Page 1

OWNER‘S MANUAL

Page 2

2

3

3

4

5

5

6

7

7

7

CONTROL PORT

8

ADDRESS

8

8

9

9

OUTPUT VOLTAGE CONFIGURATION

GROUND-LIFT SWITCH

CABLING

CAN-BUS

SPECIFICATIONS / TECHNISCHE DATEN

32

34

35

36

WICHTIGE SICHERHEITSHINWEISE

WICHTIGE SERVICEHINWEISE

20

AUSPACKEN & GARANTIE

INSTALLATIONSHINWEISE

22

23

23

23

23

CONTROL PORT

23

ADDRESS

25

25

26

GROUND-LIFT SCHALTER

26

26

VERKABELUNG

27

28

CAN-BUS

30

30

31

SPECIFICATIONS / TECHNISCHE DATEN

32

34

35

ABMESSUNGEN

36

Page 3

3

The lightning ash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

the product’s enclosure that may be of suf cient

The exclamation point within an equilateral

triangle is intended to alert the user to

the presence of important operating and

2.

3.

4.

5.

ensure that no objects lled with liquids, such as vases, are placed on this apparatus.

6.

Clean only with a dry cloth.

7.

8.

9.

Only use attachments/accessories speci ed by the manufacturer.

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped

To completely disconnect mains power from this apparatus, the power supply cord must be

CAUTION:

These servicing instructions are for use by quali ed personnel only. To reduce

the risk of electric shock, do not perform any servicing other than that ontained

to quali ed service personnel.

2.

opened, needs to be operated and is connected to the mains

3.

4.

The minimum distance between parts carrying mains voltage and any accessible metal piece (metal

enclosure), respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not

connected to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5.

only rmissible when using original parts.

6.

Altering the circuitry without prior consent or advice is not legitimate.

7.

Any work security regulations that are applicable at the location where the appliance is being serviced

8.

All instructions concerning the handling of MOS - circuits have to be observed.

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART )

grounding prong. The wide blade or the third prong are provided for your safety. When the provided plug does not

t into your outlet, consult an electrican for replacement of the absolete outlet.

Page 4

4

Congratulations!

With buying an Electro-Voice PRECISION SERIES power ampli er you have chosen

an appliance that employs the most advanced technology.

stability. Each power ampli er employs an RCM-24 Remote Control module allowing centralized

con guration, control and monitoring of all relevant power amp parameters (like output current, output

voltage, load impedance, etc.).

The power ampli ers employ two high-performance output transformers each and offer oating

The gapless protection circuitry concept not only prevents the power amp itself but also the connected

and of course Thermal Overload Protection for the output transistors and mains transformers.

Three-speed high performance fans guarantee outstanding thermal stability at absolute low running

Comprehensively dimensioned power supply units with low-leakage toroidal transformers provide

extensive headroom far above the stated nominal power.

The RCM-24 provides full-size

overview of the system’s entire status

and control over all rele vant system

Control Network consisting of up to 250 power amps. The Windows Software IRIS – Intelligent Remote &

the opportunity to take speci c measures prior to the occurrence of critical operational states. Programming

an automatic response for exceeding or falling below speci c limits is possible as well. All parameters,

e.g. power-on/off, levels, muting, lters, etc. can be controlled in real-time and saved in any power amp

and –voltages of the two power ampli er channels. Each time the signal falls below or exceeds set

checking the connected loudspeaker systems. The integrated signal generator is employed together

with the current/voltage testing to measure the connected loudspeakers’ and cable’s impedance

Comparing the measured impedance progression to a reference value is possible at all times, which

allows recognizing even the slightest loudspeaker defects or irregularities.

Page 5

5

stored in the module’s 8 user presets. Independent from network control all DSP-settings ( lter, delay,

for network-independent switching to another preset (e.g. alarm settings with maximum energy for voice

and text announcements). Therefore, P-Series amps with RCM-24 modules installed ful l even the

When designing the RCM-24, uncompromising audio quality was the highest maxim. AD/DA-conversion

value for digital audio appliances.

All con guration, control and monitoring details of P-Series power amps are explained in the

documentation accompanying the PC Windows software IRIS.

Carefully open the packaging and take out the power ampli er. Next to the power ampli er itself, the

screw-on connectors (1x 2-pole, 4x 3-pole, 1x 6-pole) plus a set of rack shelf mounting adapters. Please

only a completely lled in warranty certi cate entitles you to stake any warranty claims. The appliance

comes with a 36 months warranty, starting with the date when receiving the good from your dealer.

system make sure to provide suf cient ventilation. Leave a gap of at least 60mm x 330mm (up to the

cabinet’s top ventilation louvers) for air circulation between the rear of the power ampli er and the

cabinet’s/rack’s rear wall. Make sure to leave at least 100mm of space above the cabinet or rack shelf

system. Since the temperature inside of the cabinet or rack shelf system can easily rise up to 40°C

during operation, bearing in mind the maximally allowable environmental temperature during operation

for all other appliances installed in the same rack shelf system is mandatory. (also refer to “MAINS

OPERATION & RESULTING TEMPERATURE”)

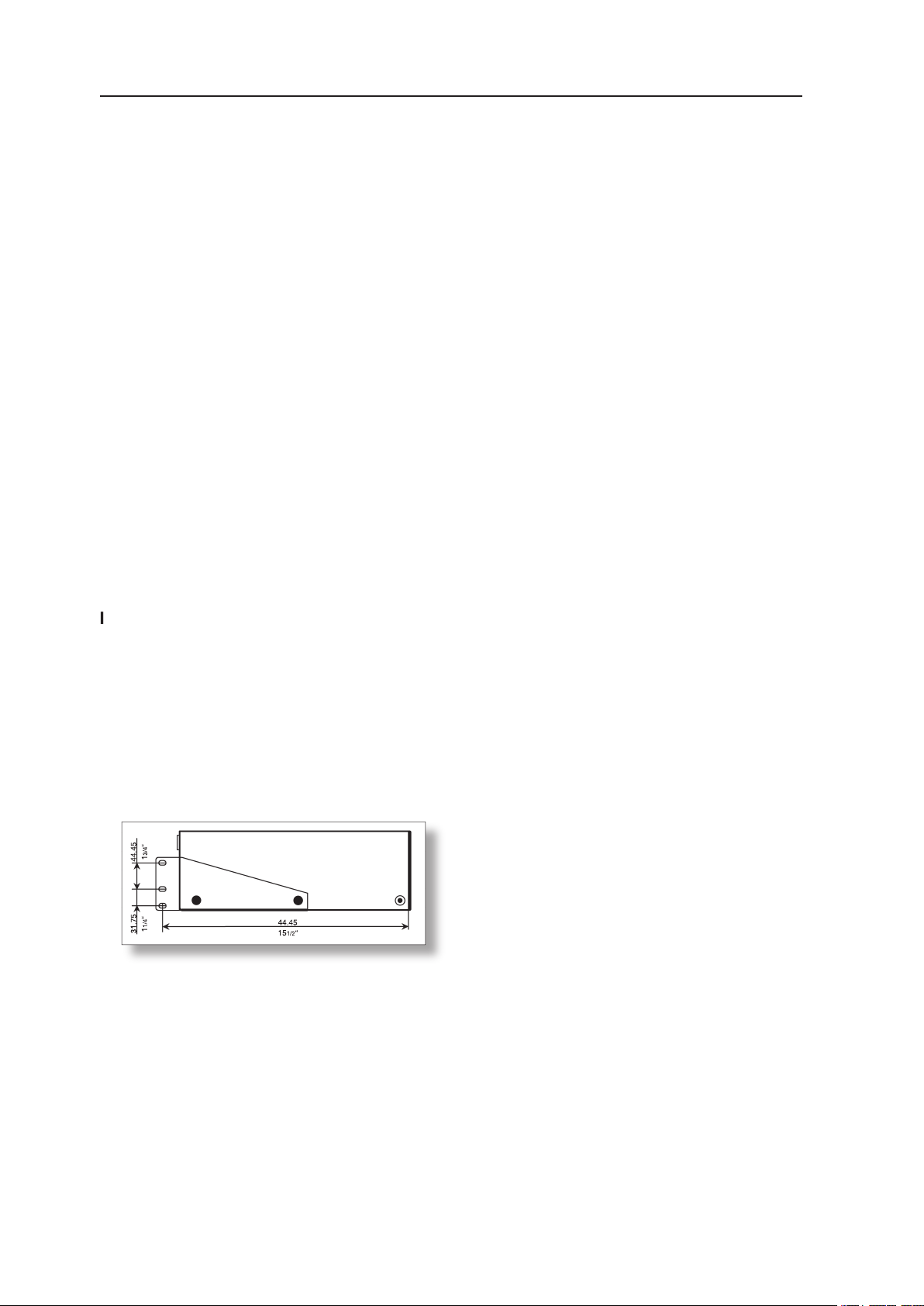

The use of rails or optionally available rack

adapters – NRS 90235 (112733) – is

appliance in a rack shelf system to prevent

the front panel from bending.

Caution:

temperature or +40°C is not permissible.

The power ampli er has to be protected against: dripping or splashing water, direct sunlight, high

temperatures or direct in uence of heat sources, high humidity, extensive dust and vibrations.

Condensation on internal parts may occur after transporting the power ampli er from a cold into a

warmer environment. In that case operation is only permissible after the appliance has gained the

ampli er’s enclosure make sure to instantly separate the appliance from the mains power and contact

an authorised DYNACORD service centre for inspection before continuing operation.

surface of the enclosure or lead to dangerous re hazard.

