Page 1

Thermal Energy

Management and Protection

Limiter Technology

1

Page 2

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

Version 1 Electro-Voice, Burnsville, Minnesota, USA October 2010

© Bosch Security Systems Inc.

Thermal Energy

Management and

Protection Limiter

Technology

Rev. 1 / October 20, 2010

1. Introduction:

This application note discusses the use of the Electro-Voice Thermal Energy Management and

Protection (TEMP) Limiter. This document will cover the reasons for its development, the significant

advantages it provides in protecting loudspeaker transducers against thermal failures and how to

implement and use the TEMP Limiter in IRIS-Net project files and hardware.

2. The Need for the TEMP Limiter

Loudspeakers are designed for reliability. The design and testing process covers all components

and aims to provide the optimum performance, while simultaneously testing and analyzing the ability

to continue to function and be reliable even during extreme or abusive use. In the world of

transducer design there’s a lot that can be done to optimize thermal and mechanical parameters to

maximize output. Electro-Voice engineers work to constantly increase the peak voltage capacity and

the power handling capacity of our transducers. All components are selected and tested to work at

extreme temperatures.

Modern professional amplifier design has significantly increased the output power ratings and

instantaneous peak output capabilities to keep pace with sound reinforcement requirements. These

modern designs can present instantaneous peak voltages well above and beyond previous

generations. As a case in point, the TG7 is capable of producing 180-volt instantaneous peaks.

2

Page 3

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

While this provides tremendous dynamic range and power performance, instantaneous output

voltages in these extreme ranges present new challenges to operators and designers to ensure that

the loudspeakers are being driven with a safe RMS output level from the amplifier. In order to keep

the loudspeakers functioning reliably, tools must be provided to prevent against both mechanical

and thermal failures.

So, how is the user to know what RMS level they are sending to each speaker? How does the user

determine the temperature of their loudspeakers and how safely they’re driving their system? The

answer is that this is practically impossible for users to do, and that system techs should not have to

concern themselves with guesswork about voicecoil temperature. This is the reason that ElectroVoice has created the Thermal Energy Management and Protection (TEMP) limiter.

3. The TEMP Limiter in Action

The Thermal Energy and Management and Protection (or TEMP) limiter is based on a detailed

thermal model of the connected loudspeaker. It continuously calculates the temperature of the

loudspeaker voice coil as signal is applied and the speaker heats up and cools down. The thermal

model approach was selected because it proves to be more reliable and accurate than other

methods. A simple RMS voltage limiter would function, but it would neglect the fact that

loudspeakers can handle large RMS voltages for sufficiently short periods of time, so this approach

would potentially provide too much limiting. Another method would be a combined approach of

monitoring the voltage and current delivered by the amplifier. Unfortunately, this would make the

parameters depend upon how many speakers the user had paralleled on each channel and would

be limited to amplifiers with DSPs on board. The thermal model approach does not have such

limitations.

Sample by sample, the TEMP limiter tracks the voltage applied to the loudspeaker terminals and

uses this to calculate the instantaneous temperature of the voice coil. To minimize gain reduction

and maximize output, the temperature scale has been broken up into several regions. The first

temperature region is between

T (ambient temperature) and

Ambient

soft knee). For a voice coil temperature in this range, no gain reduction is applied. Above

T (the lower threshold of the

Knee

T gain

Knee

reduction is applied based on the RMS drive level and the voice coil temperature. The amount of

gain reduction and the rate at which it’s applied depends on the voice coil temperature. If

something goes terribly wrong, there is a

T (critical temperature) above which a lot of gain

Critical

reduction is applied quickly. These parameters are not user-adjustable. They are the result of

extensive simulation and testing under a variety of abusive conditions.

3

Page 4

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

)

