Electro-Voice X1-212/90, X12-128, X12TE-GRID, X2-212/90, X12T-DOLLY Installation Manual

...

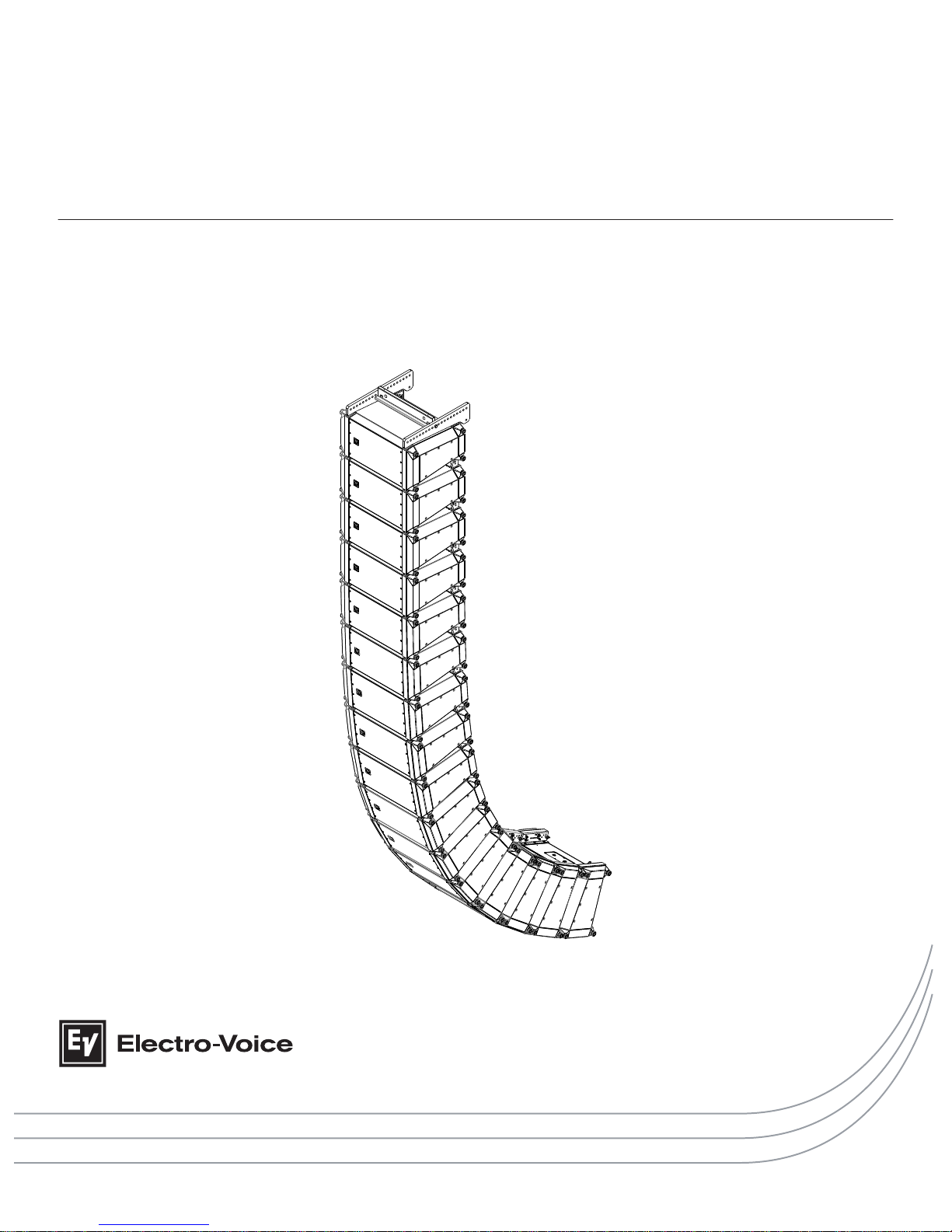

X-LINE ADVANCE Systems

X1-212/90, X12-128, X2-212/90, X12TC-GRID, X12TE-GRID, X12PU-BGK, X12T-DOLLY, and

X12-128-DOLLY

en | Installation Manual

Table of contents

1

Safety 5

1.1 Important Safety Instructions 6

1.2 Precautions 6

1.3 Suspension 6

2

Introduction 7

3

System overview 8

3.1 Dimensions 9

3.1.1 Accessories dimensions 10

4

Designing an X1 or X2 array 13

4.1 Applications for which X-Line Advance arrays are most appropriate 13

4.2 Determining X1 and X2 array configuration with LAPS 3 13

5

Preparing X-Line Advance elements for installation 14

5.1 Recommended preflight procedures 14

5.2 Element configuration 14

6

Rigging system 15

6.1 Overview of the flying system 15

6.2 Rigging the boxes together 15

6.3 Setting rear link angles 17

6.4 Deciding which grid configuration to use 20

6.4.1 X12TC-GRID compact grid 20

6.4.2 X12TE-GRID extended grid 23

6.4.3 X12PU-BGK pull-up kit 28

6.5 X12T-DOLLY and X12-128-DOLLY 31

6.5.1 Stacking X1 & X2 loudspeakers onto a X12T-DOLLY 32

6.5.2 Stacking X12-128 subwoofer(s) onto a X12-128-DOLLY 35

6.6 Assembling and flying an array 37

6.6.1 Flying arrays from the dolly 37

6.6.2 X12TC-GRID with pull-back to venue 41

6.6.3 X12TE-GRID using X12PU-BGK to pull-up to grid 43

6.6.4 Storing empty dollies 44

6.6.5 Landing arrays onto a dolly 45

6.7 Array building techniques 48

6.7.1 Multiple ways to fly the X12TC-GRID 48

6.7.2 Multiple ways to fly the X12TE-GRID 49

6.7.3 Array build strength considerations 50

7

Subwoofer arrays 52

7.1 Subwoofer array configuration 52

7.2 Subwoofer cardioid options 53

8

Rigging structural strength ratings and safety factors 54

8.1 Structural introduction 54

8.2 Structural rating overview 54

8.3 LAPS 3 structural evaluations simplified structural rating guidelines 55

8.4 Specific safety considerations 55

8.5 Working-load limit and safety factor definitions 56

en 3

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

9

Rigging inspection and precautions 58

10

Technical data 59

11

References 62

11.1 Rigging (printed) 62

11.2 Mechanical engineering (printed) 62

11.3 Rigging (websites) 62

12

Notes 63

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Safety

This document details general rigging practices appropriate to the entertainment industry, as

they would apply to the rigging of X1 and

X2 loudspeaker systems from Electro-Voice. It is

intended to familiarize the user with standard rigging hardware and techniques for suspending

X1 and X2 loudspeaker systems overhead. Only persons with the knowledge of proper

hardware and safe rigging techniques should attempt to suspend any sound systems

overhead. Prior to suspending any X1 and X2 loudspeaker systems overhead, it is essential the

user is familiar with the strength ratings, rigging techniques and special safety considerations

outlined in this manual. The rigging techniques and practices recommended in this manual

are, of necessity, in general terms to accommodate the many variations in loudspeaker arrays

and rigging configurations. As such, the user is expressly responsible for the safety of all

specific X1 and X2 loudspeaker array designs and rigging configurations as implemented in

practice.

All the general rigging material contained in this manual is based on the best available

engineering information concerning materials and practices, as commonly recognized in the

United States, and is believed to be accurate at the time of original printing. As such, the

information may not be directly applicable in other countries. Furthermore, the regulations

and requirements governing rigging hardware and practices may be superseded by local

regulations. It is the responsibility of the user to ensure any Electro-Voice loudspeaker system

is suspended overhead in accordance with all current federal, state, and local regulations.

All specific material concerning the strength ratings, rigging techniques, and safety

considerations for the X1 and X2 loudspeaker systems is based on the best available

engineering information concerning the use and limitations of the products. Electro-Voice

continually engages in testing, research and development of its loudspeaker products. As a

result, the specifications are subject to change without notice. It is the responsibility of the

user to ensure that any Electro-Voice loudspeaker system is suspended overhead in

accordance with the strength ratings, rigging techniques, and safety considerations given in

this document and any manual update notices. Visit our website: www.electrovoice.com for

current product technical documentation or software. All non-Electro-Voice associated

hardware items necessary to rig a complete X1 and X2 loudspeaker array (chain hoists,

building or tower supports, and miscellaneous mechanical components) are the responsibility

of others.

Electro-Voice

April 2015

1

en 5

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Important Safety Instructions

1. Read these instructions.

2.

Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Clean only with a dry cloth.

6. Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat.

Old electrical and electronic appliances

Electrical or electronic devices that are no longer serviceable must be collected separately and

sent for environmentally compatible recycling (in accordance with the European Waste

Electrical and Electronic Equipment Directive).

To dispose of old electrical or electronic devices, you should use the return and collection

systems put in place in the country concerned.

Precautions

!

These Electro-Voice loudspeakers were designed for use in an environment with

ambient temperatures between -20°C (-4°F) and +50°C (122°F).

!

These Electro-Voice loudspeakers are not rated for continuous outdoor

conditions. However, they may be exposed to occasional short-term rain, water,

or high humidity.

!

Electro-Voice loudspeakers are easily capable of generating sound pressure

levels sufficient to cause permanent hearing damage to anyone within normal

coverage distance. Caution should be taken to avoid prolonged exposure to

sound pressure levels exceeding 90 dB.

Suspension

!

Warning!

Suspending any object is potentially dangerous and should only be attempted by individuals

who have a thorough knowledge of the techniques and regulations of suspending objects

overhead.

Electro-Voice

strongly recommends all loudspeakers be suspended taking into

account all current national, federal, state, and local laws and regulations. It is the

responsibility of the installer to ensure all loudspeakers are safely installed in accordance

with all such requirements. When loudspeakers are suspended, Electro-Voice strongly

recommends the system be inspected at least once per year or as laws and regulations

require. If any sign of weakness or damage is detected, remedial action should be taken

immediately. The user is responsible for making sure the wall, ceiling, or structure is capable

of supporting all objects suspended overhead. Any hardware used to suspend a loudspeaker

not associated with Electro-Voice is the responsibility of others.

1.1

1.2

1.3

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Introduction

The X1 and X2

loudspeaker system line-array elements by Electro-Voice represent an

important step in line-array technology for small- to large-scale fixed-installation and live

sound reinforcement. The various models are designed to significantly simplify the physical

assembly of a line array. Also, X1 in passive mode may be designed so that up to three

elements are powered from one (1) amplifier channel, the necessary crossover and EQ

functions accomplished with sophisticated internal passive networks. X2 is designed to

operate in Bi-amp mode only. The individual loudspeaker drivers, Hydra planar-wave

generators, acoustic waveguides, enclosures and rigging hardware were all designed

specifically for the X1 and X2 product line to not only achieve the highest acoustic output with

the highest fidelity, but also produce a precise wave front from each element to achieve stateof-the-art line-array performance. The X12 subwoofer elements are designed to compliment

the performance of X1 and X2 full-range elements in applications where additional lowfrequency output is desired.

Although the X1 and X2 full-range elements are not physically symmetrical, their acoustic polar

responses are substantially symmetrical. Thus, stereo left and right arrays or left-center-right

arrays may be constructed with the elements in their normal right-side-up orientation.

2

en 7

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

System overview

Each X1-212/90 full-range element consists of one (1) SMX2121 12-inch (304.8 mm) LF

drivers coupled to a MBH

(Mid Band Hydra) and two (2) ND2R 2-inch-diaphragms (50.8 mm)

HF drivers. Each HF driver is mounted on a WCH (Wavefront-shaping Circular Hydra)

planar-wave generator and vertically orientated.

X1 is designed in a two-way configuration with a 90° horizontal x 10° vertical coverage pattern

and an internally selectable passive crossover/EQ network. The enclosure is trapezoidal in the

vertical plane with a 10° total included angle.

Each X2-212/90 full-range element consists of one (1) DVN3125 12-inch (304.8 mm) LF drivers

coupled to a MBH and two (2) ND6A 3-inch-diaphragms (76.2 mm) HF drivers. Each HF driver

is mounted on a PDH (Pin Diffraction Hydra) planar-wave generator and vertically orientated.

X2 is designed in a two-way configuration with a 90° horizontal x 10° vertical coverage pattern

for bi-amp use only. A passive crossover/EQ network is neither included nor available. The

enclosure is trapezoidal in the vertical plane with a 10° total included angle.

The X12-128 dual-18-inch subwoofer includes two (2) DVF4180 woofers designed specifically

for subwoofer applications, providing reliable low-frequency performance at high SPL levels

with low distortion and solid impact. Subwoofer elements do not have internal passive

crossovers and require an active crossover and dedicated amplifier channel(s) for proper

operation.

X12 is a compact rectangular dual-18-inch subwoofer element designed for use only as a

ground stack subwoofer array. The X12-128 is also designed to be used in ground stack

cardioid arrays.

All X1 & X2 elements are available in black and are supplied with the hardware necessary to

interface one element to another.

X12TC-GRID: standard grids for up to 24 X1 or X2 elements for simple or mostly straight

arrays, where extreme tilt angles are not required.

X12TE-GRID: extended grids for up to 24 X1 or X2 elements for extreme down angles in small

to medium arrays and typical up or down angles in large arrays.

X12PU-BGK: Pull Up Bottom Grid Kit for X1 or X2 elements. A pull-up kit is used when the

compression rigging method is being used with an array or when extreme down angles beyond

the capabilities of the extended grid are required.

The three (3) different grid options (X12TC, X12TE and X12PU-BGK) are sold separately.

Consult LAPS 3 for proper grid selection and array design.

