Page 1

OWNER‘S MANUAL

BEDIENUNGSANLEITUNG

Page 2

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ....................... 3

IMPORTANT SERVICE INSTRUCTIONS ....................... 3

DESCRIPTION ....................... 4

UNPACKING & WARRANTY ....................... 5

INSTALLATION NOTES ....................... 5

FRONT VIEW ....................... 6

REAR VIEW ....................... 7

INPUT A / INPUT B ....................... 7

PARALLEL CONNECTION ....................... 7

DSP OUT ....................... 7

CONTROL PORT ....................... 7

RS-232 INTERFACE ....................... 8

ADDRESS ....................... 8

REMOTE CAN-BUS ....................... 8

EASY REMOTE ....................... 9

POWER AMP OUTPUT ....................... 9

GROUND-LIFT SWITCH ....................... 9

LIMITER ....................... 10

BRIDGED MODE ....................... 10

CABLING ....................... 11

LF-CONNECTION CORDS ....................... 11

REMOTE CONTROL NETWORK ....................... 11

NETWORK EXAMPLES ....................... 12

CAN-BUS ....................... 14

CABLING SPECIFICATIONS ....................... 14

MAINS OPERATION & RESULTING TEMP ....................... 15

SPECIFICATIONS / TECHNISCHE DATEN ....................... 32

BLOCK DIAGRAM AMPLIFIER ....................... 34

BLOCK DIAGRAM RCM-24 ....................... 35

DIMENSIONS / ABMESSUNGEN ....................... 36

INHALT

WICHTIGE SICHERHEITSHINWEISE ....................... 19

WICHTIGE SERVICEHINWEISE ....................... 19

BESCHREIBUNG ....................... 20

AUSPACKEN & GARANTIE ....................... 21

INSTALLATIONSHINWEISE ....................... 21

FRONTSEITE ....................... 22

RÜCKSEITE ....................... 23

INPUT A / INPUT B ....................... 23

PARALLEL ....................... 23

DSP OUT ....................... 23

CONTROL PORT ....................... 23

RS-232 INTERFACE ....................... 24

ADDRESS ....................... 24

REMOTE CAN-BUS ....................... 24

EASY REMOTE ....................... 25

ENDSTUFENAUSGÄNGE ....................... 25

GROUND-LIFT SCHALTER ....................... 25

LIMITER ....................... 26

BRIDGED MODE ....................... 26

VERKABELUNG ....................... 27

NF-VERBINDUNGSKABEL ....................... 27

REMOTE CONTROL NETZWERK ....................... 27

NETZWERK-BEISPIELE ....................... 28

CAN-BUS ....................... 30

LEITUNGSSPEZIFIKATIONEN ....................... 30

NETZBETRIEB & WÄRMEENTWICKLUNG ....................... 31

SPECIFICATIONS / TECHNISCHE DATEN ....................... 32

BLOCK DIAGRAM AMPLIFIER ....................... 34

BLOCK DIAGRAM RCM-24 ....................... 35

ABMESSUNGEN ....................... 36

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

The lightning ash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated „dangerous voltage“ within

the product’s enclosure that may be of sufcient

magnitude to constitute a risk of electric shock to

persons

The exclamation point within an equilateral

triangle is intended to alert the user to

the presence of important operating and

maintance (servicing) instructions in the

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water. Do not expose this apparatus to dripping or splahing and

ensure that no objects lled with liquids, such as vases, are placed on this apparatus.

6. Clean only with a dry cloth.

7. Do not block any of the ventilation openings. Install in accordance with the anufactures instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including ampliers) that produce heat.

9. Only use attachments/accessories specied by the manufacturer.

10. Refer all servicing to qualied service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped

11. To completely disconnect mains power from this apparatus, the power supply cord must be

unplugged..

For US and CANADA only:

Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third

grounding prong. The wide blade or the third prong are provided for your safety. When the provided plug does not

t into your outlet, consult an electrican for replacement of the absolete outlet.

literature accompanying the appliance.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualied personnel only. To reduce

the risk of electric shock, do not perform any servicing other than that ontained

in the Operating Instructions unless you are qualied to do so. Refer all ervicing

to qualied service personnel.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to

be obeyed when servicing the appliance

2. Use of a mains separator transformer is mandatory during maintenance while the appliance is

opened, needs to be operated and is connected to the mains

3. Switch off the power before retrotting any extensions, changing the mains voltage or the output voltage.

4. The minimum distance between parts carrying mains voltage and any accessible metal piece (metal

enclosure), respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not

connected to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the security symbol (Note) is

only rmissible when using original parts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the location where the appliance is being serviced

have to be strictly obeyed. This applies also to any regulations about the work place itself.

8. All instructions concerning the handling of MOS - circuits have to be observed.

NOTE:

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART )

3

Page 4

5

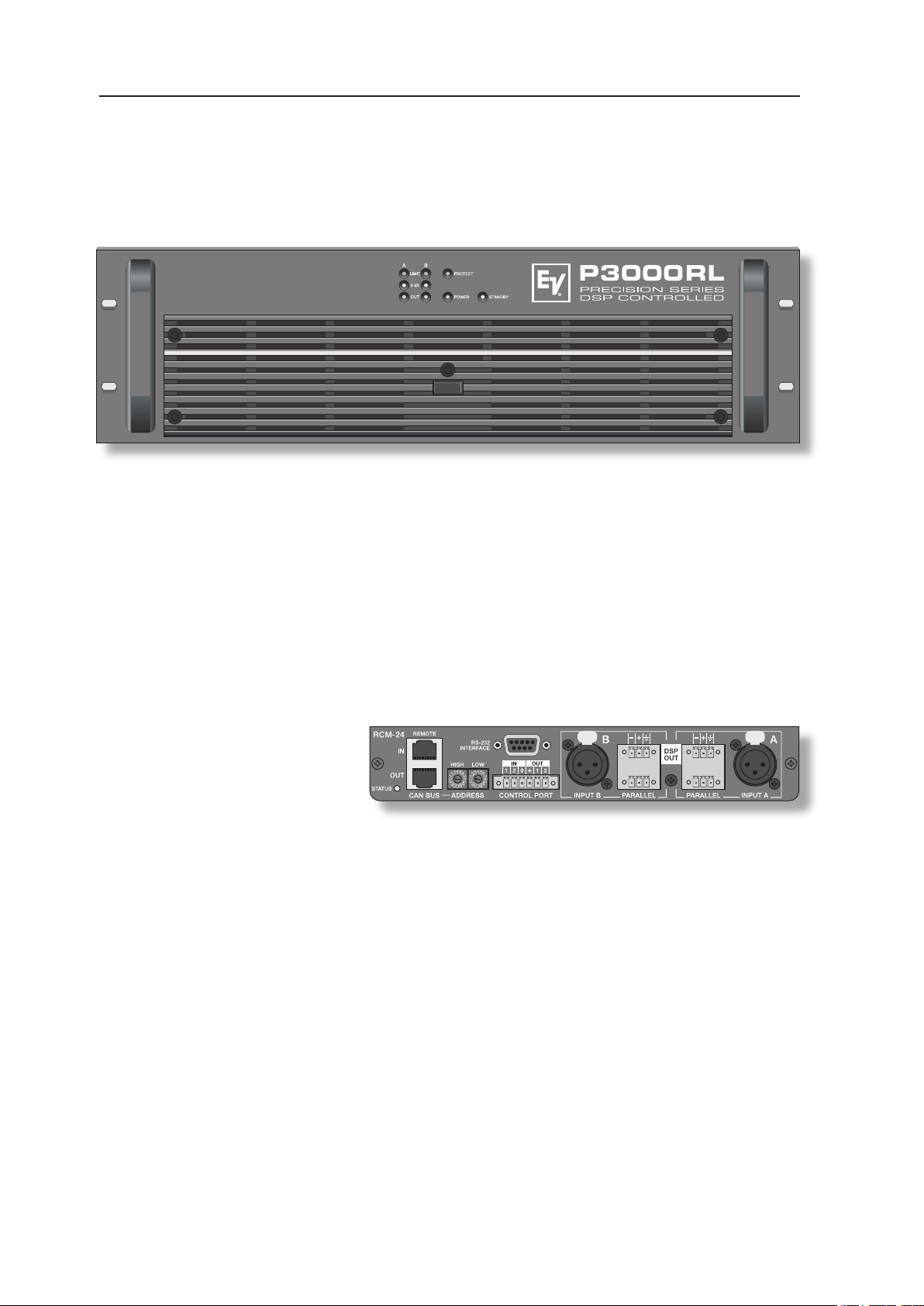

DESCRIPTION

Congratulations! With buying an Electro-Voice PRECISION SERIES power amplier you have chosen

an appliance that employs the most advanced technology.

P-Series power amps combine outstanding audio performance, highest reliability and operational

stability. Each power amplier employs an RCM-24 Remote Control module allowing centralized

conguration, control and monitoring of all relevant power amp parameters (like output current, output

voltage, load impedance, etc.).

The gapless protection circuitry concept not only prevents the power amp itself but also the connected

loudspeaker systems from being damaged. These extensive protections include Dynamic Audio

Limiters, DC/HF-Protections, Back-EMF-Protection, Inrush Current Limiter, Short Circuit Protection

and of course Thermal Overload Protection for the output transistors and mains transformers.

Four-speed high performance fans guarantee outstanding thermal stability at absolute low running

noise. The ventilation is directed front-to-rear allowing trouble-free operation even in smaller amp-racks.

Comprehensively dimensioned power supply units with low-leakage toroidal transformers provide

extensive headroom far above the stated nominal power.

Mechanical construction and workmanship also comply with the highest precision manufacturing

standards. The rigid sheet steel chassis resists even the most wearing tour operation.

The RCM-24 provides full-size

overview of the system’s entire status

and control over all relevant system

parameters at any time.

The RCM-24 module allows integration into a Remote Control Network consisting of up to 250 power

amps. The Windows Software IRIS – Intelligent Remote & Integrated Supervision – allows controlling

and monitoring an entire PA-system from a single or several PCs. Any operational status like initial

power-on status, temperature, modulation, limiting, activation of protections, deviation in the load

impedance, etc., are centrally registered and displayed, which provides the opportunity to take specic

measures prior to the occurrence of critical operational states. Programming an automatic response for

exceeding or falling below specic limits is possible as well. All parameters, e.g. power-on/off, levels,

muting, lters, etc. can be controlled in real-time and saved in any power amp.

Monitoring the connected loudspeaker systems is performed through measuring output currents

and –voltages of the two power amplier channels. Each time the signal falls below or exceeds set

limit values is immediately indicated and logged, thus detecting and indicating short circuits and line

interruption during normal operation. The integrated impedance test function allows more precise

checking the connected loudspeaker systems. The integrated signal generator is employed together

with the current/voltage testing to measure the connected loudspeakers’ and cable’s impedance

plus over the entire frequency range. The resulting impedance graph is displayed on the PC-screen.

Comparing the measured impedance progression to a reference value is possible at all times, which

allows recognizing even the slightest loudspeaker defects or irregularities.

4

Page 5

DESCRIPTION

Next to controlling and monitoring, the RCM-24 Remote Control module provides comprehensive

signal processing functions. It includes a total of 20 parametric lter–, X-over functions, delays, routing

and level control as well as compressors and limiters per channel. All parameters can be freely edited

and stored in the module’s 8 user presets. Independent from network control all DSP-settings (lter,

delay, level) are maintained in case of failure. Additionally, the control inputs of the power amps can be

used for network-independent switching to another preset (e.g. alarm settings with maximum energy

for voice and text announcements).

Therefore, P-Series amps with RCM-24 modules installed full even the highest safety requirements.

When designing the RCM-24, uncompromising audio quality was the highest maxim. AD/DAconversion is performed at a resolution of 24-bit and 128-times oversampling with linear phase; the

internal word length is 48 bits. With this the RCM-24‘s dynamic range reaches 115 dB, which is an

absolute peak value for digital audio appliances.

All conguration, control and monitoring details of P-Series power amps are explained in the

documentation accompanying the PC Windows software IRIS.

UNPACKING & WARRANTY

Carefully open the packaging and take out the power amplier. Next to the power amplier itself, the

package also includes this owner’s manual, the warranty certicate, four stand-feet, six screw-on

connectors (1x 2-pole, 4x 3-pole, 1x 6-pole) plus a set of rack shelf mounting adapters. Please inspect

carefully whether all information in the warranty certicate has been lled in completely, since only a

completely lled in warranty certicate entitles you to stake any warranty claims. The appliance comes

with a 36 months warranty, starting with the date when receiving the good from your dealer. Therefore,

keep the original invoice together with the warranty certicate at a safe place.