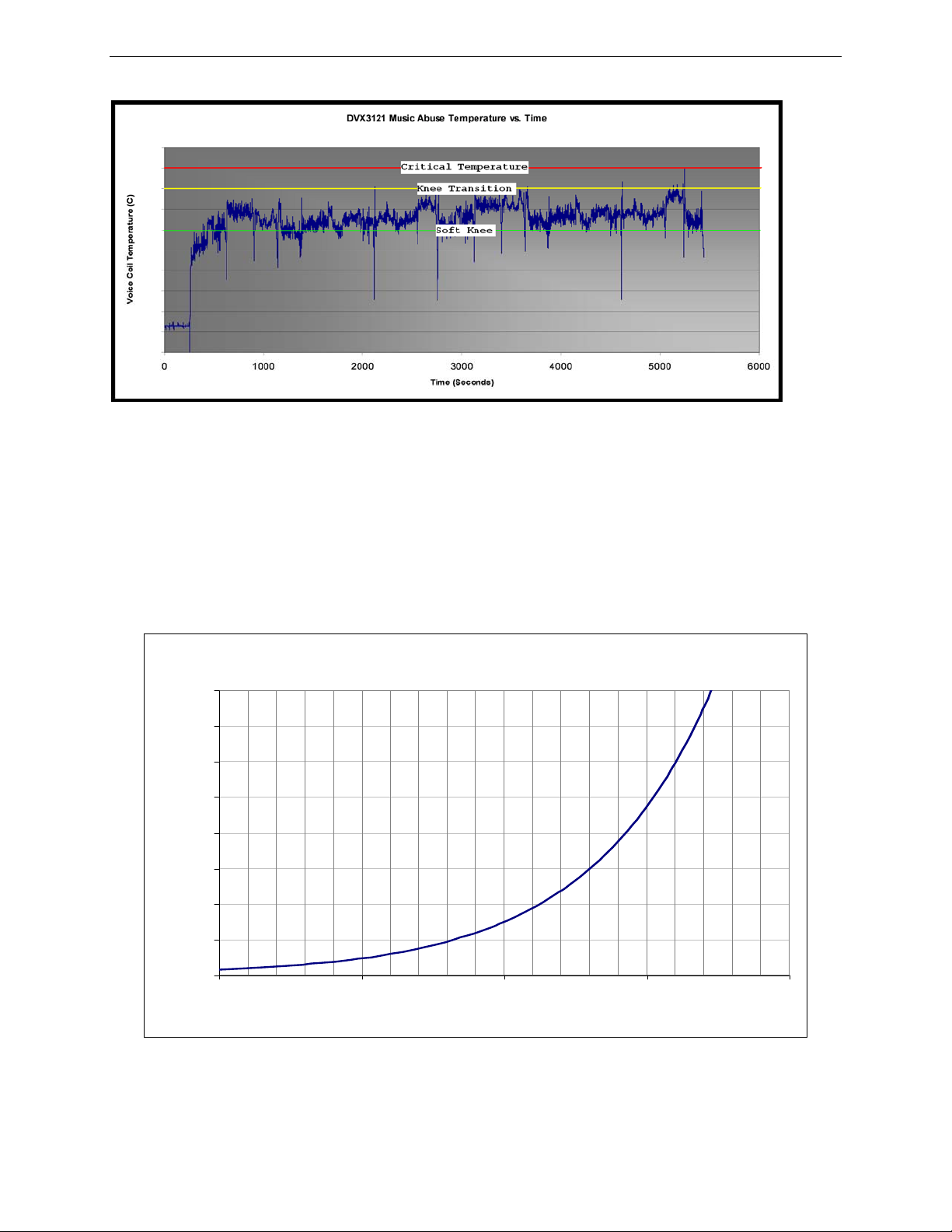

Figure 1: An example of an abusive test with a soft knee at 120C and a critical temperature of

180C.

The TEMP limiter should not have to provide a significant amount of gain reduction under normal

operating conditions. It is designed to prevent component failures in the case where the user is

riding the fine line between pushing their system hard and pushing it to failure. The difference

between these two cases can be smaller than 1dB!