X12T-Dolly: Dolly is used for transporting X1 or X2 loudspeaker systems. The dolly

accommodates two (2) columns of X1 or X2 loudspeaker systems stacked three (3) high for

transportation (Total of six (6) systems per dolly). Systems are secured to the dolly via their

rigging pins. A rigid top cover provides a solid surface for stacking and two (2) dolly side

panels provide protection for speaker grilles. The dolly may also be used as a ground stack

platform, either wheeled or stationary by using the dolly top cover.

3

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

X12-128-Dolly: Dolly is used for transporting X12-128 subwoofers. The dolly will accommodate

one (1) column of X12-128 subwoofers stacked two (2) high for transportation. The systems

are strapped down with ratchet straps for additional protection during transport.

Dimensions

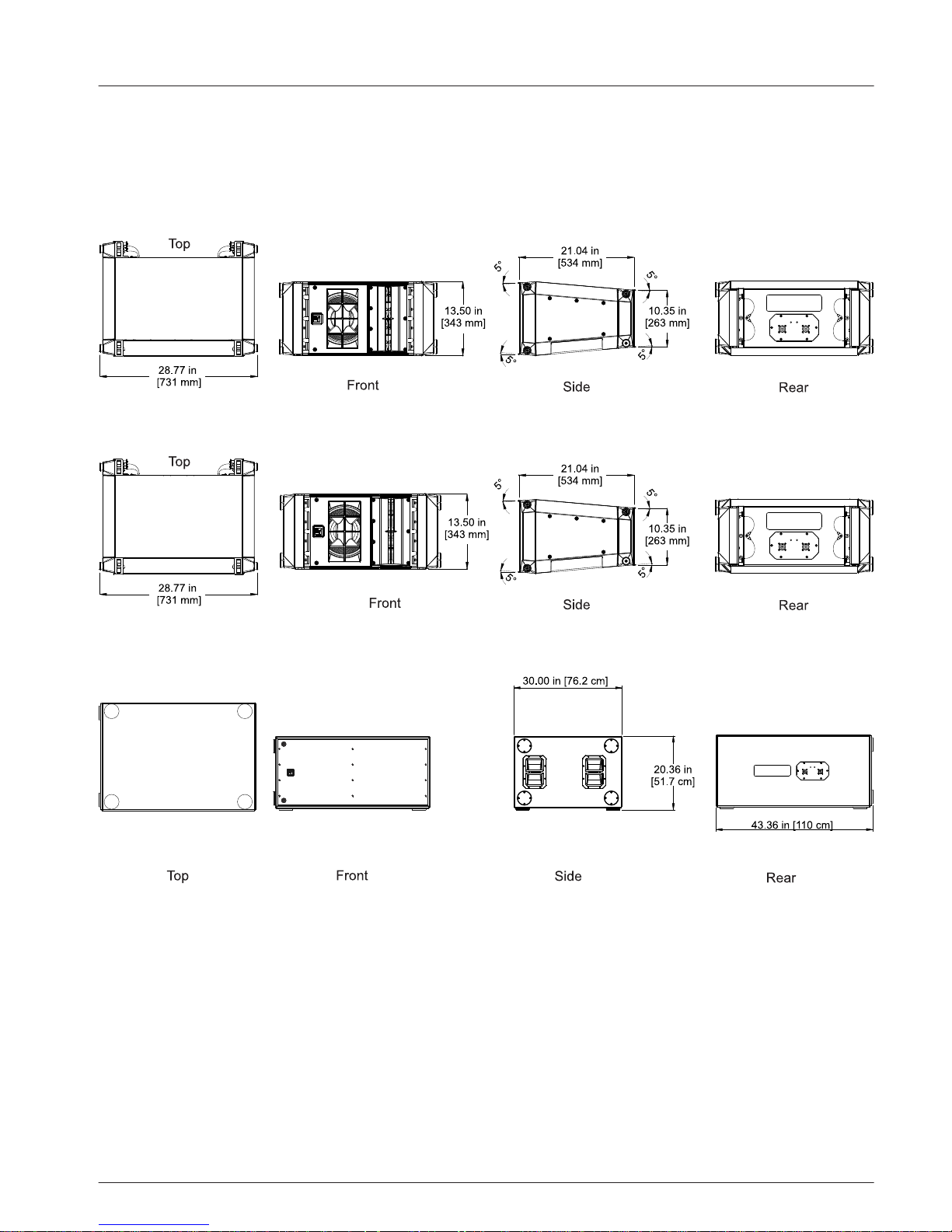

Figure 3.1: X1-212/90 dimensions

Figure 3.2: X2-212/90 dimensions

Figure 3.3: X12-128 dimensions

3.1

en 9

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Accessories dimensions

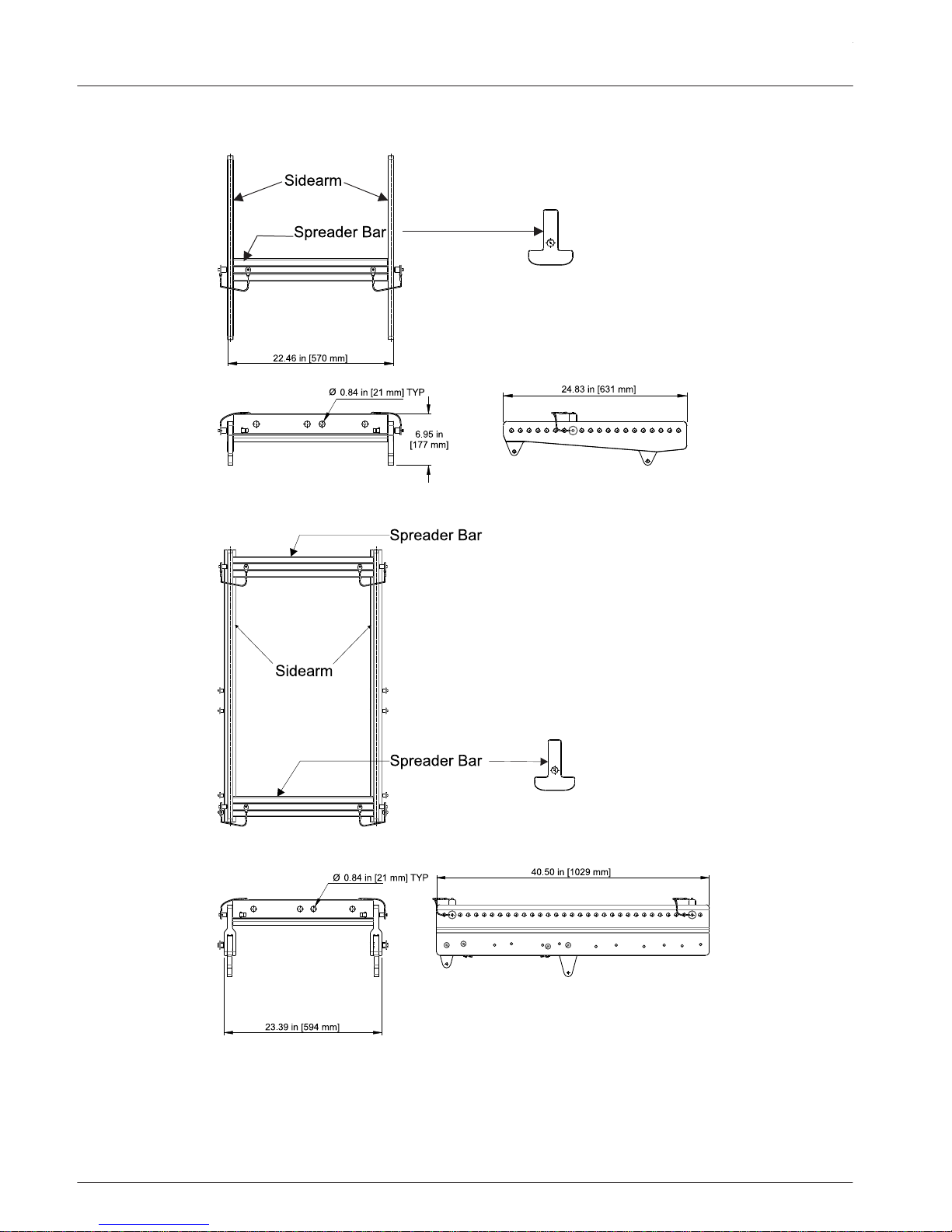

Figure 3.4: X12TC-GRID compact grid dimensions

Figure 3.5: X12TE-GRID extended grid dimensions

3.1.1

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

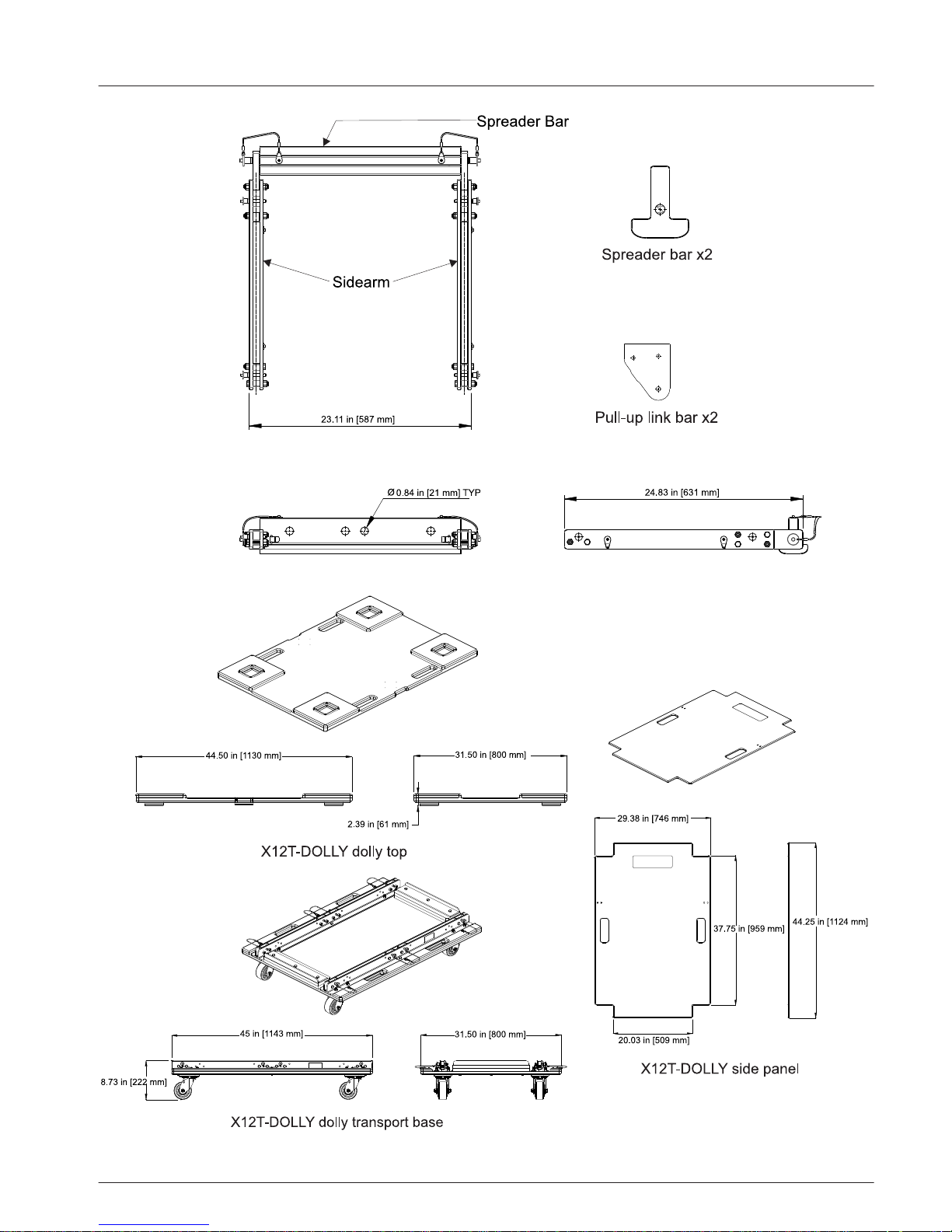

Figure 3.6: X12PU-BGK Pull-up grid dimensions

Figure 3.7: X12T-DOLLY dimensions

en 11

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Figure 3.8: X1/X2 groundstack dimensions