44.45

1/2

Page 6

6

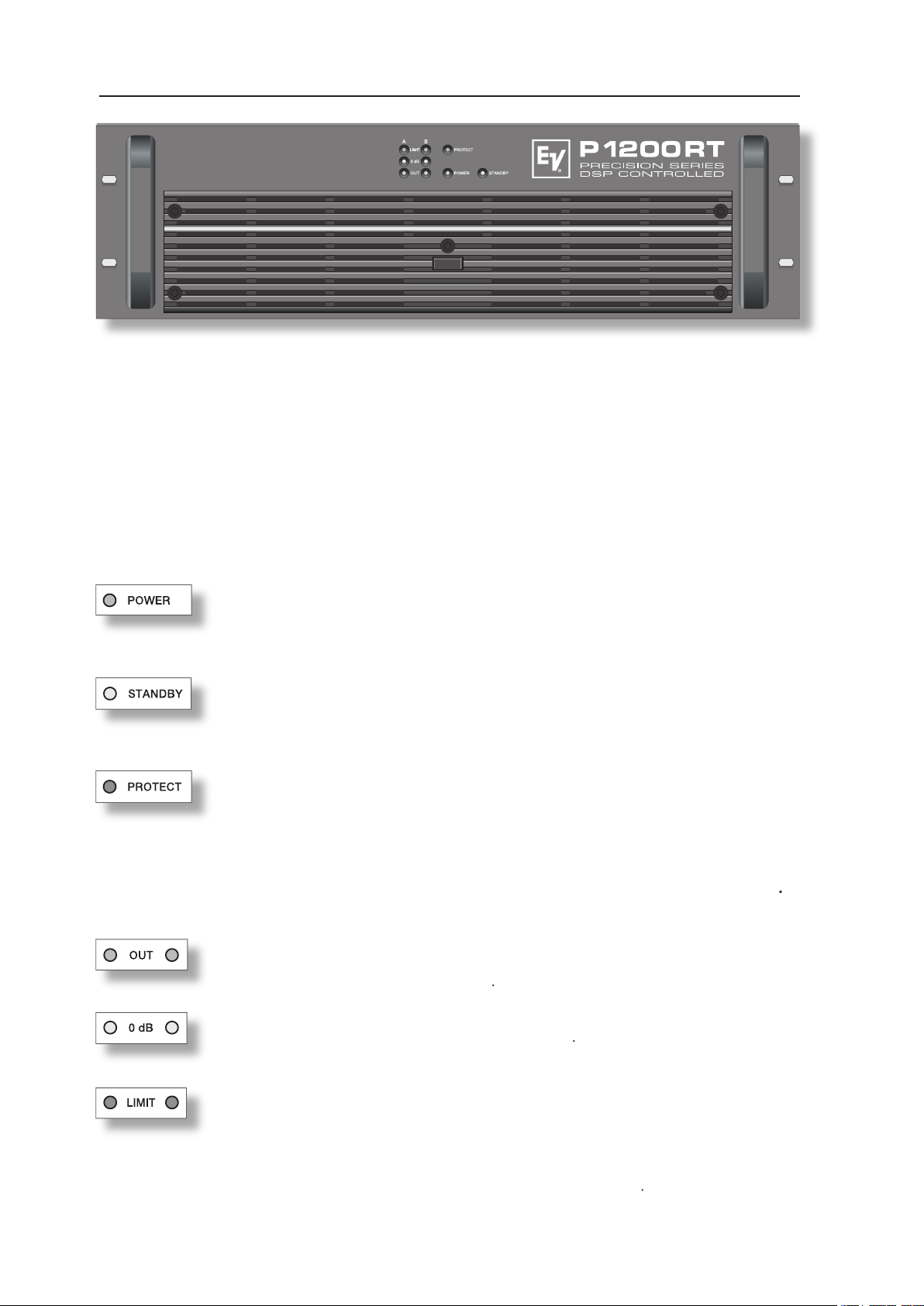

This indicator lights when the power ampli er has been switched on. Causes for

the POWER-indicator not lighting are: the appliance is not connected to the mains

This indicator light when the power ampli er is in stand-by mode, which can be

activated from the RCM-24 or via Easy Remote. In stand-by operation only the

separated from the mains.

The PROTECT LED lights indicating that one of the internal protection circuits

against thermal overload, short-circuit, Back-EMF, HF-occurrence at the output, etc.,

the load connected to prevent the connected loudspeaker systems and the power

ampli ers as well from being damaged. Whatever caused the fault – e.g. a short-

circuited speaker cable –

.

The OUT LED lights as soon as an audio signal of approximately 30dB below full

or a protection circuit has been activated

The 0dB LED lights when the power ampli er is driven at its maximum. Higher input

voltage does not result in higher peak output voltage

This indicator lights as soon as the integrated dynamic limiter is activated and the

to +21dBu down to a S/N-ratio of approximately 1%. If, on the other hand, this LED

systems connected from being damaged by probable overload

on. The soft-start function prevents current inrush peaks on the mains, which in addition prevents

the mains line protection switch from activating during power-on operation of the power ampli er.

The loudspeaker outputs are activated via relay switching with a delay of approximately 2 seconds

effectively attenuating eventual power-on noise. The PROTECT LED lights during the delay time and

the fans run at maximum speed. This is normal to con rm the immaculate operation of the protection

circuitry. Upon power-on, all power amps with RCM-24 Module installed regain the state of operation

Page 7

7

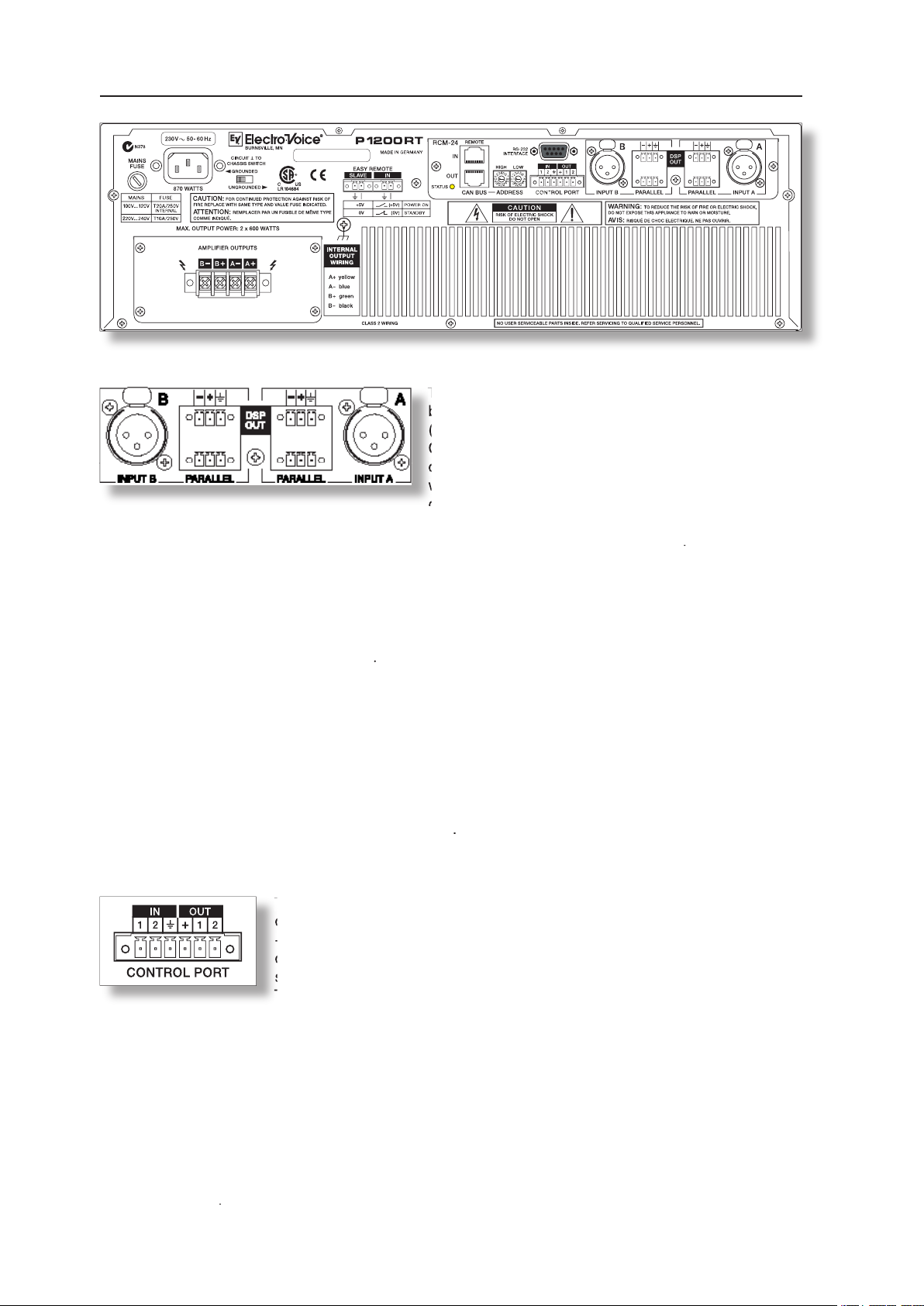

The inputs INPUT A & INPUT B are electronically

of the XLR-type input connectors is according to the

Connection can be established via the XLR-type input connectors INPUT A / INPUT B or the supplied

screw-on connectors which are connected in parallel. In addition, using the PARALLEL-connectors

without the need for extra splitter-cables

The DSP output signal – i.e. the post-digital-signal-processing-unit audio signal – is present at the

correspondingly ampli ed present at the power amp’s main outputs.