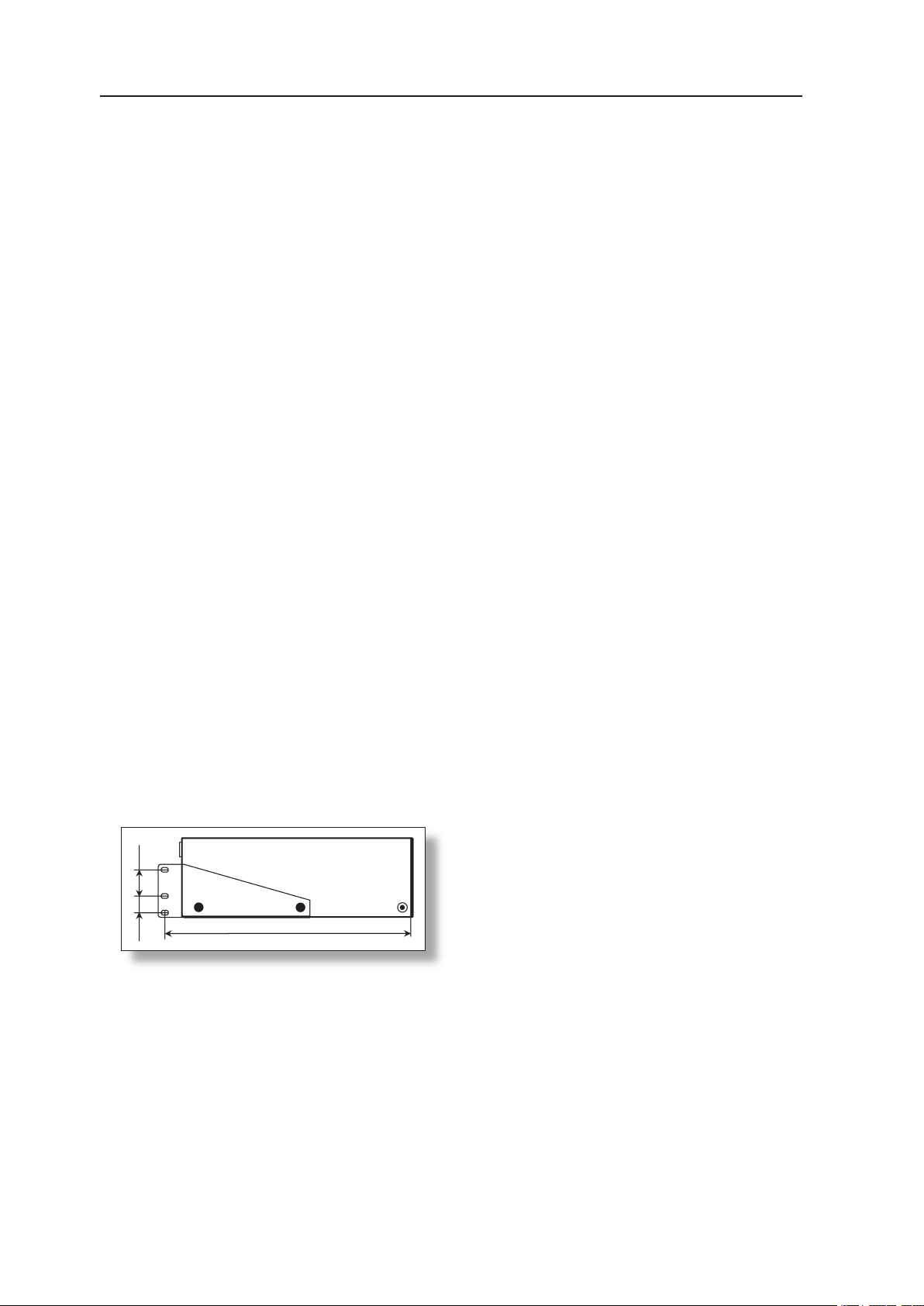

INSTALLATION NOTES

Generally, installing or mounting power amps should be carried out in a way that guarantees

continuously unopposed front-to-rear air circulation. When including an appliance in a closed cabinet

or rack shelf system make sure to provide sufcient ventilation. Leave a gap of at least 60mm x

330mm (up to the cabinet’s top ventilation louvers) for air circulation between the rear of the power

amplier and the cabinet’s/rack’s rear wall. Make sure to leave at least 100mm of space above the

cabinet or rack shelf system. Since the temperature inside of the cabinet or rack shelf system can

easily rise up to 40°C during operation, bearing in mind the maximally allowable environmental

temperature during operation for all other appliances installed in the same rack shelf system is

mandatory.

(also refer to “MAINS OPERATION & RESULTING TEMPERATURE”)

13/4“

44.45

The use of rails or optionally available rack

adapters is mandatory as well when installing

the appliance in a rack shelf system to

prevent the front panel from bending.

31.75

11/4“

Caution: For problem-free operation exceeding the maximally allowable environmental

temperature or +40°C is not permissible.

The power amplier has to be protected against: dripping or splashing water, direct sunlight, high

temperatures or direct inuence of heat sources, high humidity, extensive dust and vibrations.

Condensation on internal parts may occur after transporting the power amplier from a cold into a

warmer environment. In that case operation is only permissible after the appliance has gained the

new temperature (after approximately one hour). If foreign objects or liquids have entered the power

amplier’s enclosure make sure to instantly separate the appliance from the mains power and contact

an authorised DYNACORD service centre for inspection before continuing operation.

Do not use any sprays or solvents for cleaning the appliance, because they might severely damage

the surface of the enclosure or lead to dangerous re hazard.

44.45

151/2“

5

Page 6

7

FRONT VIEW

Use the POWER switch located in the centre of the front panel to switch the appliance’s power

on. The soft-start function prevents current inrush peaks on the mains, which in addition prevents

the mains line protection switch from activating during power-on operation of the power amplier.

The loudspeaker outputs are activated via relay switching with a delay of approximately 2 seconds

effectively attenuating eventual power-on noise. The PROTECT LED lights during the delay time and

the fans run at maximum speed. This is normal to conrm the immaculate operation of the protection

circuitry. Upon power-on, all power amps with RCM-24 Module installed regain the state of operation

prior to the last power-off.

For example: if a power amplier had been switched off using the POWER-switch while being in Standby mode, upon power-on it restarts in this exact mode.

This indicator lights when the power amplier has been switched on. Causes for the

POWER-indicator not lighting are: the appliance is not connected to the mains

network, a defective primary fuse, or the power amplier is set to stand-by operation

(STAND-BY LED lights).

This indicator light when the power amplier is in stand-by mode, which can be

activated from the RCM-24 or via Easy Remote. In stand-by operation only the

internal auxiliary power supply unit is activated. The main power supply unit is

separated from the mains.

The PROTECT LED lights indicating that one of the internal protection circuits

against thermal overload, short-circuit, Back-EMF, HF-occurrence at the output, etc.,

has been activated. In that case, the output relays separate the power amps from

the load connected to prevent the connected loudspeaker systems and the power

ampliers as well from being damaged. Whatever caused the fault – e.g. a short circuited speaker cable – needs to be remedied. In case of thermal overload you have

to wait until the power amplier automatically regains normal operation.

The OUT LED lights as soon as an audio signal of approximately 30dB below full

modulation is present. The LED is dimmed when speaker cables are short-circuited

or a protection circuit has been activated.

The 0dB LED lights when the power amplier is driven at its maximum. Higher input

voltage does not result in higher peak output voltage.

This indicator lights as soon as the integrated dynamic limiter is activated and the

power amplier is driven at the clipping limit or generally at its maximum capacity.

Short-term blinking is not a problem, since the internal limiter trims input levels of up

to +21dBu down to a S/N-ratio of approximately 1%. If, on the other hand, this LED

lights constantly, reducing the volume is recommended to prevent the loudspeaker

systems connected from being damaged by probable overload.

6

Page 7

REAR VIEW

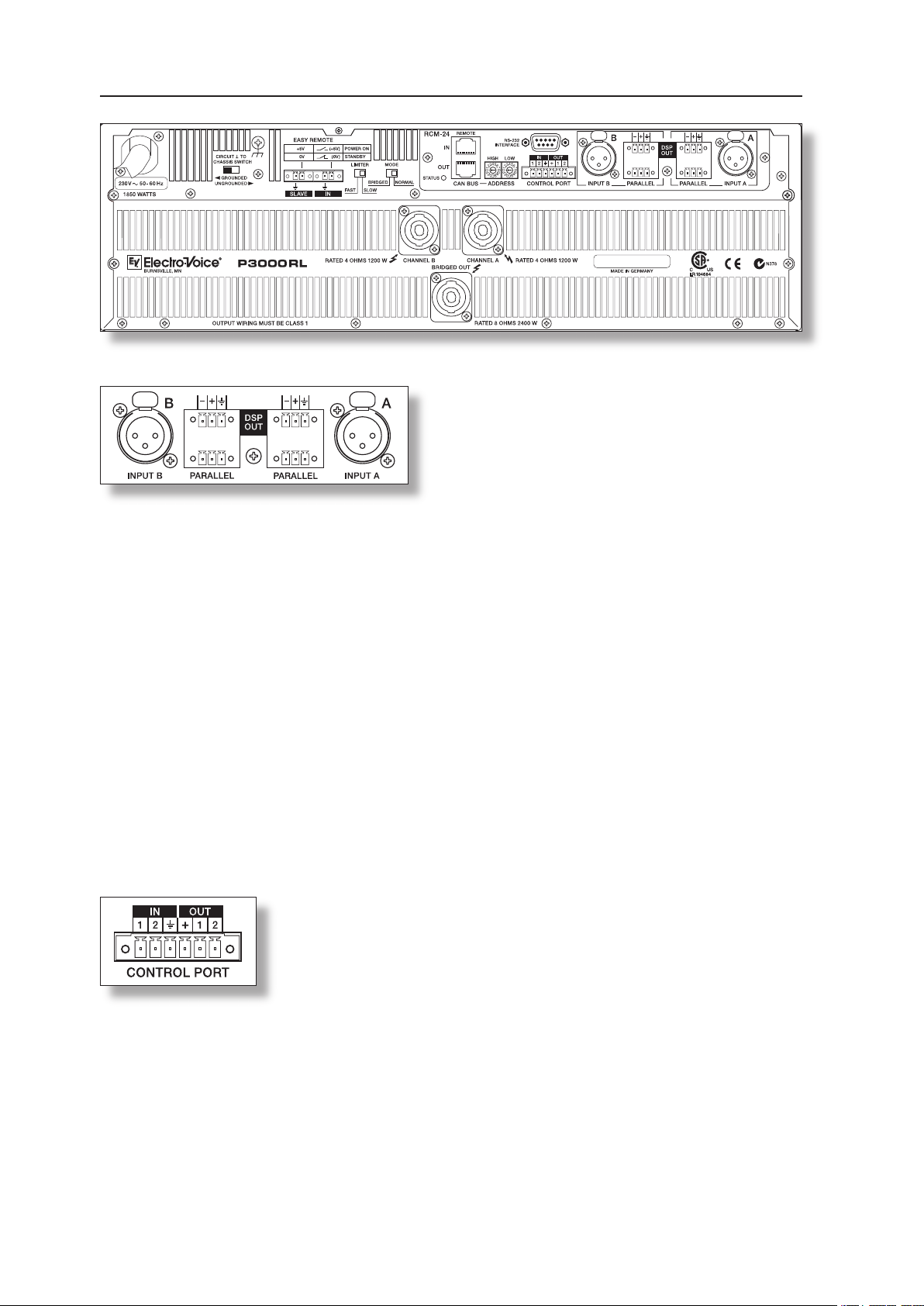

INPUT A / INPUT B

The inputs INPUT A & INPUT B are electronically

balanced offering an input sensitivity of +6dBu (1.55V)

for direct connection of mixing consoles, etc.

Connection can be established via the XLR-type input

connectors or the supplied screw-on connectors,

which are connected in parallel. The pin-assignment

of the XLR-type input connectors is according to the

IEC 268 standard. In case oating inputs are needed, retrotting optionally available input transformers

is possible. One extension-kit NRS 90208 (Order-No. 121 641) per channel is needed.

PARALLEL CONNECTION

Connection can be established via the XLR-type input connectors INPUT A / INPUT B or the supplied

screw-on connectors which are connected in parallel. In addition, using the PARALLEL-connectors

provides the possibility for connecting the input signal through to feed additional power ampliers,

without the need for extra splitter-cables.

DSP OUT

The DSP output signal – i.e. the post-digital-signal-processing-unit audio signal – is present at the

DSP OUT. The DSP output signal is simultaneously fed to the power amplier output stage and is

correspondingly amplied present at the power amp’s main outputs.

The DSP OUT can be utilized for feeding the digitally processed audio signal from the RCM-24 Remote Control Module to additional power ampliers (without DSP-module); e.g. for increasing the

overall output power. With a nominal level of +6dBu and a maximum level of +21dBu (8.7V) the output

signal is electronically balanced. Output impedance is 100Ω.

CONTROL PORT

The CONTROL PORT offers two freely programmable control inputs and

control outputs as well as the reference connections for ground potential and

+5V. Using the PC Windows software IRIS, the control inputs can be

congured and serve for instance for Power-On / Stand-by switching, preset

switching or parameter control.

The two control contacts IN1 / IN2 are internally set to +5V (open) via pull-up

resistors. Activating the control inputs is possible by closing the contacts to ground potential (pin 3)

via external switches, pushbuttons or relays. The two control outputs OUT1 / OUT2 are carried out as

Open Collector Outputs. In non-active state (Off) they provide high ohmic resistance. In the active state

(On) these outputs are connected to ground.

The outputs serve for signalling internal operational states. They can be used for the direct triggering

of LEDs, indication lights or relays. The +5V reference connector provides power supply for externally

connected appliances with amperage of maximally 100mA. The control outputs allow signal indication

of operational states (critical temperature, exceeding or decline of dened limit values, faults, etc.) at

central operator desks or to other systems (re alarm system, general alert system) even without PC.

For further detail about conguring the control ports, please refer to the documentation accompanying

the IRIS software.