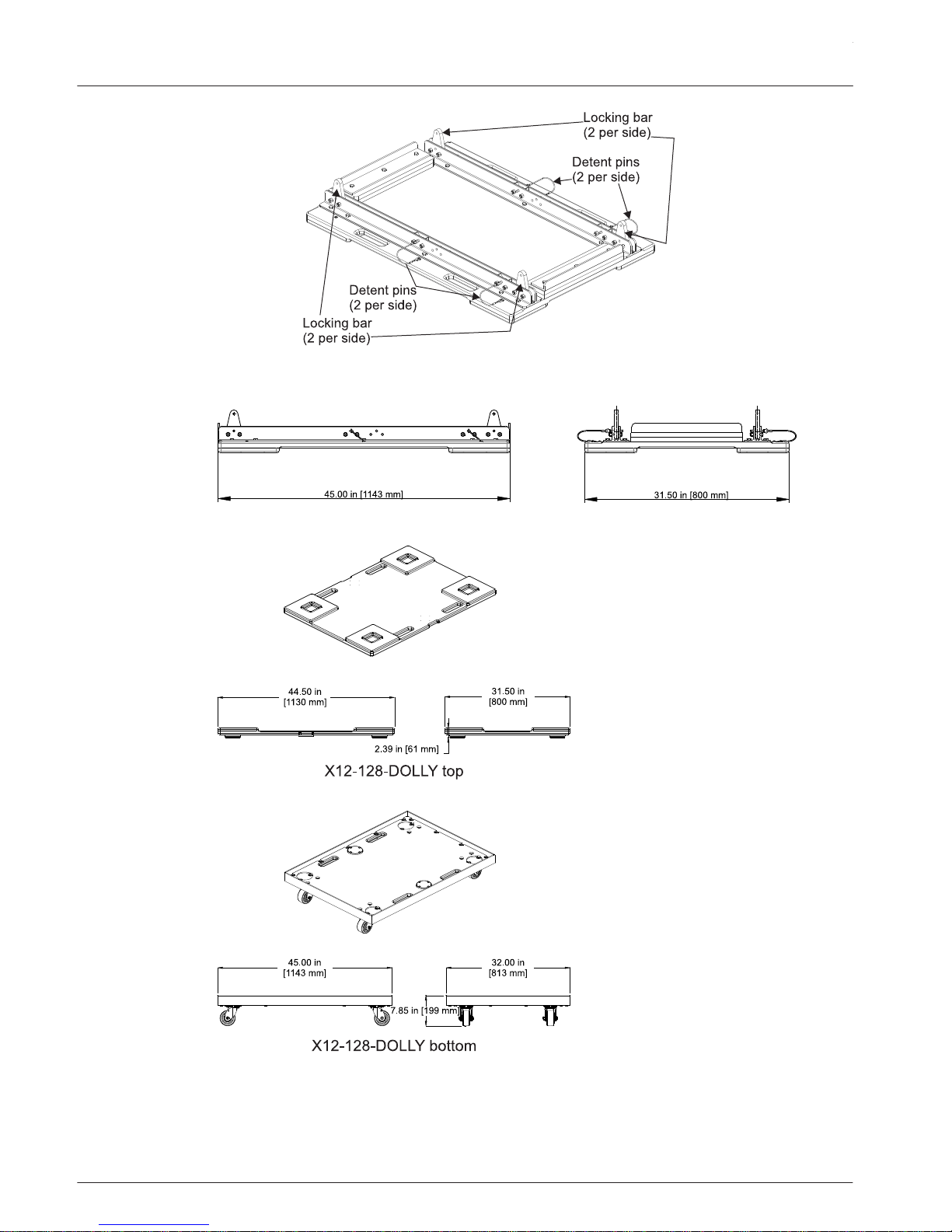

Figure 3.9: X12-128-DOLLY dimensions

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Designing an X1 or X2 array

Applications for which X-Line Advance arrays are most

appropriate

The X1 and X2 loudspeaker systems are specifically designed to construct acoustically

coherent line-arrays. Line-array systems typically consist of independent columns of

loudspeaker enclosures. The most common implementation is a stereo sound reinforcement

system with two (2) columns (left and right). Additional columns are sometimes added to

cover different seating sections of a venue, e.g., seating areas that wrap around the side or

back of a stage. An additional column is also used in left-center-right configurations, with the

center channel for speech. In some venues, where stereo is not required, good coverage can

often be obtained with a single array. A variation of such a monaural system is the exploded

array, where two (2) or more widely spaced arrays are used to provide the horizontal coverage

required. Also, a large number of arrays may be used in distributed systems, such as in an

arena.

Notice!

The X1 and X2 line arrays, even though mechanically are identical, they are not designed

acoustically to work in the same column.

The exact number of X1 or X2 loudspeaker systems in a column varies depending on the

vertical acoustic coverage required for the specific venue. Furthermore, the relative vertical

angles between the boxes and SPL also depend on the venue’s acoustic coverage

requirements. Acoustic design techniques are outside the scope of this document and the

reader is directed to LAPS 3 (Line Array Prediction Software) or later modeling software

available from the Electro-Voice website www.electrovoice.com for acoustic design assistance.

Although the full-range X1 and X2 loudspeaker systems shown in Dimensions, page 9 are not

horizontally symmetrical, their acoustical polar responses are substantially symmetrical. Thus,

stereo left and right arrays, or left-center-right arrays may be constructed with the

loudspeakers in their normal right-side-up orientation.

Determining X1 and X2 array configuration with LAPS 3

LAPS 3 is software written in MATLAB with Excel-spreadsheet-based frontend interface for

determining optimum array configurations for a given venue and trim heights. The current

version of LAPS 3 is downloadable from the Electro-Voice

website www.electrovoice.com.

4

4.1

4.2

en 13

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Preparing X-Line Advance elements for installation

Recommended preflight procedures

For any installed sound system, certain checks made at the installer’s place of business can

prevent expensive on-site delays. A short-list follows, and sets the stage for proper array

performance:

1. Unpack all loudspeakers in the shop.

2.

Check for proper model numbers.

3. Check the overall condition of the loudspeakers.

4. Check for continuity at the loudspeaker inputs.

It is a good idea, once on-site and the loudspeakers are connected, to check again for

continuity at the power-amplifier end.

Element configuration

After using LAPS 3 to design an appropriate array, it is recommended all necessary hardware

and accessories to suspend the array are checked and accounted for. Ensure all hardware is in

good working order, no defects, damage or imperfections are present, and all hardware is

capable of meeting or exceeding the total load requirements of the entire array.

5

5.1

5.2

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Rigging system

Overview of the flying system

The IRS (Integrated Rigging System) on X1 and X2 was developed as a faster, safer way of

flying, aiming and landing a large vertical array.

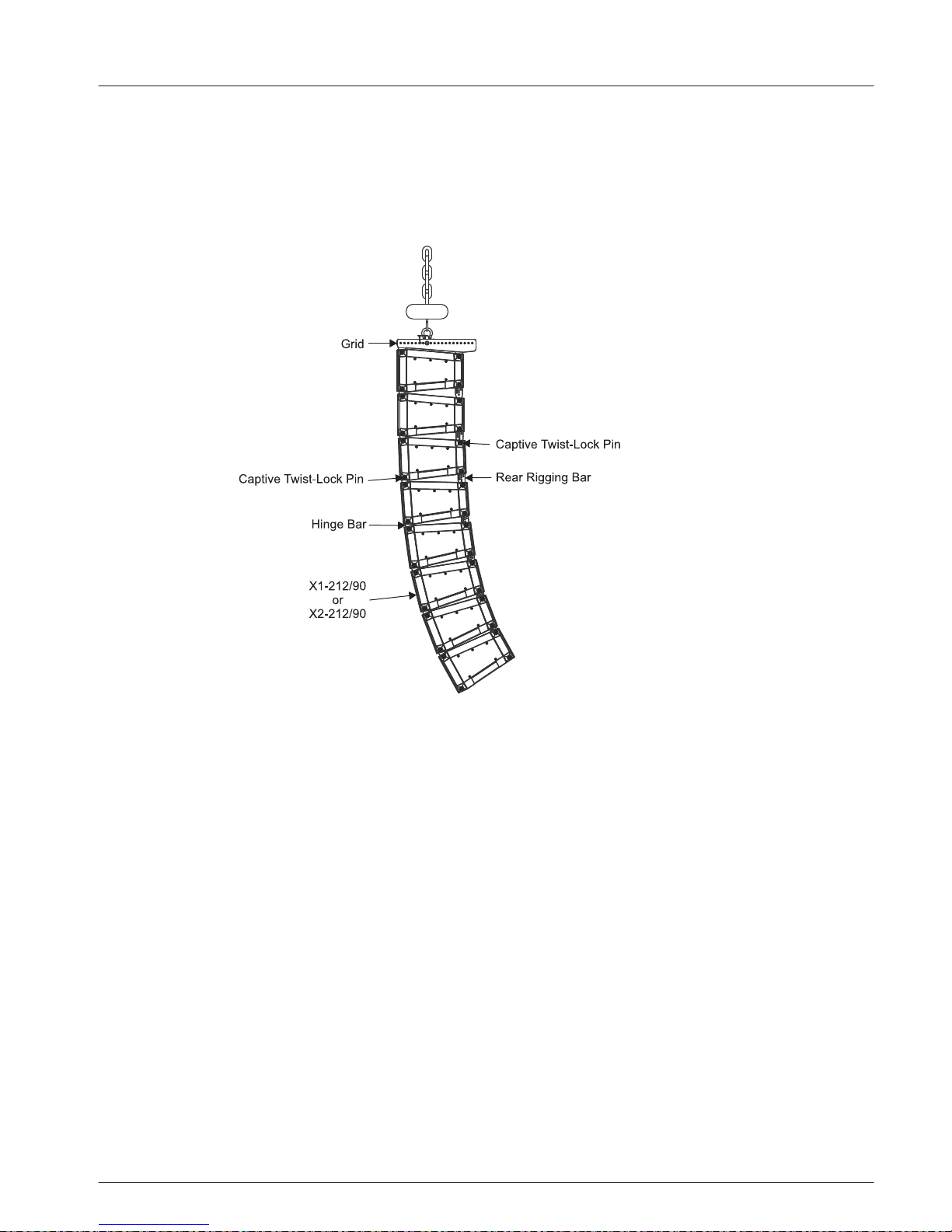

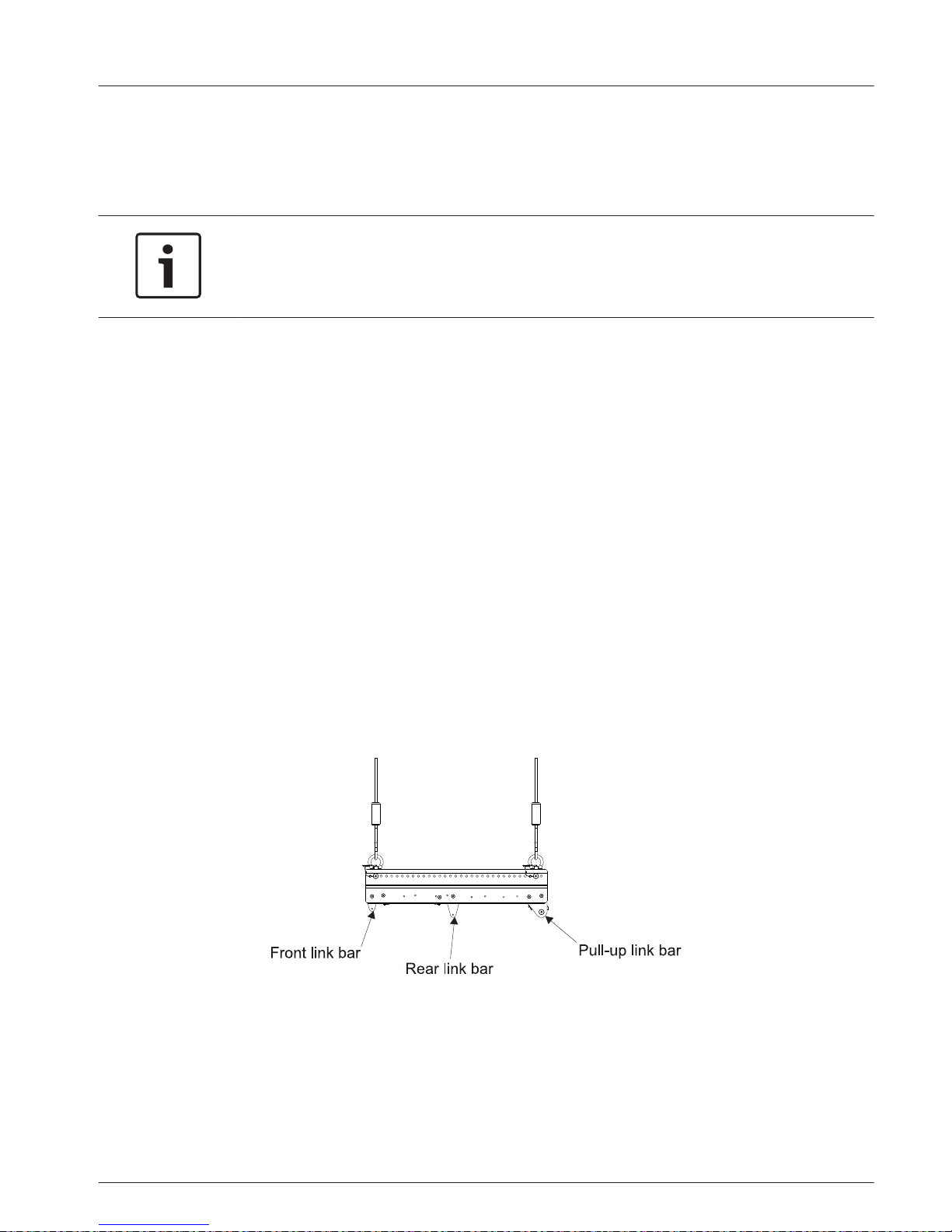

Figure 6.1: Integrated Rigging System

Rigging the boxes together

The individual elements are fastened together by spring-loaded captive twist lock pins. The

captive twist lock pins are located at each of the four (4) upper corners and two (2) lower

front corners of each box. The upper pins attach each box to the extended link bars of the box

above it or grid. The pins are locked in their retracted (Open) position by grasping each pin

knob and pulling out as far as it will go, then turning the knob left or right to lock the pin in

the retracted position. The link bars of the box or grid above can then be dropped safely into

the V-blocks located at the top corners of the aluminum rigging. There is no fumbling for pin

holes because alignment is accomplished by the V-blocks. Once seated, the pins are engaged

by simply twisting each knob to unlock, allowing the spring to fire the pin into position. Lower

front link bars are released or retracted and locked into position the same way. Rear link bars

are set to the desired splay angle position with standard quick-release pins.

