Electro-Voice P3000, P3000 Series Service Manual

P3000

PRECISION SERIES

SERVICE MANUAL

The lightning flash with arrowhead symbol, within an equilateral triangle is intended to alert the user to the presence

of uninsulated “dangerous voltage” within the product’s

enclosure that may be of sufficient magnitude to constitute

a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintance (servicing) instructions in the

literature accompanying the appliance.

IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a damp cloth.

7. Do not block any of the ventilation openings.

Install in accordance with the manufactures instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that produce heat.

9. Only use attachments/accessories specified by the manufacturer.

10. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed to rain or moisture, does not operate normally, or has

been dropped.

For US and CANADA only:

Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third grounding prong.

The wide blade or the third prong are provided for your safety. When the provided plug does not fit into your outlet, consult an

electrican for replacement of the absolete outlet.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to be obeyed when

servicing the appliance.

2. Use of a mains separator transformer is mandatory during maintenance while the appliance is opened, needs to be

operated and is connected to the mains

3. Switch off the power before retrofitting any extensions, changing the mains voltage or the output voltage.

4. The minimum distance between parts carrying mains voltage and any accessible metal piece (metal enclosure),

respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not connected

to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the security symbol (Note) is only permissible

when using original parts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the location where the appliance is being serviced have to be strictly

obeyed. This applies also to any regulations about the work place itself.

8. All instructions concerning the handling of MOS - circuits have to be observed.

Note:

SAFETY COMPONENT (HAS TO BE REPLACED WITH ORIGINAL PART ONLY)

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualified personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the

Operating Instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

1-2

TECHNICAL SPECIFICATIONS

at rated output power 8ohms, one channel

driven, unless otherwise specified

Output Power

(20Hz - 20kHz /THD≤ 0,1%)

into8 Ohms 2 x 750 W

into 4 Ohms 2 x 1200 W

into 8 Ohms bridged 1 x 2400 W

Output Power

(1kHz / THD = 1,0%)

into 8 Ohms 2 x 850 W

into 4 Ohms 2 x 1300 W

into 8 Ohms bridged 1 x 2800 W

Technical Specification

Frequency Response 10 Hz - 30 kHz /

1dB

Max. Output Level 91V / RMS

before Cliping, reference 1 KHz / THD =

1%

Voltage Gain 26 dB (constant gain option)

reference 1kHz

Input Sensitivity 0 dBu/0.775 V

at rated output power 6 dBu/1.55 V

reference 1 kHz

Maximum Input Level 21 dBu / 9 V

Input Impedance 20 kOhm

active balanced

THD < 0.05%

at rated output power

MBW = 80 kHz, f = 1kHz

IMD - SMPTE < 0.01%

60 Hz, 7 kHz, typical

IMD - SMPTE < 0.01%

60 Hz, 7 kHz, at rated output power

Signal / Noise Ratio > 105 dB

A-weighted, RMS to rated output level,

Input sensitivity + 6dBu

Crosstalk < -70 dB

at rated output power reference 1 kHz

Damping Factor > 300

internal, 1kHz

DIM 30 < 0.01%

DIM 100 < 0.01%

Slew Rate internal > 40 V / ms

Power Consumption 1650 VA

1/8 rated output power 4 Ohm

Dimensions (WxHxD) 483x132.5 x 426mm

19 x 5.2 x 16.77 (in)

Weight 29 kg (63.9 Ibs)

Optional Input Transformer 90176

DESCRIPTION

EV power amplifiers of the PRECISION

SERIES meet the stringent requirements of

tough touring applications. They are protected against over-temperature, overload,

shorted outputs, radio frequency interference

and DC faults. The power transistors are

protected from damage from reverse feeding

of electrical energy by means of an additional

special protective circuit. For the so-called

soft-start, the power outputs are switched on

delayed via relays. An inrush current limiter

circuit prevents the mains fuses from being

blown.

Maximum precision is also guaranteed as

regards mechanical construction and finish.

The robust steel chassis features remarkable torsion resistance and is specially designed to cope with the tough wear and tear

associated with going on tour. Thermal

stability is guaranteed by several low noise

3-stage fans which also means that they can

be used inside the studio.Comparator circuits constantly compare the power amplifiers’ input and output signal and control the

limiters under non-linear operating conditions. They protect the loudspeakers from

overload due to power stage clipping. The

PRECISION SERIES power amplifiers feature excellent transmission properties. The

power amplifier topology also makes for

extremely low distortion rates. Distortion factor (THD), intermodulation distortion

(SMPTE-IM) and transient intermodulation

distortion (DIM 30 and DIM 100) are so low

that they are only detectable with the most

sophisticated measuring equipment. Generously dimensioned power supplies with lowleakage toroidal-core transformers provide

considerable headroom well above the nominal ratings. V/I foldback limiter circuits

were deliberately not included in the PRECISION SERIES power amplifiers to facilitate operation at complex loads up to a phase

angle of +/- 90°.The inputs are electronically

balanced on XLR connectors. (Isolation

transformers can be retrofitted). Direct Outs

in the form of XLR connectors (male), to loop

the signal through, are also standard features.

