Page 1

SERVICE MANUAL

Dx 38

24 BIT DIGITAL SOUND SYSTEM PROCESSOR

Page 2

WARRANTY (Limited)

Electro-Voice products are guaranteed against malfunction due to defects in materials or workmanship for a specified

period, as noted in the individual product-line statement(s) below, or in the individual product data sheet or owner’s

manual, beginning with the date of original purchase. If such malfunction occurs during the specified period, the

product will be repaired or replaced (at our option) without charge. The product will be returned to the customer

prepaid.

Exclusions and Limitations: The Limited Warranty does not apply to: (a) exterior finish or appearance; (b) certain

specific items described in the individual product-line statement(s) below, or in the individual product data sheet or

owner’s manual; (c) Malfunction resulting from use or operation of the product other than as specified in the product

data sheet or owner’s manual; (d): malfunction resulting from misuse or abuse of the product; or (e): malfunction

occurring at any time after repairs have been made to the product by anyone other than Electro-Voice or any of its

authorized service representatives.

Obtaining Warranty Service: To obtain warranty service, a customer must deliver the product, prepaid, to

Electro-Voice or any of its authorized service representatives together with proof of purchase of the product in the

form of a bill of sale or receipted invoice. A list of authorized service representatives is available from Electro-Voice

at 600 Cecil Street, Buchanan, MI 49107 (616-695-6831) and/or Electro-Voice West at 9130 Glenoaks Boulevard,

Sun Valley, CA 91532 (213-875-1900).

Incidental and Consequential Damages Excluded: Product repair or replacement and return to the customer are

the only remedies provided to the customer. Electro-Voice shall not be liable for any incidental or consequential

damages including, without limitation, injury to persons or property or loss of use. Some states do not allow the

exclusion or limitation of incidental or consequential damages so the above limitation or exclusion may not apply to

you. Other Rights : This warranty gives you specific legal rights, and you may have other rights which vary from state

to state.

Electro-Voice Electronics are guaranteed against malfunction due to defects in materials or workmanship for a

period of three (3) years from the date of original purchase. Additional details are included in the Uniform Limited

Warranty Statement.

Specifications subject to change without notice.

600 Cecil Street, Buchanan, Michigan 49107, Phone 616/695-6831, Fax: 616/695-1304

TELEX/EVI Audio Canada, 705 Progress Ave. Unit 46 Toronto, Onatario, M1H 2x1, Canada , Phone: 800/881-1685, Fax: 877/522-2242

TELEX Communications A.G., Keltenstrasse 11, CH-2563 IPSACH, Switzerland, Phone: 011-41/32-51-6833, Fax: 011-41/32-51-1221

EVI Audio Deutschland GmbH, Hirschberger Ring 45, D-94315, Straubing, Germany, Phone: 011-49/9421-7060, Fax: 011-49/9421-706265

EVI Audio France S.A., Parc de Courcerin-Allee Lech Walesa, Lognes, f-77185 Marne La Vallee, France, Phone: 011-33/1-6480-0090, Fax: 011-33/1-6006-5103

EVI Audio Japan Ltd., 2-5-60 Izumi, Suginami-ku, Tokyo, Japan 168, Phone: 011-81/3-3325-7900, Fax: 011-81/3-3325-7789

EVI Audio (Aust.) Pty., Unit 24, Block C, Slough Business Park, Slough Ave., Silverwater, N.S.W 2141, Australia, Phone 011-61/2-648-3455,

Fax: 011-61/2-648-5585

EVI Audio (Hong Kong) Limited, Unit E & F, 21 /F., Luk Hop Industrial Bldg., 8 Luk Hop St., San Po Kong, Kowloon, Hong Kong, Phone: 011-852/351-3628,

Fax: 011 -852/351-3329

Page 3

Table of Contents

- Safety and Service Instructions

-

- Warranty

-

- Architects and engineers specifications

-

- Measuring data

-

- Bill of materials

-

- Service notes / infos / instructions

-

- Spare parts plan

-

- Circuit diagrams

Electro-Voice

600 Cecil Street,

Buchanan,

Michigan 49107

Phone 616/695-6831

Fax 616/695-1304

e-mail fspain@qtm.net

Page 4

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol, within an equilateral triangle is intended to alert the user to the presence

of uninsulated “dangerous voltage” within the product’s

enclosure that may be of sufficient magnitude to constitute

a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintance (servicing) instructions in the

literature accompanying the appliance.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a damp cloth.

7. Do not block any of the ventilation openings.

Install in accordance with the manufactures instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that produce heat.

9. Only use attachments/accessories specified by the manufacturer.

10. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed to rain or moisture, does not operate normally, or has

been dropped.

For US and CANADA only:

Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third grounding prong.

The wide blade or the third prong are provided for your safety. When the provided plug does not fit into your outlet, consult an

electrican for replacement of the absolete outlet.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualified personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the

Operating Instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to be obeyed when

servicing the appliance.

2. Use of a mains separator transformer is mandatory during maintenance while the appliance is opened, needs to be

operated and is connected to the mains

3. Switch off the power before retrofitting any extensions, changing the mains voltage or the output voltage.

4. The minimum distance between parts carrying mains voltage and any accessible metal piece (metal enclosure),

respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not connected

to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the security symbol (Note) is only permissible

when using original parts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the location where the appliance is being serviced have to be strictly

obeyed. This applies also to any regulations about the work place itself.

8. All instructions concerning the handling of MOS - circuits have to be observed.

Note:

SAFETY COMPONENT (HAS TO BE REPLACED WITH ORIGINAL PART ONLY)

1-2

Page 5

BESCHREIBUNG

Mit 48 Bit Filteralgorithmen, 24 Bit AD/DA Wandlern und einem Dynamikbereich von 115 dB setzt der Dx 38 neue Maßstäbe für digitale

Lautsprecher Kontroller und Prozessoren. Der Dx 38 ist ein universell

einsetzbarer Digitaler Sound System Processor mit 2 Eingängen und

4 Ausgängen, sowie zusätzlich einer internen Summe der Eingänge 1

und 2. Die Ausgänge können in einer Matrix auf einen beliebigen

Eingang oder die Eingangssumme geroutet werden. Es können Stereo bzw. Dual 2-Weg-Systeme oder 3-Weg+Direct und 4-Weg Systeme, jeweils auch mit Mono Sub-Kanal, aber auch Fullrange Systeme

konfiguriert werden.

In allen Betriebsarten stehen Hoch- und Tiefpaß-Filter für die Frequenzweichen-Funktionen zur Verfügung. Die Auswahl umfaßt LinkwitzRiley, Butterworth und Bessel Filter mit wählbaren Flankensteilheiten

von 6, 12, 18 oder 24 dB/Okt. Eine große Anzahl weiterer Filter

ermöglicht eine äußerst flexible Frequenzgangskorrektur. In den Eingängen finden Sie jeweils einen 5-Band Equalizer, dessen einzelne

Filtersektionen beliebig mit High- und Low-Pass, High- und Low-Shelving oder parametrischen Peak-Dip-Filtern belegt werden können. In

den Ausgängen sind neben den Frequenzweichen-Filtern jeweils 4

weitere Filter enthalten, die ebenfalls als High- und Low-Pass Filter,

High- oder Low-Shelving-Filter, parametrische Peak-Dip-Filter, oder

Allpass-Filter programmiert werden können. Weitere Filtermöglichkeiten sind z. B. Hochpässe 2. Ordnung zur Realisierung von B-6 Alignments, oder spezielle LPN-Filter (Lowpass Notch / Tiefpaß-Sperrfilter)

zur Korrektur des Frequenz- und Phasengangs von Baßreflexboxen.

Zusätzlich ist jeder Kanal mit einem Delay, einem Polaritätswahlschalter, einem programmierbaren Pegelsteller und einem digitalen Kompressor / Limiter ausgestattet. In den Eingängen befinden sich

außerdem noch die Master-Delays.

Der Anwender hat die Wahl zwischen zwei Bedien-Modi: Im einfachsten Fall (No Edit Mode) brauchen nur die verwendeten Lautsprecherkombinationen aus der Liste der Factory Preset Programme ausgewählt werden. Das Gerät ist danach optimal auf die Audioanlage

eingestellt und sofort betriebsbereit. Im Full Edit Mode hingegen

besteht Zugriff auf sämtliche Parameter, so daß beliebige Einstellungen programmiert und gespeichert werden können. Es stehen insgesamt 80 Programmplätze - 50 für die Factory Presets, und weitere 30

für frei programmierbare User-Programme - zur Verfügung.

Die AD/DA-Wandlung im Dx 38 erfolgt mit linearen 24 Bit Wandlern,

wobei es sich in der AD-Sektion um gainranging Sigma-Delta-Wandler

mit 128-fachem Oversampling handelt. Im DA-Bereich wird mit SigmaDelta Wandlern mit 128-fachem Oversampling gearbeitet. Die Signalverarbeitung erfolgt auf zwei 24 Bit Motorola Signalprozessoren.