The DSP OUT can be utilized for feeding the digitally processed audio signal from the RCM-24 Remote

Control Module to additional power ampli ers (without DSP-module); e.g. for increasing the overall out-

electronically balanced. Output impedance is

100

Ω

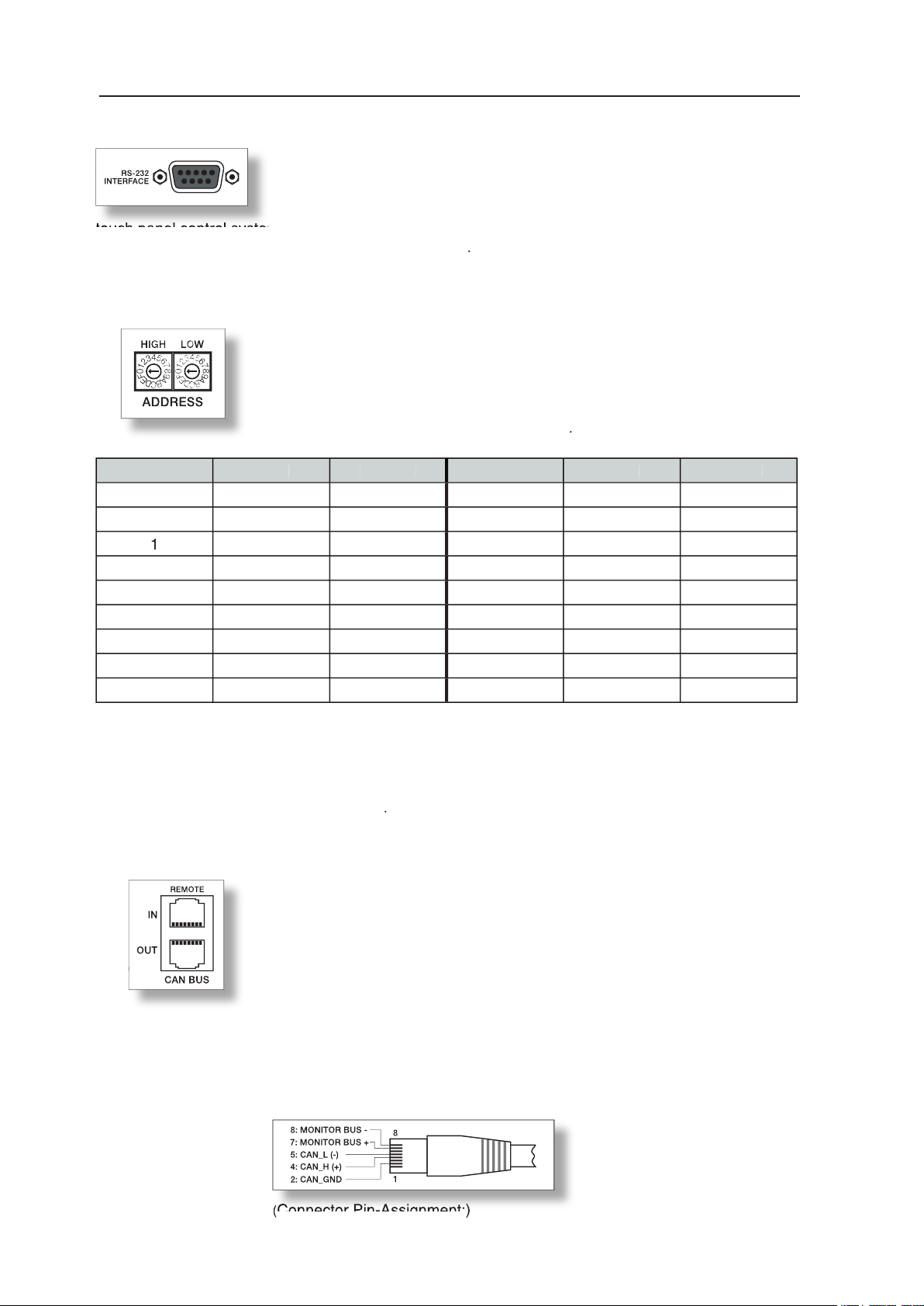

The CONTROL PORT offers two freely programmable control inputs and

external switches, pushbuttons or relays.

The two control outputs OUT1 / OUT2 are carried out as Open Collector Outputs. In non-active state

The outputs serve for signalling internal operational states. They can be used for the direct triggering

of LEDs, indication lights or relays. The +5V reference connector provides power supply for externally

connected appliances with amperage of maximally 100mA. The control outputs allow signal indication

of operational states (critical temperature, exceeding or decline of de ned limit values, faults, etc.) at

central operator desks or to other systems ( re alarm system, general alert system) even without PC.

the IRIS software

The CONTROL PORT offers two freely programmable control inputs and

control outputs as well as the reference connections for ground potential and

+5V. Using the PC Windows software IRIS, the control inputs can be

con gured and serve for instance for Power-On / Stand-by switching, preset

switching or parameter control.

The two control contacts IN1 / IN2 are internally set to +5V (open) via pull-up

The inputs INPUT A & INPUT B are electronically

Connection can be established via the XLR-type input

connectors or the supplied screw-on connectors,

which are connected in parallel. The pin-assignment

Page 8

8

The RS-232 interface is for connecting media control systems as

well

as building management systems providing control and monitoring of all

touch panel control systems. For a programmer’s guide and complete protocol description, please refer

to the documentation accompanying the IRIS software

ADDRESS

The address selection switch allows setting the ampli er’s network address,

which, within a CAN-network, can range from 01 to 250 (FA hex). Caution:

con icts might occur. Address setting has to be performed in hexadecimal

code. The selection switch LOW represents the low-value digit while the

Adress-Table:

Adress

Adress

008

0 ... F

090 ... F

0 ... F

A

0 ... F

2

0 ... F

32 ... 47

0 ... F

3

0 ... F

48 ... 63

C

0 ... F

4

0 ... F

64 ... 79

0 ... F

208 ... 223

5

0 ... F

80 ... 95

0 ... F

224 ... 239

6

0 ... F

96 ... 111

0 ... A

240 ... 250

7

0 ... F

Address 0 (00 hex, factory-pre-set) ensures that the ampli er is separated from the remote

communication, so that it does not appear in the system set-up even though it might be connected to

the CAN-bus. When the ampli er is powered-on with its address set to “0”, all internal parameters are set

to “0” respectively to bypass and the routing is set to 2-in-2. In that case the ampli er behaves absolutely

The sockets are parallel connected and serve as input as well as for

connecting through of the Remote network. Common RJ-45 patch cables

can be used for rack-shelf cabling. The CAN-bus needs to be terminated at

Detailed guidelines concerning cabling and bus length are provided in the

chapter “REMOTE CONTROL NETWORK”.

+6dBu (1.55V) while the maximum output level is +21dBu (8.7V).

Connector Pin-Assignment:

Connector Pin-Assignment:

)

Page 9

EASY REMOTE

Easy Remote provides a simple way to remotely power-on/off the power

amplier. The Easy Remote function is only useful for appliances not

employing a RCM-24 Module. Controlling appliances with RCM-24 Module

installed per Easy Remote is practically pointless.

EASY REMOTE IN

Leaving the pins of the EASY REMOTE IN socket open, i.e. when connecting +5V, the appliance power

is switched on. When connecting the EASY REMOTE IN, i.e. when feeding 0V from the control output,

the appliance enters standby mode.

EASY REMOTE SLAVE

The EASY REMOTE SLAVE connector provides connection for additional appliances with Easy-Remote

function (e.g. for switching several devices within a rack-shelf ON/OFF).

The switching of the slave-units is delayed to prevent the mains fuses from blowing.

POWER AMPLIFIER OUTPUTS

REAR VIEW

The STATUS LED provides optical indication of CAN-bus trafc. When the

power amplier’s address is set to “00” so that it is separated from the CAN bus, the STATUS LED blinks every 3 seconds.

As soon as CAN-bus communication is recognized, the LED is activated

for at least 100ms whenever the power amplier actively sends data on the

CAN-bus.

The STATUS LED may also be activated from the PC. In this case, the LED

of the according power amplier blinks fast and steady while all other status LEDs within the system stay dimmed.

4-pole binding-post terminals are provided for the power amplier channels „A“

and „B“. Two integrated audio output transformers convert the power amp’s

nominal output voltage to 100V or 70V respectively. Depending on the conguration, the corresponding output voltage is present at the oating output

terminals.

The maximum amount of connected loudspeaker systems is reached when the

loudspeaker network’s total power consumption equals the power amplier’s

nominal output capacity, without exceeding the power amp’s nominal load impedance.

For further information on nominal output capacity and nominal load impedance, please refer to the

“SPECIFICATIONS”.

Caution: During operation the binding-post terminals might carry high voltages. Therefore, installing

the loudspeaker network has to be in accordance with applicable safety regulations.

Installation has to be carried out by accordingly trained professionals only.

When installing and operating 100V PA-systems obeying the VDE-regulation DIN VDE

0800 is mandatory.

Especially when 100V alarm PA-system installations are concerned, safety measures have

to be in accordance with rating class 3. Before operating the power amplier closing the

coverlid attached to the terminal strip is mandatory.

9

Page 10

OUTPUT VOLTAGE CONFIGURATION

The power ampli er’s output voltage is factory pre-set to the corresponding voltage setting for

takes only little effort.

220V, 230V, 240V

70V Output Voltage

Caution:

Opening the appliance is necessary to recon gure the output voltage setting.

Therefore, only trained personnel may perform recon guration.

- Remove all screws securing the cover plate.

- Remove the plastic screw in the top plate.

- Open the appliance by removing the cover.

- On the printed board assembly 86276:

for 100V output voltage: close the bridge R56

for 70V output voltage: open the bridge R56

- Proceed in reverse order to reassemble the appliance.