Architects and engineers

specifications

P 3000

STEREO POWER AMPLIFIER

PRECISION SERIES

The modes DUAL/Stereo or PARALLEL/Mono can be selected via the Input

Routing Switch. Furthermore, the PRECISION SERIES power amplifiers can also be

operated in “Mono Bridged” mode. The front

panel accommodates the dB-calibrated input

Gain controls which are designed as especially precise and safe-to-operate detented

potentiometers. The LED display provides

information about the power amplifers’ operating status. For the two channels, they

demonstrate readiness to operate, whether

there is a signal at the input or output, when

the Limiters have been activated and whether

one of the protective features has been

triggered. The power outputs Channel A,

Channel B and Bridged Out are available on

Speakon connectors. The rear side of the unit

accommodates the ON/OFF switches for the

integrated Hi and Lo cut filters, a groundlift

switch which separates the housing from the

circuit ground thus helping to prevent hum

loops and the operating modes selector to

mono bridged operation. They also feature

extremely quiet fans with front-to-rear airflow,

facilitating operation in large and narrow

amplifier racks.

# SERVICE INFORMATION

WARNING: No user serviceable parts inside.

Extremely hazardous voltages and currents

may be encountered within the chassis. The

servicing information contained within this

document is only for use by Electro-Voice

Authorized warranty repair stations and qualified service personnel. To avoid electric

shock DO NOT perform any servicing other

than that contained in the Operating instructions unless you are qualified to do so.

Otherwise, refer all servicing to qualified

service personnel.

NOTICE: Modification to Electro-Voice products is not recommended. Such modifications shall be at the sole expense of the

person(s) or company responsible, and any

damage resulting therefrom shall not be covered under warranty or otherwise.

#.1 ELECTRO-VOICE UNIFORM LIMITED

WARRANTY STATEMENT

Electro-Voice products are guaranteed

against malfunction due to defects in materials or workmanship for a specified period, as

noted in the individual product-line statement(s) below, or in the individual product

data sheet or owner’s manual, beginning with

the date of original purchase. If such malfunction occurs during the specified period, the

product will be repaired or replaced (at our

option) without charge. The product will be

returned to the customer prepaid. Exclusions

and Limitations: The Limited Warranty does

not apply to: (a) exterior finish or appearance;

(b) certain specific items described in the

individual product-line statement(s) below, or

in the individual product data sheet or owner’s

manual; (c) malfunction resulting from use or

operation of the product other than as specified in the product data sheet or owner’s

manual; (d) malfunction resulting from misuse or abuse of the product; or (e) malfunction occurring at any time after repairs have

been made to the product by anyone other

than Electro-Voice or any of its authorized

service representatives. Obtaining Warranty

Service: To obtain warranty service, a customer must deliver the product, prepaid, to

Electro-Voice or any of its authorized service

representatives together with proof of

purchase of the product in the form of a bill

of sale or receipted invoice. A list of authorized service representatives is available from

MARK IV AUDIO Deutschland

Hirschberger Ring 45

D - 94315 Straubing

Postfach 0254 D- 94302 Straubing

Tel.: ++49 (0)9421/7060

Fax: ++94(0)9421/706265

MARK IV AUDIO (Europe) AG

Keltenstr. 5

CH-2563 Ipsach

Tel.: ++41 (0)32-516833

Fax: ++41 (0)32-511221.

Incidental and Consequential Damages

Excluded: product repair or replacement

and return to the customer are only remedies provided to the customer. Electro-Voice shall not be liable for any incidental or

consequential damages including, without

limitation, injury to persons or property or

loss of use. Some states do not allow the

exclusion or limitation of incidental or consequential damages so the above limitation or exclusion may not apply to you.

Other Rights: This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Electro-Voice Electronics are guaranteed

against malfunction due to defects in materials or workmanship for a period of three (3)

years from the date of original purchase.

Additional details are included in the Unifom

Limited Warranty statement.