Technische Informationen

Architects and engineers

specifications

Dx 38

24 BIT DIGITAL SOUND

SYSTEM PROCESSOR

Weitere Merkmale sind:

- FLASH Speicher für Software und Preset Updates über

serielle Schnittstellen

- PC Bedien- und Konfigurationssoftware unter Windows 95 /

Windows 98

- MIDI-Schnittstelle standardäßig

- RS-232, RS-485 Schnittstellen oder Umschaltkontakte optional

- Grafik-Display mit 122 x 32 Dots, hintergrundbeleuchtet

- Ein- und Ausgänge elektronisch symmetrisch in XLR

- Trafosymmetrierung für die Eingänge optional

- Input / Output Pegelsteller, Output Mute Schalter, KanalFunktionsanzeigen SUB, LO, MID, HI

- Input / Output Aussteueranzeigen, Kompressor- und Clip-LED’s

DESCRIPTION

Providing 48-bit filter algorithms, 24-bit AD/DA conversion and a

dynamic range of 115 dB, the Dx 38 sets new standards for digital

loudspeaker controllers and processors. The Dx 38 is an universal

Digital Sound System Processor that provides 2 inputs and 4 outputs;

plus internal summing of the inputs 1 and 2. Via matrix it is possible to

assign the outputs to any input or to the sum of the inputs. It is further

possible to establish the following configurations: Stereo or Dual

2-Way systems, 3-Way + Direct and 4-Way systems, each with Mono

Sub-channel, but also full range systems.

High and low-pass filters are provided for the frequency crossover

functions in all operation modes. The selection includes Linkwitz-Riley, Butterworth and Bessel type filters with switchable slopes between

6, 12, 18 and 24 dB/oct. A huge number of additional filters offers

extremely flexible correction of the frequency response. Each input

incorporates a 5-band equalizer, allowing to assign high and low-pass,

high and low-shelving or parametric peak-dip filters to its individual

filter sections. Next to the frequency crossover filters, four additional

filters are employed in each output channel, which also can be set to

work as high or low-pass, high or low-shelving filters, parametric

peak-dip filters, or all-pass filters. Additional filtering is provided

through 2. order high-passes for the realization of B-6 alignment, or

special LPN-filters (Low-Pass Notch filters) for correcting the frequency and phase responses of optimally vented woofer cabinets. Each

channel additionally provides a delay, a polarity switch, a programmable level control and a digital compressor / limiter while the master

delays are located in the input channels.

The user can choose between two operation modes: the “No Edit

Mode” allows to simply select the required combination of loudspeaker

systems from the factory preset program list. Afterwards, the appliance

is optimally matched to the sound system and can be operated

instantly. The “Full Edit Mode” on the other hand offers access to all

parameters, allowing to freely program and store basically any setting.

A total number of 80 memory addresses - 50 preset and 30 freely

assignable user-programs - are available.

Page 6

Within the Dx 38, AD/DA conversion is taken care of by linear 24-bit

90 - 250 V AC / 50 - 60 Hz

converters; where the AD-section employs 128 times oversampling,

gain-ranging Sigma-Delta converters. The DA-section offers 128 times

oversampling Sigma-Delta converters. The overall signal processing

is performed by two 24-bit Motorola signal processors.

Additional features are:

- FLASH memory for software and preset updates via serial

interfaces

- PC-based operation and configuration software running under

Windows ‘95 / Windows ‘98

- Standard MIDI-interface

- RS-232, RS-485 interfaces or switching contacts optionally

available

- Back-lit graphic-display with 122 x 32 dots

- Inputs and outputs are electronically balanced, XLR-type

connectors

- Input transformer-balancing is optionally available

- Input / Output level controls, Output-Mute switch, channel

function indicators SUB, LO, MID, HI

- Input / Output meter instruments, compressor and clipping LEDs

DESCRIPTION

Avec ses algorithmes de filtrage travaillant en 48 bits, ses convertisseurs A/N et N/A 24 bits et sa gamme dynamique de 115 dB, le Dx

38 définit de nouveaux standards dans le domaine des contrôleurs et

processeurs numériques de haut-parleurs. Le Dx 38 est un processeur

numérique de diffusion universel ; il est pourvu de 2 entrées et 4 sorties,

un circuit interne permettant de sommer les entrées 1 et 2. Une matrice

permet d’assigner les sous-bandes du signal d’entrée stéréo (ou

sommé en mono) à n’importe quelle(s) sortie(s). D’origine, les configurations suivantes sont disponibles : systèmes stéréo 2 voies, mono

2 voies, 3 voies + sortie directe, ou système mono 4 voies, tous offrant

éventuellement une sortie mono pour canal Subwoofer et une sortie

“large bande”.

Dans tous les modes de fonctionnement, ce sont des filtres passe-haut

et passe-bas qui se chargent de répartir le spectre audio en plusieurs

bandes de fréquences (crossover). Ces filtres peuvent être de type

Linkwitz-Riley, Butterworth ou Bessel, avec des pentes commutables

entre 6, 12, 18 et 24 dB/octave. De nombreux autres correcteurs

permettent de modeler la courbe de réponse à votre guise : chaque

entrée possède par ailleurs cinq correcteurs, pouvant être un filtre

passe-haut ou passe-bas, un correcteur d’aigus ou de graves de type

Shelve (en plateau), ou un filtre paramétrique. Une fois le signal

d’origine réparti en plusieurs bandes, quatre autres correcteurs peuvent prendre place sur chaque canal de sortie : eux aussi peuvent

travailler en modes passe-haut ou passe-bas, correcteur d’aigus ou

de graves de type Shelve (en plateau), filtre paramétrique, voire filtre

passe-tout. Des fonctions de filtrage supplémentaires sont encore

prévues, sous la forme de filtres passe-haut du second ordre permettant la réalisation d’alignements de type B-6, ou des filtres spéciaux

de type LPN (pour Low-Pass Notch, filtres passe-bas de type Notch)

permettant de corriger la réponse en fréquence et en phase d’enceintes de graves travaillant en bass-reflex.

Chaque canal offre en plus un délai, un inverseur de phase, un réglage

de niveau programmable et un compresseur/limiteur numérique, les

délais principaux se trouvant au niveau des canaux d’entrée.

Deux modes de fonctionnement sont à la disposition de l’utilisateur :

le mode “No Edit”, qui ne permet que de sélectionner la combinaison

d’enceintes désirée dans la liste donnée par le Programme Preset

d’usine. Dans ce cas, l’appareil est configuré de façon optimale en

fonction de l’installation, et peut être exploité instantanément. Enfin, le

mode “Full Edit”, lui, permet d’accéder à tous les paramètres, ce qui

permet de programmer en toute liberté et de mémoriser ses Programmes. L’appareil compte 80 emplacements mémoire - 50 pour les

Programmes Presets d’usine et 30 pour les Programmes utilisateur.

À l’intérieur du Dx 38, les conversions A/N et N/A s’effectuent en 24

bits linéaires (Delta-Sigma, suréchantillonnage 128 fois), et les traitements du signal sont calculés par deux DSP Motorola 24 bits.

Parmi les autres caractéristiques :

- Mémoire FLASH pour le logiciel d’exploitation et les Presets,

ce qui permet la mise à jour via interface série.

- Logiciel de configuration et de commande pour PC, tournant

sous Windows 95/98.

- Interface MIDI Standard.

- En option, commande via interfaces RS-232, RS-485 ou

commutation par contacts.

- Affichage graphique rétro-éclairé, 122 x 32 points.

- Entrées et sorties sur XLR, symétrie électronique.

- En option, symétrisation par transformateur d’entrée.

- Potentiomètres de réglage des niveaux d’entrée et de sortie,

commutateur de coupure des sorties (Mute) indicateurs SUB,

LO, MID, HI par canal.

- Visualisation par VU-mètres des entrées/sorties, du compresseur,

LED d’écrêtage.

TECHNICAL SPECIFICATIONS

Mains voltage

Power consumption 20 watts

Safety class I

Inputs 2 x XLR IN, electronically balanced,

transformer optional available

2 x XLR OUT (Direct Out)

Input voltage (nominal) 1.55 V / + 6 dBu

Max. input voltage 24.5 V / + 30 dBu

Input impedance 20 kohms

Common mode rejection > 40 dB

AD-conversion 24-bit, Sigma-Delta, 128 times

oversampling, linear phase

Outputs 4 x XLR OUT, electronically balanced

Output voltage (nominal) 1.55 V / + 6 dBu

Max. output voltage 8.7 V / + 21 dBu

Output impedance < 100 ohms

Min. load impedance 600 ohms

DA-conversion 24-bit, Sigma-Delta, 128 times

oversampling

Frequency response 20 Hz - 20 kHz (- 0.5 dB)

S/N ratio 115 dB (typical)

Distortion without transformer < 0.01 %

Distortion with transformer < 0.05 %

Frequency crossovers 6, 12, 18, 24 dB/oct. slope;

Butterworth, Bessel, Linkwitz-Riley

Filters 26 parametric equalizers

Low-Shelving equalizer,

LPN (Lowpass-Notch) switchable

Hi-Shelving equalizer, 6 / 12 dB slope

switchable, Lo-Cut filter (B-6 alignment

switchable), Hi-Cut filter, All-Pass filter

Compressor / limiter 4 digital compressors / limiters

Delay 3 master delays (2 ms - 900 ms)

4 channel delays (0 ms - 900 ms)

delay-increment 21 µsec.