7

Page 8

9

REAR VIEW

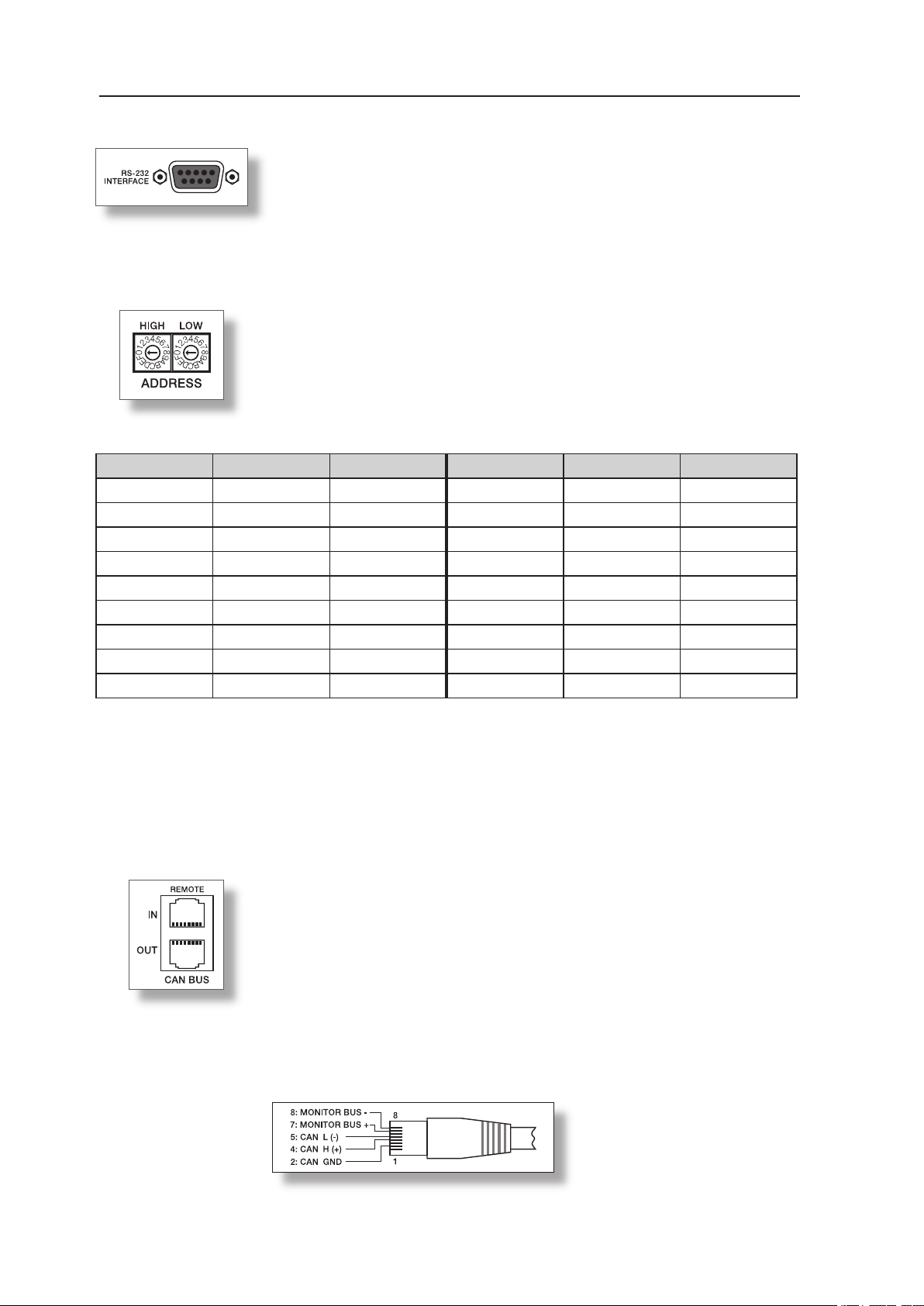

RS-232 INTERFACE

The RS-232 interface is for connecting media control systems as well as

building management systems providing control and monitoring of all

parameters. Communication is established via an easily to implement ASCII protocol allowing trouble-free integration of Remote Ampliers in media and

touch panel control systems. For a programmer’s guide and complete protocol description, please refer to the documentation accompanying the IRIS software.

ADDRESS

The address selection switch allows setting the amplier’s network address,

which, within a CAN-network, can range from 01 to 250 (FA hex). Caution:

Each address may exist only once within a network. Otherwise network

conicts might occur. Address setting has to be performed in hexadecimal

code. The selection switch LOW represents the low-value digit while the

HIGH-switch represents the high-value digit.

Adress-Table:

HIGH LOW Adress HIGH LOW Adress

0 0 Stand-alone 8 0 ... F 128 ... 143

0 1 ... F 1 ... 15 9 0 ... F 144 ... 159

1 0 ... F 16 ... 31 A 0 ... F 160 ... 175

2 0 ... F 32 ... 47 B 0 ... F 176 ... 191

3 0 ... F 48 ... 63 C 0 ... F 192 ... 207

4 0 ... F 64 ... 79 D 0 ... F 208 ... 223

5 0 ... F 80 ... 95 E 0 ... F 224 ... 239

6 0 ... F 96 ... 111 F 0 ... A 240 ... 250

7 0 ... F 112 ... 127 F B ... F reserved

Address 0 (00 hex, factory-pre-set) ensures that the amplier is separated from the remote

communication, so that it does not appear in the system set-up even though it might be connected

to the CAN-bus. When the amplier is powered-on with its address set to “0”, all internal parameters

are set to “0” respectively to bypass and the routing is set to 2-in-2. In that case the amplier behaves

absolutely linear, i.e. signal processing is deactivated.

REMOTE CAN BUS

Each amplier employs two RJ-45 sockets for Remote CAN-bus connection.

The sockets are parallel connected and serve as input as well as for

connecting through of the Remote network. Common RJ-45 patch

cables can be used for rack-shelf cabling. The CAN-bus needs to be

terminated at both ends using a 120ohms termination plug. Detailed

guidelines concerning cabling and bus length are provided in the chapter

“REMOTE CONTROL NETWORK”.

Both RJ-45 sockets additionally carry the balanced audio monitor signal.

The nominal output level is +6dBu (1.55V) while the maximum output level is +21dBu (8.7V).

Connector Pin-Assignment:

(View of Contacts)

8

Page 9

REAR VIEW

The STATUS LED provides optical indication of CAN-bus trafc. When the

power amplier’s address is set to “00” so that it is separated from the CAN bus, the STATUS LED blinks every 3 seconds. When the power amplier’s

address is set between “01” and “250” and no CAN-bus activity has taken place yet, the LED blinks

every second. As soon as CAN-bus communication is recognized, the LED is activated for at least

100ms whenever the power amplier actively sends data on the CAN-bus.The STATUS LED may also

be activated from the PC. In this case, the LED of the according power amplier blinks fast and steady

while all other status-LEDs within the system stay dimmed. This function is useful for optically monitoring communication and for quickly identifying particular power ampliers in extensive system installations (please also refer to the IRIS software documentation).

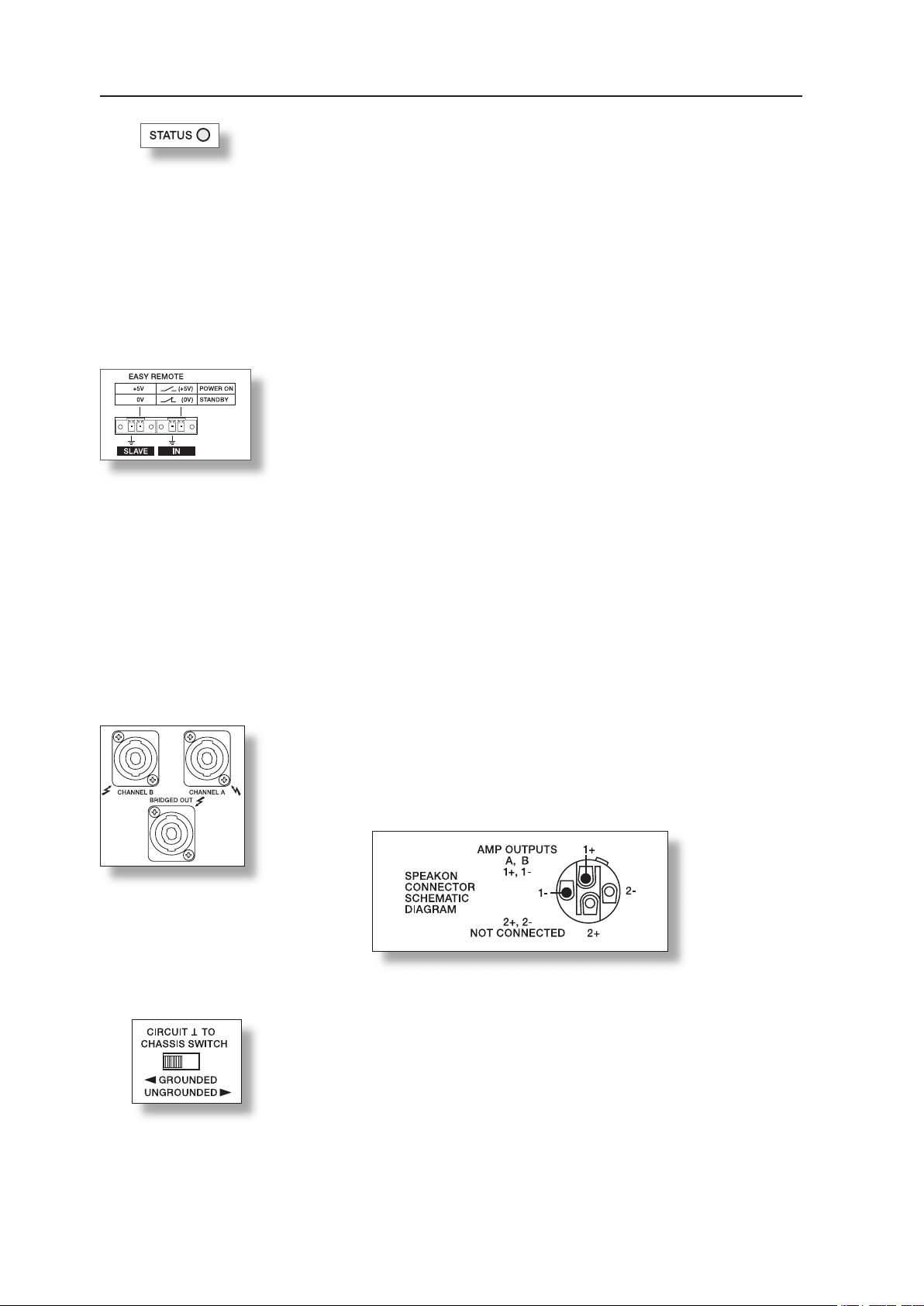

EASY REMOTE

Easy Remote provides a simple way to remotely power-on/off the power

amplier. The Easy Remote function is only useful for appliances not

employing a RCM-24 Module. Controlling appliances with RCM-24 Module

installed per Easy Remote is practically pointless.

EASY REMOTE IN

Leaving the pins of the EASY REMOTE IN socket open, i.e. when connecting +5V, the appliance

power is switched on. When connecting the EASY REMOTE IN, i.e. when feeding 0V from the control

output, the appliance enters standby mode.

EASY REMOTE SLAVE

The EASY REMOTE SLAVE connector provides connection for additional appliances with EasyRemote function (e.g. for switching several devices within a rack-shelf ON/OFF).

The switching of the slave-units is delayed to prevent the mains fuses from blowing.

POWER AMPLIFIER OUTPUTS

SPEAKON-type connectors are provided for the power amplier channels

„A“ and „B“. The BRIDGED OUT connector for bridged operation has a

plastic coverlid preventing inadvertent misconnection.

When connecting loudspeaker systems, please mind the polarity

according to the following diagram:

GROUND-LIFT SWITCH

The ground-lift switch allows eliminating noise loops. If the power amplier is

operated together with other equipment in a 19“ rack-shelf, setting the switch

to its GROUNDED position is recommended. If the power amplier is

operated together with appliances with differing ground potentials, setting

the switch to its UNGROUNDED position is recommended.