6

6.1

6.2

en 15

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

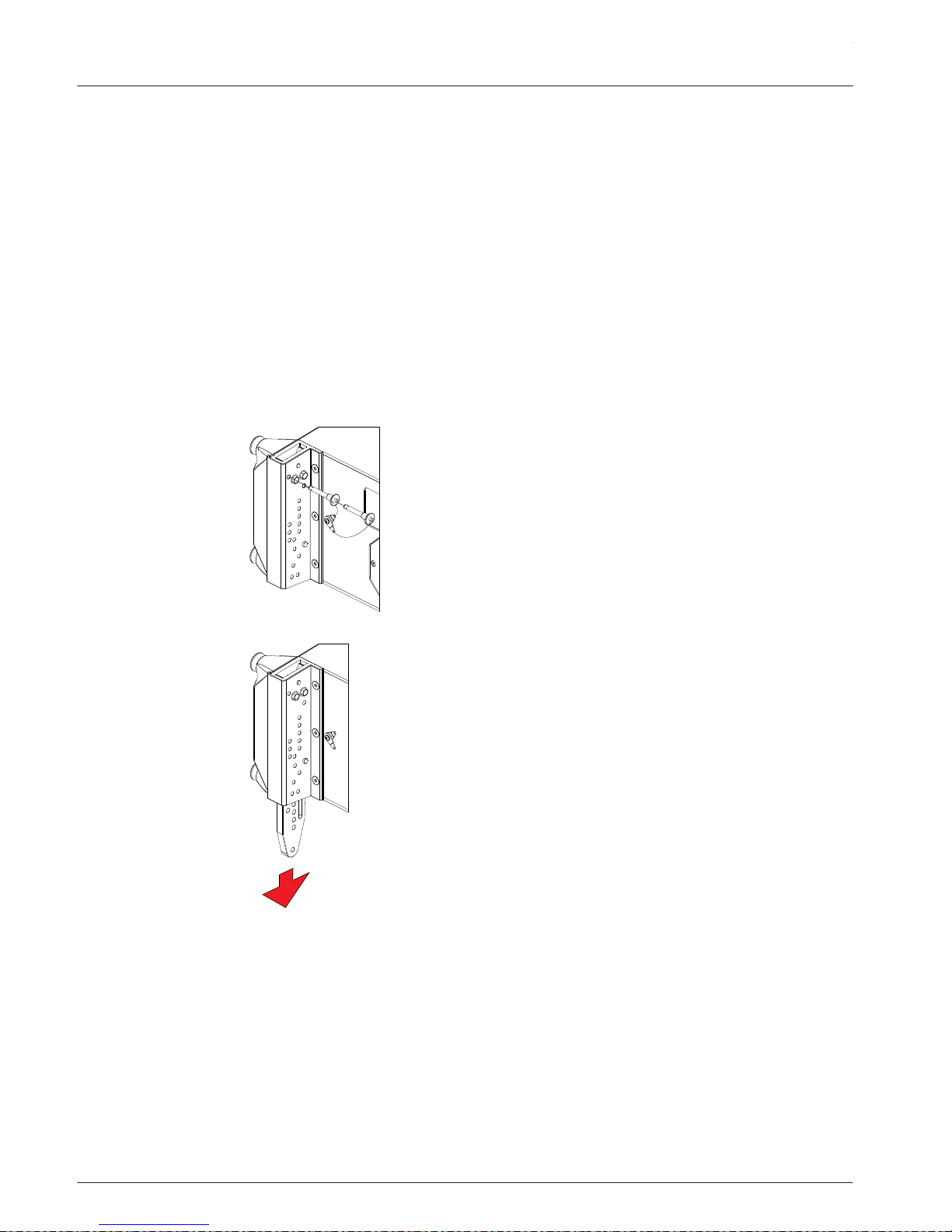

To rig the boxes together, do the following:

Notice!

Before flying the array verify the captive twist lock pins are fully engaged in the rigging (no

red showing between the pin knob and the box).

1. Pull and twist four (4) captive twist lock pins on the top of the lower enclosure.

Four (4) captive twist lock pins are locked in the retracted (open) position.

2. Extend the two (2) front link bars on the bottom of the upper enclosure.

3. Lock the two (2) captive twist lock pins for the two (2) front link bars.

4. Guide the link bars of the box or grid above into the V-blocks located at the top corners

of the aluminum rigging.

5. Twist the four (4) captive twist lock pins

top of the lower enclosure.

Four (4) captive twist lock pins are unlocked in the engaged (Closed) position.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

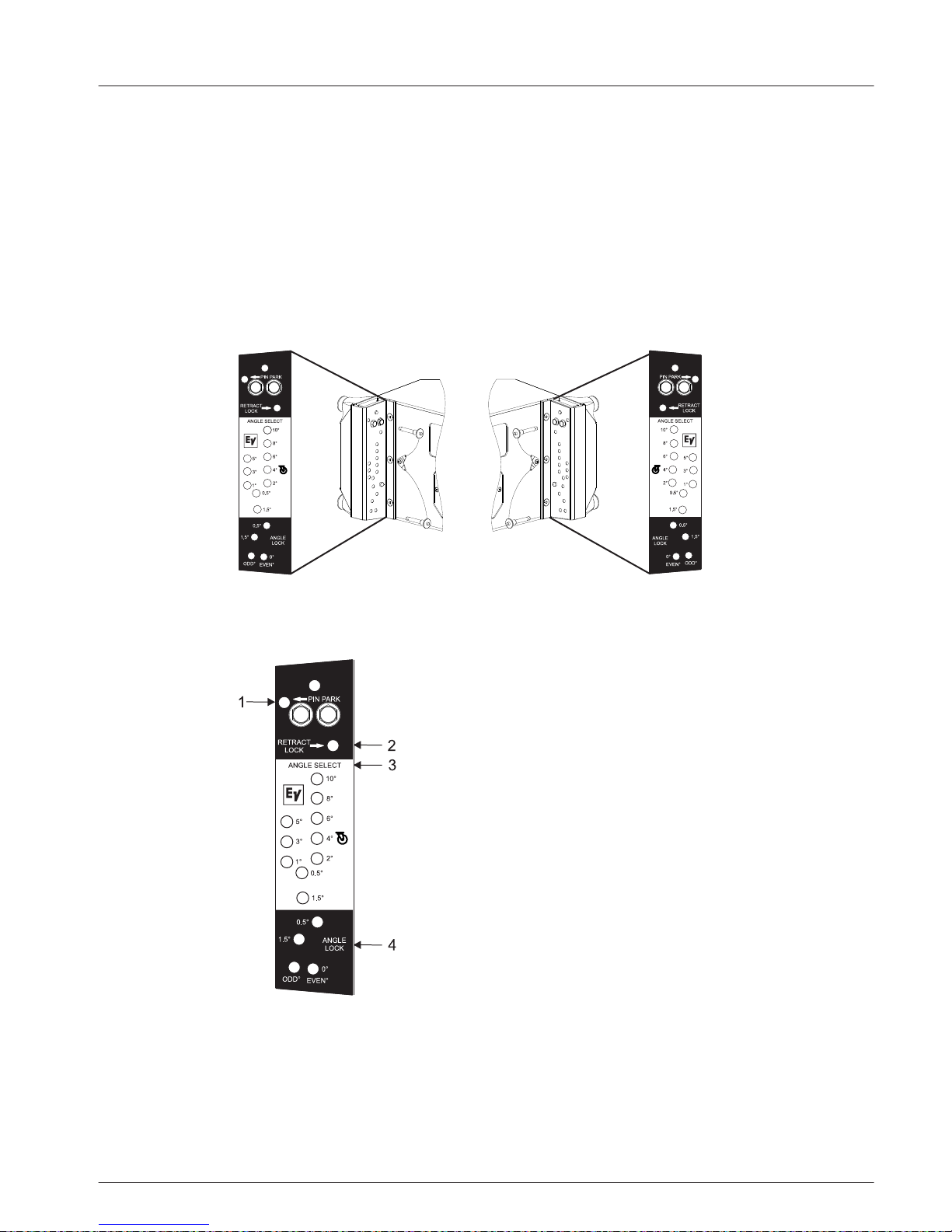

Setting rear link angles

The rear link angle is selected by choosing corresponding holes in the white ANGLE SELECT

sections of the rear rigging on each side (0°, 0.5°, 1°, 1.5°, 2°, 3°, 4°, 5°, 6°, 8°, 10°) as

determined by LAPS 3. Unless the rigging is locked into a rigid configuration by secondary pins

in the lower black ANGLE LOCK sections, the elements always default to 0° when lifted. Use

of the bottom pull-up grid accessory enables the array to be easily compressed with each

element stopping at its pre-selected splay angle. Smaller arrays may be rigidly pinned by lifting

the rear of each box until it hits the pre-selected angle stop, then inserting a second pin per

side into the appropriate hole in the ANGLE LOCK section. There is no fumbling for pin holes

because when lifted, the rigging will stop at the pre-selected position.

Figure 6.2: X1/X2 Rigging Hardware

Rear link angle selection

1. PIN PARK is used to park the unused pin.

2. RETRACT LOCK is used to lock the link bar in stored position.

3. ANGLE SELECT (in the white section) is used to set the desired splay angle from the

report from LAPS 3. This is used for both fixed-pin angles and rear-rigging compression

pull up.

▪ 0.5, 1°, 1.5, 2°, 3°, 4°, 5°, 6°, 8°, and 10° are the available angles for selection. For a 0º

angle, use the 0º angle hole in the Angle Lock section below.

6.3

en 17

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

▪ DOLLY WHEEL (the 4º hole) is used to secure the bottom box of a stack to a dolly.

4. ANGLE LOCK (in the bottom black section) is used to lock the rear link bar for fixedpinned angles. Except for a 0º angle, this section is not used for rear-rigging compression

pull up.

▪ 0.5° and 1.5° are used to lock those two (2) angles.

▪ ODD° is used to lock the odd number angles.

▪ EVEN°

is used to lock the even number angles and the 0º angle.

Single pin and double pin

Single pin compression method is used when a pull-up to the grid is employed to pull the rear

rigging together into compression. Double pin is used to set the rear rigging at fixed angles.

Ensure both sides of the loudspeaker are pinned identically.

To single pin or double pin, do the following:

1. Release the quick-release pin from RETRACT LOCK hole.

2. Lower rear link bar.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

3. Insert quick-release pin into desired ANGLE SELECT degree hole.

Verify pin is thoroughly pushed in and the blue button is released.

4. If using single pin repeat steps 1-4 on the other side of the loudspeaker.

Repeat this process on all elements in the array setting the angles per the report from LAPS

3.

OR

If using double pin continue to the next step.

5. Double pin: Push the rear link bar up until it contacts the stop pin in the angle select

hole.

6. Insert the second quick-release pin into desired ANGLE LOCK hole.

Verify pin is thoroughly pushed in and the blue button is released.

7. Repeat steps 1-7 on the other side of the loudspeaker.

Repeat this process on all elements in the array setting the angles per the report from

LAPS 3.

en 19

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Deciding which grid configuration to use

Choosing a grid is determined by the system down or up angles in combination with the

number of elements in the array and the splay angle between them. To determine which grid

model will achieve your desired angle or where the safety limitations are for the arrays, please

use LAPS 3 to design your array, and observe all warnings and limitation messages displayed

by the software.

X12TC-GRID compact grid

The X12TC-GRID compact grids are appropriate for arrays where extreme up or down angles

are not required. It is rated for a maximum hang of up to 24 X1 or X2 elements in a single

column. Use LAPS 3 to determine if X12TC-GRID combined with the number of elements will

achieve the acoustical coverage in the venue at a safe working load. For more information, see

Rigging structural strength ratings and safety factors , page 54

Notice!

X12TC-Grid comes with one (1) spreader bar only. The use of a second spreader bar is not

recommended with this grid.

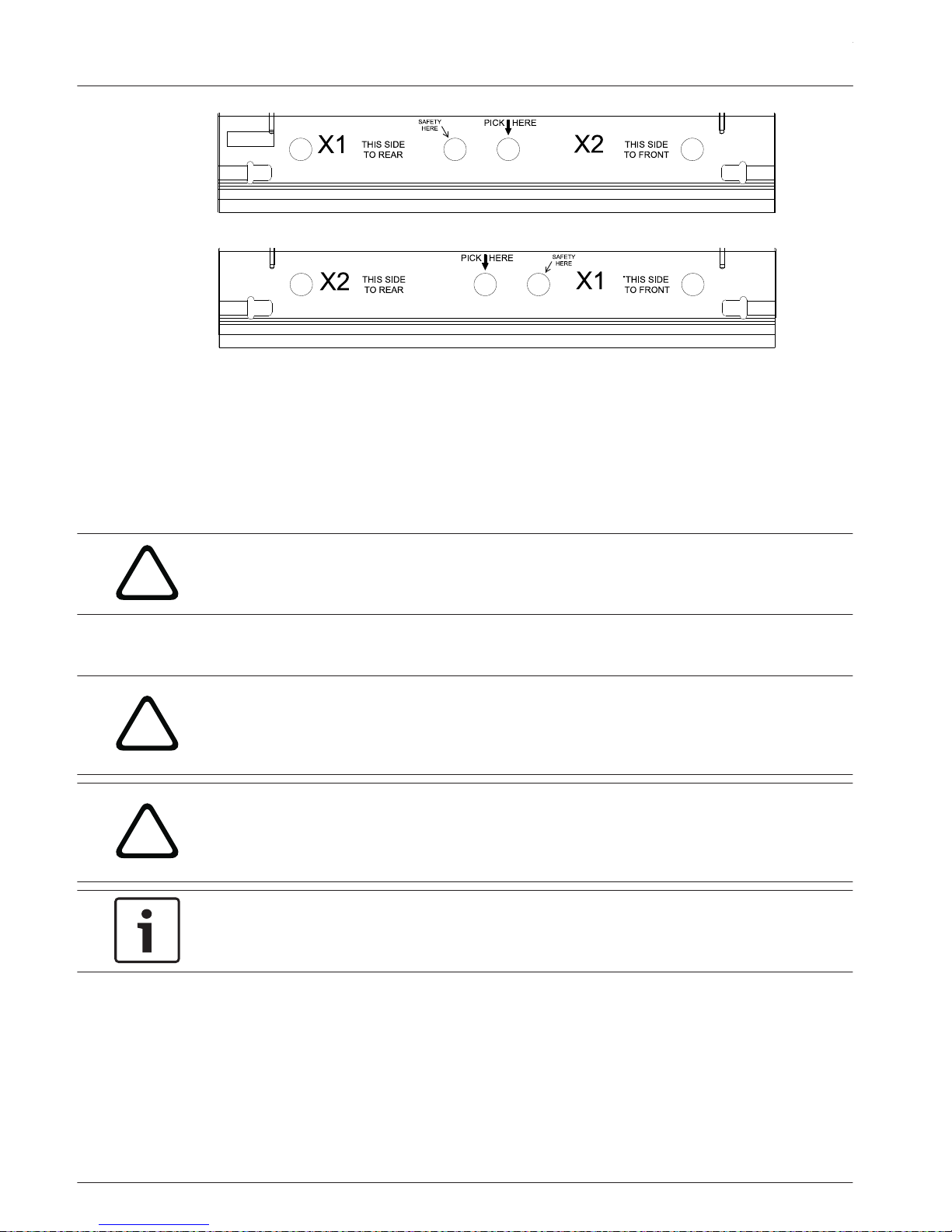

X12TC-GRID includes one (1) spreader bar and two (2) sidearms. The spreader bar has four

(4) 0.84-inch (21.4 mm) holes through it for use as attachment points. The hole near the

center of the bar labeled PICK HERE is used for lifting a single point hang. This hole is slightly

off-center to compensate for the center of gravity of the respective X1 and X2 systems.

