Page 1

Xi-A Series Loudspeaker System

Flying Manual

ELECTRO-VOICE® Xi-A Rigging Manual

Page 2

Table of Contents

0. Rigging-Safety Warning.......................................................................................................................................... 2

I. Introduction ......................................................................................................................................................... 3

1.1 The Flying Xi-A Loudspeaker Systems .................................................................................................... 3

II. Basic Xi-A Rigging Primer....................................................................................................................................... 3

2.1 Anatomy of an Xi-A Flying System........................................................................................................... 3

2.2 The Rigging Hardware ............................................................................................................................. 4

2.3 The Xi-A Flying Concept .......................................................................................................................... 7

2.3.1 Accoustical Considerations ...................................................................................................... 7

2.3.2 Practical Considerations .......................................................................................................... 8

III. Associated Rigging Hardware for Flying Xi-A Loudspeaker Systems .................................................................. 10

3.1 Grids and Associated Rigging Hardware ............................................................................................... 10

IV. Strength Ratings, Safety Factors, and Special Safety Considerations................................................................. 10

4.1 Strength Ratings and Safety Factors ..................................................................................................... 10

4.2 Special Safety Considerations for Xi-A Loudspeaker Arrays.................................................................. 12

4.3 Special Safety Considerations for Rigging Strap Assemblies................................................................. 14

4.3.1 Redundant Attachment Points................................................................................................ 14

4.3.2 Special Considerations for Polyester Webbing....................................................................... 14

4.4 Special Safety Considerations for Grid & Building Structural Supports .................................................. 14

V. Rigging Inspection and Precautions ..................................................................................................................... 15

5.1 Xi-A System Components...................................................................................................................... 15

5.1.1 Xi-A Loudspeaker Systems .................................................................................................... 15

5.1.2 Rigging Strap Assemblies ...................................................................................................... 15

5.2 Associated Hardware ............................................................................................................................. 15

5.2.1 Grid Assembly........................................................................................................................ 15

5.2.2 Chain Hoists........................................................................................................................... 15

5.2.3 Building Structural Supports...................................................................................................15

5.2.4 Mechanical Components........................................................................................................ 16

VI. Appendices ....................................................................................................................................................... 17

Appendix A Xi-A Rigging Accessories ........................................................................................................ 17

Appendix B References ............................................................................................................................. 17

B.1 Accoustical References ............................................................................................................ 17

B.2 Mechanical References............................................................................................................ 18

ELECTRO-VOICE® Xi-A Rigging Manual1

Page 3

0. Rigging-Safety Warning

This document details general rigging practices appropriate to the entertainment industry, as they

would apply to the rigging of Electro-Voice Xi-A loudspeaker systems. It is intended to familiarize

the reader with standard rigging hardware and techniques for suspending Xi-A loudspeaker

systems overhead. Only persons with the knowledge of proper hardware and safe rigging

techniques should attempt to suspend any sound systems overhead. Prior to suspending any

Electro-Voice Xi-A loudspeaker systems overhead, it is essential that the user be familiar with the

strength ratings, rigging techniques and special safety considerations outlined in this manual. The

rigging techniques and practices recommended in this manual are, of necessity, in general terms

to accommodate the many variations in loudspeaker arrays and rigging configurations. As such,

the user is expressly responsible for the safety of all specific Xi-A loudspeaker array designs and

rigging configurations as implemented in practice.

All the general rigging material contained in this manual is based on the best available

engineering information concerning materials and practices, as commonly recognized in the

United States, and is believed to be accurate at the time of the original printing. As such, the

information may not be directly applicable in other countries. Furthermore, the regulations and

requirements governing rigging hardware and practices may be superseded by local regulations.

It is the responsibility of the user to ensure that any Electro-Voice loudspeaker system is

suspended overhead in accordance with all current federal, state and local regulations.

All specific material concerning the strength ratings, rigging techniques and safety considerations

for the Xi-A loudspeaker systems is based on the best available engineering information

concerning the use and limitations of the products. Electro-Voice continually engages in testing,

research and development of its loudspeaker products. As a result, the specifications are subject

to change without notice. It is the responsibility of the user to ensure that any Electro-Voice

loudspeaker system is suspended overhead in accordance with the strength ratings, rigging

techniques and safety considerations given in this document and any manual update notices. All

non-Electro-Voice associated hardware items necessary to rig a complete Xi-A loudspeaker array

(grids, chain hoists, building or tower supports and miscellaneous mechanical components) are

the responsibility of others.

Electro-Voice

June, 2004

The exclamation point within an equilateral triangle is intended to alert the user to

the presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

ELECTRO-VOICE® Xi-A Rigging Manual 2

Page 4

I. Introduction

1.1 The Flying Xi-A Loudspeaker Systems

The flying versions of the X-Array Install™ loudspeaker systems all incorporate a unique two-point

flying system that consists of two lengths of heavy-duty, L-track, aircraft-type rigging hardware on

the top and bottom of each enclosure. The design allows arrays to be assembled very quickly, and

offers such flexibility in the vertical angling of the cabinets that pull-up points are usually

unnecessary. Furthermore, the cabinets may be oriented with the rigging track on the top and

bottom of the enclosure or on the sides of the enclosure. For fire safety and additional structural

strength in both flying orientations, top-to-bottom and side-to-side metal straps link the rigging

track assemblies inside the enclosure. In addition, a line of flying hardware accessories is

available for use with the Xi-A loudspeaker systems from Sound Manufacturing, Inc. (See

Appendix A for available rigging accessories.)