9

Page 10

11

REAR VIEW

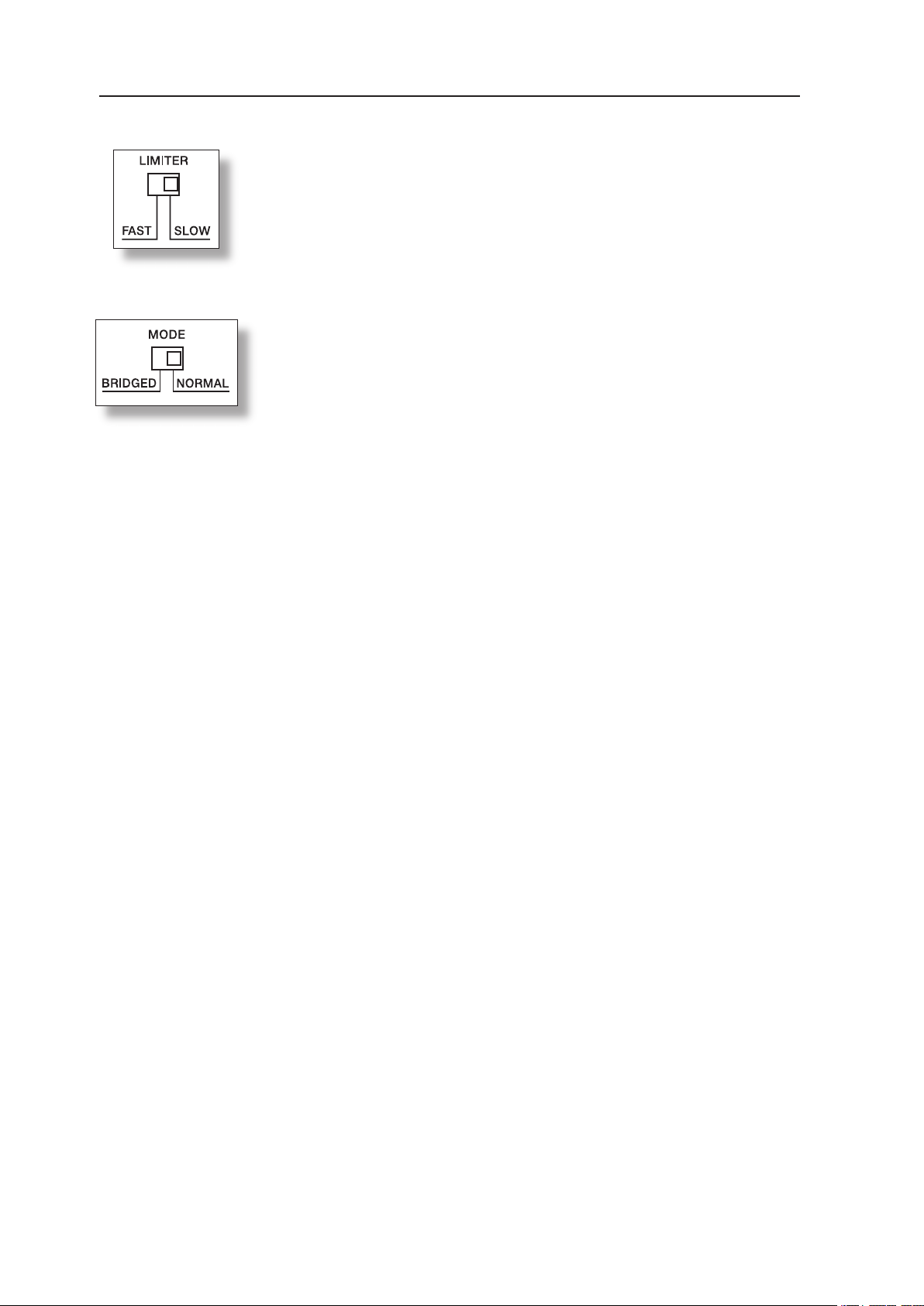

LIMITER

The integrated limiter provides reliable protection against signal clipping and

has a switchable time constant. Leaving the switch set to SLOW is

recommended for general use (factory pre-set status).

When using the power amplier as Mid/Hi power amp employed in active

multi-way systems, setting the limiter switch to FAST is recommended.

When using the power amplier as low-frequency woofer power amp

employed in active multi-way systems, setting the limiter switch to SLOW is

recommended.

BRIDGED MODE

Switch for changing from normal (stereo) operation to bridged mode. In

bridged mode the integrated power ampliers operate in „push-pull“

operation. The output voltages of cannel „A“ and channel „B“ are doubled

and present at the BRIDGED OUT connector. Channels „A“ and „B“ work

phase-shifted in push-pull operation and may not be used as loudspeaker

outputs.

10

Page 11

CABLING

LF-CONNECTION CORDS

Choosing balanced cables (two conductors for the audio signal plus separate shielding mesh) with

XLR-type connectors is recommended for LF-signal connection. Although connecting unbalanced

cables to the power amplier inputs is possible as well, using balanced cabling is always preferable.

A great number of today’s audio appliances employ balanced outputs. With balanced cabling, the

shield connects all metal enclosure parts and thus efciently eliminates the introduction of noise and

hum.

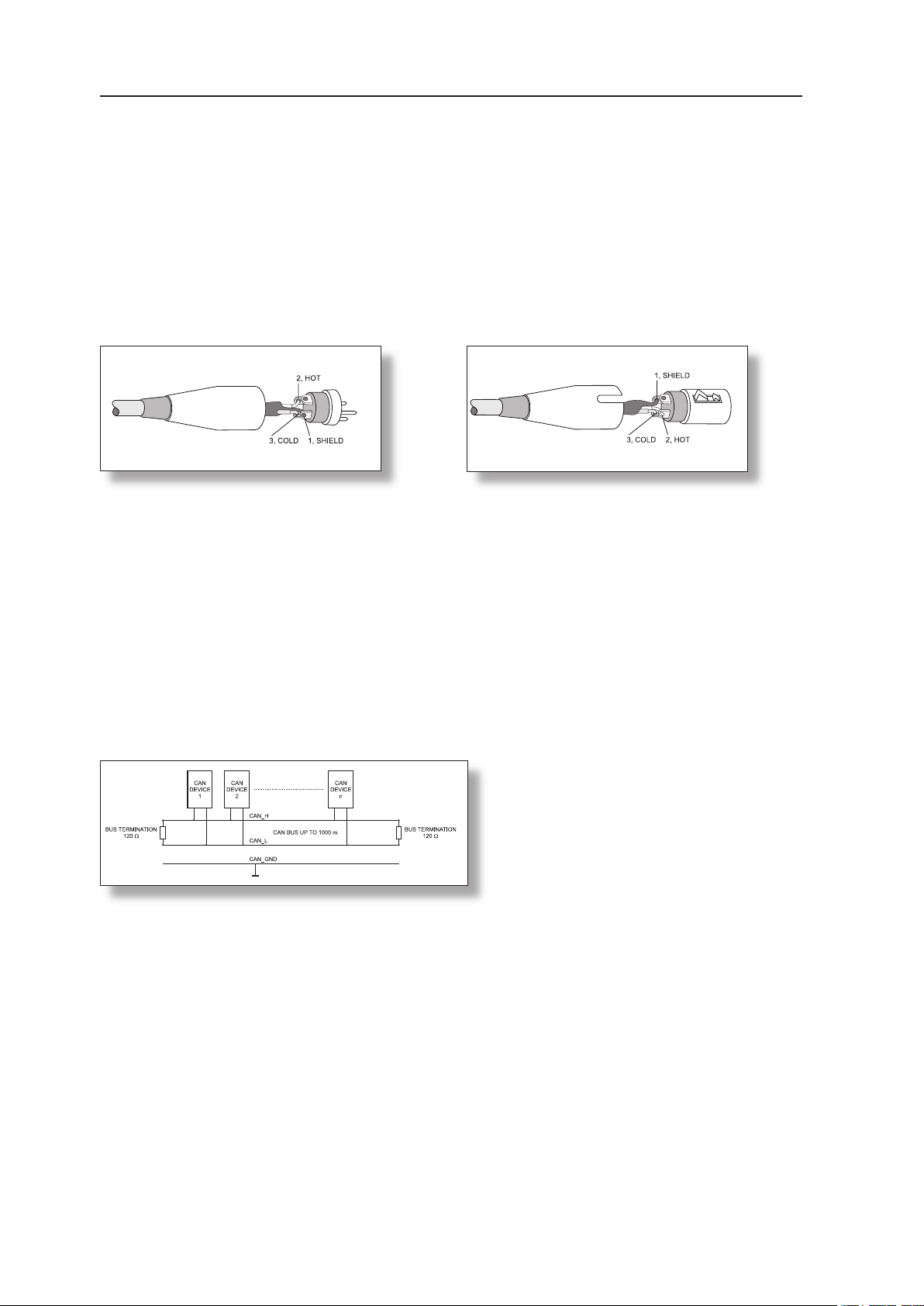

XLR-type connector pin-assignment

XLR (male) XLR (female)

REMOTE CONTROL NETWORK

The network of the remote power amps is based on the CAN-bus standard, which for years is

especially popular in automotive, industrial and security applications. The CAN-bus is a balanced

serial interface for command and data transmission. Controlling the power ampliers is performed

from a PC with IRIS – Intelligent Remote & Integrated Supervision – software installed. The UCC1

USB-CAN Converter serves as interface between the PC and the CAN-bus. Connecting up to 100

power ampliers per CAN-Bus with a maximum total cable length of 1,000 meters is possible. An

additional CAN-bus is needed for controlling more than 100 power amps while the IRIS software allows

administering a total of 250 power amps.

The network topology used by the CAN-bus is the so-called “bus or line topology”, i.e. all participants

are connected via a single two-wire cable (Twisted-Pair cable, shielded or unshielded) with the cabling

running from one participant on the bus to the next, allowing unlimited communication among all

appliances included. In general, it does not

matter whether a participant on the bus is a

power amplier or a UCC1 USB-CAN

converter, so that both – UCC1 and the PC

as well – can be inserted at any position.

Incorporating several UCC1 and PCs

on a single CAN-bus is also possible. A

total of up to 100 appliances can be operated

on a single CAN-bus. Since the CANinterfaces of all appliances are galvanically separated from the rest of the circuitry, network cabling

also carries a common ground conductor (CAN_GND) ensuring that all CAN-interfaces in the network

are connected to a common ground potential. The UCC1 provides the possibility for switching the

CAN-ground to circuit-ground.

Each participant on the bus system has two RJ-45 connectors for the Remote CAN-bus. These sockets

are connected in parallel to serve as input and output (for connecting through) for the data transfer of

the remote-network. The CAN-bus has to be terminated at both ends using 120 terminator plugs, two

of which – CAN-TERM 120 – are supplied with the UCC1. Connect one of these to the RJ-45 socket

of the rst and the other to the socket of the last appliance on the CAN-bus.

11

Page 12

13

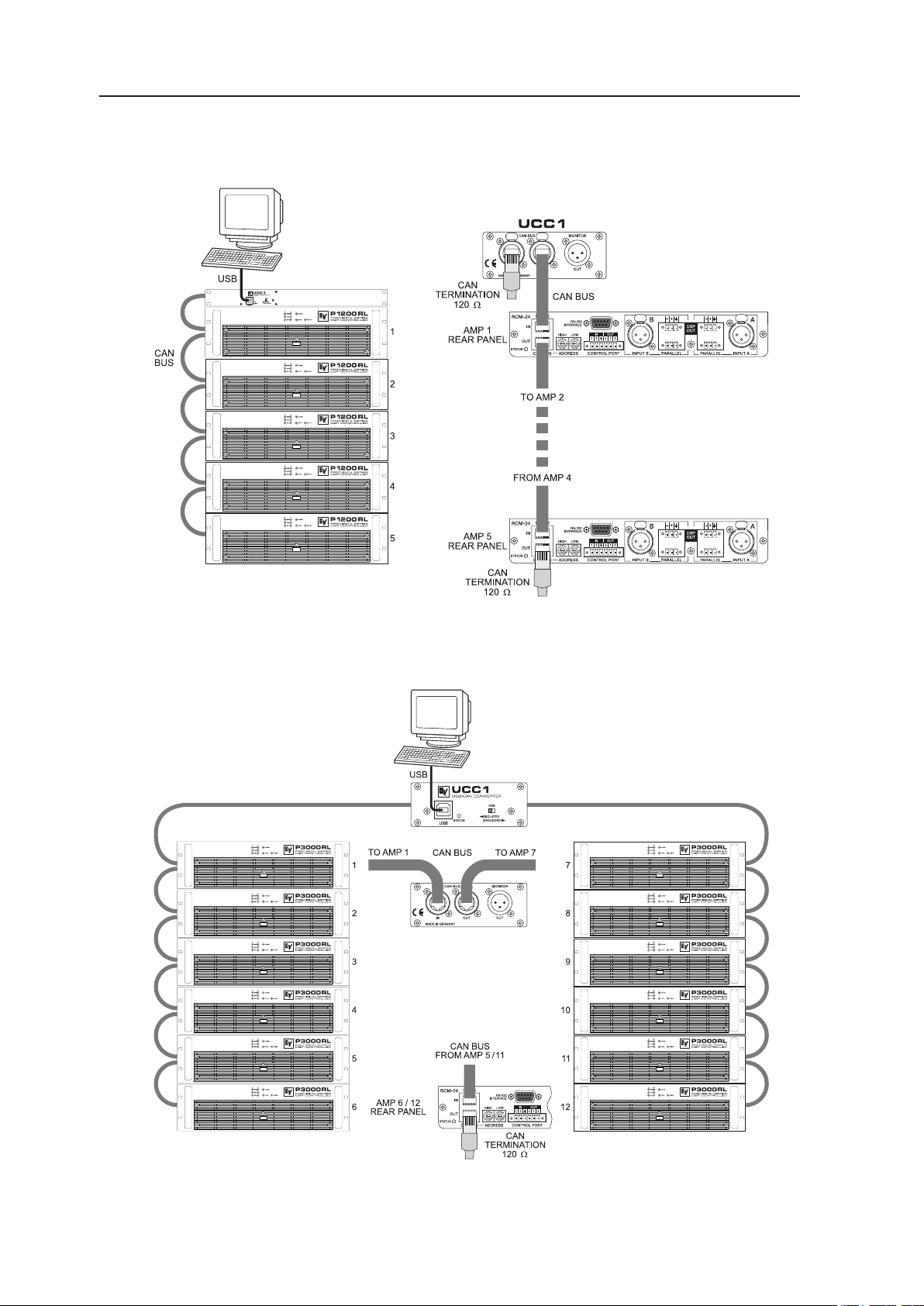

NETWORK EXAMPLES

The following diagrams show examples of the data-bus wiring for different order of size:

Terminators at the UCC1 (rst unit on the bus) and at amp 5 (last unit on the bus)

System with 5 amps and one UCC1 / PC at the beginning of the bus

Terminators at amp 6 (rst unit on the bus) and amp 12 (last unit on the bus)

System with 2 amp-racks and an UCC1 / PC in the middle

12

Page 13

NETWORK EXAMPLES

System with several amp-racks and several UCC1 / PCs

Terminators at amp 10 (rst unit on the bus) and amp 16 (last unit on the bus)

UCC1s anywhere on the CAN-bus

Next to the CAN-bus signal, network cabling also carries the balanced monitor audio signal for

monitoring the power amp inputs and outputs. This monitor-bus allows software-controlled monitoring

of the input and output signals of all power amps that are included in the remote network, without the

need for additional wiring. The monitor signal is present at the UCC1’s XLR-type MONITOR Output

connector for further distribution to (e.g.) a mixing console to be monitored via headphones or an

active monitor speaker connected.