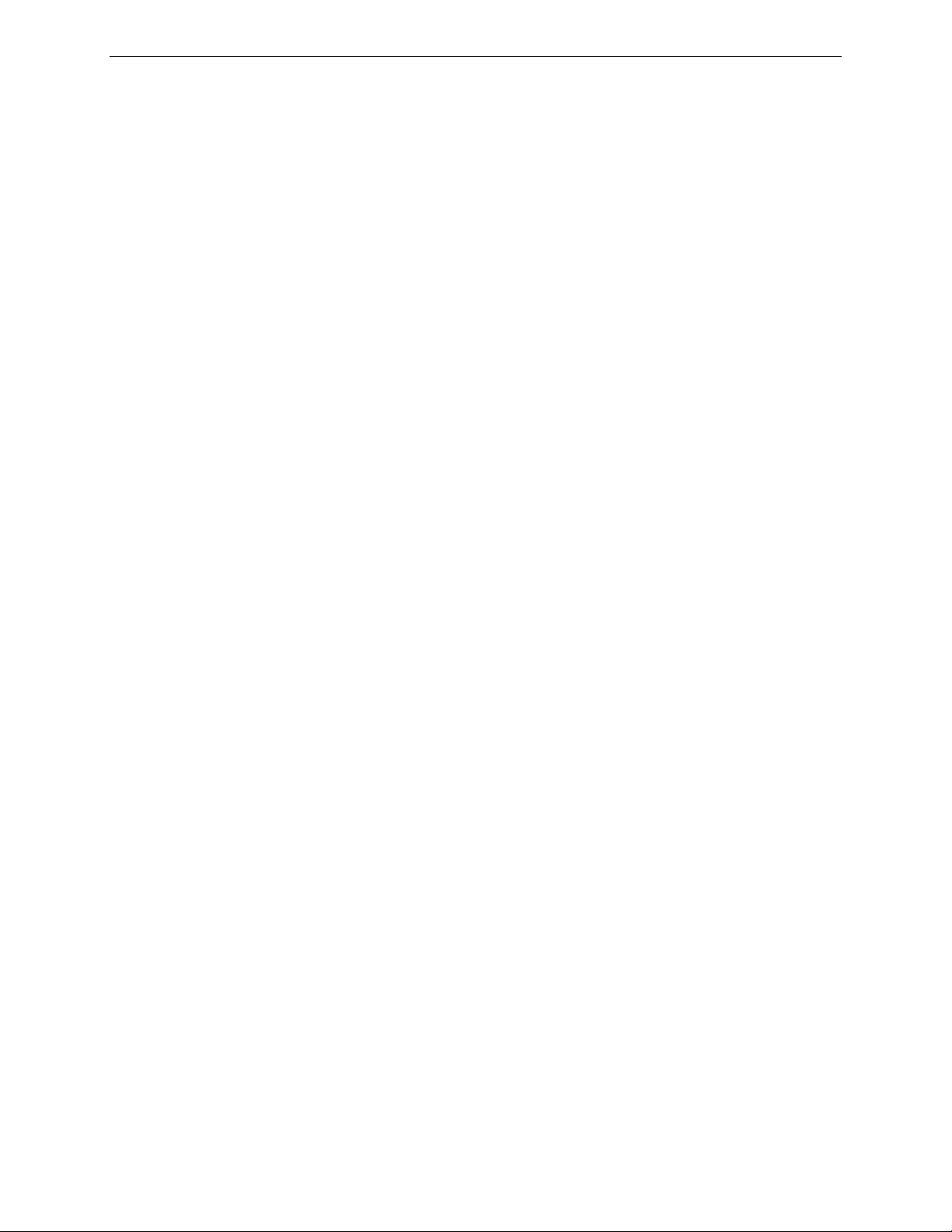

dB vs. Temperature

400

350

300

250

200

150

Coil Temperature (C

100

50

0

20 25 30 35 40

Dri ve signal (dB)

Figure 2: An example of drive level vs. voice coil temperature. The difference between a coil

temperature of 250C and 200C is 1dB. This means a 1dB level reduction can prevent component

failures!

4

Page 5

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

4. Important Points about the Temp Limiter

The following are details and notes about the functionality of the TEMP Limiter when used in

Electro-Voice systems.

• Bandpasses are not linked, so gain reduction can occur independently in different

pass-bands. If a system is driven very hard this can result in a change in the tonal

balance of the system. For small amounts of thermal gain reduction (<3dB) this is

not very perceptible. If there is a noticeable change in the tonal balance of the

system this can be corrected by reducing the input drive level (pre-DSP).

• The TEMP limiter algorithm assumes that the amplifier is not applying its own gain

reduction. In the case where the Circuit Breaker Protection on a TG7 is set to < 30

amps, in most cases the CBP will apply gain reduction before the TEMP Limiter will,

particularly when driving a very low impedance load.

• Since the TEMP limiter is temperature-based, the time constants involved are much

longer than for peak limiters. Attack and release times for the temp limiter are on the

order of seconds rather than milliseconds. This results in less audibly-noticeable

gain reduction and more transparent performance.

• The TEMP limiter takes a ‘soft knee’ approach to limiting, so seeing a small amount

of gain reduction is no cause for concern. If the amount of gain reduction applied is

> 2-3dB the drive level should be decreased.

• If, for some reason, power to the RCM module is lost the TEMP limiter will lose track

of the instantaneous voice coil temperature. Once the RCM module is powered up

again it will restart the temperature tracking from ambient temperature.

5

Page 6

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

5. Application and Use in IRIS-Net

5.1. Using the TEMP Limiter in Tour Grade Amplifiers

TEMP Limiter parameters are included in many FIR-Drive loudspeaker settings (.SPS files). These

files are available for download from the Electro-Voice website (http://www.electrovoice.com

These files will be compatible with RCM-26 modules that are operating with V.1.15.0 firmware (or

higher) and IRIS-Net V2.4.0 (or higher). Additionally, these loudspeaker settings are included in the

Speaker Settings folder of IRIS-Net V2.4.1 (or higher).

Loudspeaker settings with TEMP Limiter parameters can be imported into devices by:

o Importing the settings into an individual amplifier

o Importing the settings into a Group of amplifiers

o Importing the settings via the IRIS-Net Project Generator

Instructions for each method are listed below.

).