#. 2 TECHNICAL ASSISTANCE

For applications assistance or other technical

information, contact the Applications Engineer. You can call or write:

MARK IV AUDIO Deutschland

Hirschberger Ring 45

D - 94315 Straubing

Postfach 0254 D- 94302 Straubing

Tel.: ++49 (0)9421-7060

Fax: ++49 (0)9421-706265

MARK IV AUDIO (Europe) AG

Keltenstr. 5

CH-2563 Ipsach

Switzerland

Tel.: ++41 (0)32-516833

Fax: ++41 (0)32-511221

Specifications subject to change without

notice

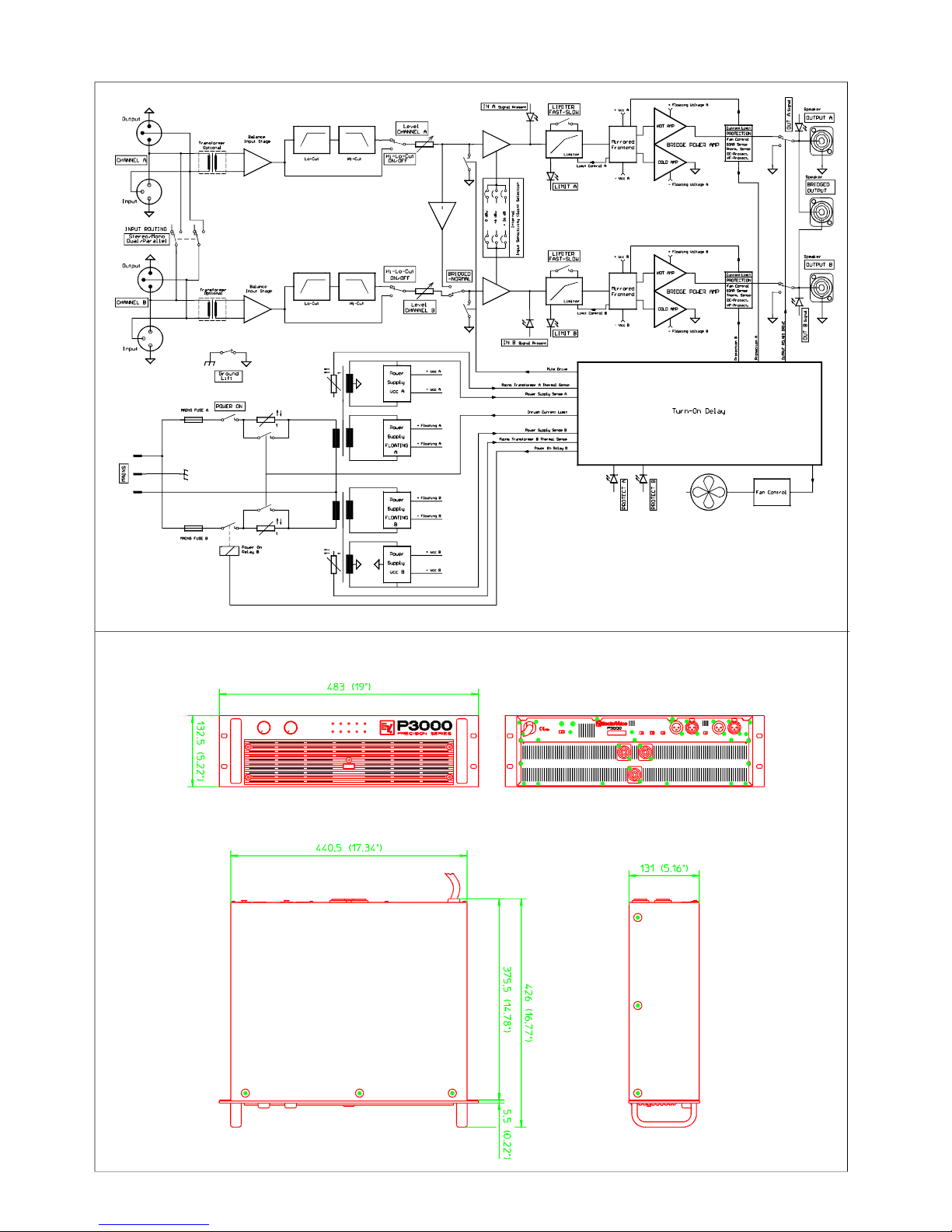

DIMENSIONS

BLOCK DIAGRAM

1

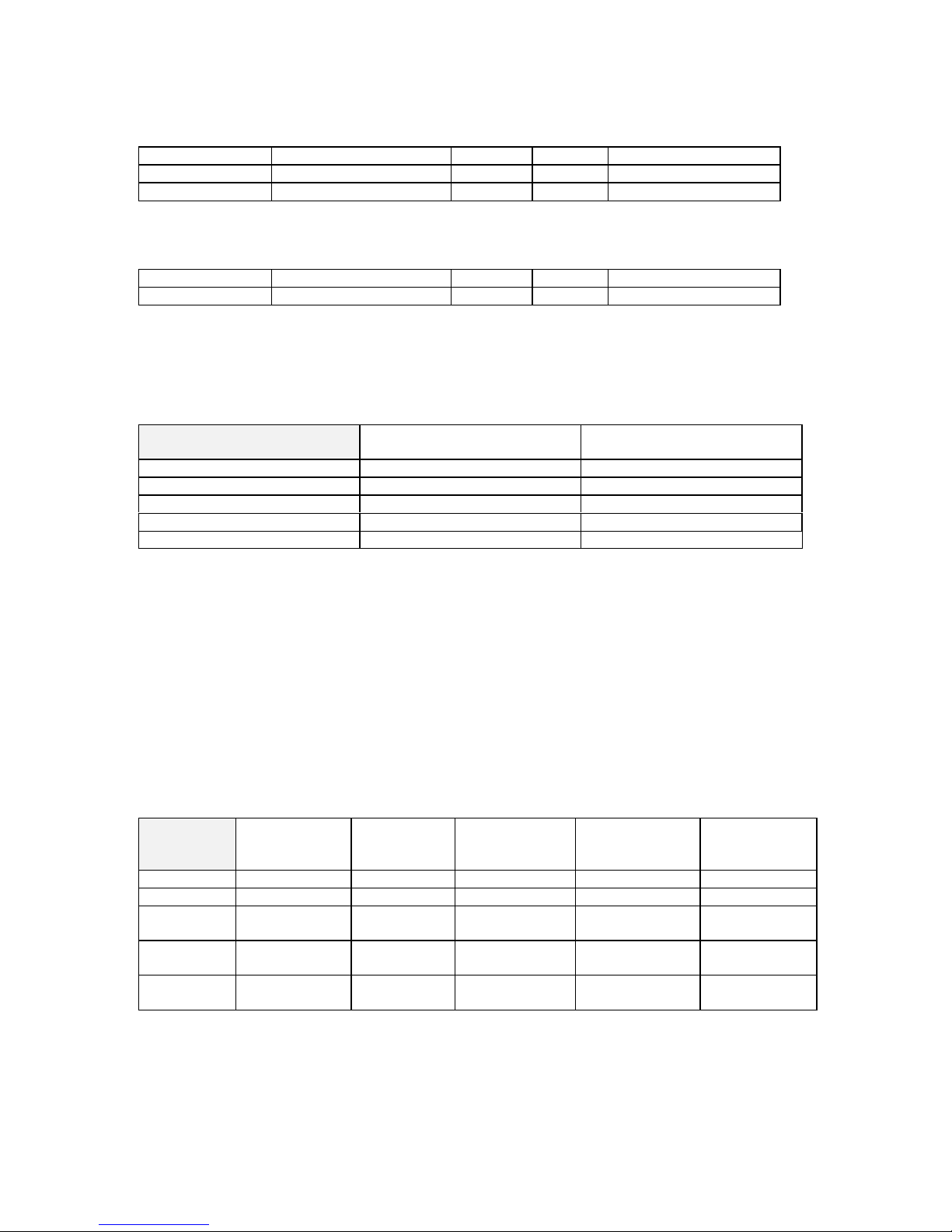

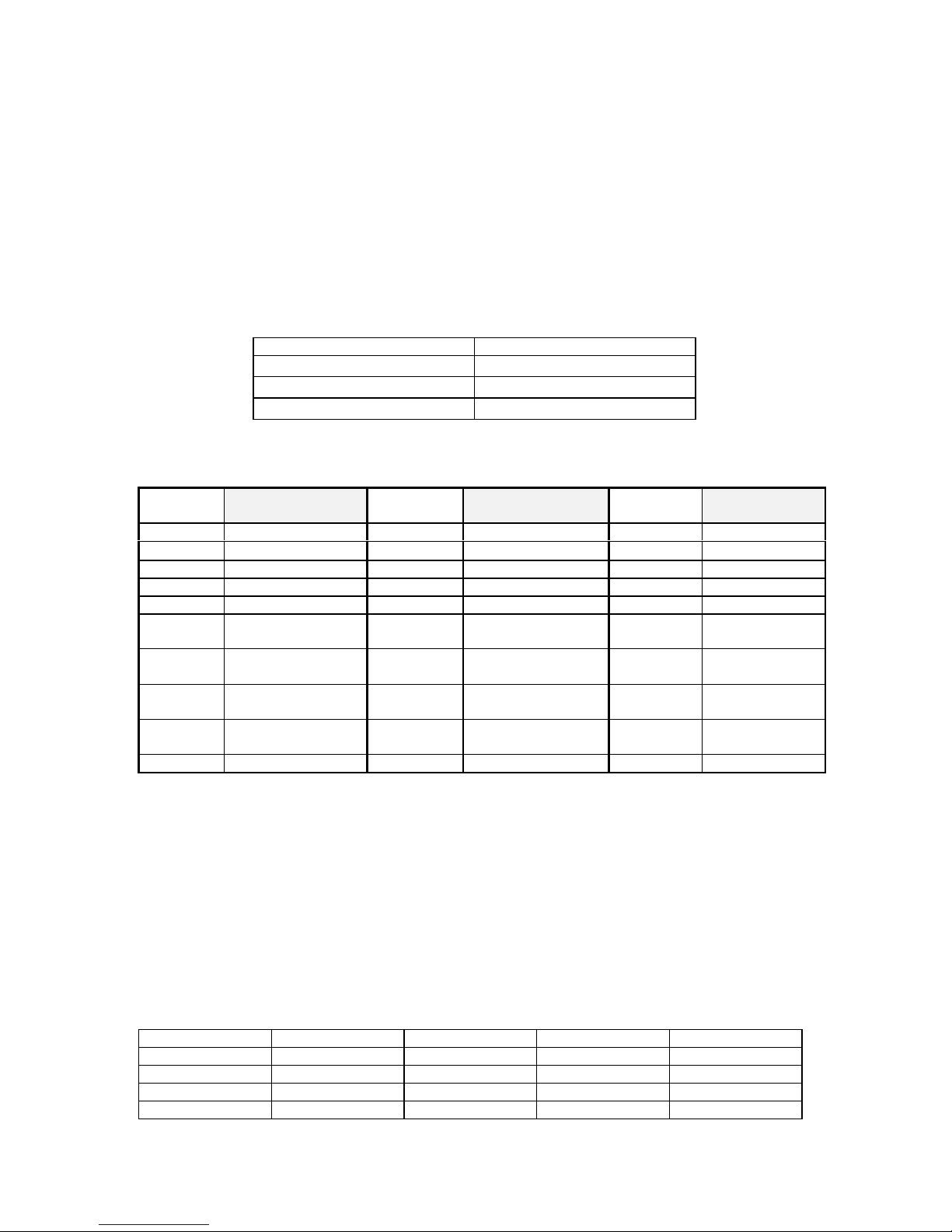

SPECIFICATIONS: P3000 entire unit

Measuring Standard IEC 268 part 3IHF-A

0 dBu = 775 mV (RMS)