Data format 24-bit linear AD / DA conversion,

48-bit processing

Sampling rate 48 kHz

MIDI IN / OUT / THRU Data Dump, Master / Slave operation,

Remote Control

Display 122 x 32 Dots, graphic LC-Display with

LED-background lighting

Dimensions 483 x 43.6 x 374 (WxHxD in mm), 19", 1 HU

Weight 5 kg / 11 lbs

Locking function Protection against inadvertent operation

via function-lock

Accessories PA 1 plexiglas cover 1 HU

Options NRS 90244 Input transformer

NRS 90247 RS-485 interface

NRS 90246 Contact Closure interface

Page 7

Page 8

Measuring data Dx 38 – complete device

1. Power Supply

1.1 Operation Voltage U Mains 90 - 250 V AC, 50 - 60 Hz

1.2 Operation Current at U Mains = 110 V AC 200 mA

at U Mains = 230 V AC 130 mA

1.3 Power Consumption 14 W

1.4 Internal Operation Voltage +5 V ± 0,1 V

+18 V ± 1 V

-18 V ± 1 V

1.5 Internal Operation Currents +5 V max. 460 mA

+18 V max. 400 mA

-18 V max. 250 mA

1.6 Power Supply Switching Frequency 192 kHz

2. Inputs

2 x XLR IN, electronically balanced, 2 x XLR Direct Out,

Input transformers (NRS 90244) are optionally available

2.1 Input Impedance electronically balanced 20 kΩ

2.2 Input Voltage [1] 4,5 V = +15 dBu

Max. Input Voltage 24,5 V = +30 dBu

2.3 Common Mode Rejection CMRR ≥ 40 dB

3. Outputs

4 x XLR OUT, electronically balanced

3.1 Output Impedance < 100 Ω

3.2 Min. Load Impedance 600 Ω

3.3 Max. Output Voltage [1] 8,7 V = +21 dBu

3.4 Output Symmetry [1] [2] ≥ -40 dB

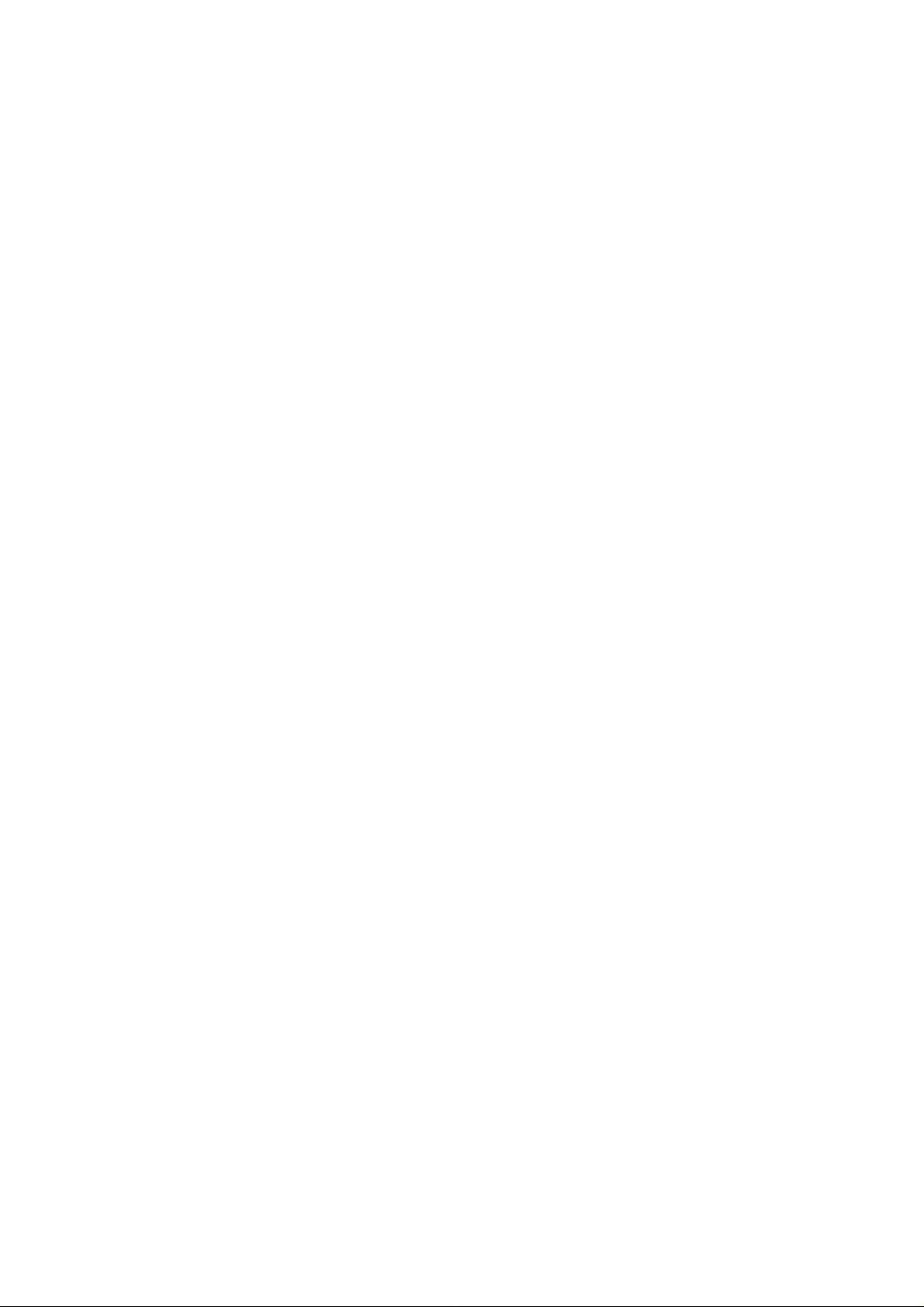

4. Frequency Response

4.1 Frequency Response [3] fig. 1 30 Hz ... 20 kHz - 0.5 dB

5. Crosstalk

5.1 Crosstalk Attenuation [3] > 80 dB

1

Page 9

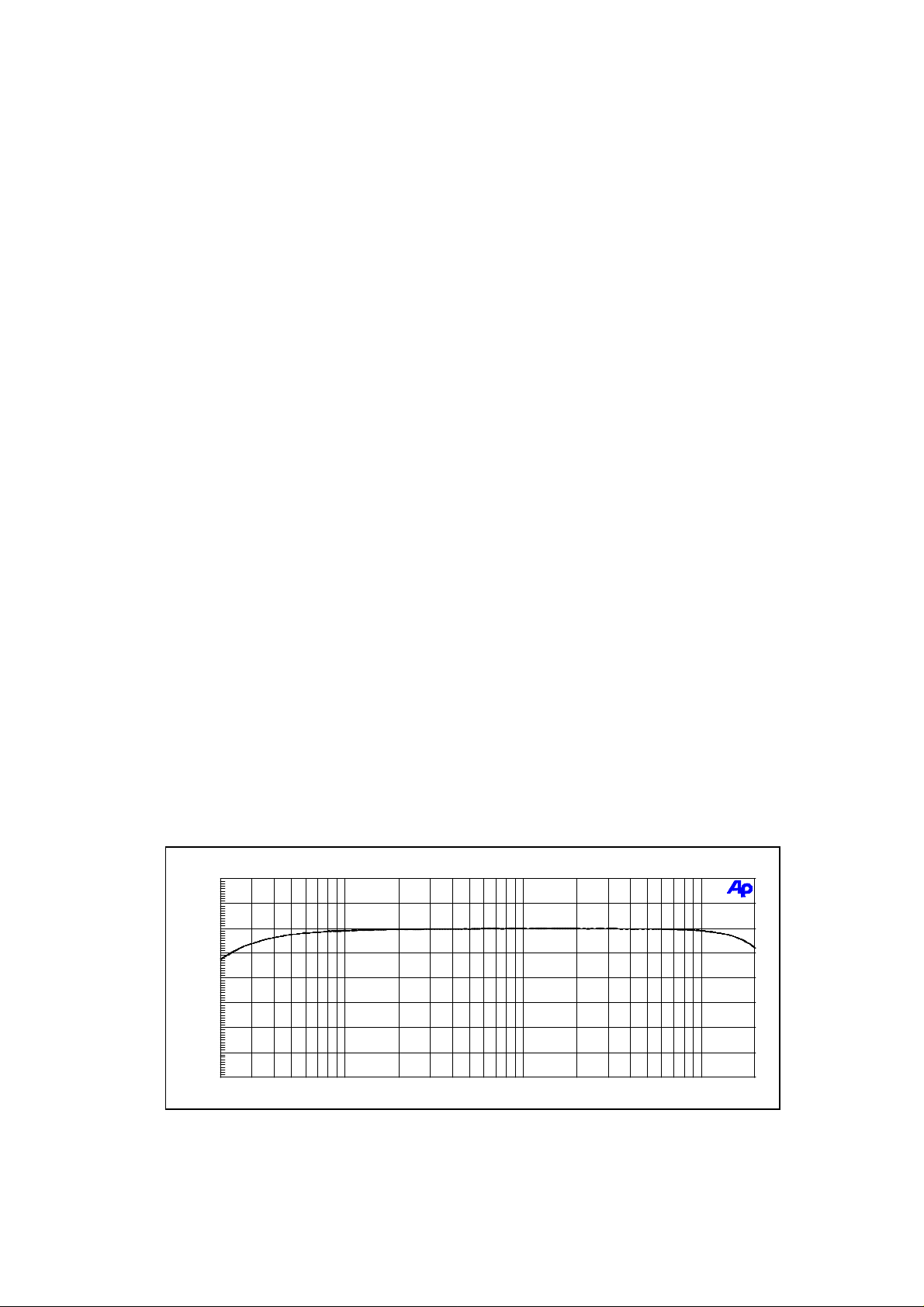

6. Distortion

6.1 THD+N [4] fig. 2 , fig. 3 20 Hz ... 20 kHz < 0.01 % @ +10 dBu

7. Interference Voltages

7.1 Wide Band Noise Voltage [5] ≤ 50 µV = -84 dBu

7.2 Noise Voltage (CCIR 468-3) [6] ≤ 140 µV = -75 dBu

7.3 Noise Voltage (A-weighted) [7] ≤ 18 µV = -93 dBu

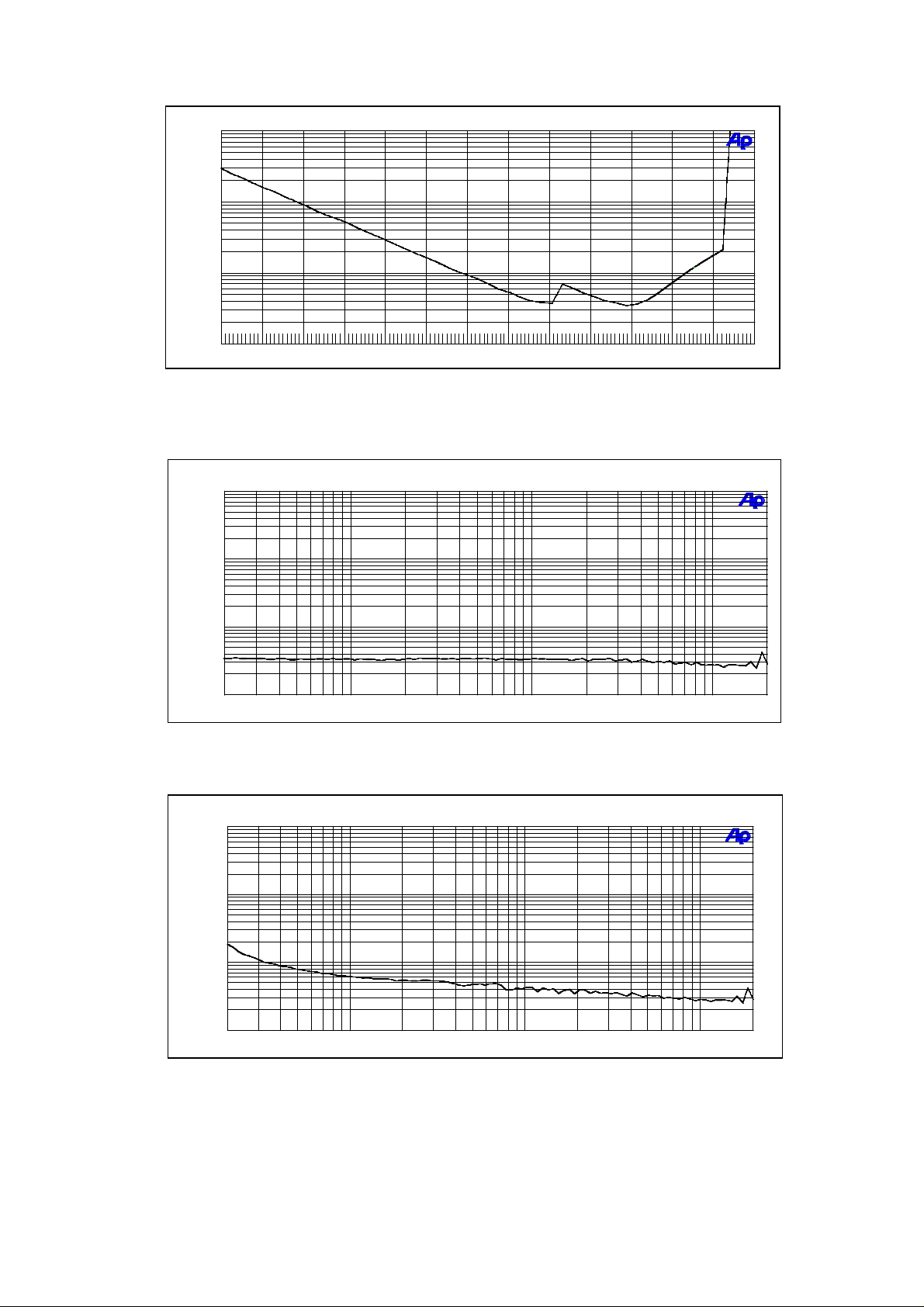

8. Retrofitting Input Transformers

Retrofitting input transformers NRS 90244 results in the change of the following values:

8.1 THD+N [4] figure 4 70 Hz ... 20 kHz < 0.01 % @ +10 dBu

THD+N [4] figure 4 20 Hz ... 20 kHz < 0.05 % @ +10 dBu

9. Other Specifications

9.1 Operation Temperature Range +5 ... +40 °C

9.2 Temperature Range During Storage And Shipment -40 ... +70 °C

10. Dimensions And Weight

