Electro-Voice X-Array Xw12 User Manual

Xw12

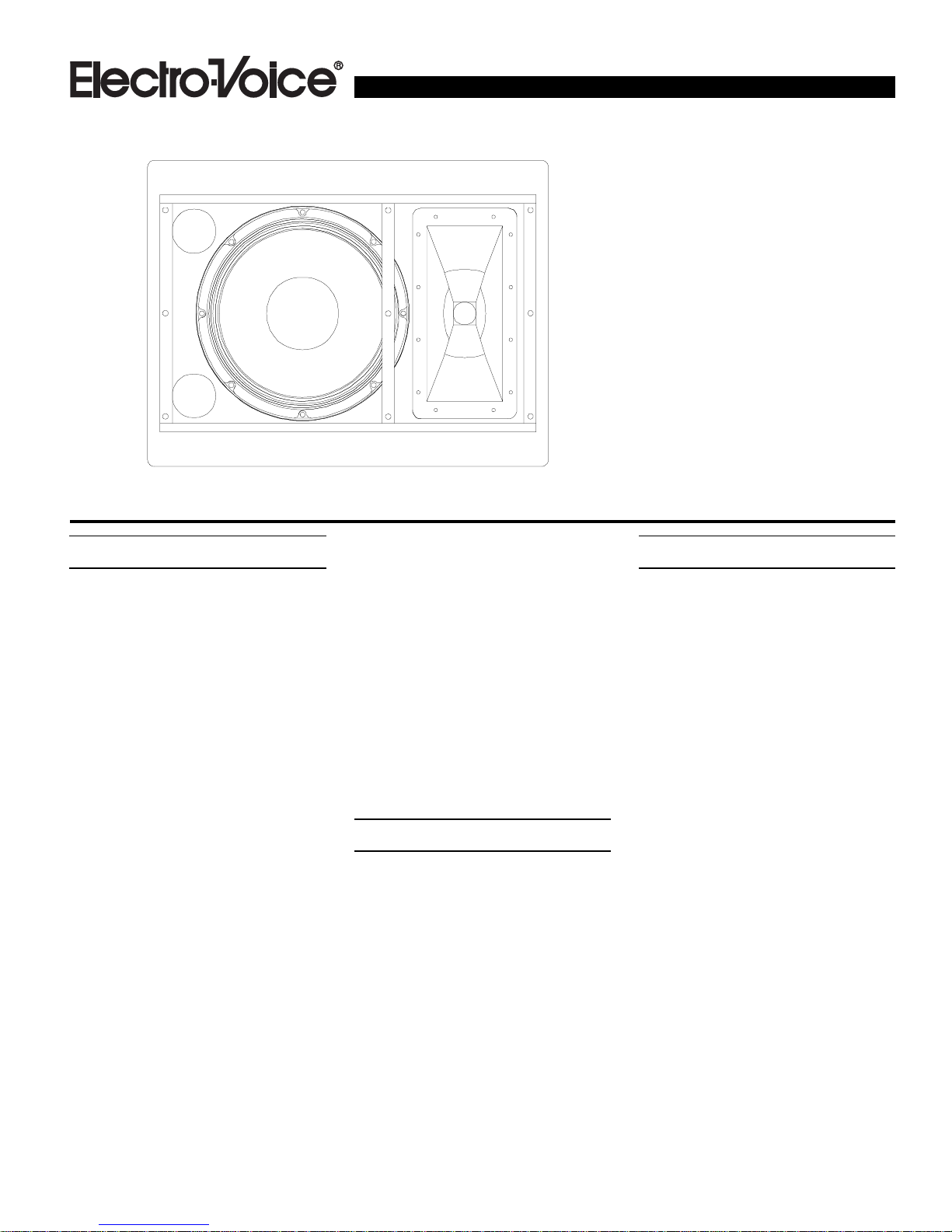

X-ArrayTM Two-Way,

Full-Range Floor Monitor

• New 12-inch woofer design

provides improved internal

damping of cone

• New DH6, 1.4-inch compression

driver

• Rugged 12-ply ultracompact,

uniquely curved enclosure

• Constant-directivity 80° x 55° horn

• Professional Neutrik Speakon

paralleled pass-through connectors

on both ends of enclosure

®

Description

The Electro-Voice Xw12 full-range, twoway, floor monitor loudspeaker system is part

of the Electro-Voice X-Array

intended for high-level sound reinforcement

in fixed-installation and touring-sound

applications. The Xw12 is a full-range

biamped floor monitor speaker system which

may be used with the Electro-Voice Dx38

digital crossover, the Klark Teknik DN8000

or any high-quality, signal-controller system.