A. POWER SUPPLY

1. voltage supply AC

2. nominal supply voltage, depending on the model: 120V/230V/240V

3. nominal mains frequency: 50 - 60 Hz

4. nominal power consumption (2x1200W/4Ω): 4100 W

5. nominal power consumption (2x120W/4Ω): 1500 W

6. power consumption at 1/8 of the nominal power (150W/4Ω): 1650 W

7. deviation range of the power supply: -10 % … +10 %

B. INPUT PROPERTIES

• level control fully open

Input Nominal input level

(nominal source EMK)

select jumper internally

Nominal

output power

Nominal load

impedance

0 dBu +6 dBu +26 dB

Channel A/B +1 dBu +7 dBu +14 dBu 750 W

8 Ω

Channel A/B 0 dBu +6 dBu +13 dBu 1200 W

4 Ω

Channel A/B -2 dBu +4 dBu +11 dBu 1500 W

2 Ω

Channel BRIDGED 0 dBu +6 dBu +13 dBu 2400 W

8 Ω

Channel BRIDGED -2 dBu +4 dBu +11 dBu 3000 W

4 Ω

Maximum input level: +21 dBu

C. OUTPUT PROPERTIES

• nominal output power with THD = 0.1 %, 20 Hz … 20 kHz, MBW = 80 kHz

• maximum output power at 1 kHz with THD = 1 %, MBW = 80 kHz

Output connector Nominal

load

impedance

Nominal output

power Dual

Mode

Maximum output

power Dual Mode,

THD=1 %

Single channel

output

power)

1

Nominal

output

voltage

SPEAKER A/B

8 Ω

750 W 850 W 950 W 77.5 V

SPEAKER A/B

4 Ω

1200 W 1300 W 1700 W 69.3 V

SPEAKER A/B

2 Ω

1500 W 1800 W 2000 W 54.8 V

SPEAKER BRIDGED

8 Ω

2400 W 2600 W 3400 W 138.6 V

)1 measured with Dynamic Headroom Test-Signal according to IHF-A: 1 kHz Burst, 20ms ON, 480 ms OFF