10.1 Dimensions W x H x D 19" (483 mm) x 1 HU (43,6 mm) x 374 mm

10.2 Installation Depth Without Connectors 356 mm

10.3 Installation Depth Incl. Connectors approx. 430 mm

10.4 Weight 5 kg

10.5 Weight with 2x NRS 90244 5.2 kg

11. Standards

11.1 Safety Class according to EN 60065 safety class I, grounded

11.2 Electrical Safety In Accordance To EN 60065 (VDE 0860) or IEC 65

UL, CSA

11.3 EMC In Accordance To EN 50081-1, EN 50082-1, EN 55022-B

12. Retrofiting-Kits

12.1 NRS 90244 input transformer for 1 input Order No. 112 757

12.2 NRS 90246 contact closure interface Order No. 112 766

12.3 NRS 90247 RS-485 interface Order No. 112 767

13. General

13.1 The following equipment had been used for measuring:

Digital Multi-Meter PM 2517 X Philips

System One Audio Precision

Oscilloscope 2465 A Tektronix

Regulation de-coupling transformer RT 5A Grundig

Watt-Meter (electronical) Dynacord

2

Page 10

13.2 Comments about measurements

04/09/99 12:28:14

Frequency response

- Unless differently stated, all measurement has been performed at 20°C ± 2°C

- All stated levels ± 1 dB

[1] all controls set to their clockwise margin

[2] Service program 'SINE WAVE OUT' , set a level of 0 dB,

Output voltage = approx. 8,9 V = +21 dBu = 0 dBr,

+ and - outputs summed via 10 kΩ / 0,1 % resistors, with VR301 ... VR601

adjusted for minimum levels U ≤ 87 mV = -19 dBu = -40 dBr

[3] measured with service program 'ORIGINAL THRU' , level 0 dB, all controls set to their

clockwise margin, input level +10 dBu

[4] measured with service program 'ORIGINAL THRU' , level 0 dB,

input controls at center position, output controls set to their clockwise margin

[5] measured with service program 'ORIGINAL THRU' , level 0 dB, all controls

set to their clockwise margin,

measurement via bandpass filter 22 Hz ... 22 kHz, weighting filter set to 20 kHz Lo-Pass,

Q-Peak, input terminated with 600 Ω

[6] measured with service program 'ORIGINAL THRU' , level 0 dB, all controls

set to their clockwise margin,

measurement via bandpass filter 22 Hz ... 22 kHz, weighting filter set to CCIR 468-3,

Q-Peak, input terminated with 600 Ω

[7] measured with service program 'ORIGINAL THRU' , level 0 dB, all controls

set to their clockwise margin,

measurement via bandpass filter 22 Hz ... 22 kHz, weighting filter set to 'A-weighting',

RMS, input terminated with 600 Ω

Figure 1 Frequency Response [dBr] [3]