II. Basic Xi-A Rigging Primer

2.1 Anatomy of an Xi-A Flying System

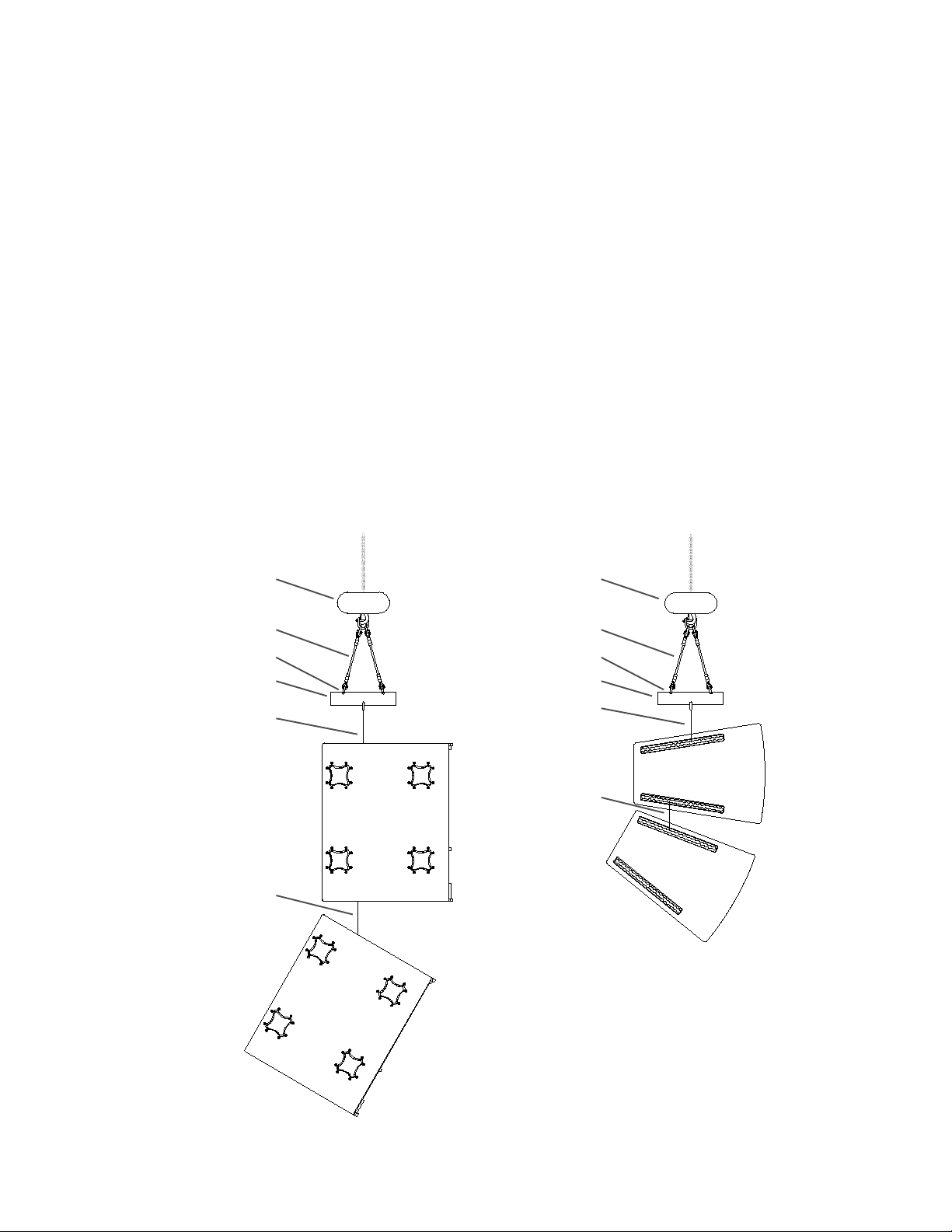

A basic two-cabinet flying system is shown in Figure 2.1a, illustrating the integral components that

make up a typical Xi-A loudspeaker array, where the enclosures are oriented with the rigging

hardware on the top and bottom of the enclosures. A similar two cabinet system is shown in

Figure 2.1b where the enclosures are oriented with the rigging hardware on the sides of the

enclosures. The top cabinets are the starting points for constructing the arrays in both examples.

These cabinets are first secured to a grid through the use of two grid straps per cabinet. (The

GS-1B grid straps are recommended.) The Xi-A enclosures are equipped with two pieces of track,

which have multiple positions where the grid straps may be attached. The linear positioning of the

attachment points along the track (front-to-back) determines the vertical angling of the enclosure.

The remaining ends of the grid straps are then secured to cross members of a grid. The relative

positioning of the straps along the cross members of the grid (front to back) determine the relative

horizontal splay angle between two adjacent columns of enclosures. A second row of enclosures

may be added below the original two by utilizing linking straps that attach from the lower track

pieces of the top enclosures to the upper track pieces of the bottom enclosures. (LS-1B, LS-2B

and LS-3B linking straps, each a different length, are recommended.) Additional cabinets may be

hung in succession in this fashion, as long as the load on any of the enclosures or rigging straps

does not exceed their working-load-limit rating. The loudspeaker/array/grid assembly is then

raised into position by a motorized chain hoist (or hoists) of sufficient load rating. Note that the

weight of such an array can be quite substantial and the building structural supports to which the

hoists are attached must be capable of supporting such a load with a sufficient safety factor. In

permanent installations, the chain hoists are often eliminated, with the grid assembly being

secured directly to the building structure. The reader is referred to Chapters IV and V of this

manual for a detailed discussion of the structural strength ratings of the Xi-A loudspeakers and Ltrack rigging accessories, and information on how to safely suspend Xi-A loudspeaker systems

overhead.

ELECTRO-VOICE® Xi-A Rigging Manual3

Page 5

2.2 The Rigging Hardware

The Xi-A flying system utilizes the highest-tech aircraft-type hardware available for securing heavy

loads. Four pieces of heavy-duty, aircraft-type, “L-Track” rigging hardware, specially machined

extrusions of very-high-strength, aluminum-alloy material, are mounted in each enclosure. The

track pieces are secured to high-strength, aluminum-alloy brackets that are an integral part of the