D. Idling output voltage

Output connector SPEAKER A/B SPEAKER BRIDGED

Max. idling voltage

91 V (RMS) 182 V (RMS)

E. Stabilizing

with nominal load impedance, Dual Mode, standard output voltage

8 Ω 4 Ω

Stabilizing

0.325 % 0.686 %

Stabilizing level

0.028 dB 0.059 dB

2

F. FREQUENCY RESPONSE

• -3 dB level drop, referenced to the level at the standard frequency of 1 kHz

• the power amplifier's border frequencies are at 13 Hz and 40 kHz respectively, referenced to -1 dB

Amplification frequency response

Input Output f (u) f (o) Remarks

INPUT A/B SPEAKER A/B <10 Hz 75 kHz HI-LO-CUT Off

INPUT A/B SPEAKER A/B 20 Hz 35 kHz HI-LO-CUT On

Distortion-limited transmission range (performance bandwidth)

• THD = 0.1 %, 1/2 nominal power at 4 ohms, MBW = 500 kHz

Input Output f (u) f (o) Remarks

INPUT A/B SPEAKER A/B <10 Hz 48 kHz HI-LO-CUT Off

G. PHASE RESPONSE ±30° (20 Hz - 20 kHz, HI/LO-CUT off)

H. INPUT IMPEDANCE 20 kΩ (20 Hz … 20 kHz)

I. AMPLITUDE NON-LINEARITY

Amplitude non-linearity Remarks

nominal overall distortion

<0.05 % MBW = 80 kHz, f = 1 kHz

standard overall distortion

<0.02 % MBW = 80 kHz, f = 1 kHz

IMD-SMPTE

<0.01 % 60 Hz, 7 kHz

DIM 30

<0.01 % 3.15 kHz, 15 kHz

DIM 100

<0.01 % 3.15 kHz, 15 kHz

J. CROSSTALK - at f = 1 kHz less than <-70 dB

K. DAMPING FACTOR - internal at f = 1 kHz >300

at f = 100 Hz >400

L. SLEW RATE - internal >40 V/µs

M. NOISE INTERFERENCE

- U(F) = external voltage un-weighted with B = 22 Hz … 22 kHz, effective value (IEC 268-1)

- U(G) = noise voltage, frequency-weighting filter according to CCIR-468-3, quasi peak weighted (IEC 268-1)

- U(A) = interference voltage A-weighted, dB(A), effective value (IEC 268-1)

- Signal-to-noise ratio referenced to a nominal output voltage of 69.3 V (1200W/4ohms)

- HI/LO-CUT ON, GND LIFT = GROUNDED

Interference

output voltage

S/N ratio Equivalent input

interference

voltage

Equivalent input

interference level

Residual

interference

output voltage

U(F)

< 615µV > 101 dB < 6.9µV < -101 dBu < 435µV

U(G)

< 3.65 mV > 85.5 dB < 41µV < -85.5 dBu < 1.55mV

U(A)

i.s.=0dBu

< 490µV > 103 dB < 5.5µV < -103 dBu < 345µV

U(A)

i.s.=6dBu

< 245µV > 109 dB < 5.5µV < -103 dBu < 170µV

U(A)

Gain=26dB

< 110µV > 116 dB < 5.5µV < -103 dBu < 90µV

The S/N ratio (A-weighted) at max. output voltage at 4Ω is >103 dB.

N. DIMENSIONS

Height : 132.5 mm (3 HU)

Width : 483 mm

Depth : 426 mm

O. WEIGHT m = 29 kg

3

P. EXTENSIONS optionally available 2 x input transformer NRS 90176

MEASURED SPECIFICATIONS: P3000 entire unit

Measurement conditions, unless differently specified:

• tolerance of measured values: ∆X = ±1.5 dB

• measuring frequency: f = 1 kHz

• stated levels refer to: U = 775 mV (0 dBu)

• level controls set to their clockwise limits

• pin assignment of the XLR-type connectors: PIN 1: GROUND

PIN 2: + INPUT

PIN 3: - INPUT

• source resistance for the induction via the XLR-type connector: R(Q) = 50 Ω

• MAIN-PCB numbers relate to the models as follows:

Type of unit MAIN - PCB

P3000 / 120 V 86211

P3000 / 230 V 86207

P3000 / 240 V 86207

• MAIN-PCB and POWER-AMP-PCB are provided with service connectors.