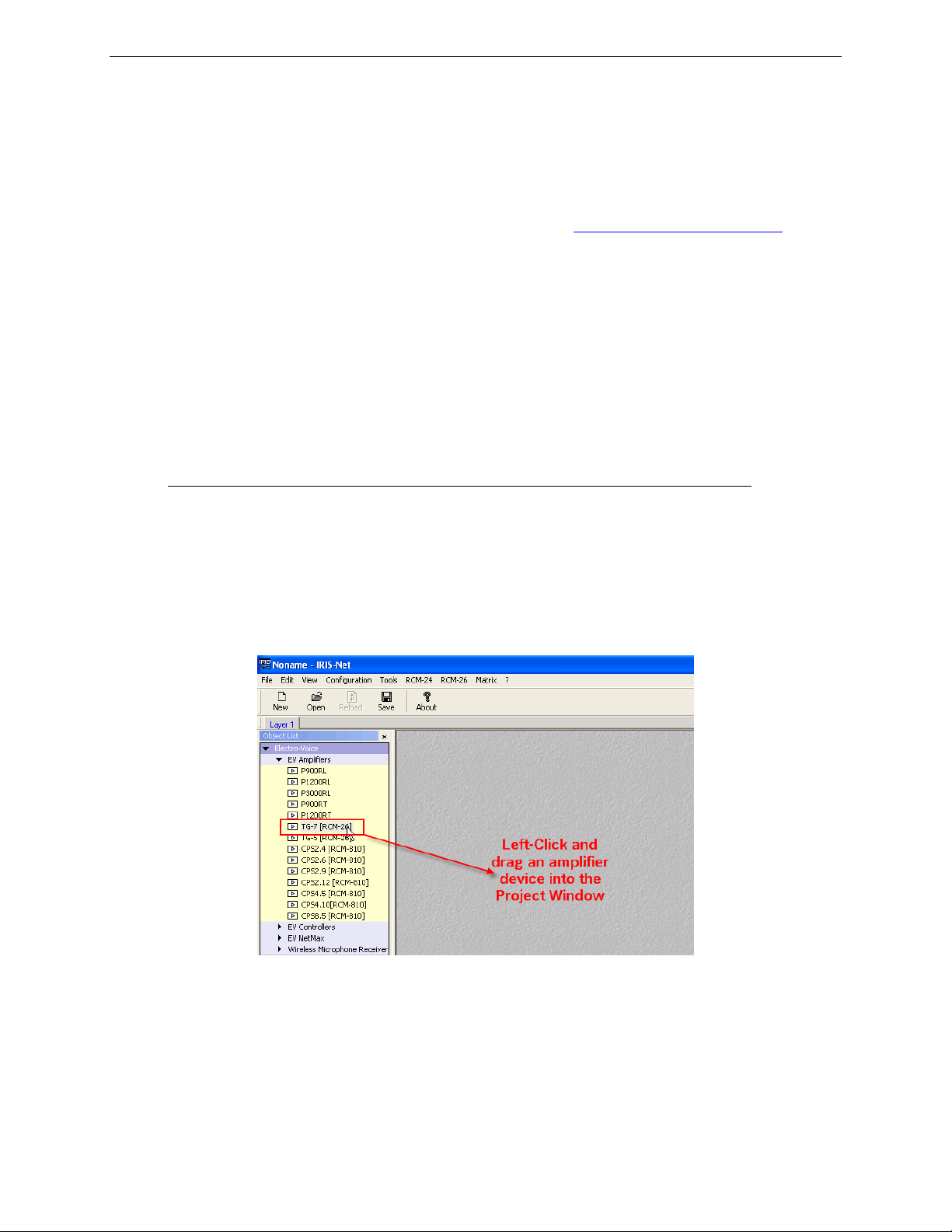

5.1.1. Importing Loudspeaker Settings into individual Amplifiers

1. If an existing project with TG Amplifier devices is already open, proceed to step # 3. If a

new, empty project is open, begin by dragging a Tour Grade Amplifier Object from the

Object List into the Project Window.

6

Page 7

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

2. In the Amplifier Dialog that appears, select the number of devices, starting CAN address and

interface to be used.

3. Double-click on the amplifier object in IRIS-Net to open the Userpanel. In the Userpanel,

press the SET button in the lower right-hand corner to open the amplifier’s configuration.