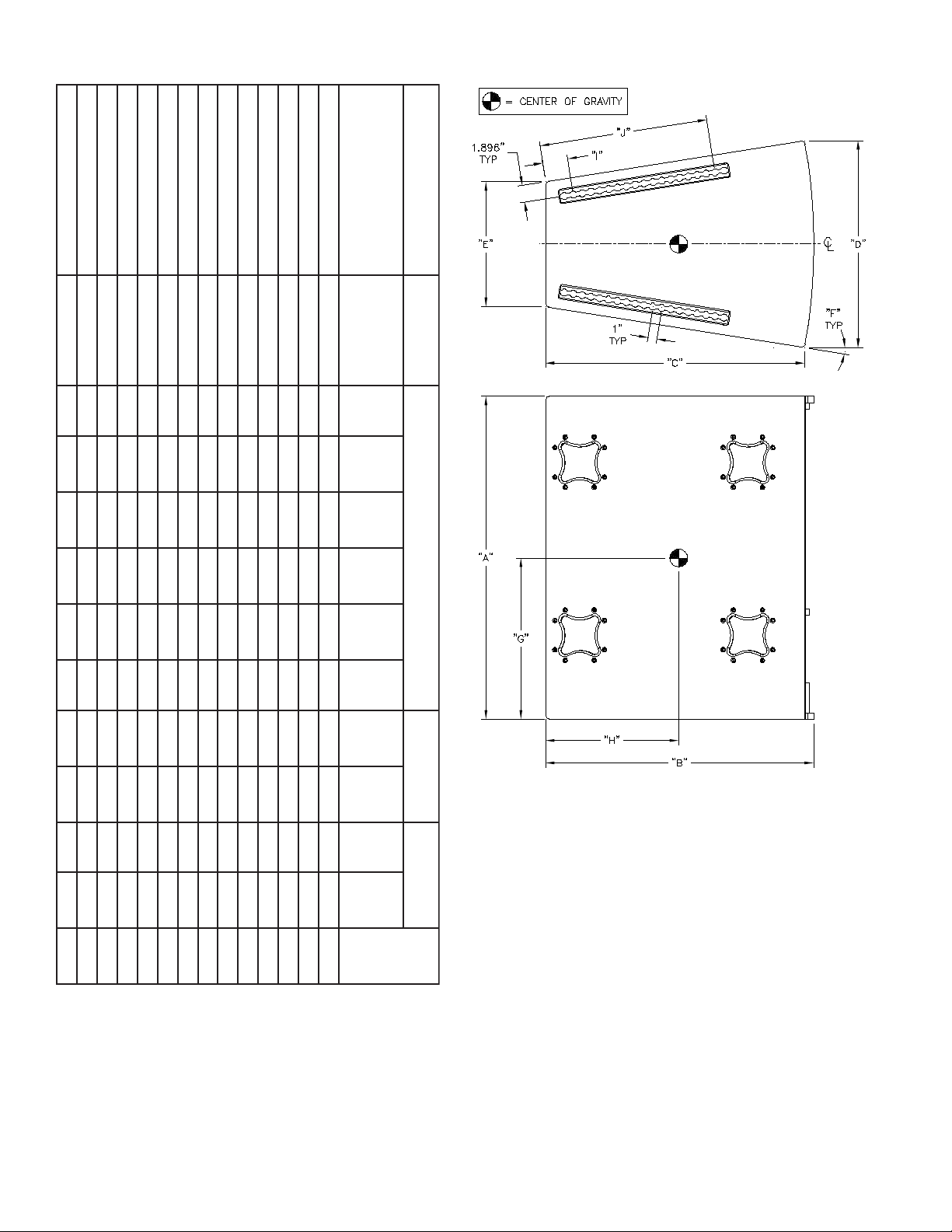

Xi-A flying enclosure. Enclosure dimensions and rigging track locations are shown in Figure 2.2 for

all of the Xi-A loudspeaker systems. For attachment to the track, the GS-1B grid-strap assembly,

the LS-1B, LS-2B and LS-3B linking strap assemblies, the RS-1B double-stud, swivel-ring fitting

assembly and the RS-2B single-stud, swivel-ring fitting assembly are available from Sound

Manufacturing, Inc. (See Appendix A for details.) These assemblies, shown in Figure 2.3, have

been specifically designed for optimal implementation of the Electro-Voice L-track flying systems.

The GS-1B includes a double-stud, swivel-ring fitting on one end for attachment to the enclosure

and a safety hook on the other end. The safety hook may be attached to 5/8-inch shackles, or

may be secured directly to the grid through a 7/8-inch diameter hole in the grid bar-stock material.

The LS-1B, LS-2B and LS-3B have double-stud swivel-ring fillings on both ends for linking two XiA enclosures together. The GS-1B, LS-1B and LS-2B rigging straps utilize polyester webbing strap

material. Polyester webbing was chosen for its tremendous strength and because of its dynamic

flexing capabilities. The force from any sudden jolt or shift in the load is absorbed by the strap

rather than transmitted directly to the loudspeaker enclosure. In addition, polyester webbing is a

flexible material that is easy to handle.

Hoist Motor

Wire Rope Sling

5/8” Shackle

Grid

GS-1B

LS-3B

Hoist Motor

Wire Rope Sling

5/8” Shackle

Grid

GS-1B

LS-1B

Figure 2.1a:

Top and Bottom of the Enclosures

ELECTRO-VOICE® Xi-A Rigging Manual 4

Rigging Hardware on the

Figure 2.1b:

Sides of the Enclosures

Rigging Hardware on the

Page 6

epyTmetsyS

gniylF,xoBssaBFA1812-iX000.63578.92768.82270.32829.31°9000.81521.61608.2608.81481

gniylF,refoowbuSFA1911-iX000.63578.92768.82270.32829.31°9318.61180.61608.2608.81051

gniylF-noN,xoBssaBA1812-iX000.63578.92768.82270.32829.31°9000.81521.61A/NA/N481

gniylF-noN,refoowbuSA1911-iX000.63578.92768.82270.32829.31°9318.61180.61A/NA/N051

erusolcnEegraLyaW-3F46/A3811-iX000.63578.92768.82270.32829.31°9969.71518.41608.2608.81591

erusolcnEegraLyaW-3F46/A3511-iX000.63578.92768.82270.32829.31°9969.71518.41608.2608.81591

erusolcnEmuideMyaW-3F601/A3212-iX356.93636.81375.71640.81084.21°9360.02521.8608.2608.01041

worhT-gnoLhgiH-diMyaW-2F24/AHM2212-iX000.63578.92768.82270.32829.31°9000.81578.31608.2608.81091

thgieH-flaHhgiH-diMyaW-2F46/AHM2211-iX264.32578.92768.82270.32829.31°9313.11005.41608.2608.81631

erusolcnEegraL-artxEyaW-3F46/A3512-iX935.84578.92768.82270.32829.31°9072.42834.51608.2608.81042

erusolcnEmuideMyaW-3F601/A3211-iX145.13636.81375.71640.81084.21°9360.61521.8608.2608.01511

erusolcnEllamSyaW-2F46/A2211-iX000.32340.41432.31639.41448.7°51526.11574.7445.2445.895

erusolcnE.deM/llamSyaW-2F49/A2511-iX578.92182.61012.51109.71057.9°51578.31578.7445.2445.908

erusolcnE.deM/llamSyaW-2F46/A2511-iX578.92182.61012.51109.71057.9°51578.31578.7445.2445.908

miD

"A"

latoT

thgieH

miD

"B"

htpeD

latoT

miD

"C"

ediS

htpeD

miD

"D"

htdiW

tnorF

snoisnemiDerusolcnE

miD

"E"

raeR

htdiW

Figure 2.2:

miD

"F"

elgnA

.parT

miD

morF

"G"

mottoB

ytivarG

foretneC

miD

morF

"H"

kcaB

Notes:

All Linear Dimensions in Inches

miD

"I"

raeR

tnioP

All Angles in Degrees

All Weights in Pounds

miD

"J"

tnioP

tnorF

kcarTgniggiR

Rigging Attachment Points Every

1.0 Inches Along Track

Front & Rear Rigging Locations

thgieW

Shown for Double-Stud Fittings

Single-Stud Fitting Locations

Shifted Linearly +/-0.5 Inches

Xi-A Dimensions, Weight, Rigging Location, and Center of Gravity

ELECTRO-VOICE® Xi-A Rigging Manual5

Page 7

GS-1B Linking Strap (with Double-Stud Fitting)

LS-1B Linking Strap (with Double-S tud Fitting)

LS-2B Linking Strap (with Double-S tud Fitting)

LS-3B Linking Strap (with Double-S tud Fitting)

RS-1B Swivel-Ring Fitting (with Double-Stud Fitting)

RS-2B Swivel-Ring Fitting (with Single-Stud Fitting)

LOCKING

RING

Figure 2.4a:

LOCKING

PIN

STUD

FEET

FITTING

BODY

RS-1B Double-Stud Fitting

LOCKING

PIN

FITTING

STUD

FOOT

BODY

Figure 2.3:

Xi-A L-Track Rigging

Figure 2.4b:

RS-2B Single-Stud Fitting

Accessories

The user is cautioned, however, that in certain permanent-installation applications, the polyester

material may not meet local fire regulations. The user is also cautioned that polyester material will

deteriorate with extended exposure to ultraviolet light (direct sunlight) or to hot, dry environments,

resulting in reduced strength capability. In such instances, wire rope or chain assemblies must be

substituted. The RS-1B double-stud fitting and the RS-2B single-stud fitting both attach to the Xi-A

enclosure’s rigging track, and have swivel rings that are suitable for attachment to various

standard rigging hardware. The user may use the RS-1B and RS-2B to construct wire rope or

chain rigging assemblies. In addition, the Xi-A enclosure’s rigging track will also accept the RS-1B

double-stud swivel-ring fillings and the RS-2B single-stud swivel-ring fillings. The user is cautioned

that the structural strength ratings of the single-stud fittings are approximately one half that of the

double-stud fittings. These lower ratings, however, are completely sufficient for suspending lighter

loads overhead (for example, when flying one or two of the smaller/lighter Xi-A loudspeaker

systems in permanent installations), making the single-stud fittings attractive lower-cost

alternatives to the double-stud fittings. The reader is referred to Chapters IV and V of this manual

for a detailed discussion of the structural strength ratings of the Xi-A loudspeakers and L-track

rigging accessories, and information on how to safely suspend Xi-A loudspeaker systems

ELECTRO-VOICE® Xi-A Rigging Manual 6

Page 8

overhead. To attach the double-stud, swivel-ring fittings (as shown in Figure 2.4a) to the

enclosure’s rigging track, push in the spring-loaded safety-locking pin and lift the outer locking ring

over the pin. Continue to lift the locking ring until the two studs on the bottom of the fitting are fully

exposed. Insert the two round feet of the studs into the round cutouts in the track and slide the

fitting to the desired position. Center the main body of the fitting over one of the track cutouts, with

the feet located on either side (i.e., with the stud feet positioned directly under the teeth of the

track). Release the outer locking ring. The round protrusion on the bottom of the fitting should lock

into the round cutout in the track with the locking ring retracting to its normal position, allowing the

safety-locking pin to reappear and extend over the locking ring. If the fitting does not lock into the

track, nudge it along the track and wiggle as necessary until it settles into position. If the outer

locking ring does not fully retract, push the ring towards the track until the safety pin reappears

and extends over the locking ring. When locked, the fitting will be immovable in the track and the

locking ring of the fitting may not be lifted. To remove the fitting, reverse the procedure.

ALWAYS CHECK TO MAKE SURE THAT THE FITTING IS SECURELY LOCKED

INTO THE TRACK, AND THAT THE SAFETY PIN IS EXTENDED OVER THE

LOCKING RING BEFORE LIFTING ANY LOUDSPEAKER ENCLOSURE

OVERHEAD.

To attach the single-stud, swivel-ring fittings (as shown in Figure 2.4b) to the enclosure’s rigging

track, remove the safety-locking pin and lift the fitting body over the hole for the locking pin.

Continue to lift the fitting body until the stud on the bottom of the fitting is fully exposed. Insert the

round foot of the stud into a round cutout in the track and slide the fitting to the desired position.

Center the main body of the fitting over one of the track teeth (i.e. with the stud foot positioned

directly under one tooth of the track). Release the fitting body. The body of the fitting should lock

into the round cutouts in the track with the fitting body retracting to its normal position, allowing the

hole for the safety-locking pin to reappear. If the fitting does not lock into the track, nudge it along

the track and wiggle as necessary until it settles into position. If the fitting body does not fully

retract, push the body towards the track until the hole for the safety pin reappears. Install the

safety-locking pin into the hole in the shaft. When locked, the fitting will be immovable in the track

and the body of the fitting may not be lifted. To remove the fitting, reverse the procedure.

ALWAYS CHECK TO MAKE SURE THAT THE FITTING IS SECURELY LOCKED

INTO THE TRACK, AND THAT THE SAFETY PIN IS INSTALLED BEFORE

LIFTING ANY LOUDSPEAKER ENCLOSURE OVERHEAD.

2.3 The Xi-A Flying Concept

2.3.1 Acoustical Considerations

The Xi-A systems lend themselves to easy array construction. All of the Xi-A loudspeaker systems

use the same L-track rigging hardware on the enclosures, and may be oriented with the rigging

track either on the top and bottom of the cabinets or on the sides of the cabinets. All of the fullrange Xi-A systems have trapezoidal enclosures, enabling high-density, point-source arrays. The

horns in many of the full-range Xi-A systems are rotatable, allowing the cabinets to be oriented for

optimal physical installation and the coverage pattern to be oriented for optimal acoustic

performance. Many of the Xi-A systems have the same dimensions, facilitating ease of rigging

and a consistent cosmetic appearance. With grilles in place, the Xi-A subwoofer systems are

indistinguishable from the large Xi-A full-range systems, allowing the option of either flying the

subwoofers or stacking them on the floor, or even a combination of the two, while still preserving