The Xw12 employs a custom-designed, 12inch woofer for low-frequency reproduction. Designed as part of the Xw12 development, this woofer uses a new cone material to provide maximum internal damping.

This woofer also employs "DL" technology

which utilizes a Thermal Inductive Ring, (TIR

a nonmagnetic pole piece extension that controls inductance and, most importantly, provides a major heat transfer path from the top

of the voice coil to minimize power compression. For high frequencies, the Xw12 uses the

DH6, a 1.4-inch-exit variant of the DH1A compression driver designed as part of the Xw12

development. Its unique one-piece geometrically optimized titanium dome and suspension combined with its unusually powerful

magnetic motor provide maximum efficiency

and precise control of the diaphragm mo-

™

series and is

™

tion. The compression driver is coupled

to an 80º x 55º horn. This flat-front, constantdirectivity horn is based on the Electro-Voice

HP series, and is geometrically optimized for

performance from 1,250-20,000 Hz.

The XW12 is constructed of 18-mm voidfree, 3/4-inch 12-ply curved plywood shell

which is extremely rigid. The baffle and end

pieces are made from 18-mm 13-ply birch

plywood. This high-strength enclosure

is sprayed with a resilient, textured black

finish for a truly professional appearance.

The end-mounted, recessed handle makes

transportation relatively easy.

Applications

The XW12 loudspeaker system is ideal for

use as a professional stage touring or installation application floor monitor where ex-

),

tremely high power and low distortion, as

well as accurate vocal coverage and maximized intelligibility are required from a system housed in a compact, low-profile enclosure. Its symmetrical design will allow two

monitors to be placed head to head so that

the high-frequency horns are coupled for

high-level large stage applications. The

Xw12 and associated controller combinations are recommended for applications requiring full bandwidth down to 60 Hz.

Power-Handling T est

Electro-Voice components and systems are

manufactured to exacting standards to ensure reliability in continuous use in arduous

real-life conditions. Besides utilizing industry-standard power tests, extreme in-house

power tests which push the performance

boundaries of the loudspeakers are also performed for an extra measure of reliability.

The XW12 systems are rated per ANSI/

EIA RS-426-A Loudspeaker Power Rating,

Full Range Test, which uses a shaped-random-noise signal to simulate typical music

to test the mechanical and thermal capabilities of the loudspeakers. The Dx38 digital electronic unit was used to provide the

necessary crossover filters and equalization during power testing. Specifically, the

Xw12 passes the ANSI/EIA RS-426-A

power test with the following test parameters:

Low-Frequency Section:

P

: 300 watts

E(MAX)

Test Voltages: 47.0-volts rms

94.0-volts peak

R

(1.15 RE): 7.36 ohms

SR

High-Frequency Section:

: 75 watts

P

E(MAX)

Test Voltages: 28.0-volts rms

54.0-volts peak

(1.15 RE): 10.5 ohms

R

SR

Xw12 T wo-W ay, Full-Range Floor Monitor

Crossover , Equalization and Time-Delay

Controller

The Xw12 speaker system was designed

as an integrated package that utilizes

the Electro-Voice Dx38 digital crossover

system.

The Dx38 features a 125-Hz crossover frequency utilizing 24-dB-per-octave

Linkwitz-Riley filters, and contains time

delay and equalization for optimum performance of the Xw12.

Electrical Connection and System

Wiring

Electrical connections to the Xw12 are

made on the sides of the enclosure via parallel pass through 4-pin connectors. There

are two connectors on each of the input

Xw12 Two-Way, Full-Range Floor Monitor

panels to allow paralleling of other Xw12

systems. The Neutrik Speakon

®

NL4MPR

is used for both connections. The pin assignments are as follows:

Pin 1+: LF(+)

Pin 1-: LF(–)

Pin 2+: HF(+)

Pin 2-: HF(–)

The wiring diagram of the loudspeaker

system is shown in Figure 7. The electrical

impedance is shown in Figure 6.

Amplifier Requirements

Power amplifiers with the following ratings

are recommended for use with the Xw12

speaker systems:

LF: 600 watts per channel into 8 ohms.

HF: 600 watts per channel into 8 ohms.