7

Page 8

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

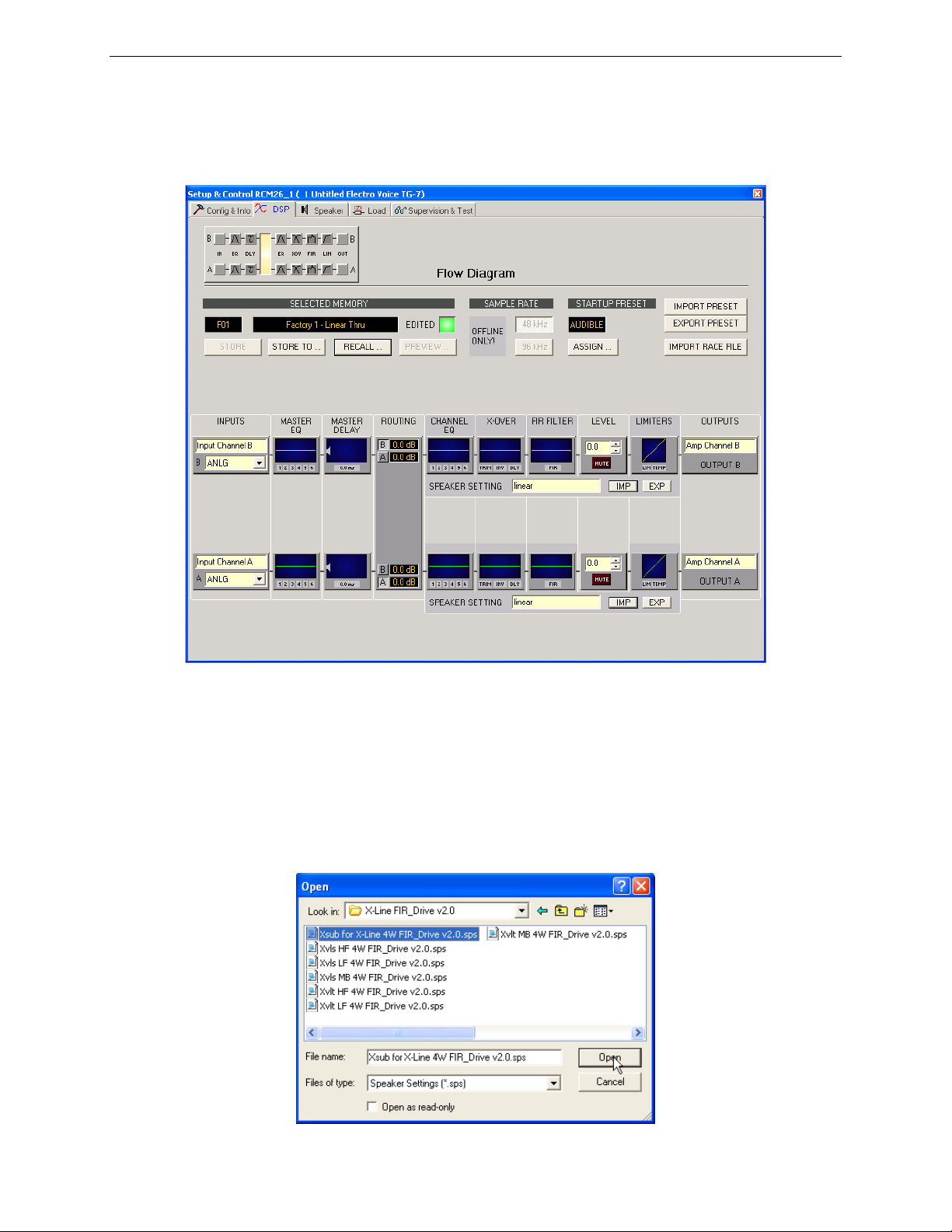

4. In the Amplifier Setup & Control screen, click on the DSP tab at the top of the window. This

will open a block diagram of the RCM-26’s DSP structure.

5. Below each output channel, there are buttons to import and export Speaker Settings files.

To import a Speaker Settings file with TEMP Limiter parameters, click the IMP button. This

will open a dialog which will allow navigation to the location of the file for import. The files

are available via the Electro-Voice website or are included with IRIS-Net V2.4.1. Navigate to

the location of the file to be imported, highlight the file and click Open.

8

Page 9

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

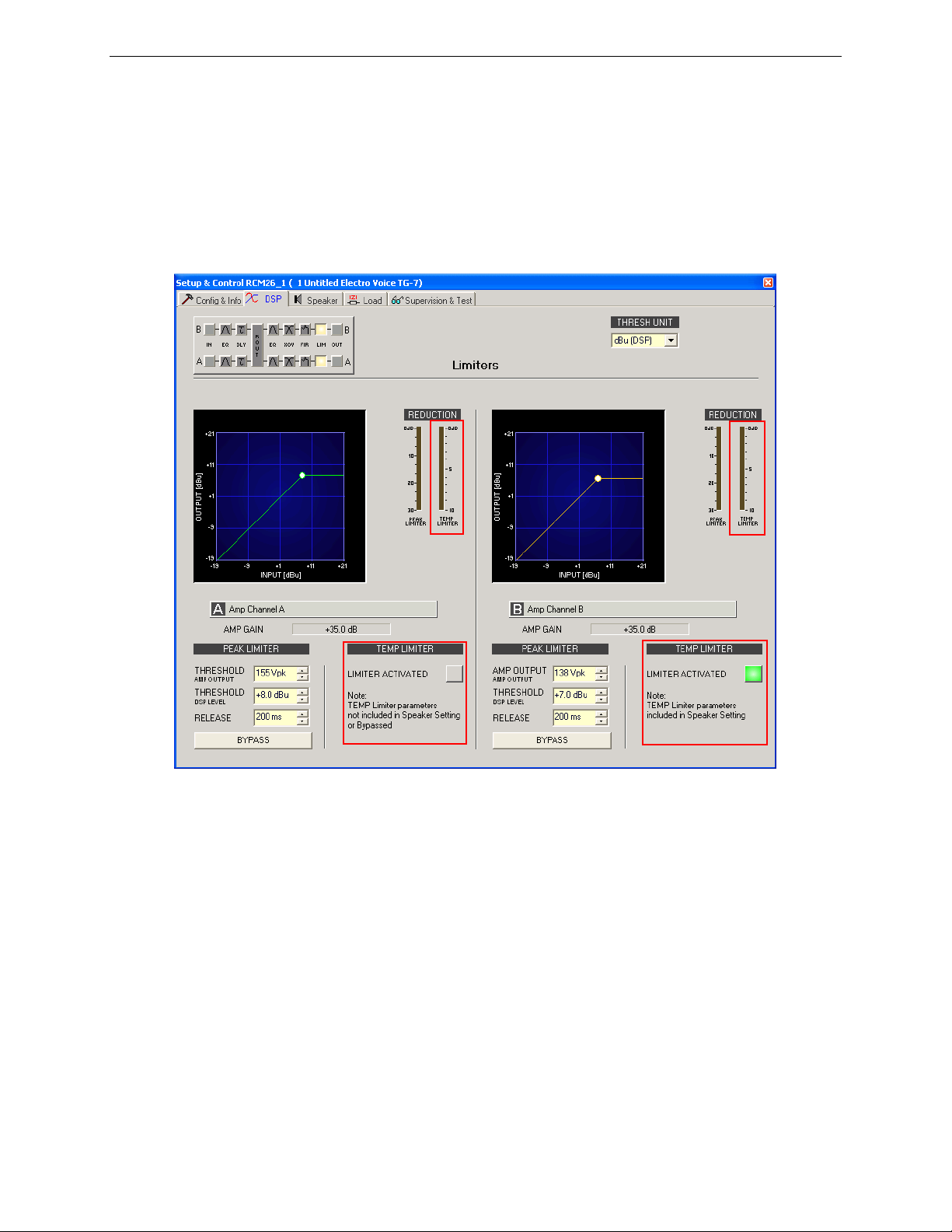

6. After loading a SPS file containing TEMP Limiter parameters, you will see an indication in the

Limiters block in the DSP block diagram. A green TEMP LED under the block indicates

successful loading, while a gray block indicates that the file loaded did not contain TEMP

Limiter parameters. In the example below, amplifier Channel A has loaded a .SPS file that

does not contain TEMP Limiter parameters, while Channel B has loaded a .SPS file that

does contain TEMP Limiter parameters.