Pay close attention to which way the spreader bar is oriented with respect to the loudspeaker

systems. Compare the wording on the left end of the spreader bar to the input panel label on

the loudspeaker. For an X1 system, the bar should read X1 THIS SIDE TO REAR and for an X2

system it should read X2 THIS SIDE TO REAR.

!

Caution!

Verify the correct spreader bar orientation before lifting the array.

Failure to comply with this instruction results in the entire array tilting to one (1) side at an

unsafe angle.

Figure 6.3: X1/X2 spreader bar

The hole labeled SAFETY HERE is for attachment of a safety line if required by local

regulations. If used, ensure there is minimal slack in the safety line but it is not so tight as to

interfere with the vertical alignment of the array hanging from the pick point. The two (2)

6.4

6.4.1

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

outer holes may be used for lifting as a two-point lateral hang, often useful to prevent twisting

of the array. In this situation, lifting and suspension lines must not exceed 15° from vertical

and both points must be lifted equally so the array is never more than ±5° from horizontal

during the lift.

!

Caution!

Do not lift an array by attaching directly to the sidearms.

Lift with the supplied spreader bar(s) only.

The compact grid sidearms are usually attached with the excess overhang at the rear to allow

for greater down-angle possibilities. For situations where more up-angle is possibly required,

such as covering a high balcony in a theater, the grid can be reversed with the excess grid

length overhanging the front of the array.

Installing the X12TC-GRID to an X1 or X2 loudspeaker

When the compact grid with its single spreader bar is used, the trim angle of the array is

determined by the front-to-back attachment position of the spreader bar. This information is

provided by LAPS 3, a function of the array makeup and desired vertical aiming.

!

Caution!

Verify each end of the spreader bar is pinned in the same number hole on both sidearms.

Ensure the pins attaching the grid sidearms are fully locked into the holes in the ends of the

spreader bar.

Notice!

Using the PICK HERE alone requires a tie-off to stabilize the horizontal rotation of the array.

Notice!

Before flying the array verify the captive twist lock pins are fully engaged in the rigging (no

red showing between the pin knob and the box).

To install the X12TC-GRID, do the following:

1. Pull and twist two (2) captive twist lock pins (A) on one side of the loudspeaker.

Two (2) captive twist lock pins are locked in the retracted (Open) position.

2. Guide one (1) sidearm (B) into the rigging tubes until it is fully seated in the V-blocks.

en 21

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

3. Twist the two (2) captive twist lock pins.

Two (2) captive twist lock pins are unlocked in the engaged (Closed) position.

4. Repeat steps 1-3 on the opposite side of the loudspeaker.

Two (2) sidearms are attached to the loudspeaker.

5. Attach

one (1) spreader bar to the two (2) sidearms using the hole locations from LAPS

3.

6. Verify the spreader bar is correctly oriented for the model of loudspeaker (X1 or

X2)

being rigged.

7. Attach a 5/8-inch shackle to the hole labeled PICK HERE on the spreader bar.

Ensure the shackle is rated for overhead lifting.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

8. Attach the lifting cable/chain to the shackle.

9. Verify all hooks, pins, shackles, and other associated rigging components are properly

positioned and secure before lifting the array.

X12TE-GRID extended grid

X12TE-GRID extended grid is available for flying arrays that require greater up or down angles

than what are possible with the X12TC-GRID compact grid. The front and rear link bars are

adjustable in three different positions to facilitate the extreme up-angles sometimes required

in venues with multiple high balconies. The additional length of the X12TE-GRID also enables

more extreme down-angles from a single point than would otherwise be possible. Note that

de-rating occurs as the angle becomes more extreme. Consult LAPS 3 for limitations in a

particular array configuration. The X12TE-GRID is also required in order to use the X12PU-BGK

pull-up grid to aim an array using the rear compression rigging method. The X12TE-GRID

comes with two spreader bars to allow the use of two motors to provide easy angle control of

large arrays, especially when compression rigging is used. The resulting fore-and-aft pick

points also provide better horizontal stability than a typical rear tie-off point.

Each spreader bar has four (4) 0.84-inch (21.4 mm) holes through it for use as attachment

points. The hole near the center of the bar labeled PICK HERE is used for lifting a single point

hang. This hole is slightly off-center to compensate for the center of gravity of the respective

X1 and X2 systems.

Pay close attention to which way the spreader bar is oriented with respect to the loudspeaker

systems. Compare the wording on the left end of the spreader bar to the input panel label on

the loudspeaker. For an X1 system, the bar should read X1 THIS SIDE TO REAR and for an X2

system it should read X2 THIS SIDE TO REAR.

!

Caution!

Verify the correct spreader bar orientation before lifting the array.

Failure to comply with this instruction results in the entire array tilting to one (1) side at an

unsafe angle.

6.4.2

en 23

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Figure 6.4: X1/X2 spreader bar

The hole labeled SAFETY HERE is for attachment of a safety line if required by local law. If

used, ensure there is minimal slack in the safety line(s) but it is not so tight as to interfere

with the vertical alignment of the array hanging from the pick point. The two (2) outer holes

may be used for lifting as a two-point lateral hang, often useful to prevent twisting of the array

or in situations where a 4-point hang is required with two (2) spreader bars. In this situation,

lifting and suspension lines must not exceed 15° from vertical and all points must be lifted

equally so the array is never more than ±5° from horizontal during the lift.

!

Caution!

Do not lift an array by attaching directly to the sidearms.

Lift with the supplied spreader bar(s) only.

Installing the X12TE-GRID to an X1 or X2 loudspeaker

!

Caution!

The extended grid sidearms are heavy and likely to tip if not secured, potentially causing

damage and/or personal injury if one (1) should fail.

Always maintain a good grip on the sidearm until both twist-lock pins are fully engaged.

!

Caution!

Verify each end of the spreader bar is pinned in the same number hole on both sidearms.

Ensure the pins attaching the grid sidearms are fully locked into the holes in the ends of the

spreader bar.

Notice!

Before flying the array verify the captive twist lock pins are fully engaged in the rigging (no

red showing between the pin knob and the box).

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

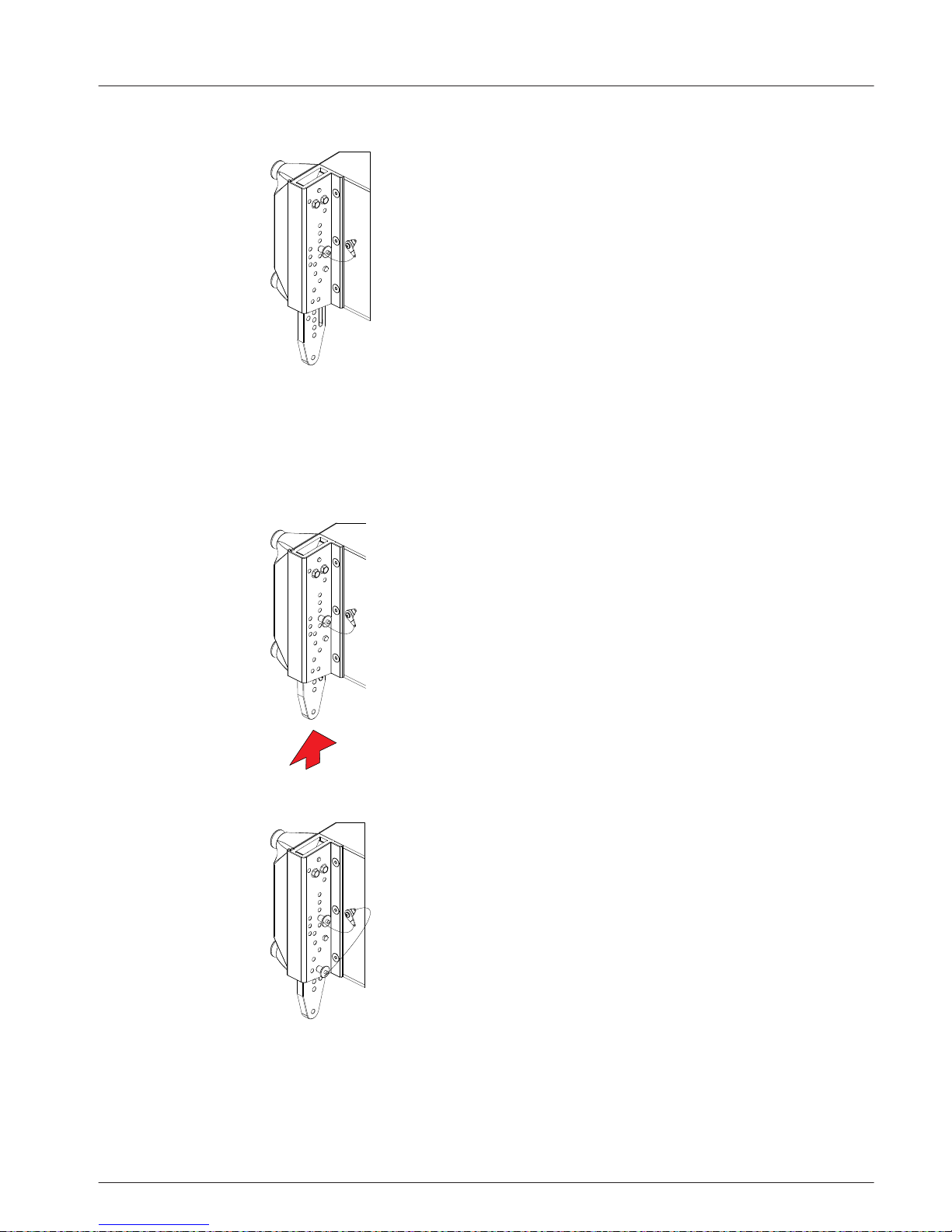

To install the X12TE-GRID, do the following:

1. Attach

front link bars (A) to the sidearms.

Consult LAPS 3 for the A, B, or C position of the front link bar for the particular array being

flown.

2. Insert the attached quick-release pins (B).

Verify all quick-release pins are inserted completely through the sidearm and securely locked

in position.

3. Attach

rear link bars (C) to the sidearms.

Consult LAPS 3 for the rear link bars position corresponding to the A, B, or C position of the

front link bar for the particular array being flown.

4. Insert the attached quick-release pins (D).

Verify all quick-release pins are inserted completely through the sidearm and securely locked

in position.

5. Pull and twist two (2) captive twist lock pins

(E).

Two (2) captive twist lock pins are locked in the retracted (open) position.

6. Guide one (1) sidearm (F) into the rigging tubes until it is fully seated in the V-blocks.

Keep a good grip on the sidearm until both pins are completely engaged through the rigging.

en 25

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

7. Twist the two (2) captive twist lock pins (G).

Two (2) captive twist lock pins are unlocked in the engaged (Closed) position.

8. Repeat steps 6-8 on the opposite side of the enclosure.

The second sidearm is attached to the loudspeaker.

9. Verify the spreader bar

is correctly oriented for the model of loudspeaker (X1 or X2)

being rigged.

Both spreader bars must face the same way with their pick point holes aligned.

10. Attach a single spreader bar (H) to the two (2) sidearms at the hole position determined

by LAPS 3.

11. If using two (2) motors and two (2) spreader bars, attach one (1) spreader bar (H) at

hole #1 and one (1) spreader bar (I) at hole #33.

12. Attach a 5/8-inch shackle to the hole labeled PICK HERE on the spreader bar(s).

Ensure the shackle is rated for overhead lifting.

13. Attach the

lifting cable/chain(s) to the shackle(s).

14. Verify all hooks, pins, shackles, and other associated rigging components are properly

positioned and secure before lifting the array.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

X1 or X2 Extended Grid Rigging Configurations

!

Caution!

Do not lift an array by attaching directly to the sidearms.

Lift with the supplied spreader bar(s) only.

Figure 6.5: X12TE-GRID - Single

Figure 6.6: X12TE-GRID - Dual

en 27

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

X12PU-BGK pull-up kit

X12PU-BGK pull-up kit is used when the compression rigging method is being used with an

array or when extreme down angles beyond the capabilities of the extended grid are required.