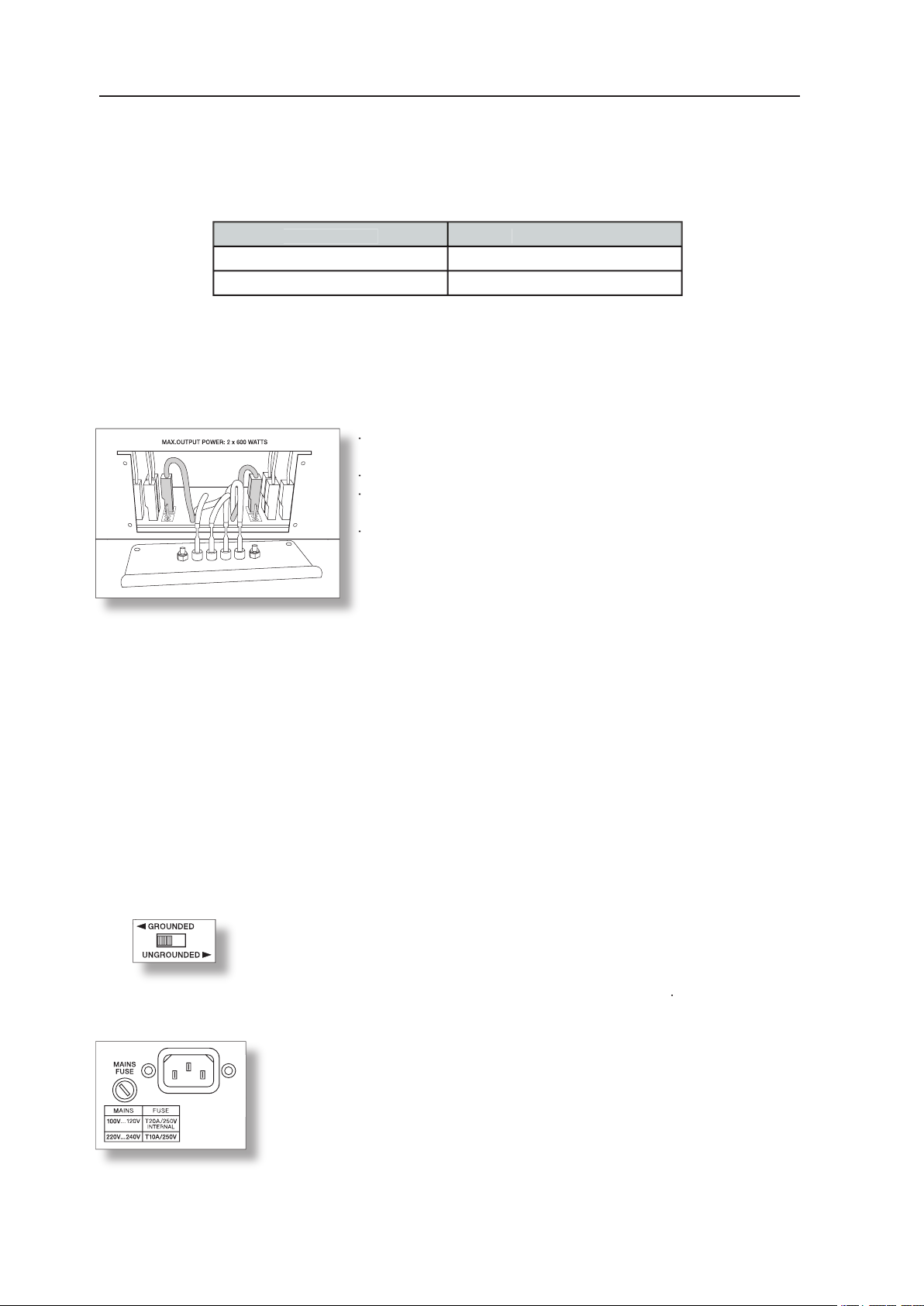

The ground-lift switch allows eliminating noise loops. If the power ampli er

switch to its GROUNDED position is recommended. If the power ampli er

the switch to its UNGROUNDED position is recommended

type with identical amperage, voltage and blow characteristics. If the mains

fuse blows more often, please contact an authorized service centre.

- Disconnect any cables connected to the appliance; especially

the mains cord.

- Remove all xing screws of the output connectors panel.

- Pull out the panel by holding it at the terminal strips

(see diagram).

- The connector pins 100V and 70V are for selecting the desired

output voltage for channel A (right channel) & B (left channel).

output voltage for channel A (right channel) & B (left channel).

- Change the output voltage by pulling the corresponding

connector (grey shaded in the diagram) and inserting it to the

connector (grey shaded in the diagram) and inserting it to the

connector pin for the desired voltage setting.

connector pin for the desired voltage setting.

- The diagram shows the con guration with both channels set

to 70V.

Page 11

Choosing balanced cables (two conductors for the audio signal plus separate shielding mesh) with

XLR-type connectors is recommended for LF-signal connection. Although connecting unbalanced

cables to the power ampli er inputs is possible as well, using balanced cabling is always preferable. A

great number of today’s audio appliances employ balanced outputs. With balanced cabling, the shield

connects all metal enclosure parts and thus ef ciently eliminates the introduction of noise and hum

XLR-type connector pin-assignment

XLR (male)

XLR (female)

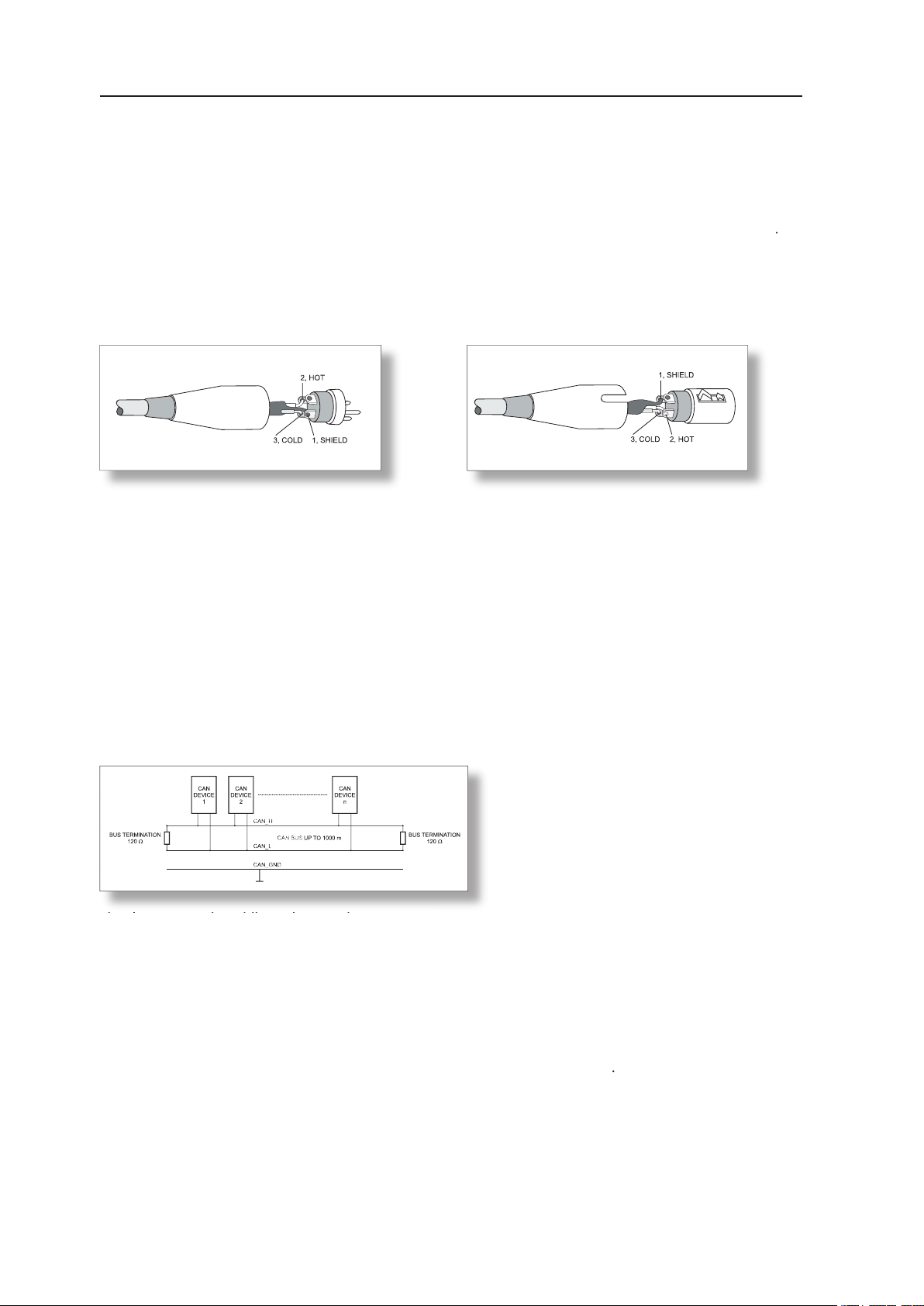

The network of the remote power amps is based on the CAN-bus standard, which for years is especially

for command and data transmission. Controlling the power ampli ers is performed from a PC with IRIS

– Intelligent Remote & Integrated Supervision – software installed. The UCC1 USB-CAN Converter

serves as interface between the PC and the CAN-bus. Connecting up to 100 power ampli ers per CAN-

for controlling more than 100 power amps while the IRIS software allows administering a total of 250