3

Page 11

Figure 2 THD+N [%] as a function of the input level [dBu] [4] , f = 1 kHz

04/19/99 17:01:22

THD+N vs Level

04/20/99 08:53:11

THD+N vs Frequency

04/20/99 11:46:46

THD+N vs Frequency

Figure 3 THD+N [%] as a function of the frequency [Hz] [4] , input level = +10 dBu

Figure 4 THD+N [%] as a function of the frequency [Hz] [4] , input level = +10 dBu

with input transformer (NRS 90244) installed

4

Page 12

14. Specifications

Mains voltage 90 - 250 V AC / 50 - 60 Hz

Power consumption 20 watts

Safety class I

Inputs 2 x XLR IN, electronically balanced, transformer optional

available 2 x XLR OUT (Direct Out)

Input voltage (nominal) 1.55 V / + 6 dBu

Max. input voltage 24.5 V / + 30 dBu

Input impedance 20 kohms

Common mode rejection > 40 dB

AD-conversion 24-bit, Sigma-Delta, 128 times oversampling, linear phase

Outputs 4 x XLR OUT, electronically balanced

Output voltage (nominal) 1.55 V / + 6 dBu

Max. output voltage 8.7 V / + 21 dBu

Output impedance < 100 ohms

Min. load impedance 600 ohms

DA-conversion 24-bit, Sigma-Delta, 128 times oversampling

Frequency response 20 Hz - 20 kHz (- 0.5 dB)

S/N ratio 115 dB (typical)

Distortion without transformer < 0.01 %

Distortion with transformer < 0.05 %

Frequency crossovers 6, 12, 18, 24 dB/oct. slope;

Butterworth, Bessel, Linkwitz-Riley

Filters 26 parametric equalizers

Low-Shelving equalizer, LPN (Lowpass-Notch) switchable

Hi-Shelving equalizer, 6 / 12 dB slope switchable,

Lo-Cut filter (B-6 alignment switchable),

Hi-Cut filter, All-Pass filter

Compressor / limiter 4 digital compressors / limiters

Delay 3 master delays (2 ms - 900 ms)

4 channel delays (0 ms - 900 ms)

delay-increment 21 µsec.

Data format 24-bit linear AD / DA conversion, 48-bit processing

Sampling rate 48 kHz

MIDI IN / OUT / THRU Data Dump, Master / Slave operation/ Remote Control

Display 122 x 32 Dots, graphic LC-Display with

LED-background lighting

Dimensions 483 x 43.6 x 374 (W x H x D in mm), 19", 1 HU

Weight 5 kg / 11 lbs

Locking function protection against inadvertent operation via function-lock

Accessories / Options PA 1 plexiglas cover 1 HU

NRS 90244 Input transformer

NRS 90247 RS-485 interface

NRS 90246 Contact Closure interface

5

Page 13

15. Service Programs

The Dx 38 provides several onboard service programs that allow testing internal function blocks.

The service mode is entered by simultaneously pressing the ' EDIT ' and ' > ' keys while the unit is

powered on.

The display shows briefly: SERVICE MODE

Selecting the service programs in sequence is possible by using the SELECT keys or via the rotary

encoder. Pressing the ' RECALL ' key launches the previously selected program or, while a service

program is running, to cancel the test.

Switching the device off or by use of the < QUIT > command, the service mode is ceased.

Available Service Programs:

• µP-ROM TEST

• µP-RAM TEST

• EEPROM TEST

• KEY TEST

• ENCODER TEST

• LED TEST

• DISPLAY TEST

• RS232 TEST

• RS485 TEST

• CONTACT P TEST

• MIDI TEST

• DSP-RAM TEST

• HW-CONN TEST

• ORIGINAL THRU

• SINE WAVE OUT

• PINK NOISE

• WHITE NOISE

• A/D GAIN CALIB

• A/D GAIN RNG 1

• A/D GAIN RNG 2

• INITIALIZE MEM

• FLASH PROGRAM

• STATISTICS

• QUIT

µP-ROM TEST

The Flash-ROM (IC102 on the 80449 Digital Board) gets tested by calculating the checksum of

the memory contents. If no error has been detected, the display shows ' OK '. If a faulty condition

has been detected, the calculated checksum appears on the display.

µP-RAM TEST

The µP-RAM (IC103 on the 80449 Digital Board) is tested. If no error has been detected, the

display shows ' OK '. If a faulty condition has been detected, the corresponding address or

respectively the erroneously read data appear on the display.

6

Page 14

EEPROM TEST

The EEPROM (IC105 on the 80449 Digital Board) is tested. If no error has been detected, the

display shows ' OK '. If a faulty condition has been detected, the corresponding address or

respectively the erroneously read data appear on the display.

KEY TEST

The function of all keys gets tested. The function of the key that gets pressed appears on the

display. Testing is canceled by pressing the rotary encoder.

ENCODER TEST

The function of the rotary encoder gets tested. When turning the wheel, the direction (+/-) and

the amount of impulses is displayed.

LED TEST

All LEDs on the front of the appliance are checked. All LEDs are accessed in sequential order.

Upon ending the test, all LEDs light.

DISPLAY TEST

This program is meant for testing the LC-display and setting its contrast. Using the rotary

encoder lets you adjust the LCD-contrast in a range between -10 to +10.

After pressing any key, a graphic pattern appears on the display, which allows checking whether

all pixels are active.

RS232 TEST

The RS-232 interface gets tested by sending and reading back data. During this test, pins 2 and

3 of the RS-232 connector have to be bridged by using a special bridging-plug.

If no error has been detected, the display shows ' OK '. If a faulty condition has been detected,

the display shows whether the data was corrupted during the internal reading (in the UART, IC1)

or at the external bridging plug.

RS-485 TEST

The optional RS-485 interface gets tested by sending and reading back data.

If no error has been detected, the display shows ' OK '. If a faulty condition has been detected,

the display shows whether the data was corrupted during the internal reading (in the UART, IC1)

or at the external RS-485 driver (IC2).

CONTACT P TEST

The optional contact closure port is tested. Therefore the bit-pattern which is present at pins 1-8

is read and shown on the display. By connecting external contacts to ground potential, the pins

can be pulled to "0". The test is completed with OK when each contact had been closed at least

once.

MIDI TEST

The MIDI interface gets tested. Therefore you have to connect the MIDI IN and MIDI OUT

connectors with a MIDI-cable. If no error has been detected, the display shows ' OK '. Otherwise,

the display shows: FAIL (no receive).

DSP-RAM TEST

Here, the delay memory gets tested. The data and address busses from the DSP to the RAMs

(IC203 and IC204 on the 80449 Digital Board) are tested in sequential order. If no error has been

detected, the display shows ' OK '. If a faulty condition has been detected, the number of the

faulty data or address bus appears on the display.

HW-CONN TEST

This test checks internal status and control lines. Special hardware is necessary to perform this

test. It is not recommended to perform this test with the appliance being a standalone

unit. Instead, always use a testing-adapter.

7

Page 15

ORIGINAL THRU

Within this program, the incoming data is directly send to the outputs, without employing

additional signal processing. Output is carried out in a 2 in 2 configuration, i. e. input 1 is

assigned to the outputs 1 and 2, Input 2 is assigned to 3 and 4.

The rotary encoder lets you control the level in the range between 0 to -99 dB.

SINE WAVE OUT

This program tests the entire output signal path (DSP, D/A converters, output channels). After

starting the program, a 1 kHz sine signal is generated in the DSP, which is output to all 4

channels.

The default level setting is -24 dB. The rotary encoder lets you control the level in the range

between 0 to -99 dB.

PINK NOISE

"Pink noise" is generated in the DSP, which then is output to all 4 channels. The default level

setting is -24 dB. The rotary encoder allows controlling the level in the range between 0 and

-99 dB.

WHITE NOISE

"White noise" is generated in the DSP, which then is output to all 4 channels. The default level

setting is -24 dB. The rotary encoder allows controlling the level in the range between 0 and

-99 dB.

A/D GAIN CALIB

This program serves for calibrating the gain-ranging AD-converters. The difference in the levels

between high and low inputs at the ADC is automatically measured and stored.

For automatic calibration, a sine signal with approx. 0dBu / 1kHz has to be fed to both inputs.

Level differences are measured and displayed. Too high or too low signal levels are also

indicated on the display. CAUTION: The use of this program should be left to the

experienced and well-educated service technician. Inaccurate calibration can result in the

degradation of the dynamic range or even in erroneous functioning of the appliance.

A/D GAIN RNG 1

This program serves for precisely displaying and adjusting the level difference between the gainranging A/D converter's two channels of input 1. The value is indicated in dB and in hex-code. in

the degradation of the dynamic range or even in erroneous functioning of the appliance.

CAUTION: The use of this program should be left to the experienced and well-educated

service technician. Inaccurate calibration can result in the degradation of the dynamic

range or even in erroneous functioning of the appliance.