ELECTRO-VOICE® Xi-A Rigging Manual7

Page 9

the uniform appearance of both the ground stack and the flown array. When designing an Xi-A

loudspeaker array, three primary acoustic goals should be kept in mind. First, the array should be

designed so that the acoustic energy is directed at the audience and away from reflecting

surfaces outside the listening area. This maximizes the intelligibility and clarity throughout the

listening area. Second, the array should be designed to achieve even coverage throughout the

audience. This ensures consistent levels and sound quality throughout the listening area. Third,

the array should be designed to achieve the required sound pressure levels throughout the

audience. This also maximizes the intelligibility and clarity throughout the listening area. The key

to achieving these three goals is to select the Xi-A loudspeaker system with appropriate coverage

patterns and acoustic-output capabilities, orient the enclosures and coverage patterns for optimal

array performance, and accurately aim the systems in the array. The reader is referred to

Appendix B.1 for a list of references covering the topics of acoustics and loudspeaker array

design. Because sound coming from numerous loudspeakers should arrive at any seat at the

same time, the speakers in an array should be curved as if mounted on the outside of an

imaginary sphere. The loudspeakers should be close-spaced to minimize lobing and maximize

coupling and each speaker must be accurately aimed. The apparent source then becomes the

single point at the center of the sphere. The horizontal array curve is simply achieved by hanging

the cabinets closely spaced, aimed outward at diverging angles. Achieving the vertical array curve

is a bit more complex to obtain. The Xi-A loudspeaker systems utilize a unique two-point

suspension system (shown in Figure 2.1) that can achieve all of the design criteria for a true pointsource array. To tilt an Xi-A loudspeaker system downward, the rigging straps at the top of that

cabinet are shifted along the rigging track towards the rear of the enclosure. To align the top-rear

corner of an Xi-A cabinet with the bottom-rear corner of an Xi-A cabinet above it, the rigging straps

at the bottom of the upper cabinet are shifted along the rigging track until the rear corners of the

adjacent cabinets are in alignment. A number of examples are presented in the following section

that will demonstrate both the mechanical and acoustical aspects of an array design with the Xi-A

loudspeaker systems.

2.3.2 Practical Considerations

The vertical angle of the flying Xi-A loudspeaker system may be adjusted by choosing different

positions of attachment along the rigging track on the cabinet. There are a number of attachment

points allowing for a wide variety of angles. Although the center of gravity is slightly different for

each of the systems, the balancing concept is the same. The further the top attachment point is

towards the back of the cabinet, the greater the downward angle, as shown in Figure 2.5. As the

attachment point is moved forward, the cabinet will have less downward angle and, at the furthest

point forward, will have an upward tilt. This principle holds true when hanging any of the Xi-A

systems in either rigging orientation (rigging track on the top and bottom, or on the sides). Vertical

arrays are constructed by hanging Xi-A systems from one another in succession. Both the

curvature of the array and the angles of the individual cabinets are controlled by the rigging

attachment positions. The shape of the array curve is determined by the position on the lower

track of an already hanging cabinet from which the next cabinet is hung, the further back the

attachment point is on the upper box, the further back the lower cabinet is shifted and, hence, the

greater the curvature of the array. The goal is to have the back, top and bottom edges to adjacent

cabinets in alignment. Hanging one cabinet from another affects the angle of the first. This is best

demonstrated in an example. In Figure 2.6a, one Xi-A enclosure is hung so that it points straight

ahead and a second is added below. The addition of the second enclosure causes the top cabinet

to point upward. Shifting the upper attachment point of the first cabinet back, as shown in Figure

2.6b, counteracts the additional load and results in the upper cabinet pointing straight ahead

ELECTRO-VOICE® Xi-A Rigging Manual 8

Page 10

again. Note that this change has no affect on the angle of the lower cabinet. Additional Xi-A

enclosures may be hung in succession in this fashion, creating a tall vertical line array (as long as

the working-load limit of all of the mechanical components are not exceeded and a sufficient

safety factor is maintained throughout the array). With the Xi-A loudspeaker systems oriented with

the rigging track on the top and bottom of the cabinets, a short rigging strap is used between the

cabinets to minimize the spacing between the systems. Typically, the LS-3B is used for this task.

If, however, Xi-A enclosures having different dimensions are hung from one another (an Xi-1122A

suspended beneath an Xi-1191AF, for example), a longer strap would be required to

accommodate the different distances In width between the rigging tracks. In this instance, the LS1B could be employed. Another option would be to use two RS-1B double-stud swivel-ring fittings

linked with a threaded-chain connector or a carabineer snap hook. (The RS-2B single-stud-ring

fittings could be used in lighter-weight applications.) With the Xi-A loudspeaker systems oriented

with the rigging track on the sides at the cabinets, a longer rigging strap is required between the

cabinets to minimize the spacing between the systems. Typically, the LS-1B is used for this task.

If, however, Xi-A enclosures having different dimensions are hung from one another (an Xi-1122A

suspended beneath an Xi-1191AF, for example), a longer strap would be required to

accommodate the different distances in width between the rigging tracks. In this instance, the LS2B could be employed. Another option would be to use two RS-1B double-stud-ring fittings linked

with a wire-rope assembly. (The RS-2B single-stud ring fittings could be used in lighter-weight

applications.)

Figure 2.5a:

Enclosure Oriented so the

Rigging is on the Top or Bottom

Figure 2.5b:

Enclosure Oriented so the

Rigging is on the Sides

Figure 2.6a:

Adding a Bottom Enclosure

Affects the Top Enclosure Angle

Figure 2.6b:

Change the Rigging

Attachment Point on Top Enclosure to

Readjust Top Enclosure Angle

ELECTRO-VOICE® Xi-A Rigging Manual9

Page 11

III. Associated Rigging Hardware for Flying Xi-A

Loudspeaker Systems

3.1 Grids and Associated Rigging Hardware

The GS-1B, LS-1B, LS-2B, LS-3B, RS-1B and RS-2B rigging accessories described throughout

this manual for use with the flying Xi-A loudspeaker systems are available from Sound

Manufacturing, Inc. (See Appendix A for details.) Electro-Voice does not manufacture grids or any

of the other associated hardware required for suspending Xi-A loudspeaker arrays overhead. In

the case of both permanent-installation and touring sound applications, it is generally most

efficient and cost effective to design a support system specific to the application, taking into

account the loudspeaker array requirements. In some permanent installations, it may even be

possible in some circumstances to eliminate the grid and secure the loudspeakers directly to the

building structural supports. The sound-system designer is instructed to evaluate each individual

circumstance and design a support system tailored to the specific application. To aid rigging

designers, the user is directed to two companies that manufacture and sell generalized and semicustom rigging hardware and accessories for flying loudspeaker systems - ATM Fly-Ware™ and

Sound Manufacturing, Inc. (See Appendix A for details on how to contact these companies.)