The network topology used by the CAN-bus is based on the so-called “bus or line topology”, i.e. all

the cabling running from one participant on the bus to the next, allowing unlimited communication among

all appliances. In general, it does not matter whether a participant on the bus is a power ampli er

or an UCC1 USB-CAN converter, so that

can be operated on a single CAN-bus. Since

the CAN-interfaces of all appliances are

galvanically separated from the rest of the

circuitry, network cabling also carries a common ground conductor (CAN_GND) ensuring that all

CAN-interfaces in the network are connected to a common ground potential. The UCC1 provides the

are connected in parallel to serve as input and output (for connecting through) for the data transfer within

the remote-network. The CAN-bus has to be terminated at both ends using 120

terminator plugs, two

of which – CAN-TERM 120

Ω

– are supplied with the UCC1. Connect one of these to the RJ-45 socket

of the rst and the other to the socket of the last appliance on the CAN-bus

Page 12

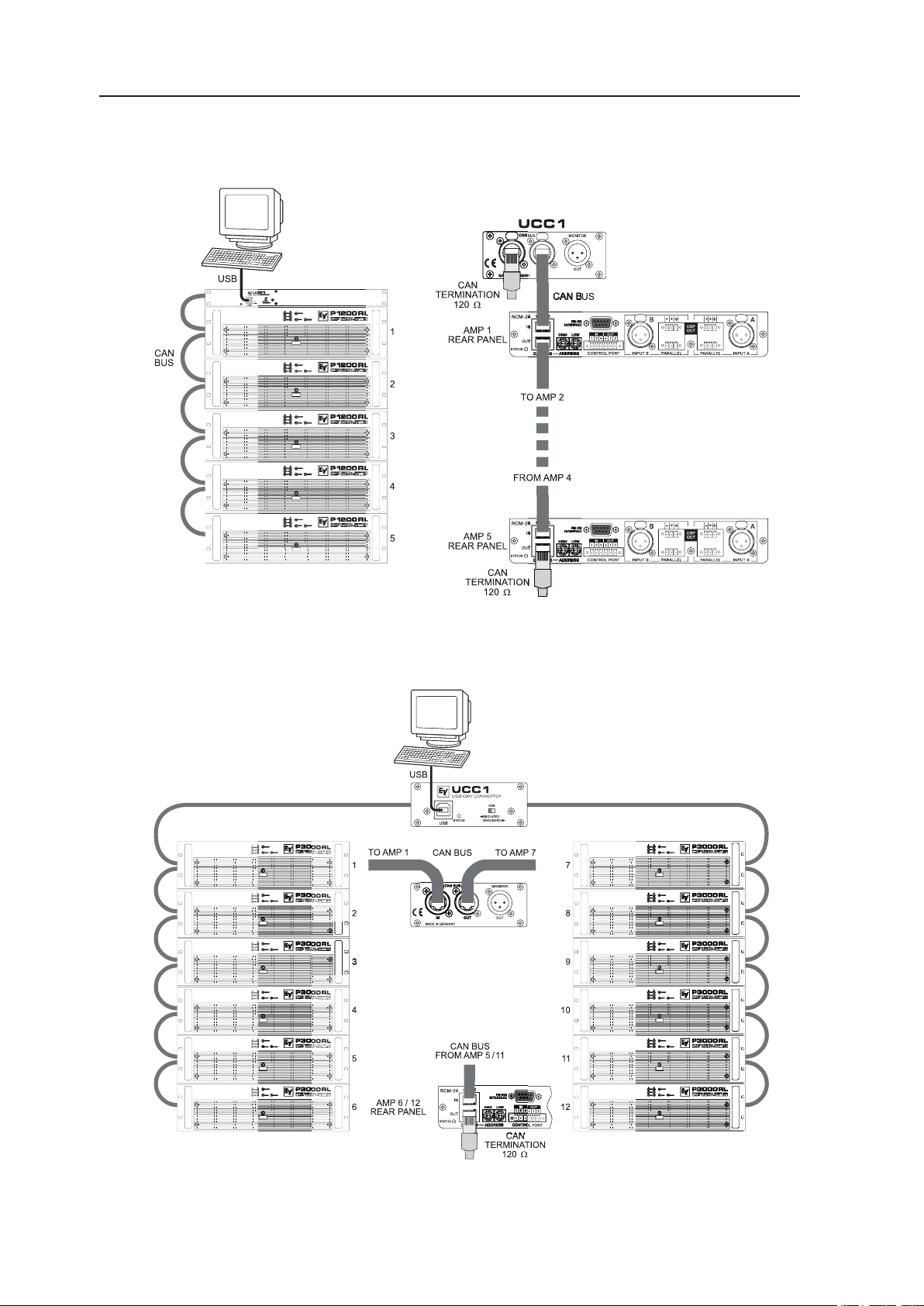

The following diagrams show examples of the data-bus wiring for different order of size:

System with 5 amps and one UCC1 / PC at the beginning of the bus

Terminators at the UCC1 ( rst unit on the bus) and at amp 5 (last unit on the bus)

System with 2 amp-racks and an UCC1 / PC in the middle

Terminators at amp 6 ( rst unit on the bus) and amp 12 (last unit on the bus)

Page 13

System with several amp-racks and several UCC1 / PCs

Terminators at amp 10 ( rst unit on the bus) and amp 16 (last unit on the bus)

the power amp inputs and outputs. This monitor-bus allows software-controlled monitoring of the input and

output signals of all power amps that are included in the remote network, without the need for additional wiring.

The monitor signal is present at the UCC1’s XLR-type MONITOR Output connector for further distribution

to (e.g.) a mixing console to be monitored via headphones or an active monitor speaker connected

Page 14

The CAN-bus allows using different data rates, with the data

works allow baud rates up to 500kbit/s.

exceeds 1,000m

500 kbit/s

250 kbit/s

250 m

500 m

62.5 kbit/s

20 kbit/s

2500 m

5000 m

According to the ISO 11898-2 standard, CAN-bus data transfer cabling has to be carried out using

Twisted-Pair cables with or without shielding providing a characteristic impedance of 120

Ω

a CAN-bus need to be terminated with 120

termination-plugs.

The maximum bus-length depends on the actual data transfer rate, the kind of data transfer cable being

coherencies for CAN-networks consisting of up 64 participants

Cable for data Transmission

Termination

Cable Diameter

0 ... 40 m

Ω

/m

0.25 ... 0.34 mm²

AWG23, AWG22

Ω

40 ... 300 m

/m

0.34 ... 0.6 mm²

AWG22, AWG20

500 kbit/s bei 100 m

300 ... 600 m

Ω

/m

0.5 ... 0.6 mm²

AWG20

... 300

600 ... 1000 m

Ω

/m

0.75 ... 0.8 mm²

AWG18

Ω

... 300

Ω

62.5 kbit/s bei 1000 m

With longer cables and many participants on the CAN-bus, termination resistors with higher impedance than the

speci ed 120

are recommended to reduce the ohmic load of the interface drivers and therefore the voltage drop

The following table is meant for rst assessment of necessary cable diameters for different bus lengths

and bus-participant numbers

32

64

0.25 mm² bzw. AWG24

0.34 mm² bzw. AWG22

0.34 mm² bzw. AWG22

250 m

0.34 mm² bzw. AWG22

0.5 mm² bzw. AWG20

0.5 mm² bzw. AWG20

500 m

0.75 mm² bzw. AWG18

0.75 mm² bzw. AWG18

Additionally, the length of branch lines – for participants that are not directly connected to the CAN-bus

– is also of importance. For data transfer rates of up to 125kbit/s, the maximum length of a single stub

cable should not exceed 2m. For higher bit rates a maximum length of only 0.3m is still permissible. The

entire length of all branch lines should not exceed 30 m.

General Note:

As long as only short distances (up to 10m) are concerned, common RJ-45 patch cables with

Ω

characteristic impedance (AWG 24 / AWG 26) can be used for the cabling inside of a rack-

shelf system. The previously outlined guidelines for network cabling are mandatory as far as the

.

Page 15

The following tables allow determining power supply and cabling requirements. The values of the

column „1/8 max. Output“ are relevant for „normal“ operation. These values are based on operating the

The power drawn from the mains network is converted into acoustic output power to feed the connected

auxiliary means for calculating the temperatures inside of a rack-shelf system/cabinet and the ventilation

efforts necessary. The column “Pd” lists the leakage power in relation to different operational states. The

column “BTU/hr” lists the dispensed heat amount per hour

[V]

[A]

[W]

out

[W]d [W]

(3)

230V

0.558585

290

(1)

Ω

Ω

230V

6.40

2 x 380

425

(1)

230V

2030

2 x 600

830

2832

(1)

230V

6.60

2 x 200

830

2832

(2)

Ω

Ω

230V

3.80

675

2 x 75

525

(1)

Ω

Ω

230V

3.78

670

2 x 50

570

(1)

Ω

Ω

230V

9.69

2 x 500

870

2969

Alarm Operation (-3dB)

(1)

230V

7.27

2 x 250

870

2969

[V]

[A]

[W]

out

[W]d [W]

(3)

230V

0.457070

239

(1)

Ω

Ω

230V

4.97

920

2 x 280

360

(1)

Ω

Ω

230V

8.16

2 x 450

680

2320

(1)

Ω

Ω

230V

5.13

960

2 x 150

660

2252

(2)

230V

2.90

520

2 x 56.3

407.5

(1)

230V

2.84

505

2 x 35

435

(1)

Ω

Ω

230V

7.32

2 x 350

710

2423

Alarm Operation (-3dB)

(1)

Ω

Ω

230V

5.48

2 x 175

680

2320

Page 16

Page 17

Page 18

WICHTIGE SICHERHEITSHINWEISE

WICHTIGE SERVICEHINWEISE

20

AUSPACKEN & GARANTIE

INSTALLATIONSHINWEISE

23

23

23

23

CONTROL PORT

23

ADDRESS

25

25

26

GROUND-LIFT SCHALTER

26

26

VERKABELUNG

27

28

CAN-BUS

30

30

31

SPECIFICATIONS / TECHNISCHE DATEN

32

34

35

ABMESSUNGEN

36

Page 19

WICHTIGE SICHERHEITSHINWEISE

ecks soll den Anwender auf nicht isolierte Leitungen

führen können.

sowie Servicehinweise in der zum Gerät gehör-

enden Literatur aufmerksam machen.