9

Page 10

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

7. It is possible to get additional information about the behavior of both the PA Limiter and the

TEMP limiter by clicking on the Limiters Block in the DSP block diagram. This will open a

window that contains detailed information about both limiters, including whether or not

TEMP Limiters are active and loaded. Additionally, while online with IRIS-Net during

operation and dedicated gain reduction meter is provided for both the PA Limiter and the

TEMP Limiter.

10

Page 11

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

5.1.2. Importing Loudspeaker settings into a Group of amplifiers

1. If an existing project with Groups of TG Amplifier devices is already open, proceed to step #

2. If a new, empty project is being created, please refer to the IRIS-Net Help documentation

and Quick Start Guide for details and instructions on how to create and configure Groups.

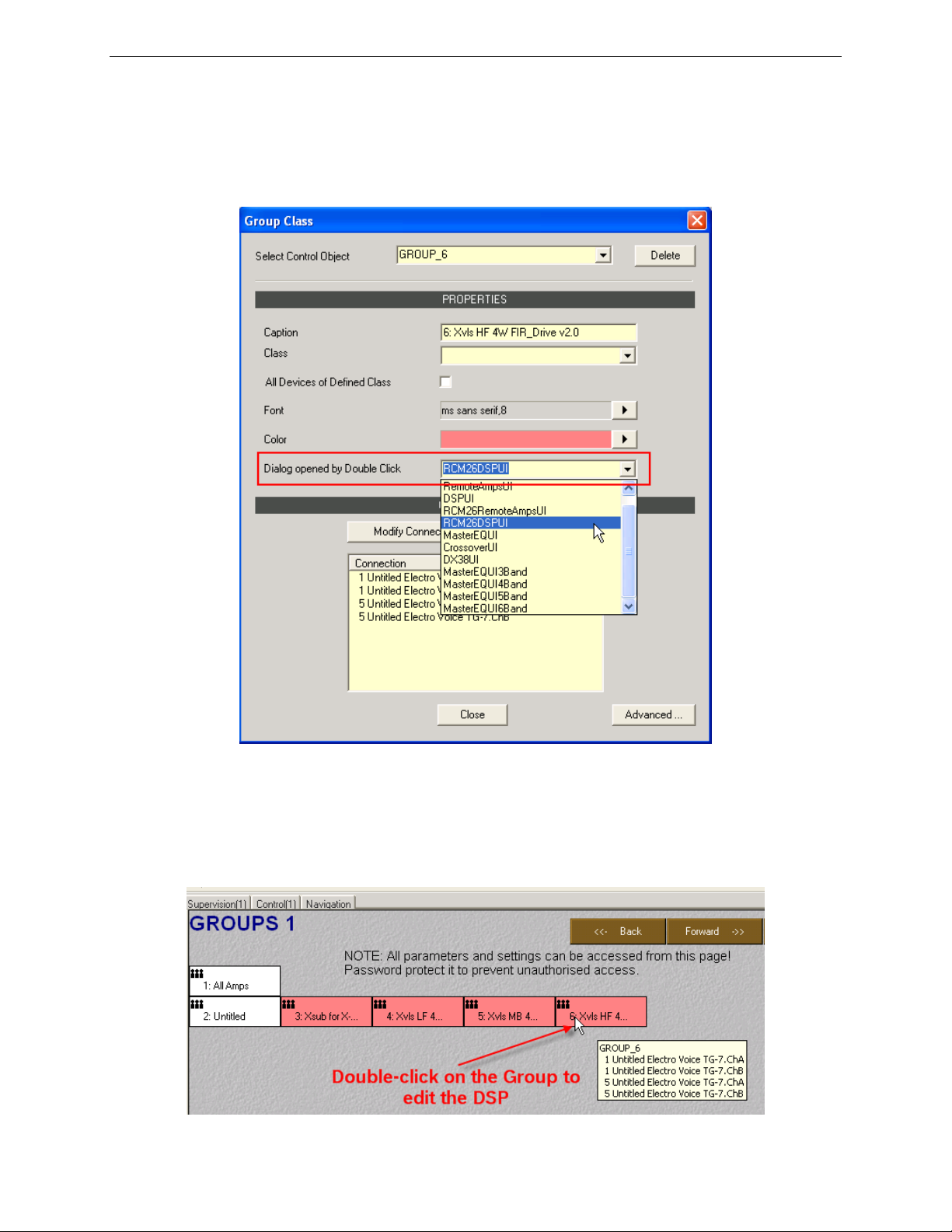

2. To begin importing Speaker Settings into the amplifiers connected to the Groups, the

proper DSP dialog for the Group must first be selected. To do this, right-click on the Group

and select Modify properties.

11

Page 12

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

3. In the Group Class dialog that opens, click on the drop-down menu for the Dialog Opened

by Double-Click entry. From this menu, select “RCM26DSPUI”. The Group Class dialog

can then be closed.

4. The RCM-26 DSP dialog can now be opened by double-clicking on the Group that is to be

edited.