Attention: All associated non-Electro-Voice rigging hardware used for suspending

any X-Array Install™ (Xi-A) loudspeaker systems overhead is expressly the

responsibility of others.

IV. Strength Ratings, Safety Factors and Special Safety

Considerations

4.1 Strength Ratings and Safety Factors

Electro-Voice provides strength ratings for the Xi-A loudspeaker systems in terms of the workingload limit rating based on an 8:1 minimum safety factor. The working-load-limit rating is defined as

the maximum allowable force that may be applied to the mechanical component. The rated safety

factor is defined as the ratio of the ultimate-break-strength rating to the working-load-limit rating.

The ultimate break-strength rating represents the force applied to a mechanical component at

which the component will structurally fail. As such, the force that would result in a structural failure

in the Xi-A loudspeaker system will be at least eight times greater than the specified working-loadlimit ratings. The safety factor provides a margin of error to accommodate normal dynamic shock

loading, wear and tear on the hardware components, etc.

THE USER MUST NEVER APPLY A LOAD TO AN Xi-A LOUDSPEAKER SYSTEM THAT

EXCEEDS THE WORKING-LOAD LlMIT RATINGS.

There are two independent strength ratings that, together, give a complete description of the

overall structural performance capabilities of any Xi-A loudspeaker system:

1. The working-load-limit rating for each individual rigging point; which is a function of the

rigging track mounted on the enclosure combined with the specified quick-release rigging

hardware. This rating varies as a function of the angle of pull.

2. The working-load-limit rating for the overall enclosure; which is a function of the combined

forces from multiple rigging points simultaneously acting on the enclosure as a whole. This rating

is independent of the rigging pull angles.

ELECTRO-VOICE® Xi-A Rigging Manual 10

Page 12

WHEN SUSPENDING ANY Xi-A LOUDSPEAKER SYSTEM OVERHEAD, THE

WORKING-LOAD LIMIT MUST NEVER BE EXCEEDED FOR EACH INDIVIDUAL

RIGGING POINT, AND THE WORKING-LOAD LIMIT MUST NEVER BE

EXCEEDED FOR THE OVERALL ENCLOSURE.

The user must be aware of both of the above working-load-limit ratings at all times. An Xi-A loudspeaker system is only as strong as its weakest link. In most applications, it is usually the case

that one of the working-load limits will be approached sooner than the other. For example, if only

two rigging points are employed, the weakest link will always be the individual rigging points and

the working-load limit for the individual rigging points will always be the dominant factor If, however, four rigging points are used, the weakest link may be either the overall enclosure or the

individual rigging points depending on the angles of pull on the rigging points. The individual

rigging points on each Xi-A loudspeaker system have two working-load-limit ratings, one when

used with a double-stud ring fitting (as used on the GS-1B, LS-1B, LS-2B, LS-3B and RS-1B

rigging accessories), and one when used with a single-stud fitting (as used on the RS-2B rigging

accessory). Two working-load-limit ratings are required because the double-stud and single-stud

fittings have different strength ratings. In addition, those strength ratings will vary with the angle of

pull relative to the surface on which the rigging track is mounted. There is only one working-loadlimit rating for the overall enclosure of each Xi-A loudspeaker system, and that rating is independent of the angles of pull. Specifically, the flying Xi-1191AF, Xi-1183A, Xi-1153A, Xi-2181AF, Xi2153A, Xi-1122MHA, and Xi-2122MHA loudspeaker systems have the following strength ratings.

When used with double-stud fillings (as used on the GS-1B LS-1B, LS-2B, LS-3B and RS-1B

rigging accessories), the working-load limit rating of each individual rigging point is 500 pounds at

a pull angle of 0° (i.e., perpendicular to the surface on which the track is mounted), 437 pounds at

a pull angle of 45° and 375 pounds at a pull angle of 90° (i.e., parallel to the surface on which the

track is mounted). When used with single-stud fittings (as used on the RS-2B rigging accessory),

the working-load-limit rating of each individual rigging point is 250 pounds at any pull angle. The

working-load-limit rating of the overall enclosure is 1,000 pounds. Electro-Voice insists that the

user must never apply a load to any Xi-A flying loudspeaker system that exceeds the working-load

limit rating of either the individual rigging point or the overall enclosure. The strength ratings of the

flying Xi-1191AF, Xi-1183A, Xi-1153A, Xi-2181AF, Xi-2153A, Xi-1122MHA, and Xi-2122MHA loudspeaker systems are summarized in Figure 4.1a. Specifically, the flying Xi-1122A, Xi-1152A, Xi1123A and Xi-2123A loudspeaker systems have the following strength ratings. When used with

double-stud fittings (as used on the GS-1B LS-1B LS-2B, LS-3B and RS-1B rigging accessories),

the working-load limit rating of each individual rigging point is 500 pounds at any pull angle. When

used with single-stud fittings (as used on the RS-2B rigging accessory), the working-load-limit

rating of each individual rigging point is 250 pounds at any pull angle. The working-load-limit rating

of the overall enclosure is 750 pounds. Electro-Voice insists that the user must never apply a load

to any Xi-A flying loudspeaker system that exceeds the working-load limit rating of either the

individual rigging point or the overall enclosure. The strength ratings of the flying Xi-1122A, Xi1152A, Xi-1123A and Xi-2123A loudspeaker systems are summarized in Figure 4.1b. All associated mechanical components used with any Xi-A flying system (shackles, chains, hoists, wire-rope

slings, nylon and/or polyester slings, etc.) should be load rated for overhead lifting. All load-rated

hardware will typically have its load rating displayed on each piece in a visible location. Typical

ratings are denoted as the static-working load (SWL), or the working-load limit (WLL). These

ratings generally assume a safety factor of 5:1; however, the user should consult the hardware

manufacturer to confirm the rating. Occasionally, the load rating is given as the ultimate-break

ELECTRO-VOICE® Xi-A Rigging Manual11

Page 13

strength. This requires the user to calculate the safety factor directly for a given load. The actual

safety factor for a given load is defined as the ratio of the ultimate-break-strength rating of a

mechanical component to the actual load applied to that component. Electro-Voice suggests that

the user maintain an overall safety factor of at least 8:1 when implementing an Xi-A flying system.