2.

3.

5.

Spritzwasser ins Geräteinnere eindringen kann. Platzieren Sie keine mit Flüssigkeiten gefüllte Objekte, wie Vasen

oder Trinkgefässe, auf dem Gerät ab.

6.

Verwenden Sie zum Reinigen des Gerätes ausschliesslich ein trockenes Tuch.

7.

Verdecken Sie keine Lüftungsschlitze. Beachten Sie bei der Installation des Gerätes stets die entsprechenden

8.

Vermeiden Sie die Installation des Gerätes in der Nähe von Heizkörpern, Wärmespeichern, Öfen oder anderer

Wärmequellen.

9.

Verwenden Sie mit dem Gerät ausschliesslich Zubehör/ Erweiterungen, die vom Hersteller hierzu vorgesehen sind.

WICHTIGE SERVICEHINWEISE

ACHTUNG:

die nicht in der Bedienungsanleitung beschrieben sind, ausser Sie sind hierfür quali ziert. Überlassen

Sie sämtliche Servicearbeiten und Reparaturen einem ausgebildeten Kundendiensttechniker.

Trenntransformator zu verwenden.

3.

Vor einem Umbau mit Nachrüstsätzen, Umschaltung der Netzspannung oder sonstigen Modi kationen ist das Gerät

stromlos zu schalten.

verbunden sind (sekundär), betragen 6mm und sind unbedingt einzuhalten.

5.

Spezielle Bauteile, die im Stromlaufplan mit dem Sicherheitssymbol gekennzeichnet sind, (Note) dürfen nur durch

Originalteile ersetzt werden.

6.

auch die Beschaffenheit des Arbeitsplatzes.

8.

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART )

Page 20

20

Sie haben sich mit einer Endstufe der PRECISION SERIES von Electro-Voice

für ein Gerät modernster Technologie entschieden.

triebssicherheit. Jede Endstufe ist mit dem RCM-24 Remote Control Modul ausgestattet, welches

die zentrale Kon guration, Steuerung und Überwachung aller relevanten Endstufenparameter (wie

Ausgangsstrom, -spannung, Lastimpedanz, ...) ermöglicht.

senen Lautsprecher. Zu diesen Schutzschaltungen gehören dynamische Audio-Limiter, DC/HF-Protec-

tions, Back-EMF-Protection, Inrush Current Limiter, Short Circuit Protection

turüberwachung der Endtransistoren und der Netztransformatoren.

gewährleistet. Die Luftführung ist Front-to-Rear, was den problemlosen Betrieb in grossen und

schmalen Endstufen-Racks ermöglicht.

einen vollständigen Überblick über den

gesamten Systemzustand und die

temparameter. Das RCM-24 Modul

erlaubt die Anbindung an ein Remote Control Netzwerk mit bis zu 250 Endstufen. Ein komplettes

z. B. Einschaltstatus, Temperatur, Aussteuerung, Limiting, Ansprechen von Schutzschaltungen, Ab-

weichungen der Lastimpedanz usw., werden zentral erfasst und dargestellt. Dadurch

eingegriffen werden. Eine automatische Reaktion auf Über- oder Unterschreitung bestimmter

der beiden Endstufenkanäle überwacht. Jede Über- oder Unterschreitung der eingestellten

werden so während des normalen Anlagenbetriebs erkannt und dargestellt. Eine wesentlich

genauere Überprüfung der angeschlossenen Lautsprecher ermöglicht die integrier-

te Impedanz-Messfunktion. Dabei wird mit Hilfe des internen Signal-Generators und der

gen über den gesamten Frequenzbereich gemessen und als Impedanzkurve am PC Bild-

schirm dargestellt. Der gemessene Impedanzverlauf kann jederzeit mit einem Referenz-

wert verglichen werden, wodurch schon geringste Lautsprecherdefekte oder Mängel erkennbar sind.

Page 21

21

che Signalverarbeitungsfunktionen zur Verfügung. Enthalten sind insgesamt 20 parametrische

sich die Steuereingänge der Endstufen zur netzwerkunabhängigen Umschaltung auf ein ande-

ein absoluter Spitzenwert für digitale Audiogeräte.

AUSPACKEN & GARANTIE

Öffnen Sie die Verpackung und entnehmen Sie die Endstufe. Zusätzlich zu dieser Bedienungsanleitung

ausgefüllt ist, denn nur so können Sie etwaige Garantieansprüche geltend machen. Sie haben

auf das Gerät 36 Monate Garantie, die ab dem Zeitpunkt der Aushändigung durch den Händler gilt.

die Entlüftung an der Geräterückseite nicht behindert wird. Für den Einbau in Gehäuse und Gestell-

schränke ist zu beachten, daß eine ausreichende Belüftung der Geräte möglich ist. Zwischen der End-

stufen Rückseite und der Schrank/Rack-Innenseite ist ein freier Luftkanal bis zur oberen Rack- oder

temperatur der übrigen im Gestellschrank be ndlichen Geräte beachtet werden.

jedem Fall Einbauschienen oder die als Zubehör

erhältlichen Rackeinbauwinkel NRS 90235

der Frontblende zu verhindern.

Achtung:

starken Staubablagerungen und starken Vibrationen

Wenn die Endstufe direkt von einem kalten an einen warmen Ort gebracht wird, kann sich Feuchtigkeit

auf Innenteilen niederschlagen. Das Gerät darf erst in Betrieb genommen werden, wenn es sich

auf die geänderte Temperatur erwärmt hat (nach etwa einer Stunde). Sollte ein fester Gegenstand

oder Flüssigkeit in das Gehäuse gelangen, trennen Sie sofort die Stromquellen vom Gerät ab und

Zur Reinigung des Gerätes dürfen keine Sprühmittel verwendet werden, da diese dem Gerät schaden

44.45

1/2

Page 22

22

zeige nicht leuchtet, ist das Gerät nicht mit dem Stromnetz verbunden, die

welcher über das RCM-24 oder über Easy Remote aktiviert werden kann.

Wenn die PROTECT-Anzeige au euchtet, hat eine der internen Schutzschaltungen

wie Übertemperatur, Kurzschluss, Back-EMF, Hochfrequenz am Ausgang.... ange-

sprochen. Die Endstufen werden in diesem Fall über die Ausgangsrelais von der Last

getrennt, um etwaige Schäden an den Lautsprechern oder der Endstufe

selbst zu verhindern. Die Fehlerursache, beispielsweise eine kurzgeschlossene

wartet werden, bis die Endstufe sich selbständig wieder in den normalen Betriebs-

zustand schaltet.

verlischt diese Anzeige.

trieben wird. Eine höhere Eingangsspannung hat keine Erhöhung der Spitzenausgangs-

spannung zur Folge.

tisch, da der interne Limiter Eingangspegel bis zu +21dBu auf einen Klirrfaktor von

ca. 1% ausregeln kann. Leuchtet diese LED jedoch dauerhaft sollte die Lautstärke

in der Mitte der Frontblende wird das Gerät eingeschaltet. Eine

dass der Leitungsschutzschalter des Stromnetzes beim Einschalten der Endstufe anspricht. Die

wodurch etwaige Einschaltgeräusche effektiv unterdrückt werden. Während dieser Verzögerung

Wurde das Gerät z.B. im Standby Modus per POWER Schalter ausgeschaltet, so wird es sich nach

dem Einschalten wieder in diesem Modus be nden.

Page 23

23

steckverbindungen, die im Lieferumfang enthalten sind, erfolgen. Die XLR-Eingangsbuchsen

sind nach IEC Norm 268 beschaltet. Für den Fall, dass die Eingänge potenzialfrei sein müssen,

geschalteten Schraubsteckverbindungen erfolgen. Die Buchsen PARALLEL ermöglichen aber

auch ein einfaches „Durchschleifen“ des Signals zu weiteren Endstufen ohne aufwändige Splitkabel.

An der Buchse DSP OUT liegt das DSP-Ausgangssignal, also das Signal hinter dem digitalen Signal-

gelangt entsprechend verstärkt an die Endstufenausgänge.

z.B. zur Leistungserweiterung. Das Ausgangssignal ist elektronisch symmetrisch, der Nennpegel

Ω

Widerstände auf +5V (offen). Zum Aktivieren können die Steuereingänge über externe

Zustand (Off) hochohmig sind. Im aktiven Zustand (On) sind die Ausgänge gegen Masse geschlossen.

oder Relais ansteuern. Der +5V Referenzanschluss dient zur Versorgung der extern angeschlossenen

gemeldet werden. Nähere Hinweise zur Kon guration des Control Ports nden Sie in

der IRIS Dokumentation.

zur Presetumschaltung oder zur Parameterkontrolle.

symmetrisch mit einer Eingangsemp ndlichkeit von

+6dBu (1.55V) für den direkten Betrieb mit Misch-

Page 24

24

se können die Remote Verstärker problemlos in Medien- und Touchpanel-Steuerungen integriert

werden. Programmierhinweise und eine vollständige Protokollbeschreibung nden Sie in der

ADDRESS

des Verstärkers ein. In einem CAN-Netzwerk können Sie die Adressen

01 bis 250 (FA hex) verwenden. Achtung: Jede Adresse darf im System nur

einmal vorkommen, da es sonst zu Netzwerk-Kon ikten kommt. Die

Adresseinstellung erfolgt in Hexadezimal. Der Wahlschalter LOW ist

das niederwertige Digit, der Schalter HIGH ist das höherwertige Digit.