The Pin-assignment of these service connectors is as follows:

84157 86207

86211

86207

86211

CNSERV Assignment CNASERV Assignment CNBSERV Assignment

1 Kodierung 1

Limiter A&B OFF

1 n.c.

2 BIAS Hot - Side + 2 Service Limiter A 2 Service Limiter B

3 BIAS Hot - Side - 3 -15V 3 - 15 V

4 Hot - Out 4 GND 4 Fan voltage

5 BIAS Cold - Side + 5 + 15 V 5 Service Fan

Switch

6 BIAS Cold - Side - 6 heat sink temperature

A&B

6 Service Fan

Switch

7 GND 7 + U1 front-end A 7 + U1

front-end B

8 floating voltage + 8 - U1 front-end A 8 - U1

front-end B

9 floating voltage - 9 coding 9 coding

1. Operating voltage: U(B) = 120V/ 230V/ 240V

depending on the model: 50Hz ... 60Hz

2. Deviation limit of the operation voltage: ±10%

3. Power consumption (both channels driven):

3.1. at idling condition P(B) = 180 - 260 W

3.2. at standard operation (120W/4Ω) P(B) = 1500 W

3.3. at nominal condition (1200W/4Ω) P(B) = 4100 W

3.4. at 1/8 of the nominal power (150W/4Ω) P(B) = 1650 W

4. Settings / Adjustments

4.1. IDLING CURRENT ADJUSTMENT

Connect the DC-volt meter at the BIAS measuring points (refer to table) and adjust the idling current via the trim

potentiometer (on the printed board assembly 84157). Adjust both channels of the power amplifier A&B.

Setting Measuring point 1 Measuring point 2 U (DC) BIAS trimmer

BIAS HOT A CNSERV 2 CNSERV 3 15 mV VR1

BIAS COLD A CNSERV 5 CNSERV 6 15 mV VR2

BIAS HOT B CNSERV 2 CNSERV 3 15 mV VR1

BIAS COLD B CNSERV 5 CNSERV 6 15 mV VR2

4

Adjusting the idling current has to be performed at normal room temperature. In case the power amplifier had

previously been operated, it has to be given several hours to cool off.

4.2. FLOATING - SYMMETRY

Immediately after setting the idle current, a symmetry check of the floating voltage has to be performed. The

power amplifier has to be operated in idling condition. DC-volt meters have to be connected between the

measuring points 1 - 2, and 2 - 3. Using the FLOATING-trim potentiometers that are located on the printed

board assembly 86207/86211, the floating voltage is set symmetric to the ground potential. Not the actual

voltage value is relevant but the symmetry of the + floating voltage and the - floating voltage to the ground

potential.

Setting Measuring

point 1

Measuring

point 2

Measuring

point 3

U(DC) Trim

potentiometer

FLOTING SYMMETRIE A CNSERV 8

AMP-A

CNSERV 7

AMP-A

CNSERV 9

AMP-A

ca. ± 67V

VR102

FLOTING SYMMETRIE B CNSERV 8

AMP-B

CNSERV 7

AMP-B

CNSERV 9

AMP-B

ca. ± 67V

VR202

4.3. VCA - OFFSET:

Rhythmically open and short-circuit the service switch S101 respectively S201 which are located on the printed

board assembly 86207/86211. Use VR101 respectively VR201 to adjust the power amplifier outputs to their

minimum offset (with oscilloscope to minimal peak value or to the audible minimal volume of the interfering

pulse).

Instead of using the service switch, it is also possible to employ the service connector with short-circuited pins

CNASERV 2 and CNASERV 3 for the power amplifier A, or short-circuited pins CNBSERV 2 and CNBSERV

3 for the power amplifier B.

4.4. ADJUSTING THE METER INSTRUMENTS

• level control set all the way to its clockwise position

• f = 1 kHz

Feed the signal to the inputs A or B so that the IN-LED just lights (U(E) approx. -34 dBu). Adjust the OUT-LED

to approximately the same brightness, using the trim potentiometers VR600 respectively VR601 which are

located on the printed board assembly 86207/86211.

4.5. ADJUSTING THE FANS

Close the service switch S001 on the printed board assembly 86207/86211 or insert a bridge between CNBSERV

5 and CNBSERV 6. Adjust the voltage at CNBSERV 4 to 27.5 V (DC), using the VR700. Switch the service

switch back to normal or detach the bridge.

4.6. GAIN SELECTION:

The power amplifier's input sensitivity can be set using the jumpers J11 … J13 or J21 … J23 which are located

on the printed board assembly 86207/86211. The stated values for the input sensitivity or gain are always

referenced to the level control being set to its fully clockwise position.

