement dangereuses !

Attention !

Ne jamais souder une pièce reliée à la

terre.

Une dégradation éventuelle du conducteur de protection par des courants de

fuite est ainsi évitée (par couplage).

Attention !

Toujours fixer l'étrier du circuit retour du

courant de soudage directement au

niveau de la pièce et le plus près possible de la soudure.

Attention !

Faire très attention lorsque les travaux

de soudage s'effectuent à proximité

d'ordinateurs, d'appareils à commande

électronique, ou encore près de supports de données magnétiques (bandes

sonores, disquettes, bandes magnétiques, cartes bancaires, etc.).

Des anomalies ou des pertes de données peuvent se produire pendant

l'amorçage à l'arc.

2.1 Utilisation conforme aux

prescriptions

Les appareils

− Powerbox (source de courant de

soudage)

− SDV (dispositif d'avance de fil

séparé)

− SWK (refroidissement à eau séparé

disponible en option sur les appareils 232/302 EP)

forment ensemble un appareil de soudage complet pour l'industrie et le travail

en atelier.

Remarque :

Ces appareils reliés entre eux et

prêts à l'emploi sont désignés dans ce

manuel sous le terme d'"appareil de soudage".

Caractéristiques principales :

− Convertisseur à découpage au

secondaire pour le soudage à l'arc

sous protection gazeuse

− Fonction de soudage à électrodes

intégré

− Soudage à l'arc sous protection

gazeuse avec courbes caractéristiques pré-programmées

− Courbe caractéristique de brasage

MIG intégrée

20

Page 12

U3S0021.fm

A 1) 090 201 9413

2) 090 201 9421

3) 090 201 9430

D 1) 090 200 8462

2) 090 200 8470

3) 090 200 8489

B 1) 090 200 8411

2) 090 200 8420

3) 090 200 8438

E 1) 090 201 1307

2) 090 201 1315

3) 090 201 1323

C 1) 090 200 8373

2) 090 200 8381

3) 090 200 8390

F 1) 090 201 9472

2) 090 201 9480

G 1) 090 201 9499

2) 090 201 9502

H 1) 090 201 9510

2) 090 201 9529

I 090 200 5293

59

Loading...

Loading...