Adress-Tabelle:

Adresse

Adresse

008

0 ... F

090 ... F

0 ... F

A

0 ... F

2

0 ... F

32 ... 47

0 ... F

3

0 ... F

48 ... 63

C

0 ... F

4

0 ... F

64 ... 79

0 ... F

208 ... 223

5

0 ... F

80 ... 95

0 ... F

224 ... 239

6

0 ... F

96 ... 111

0 ... A

240 ... 250

7

0 ... F

CAN-Bus angesteckt ist. Wenn der Verstärker mit Adresse 0 eingeschaltet wird, werden

sämtliche internen Parameter auf 0 bzw. Bypass und das Routing auf 2-in-2 gestellt. Der Ver-

stärker verhält sich dann völlig linear, die Signalverarbeitungsfunktionen sind deaktiviert.

Jeder Verstärker hat zwei RJ-45 Buchsen für den Remote CAN-Bus.

Weiterschleifen des Remote-Netzwerkes. Zur Verkabelung im Rack können

Abschlusswiderstand (im Lieferumfang).

Ausführliche Richtlinien zur Verdrahtung und Buslänge nden Sie im

An den beiden RJ-45 Buchsen liegt auch das symmetrische Audio-

Page 25

EASY REMOTE

Über Easy-Remote kann die Endstufe auf einfache Weise ferngesteuert,

ein- und ausgeschaltet werden. Die Easy Remote Funktion kommt

nur bei Geräten ohne RCM-24 Modul zum Tragen. Eine Steuerung

von Geräten mit RCM-24 Modul per Easy Remote ist nicht sinnvoll.

EASY REMOTE IN

Werden die Pins der EASY REMOTE IN Buchse offen gelassen bzw. mit +5V beaufschlagt, so schaltet

das Gerät ein. Bei einer Verbindung der Pins oder 0V vom Steuerausgang, schaltet das Gerät in

den Standby Modus.

EASY REMOTE SLAVE

An EASY REMOTE SLAVE können weitere Geräte mit Easy Remote Funktion angeschlossen werden

(z.B. zur Rack-ON/OFF Steuerung bei mehreren Geräten in einem Rack).

Das Einschalten der Slave-Geräte erfolgt zeitverzögert um ein Ansprechen von Netzsicherungen

zu vermeiden.

ENDSTUFENAUSGÄNGE

RÜCKSEITE

Die LED STATUS dient zur Kontrolle der Kommunikation am CAN-Bus.

Wenn die Adresse 00 eingestellt und die Endstufe softwaremässig vom

CAN-Bus abgekoppelt ist, blinkt die LED regelmässig alle 3 Sek. kurz

auf.

Sobald eine Kommunikation am CAN-Bus erkannt wurde, wird die LED immer dann für mindestens

100 ms aktiviert, wenn die Endstufe selbst Daten auf den CAN-Bus sendet.

Die STATUS LED kann auch vom PC aktiviert werden. Die LED der betreffenden Endstufe blinkt dann

in einem schnellen regelmässigen Rhythmus, alle anderen Status-LEDs im System bleiben dunkel.

Diese Funktion dient zur Überprüfung der Kommunikation und zur schnellen Identikation einer

Endstufe in einem grösseren System (s. a. IRIS Dokumentation).

Für die Endstufenkanäle A und B sind 4-polige Schraubklemmen vorgesehen.

Über zwei eingebaute Audio-Ausgangsübertrager wird die Nennausgangs-

spannung der Endstufe auf 100V bzw. 70V für Lautsprechernetze

transformiert. Je nach Konguration steht die entsprechende Ausgangs-

spannung potentialfrei an den Ausgangsklemmen zur Verfügung.

Die Anzahl der maximal anschliessbaren Lautsprecher ist erreicht, wenn die

Gesamtleistungsaufnahme des Lautsprechernetztes dem Nennleistungswert der Endstufe entspricht.

Der Nennlastwiderstand der Endstufe sollte dabei nicht unterschritten werden.

Die Nennleistungswerte und Nennlastwiderstände entnehmen Sie bitte dem Kapitel „Technische Daten“.

Vorsicht: Die Ausgänge können im Betrieb berührungsgefährliche Spannungen annehmen. Die

angeschlossenen Lautsprecherkreise sind aus diesem Grund gemäss den geltenden

Sicherheitsbestimmungen zu installieren. Die Installation darf nur durch entsprechend

geschulte Fachkräfte durchgeführt werden.

Für das Errichten und Betreiben von 100V-Lautsprecheranlagen ist die VDE-Bestimmung

DIN VDE 0800 zu beachten.

Besonders bei 100V-Lautsprecheranlagen für Alarmierungszwecke sind alle Schutz massnahmen für die Bemessungsklasse 3 auszulegen. Vor der Inbetriebnahme der

Endstufe muss in jedem Fall die an der Klemmleiste montierte Abdeckung

geschlossen werden.

25

Page 26

26

Auslieferungszustand

220V, 230V, 240V

70V Ausgangsspannung

Achtung:

durch Ziehen des Netzsteckers sichergestellt werden.

Alle Schrauben zur Haubenbefestigung entfernen

- Gerät durch Abnehmen der Haube öffnen

Auf Printplatte 86276:

für 100V Ausgangsspannung: Brücke R56 schliessen

für 70V Ausgangsspannung: Brücke R56 öffnen

die Endstufe zusammen mit anderen Geräten in einem 19“-Rack betrieben

wird, sollte der Schalter in Stellung GROUNDED stehen. Wird die Endstufe

aus. Die Sicherung darf nur gegen eine gleichwertige Sicherung mit

gleicher Strom-, Spannungs- und Auslösecharakteristik getauscht werden.

durchbrennen, kontaktieren Sie bitte die

Alle an das Gerät angeschlossenen Kabel, insbesondere das

Alle Schrauben zur Befestigung der Ausgangsbuchsenblende

entfernen.

Zur Auswahl der Ausgangsspannung dienen die Steckkontakte

sprechenden Stecker (grau hinterlegt) ab und stecken ihn auf

den Steckkontakt für die gewünschte Spannung

Page 27

27

Als NF-Verbindung wählen Sie am besten symmetrisch ausgelegte Kabel (2 Signaladern + Schirm-

ge echt) mit XLR-Stecker. Obwohl alle Endstufeneingänge auch unsymmetrisch beleget werden

symmetrischen Verbindung dar. Die meisten Audiogeräte verfügen über symmetrisch aufgebaute Aus-

gänge. Der Schirm im Kabel verbindet bei symmetrischer Signalführung alle metallischen Gehäuse

XLR-Steckerbelegung

XLR (male)

XLR (female)

tive-, Industrie- und Sicherheits-Bereich durchgesetzt und über Jahre hinweg bewährt hat. Der

CAN-Bus ist eine symmetrische serielle Schnittstelle zur Übertragung von Kommandos und Da-

ten. Die Steuerung der Endstufen erfolgt von einem PC mit IRIS Intelligent Remote & Integra-

ted Supervision Software. Als Interface zwischen PC und CAN-Bus dient der UCC1 USB-CAN

Converter. Pro CAN-Bus lassen sich 100 Endstufen bis zu einer maximalen Kabellänge von

terer CAN-Bus notwendig. Insgesamt kann die IRIS Software bis zu 250 Endstufen verwalten.

alle Teilnehmer sind an einer einzigen Zweidrahtleitung (Twisted-Pair-Kabel, geschirmt oder ungeschirmt)

angeschlossen, wobei die Verkabelung von einem Busteilnehmer zum nächsten verlaufen muss. Jedes

auch eine gemeinsame Masseleitung (CAN_GND) in der Netzwerkverkabelung mitgeführt. Damit

Jeder Bus-Teilnehmer hat 2 RJ-45 Buchsen für den Remote CAN-Bus. Die Buchsen sind parallel

geschaltet und dienen als Eingang und Ausgang (zum Weiterschleifen) des Remote-Netzwerkes.

Ω

Abschlusswiderstand terminiert werden. Zu

diesem Zweck liegen dem UCC1 zwei Abschluss-Stecker CAN-TERM 120

bei. Stecken Sie diese

Abschluss-Stecker in die freien RJ-45 Buchsen des ersten und des letzten Gerätes am CAN-Bus.

oder ein UCC1 USB-CAN Converter ist. Somit

Auch mehrere UCC1 und PCs am CAN-Bus

sind möglich. Ingesamt können bis zu 100

werden. Da die CAN-Schnittstel-

Page 28

28

ordnungen:

System mit 5 Verstärkern und einem UCC1 / PC am Bus-Anfang

Abschluss-Stecker am UCC1 (Bus-Anfang) und am Verstärker 5 (Bus-Ende)

System mit 2 Racks und einem UCC1 / PC in der Mitte

Abschluss-Stecker an Verstärker 6 (Bus-Anfang) und Verstärker 12 (Bus-Ende)

Page 29

29

System mit mehreren Racks und mehreren UCC1 / PCs

Abschluss-Stecker an Verstärker 10 (Bus-Anfang) und Verstärker 16 (Bus-Ende)

zum Abhören der Endstufeneingänge und –ausgänge mitgeführt. Dieser Monitorbus ermöglicht das

softwaregesteuerte Abhören der Eingangs- oder Ausgangssignale aller im Remote-Netzwerk

vorhandenen Endstufen ohne zusätzlichen Verdrahtungsaufwand. Am UCC1 liegt das Monitor

eingang gelegt und über Kopfhörer oder direkt über eine aktive Monitorbox abgehört werden.