A/D GAIN RNG 2

This program serves for precisely displaying and adjusting the level difference between the gainranging A/D converter's two channels of input 2. The value is indicated in dB and in hex-code.

CAUTION: The use of this program should be left to the experienced and well-educated

service technician. Inaccurate calibration can result in the degradation of the dynamic

range or even in erroneous functioning of the appliance.

INITIALIZE MEM

This program erases all entries of the user preset memory U01 - U30 and re-sets the unit's

programming to the initial state (as shipped). The initialize function is ended with a software

reset. Upon re-start the appliance is set to the factory program F01.

CAUTION: To prevent the total loss of user-defined data, previously backing-up the

contents of the user preset memory, using the Dx 38 editor software, onto a PC or

notebook computer is strongly recommended.

8

Page 16

ENCODER TYPE

This program allows setting the appliance to the employed type of encoder. Changing the

encoder type is only necessary when older models with serial numbers up to 11228 (Dx 38) are

updated to a new operating system (V1.10 or newer). When shipped, the appliance is always

correctly factory-set, matching the employed encoder type.

STATISTICS

This program provides indication of how often the appliance has been switched on (Power on

count) and its hours of operation (Opr. Time).

QUIT

This command ceases the test mode. The appliance re-starts with the program that was active

before entering test mode.

Testing The µP-System During Power-On

During switching on the unit or performing a hardware reset, the indication of the status-LEDs D101

and D102 (located on the Digital PCB 80449) lets you localize a fault in the processor system.

The following happens in sequential order during a hardware reset of the Dx 38 CPU-system:

1. Hardware Reset → D101 lights D102 lights

2. CPU Start and Initialization

o. k. → D101 dimmed D102 lights

3. Checksum Test Bootload-ROM

fault → System 'hangs'

o. k. → D101 lights D102 dimmed

4. External RAM Test

fault → System 'hangs'

o. k. → D101 dimmed D102 dimmed

5. Checksum Test Application-ROM

fault → bootloader controls LEDs and RS232

D101 blinks with non-irq-task

D102 blinks with irq-task

o. k. → application starts and controls LEDs and RS232

D101 blinks with non-irq-task

D102 blinks with irq-task

9

Page 17

Page 18

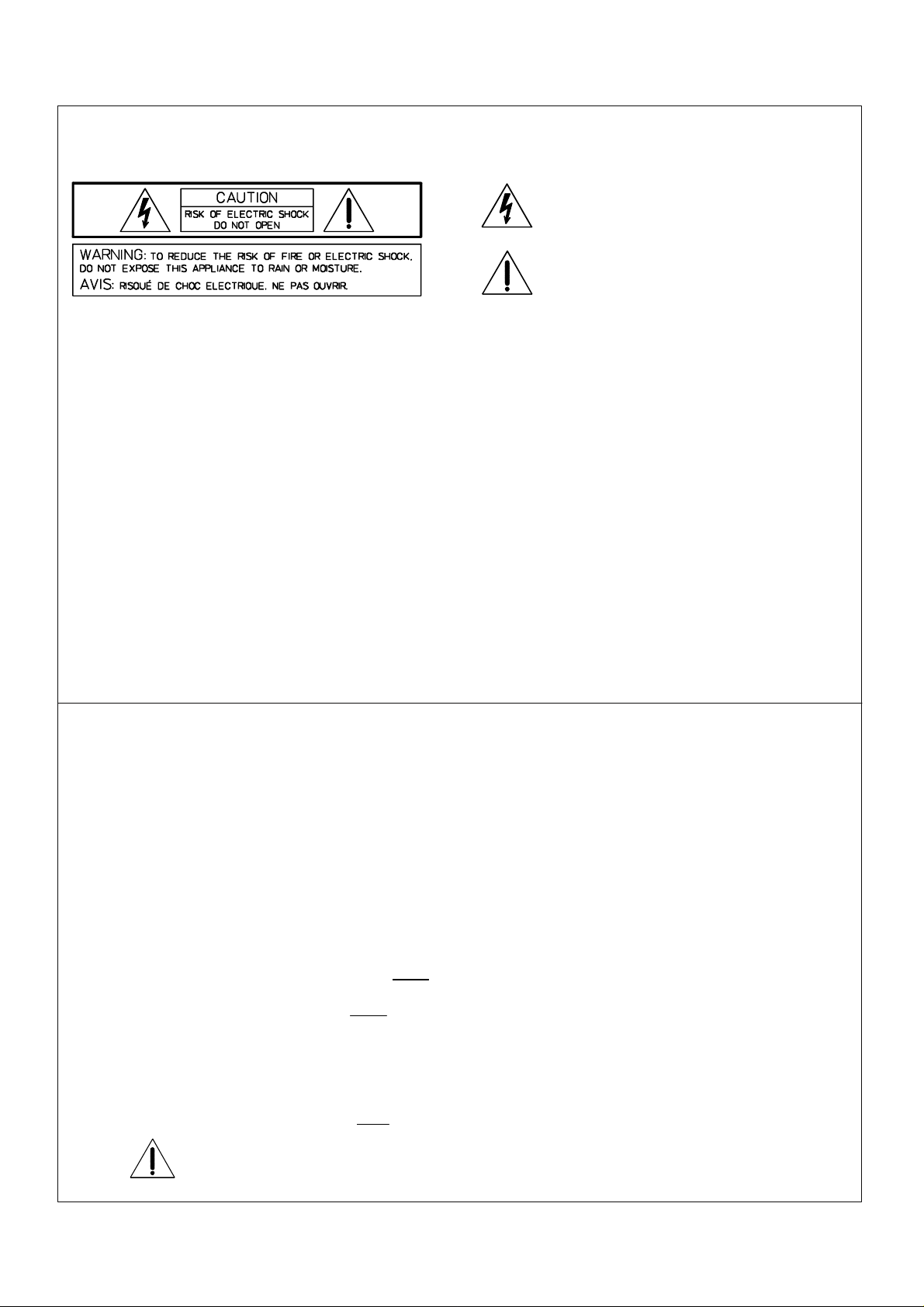

IN 1 LEFT

/ MONO

IN 2

RIGHT

90 - 250V ac

50-60Hz 30W

1 2

3

1 2

3

1 2

3

1 2

3

AC

DC

INPUT 1

INPUT 2

+18V

-18V

+5V

A

D

A

D

GAINRANGING

24 BIT ADC

A

D

A

D

GAINRANGING

24 BIT ADC

AUDIO

CONTROL

CLOCK

48 kHz

DRAM

1M x 8

24 BIT

DIGITAL

SIGNAL PROCESSOR

SPI

16 BIT

HOST

CPU

D

D

DUAL

24 BIT DAC

D

D

DUAL

24 BIT DAC

128k x 16

FLASH

12

OUT 1

3

LPF

LPF

OUTPUT 1

12

OUT 2

3

A

A

OUTPUT 2

12

OUT 3

3

LPF

LPF

OUTPUT 3

12

OUT 4

3

A

A

OUTPUT 4

Option:

RS-485

INTERFACE

Option:

CONTACT

CLOSURE PORT

32k x 8

RAM

8k x 8

EEPROM

RS-232

PC INTERFACE

RESET

WATCHDOG

KEYBOARD

ROTARY ENCODER

SPI

LEDs

LEVEL METER

UART

LCD

122 x 32 DOTS

MIDI

OUTTHRUIN

I/O

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Stücklisten - Bill of materials

170086

DX 38

Pos. Nr.

Best. Nr.

Zubehör

Accessories

Mechanische Teile

Metal work

Platinen

printed circuit boards

804488

PCBAR#DX 38

pcb assy 80448

Ref. No.

Z 020 345095 FUSS-GUMMI 12.7X 3.5 rubber foot

Z0050 356311 BEDIENUNGSANL. DX 38 owner's manual

Z0052 357771 BEDIENUNGSANL. DX 38 FRA. owner's manual french

Z0055 357755 PRESET LIST DX 38 list of presets

Z0060 300425 KABEL-NETZ 2.0 M 10A power cable Europe

Z0070 357653 * ZUBEHÖR: SOFTWARE DX 38 software dx38

Z0080 356958 KABEL-SCHNITTSTELLE cable interface

Part No. Bezeichnung Description

354617 KABEL-NETZ UL/CSA 15A/125V power cable US

337059 KNOPF-TASTE 12X7 SW 3.3 push button black 12x7

347430 TK 10X6 SW 2,8 push button black 10x6

356454 DK 11 SW/GR/SW A 6FL rotary knob

356272 DK 28 SW 6 rotary knob

356275 KAPPE 28 SW cap for rotary knob

356062 EINLEGEFOLIE DSP 244 mylar for display

356507 STECKER-KALTGERÄTE mains connector male

302581 SICHER T 800 MA 250V fuse 800 mA slow blow

356499 KRT. DSP 244 512X422X102 carton

357500 STYROPOR-EINLAGE DSP 244 carton filler

333375 SCHUTZHÜLLE 500X700X0,05 poly bag

357961 DAT.BLATT/EDS DX 38 eds dx38

356216 FB.DX 38 BED front panel dx38

356466 BLEND.DX38/DSP244 BED panel sub

356218 DEC.DX 38 BED cover chassis

old 357036 NETZTEIL-SCHALT BEARB.AUS power supply switching

new !! *1 357007 NETZTEIL-SCHALT switching power supply

CN101 345489 MESSERLST. 6POL connector male 6-pin

CN301 345489 MESSERLST. 6POL connector male 6-pin

CN501 345489 MESSERLST. 6POL connector male 6-pin

CN701 352198 MESSERLST. 48POL connector male 48-pin

CN702 348676 STIFTLEISTE 3POL MLSS connector male 3-pin

CN703 356589 STIFTLEISTE 26POL connector male 36-pin

C0101 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0102 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0103 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0104 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0105 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0106 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0107 335787 KO-KER 15.0PF 100V 2% cap ceramic 15pF

C0108 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0109 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0110 340988 KO-FOL 0.470MF 63V 5% cap mylar 470nF

Page 31

Pos. Nr.