This is a way to achieve extreme down angles, such as might be encountered in a distributed

arena system. When using one (1) X12TC-GRID and one (1) X12PU-BGK in this fashion, the

angle between the suspension lines must never be allowed to exceed 30°. For maximum

angles, restrictions and limitations, consult LAPS 3 and follow all warning, limitations and

restrictions recommended by the software.

Figure 6.7: Double pick point maximum angle

For rear-rigging compression, the user must build a pull-up assembly. The X12PU-BGK includes

two (2) spreader bars and two (2) pull-up link bars. One (1) spreader bar attaches to the

X12PU-BGK bottom. The other spreader and the two (2) pull-up link bars attach to the bottom

of the X12TE-GRID top grid at the rear-most attachment position. The pull-up assembly

attaches between the two (2) spreader bars. The remaining components of the pull-up

assembly must be provided by the user.

A lever hoist will be used for the pull-up assembly. The user extends the chain from the hoist

and attach to the pull-up spreader bar on the X12TE-GRID using a 5/8 shackle. One (1) end of

a 3-foot-long (or one-meter-long) wire rope sling attaches to the bottom hook of the hoist. The

other end of the wire rope sling attaches to the spreader bar on the X12PU-BGK using a 5/8inch shackle.

The user provides the two (2) 5/8-inch shackles, wire rope sling, and lever hoist. Electro-Voice

recommends using a wire rope sling with a load rating of at least 2400 pounds (or 1100 kg)

for vertical configuration.

Electro-Voice recommends using a Columbus-McKinnon model 653

lever hoist having a 1.5-ton rating and 20 feet of chain.

Using these components, the pull-up assembly accommodates a quantity of 8 to 20 X1 or X2

loudspeaker systems. This pull-up assembly has been modeled in LAPS 3. If a different pull-up

assembly is used, the angle at which an array hangs may different from what LAPS 3 predicts.

Proper spreader bar orientation must be maintained when used in conjunction with the

pull-up grid. Always orient bars to the system model when viewed right-side-up, and then

simply rotate the top pull-up spreader bar upside-down before attaching to the pull-up bars at

the rear of a X12TE-GRID. Do not swap ends! Correct orientation puts the pick holes of all

spreader bars in alignment in the same vertical plane. The spreader bar at the bottom of an

array will always be oriented right-side-up.

6.4.3

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Figure 6.8: X1/X2 spreader bars properly orientated for use with pull-up grid for X2 array.

Figure 6.9: X12PU-BGK installed

Using the X12PU-BGK with an X12TE-GRID for compressing an X1 or X2 array

The X12PU-BGK pull-up bar is installed on the bottom-most element in the array.

!

Caution!

Verify each end of the spreader bar is pinned in the same number hole on both sidearms.

Ensure the pins attaching the grid sidearms are fully locked into the holes in the ends of the

spreader bar.

To install the X12PU-BGK, do the following:

1. Extend and lock the front

link bars.

2. Extend and lock the rear link bars.

3. With the sidearm V-blocks facing up and the solid bar facing the rear, guide the V-blocks

on the extended link bars (A).

Do not release the sidearm until it is securely attached to the loudspeaker.

4. Insert the attached quick-release pins (B) through each sidearm and link bars, front and

rear.

Ensure all quick-release pins are completely through the sidearms and securely locked.

en 29

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

5. Attach a spreader bar to the two (2) side arms in the rear.

6. X12PU-BGK is assembled.

Using the X12PU-BGK with the X12TE-GRID

To use the X12PU-BGK with theX12TE-GRID, do the following:

1. Attach the

two (2) pull-up link bars to the sidearms.

2. Insert the attached quick-release pins.

Verify all quick-release pins are inserted completely through the sidearm and securely locked

in position.

For more information, see X12TE-GRID using X12PU-BGK to pull-up to grid, page 43.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

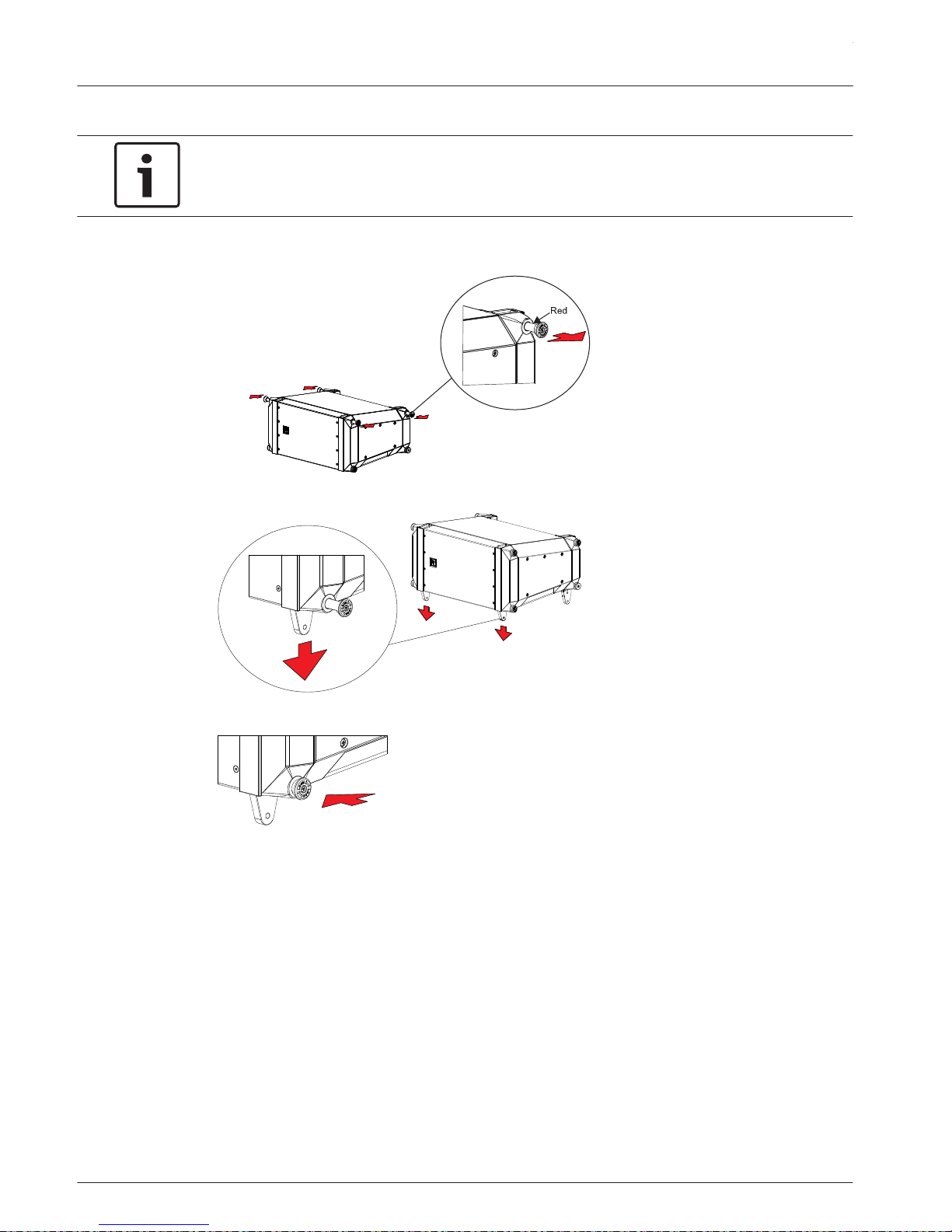

X12T-DOLLY and X12-128-DOLLY

X12T-Dolly: Dolly is used for transporting X1

or X2 loudspeaker systems. The dolly

accommodates two (2) columns of X1 or X2 loudspeaker systems stacked three (3) high for

transportation (Total of six (6) systems per dolly). Systems are secured to the dolly via their

rigging pins. A rigid top cover provides a solid surface for stacking and two (2) dolly side

panels provide protection for speaker grilles. The dolly may also be used as a ground stack

platform, either wheeled or stationary by using the dolly top cover.

X12-128-Dolly: Dolly is used for transporting X12-128 subwoofers. The dolly will accommodate

one (1) column of X12-128 subwoofers stacked two (2) high for transportation. The systems

are strapped down with ratchet straps for additional protection during transport.

Notice!

Dolly stacking limits

X12T-DOLLY accommodates two (2) columns of

X1 or X2 loudspeaker systems stacked three

(3) high for transportation. The dolly is designed for a total of six (6) loudspeakers per dolly.

X12-128-DOLLY accommodates one (2) column of

X12-128 subwoofers stacked two (2) high

for transportation. The dolly is designed for a total of two (2) subwoofers per dolly.

6.5

en 31

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Stacking X1 & X2 loudspeakers onto a X12T-DOLLY

!

Caution!

Two (2) person lift and placement is recommended for the heavier loudspeakers. Single

person lift and placement of heavier loudspeakers could cause injury.

!

Caution!

Ensure the correct dolly pins are released from the dolly base. There are four (4) dolly pins

for each stack on the dolly base. There is a total of eight (8) pins on the dolly base.

If the column of enclosures is lifted with the dolly pins still locking to the speakers to the

base, the dolly base will lift and tip. Property damage and personal injuries may occur.

Notice!

Dolly Wheel (the 4º hole):

The bottom element to be landed on the dolly base must be pinned in 4° hole ( ) in the

ANGLE SELECT section. Compress the rear link bars until they contact the angle select pin

and lock by adding a second pin in the EVEN holes of the ANGLE LOCK section.

Ensure the two (2) front link bars are lowered and locked.

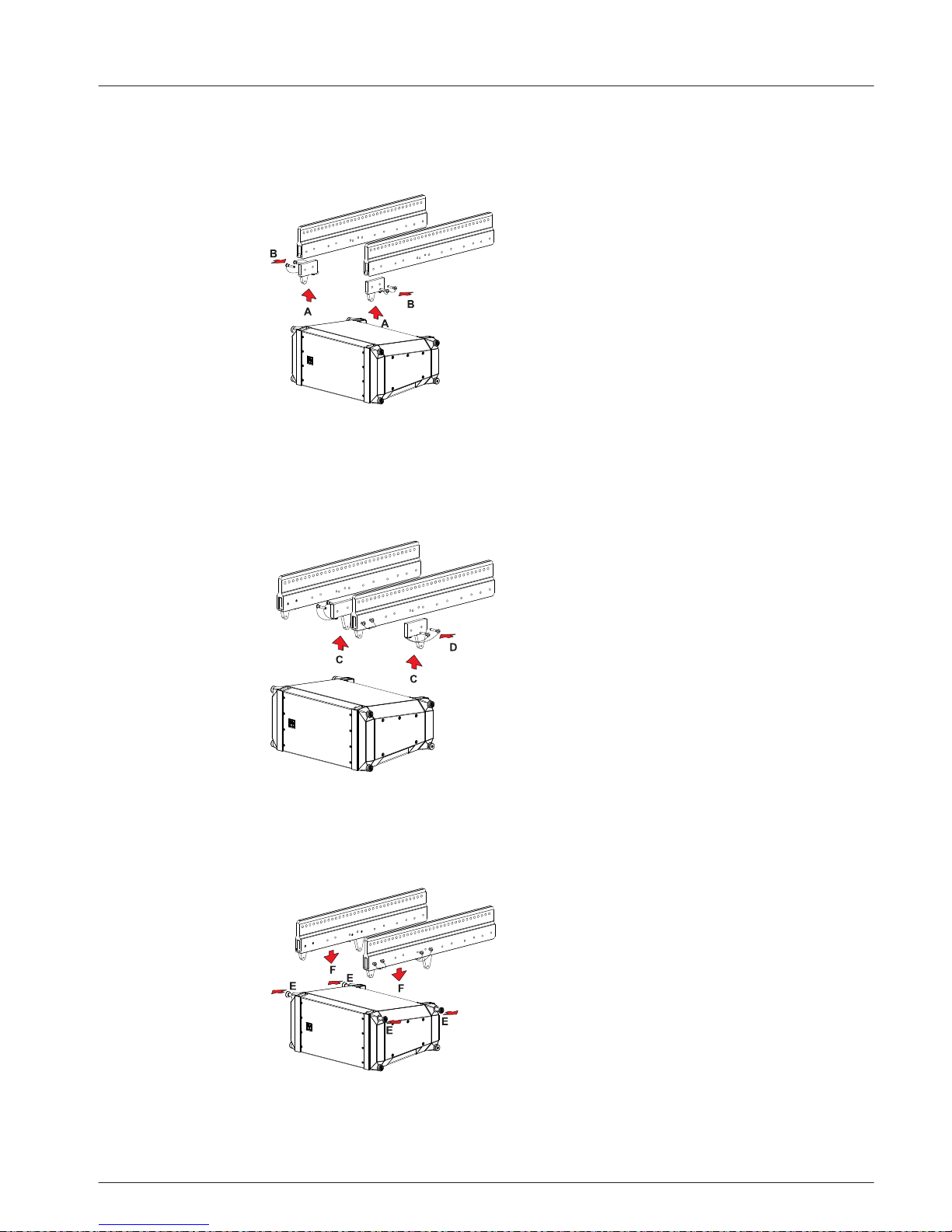

To stack X1 or X2 loudspeakers onto a dolly, do the following:

1. Release the four (4) dolly pins (A)

on the dolly.

All four (4) dolly lock pins are released and hanging from the dolly.

2. Guide the loudspeaker (B) onto the dolly with the grille facing out.

3. Insert the

four (4) dolly pins (C) to lock the loudspeaker onto the dolly.

Ensure the dolly pins are secure.

4. Pull and twist the four (4) captive twist lock pins (D).

All four (4) captive twist lock pins are in the unlock position.