Xw12 speakers may be paralleled only with

other Xw12 speakers if the amplifier is capable of delivering full power at the lower

impedances. The use of amplifiers with

lower power ratings is acceptable; however, the full-power capabilities of the Xw12

speakers will not be realized. The use of

amplifiers with significantly higher power

ratings will generate maximum dynamic

range and fidelity, but care must be utilized for longer duration signals as mechanical and thermal damage are possible in the

system. Under certain circumstances, higher

rated amplifiers are acceptable. It is acceptable to drive the Xw12 speakers with a stereo power amp utilizing one channel to drive

2

the low frequencies and the other channel

to drive the high frequencies.

Field Replacement

The Xw12 may be serviced in the following

ways. Remove the grille to allow access to

both the woofer and high-frequency driver.

Remove the woofer bolts to allow the woofer

to easily be removed for repair or replacement.

In case of a compression driver failure, a diaphragm assembly replacement kit is available.

T o remove the compression driver, remove the

horn-mounting screws. Remove the woofer

to gain access to the compression driver. Remove the two accessable hex socket screws

attaching the horn to the driver through the

woofer cut-out opening. After removing the

screws, lift the high-frequency horn and rotate 180 degrees allowing access to remove

the remaining screws. Remove the compression driver through the woofer cut-out opening. If desired, the complete driver may be returned for service.

The following replacement parts are available from EVI Audio Service in Buchanan,

Michigan:

LF: Complete woofer: EV Part No. 812-2997

HF: Diaphragm kit: EV Part No. 84233-XX

Architects' And Engineers'

Specifications

The loudspeaker speaker system shall be a

two-way biamped system with performance

controlled by a variety of dedicated electronic

control units. The loudspeaker system shall

have a 305-mm (12-inch) direct-radiating

driver with an 8-ohm, 63.5-mm (2.5-inch)

voice coil constructed of aluminum wire, and

shall be capable of a 300-watt shaped pinknoise signal with a 6-dB crest factor for eight

hours (as per ANSI/EIA RS-426-A 1980).

The loudspeaker system shall have a 35.6-mm

(1.4-inch) exit compression driver mounted on

a high-frequency horn. The compression

driver shall have 76.2-mm (3.0-inch) diameter, titanium dome and a 16-ohm nominal,

76.2-mm (3.0-inch) di ameter voice coil constructed of aluminum wire, and shall be capable of handling a 75-watt, 1,600- 20,000Hz pink-noise signal with a 6-dB crest factor

for eight hours (as per ANSI/EIA RS-426-A

1980 standard). The high-frequency horn shall

be of the constant-directivity type and shall

produce a nominal horizontal beamwidth

(6-dB-down angle) of 80° from 2,000-20,000

Hz and a nominal vertical beamwidth of 55°

from 1,600-20,000 Hz. The loudspeaker

system enclosure shall be constructed of 18-mm

thick, 12-ply flat birch plywood and .75-inch

thick, 12-ply curved birch plywood, covered

with black textured paint and shall have a

14-gauge perforated steel grille.

When used with the electronic control unit,

the loudspeaker system shall have a flat onaxis frequency response from 60 -16,000 Hz.

The loudspeaker enclosure dimensions

shall be 358.3 mm (14.11 in.) high, 584.2 mm

(23.00 in.) wide and 408.8 mm (16.10 in.) deep

and shall weigh 28.2 kg (62 lb).

The loudspeaker shall be the Electro-Voice

Xw12 .

Uniform Limited Warranty

Electro-Voice products are guaranteed

against malfunction due to defects in materials or workmanship for a specified period,

as noted in the individual product-line

statement(s) below, or in the individual product data sheet or owner’s manual, beginning

with the date of original purchase. If such

malfunction occurs during the specified period, the product will be repaired or replaced

(at our option) without charge. The product

will be returned to the customer prepaid.

Exclusions and Limitations: The Limited

W arranty does not apply to: (a) exterior finish or appearance; (b) certain specific items

described in the individual product-line

statement(s) below, or in the individual product data sheet or owner’s manual; (c) malfunction resulting from use or operation of

the product other than as specified in the

product data sheet or owner’s manual; (d)

malfunction resulting from misuse or abuse

of the product; or (e) malfunction occurring

at any time after repairs have been made

to the product by anyone other than

Electro-Voice Service or any of its authorized service representatives. Obtaining

Warranty Service: To obtain warranty service, a customer must deliver the product,

prepaid, to Electro-Voice Service or any of

its authorized service representatives together with proof of purchase of the product in the form of a bill of sale or receipted

invoice. A list of authorized service repre-

Loading...

Loading...