Ref. No.

Best. Nr.

C0111 340988 KO-FOL 0.470MF 63V 5% cap mylar 470nF

C0112 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0113 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0114 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0115 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0116 326922 KO-FOL 1000.000PF 100V 5% cap mylar 1nF

C0117 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0118 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0119 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0120 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0121 326922 KO-FOL 1000.000PF 100V 5% cap mylar 1nF

C0122 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0123 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0124 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0125 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0126 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0127 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0128 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0129 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0130 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0131 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0132 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0133 301472 KO-EL 10.000MF 63V cap electrolytic 10uF/63V

C0201 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0202 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0203 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0204 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0205 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0206 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0207 335787 KO-KER 15.0PF 100V 2% cap ceramic 15pF

C0208 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0209 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0210 340988 KO-FOL 0.470MF 63V 5% cap mylar 470nF

C0211 340988 KO-FOL 0.470MF 63V 5% cap mylar 470nF

C0212 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0213 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0214 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0215 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0216 326922 KO-FOL 1000.000PF 100V 5% cap mylar 1nF

C0217 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0218 301524 KO-KER 47.0PF 500V 10% cap ceramic 47pF

C0219 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0220 327365 KO-EL 47.000MF 25V BIP cap electr. bip 47uF/25V

C0221 326922 KO-FOL 1000.000PF 100V 5% cap mylar 1nF

C0222 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0223 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0224 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0225 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0226 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0227 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0228 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0229 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0230 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

Part No. Bezeichnung Description

Page 32

Pos. Nr.

Ref. No.

Best. Nr.

C0231 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0301 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0302 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0303 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0304 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0305 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0306 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0307 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0308 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0309 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0310 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0311 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0312 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0313 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0314 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0315 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0316 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0317 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0318 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0319 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0320 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0350 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0351 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0352 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0353 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0354 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0355 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0356 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0357 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0358 301472 KO-EL 10.000MF 63V cap electrolytic 10uF/63V

C0359 301472 KO-EL 10.000MF 63V cap electrolytic 10uF/63V

C0360 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0361 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0362 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0363 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0364 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0365 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0366 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0367 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0368 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0369 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0401 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0402 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0403 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0404 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0405 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0406 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0407 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0408 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0409 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0410 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0411 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0412 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

Part No. Bezeichnung Description

Page 33

Pos. Nr.

Ref. No.

Best. Nr.

C0413 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0414 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0415 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0416 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0417 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0418 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0419 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0420 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0501 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0502 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0503 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0504 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0505 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0506 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0507 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0508 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0509 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0510 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0511 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0512 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0513 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0514 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0515 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0516 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0517 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0518 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0519 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0520 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0550 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0551 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0552 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0553 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0554 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0555 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0556 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0557 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0558 301472 KO-EL 10.000MF 63V cap electrolytic 10uF/63V

C0559 301472 KO-EL 10.000MF 63V cap electrolytic 10uF/63V

C0560 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0561 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0562 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0563 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0564 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0565 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0566 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0567 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0568 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0569 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0601 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0602 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0603 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0604 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0605 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

Part No. Bezeichnung Description

Page 34

Pos. Nr.

Ref. No.

Best. Nr.

C0606 327568 KO-FOL 0.010MF 63V 5% cap mylar 10nF

C0607 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0608 326924 KO-FOL 2200.000PF 100V 5% cap mylar 2200pF

C0609 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0610 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0611 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0612 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0613 343530 KO-EL 47.000MF 50V cap electrolytic 47uF/50V

C0614 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0615 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0616 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0617 301530 KO-KER 100.0PF 500V 10% cap ceramic 100pF

C0618 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0619 343533 KO-EL 220.000MF 25V cap electrolytic 220uF/25V

C0620 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0701 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0702 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0703 342923 KO-FOL 0.220MF 63V 5% cap mylar 220nF

C0704 342923 KO-FOL 0.220MF 63V 5% cap mylar 220nF

C0705 335909 KO-EL 220.000MF 50V cap electrolytic 220uF/50V

C0706 335909 KO-EL 220.000MF 50V cap electrolytic 220uF/50V

C0707 342937 KO-FOL 1.000MF 63V 5% cap mylar 1uF

C0708 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0709 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0710 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0711 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0712 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0713 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0714 356763 KO-EL 47.000MF 35V cap electrolytic 47uF/35

C0715 356763 KO-EL 47.000MF 35V cap electrolytic 47uF/35

C0716 301566 KO-KER 2200.0PF 100V 10% cap ceramic 2200pF

C0717 356763 KO-EL 47.000MF 35V cap electrolytic 47uF/35

C0718 356763 KO-EL 47.000MF 35V cap electrolytic 47uF/35

C0719 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0720 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0721 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0722 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0723 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0724 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0725 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0726 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0727 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0728 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0729 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0730 356508 KO-KER 0.10MF 50V 20% cap ceramic 100nF

C0801 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0804 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

D0101 301297 DIODE BAT 85 diode BAT 85

D0102 301297 DIODE BAT 85 diode BAT 85

D0103 301297 DIODE BAT 85 diode BAT 85

D0104 301297 DIODE BAT 85 diode BAT 85

D0105 301297 DIODE BAT 85 diode BAT 85

D0106 301297 DIODE BAT 85 diode BAT 85

Part No. Bezeichnung Description

Page 35

Pos. Nr.

Ref. No.

Best. Nr.

D0107 301297 DIODE BAT 85 diode BAT 85

D0108 301297 DIODE BAT 85 diode BAT 85

D0110 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0111 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0112 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0201 301297 DIODE BAT 85 diode BAT 85

D0202 301297 DIODE BAT 85 diode BAT 85

D0203 301297 DIODE BAT 85 diode BAT 85

D0204 301297 DIODE BAT 85 diode BAT 85

D0205 301297 DIODE BAT 85 diode BAT 85

D0206 301297 DIODE BAT 85 diode BAT 85

D0207 301297 DIODE BAT 85 diode BAT 85

D0208 301297 DIODE BAT 85 diode BAT 85

D0210 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0211 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0301 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0401 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0501 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0601 301254 DIODE 1N 4148 AXIAL diode 1N 4148

D0701 352129 DIODE MUR 120 RL diode mur 120 rl

D0801 301254 DIODE 1N 4148 AXIAL diode 1N 4148

FL101 346765 KO-SO MTB 271 KB FILTER safety component

FL102 346765 KO-SO MTB 271 KB FILTER safety component

FL201 346765 KO-SO MTB 271 KB FILTER safety component

FL202 346765 KO-SO MTB 271 KB FILTER safety component

FL301 346765 KO-SO MTB 271 KB FILTER safety component

FL302 346765 KO-SO MTB 271 KB FILTER safety component

FL401 346765 KO-SO MTB 271 KB FILTER safety component

FL402 346765 KO-SO MTB 271 KB FILTER safety component

FL501 346765 KO-SO MTB 271 KB FILTER safety component

FL502 346765 KO-SO MTB 271 KB FILTER safety component

FL601 346765 KO-SO MTB 271 KB FILTER safety component

FL602 346765 KO-SO MTB 271 KB FILTER safety component

IC101 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC102 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC103 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC104 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC106 332984 IC LM 339 4FACH VCOMP IC LM 339

IC201 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC202 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC203 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC204 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC302 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC303 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC304 344864 IC NJM 4556 AD 2-FACH OP IC NJM 4556 D

IC402 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC403 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC404 344864 IC NJM 4556 AD 2-FACH OP IC NJM 4556 D

IC502 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC503 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC504 344864 IC NJM 4556 AD 2-FACH OP IC NJM 4556 D

IC602 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

IC603 327197 IC NE 5532 P 2FACH OP IC NE 5532 N

Part No. Bezeichnung Description

Page 36

Pos. Nr.

Ref. No.

Best. Nr.

804568

PCB--*DX 38 N 3

pcb assy 80456

IC604 344864 IC NJM 4556 AD 2-FACH OP IC NJM 4556 D

IC701 357034 IC SPNG.REGL. LM 2940 CT-15 IC LM 2940 voltage regul.