6.5.1

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

5. Guide the next loudspeaker (E) onto the stack.

Ensure the loudspeaker rear link bars angles are set to 0° EVEN.

6. Twist the four (4) captive twist lock pins (F).

All four (4) captive twist lock pins are in the lock position. Ensure the loudspeaker is secure.

7. Repeat steps 4-6

to add up to three (3) X1 or X2’s in a single column.

8. Rotate the dolly.

9. Repeat steps 1-6 to stack the second column.

The loudspeakers can be transported on the dolly. For more information, see Transporting X1

or X2 loudspeakers, page 47.

en 33

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Groundstacking X1 or X2 loudspeakers

The dolly top is designed to be used as a groundstacking kit. Maximum recommended

groundstack height is six (6) elements.

Figure 6.10: X1 or X2 groundstacking

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Stacking X12-128 subwoofer(s) onto a X12-128-DOLLY

!

Caution!

Two (2) person lift and placement is recommended for the heavier loudspeakers. Single

person lift and placement of heavier loudspeakers could cause injury.

To stack X12-128 subwoofers onto a dolly, do the following:

1. Guide one (1)

subwoofer onto the dolly.

2. Guide a second subwoofer onto the stack.

6.5.2

en 35

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Transporting subwoofers

The subwoofer dolly can be used for long-range transport.

To prepare subwoofers for transport, do the following:

1. Place the dolly top

onto the stack.

2. Run the ratchet strap under the dolly.

The ratchet strap is flat against the subwoofers and it is not twisted.

3. Align the ratchet strap

on the strap cutout on the dolly top.

4. Tighten the ratchet strap.

Dolly contents secured for transport.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Assembling and flying an array

Use LAPS 3 to design the array.

Flying arrays from the dolly

Arrays can be flown from the dolly and angles set before the array is lifted.

!

Caution!

When suspending any Electro-Voice

loudspeaker array overhead, the working-load limit must

never be exceeded for the individual enclosure rigging point, for the overall enclosure, or for

any of the rigging accessories.

!

Caution!

Do not lift an array by attaching directly to the sidearms.

Lift with the supplied spreader bar(s) only.

!

Caution!

Ensure the correct dolly pins are released from the dolly base. There are four (4) dolly pins

for each stack on the dolly base. There is a total of eight (8) pins on the dolly base.

If the column of enclosures is lifted with the dolly pins still locking to the speakers to the

base, the dolly base will lift and tip. Property damage and personal injuries may occur.

To fly an array from a dolly, do the following:

1.

If using the X12TC-GRID

, choose the forward or reversed orientation.

OR

If using the X12TE-GRID, preassemble each sidearm with front and rear link bars in the

appropriate A, B or C position.

2. Pull and twist four (4) captive twist lock pins.

Four (4) captive twist lock pins are locked in the retracted (Open) position.

3. Place one (1) grid sidearm into the rigging tubes of the first stack to be lifted and engage

both V-blocks on that side.

Ensure the sidearm is secure before releasing it.

6.6

6.6.1

en 37

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

4. Twist the two (2) captive twist lock pins (A) to the unlock position.

Ensure the pins are engaged in the closed position.

5. Repeat steps 3-4 on the opposite side.

The grid is attached to the column of enclosures.

6. Using a single spreader bar with X12TC-GRID, install one (1) spreader bar between the

sidearm’s in the appropriate hole as determined by LAPS 3.

OR

If using two (2) spreader bars with X12TE-GRID, install one (1) spreader bar at hole #1

and install one (1) spreader bar at hole #33.

7.

Attach a 5/8-inch shackle(s) to the pick point on the spreader bar(s).

Ensure the shackle is rated for overhead lifting.

8. Attach the hoist chain hook to the shackle.

9. Disengage all four (4) dolly pins (B) from the bottom rigging on the column to be lifted.

10. Verify all hooks, pins, shackles, and other associated rigging components are properly

positioned and secure before lifting the array.

11. Lift column of enclosures (C).

A single column of three (3) loudspeakers is on the dolly.

12. Roll the dolly out from under the lifted column.

13. Turn the dolly around.

For more information, see X12TC-GRID compact grid, page 20 or X12TE-GRID extended grid,

page 23.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Adjusting the splay angles

Use the report from LAPS 3 to set the angles to build the array. The angle between boxes is

set on the box above. If using compression, the unused quick-release pins should be placed in

the PIN PARK holes. If using a fixed hang, lift the bottom rear of each successive box starting

from the bottom until it hits the stop at the selected angle.

Notice!

Use of a separate cable pick to support the weight of cabling is recommended, especially on

very tall arrays.

Cable weight can change the aiming angle of an array.

To set the splay angle, do the following:

1. Insert an attached quick-release pin in the correct ANGLE SELECT hole.

2. Repeat step 1 on the opposite side.

Verify both sides are identical.

3.

Single pin compression method place the second pin in PIN PARK.

OR

Double pin compress the boxes until the rear link bars contact the angle select pin.

Insert the other attached quick-release pins into the corresponding holes in the lower

black ANGLE LOCK section.

For example: 0.5°, 1.5°, EVEN numbered or ODD numbered degrees.

4. Connect the speaker cables to the input panels.

For more information, see Setting rear link angles, page 17.

For single pin compression method add a pull up assembly to X12TE-GRID only

These instructions apply only to the X12TE-GRID and using the second spreader bar with the

X12PU-BGK to pull-up to the grid. If you are using the X12TC-GRID, skip this section and

continue to the next section.

To add the pull-up assembly to the X12TE-GRID, do the following:

1. Attach the pull-up link bars to the rear of the X12TE-GRID.

2. Attach the spreader bar to the pull-up link bars on the top grid.

3. Attach a 5/8-inch shackle(s)

to the pick point on the spreader bar(s).

Ensure the shackle is rated for overhead lifting.

4. Attach the chain hook from the pull-up hoist to the shackle.

For more information, see X12PU-BGK pull-up kit, page 28.

en 39

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Adding additional elements to the array

1. Verify all hooks, pins, shackles, and other associated rigging components

are properly

positioned and secure before lifting the array.

2. Lift the first column high enough to allow the next column on the dolly to be positioned

below it.

3. Pull the four (4) captive twist lock pins (A) on the top enclosure of the next column.

All four (4) captive twist lock pins are in the unlock (Open) position.

4. Lower the suspended column (B) guiding the front link bars into the front V-blocks of the

waiting column.

Continue lowering until the rear link bars have also seated into the rear V-blocks.

5. Twist the four (4) captive twist lock pins.

Four (4) captive twist lock pins are unlocked in the engaged (Closed) position.

6.

Release the four (4) dolly pins (C) on the dolly.

All four (4) dolly lock pins are released and hanging from the dolly.

7. Repeat steps 1-6 to add additional columns to the array.

For more information, see Setting rear link angles, page 17.

If you are using the X12TE-GRID to pull-up to the grid, continue to X12TE-GRID using X12PU-

BGK to pull-up to grid, page 43.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

X12TC-GRID with pull-back to venue

Using a X12TC-GRID combined with the X12PU-BGK an array can be pulled up to the venue.

Notice!

Only the double pin method is allowed when pull back to the venue is planned. Do not use

single pin compression method in this instance.

To pull-back to the venue, do the following:

1. Attach the

X12PU-BGK bottom section with spreader bar to the bottom element.

2. Attach a 5/8-inch shackle (A) to the pick point on the spreader bar.

Ensure the shackle is rated for overhead lifting.

3. Attach the pull-back hoist chain hook (B) to the shackle.

4. Verify all hooks, pins, shackles, and other associated rigging components are properly

positioned and secure before lifting the array.

6.6.2

en 41

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

5. Lift the array to the desired height.

6. Adjust the top grid hoist and

bottom pull-back hoist to tilt the array to the angle

recommended by LAPS 3.

For more information, see X12TC-GRID compact grid, page 20 and Flying arrays from the dolly,

page 37.

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

X12TE-GRID using X12PU-BGK to pull-up to grid

Using a X12TE-GRID combined with the X12PU-BGK can be pulled up to the grid.

To pull-up to the X12TE-GRID, do the following:

1. Attach the

two (2) pull-up link bars to the sidearms.

2. Insert the attached quick-release pins.

Verify all quick-release pins are inserted completely through the sidearm and securely locked

in position.

3. Attach the

X12PU-BGK bottom section to the bottom element.

4. Attach a 5/8-inch shackle (A) to the pick point on the spreader bar.

Ensure the shackle is rated for overhead lifting.

5. Attach one (1) end (B) of the 3-foot wire rope sling to the shackle.

6. Attach the opposite end (C) of the 3-foot wire rope to the pull-up hoist.

7. Attach a chain bag to the pull-up hoist and insert the unextended chain into the chain

bag.

8. Verify all hooks, pins, shackles, and other associated rigging components are properly

positioned and secure before lifting the array.

6.6.3

en 43

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

9. Lift with the pull-up host to raise the bottom element to compress the rear rigging of all

the elements in the array.

10. Lift the array to the desired height.

11. Adjust the front

and rear grid hoists to tilt the angle recommended by LAPS 3.

!

Caution!

LAPS 3 will report the force required to compress the rear rigging of all the elements.

Applying excess force can cause damage to the rigging. The use of a load cell is

recommended.

For more information, see X12TE-GRID extended grid, page 23, X12PU-BGK pull-up kit, page 28

and Flying arrays from the dolly, page 37.

Storing empty dollies

Six (6) or more dollies can easily be stored in the floor space of one (1).

X12T-DOLLY: Place the two (2) dolly side panels on top of each other with their carpeted

sides together on the dolly base between the transport rails. Pick up the top cover with link

bars pointing down and set it squarely onto the dolly base so as to nest the four (4) link bars

into the V-blocks on each corner. Insert an attached dolly pin into each corner V-block to lock

the two parts together.

X12-128-DOLLY: Nest the top cover into the dolly base and secure with ratchet strap. There is

enough clearance between the wheels that the ratchet mechanism does not interfere with

stacking. Once secured in this manner, dollies may be stacked on top of one another. Wheel

locations are the same for both dollies, as are the corresponding wheel pockets on their top

covers. Use caution when moving a tall stack of dollies. While the wheel pockets prevent the

dollies from rolling off of each other they are not enough to keep the stack together if the

bottom one (1) stops abruptly on an obstruction like the bottom of a ramp. If this is likely to

be encountered, use ratchet straps to tie the entire stack together.

6.6.4

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Landing arrays onto a dolly

Landing the array elements directly onto a dolly makes transportation easier.

Notice!

Dolly stacking limits

X12T-DOLLY accommodates two (2) columns of

X1 or X2 loudspeaker systems stacked three

(3) high for transportation. The dolly is designed for a total of six (6) loudspeakers per dolly.

X12-128-DOLLY accommodates one (2) column of

X12-128 subwoofers stacked two (2) high

for transportation. The dolly is designed for a total of two (2) subwoofers per dolly.

Notice!

Dolly Wheel (the 4º hole):

The bottom element to be landed on the dolly base must be pinned in 4° hole ( ) in the

ANGLE SELECT section. Compress the rear link bars until they contact the angle select pin

and lock by adding a second pin in the EVEN holes of the ANGLE LOCK section.

Ensure the two (2) front link bars are lowered and locked.

To land an array onto a dolly, do the following:

1. Lower the array

(A) to a convenient working height above the floor.

2. If single pin compression method was used, carefully reverse the hoist and uncompress

the back of the array so the hoist has not tension and all of the elements in the array have

returned to the 0° position.

OR

If double pin method was used, lift up slightly on the rear of each of the bottom three (3)

elements and remove the quick-release pins from the lock holes. Gravity will cause the

unlocked rigging splay to revert to 0° position.

3. Disengage the eight (8) dolly pins (B) on the dolly base.

All eight (8) dolly pins are disengaged and hanging from the dolly.

6.6.5

en 45

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

4. Verify the V-blocks are unobstructed and clear.

5.

Position the empty dolly under the array.

6. Ensure grilles are facing out.

7. Lower the array until the link bars engage the V-blocks on the dolly.

Guide the array to land the link bars onto the dolly rails.

8. Insert the four (4) dolly pins (C) to lock the enclosures onto the dolly.

Verify pin is thoroughly pushed in and thorough both sides of the rail.

9. Pull and twist the four (4) captive twist lock pins (D).

All four (4) captive twist lock pins are in the unlock position.

10. Lift the

column of enclosures (E).

A single column of three (3) elements is on the dolly.

11. Rotate the dolly.

12. Repeat step 2 ensuring the elements are set to 0° position.

Verify the front link bars are extended and locked and rear link bars of the bottom element

are set and locked at 4° (see Notice regarding the Dolly Wheel).

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

13. Repeat steps 6-8 on this column (G).

14. Insert the four (4) dolly pins to lock the enclosures onto the dolly.

Verify pin is thoroughly pushed in and thorough both sides of the rail.

Removing the grid

!

Caution!

The extended grid sidearms are heavy and likely to tip if not secured, potentially causing

damage and/or personal injury if one (1) should fail.

Always maintain a good grip on the sidearm until both twist-lock pins are fully engaged.

1. Remove the 5/8-inch shackle from the spreader bar(s).

2. Lift hoist motor to a safe height.

3.

Remove spreader bar.

4. Pull and twist the four (4) captive twist lock pins.

All four (4) captive twist lock pins are in the unlock position.

5. Remove the grid sidearms.

Transporting X1 or X2 loudspeakers

The loudspeaker dolly can be used for long-range transport.

To prepare loudspeakers for transport, do the following:

1. Ensure the scribble strip is facing out and the carpet is towards the grilles.

2. Insert a dolly side panel into the dolly base (A) to cover the grilles.

en 47

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

3. Secure the locking straps to the top and bottom captive twist lock pin knobs to secure

side panels.