12

Page 13

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

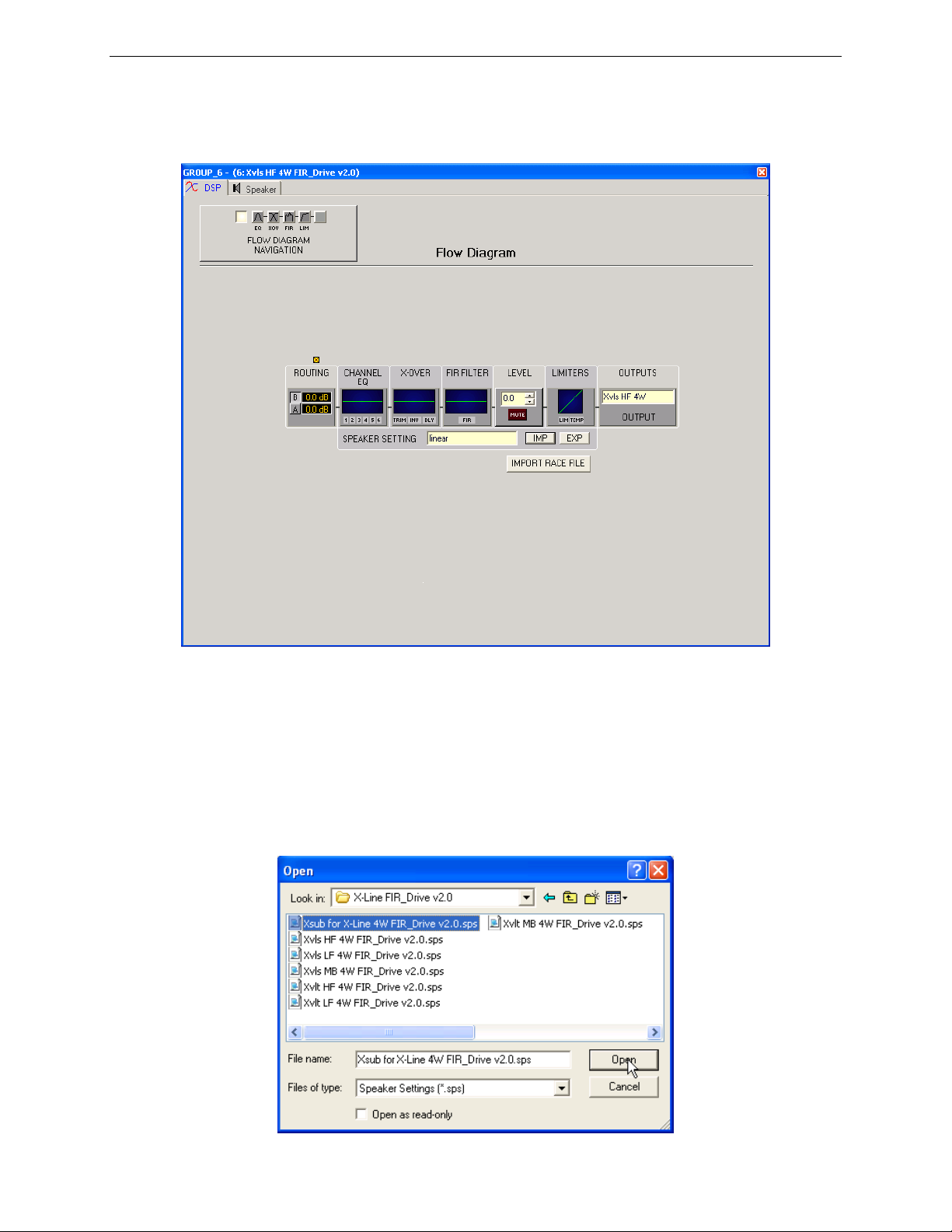

5. The RCM-26 DSP dialog will open for the Group.

6. Below the block diagram, there are buttons to import and export Speaker Settings files. To

import a Speaker Settings File with TEMP Limiter parameters, click the IMP button. This will

open a dialog which will allow navigation to the location of the file for import. The files are

available via the Electro-Voice website or are included with IRIS-Net V2.4.1. Navigate to the

location of the file to be imported, highlight the file and click Open.

13

Page 14

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

7. After loading a SPS file containing TEMP Limiter parameters, you will see an indication in the

Limiters block in the DSP block diagram. A green TEMP LED under the block indicates

successful loading, while a gray block indicates that the file loaded did not contain TEMP

Limiter parameters. In the example below, a .SPS file has been loaded that does contain

TEMP Limiter parameters.

14

Page 15

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

8. It is possible to get additional information about the behavior of both the PA Limiter and the

TEMP limiter by clicking on the Limiters Block in the DSP block diagram. This will open a

window that contains detailed information about both limiters, including whether or not

TEMP Limiters are active and loaded. Additionally, while online with IRIS-Net during

operation and dedicated gain reduction meter is provided for both the PA Limiter and the

TEMP Limiter.

5.1.3. Importing Loudspeaker settings With the IRIS-Net Project

Generator

The IRIS-Net Project Generator is capable of creating complete IRIS-Net projects, including

devices, Groups, User Interfaces and output DSP setting based on simple user input. For additional

information on using the Project Generator, please see the IRIS-Net Project Generator Help File.