Page 30

30

zur Buslänge ist. Wenn das Netzwerk nur eine geringe

Ausdehnung hat, sind höhere Baudraten bis zu 500 kbit/s

500 kbit/s

250 kbit/s

250 m

500 m

62.5 kbit/s

20 kbit/s

2500 m

5000 m

zugsweise Twisted-Pair-Leitungen, geschirmt oder ungeschirmt, mit einem Wellenwiderstand von

zum Einsatz kommen. Als Leitungsabschluss muss an beiden Enden ein Abschlusswiderstand

von 120

Ω

vorgesehen werden.

tenübertragungskabels sowie von der Anzahl der Bus-Teilnehmer. Die folgende Tabelle zeigt

die wesentlichen Zusammenhänge für CAN-Netzwerke mit bis zu 64 Teilnehmern:

Abschlusswider-

stand

Widerstandsbelag

0 ... 40 m

Ω

/m

0.25 ... 0.34 mm²

AWG23, AWG22

Ω

40 ... 300 m

/m

0.34 ... 0.6 mm²

AWG22, AWG20

500 kbit/s bei 100 m

300 ... 600 m

Ω

/m

0.5 ... 0.6 mm²

AWG20

... 300

600 ... 1000 m

Ω

/m

0.75 ... 0.8 mm²

AWG18

Ω

... 300

Ω

62.5 kbit/s bei 1000 m

spezi zierten 120

empfohlen, um die ohmsche Last für die Schnittstellentreiber und damit den Spannungs-

abfall von einem zum anderen Leitungsende zu verringern.

schiedliche Buslängen und verschiedene Anzahl der Bus-Teilnehmer:

Anzahl der Geräte am CAN-Bus

32

64

0.25 mm² bzw. AWG24

0.34 mm² bzw. AWG22

0.34 mm² bzw. AWG22

250 m

0.34 mm² bzw. AWG22

0.5 mm² bzw. AWG20

0.5 mm² bzw. AWG20

500 m

0.75 mm² bzw. AWG18

0.75 mm² bzw. AWG18

Zu beachten ist noch die Länge der Abzweigleitungen, wenn ein Teilnehmer nicht direkt am CAN-Bus

angeschlossen ist. Diese Stichleitungen sollten bei Datenübertragungsraten bis zu 125 kbit/s

eine Einzellänge von max. 2 m und bei höheren Bitraten von max. 0,3 m nicht überschreiten.

Grundsätzlich gilt:

Wellenwiderstand

verwendet werden (AWG 24 / AWG 26), wenn es sich nur um kurze Strecken handelt (bis zu 10 m).

oben genannten Richtlinien für die Netzwerkverkabelung einzuhalten.

Page 31

31

verwendet werden. Die Endstufe wurde hier mit VDE-Rauschen bei

der maximalen Ausgangs-

der Aussteuerungsgrenze betrieben wird.

WÄRMEENTWICKLUNG IN DER ENDSTUFE

d

). Die durch Verluste entstehende Wärmemenge verbleibt u.U. im Rack und

d

zeigt die Verlustleistung bei verschiedenen Betriebszuständen. Die Spalte BTU/hr

zeigt die abgegebene Wärmemenge je Stunde.

[V]

[A]

[W]

out

[W]d [W]

(3)

230V

0.558585

290

(1)

Ω

Ω

230V

6.40

2 x 380

425

(1)

230V

2030

2 x 600

830

2832

(1)

230V

6.60

2 x 200

830

2832

(2)

Ω

Ω

230V

3.80

675

2 x 75

525

(1)

Ω

Ω

230V

3.78

670

2 x 50

570

(1)

Ω

Ω

230V

9.69

2 x 500

870

2969

Alarmbetrieb (-3dB)

(1)

230V

7.27

2 x 250

870

2969

[V]

[A]

[W]

out

[W]d [W]

(3)

230V

0.457070

239

(1)

Ω

Ω

230V

4.97

920

2 x 280

360

(1)

Ω

Ω

230V

8.16

2 x 450

680

2320

(1)

Ω

Ω

230V

5.13

960

2 x 150

660

2252

(2)

230V

2.90

520

2 x 56.3

407.5

(1)

230V

2.84

505

2 x 35

435

(1)

Ω

Ω

230V

7.32

2 x 350

710

2423

Alarmbetrieb (-3dB)

(1)

Ω

Ω

230V

5.48

2 x 175

680

2320

(1)

Aussteuerung mit Sinus-Signal

(2)

Aussteuerung mit VDE-Rauschen

(3)

Page 32

32

70V

70V

28.5209.8

THD = 1%, 1kHz

410W

400W

590W

580W

THD = 1%, 1kHz, RMS, rated load

74.8V

75.4V

THD < 0.2%, 20Hz ... 20kHz

350W

350W

500W

500W

THD < 0.2%, 20Hz ... 20kHz

70V

70V

THD = 1%, 1kHz, no load

87V

88V

THD at rated output power,

< 0.05%

60Hz, 7kHz

< 0.1%

3.15kHz, 15kHz

< 0.2%

Crosstalk Attenuation

> 80dB

-3dB, ref. 1kHz

45Hz ... 22.5kHz

at 100Hz / 1kHz, 8

> 300 / > 200

Signal to Noise Ratio, Ampli er

A-weighted

Signal to Noise Ratio, System

A-weighted

at rated output power @ 4

+6dBu (1.55V)

+21dBu (8.7V)

20Hz ... 20kHz, balanced

20k

CMR

80dB

Output Voltage

Output Impedance

< 100

600

AD & DA Conversion

24 Bit, Sigma-Delta, 128 x Oversampling, Linear Phase

Sample Rate

48kHz

48 bit

Volume Control, Routing,

X-Over

Compressor / Limiter,

System (ampli er) at rated conditions, both channels driven, rated loads, unless otherwise speci ed.

Page 33

33

CAN-Bus, 10 ... 500 kbit/s, RJ-45 (PC Control)

Control Port / GPIO

6-pol. Phoenix

2 Control Inputs

Active / ON

0V (< 0.8V)

2 Control Outputs

Inactive / OFF High (Open Collector)

Active / ON

Low (< 0.5V / I = 0.7A)

Input Voltage

+32.0V max.

Switching Current 1.0A max.

240V, 230V, 120V, 100V / 50Hz ... 60Hz,factory con gured

max. output voltage at rated load

690W

870W

Audio limiters, High temperature, DC, HF, Back-EMF,

Cooling

483 x 132.5 x 426

Weight

22kg

24kg

Optional Input Transformer

Optional Output Transformer

Page 34

34

Page 35

35

ADA

D

DAD

A

ADA

D

24 BIT

DSP

SRAM

512k x

8

GAINRANGING

24 BIT ADC

GAINRANGING

24 BIT ADC

LP

F

LP

F

DUAL

24 BIT DAC

INPUT

PARALLEL

-15V

+15V

AMPLIFIER

INTERFACE

CONTROL / SUPERVISION:

INPUT / OUTPUT LEVEL METER

PILOT SIGNAL GENERATOR

PILOT SIGNAL DETECTION

IMPEDANCE MEASUREMEN

T

AMP INPUT CH. A (SIGNALA / SENSINA)

AMP INPUT CH. B (SIGNALB / SENSINB)

ANALOG

POWER

SUPPLY

CLOCK

12.288 MHz

POWER

SUPPLY

CPU +

FLASH

RAM

A

D

CAN

UART

RESET

WATCHDOG

EEPRO

M

AMP TEMPERATURE (TEMP)

OUTPUT CURRENT CH.A (OUTCURA+/-)

OUTPUT CURRENT CH.B (OUTCURB+/-)

AMP OUTPUT RELAYS (TIMER)

OUTPUT VOLTAGE CH.A (OUTVOLA+/-)

STANDBY POWER SOURCE

+5V

+3.3V

DC

DC

RJ-45

MONITOR BUS

CAN / RS-485

+5V

CAN / RS-485

TRANSCEIVER

MONITOR

OUT B

MONITOR

IN A

MONITOR

IN B

MONITOR

OUT A

SLAVE OUT A

SLAVE OUT B

CLOCK

SPI

D

A

D

A

DUAL ADC

DUAL AD

C

I/O

DEVICE

ADDRESS

STATUS

SIGNAL PROCESSING:

FILTERS, X-OVER

DELAY

COMPRESSOR, LIMITER

ROUTING, LEVEL, POLARITY

I/O

MAINS POWER ON/OFF (POWER_ON)

AMP TYPE CODE (AMP_ID1-8)

LIMITER CH. A (LIMOUTA)

LIMITER CH. B (LIMOUTB)

GPIO

CONTROL

PORT

8

OUTPUT VOLTAGE CH.B (OUTVOLB+/-)

INPUT LEVEL CH. B

INPUT LEVEL CH.

A

+5V

GND

GROUND

FAULT

DETECTION

AMP PROTECT (PROTECT)

CHASSIS

8

STANDBY/ON SIGNAL (STANDBY)

4

CHANNEL A

INPUT

CHANNEL B

PARALLEL

GROUND FAULT CH. A (GNDFLTA)

GROUND FAULT CH. B (GNDFLTB)

VU INPUT A

VU INPUT B

DSP DIGITALBOARD

80477

NRS 90227

NRS 90208

NRS 90208

Page 36

36

5,5

440,5

131

483

132,5

389,5

440

Page 37

373839

Page 38

Page 39

Page 40

40

Telex Communications Inc., 12000 Portland Ave. South, Burnsville, MN 55337, Phone: +1 952-884-4051, FAX: +1 952-884-0043

Germany

Subject to change without prior notice.

www.electro-voice.de

Loading...

Loading...