13

Page 14

15

CAN-BUS

The CAN-bus allows using different data rates, with the data

Baud Rate Bus Length

rate being indirectly proportional to the bus length. Small

500 kbit/s 100 m

networks allow baud rates up to 500kbit/s.

250 kbit/s 250 m

For sizable dimensioned networks reducing the baud rate

(minimum 10kbit/s) is necessary.

125 kbit/s 500 m

The integration of repeaters is generally recommended

62.5 kbit/s 1000 m

when the bus-length exceeds 1,000m.

20 kbit/s 2500 m

10 kbit/s 5000 m

CABLE SPECIFICATIONS

According to the ISO 11898-2 standard, CAN-bus data transfer cabling has to be carried out using

Twisted-Pair cables with or without shielding providing a characteristic impedance of 120Ω. Both ends

of a CAN-bus need to be terminated with 120Ω termination-plugs.

The maximum bus-length depends on the actual data transfer rate, the kind of data transfer cable

being used, as well as the total number of participants on the bus. The following table shows the most

essential coherencies for CAN-networks consisting of up 64 participants:

Cable for data Transmission

Bus Length

0 ... 40 m < 70 mΩ/m

40 ... 300 m < 60 mΩ/m

300 ... 600 m < 40 mΩ/m

600 ... 1000 m < 26 mΩ/m

*

With longer cables and many participants on the CAN-bus, termination resistors with higher impedance than the

specied 120Ω are recommended to reduce the ohmic load of the interface drivers and therefore the voltage drop

between the two cable ends.

Resistance per

Unit Length

Cable Diameter

0.25 ... 0.34 mm²

AWG23, AWG22

0.34 ... 0.6 mm²

AWG22, AWG20

0.5 ... 0.6 mm²

AWG20

0.75 ... 0.8 mm²

AWG18

Termination

Data Transfer Rate

124 Ω 1000 kbit/s at 40 m

127 Ω 500 kbit/s at 100 m

*

150 Ω ... 300 Ω

150 Ω ... 300 Ω

100 kbit/s at 500 m

*

62.5 kbit/s at 1000 m

max.

The following table is meant for rst assessment of necessary cable diameters for different bus lengths

and bus-participant numbers:

Bus Length Number of Appliance on the CAN-Bus

32 64 100

100 m 0.25 mm² or AWG24 0.34 mm² or AWG22 0.34 mm² or AWG22

250 m 0.34 mm² or AWG22 0.5 mm² or AWG20 0.5 mm² or AWG20

500 m 0.75 mm² or AWG18 0.75 mm² or AWG18 1.0 mm² or AWG17

Additionally, the length of branch lines – for participants that are not directly connected to the CAN-bus

– is also of importance. For data transfer rates of up to 125kbit/s, the maximum length of a single stub

cable should not exceed 2m. For higher bit rates a maximum length of only 0.3m is still permissible.

The entire length of all branch lines should not exceed 30 m.

General Note:

As long as only short distances (up to 10m) are concerned, common RJ-45 patch cables with

100Ω characteristic impedance (AWG 24 / AWG 26) can be used for the cabling inside of a rackshelf system. The previously outlined guidelines for network cabling are mandatory as far as

the rack-shelve interconnection or xed installations are involved.

14

Page 15

MAINS OPERATION & RESULTING TEMPERATURE

MAINS OPERATION

The following tables allow determining power supply and cabling requirements. The values of the

column „Max. Output @ 4Ω” are relevant for “normal” operation. These values are based on operating

the power amplier with VDE-noise at 1/8 of the maximum output power, which approximately equates

the load of the power amplier being operated with a music signal at maximum volume possible,

without noticeable clipping.

RESULTING TEMPERATURE INSIDE THE POWER AMPLIFIER

The power drawn from the mains network is converted into acoustic output power to feed the

connected loudspeaker systems & heat. The difference between drawn power and dispensed power

is called leakage power or dissipation (Pd). The amount of heat resulting from power dissipation might

remain inside of a rack-shelf and needs to be diverted using appropriate measures. The following

table provides auxiliary means for calculating the temperatures inside of a rack-shelf system/cabinet

and the ventilation efforts necessary.

The column “Pd” lists the leakage power in relation to different operational states. The column “BTU/hr”

lists the dispensed heat amount per hour.

P3000RL Normal Mode U

Mains

[V] I

Mains

[A] P

Mains

P

[W] Pd [W] BTU/hr

out

[W]

Idling 230V 1.0 152 - 152 519

Max. Output @ 8Ω

Max. Output @ 4Ω

max. Output @ 4Ω

max. Output @ 4Ω

Normal Operation (-10dB) @ 4Ω

Nominal Operation (0dB) @ 4Ω

Alarm Operation (-3dB) @ 4Ω

(1)

(1)

(1)

(2)

(1)

(1)

230V 13.8 2560 2 x 850 860 2934

230V 22.4 4330 2 x 1300 1730 5903

230V 13.9 2575 2 x 433 1709 5831

230V 7.8 1350 2 x 163 1024 3494

(1)

230V 8.0 1420 2 x 120 1180 4026

230V 21.6 4170 2 x 1200 1770 6040

230V 16.0 3020 2 x 610 1800 6142

For approximation; when operating the appliance at 120V mains the stated current values need to be

doubled.

(1) modulated with sine signal

(2) modulated with VDE-noise

(3) 1BTU = 1055.06J = 1055.06Ws

(3)

15

Page 16

17

16

Page 17

BEDIENUNGSANLEITUNG

Page 18

INHALT

WICHTIGE SICHERHEITSHINWEISE ....................... 19

WICHTIGE SERVICEHINWEISE ....................... 19

BESCHREIBUNG ....................... 20

AUSPACKEN & GARANTIE ....................... 21

INSTALLATIONSHINWEISE ....................... 21

FRONTSEITE ....................... 22

RÜCKSEITE ....................... 23

INPUT A / INPUT B ....................... 23

PARALLEL ....................... 23

DSP OUT ....................... 23

CONTROL PORT ....................... 23

RS-232 INTERFACE ....................... 24

ADDRESS ....................... 24

REMOTE CAN-BUS ....................... 24

EASY REMOTE ....................... 25

ENDSTUFENAUSGÄNGE ....................... 25

GROUND-LIFT SCHALTER ....................... 25

LIMITER ....................... 26

BRIDGED MODE ....................... 26

VERKABELUNG ....................... 27

NF-VERBINDUNGSKABEL ....................... 27

REMOTE CONTROL NETZWERK ....................... 27

NETZWERK-BEISPIELE ....................... 28

CAN-BUS ....................... 30

LEITUNGSSPEZIFIKATIONEN ....................... 30

NETZBETRIEB & WÄRMEENTWICKLUNG ....................... 31

SPECIFICATIONS / TECHNISCHE DATEN ....................... 32

BLOCK DIAGRAM AMPLIFIER ....................... 34

BLOCK DIAGRAM RCM-24 ....................... 35

ABMESSUNGEN ....................... 36

18

Page 19

WICHTIGE SICHERHEITSHINWEISE

Das Blitzsymbol innerhalb eines gleichseitigen Dreiecks soll den Anwender auf nicht isolierte Leitungen

und Kontakte im Geräteinneren hinweisen, an denen

hohe Spannungen anliegen, die im Fall einer

Berührung zu lebensgefährlichen Stromschlägen

führen können.

Das Ausrufezeichen innerhalb eines gleichseitigen

Dreiecks soll den Anwender auf wichtige Bedienungssowie Servicehinweise in der zum Gerät gehörenden Literatur aufmerksam machen.

1. Lesen Sie diese Hinweise.

2. Heben Sie diese Hinweise auf.

3. Beachten Sie alle Warnungen.

4. Richten Sie sich nach den Anweisungen.

5. Betreiben Sie dieses Gerät nicht in unmittelbarer Nähe von Wasser. Stellen Sie bitte sicher, dass kein Tropf- oder

Spritzwasser ins Geräteinnere eindringen kann. Platzieren Sie keine mit Flüssigkeiten gefüllten Objekte, wie Vasen

oder Trinkgefässe, auf dem Gerät ab.

6. Verwenden Sie zum Reinigen des Gerätes ausschliesslich ein trockenes Tuch.

7. Verdecken Sie keine Lüftungsschlitze. Beachten Sie bei der Installation des Gerätes stets die entsprechenden

Hinweise des Herstellers.

8. Vermeiden Sie die Installation des Gerätes in der Nähe von Heizkörpern, Wärmespeichern, Öfen oder anderer

Wärmequellen.

9. Verwenden Sie mit dem Gerät ausschliesslich Zubehör/ Erweiterungen, die vom Hersteller hierzu vorgesehen sind.

10. Überlassen Sie sämtliche Servicearbeiten und Reparaturen einem ausgebildeten Kundendiensttechniker.

Bringen Sie das Gerät direkt zu unserem Kundendienst, wenn es beschädigt wurde oder eine Funktionsstörung zeigt.

11. Um das Gerät komplett spannungsfrei zu schalten, muss der Netzstecker gezogen werden.

WICHTIGE SERVICEHINWEISE

ACHTUNG: Diese Servicehinweise sind ausschliesslich zur Verwendung durch qualiziertes Servicepersonal.

Um die Gefahr eines elektrischen Schlages zu vermeiden, führen Sie keine Wartungsarbeiten durch,

die nicht in der Bedienungsanleitung beschrieben sind, ausser Sie sind hierfür qualiziert. Überlassen

Sie sämtliche Servicearbeiten und Reparaturen einem ausgebildeten Kundendiensttechniker.

1. Bei Reparaturarbeiten im Gerät sind die Sicherheitsbestimmungen nach EN 60065 ( VDE 0860 ) einzuhalten.

2. Bei allen Arbeiten, bei denen das geöffnete Gerät mit Netzspannung verbunden ist und betrieben wird, ist ein Netz Trenntransformator zu verwenden.

3. Vor einem Umbau mit Nachrüstsätzen, Umschaltung der Netzspannung oder sonstigen Modikationen ist das Gerät

stromlos zu schalten.

4. Die Mindestabstände zwischen netzspannungsführenden Teilen und berührbaren Metallteilen

(Metallgehäuse) bzw. zwischen den Netzpolen betragen 3 mm und sind unbedingt einzuhalten.

Die Mindestabstände zwischen netzspannungsführenden Teilen und Schaltungsteilen, die nicht mit dem Netz

verbunden sind (sekundär), betragen 6mm und sind unbedingt einzuhalten.

5. Spezielle Bauteile, die im Stromlaufplan mit dem Sicherheitssymbol gekennzeichnet sind, (Note) dürfen nur durch

Originalteile ersetzt werden.

6. Eigenmächtige Schaltungsänderungen dürfen nicht vorgenommen werden.

7. Die am Reparaturort gültigen Schutzbestimmungen der Berufsgenossenschaften sind einzuhalten. Hierzu gehört

auch die Beschaffenheit des Arbeitsplatzes.

8. Die Vorschriften im Umgang mit MOS - Bauteilen sind zu beachten.

NOTE:

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART )

19

Page 20

BESCHREIBUNG

BESCHREIBUNG

21

Herzlichen Glückwunsch! Sie haben sich mit einer Endstufe der PRECISION SERIES von ElectroVoice für ein Gerät modernster Technologie entschieden.

Die Endstufen der P-Serie vereinen überragende Audio-Performance mit höchster Zuverlässigkeit und

Betriebssicherheit. Jede Endstufe ist mit dem RCM-24 Remote Control Modul ausgestattet, welches

die zentrale Konguration, Steuerung und Überwachung aller relevanten Endstufenparameter (wie

Ausgangsstrom, -spannung, Lastimpedanz, ...) ermöglicht.

Ein lückenloses Konzept an Protections schützt nicht nur die Endstufen, sondern auch die angeschlossenen Lautsprecher. Zu diesen Schutzschaltungen gehören dynamische Audio-Limiter, DC/HF-Protections, Back-EMF-Protection, Inrush Current Limiter, Short Circuit Protection und natürlich die Temperaturüberwachung der Endtransistoren und der Netztransformatoren.

Die thermische Stabilität wird durch vierstuge Hochleistungslüfter mit sehr niedrigem Geräuschpegel

gewährleistet. Die Luftführung ist Front-to-Rear, was den problemlosen Betrieb in grossen und schmalen Endstufen-Racks ermöglicht.

Durch zwei grosszügig dimensionierte Netzteile mit streuarmen Ringkerntransformatoren wird ein

grosser Headroom weit oberhalb der ausgewiesenen Nennleistung erzielt. Höchste Präzision ist auch

in der mechanischen Konstruktion und Verarbeitung gewährleistet. Das robuste Stahlblech-Chassis ist

besonders verwindungssteif und auf den harten Tourbetrieb ausgelegt.