The Project Generator directly accesses the IRIS-Net Speaker Settings folder to import the DSP

settings. IRIS-Net V2.4.1 (or higher) provides Speaker Settings files that include TEMP Limiter

parameter settings, where available. Any additional Speaker Settings files that include TEMP Limiter

parameters which may be downloaded from the Electro-Voice website simply need to be placed in

the IRIS-Net Speaker Settings folder for the Project Generator to be able to access them and

import the data directly. Additionally, Speaker Settings may be imported into devices or Groups in a

project file created by the Project Generator after it is created.

15

Page 16

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

5.2. Using the TEMP Limiter in Dx46 Processors

TEMP Limiter parameters are included in many FIR-Drive loudspeaker settings (.SPS files). These

files are available for download from the Electro-Voice website (http://www.electrovoice.com

).

These files will be compatible with Dx46 hardware that is operating with V.1.0.0 firmware (or higher)

and IRIS-Net V2.4.0 (or higher). Additionally, these loudspeaker settings are included in the

Speaker Settings folder of IRIS-Net V2.4.1 (or higher).

1. If an existing project with Dx46 devices is already open, proceed to step # 3. If a new,

empty project is open, begin by dragging a Dx46 Object from the Object List into the

Project Window.

2. Double-click on the Dx46 object in IRIS-Net to open the Userpanel. In the Userpanel, press

the DSP button in the lower right-hand corner to open the amplifier’s configuration.

16

Page 17

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

3. In the Dx46 Configuration panel screen, click on the DSP tab at the top of the window. This

will open a block diagram of the Dx46’s DSP structure.

9. Below each output channel, there are buttons to import and export Speaker Settings files.

To import a Speaker Settings file with TEMP Limiter parameters, click the IMP button. This

will open a dialog which will allow navigation to the location of the file for import. The files

are available via the Electro-Voice website or are included with IRIS-Net V2.4.1. Navigate to

the location of the file to be imported, highlight the file and click Open.

17

Page 18

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

10. After loading a SPS file containing TEMP Limiter parameters, you will see an indication in the

Limiters block in the DSP block diagram. A green TEMP LED under the block indicates

successful loading, while a gray block indicates that the file loaded did not contain TEMP

Limiter parameters. In the example below, a .SPS file has been loaded that does contain

TEMP Limiter parameters.

11. It is possible to get additional information about the behavior of both the PA Limiter and the

TEMP limiter by clicking on the Limiters Block in the DSP block diagram. This will open a

window that contains detailed information about both limiters, including whether or not

TEMP Limiters are active and loaded. Additionally, while online with IRIS-Net during

operation a dedicated gain reduction meter is provided for both the PA Limiter and the

TEMP Limiter. When configuring both the PA Limiter and TEMP limiter in this section, it is

very important to take note of the amplifier selection for each channel. This selection

provides information about the amplifier that is connected to this output that is used to

calculate certain parameters for the limiters. A selection of Electro-Voice amplifier models is

available for selection, and users are also able to enter their own information for amplifiers

not included in the list. For additional information, please refer to the Dx46 User Manual and

IRIS-Net Help File.

18

Page 19

THERMAL ENERGY MANAGEMENT AND PROTECTION LIMITER TECHNOLOGY

6. Let Us help Fine Tune Your System

Let us help you get the most out of your sound reinforcement system with the highest reliability. We

can make sure that you have the best loudspeaker settings, firmware and software for the

loudspeaker, processor and amplifier combination that you are using, and the most up-to-date

support literature and software.

Contact one of the Electro-Voice Technical Support Team at one of the locations listed below.

Bosch Communications Systems

Americas

Headquarters Americas

Bosch Security Systems, Inc.

12000 Portland Ave South,

Burnsville, MN 55337, USA

Phone: 1 800 392 3497

Fax: 1 800 955 6831

Canada

Phone: 1 866 505 5551

Fax: +1 866 336 8467

Latin America

Phone: 1 952 887 5532

Fax: 1 952 736 4212

EMEA

Headquarters Europe,

Middle East & Africa

Bosch Sicherheitssysteme GmbH

Robert-Koch-Strasse 100

85521 Ottobrunn, Germany

Contact & Visitor Address

EVI Audio GmbH

Sachsenring 60

94315 Straubing, Germany

Phone: +49 9421 706 0

Fax: +49 9421 706 265

France

EVI Audio France S.A.S

Phone: +33 1 6480 0090

Fax: +33 1 6006 5103

Middle East

Robert Bosch Middle East FZE

Phone: +97 14 212 3300

Fax: +97 14 212 3388

Asia & Pacific

Headquarters APR

Robert Bosch (SEA) Pte Ltd

38 C Jalan Pemimpin

Singapore 577180

Phone: +65 6319 0616

Fax: +65 6319 0620

Australia

Bosch Security Systems Pty Ltd

Phone: +61 2 9683 4752

Fax: +61 2 9890 5928

China

Telex EVI Audio

(Shanghai) Co., Ltd.

Phone: +86 21 6317 2155

Fax: +86 21 6317 3025

India

Bosch Limited

Phone: +91 80 4176 8378

Fax: +91 80 4176 8263

Japan

EVI Audio Japan

Phone: +81 3 5485 4427

Fax: +81 3 5485 4428

Thailand

Robert Bosch Limited

Phone: +662 639 3111

Fax: +662 631 2030

Korea

Robert Bosch Korea

Phone: +82 31 270 4765

Fax: +82 31 270 46

19

Loading...

Loading...