In other words, the ultimate break-strength of each of the mechanical components in the system

should be at least eight times greater than the actual force applied to those components. This

includes the Xi-A enclosures, the rigging-strap assemblies, the grid the hoist and all other mechanical components and hardware. The working-load limits discussed throughout this manual for

the strength of the Electro-Voice Xi-A enclosures rigging hardware, and the GS-1B, LS-1B, LS-2B,

LS-3B, RS-1B and RS-2B rigging accessories are based on an 8:1 minimum safety factor. Where

local regulations require safety factors greater than 8:1, Electro-Voice insists that the user must

meet the required safety factor. Where local regulations permit safety factors less than 8:1,

Electro-Voice still insists that the working-load limit of the Xi-A enclosures/rigging hardware, and

the GS-1B, LS-1B, LS-2B, LS-3B, RS-1B and RS-2B rigging accessories never be exceeded.

4.2 Special Safety Considerations for Xi-A Loudspeaker Arrays

The techniques discussed in Chapter II for constructing arrays may be expanded upon to create

different arrays utilizing different combinations of Xi-A loudspeaker systems, as long as a sufficient

safety factor is maintained. The user is reminded that the top cabinet in an array supports the

weight of all the cabinets hung beneath it, and that the weight distribution between the rigging

points will depend on the exact configuration. For example, the center of gravity of the Xi-1152A

loudspeaker system is not perfectly centered but rather shifted slightly towards the high-frequency

side of the box. As a result, when an Xi-1152A is hung sideways (i.e., with the cabinet oriented so

the rigging track is on the sides), the load on the rigging strap on the high-frequency side of the Xi1152A system would be slightly higher than the load on the horn/compression-driver side. On the

other hand, the load would be distributed equally between the two rigging straps at the top of a

column of Xi-1152A systems hung with the enclosures oriented with the rigging track on the top

and bottom. The weight distribution of any Xi-A array can be calculated with the information

presented in Figure 2.2. Readers unfamiliar with the process of calculating load distributions

should consult the list of references in Appendix B.2 that cover the topics of rigging and

engineering mechanics. When arrays are constructed with columns of Xi-A systems oriented with

the rigging tracks on the top and bottom of the enclosures the rigging straps between the

enclosures will not hang straight down with a 0° vertical angle if the center-to-center spacing of the

rigging attachment positions are different from the bottom of one cabinet to the top of the cabinet

immediately beneath it. The rigging straps will deviate from a 0° vertical angle when trapezoidal

cabinets are employed, or cabinets of differing size are mixed in the same column. These verticalangle differences will result in forces (i.e., tension loads) of the top cabinets (including the top

rigging straps). However, if the rigging straps throughout the array are at unusual and or extreme

angles, the worst-case forces in an array may occur somewhere other than the top riggingattachment point of the top cabinets.

Attention: Array details and rigging configurations will affect the load on the

loudspeaker systems, the rigging straps and all associated rigging hardware. The

user is responsible for determining the loads on all of the mechanical components

throughout the loudspeaker array, and for ensuring that the working-load limits and

resulting safety factors are not exceeded. A qualified structural engineer should be

consulted to evaluate the design.

ELECTRO-VOICE® Xi-A Rigging Manual 12

Page 14

Figure 4.1a:

Working-Load Limit Strength Rating for Xi-1153A, Xi-1183A, Xi-2153A,

Xi-1191AF, Xi-2181AF, Xi-1122MHA, and Xi-2122MHA

Figure 4.1b:

Working-Load Limit Strength Rating for Xi-1122A, Xi-1152A, Xi-1123A,

and Xi-2123A

ELECTRO-VOICE® Xi-A Rigging Manual13

Page 15

4.3 Special Safety Considerations for Rigging Strap Assemblies

4.3.1 Redundant Att achment Points

As an added safety measure, it is suggested that the user install a second set of grid straps from

the top rigging points of the top cabinets in an array back to the grid (or building structural

supports). These redundant safely straps can be secured to an open section of rigging track next

to the primary grid straps. The safety straps should have as little slack as possible (less than one

inch is preferable).

4.3.2 Special Considerations for Polyester Webbing

The GS-1B, LS-1B and LS-2B utilize polyester webbing in their construction. The user is

cautioned, however, that in certain permanent installation applications, the polyester material may

not meet local fire regulations. The user is also cautioned that polyester material will deteriorate

with extended exposure to ultraviolet light (direct sunlight) or to hot, dry environments, resulting in

reduced strength capability. In such instances, wire rope or chain assemblies must be substituted.

4.4 Special Safety Considerations for Grid & Building Structural Supports

When suspending loudspeaker arrays from grids or building supports the associated rigging

hardware employed (i.e., rigging straps, slings, chains, wire-rope assemblies, chains, etc.) may

not hang at a 0° vertical angle. These vertical angle differences will result in forces (i.e., tension

loads) in that rigging hardware that are greater than the weight suspended below. These

increased forces must be taken into account when evaluating the load on the mechanical

components and the safety factor of an array. The greater the angle difference from the 0°

vertical, the greater is the increase in force above what it would be if the straps were at 0°. Any

users unfamiliar with the process of calculating the increased load as a function of lifting angles

should consult the list of references in Appendix B.2 which cover the topics of rigging and

engineering mechanics.

Attention: Array details and rigging configurations will affect the load on the building

structure, the grids, the loudspeaker systems, the rigging straps and all associated

rigging hardware. The user is responsible for determining the loads on all of the

mechanical components throughout the loudspeaker array, and for ensuring that the

working-load limits and resulting safety factors are not exceeded. A qualified

structural engineer should be consulted to evaluate the design.

ELECTRO-VOICE® Xi-A Rigging Manual 14

Page 16

V. Rigging Inspection, Maintenance and Precaution

5.1 Xi-A System Component s

5.1.1 Xi-A Loudspeaker Systems

Prior to each use, inspect the loudspeaker enclosures for any cracks, deformations, missing or

damaged components that could reduce enclosure strength. Inspect the track and bracket

assemblies on the enclosures for any cracks, deformations, missing or loose screws which could

reduce the flying hardware strength. Replace any loudspeaker systems that are damaged or

missing hardware. Never exceed the limitations or maximum recommended load for the Xi-A

systems.

5.1.2 Rigging Strap Assemblies

Prior to each use, inspect the webbing for cuts abrasion, tears, knots, chemical damage, burns

and broken stitches that could reduce rigging-strap assembly strength. Inspect the rigging fittings

and hooks for any cracks, burrs, deformations, or missing or damaged components that could

reduce strap assembly strength. Replace any rigging-strap assemblies that have damaged

webbing, or damaged or missing hardware. Always double check that each fitting on each of the

rigging-strap assemblies is securely locked into position in the track on the Xi-A enclosures and

that the safety locking pin is engaged before lifting.