Mit dem RCM-24 hat man zu jeder Zeit

einen vollständigen Überblick über den

gesamten Systemzustand und die

Kontrolle über alle relevanten Systemparameter. Das RCM-24 Modul

erlaubt die Anbindung an ein Remote Control Netzwerk mit bis zu 250 Endstufen. Ein komplettes PASystem kann von einem oder mehreren PCs mit Hilfe der Windows Software IRIS – Intelligent Remote

& Integrated Supervision – gesteuert und überwacht werden. Sämtliche Betriebszustände, z. B. Einschaltstatus, Temperatur, Aussteuerung, Limiting, Ansprechen von Schutzschaltungen, Abweichungender Lastimpedanz usw., werden zentral erfasst und dargestellt. Dadurch kann schon vor dem Auftreten

von kritischen Betriebszuständen reagiert und gezielt eingegriffen werden. Eine automatische Reaktion auf Über- oder Unterschreitung bestimmter Grenzwerte ist ebenfalls programmierbar. Alle Parameter, z. B. Power On/Off, Level, Mute, Filter usw. sind in Echtzeit steuerbar und können in jeder Endstufe

abgespeichert werden.

Die angeschlossenen Lautsprecher werden durch Messung der Ausgangsströme und -spannungen

der beiden Endstufenkanäle überwacht. Jede Über- oder Unterschreitung der eingestellten Grenzwerte wird sofort gemeldet und protokolliert. Kurzschlüsse oder Leitungsunterbrechungen werden so während des normalen Anlagenbetriebs erkannt und dargestellt. Eine wesentlich genauere Überprüfung

der angeschlossenen Lautsprecher ermöglicht die integrierte Impedanz-Messfunktion. Dabei wird mit

Hilfe des internen Signal-Generators und der Strom-/Spannungsmessung die Impedanz des oder der

Lautsprecher plus der Zuleitungen über den gesamten Frequenzbereich gemessen und als Impedanzkurve am PC Bildschirm dargestellt. Der gemessene Impedanzverlauf kann jederzeit mit einem Referenzwert verglichen werden, wodurch schon geringste Lautsprecherdefekte oder Mängel erkennbar

sind.

20

Page 21

BESCHREIBUNG

Neben der Steuerung und Überwachung stellt das RCM-24 Remote Control Modul umfangreiche Signalverarbeitungsfunktionen zur Verfügung. Enthalten sind insgesamt 20 parametrische Filter, X-Over

Funktionen, Delays, Routing und Level Control, sowie Kompressor und Limiter pro Kanal. Sämtliche

Parameter sind frei editierbar und können auf dem Modul in bis zu 8 User Memories abgespeichert

werden. Unabhängig von der Kontrolle durch das Netzwerk bleiben in einem Havariefall alle DSP-Einstellungen (Filter, Delay, Level) erhalten. Ausserdem lassen sich die Steuereingänge der Endstufen zur

netzwerkunabhängigen Umschaltung auf ein anderes Preset (z.B. Alarmierungs-Einstellung mit maximaler Energie im Sprachbereich) verwenden.

Damit wird die P-Serie mit RCM-24 Modul auch höchsten Sicherheitsanforderungen gerecht.

Beim Hardware-Design des RCM-24 wurde auf kompromisslose Audioqualität höchster Wert gelegt.

Die AD/DA-Wandlung ndet mit 24-Bit Auösung und 128-fachem Oversampling mit linearer Phase

statt; die interne Wortlänge ist 48 Bit. Damit erreicht das RCM-24 eine Dynamik von 115 dB, ein absoluter Spitzenwert für digitale Audiogeräte.

Sämtliche Details zur Konguration, Steuerung und Überwachung der P-Series Endstufen nden Sie

in der Dokumentation der PC Windows Software IRIS.

AUSPACKEN & GARANTIE

Öffnen Sie die Verpackung und entnehmen Sie die Endstufe. Zusätzlich zu dieser Bedienungsanleitung liegen dem Gerät die Garantiekarte, vier Gerätefüsse, sechs Schraub-Steckverbinder (1 mal

2-polig, 4 mal 3-polig, 1 mal 6-polig) und ein Satz Rackeinbauwinkel bei. Überprüfen Sie bitte ob die

Garantiekarte vollständig ausgefüllt ist, denn nur so können Sie etwaige Garantieansprüche geltend

machen. Sie haben auf das Gerät 36 Monate Garantie, die ab dem Zeitpunkt der Aushändigung durch

den Händler gilt.

Bewahren Sie zur Garantiekarte auch den Kaufbeleg, der den Termin der Übergabe festlegt, auf.

INSTALLATIONSHINWEISE

Generell sind die Endstufen so aufzustellen oder zu montieren, daß die Luftzufuhr an der Frontseite

und die Entlüftung an der Geräterückseite nicht behindert wird. Für den Einbau in Gehäuse und Gestellschränke ist zu beachten, daß eine ausreichende Belüftung der Geräte möglich ist. Zwischen der

Endstufen Rückseite und der Schrank/Rack-Innenseite ist ein freier Luftkanal von mindestens

60mm x 330mm bis zur oberen Rack- oder Schrankentlüftung vorzusehen. Oberhalb des Schrankes

soll ein freier Raum von mindestens 100mm für die Entlüftung vorgesehen werden. Da beim Betrieb

die Temperatur im Gehäuse- oder Schrank bis zu 40°C ansteigen kann, muß die maximal zulässige

Umgebungstemperatur der übrigen im Gestellschrank bendlichen Geräte beachtet werden.

(siehe „NETZBETRIEB UND WÄRMEENTWICKLUNG“)

Beim Einbau in Gestellschränken sollen in jedem

Fall Einbauschienen oder die beiliegenden

Rackeinbauwinkel verwendet werden, um ein Ver winden der Frontblende zu verhindern.

Achtung: Die max. Umgebungstemperatur von +40°C soll für störungsfreien Betrieb nicht

überschritten werden.

Die Endstufe ist zu schützen vor: Tropf- oder Spritzwasser, direkter Sonnenbestrahlung, hoher Umgebungstemperatur oder unmittelbarer Einwirkung von Wärmequellen, hoher Luftfeuchtigkeit, starken

Staubablagerungen und starken Vibrationen.

Wenn die Endstufe direkt von einem kalten an einen warmen Ort gebracht wird, kann sich Feuchtigkeit

auf Innenteilen niederschlagen. Das Gerät darf erst in Betrieb genommen werden, wenn es sich auf

die geänderte Temperatur erwärmt hat (nach etwa einer Stunde). Sollte ein fester Gegenstand oder

Flüssigkeit in das Gehäuse gelangen, trennen Sie sofort das Gerät von der Stromquelle ab und lassen

Sie das Gerät von einer autorisierten Servicestelle überprüfen, bevor Sie es weiterverwenden.

Zur Reinigung des Gerätes dürfen keine Sprühmittel verwendet werden, da diese dem Gerät schaden

und sich plötzlich entzünden können.

44.45

31.75

13/4“

11/4“

44.45

151/2“

21

Page 22

23

FRONTSEITE

Mit dem POWER Schalter in der Mitte der Frontblende wird das Gerät eingeschaltet. Eine SoftstartSchaltung vermeidet dabei Einschaltstromspitzen auf der Netzleitung. Dadurch wird verhindert, dass

der Leitungsschutzschalter des Stromnetzes beim Einschalten der Endstufe anspricht. Die Lautsprecher werden über die Ausgangsrelais um ca. 2 Sekunden verzögert zugeschaltet, wodurch etwaige

Einschaltgeräusche effektiv unterdrückt werden. Während dieser Verzögerung leuchtet die PROTECT

LED und die Lüfter laufen mit maximaler Geschwindigkeit. Dies ist normal und bestätigt die einwandfreie Funktion der Schutzschaltungen. Alle Endstufen mit RCM-24 Modul benden sich nach dem Einschalten wieder in dem Zustand, in dem sie ausgeschaltet wurden.

Wurde das Gerät z.B. im Standby Modus per POWER Schalter ausgeschaltet, so wird es sich nach

dem Einschalten wieder in diesem Modus benden.

Diese Anzeige leuchtet auf, wenn die Endstufe eingeschaltet ist. Falls die POWER

Anzeige nicht leuchtet, ist das Gerät nicht mit dem Stromnetz verbunden, die Primär sicherung defekt oder die Endstufe bendet sich im Standby Modus (STANDBY LED

leuchtet).

Diese Anzeige leuchtet, wenn sich die Endstufe im Standby Modus bendet, welcher

über das RCM-24 oder über Easy Remote aktiviert werden kann.

Im Standby Modus ist nur das interne Hilfsnetzteil aktiviert. Das Leistungsnetzteil ist

netzseitig getrennt.

Wenn die PROTECT-Anzeige aueuchtet, hat eine der internen Schutzschaltungen

wie Übertemperatur, Kurzschluss, Back-EMF, Hochfrequenz am Ausgang.... ange-

sprochen. Die Endstufen werden in diesem Fall über die Ausgangsrelais von der Last

getrennt, um etwaige Schäden an den Lautsprechern oder der Endstufe selbst zu

verhindern. Die Fehlerursache, beispielsweise eine kurzgeschlossene Lautsprecher leitung muss beseitigt werden. Bei Überhitzung muss einige Zeit gewartet werden,

bis die Endstufe sich selbständig wieder in den normalen Betriebszustand schaltet.

Die OUT-LED beginnt ca. 30dB unter Vollaussteuerung zu leuchten. Bei Kurzschluss

von Lautsprecherleitungen oder Ansprechen einer Schutzschaltung verlischt diese

Anzeige.

Die 0dB Anzeige leuchtet auf, wenn die Endstufe mit maximaler Aussteuerung be trieben wird. Eine höhere Eingangsspannung hat keine Erhöhung der Spitzenaus gangsspannung zur Folge.

Diese Anzeige leuchtet auf, sobald der eingebaute dynamische Limiter anspricht und

die Endstufe an der Aussteuerungsgrenze oder generell im Grenzbereich betrieben

wird. Kurzzeitiges Aueuchten ist dabei unproblematisch, da der interne Limiter Ein gangspegel bis zu +21dBu auf einen Klirrfaktor von ca. 1% ausregeln kann. Leuchtet

diese LED jedoch dauerhaft sollte die Lautstärke reduziert werden, um etwaige Über lastungsschäden der angeschlossenen Lautsprecherboxen zu vermeiden.

22

Page 23

RÜCKSEITE

INPUT A / INPUT B

Die Eingänge INPUT A & INPUT B sind elektronisch

symmetrisch mit einer Eingangsempndlichkeit von

+6dBu (1.55V) für den direkten Betrieb mit Mischpul ten usw. ausgelegt.

Der Anschluss kann entweder über die XLR-Ein-

gangsbuchsen oder die parallelgeschalteten Schraubsteckverbindungen, die im Lieferumfang enthalten sind, erfolgen. Die XLR-Eingangsbuchsen sind nach

IEC Norm 268 beschaltet. Für den Fall, dass die Eingänge potenzialfrei sein müssen, ist die Nachrüstung von Eingangsübertragern vorgesehen. Es wird dazu je Kanal der Nachrüstsatz NRS 90208 (Nr.

121 641) benötigt.

PARALLEL

Das Eingangssignal kann entweder über die XLR-Buchsen INPUT A / INPUT B oder über die parallelgeschalteten Schraubsteckverbindungen erfolgen. Die Buchsen PARALLEL ermöglichen aber auch

ein einfaches „Durchschleifen“ des Signals zu weiteren Endstufen ohne aufwändige Splitkabel.

DSP OUT

An der Buchse DSP OUT liegt das DSP-Ausgangssignal, also das Signal hinter dem digitalen Signalprocessing, an. Dieses Signal wird gleichzeitig in den Leistungsblock der Endstufe eingespeist und

gelangt entsprechend verstärkt an die Endstufenausgänge.

Der Ausgang DSP OUT kann verwendet werden, um weitere Endstufen (ohne DSP Modul) mit dem

verarbeiteten Signal aus dem RCM-24 Remote Control Modul zu versorgen, z.B. zur Leistungserweiterung. Das Ausgangssignal ist elektronisch symmetrisch, der Nennpegel beträgt +6dBu, der Maximalpegel beträgt +21dBu (8.7V). Die Ausgangsimpedanz beträgt 100Ω.

CONTROL PORT

Der CONTROL PORT enthält zwei frei-programmierbare Steuereingänge

und Steuerausgänge, sowie die Referenzanschlüsse für Masse und +5V. Die

Steuereingänge sind mit Hilfe der PC Windows Software IRIS kongurierbar,

und dienen z. B. zur Power On / Standby Umschaltung, zur Presetumschal tung oder zur Parameterkontrolle.

Die beiden Steuerkontakte IN1 / IN2 liegen intern über Pull-Up Widerstände

auf +5V (offen). Zum Aktivieren können die Steuereingänge über externe Schalter, Taster oder Relais

gegen Masse (Pin 3) geschlossen werden.

Die beiden Steuerausgänge OUT1 / OUT2 sind Open Collector Outputs, die im nichtaktiven Zustand

(Off) hochohmig sind. Im aktiven Zustand (On) sind die Ausgänge gegen Masse geschlossen.

Die Ausgänge dienen zur Signalisierung interner Zustände und können direkt LEDs, Kontrollleuchten

oder Relais ansteuern. Der +5V Referenzanschluss dient zur Versorgung der extern angeschlossenen

Elemente mit einem Strom bis zu 100mA max. Über die Steuerausgänge können Betriebszustände

(kritische Temperatur, Über- oder Unterschreitung denierter Grenzwerte, Fehler, usw.) an zentrale Bedienplätze oder andere Systeme (Brandmeldeanlage, Alarmierungsanlage) auch ohne PC gemeldet

werden. Nähere Hinweise zur Konguration des Control Ports nden Sie in der IRIS Dokumentation.