4. Repeat steps 1-3 on the opposite side.

5. Guide and land the dolly top link bars to align with the front V-blocks of the top

elements.

6.

Ensure the dolly top has captured the dolly side panels.

7. Push and twist the eight (8) captive twist lock pins.

All eight (8) captive twist lock pins are in the lock position. Ensure the loudspeakers are

secure.

Array building techniques

Multiple ways to fly the X12TC-GRID

X12TC-GRID can be flown in two (2) different ways—with a single grid pick point and with a

single grid pick point plus a pullback to the venue. Additionally, the grid has two (2)

orientations forward and reversed. In LAPS 3, the user must choose which way the grid will be

flown, plus the orientation of the grid.

Figure 6.11: Flying the X12TC-GRID

Single grid pick point:

In the forward orientation (1a), a small section of the grid extends behind the rear of the

loudspeaker, enabling more down tilt.

In the reversed orientation (1b), a small section of the grid extends in front of the

loudspeaker, enabling more up tilt.

Choose the pick point on the grid to achieve the desired angle as reported by LAPS 3.

Single grid pick point with a pullback to the venue:

A pullback to the venue is used when more down tilt is required than can be achieved by a

single grid pick alone. The X12PU-BGK is used at the bottom of the array.

The most common orientation would be to use the grid in the forward position (1c).

The grid can also be used in the reversed orientation with a pullback to the venue (1d). The

purpose of the pullback is to enable greater down tilt.

Choose a grid pick point near the front of the grid. This tilts the array up slightly, which makes

it easier to build because the bottom of a flown box will be a closer match to the top box on a

dolly stack.

For more information, see

6.7

6.7.1

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Multiple ways to fly the X12TE-GRID

X12TE-GRID can be flown in four (4) different ways—with a single grid pick point, with a single

grid pick point plus a pullback to the venue, with two (2) grid pick points, and with two grid

picks points plus a pull-up to the grid. Additionally, the loudspeakers may be attached to the

grid in three different positions. In LAPS 3, the user must choose which way the grid will be

flown, plus the attachment position of the loudspeakers.

Figure 6.12: Flying the X12TE-GRID

Single grid pick point:

With the loudspeakers attached in the A position (2a), a large section of the grid extends

behind the rear of the loudspeaker, enabling the maximum amount of down tilt.

With the loudspeakers attached in the B position (2b), a portion of the grid extends both

behind and in front of the loudspeaker, enabling moderate tilt both up and down.

With the loudspeakers attached in the C position (2c), a large section of the grid extends in

front of the loudspeaker, enabling the maximum amount of up tilt.

Choose the pick point on the grid to achieve the desired angle as reported by LAPS 3.

Single grid pick point with a pullback to the venue:

A pullback to the venue should be used when more down tilt is required than can be achieved

by a single grid pick alone. The X12PU-BGK is used at the bottom of the array.

The most common orientation would be to use the grid with the loudspeakers attached in the

A position (2d).

A pullback to the venue can also be used with the loudspeakers attached in the B position

(2e) or in the C position (2f). Choose a grid pick point near the front of the grid. This will tilt

the array up slightly, which will make it easier to build because the bottom of a flown box will

be a closer match to the top box on a dolly stack.

6.7.2

en 49

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Double grid pick points:

Always attach the two grid pick points at the front-most and rear most attachment points on

the grid.

With the loudspeakers attached in the A position (2g), the maximum down tilt can be

obtained.

With the loudspeakers attached in the B position (2h), moderate down-tilt and up tilt can be

obtained.

With the loudspeakers attached in the C position (2i), the maximum up tit can be obtained.

The user must adjust the front and back hoist motors to achieve the angle reported by LAPS 3.

Double grid pick points plus a pull-up to the grid:

Using a pull-up to the grid enables the loudspeaker to be lifted off the dollies with the boxes

hanging straight at 0º, then pull the boxes their correct angle using a hoist in the pull-up

assembly.

The X12PU-BGK is used at the bottom of the array.

Always attach the two grid pick points at the front-most and rear most attachment points on

the grid.

Always attach the loudspeakers in the A position, furthest away from the pick point (2j).

It is not recommended to use a pull-up to the grid with the loudspeakers in the B position (2k)

or the C position (2l). Because the B and C positions are so close to the pull-up attachment

point on the grid, excessive forces result in the pull-up assembly.

With large arrays, it is possible for a single grid pick point to be in a safe condition once the

pull-up is pulled into compression, but the user would pass through an unsafe condition while

building an array. Therefore we recommend using two grid pick points to avoid the possibility

of an unsafe condition.

For large arrays, the force required to pull the rear rigging of all boxes into compression may

exceed the pull-up assembly maximum rating. If this occurs, it may be necessary to pin several

boxes at the top of the array at fixed angles. If so, LAPS 3 will return a message telling the

user how many boxes to fix pin.

For more information, see .

Array build strength considerations

LAPS 3 reports when the working-load limits for any of the elements in the array are

exceeded. Having an understanding of the structural advantages and disadvantages of

different array build configurations allows the user to select the best option to meet their

needs.

Comparing array structure strengths shows the same array constructed in four (4) different

ways: single grid pick point, single double grid pick points, double grid pick points with a pullup to the grid, and single pick point with a pullback to venue. Because the array construction

is different, the forces throughout the array are different. This results in different structural

ratings.

6.7.3

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Figure 6.13: Comparing Array Structural Strengths

The arrays in Figures 3a and 3b are the weakest. The highest force in both of these arrays will

be on the rear rigging points of the top box. The long length of the X12TE-GRID extended

behind the loudspeaker acts as a large lever arm (like a wrench) that significantly increases

the force on the top enclosure rear rigging. Another way to visualize this is to think of the grid

being held in a fixed position. Because the center of gravity of the entire loudspeaker column

is so far towards the back, the column will tend to rotate counterclockwise to tilt up. The rear

rigging of the top enclosure will be in tension resisting the rotation.

Whenever a large portion of grid is extended behind the top loudspeaker as shown in Figures

3a and 3b, fewer boxes will be allowed to be suspended before the working-load limit of the

top box rear rigging is exceeded. This condition most commonly occurs with the X12TE-GRID

with the loudspeakers are in the A position. The same condition can occur when a large

portion of grid is extended in front of the top loudspeaker. This could occur with a steep uptilt angle with the X12TE-GRID with the loudspeakers in the C position on the grid. The X12TCGRID is not subject to this condition, because the grid is just slightly longer than the

loudspeaker enclosures.

The array in Figure 3d is the strongest because the load is shared between the top and bottom

of the array. This configuration will allow the highest number of boxes to be suspended and is

most commonly employed when a greater down-tilt angle is required.

Unless extreme down-tilt angles are employed, the highest forces in the array in Figure 3d will

be on the rigging of the top box. The X12PU-BGK bottom grid does not have as high of

strength rating as the top grids X12TC-GRID or X12TE-GRID. In the unlikely event that the

working-load limits of the X12PU-BGK are exceeded, one of the top grids may be substituted.

The array configuration shown in Figure 3c has greater capability than those shown in Figure

3a and 3b, but less capability than the array shown in Figure 3d. In this case, the load of the

loudspeaker column is shared between the rigging attachment points of the top box and the

pull-up assembly. However, the pull-up to the grid introduces forces that otherwise would not

exist due to gravity alone. For the array configuration in Figure 3c, the highest forces typically

occur at either the top box or at one of the boxes near the bottom of the array.

en 51

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Subwoofer arrays

The X12-128

is designed for multiple applications. It may be used as a forward standard array

or as a cardioid array. It has rubber feet on the bottom for horizontal orientation or on one (1)

side panel for vertical orientation.

In the input panel you have a choice to connect the subwoofer in either parallel (4 ohm) or

dual (8 ohm) modes for optimum subwoofer array control.

Subwoofer array configuration

Notice!

For cardioid arrays you must use the correct system setting processing and amplifying

forward firing and rear firing subwoofers separately.

7

7.1

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

Subwoofer cardioid options

The X12-128

cardioid subwoofer arrays can be used to direct the output of an array of

subwoofers in order to limit excessive amounts of bass in undesired areas. These arrays can

be used to keep bass off of a stage, provide more consistent bass coverage in the audience,

and reduces bass in the surrounding area.

Multiple X12-128 can be arrayed to create a cardioid polar pattern.

Figure 7.1: Cardioid pattern top view

The rejection may be less in smaller indoor environments than in larger outdoor environments.

The subwoofers must be physically placed in one (1) of the options shown.

Figure 7.2: X12-128 Cardioid Options

Cardioid option A:

Two (2) X12-128 subwoofers orientated horizontally. Direct the top subwoofer towards the

audience and the bottom subwoofer away from the audience (Rejection direction).

Cardioid option B:

Three (3)

X12-128 subwoofers orientated horizontally. Direct the top two (2) subwoofers

towards the audience and the bottom subwoofer away from the audience (Rejection

direction).

Cardioid option C:

Three (3)

X12-128 subwoofers orientated vertically. Direct the left and right subwoofers

towards the audience and the center subwoofer away from the audience (Rejection direction).

7.2

en 53

Electro-Voice Installation Manual 2015.04 | 02 | F.01U.310.953

Rigging structural strength ratings and safety factors

Structural introduction

The X1 and X2 loudspeakers systems, grids and accessories were designed as a complete

system to ensure safety and compatibility. The maximum possible number of X1 or X2

loudspeaker systems may be suspended in a single column is 24 while maintaining an 8:1

safety factor. For more information, see Working-load limit and safety factor definitions, page

56

.

The actual forces on the rigging components within an array will depend on the specific

configuration of the loudspeakers and grids. The tilt angles of the individual boxes, grids and

the entire array will change the forces in the rigging components throughout an array. Pick

points from the grid, pull backs to the venue, and pull ups to the grid will also affect load

distribution. The result is that the actual maximum number of X1 and X2 systems will be

dependent on the array configuration.

All components are included as part of the Electro-Voice line array prediction software LAPS 3.

The software calculates the forces throughout the array and informs the user of the

limitations. LAPS 3 also reports the loads for the pick points going to the venue.

Structural rating overview

Designing a safe structural array is a very complex process best left to experienced

professionals. There are two (2) independent strength considerations, together, that give a

complete description of the overall structural capabilities of any loudspeaker system; these

are:

1. The strength of each individual enclosure rigging point; which is the combined strength of

the rigging tube, hinge bars, link bars, quick-release rigging pins internal rigging straps,

external tie plates, bolts, and enclosure.

2.

The total strength of the overall array; which is a function of the combined forces from all

of the rigging points acting on the rigging components and the array as a whole.

For grids, there are two (2) independent strength considerations, together, give a complete

description of the overall structural capabilities of the grid; these are:

1. The strength of each individual grid rigging point; which is the combined strength of the

bolts, grid side arms, and spreader bars, and quick-release pins.

2. The total strength of the overall grid; which is a function of the combined forces from all

of the rigging points acting on the rigging components, and the grid as a whole.

In any system loudspeaker array, the forces acting on each loudspeaker system (on each

individual rigging points and on the overall enclosure) and the forces acting on each grid

rigging accessory (on each sidearm and spreader bar and on the overall grid grids and

spreader bars) vary varies with each array configuration. Determining those forces throughout

an array requires complex mathematical calculations.

To make the X1 and X2 systems both safe and easy to use, Electro-Voice engineers have built

calculations into the LAPS 3 software, enabling a user to immediately determine if an array is

safe without having to do a complex structural analysis.

8

8.1

8.2

X-LINE ADVANCE Systems

2015.04 | 02 | F.01U.310.953 Installation Manual Electro-Voice

LAPS 3 structural evaluations simplified structural rating

guidelines

Using a combination of computer modeling, destructive and non-destructive testing, ElectroVoice

engineers have developed calculations to determine the forces within an array that act

on the loudspeaker systems and grid rigging accessories. The results of these calculations are

compared to the working-load limits of each loudspeaker and grid element, and their

individual components.

LAPS 3 will take into account all the complex factors to ensure that an array is strong enough

to maintain an 8:1 safety factor. If a particular array designed by a user exceeds a working-load

limit, the software will return warning messages. The messages will provide information

describing what is causing the overload, and will offer suggestions to the user for changes that

can be made to the array to eliminate the overload. The user can then decide the best solution

for their particular application.

LAPS 3 will also report the loads on the rigging pick points (typically hoist motors) that

suspend the array from the venue. The software assumes that these rigging points are plumb

vertical. The user must calculate the increased tension in the suspension lines if they are

angled.

!

Caution!

The user should never apply a load that exceeds the working-load limits of any of the rigging

components or complete loudspeaker systems described in this manual.

The user should never exceed the safety limitations reported by LAPS 3 or higher.

Specific safety considerations

X1 and X2 loudspeaker systems

The X1 and

X2

loudspeaker systems must only be suspended using the Electro-Voice grids.

The X12TC-GRID and X12TE-GRID should be used as top grids. For a pull back to a venue or a

pull up to grid, the X12PU-BGK may be used as the bottom grid. For an extreme down angle,

the X12TC-GRID may also be used at the bottom.

The X1 and X2 rigging and grids were designed to be tilted up or down (front to back tilt).

However, they are not intended to hang sideways. Columns of X1 or X2 loudspeaker systems

must never be angled off be hanging plumb vertical ±5°.

X12TC-GRID and X12TE-GRID top grids

The X12TC-GRID and X12TE-GRID top grids may be suspended using one (1) or two (2)

spreader bars. Additionally, one (1) or two (2) pick points may be used with the spreader

bars.

When multiple pick points are used to suspend the grids from a venue roof, LAPS 3 calculates

the loads on the pick points assuming that the suspension lines are plumb vertical. If the lines