5.2 Associated Hardware

5.2.1 Grid Assembly

Prior to each use, inspect the grid assembly and associated hardware for any cracks,

deformations, broken welds, corrosion, or missing or damaged components that could reduce the

grid assembly strength. Replace any damaged grid assemblies. Never exceed the limitations or

maximum recommended load intended for grid assembly design.

5.2.2 Chain Hoists

Prior to each use, inspect the chain hoist and associated hardware (including motor, if applicable)

for any cracks, deformation, broken welds, corrosion, or missing or damaged components that

could reduce the hoist strength. Replace any damaged chain hoists. Never exceed the limitations

or maximum recommended load specified by the hoist manufacturer. Always raise and lower the

load slowly and evenly, avoiding any rapid changes in speed or shifting loads that could result in a

sudden jolt to the suspended system.

5.2.3 Building Structural Supports

Prior to each use, the strength and load-bearing capabilities of the building structural supports

should be evaluated and certified by a professional engineer as being adequate for supporting the

intended rigging system (including the loudspeakers, grids, chain hoists and all associated

hardware). Prior to each use, inspect the building structural supports for any cracks, deformation,

broken welds, corrosion, or missing or damaged components that could reduce the structural

strength. Damaged building structural supports should be replaced or repaired and re-certified by

a professional engineer.

ELECTRO-VOICE® Xi-A Rigging Manual15

Page 17

5.2.4 Mechanical Components

Prior to each use, inspect all mechanical components (chain, wire ropes, slings, shackles, hooks,

fittings, etc.) for any cracks, deformation, broken welds, slipping crimps, fraying, abrasion, knots,

corrosion chemical damage, loose screws, missing or damaged components which would reduce

the maximum strength specified by the component manufacturer. Replace any damaged

mechanical components.

ELECTRO-VOICE® Xi-A Rigging Manual 16

Page 18

VI. Appendices

Appendix A: Xi-A Rigging Accessories

GS-1B, LS-1B, LS-2B, LS-3B, RS-1B and RS-2B Xi-A Rigging Accessories: These rigging

accessories described throughout this manual are available from:

Sound Manufacturing, Inc.

P.O. Box 1907

Big Bear Lake, CA 92315, USA

(909) 878-9104

www .smirigging.com

smiller@smirigging.com

Custom Rigging Strap Assemblies: Custom wire rope or webbing rigging strap assemblies that

use the RS-1B and RS-2B fittings may be ordered from:

Sound Manufacturing, Inc.

P.O. Box 1907

Big Bear Lake, CA 92315, USA

(909) 878-9104

www .smirigging.com

smiller@smirigging.com

General Rigging Supplies: A wide variety of standard and specialty rigging hardware

components for both touring and permanent-installation applications are available from:

Sound Manufacturing, Inc.

P.O. Box 1907

Big Bear Lake, CA 92315, USA

(909) 878-9104

www .smirigging.com

smiller@smirigging.com

ATM Fly-ware™

21000 S. Wilmington Ave.

Carson, CA 90810 USA

(310) 834-5914

www.atmflyware.com

clientservice@atmflyware.com

ELECTRO-VOICE® Xi-A Rigging Manual17

Page 19

Appendix B

B.1 Acoustical References

A brief list of references covering the topics of acoustics and sound-system design is presented

below:

(1) D. Davis & C. Davis, Sound System Engineering, Howard Sams & Co., Indianapolis, IN

(1987).

(2) J. Eargle, Handbook of Sound System Design, ELAR Publishing Co., Commack, NY

(1989).

(3) G. Davis & R. Jones, Sound Reinforcement Handbook, Hal Leonard Publishing Corp.,

Milwaukee, WI (1989).

(4) L.L. Beranek, Acoustics, American Institute of Physics, Inc. New York, NY (1986).

(5) H.F. Olson, Acoustical Engineering, Professional Audio Journals, Inc., Philadelphia, PA

(1991).

(6) L.E. Kinsler. A.R. Frey, A.B. Coppens, & J.V. Sanders, Fundamentals of Acoustics, John

Wiley & Sons, New York, NY (1980).

(7) D.B. Keele, Electro-Voice, Inc., “What’s So Sacred About Exponential Horns,” presented at the

51St Convention of the AES (May, 1975), preprint #1038.

(8) P.F. Fidlin & D.E. Carlson Electro-Voice, Inc., Comparative Performance of Directional Devices

Used as Concert-Sound Loudspeaker Array Elements,” Journal of the AES (April,

1990).

B.2 Mechanical References

A brief list of references covering the topics of rigging and engineering mechanics is presented

below:

(1) W.E. Rossnagel, L.R. Higgins & J.A. MacDonald, Handbook of Rigging for Construction

and Industrial Operations, McGraw-Hill Book Company, New York, NY, USA (1988).

(2) A. Jensen & H. Chenoweth, Applied Engineering Mechanics, McGraw-Hill Book Co.,

New York, NY (1983).

(3) J.O. Glerum, Stage Rigging Handbook, Southern Illinois University Press, Carbondale, IL,

USA (1987).

(4) P. Carter, Backstage Handbook, Broadway Press, New York, NY, USA (1988).

(5) Wire Rope Technical Board, Wire Rope Users Manual, American Iron and Steel Institute,

Stevensville, MD, USA (1985).

(6) ATM FIy-Ware™, ATM Fly-Ware™ Catalog of Rigging Hardware and Supplies, ATM

Group, Inc., Carson, CA (1996).

(7) Broderick & Bascom Rope Company, Rigger’s Handbook, Sedalia, MO, USA (1993).

(8) MacWhite Wire Rope Company, Catalog of Tables, Data and Helpful Information,

Kenosha, WI, USA (1991).

(9) Acco Chain & Lifting Division, Chain Sling User’s Manual, Acco Corporation, York,

PA, USA (1992).

(10) Newberry, W.G., Handbook for Riggers, Newberry Investments Company, Calgary,

Alberta, Canada (1989).

ELECTRO-VOICE® Xi-A Rigging Manual 18

Page 20

U.S.A. and Canada:

For customer orders, contact the Customer Service department at:

800/392-3497 Fax: 800/955-6831

For warranty repair or service information, contact the Service Repair Department at:

800/685-2606

For technical assistance, contact Technical Support at:

866/78-AUDIO

Specifications subject to change without notice.

All Other International Locations:

952-884-4051 Fax: 952-736-4212

www.electrovoice.com

Printed in U.S.A

© Telex Communications, Inc. 10/2004

Part Number 534993 Rev B

Telex Communications, Inc.

www.telex.com

ELECTRO-VOICE® Xi-A Rigging Manual

Loading...

Loading...