CHANNEL A CHANNEL B SELECTION

J11 J21 Input Sensitivity 0 dBu

J12 J22 Input Sensitivity +6 dBu

J13 J23 Gain +26 dB

When shipped, the input sensitivity is set to a value of 0 dBu.

5. Function test

5.1. OUTPUT - offset voltage

DC-voltage measuring at the loudspeaker outputs CHANNEL A/B with U(DC) ≤ ±10 mV.

5.2 LIMITER

5.2.1. Attenuation test

Both channels separately driven with a 1 kHz signal up to U(A) = 89 V (without load). Increase the input voltage

by 10 dB. The LIMITER LED lights and the output voltage ascents by approx. 0.5 dB to 91 volts, with slight

5

clipping. The distortion rate of the limited signal is at THD = 1 % … 2 %. Increasing the input signal up to a

value of +21 dBu should not result in remarkably higher clipping.

5.2.2. LIMITER FAST/SLOW-Test

• tests have to be performed for both channels of the power amplifier individually: testing has to be

performed without load resistors connected.

1.) Drive the power amplifier with a burst signal (f = 1 kHz, 1-10 cycles, rate: ≈ 0.5 sec.) and U(E) =

+10 dB above the nominal input voltage.

2.) When monitoring the output signal via oscilloscope, continuously press the FAST/SLOW-switch.

• SLOW: after 2-3 signal periods, the limiter controlled the major distortion down to a minor residual

distortion (THD = 1 % … 2 %).

• FAST: already after 1-2 signal periods, the limiter controlled the major distortion down to a minor

residual distortion (THD = 1 % … 2 %).

When shipped, the appliance is set to SLOW!

5.3. POWER-ON DELAY:

Approximately 2 seconds after switching the power on, the relays E1 and E3 which are located on the printed

board assembly 86207/86211 and the relay E1 on the printed board assembly 84157 (channel A/B) pull

simultaneously.

5.4. FAN CONTROL:

Upon powering-on the power amplifier, the fans will run for approximately 2 seconds and stop when the power

amplifier has re-gained its "normal" temperature. In idling condition (power-on, no signal present) the fans are

switched between the SLOW and OFF mode, depending on the heat sink's temperature. When the switch S001

on the printed board assembly 86207/86211 is closed, the fans will run with FAST speed. When shipped, the

S001 switch is set to "OPEN"!

Connecting a variable resistor (approx. 50 kΩ) between CNBSERV 5 and CNBSERV 6 allows for testing the

functioning of the fans. During operation, CNASERV 6 can be utilized to monitor the temperature of the heat

sink.

FAN SPEED U(DC)

CNASERV 6

U(DC)

CNBSERV 4

Remarks

Stufe 0 < 6.5 V 0 V Fans are not running

Stufe 1 6.5 V ... 7.5 V 12.5 V

Stufe 2 7.5 V ... 9 V 19.5 V

Stufe 3 9 V ... 12.5 V 27.5 V

Protect > 12.5 V 27.5 V Power amplifier is switched off

5.5. SOAR-PROTECTION TEST:

Channels separately driven up to 69.3 V on 4 Ω. Parallel connect a 0.1 Ω resistor. The protection circuit reacts

and tries continuously to re-start! The protect-LED blinks in the same rhythm.

5.6. SHORT-CIRCUIT CURRENT-LIMITING TEST

testing has to be performed for both channels of the power amplifier individually:

- drive the channel with a burst signal (f = 1 kHz, 1-10 cycles, rate ≈ 1 sec.) without load, with U(A) = 89 V

- connect a load resistor of 1 Ω.

- the short-circuit current-limiter limits the output voltage at the load resistor symmetrically (monitor via

oscilloscope!) to a peak voltage value of 45 V ( approx. 45 A).

5.7. DC-VOLTAGE-PROTECTION TEST

• HI/LO-Cut off, Limiter set to SLOW

testing has to be performed for both channels of the power amplifier individually:

- drive the power amplifier with a test signal (f = 7 Hz) and without load resistor connected.

- at an input voltage of approx. 3 Vpeak the protection circuit reacts and tries continuously to re-start!

The protect-LED blinks with the same frequency.

- Repeat the test with f = 14 Hz; the power amplifier should not switch off.

5.8. HF-PROTECTION TEST

Caution: it is mandatory to drive the power amplifier without load resistors connected. Set the fan service

switch to ON and the HI/LO-Cut to OFF. Switch off the limiter via S102 or by disconnecting the bridge between

CNASERV 1 and CNASERV 3. Drive the power amplifier with a with 7 Vrms and a sine burst of f = 60 kHz

Loading...

Loading...