23

Page 24

25

RÜCKSEITE

RS-232 INTERFACE

Das RS-232 Interface dient als Schnittstelle zu Mediensteuerungssystemen

bzw. Gebäudemanagementsystemen. Über RS-232 können sämtliche Para meter gesteuert und abgefragt werden. Die Kommunikation erfolgt über ein

einfach zu implementierendes ASCII Protokoll. Auf diese Weise können die

Remote Verstärker problemlos in Medien- und Touchpanel-Steuerungen integriert werden. Programmierhinweise und eine vollständige Protokollbeschreibung nden Sie in der IRIS Dokumentation.

ADDRESS

Mit Hilfe der Adress-Wahlschalter stellen Sie die Netzwerk-Adresse des Ver stärkers ein. In einem CAN-Netzwerk können Sie die Adressen 01 bis 250

(FA hex) verwenden. Achtung: Jede Adresse darf im System nur einmal vor kommen, da es sonst zu Netzwerk-Konikten kommt. Die Adresseinstellung

erfolgt in Hexadezimal. Der Wahlschalter LOW ist das niederwertige Digit,

der Schalter HIGH ist das höherwertige Digit.

Adress-Tabelle:

HIGH LOW Adresse HIGH LOW Adresse

0 0 Stand-alone 8 0 ... F 128 ... 143

0 1 ... F 1 ... 15 9 0 ... F 144 ... 159

1 0 ... F 16 ... 31 A 0 ... F 160 ... 175

2 0 ... F 32 ... 47 B 0 ... F 176 ... 191

3 0 ... F 48 ... 63 C 0 ... F 192 ... 207

4 0 ... F 64 ... 79 D 0 ... F 208 ... 223

5 0 ... F 80 ... 95 E 0 ... F 224 ... 239

6 0 ... F 96 ... 111 F 0 ... A 240 ... 250

7 0 ... F 112 ... 127 F B ... F reserviert

Die Adresse 0 (00 hex, Auslieferungszustand) sorgt dafür, dass der Verstärker von der Remote-Kommunikation getrennt ist, und somit nicht mehr im System erscheint, auch wenn er am CAN-Bus angesteckt ist. Wenn der Verstärker mit Adresse 0 eingeschaltet wird, werden sämtliche internen Parameter

auf 0 bzw. Bypass und das Routing auf 2-in-2 gestellt. Der Verstärker verhält sich dann völlig linear, die

Signalverarbeitungsfunktionen sind deaktiviert.

REMOTE CAN BUS

Jeder Verstärker hat zwei RJ-45 Buchsen für den Remote CAN-Bus. Die

Buchsen sind parallel geschaltet und dienen als Eingang und zum Weiter schleifen des Remote-Netzwerkes. Zur Verkabelung im Rack können han delsübliche RJ-45 Netzwerkkabel verwendet werden. Der CAN-Bus benötigt

an beiden Enden einen Abschluss-Stecker mit 120 Ohm Abschlusswider stand. Ausführliche Richtlinien zur Verdrahtung und Buslänge nden Sie im

Kapitel „REMOTE CONTROL NETZWERK“.

An den beiden RJ-45 Buchsen liegt auch das symmetrische Audio-Monitor signal. Der Nenn-Ausgangspegel beträgt +6dBu (1.55V), der maximale Aus gangspegel ist +21dBu (8.7V).

Steckerbelegung:

(Ansicht Kontaktseite)

24

Page 25

RÜCKSEITE

Die LED STATUS dient zur Kontrolle der Kommunikation am CAN-Bus.

Wenn die Adresse 00 eingestellt und die Endstufe softwaremässig vom

CAN-Bus abgekoppelt ist, blinkt die LED regelmässig alle 3 Sek. kurz auf.

Wenn eine Adresse zwischen 01 und 250 eingestellt ist, aber noch keine CAN-Bus Aktivität stattgefunden hat, blinkt die LED regelmässig jede Sekunde kurz auf. Sobald eine Kommunikation am CAN-Bus

erkannt wurde, wird die LED immer dann für mindestens 100 ms aktiviert, wenn die Endstufe selbst

Daten auf den CAN-Bus sendet.

Die STATUS LED kann auch vom PC aktiviert werden. Die LED der betreffenden Endstufe blinkt dann

in einem schnellen regelmässigen Rhythmus, alle anderen Status-LEDs im System bleiben dunkel.

Diese Funktion dient zur Überprüfung der Kommunikation und zur schnellen Identikation einer Endstufe in einem grösseren System (s. a. IRIS Dokumentation).

EASY REMOTE

Über Easy-Remote kann die Endstufe auf einfache Weise ferngesteuert ein-

und ausgeschaltet werden. Die Easy Remote Funktion kommt nur bei Gerä ten ohne RCM-24 Modul zum Tragen.

Eine Steuerung von Geräten mit RCM-24 Modul per Easy Remote ist nicht

sinnvoll.

EASY REMOTE IN

Werden die Pins der EASY REMOTE IN Buchse offen gelassen bzw. mit +5V beaufschlagt, so schaltet das Gerät ein. Bei einer Verbindung der Pins oder 0V vom Steuerausgang schaltet das Gerät in

den Standby Modus.

EASY REMOTE SLAVE

An EASY REMOTE SLAVE können weitere Geräte mit Easy Remote Funktion angeschlossen werden

(z.B. zur Rack-ON/OFF Steuerung bei mehreren Geräten in einem Rack).

Das Einschalten der Slave-Geräte erfolgt zeitverzögert um ein Ansprechen von Netzsicherungen zu

vermeiden.

ENDSTUFENAUSGÄNGE

Für die Endstufenkanäle A und B sind jeweils SPEAKON Ausgangsbuchsen

vorgesehen. Die BRIDGED OUT Buchse für den Brückenbetrieb ist mit ei nem Kunststoffdeckel geschlossen, um Anschlussfehler zu vermeiden.

Bitte beachten Sie beim Anschluss von Lautsprechern die Polarität ent-

sprechend der nachfolgenden Zeichnung:

GROUND-LIFT SCHALTER

Mit dem Groundlift-Schalter können Sie Brummschleifen verhindern. Wenn

die Endstufe zusammen mit anderen Geräten in einem 19“-Rack betrieben

wird, sollte der Schalter in Stellung GROUNDED stehen. Wird die Endstufe

mit Geräten mit unterschiedlichem Erdungspotenzial betrieben, sollte der

Schalter in Stellung UNGROUNDED stehen.

25

Page 26

27

RÜCKSEITE

LIMITER

Der eingebaute Limiter zur Vermeidung von Übersteuerungen ist in seiner

Zeitkonstante umschaltbar. Normalerweise sollte die Stellung SLOW benutzt

werden (Auslieferungszustand).

Bei Verwendung der Endstufe als Mittel-Hochtonendstufe in aktiven Mehr wegsystemen sollte der Limiter in Position FAST betrieben werden.

Bei Verwendung der Endstufe als Bassendstufe in aktiven Mehrwegsyste men sollte der Limiter in Position SLOW betrieben werden.

BRIDGED MODE

Schalter zum Umschalten von Normal- (Stereo) in den Bridged-Mode. Im

Bridged-Mode arbeiten die eingebauten Endstufen im „Gegentakt“ und an

der Bridged Buchse erscheint die doppelte Ausgangsspannung von Kanal A

und B. Kanal A und B arbeiten also gegeneinander phasengedreht und dür fen nicht mehr als Lautsprecherausgänge benutzt werden.

26

Page 27

VERKABELUNG

NF-VERBINDUNGSKABEL

Als NF-Verbindung wählen Sie am besten symmetrisch ausgelegte Kabel (2 Signaladern + Schirmgeecht) mit XLR-Stecker. Obwohl alle Endstufeneingänge auch unsymmetrisch belegt werden können,

stellt ein symmetrisch ausgeführtes NF-Verbindungskabel die bessere Alternative zu einer unsymmetrischen Verbindung dar. Die meisten Audiogeräte verfügen über symmetrisch aufgebaute Ausgänge.

Der Schirm im Kabel verbindet bei symmetrischer Signalführung alle metallischen Gehäuse und verhindert dadurch lückenlos ein Einkoppeln von externen Störsignalen, im wesentlichen Brummen, auf

den Audiosignalpfad.

XLR-Steckerbelegung

XLR (male) XLR (female)

REMOTE CONTROL NETZWERK

Das Netzwerk der Remote Endstufen basiert auf dem CAN-Bus Standard, der sich im Automotive-,

Industrie- und Sicherheits-Bereich durchgesetzt und über Jahre hinweg bewährt hat. Der CAN-Bus ist

eine symmetrische serielle Schnittstelle zur Übertragung von Kommandos und Daten. Die Steuerung

der Endstufen erfolgt von einem PC mit IRIS Intelligent Remote & Integrated Supervision Software. Als

Interface zwischen PC und CAN-Bus dient der UCC1 USB-CAN Converter. Pro CAN-Bus lassen sich

100 Endstufen bis zu einer maximalen Kabellänge von 1000 Metern anschliessen. Wenn mehr als 100

Endstufen kontrolliert werden sollen, ist ein weiterer CAN-Bus notwendig. Insgesamt kann die IRIS

Software bis zu 250 Endstufen verwalten.

Der CAN-Bus verwendet als Netzwerktopologie die sogenannte „Bus- oder Linien-Topologie“. Das

heisst, alle Teilnehmer sind an einer einzigen Zweidrahtleitung (Twisted-Pair-Kabel, geschirmt oder ungeschirmt) angeschlossen, wobei die Verkabelung von einem Busteilnehmer zum nächsten verlaufen

muss. Jedes Gerät kann hierbei uneingeschränkt mit jedem anderen Gerät kommunizieren. Dabei ist

es grundsätzlich egal, ob der Busteilnehmer

eine Endstufe oder ein UCC1 USB-CAN Con verter ist. Somit kann der UCC1 (und damit

der PC) an beliebiger Stelle im CAN-Bus sit zen. Auch mehrere UCC1 und PCs am CAN Bus sind möglich. Ingesamt können bis zu

100 Geräte an einem CAN-Bus betrieben

werden. Da die CAN-Schnittstelle in allen Geräten galvanisch getrennt von den übrigen Schaltungsteilen aufgebaut ist, wird auch eine gemeinsame

Masseleitung (CAN_GND) in der Netzwerkverkabelung mitgeführt. Damit ist sichergestellt, dass alle

CAN-Schnittstellen im Netzwerk auf einem gemeinsamen Potenzial liegen. Im UCC1 besteht die Möglichkeit, den CAN-Ground auf Schaltungsmasse zu legen.

Jeder Bus-Teilnehmer hat 2 RJ-45 Buchsen für den Remote CAN-Bus. Die Buchsen sind parallel geschaltet und dienen als Eingang und Ausgang (zum Weiterschleifen) des Remote-Netzwerkes. Der

CAN-Bus muss an beiden Enden mit einem 120Ω Abschlusswiderstand terminiert werden. Zu diesem

Zweck liegen dem UCC1 zwei Abschluss-Stecker CAN-TERM 120Ω bei. Stecken Sie diese AbschlussStecker in die freien RJ-45 Buchsen des ersten und des letzten Gerätes am CAN-Bus.

27

Page 28

29

NETZWERK-BEISPIELE

Die folgenden Bilder zeigen Beispiele von Datenbusverdrahtungen in unterschiedlichen Grössenordnungen:

System mit 5 Verstärkern und einem UCC1 / PC am Bus-Anfang

Abschluss-Stecker am UCC1 (Bus-Anfang) und am Verstärker 5 (Bus-Ende)

System mit 2 Racks und einem UCC1 / PC in der Mitte

Abschluss-Stecker an Verstärker 6 (Bus-Anfang) und Verstärker 12 (Bus-Ende)

28

Page 29

NETZWERK-BEISPIELE

System mit mehreren Racks und mehreren UCC1 / PCs

UCC1 an beliebigen Stellen im CAN-Bus

Abschluss-Stecker an Verstärker 10 (Bus-Anfang) und Verstärker 16 (Bus-Ende)

In der Netzwerk-Verkabelung ist neben dem CAN-Bus auch das symmetrische Audio-Monitor Signal

zum Abhören der Endstufeneingänge und -ausgänge mitgeführt. Dieser Monitorbus ermöglicht das

softwaregesteuerte Abhören der Eingangs- oder Ausgangssignale aller im Remote-Netzwerk vorhandenen Endstufen ohne zusätzlichen Verdrahtungsaufwand. Am UCC1 liegt das Monitor Signal an der

XLR Output Buchse MONITOR an und kann beispielsweise auf einen Mischpulteingang gelegt und

über Kopfhörer oder direkt über eine aktive Monitorbox abgehört werden.

29

Page 30

31

CAN-BUS

Der CAN-Bus erlaubt die Verwendung unterschiedlicher

Baud Rate Bus Länge

Datenraten, wobei die Datenrate indirekt proportional zur

500 kbit/s 100 m

Buslänge ist. Wenn das Netzwerk nur eine geringe Ausdeh-

250 kbit/s 250 m

nung hat, sind höhere Baudraten bis zu 500 kbit/s möglich.

Bei grösseren Ausdehnungen muss die Baudrate herabge-

125 kbit/s 500 m

setzt werden (min. 10 kbit/s). Buslängen über 1000 m sollten

62.5 kbit/s 1000 m

grundsätzlich nur mit Repeatern realisiert werden.

20 kbit/s 2500 m

10 kbit/s 5000 m

LEITUNGSSPEZIFIKATIONEN

Gemäss dem ISO 11898-2 Standard sollten für den CAN-Bus als Datenübertragungskabel vorzugsweise Twisted-Pair-Leitungen, geschirmt oder ungeschirmt, mit einem Wellenwiderstand von 120Ω

zum Einsatz kommen. Als Leitungsabschluss muss an beiden Enden ein Abschlusswiderstand von

120Ω vorgesehen werden.

Die maximale Buslänge ist abhängig von der Datenübertragungsrate, von der Art des Datenübertragungskabels sowie von der Anzahl der Bus-Teilnehmer. Die folgende Tabelle zeigt die wesentlichen

Zusammenhänge für CAN-Netzwerke mit bis zu 64 Teilnehmern:

Buslänge

Widerstandsbelag Kabelquerschnitt

0 ... 40 m < 70 mΩ/m

40 ... 300 m < 60 mΩ/m

300 ... 600 m < 40 mΩ/m

600 ... 1000 m < 26 mΩ/m

*

Bei langen Leitungen und vielen Geräten am CAN-Bus werden hochohmigere Abschlusswiderstände als die

spezizierten 120Ω empfohlen, um die ohmsche Last für die Schnittstellentreiber und damit den Spannungs abfall von einem zum anderen Leitungsende zu verringern.

Datenübertragungskabel

0.25 ... 0.34 mm²

AWG23, AWG22

0.34 ... 0.6 mm²

AWG22, AWG20

0.5 ... 0.6 mm²

AWG20

0.75 ... 0.8 mm²

AWG18

Abschlusswider-

stand

Datenübertragungsrate

max.

124 Ω 1000 kbit/s bei 40 m

127 Ω 500 kbit/s bei 100 m

*

150 Ω ... 300 Ω

150 Ω ... 300 Ω

100 kbit/s bei 500 m

*

62.5 kbit/s bei 1000 m

Die nächste Tabelle dient zur ersten Abschätzung des erforderlichen Kabelquerschnitts für unterschiedliche Buslängen und verschiedene Anzahl der Bus-Teilnehmer:

Buslänge Anzahl der Geräte am CAN-Bus

32 64 100

100 m 0.25 mm² bzw. AWG24 0.34 mm² bzw. AWG22 0.34 mm² bzw. AWG22

250 m 0.34 mm² bzw. AWG22 0.5 mm² bzw. AWG20 0.5 mm² bzw. AWG20

500 m 0.75 mm² bzw. AWG18 0.75 mm² bzw. AWG18 1.0 mm² bzw. AWG17

Zu beachten ist noch die Länge der Abzweigleitungen, wenn ein Teilnehmer nicht direkt am CAN-Bus

angeschlossen ist. Diese Stichleitungen sollten bei Datenübertragungsraten bis zu 125 kbit/s eine Einzellänge von max. 2 m und bei höheren Bitraten von max. 0,3 m nicht überschreiten. Die Gesamtlänge

aller Abzweigleitungen sollte 30 m nicht übersteigen.

Grundsätzlich gilt:

Für die Rack-Verdrahtung können handelsübliche RJ-45 Patchkabel mit 100Ω Wellenwiderstand

verwendet werden (AWG 24 / AWG 26), wenn es sich nur um kurze Strecken handelt (bis zu

10 m). Für die Verdrahtung der Racks untereinander und in der Gebäudeinstallation sind unbedingt die oben genannten Richtlinien für die Netzwerkverkabelung einzuhalten.

30

Page 31

NETZBETRIEB & WÄRMEENTWICKLUNG

NETZBETRIEB

Mit Hilfe der folgenden Tabellen können die Anforderungen für Stromversorgung und Zuleitungen bestimmt werden. Für „normalen“ Betrieb können die Werte der Spalte „ max. Ausgangsleistung @ 4Ω“

verwendet werden. Die Endstufe wurde hier mit VDE-Rauschen bei der maximalen Ausgangsleitung

betrieben. Dies entspricht etwa der Belastung wenn die Endstufe mit Musiksignal mit der maximal

möglichen Lautstärke betrieben wird, ohne merklich in den Grenzbereich zu fahren.

WÄRMEENTWICKLUNG IN DER ENDSTUFE

Die vom Stromnetz aufgenommene Leistung wird in Ausgangsleistung für die Lautsprecher & Wärme

umgewandelt. Die Differenz aus aufgenommener Leistung und abgegebener Leistung nennt man Verlustleistung (Pd). Die durch Verluste entstehende Wärmemenge verbleibt u.U. im Rack und muss durch

geeignete Massnahmen abgeleitet werden. Zur Berechnung der Wärmeverhältnisse im Rack/Schrank

bzw. nötiger Abluftmassnahmen kann die nachfolgende Tabelle benutzt werden.

Die Spalte Pd zeigt die Verlustleistung bei verschiedenen Betriebszuständen. Die Spalte BTU/hr zeigt

die abgegebene Wärmemenge je Stunde.

P3000RL Normal Mode U

Netz

[V] I

Netz

[A] P

Netz

Leerlauf 230V 1.0 152 - 152 519

Max. Ausgangsleistung @ 8Ω

Max. Ausgangsleistung @ 4Ω

max. Ausgangsleistung @ 4Ω

max. Ausgangsleistung @ 4Ω

Normalbetrieb (-10dB) @ 4Ω

Nennbetrieb (0dB) @ 4Ω

Alarmbetrieb (-3dB) @ 4Ω

(1)

(1)

(1)

(1)

(1)

230V 13.8 2560 2 x 850 860 2934

230V 22.4 4330 2 x 1300 1730 5903

(1)

230V 13.9 2575 2 x 433 1709 5831

(2)

230V 7.8 1350 2 x 163 1024 3494

230V 8.0 1420 2 x 120 1180 4026

230V 21.6 4170 2 x 1200 1770 6040

230V 16.0 3020 2 x 610 1800 6142

Für 120V Netzspannung sind die Stromangaben in etwa zu verdoppeln

(1)

Aussteuerung mit Sinus-Signal

(2)

Aussteuerung mit VDE-Rauschen

(3)

1BTU = 1055.06J = 1055.06Ws

[W] P

[W] Pd [W] BTU/hr

out

(3)

31

Page 32

33

SPECIFICATIONS / TECHNISCHE DATEN

- System (amplier) at rated conditions, both channels driven, 8Ω loads, unless otherwise specied.

- Depending on the ambient temperature, the unit might not operate continuously at 2Ω load.

Load Impedance

Maximum Midband Output Power

THD = 1%, 1kHz

Rated Output Power

THD < 0.2%, 20Hz ... 20kHz

Max. Single Channel Output Power

Dynamic-Headroom, IHF-A

Maximum Bridged Output Power

THD = 1%, 1kHz

Maximum RMS Voltage Swing

THD = 1%, 1kHz

Power Consumption

at 1/8 maximum output power @ 4Ω

THD at rated output power,

MBW = 80kHz, 1kHz

IMD-SMPTE

60Hz, 7kHz

DIM30

3.15kHz, 15kHz

Crosstalk Attenuation

ref. 1kHz, at rated output power

Frequency Response

-0.5dB, ref. 1kHz

Damping Factor

1kHz

Signal to Noise Ratio, Amplier

A-weighted

Signal to Noise Ratio, System

A-weighted

Input Sensitivity

at rated output power @ 8Ω, 1kHz

internal selectable

8Ω 4Ω 2Ω

2x

850W

2x

750W

2x

1300W

2x

1200W

2x

1800W

2x

1700W

950W 1700W 2000W

2800W 3600W -

91V

1850W

< 0.05%

< 0.05%

< 0.05%

> 70dB

20Hz ... 20kHz

> 300

109dB

100dB

+6dBu (factory congured)

0dBu

26dB constant gain

Max. Input Voltage

Input Impedance

20Hz ... 20kHz, balanced

CMR

1kHz

Output Voltage

DSP OUT / Monitor

Output Impedance

DSP OUT / Monitor

Minimum Output Load

DSP OUT / Monitor

AD & DA Conversion

Sample Rate

Internal Wordlength

Dynamic Range

+21dBu (8.7V)

20kΩ

80dB

rated: +6dBu (1.55V)

max: +21dBu (8.7V)

< 100Ω

600Ω

Digital Signal Processing

24 Bit, Sigma-Delta, 128 x Oversampling, Linear Phase

48kHz

48 bit

115dB (typical)

32

Page 33

Functions

Interfaces

Control Port / GPIO

SPECIFICATIONS / TECHNISCHE DATEN

Volume Control, Routing,

X-Over (6, 12, 18, 24 dB/Oct Slope, Butterworth, Bessel, Linkwitz-Riley),

Filter (Parametric EQ, Lo / Hi Shelving EQ, LPN, Lo / Hi Pass, Allpass),

Compressor / Limiter, Delay

CAN-Bus, 10 ... 500 kbit/s, RJ-45 (PC Control)

RS-232, 19.2 kbit/s, 9-pol. SUB-D (Multi Media Control)

6-pol. Phoenix

2 Control Inputs

Inactive / OFF +5.0V (> 2.4V) or open (internal pull-up)

Active / ON 0V (< 0.8V)

2 Control Outputs

Inactive / OFF High (Open Collector)

Active / ON Low (< 0.5V / I = 0.7A)

Input Voltage +32.0V max.

Switching Current 1.0A max.

Reference Outputs +5.0V / 100mA and GND

Power Requirements

Protection

Cooling

Dimensions

(W x H x D), mm

Weight

240V, 230V, 120V, 100V / 50Hz ... 60Hz, factory congured

Audio limiters, High temperature, DC, HF, Back-EMF,

Peak current limiters, Inrush current limiters, Turn-on delay

Front-to-rear, 4-stage-fans

483 x 132.5 x 389.5

29kg

33

Page 34

35

BLOCK DIAGRAM AMPLIFIER

34

Page 35

A

D

A

D

D

A

D

A

A

D

A

D

24 BIT

DSP

SRAM

512k x

8

GAINRANGING

24 BIT ADC

GAINRANGING

24 BIT ADC

LP

F

LP

F

DUAL

24 BIT DA

C

INPUT

PARALLEL

-15V

+15V

AMPLIFIER

INTERFACE

CONTROL / SUPERVISION:

INPUT / OUTPUT LEVEL METE

R

PILOT SIGNAL GENERATOR

PILOT SIGNAL DETECTION

IMPEDANCE MEASUREMEN

T

AMP INPUT CH. A (SIGNALA / SENSINA)

AMP INPUT CH. B (SIGNALB / SENSINB)

ANALOG

POWER

SUPPLY

CLOCK

12.288 MHz

POWER

SUPPLY

CPU +

FLASH

RAM

A

D

CAN

UART

RESET

WATCHDOG

EEPROM

AMP TEMPERATURE (TEMP)

OUTPUT CURRENT CH.A (OUTCURA+/-)

OUTPUT CURRENT CH.B (OUTCURB+/-)

AMP OUTPUT RELAYS (TIMER)

OUTPUT VOLTAGE CH.A (OUTVOLA+/-)

STANDBY POWER SOURCE

+5V

+3.3V

DC

DC

RJ-45

MONITOR BUS

CAN / RS-485

+5V

CAN / RS-485

TRANSCEIVER

MONITOR

OUT B

MONITOR

IN A

MONITOR

IN B

MONITOR

OUT A

SLAVE OUT A

SLAVE OUT B

CLOCK

SPI

D

A

D

A

DUAL ADC

DUAL AD

C

I/O

DEVICE

ADDRESS

STATUS

SIGNAL PROCESSING:

FILTERS, X-OVER

DELAY

COMPRESSOR, LIMITER

ROUTING, LEVEL, POLARITY

I/O

MAINS POWER ON/OFF (POWER_ON)

AMP TYPE CODE (AMP_ID1-8)

LIMITER CH. A (LIMOUTA)

LIMITER CH. B (LIMOUTB)

GPIO

CONTROL

PORT

8

OUTPUT VOLTAGE CH.B (OUTVOLB+/-)

INPUT LEVEL CH. B

INPUT LEVEL CH.

A

+5V

GND

GROUND

FAULT

DETECTION

AMP PROTECT (PROTECT)

CHASSIS

8

STANDBY/ON SIGNAL (STANDBY)

4

CHANNEL A

INPUT

CHANNEL B

PARALLEL

GROUND FAULT CH. A (GNDFLTA)

GROUND FAULT CH. B (GNDFLTB)

VU INPUT A

VU INPUT B

DSP DIGITALBOARD

80477

NRS 90227

NRS 90208

NRS 90208

BLOCK DIAGRAM RCM-24

35

Page 36

37

5,5

375,5

426

132,5

483

440,5

131

ERNS

T

ERNS

T

DIMENSIONS / ABMESSUNGEN

36

Page 37

NOTES

37

Page 38

39

NOTES

38

Page 39

NOTES

39

Page 40

USA Telex Communications Inc., 12000 Portland Ave. South, Burnville, MN 55337, Phone: +1 952-884-4051, FAX: +1 952-884-0043

Germany EVI AUDIO, Hirschberger Ring 45, D 94315, Straubing, Germany Phone: 49 9421-706 0, FAX: 49 9421-706 265

Subject to change without prior notice. Printed in Germany 10/08/2002 / 361 711

www.electro-voice.de

Loading...

Loading...