IC702 357033 IC SPNG.REGL. LM 2990 T -15 IC LM 2990 voltage regul.

IC703 354201 IC SPNG.REGL. LM 2594N ADJ IC LM2594N voltage regul.

IC704 356764 IC SPNG.REGL. BA 05 T IC BA 05 voltage regul.

IC801 333739 IC PC 900 OPTOKOPPLER IC PC 900

IC802 333458 IC MC 74 HC 14 AN IC MC 74 HC 14

JS101 354555 BUCHSE-FL. XLR 3POL connector xlr female 3-pin

JS102 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male

JS201 354555 BUCHSE-FL. XLR 3POL connector xlr female 3-pin

JS202 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male

JS301 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male

JS401 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male

JS501 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male

JS601 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male

JS801 303093 BUCHSE-DIODE 5POL socket DIN 5-pole

JS802 303093 BUCHSE-DIODE 5POL socket DIN 5-pole

JS803 303093 BUCHSE-DIODE 5POL socket DIN 5-pole

L0701 354450 DROSSEL 150.00UH/0.70A coil 150uH

L0702 354450 DROSSEL 150.00UH/0.70A coil 150uH

L0703 335966 DROSSEL 47.00UH/0.45A coil 47 UH

L0704 354450 DROSSEL 150.00UH/0.70A coil 150uH

L0705 354202 DROSSEL 47.00UH/1.10A inductor 47uH/1.1A

L0801 339139 FERRITPERLE EXC-ELDR35C coil

L0802 339139 FERRITPERLE EXC-ELDR35C coil

L0803 339139 FERRITPERLE EXC-ELDR35C coil

L0804 339139 FERRITPERLE EXC-ELDR35C coil

L0805 339139 FERRITPERLE EXC-ELDR35C coil

L0806 339139 FERRITPERLE EXC-ELDR35C coil

Q0350 346764 TRANS BS 170 N-CHAN trans. BS 170

Q0351 301184 TRANS BC 550 C transistor BC 550 B

RL301 356761 RELAIS M4-12H relay m4-12h

RL401 356761 RELAIS M4-12H relay m4-12h

RL501 356761 RELAIS M4-12H relay m4-12h

RL601 356761 RELAIS M4-12H relay m4-12h

R0135 340299 WI-SI 2.20 OHM 0.30W 5% safety resistor 2.20 Ohm

R0235 340299 WI-SI 2.20 OHM 0.30W 5% safety resistor 2.20 Ohm

R0350 329215 WI-SI 10.00 OHM 0.30W 5% safety resistor 10 ohm

R0550 329215 WI-SI 10.00 OHM 0.30W 5% safety resistor 10 ohm

VR301 348487 WI-TRI 4.70 KOHM LIN pot trim 4.7 kohm lin

VR401 348487 WI-TRI 4.70 KOHM LIN pot trim 4.7 kohm lin

VR501 348487 WI-TRI 4.70 KOHM LIN pot trim 4.7 kohm lin

VR601 348487 WI-TRI 4.70 KOHM LIN pot trim 4.7 kohm lin

Part No. Bezeichnung Description

CN301 348676 STIFTLEISTE 3POL MLSS connector male 3-pin

CN302 356505 MESSERLST. 26POL MICS 26 connector male 26-pin

CN303 346759 MESSERLST. 18POL connector male 18-pin

CN304 345489 MESSERLST. 6POL connector male 6-pin

CN305 356742 FEDERLEISTE 48POL V42254-B2 connector female 48-pole

C0201 340988 KO-FOL 0.470MF 63V 5% cap mylar 470nF

C0202 340244 KO-FOL 0.330MF 63V 5% cap mylar 330nF

C0303 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

Page 37

Pos. Nr.

Ref. No.

Best. Nr.

862468

PCBSB*DX 38

pcb assy 86246

862478

PCBSB*DX 38

pcb assy 86247

C0305 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0306 340522 KO-EL 10.000MF 35V cap electrolytic 10uF/35

C0308 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0309 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

D0101 351469 LED RT 3MM LS 3369-EH led red

D0102 351469 LED RT 3MM LS 3369-EH led red

X0201 348962 QUARZ-OSZIL. 12.2880MHZ crystal 12.288 mhz

CN001 356505 MESSERLST. 26POL MICS 26 connector male 26-pin

CN002 356504 FEDERLEISTE 20POL SL-120-TT connector female 20-pole

CN003 345489 MESSERLST. 6POL connector male 6-pin

CN004 345489 MESSERLST. 6POL connector male 6-pin

CN005 345489 MESSERLST. 6POL connector male 6-pin

CN006 354851 STECKERLEISTE 2POL 11730 connector male 2-pin

D0001 354003 LED RT 3MM LOW CURRENT led red

D0002 354004 LED GN 3MM LOW CURRENT led green

D0003 354004 LED GN 3MM LOW CURRENT led green

D0004 354004 LED GN 3MM LOW CURRENT led green

D0005 354004 LED GN 3MM LOW CURRENT led green

D0006 354004 LED GN 3MM LOW CURRENT led green

D0007 354003 LED RT 3MM LOW CURRENT led red

D0008 354004 LED GN 3MM LOW CURRENT led green

D0009 354004 LED GN 3MM LOW CURRENT led green

D0010 354004 LED GN 3MM LOW CURRENT led green

D0011 354004 LED GN 3MM LOW CURRENT led green

D0012 354004 LED GN 3MM LOW CURRENT led green

LCD01 356588 DISPLAY LCD PS 12232LRU-BNN lcd display

S0001 346243 SCHALTER-TAST 2XUM switch momentary dpdt

S0002 346243 SCHALTER-TAST 2XUM switch momentary dpdt

S0003 346243 SCHALTER-TAST 2XUM switch momentary dpdt

S0004 346243 SCHALTER-TAST 2XUM switch momentary dpdt

S0005 349114 SCHALTER-NETZ mains switch

VR001 354889 P-DREH 10KOHM LIN B pot rotary 10k lin

VR002 354889 P-DREH 10KOHM LIN B pot rotary 10k lin

VR003 354889 P-DREH 10KOHM LIN B pot rotary 10k lin

VR004 354889 P-DREH 10KOHM LIN B pot rotary 10k lin

Part No. Bezeichnung Description

CN020 345489 MESSERLST. 6POL connector male 6-pin

CN021 346759 MESSERLST. 18POL connector male 18-pin

D0020 356501 LED RT 3MM L-934 LID led red

D0021 356503 LED GE 3MM L-934 LYD led yellow

D0022 356502 LED GN 3MM LOW CURRENT led green

D0023 356502 LED GN 3MM LOW CURRENT led green

D0024 356502 LED GN 3MM LOW CURRENT led green

D0025 356503 LED GE 3MM L-934 LYD led yellow

D0026 356503 LED GE 3MM L-934 LYD led yellow

D0027 356503 LED GE 3MM L-934 LYD led yellow

D0028 356501 LED RT 3MM L-934 LID led red

D0029 356503 LED GE 3MM L-934 LYD led yellow

D0030 356502 LED GN 3MM LOW CURRENT led green

D0031 356502 LED GN 3MM LOW CURRENT led green

Page 38

Pos. Nr.

Ref. No.

Best. Nr.

831138

PCBAR"DSP 244 N 6

pcb assy 83113

D0032 356502 LED GN 3MM LOW CURRENT led green

D0033 356503 LED GE 3MM L-934 LYD led yellow

D0034 356503 LED GE 3MM L-934 LYD led yellow

D0035 356503 LED GE 3MM L-934 LYD led yellow

D0036 356501 LED RT 3MM L-934 LID led red

D0037 356503 LED GE 3MM L-934 LYD led yellow

D0038 356502 LED GN 3MM LOW CURRENT led green

D0039 356502 LED GN 3MM LOW CURRENT led green

D0040 356502 LED GN 3MM LOW CURRENT led green

D0041 356503 LED GE 3MM L-934 LYD led yellow

D0042 356503 LED GE 3MM L-934 LYD led yellow

D0043 356503 LED GE 3MM L-934 LYD led yellow

D0044 356501 LED RT 3MM L-934 LID led red

D0045 356503 LED GE 3MM L-934 LYD led yellow

D0046 356502 LED GN 3MM LOW CURRENT led green

D0047 356502 LED GN 3MM LOW CURRENT led green

D0048 356502 LED GN 3MM LOW CURRENT led green

D0049 356503 LED GE 3MM L-934 LYD led yellow

D0050 356503 LED GE 3MM L-934 LYD led yellow

D0051 356503 LED GE 3MM L-934 LYD led yellow

D0052 356503 LED GE 3MM L-934 LYD led yellow

D0053 356503 LED GE 3MM L-934 LYD led yellow

D0054 356503 LED GE 3MM L-934 LYD led yellow

D0055 356503 LED GE 3MM L-934 LYD led yellow

D0056 336399 LED RT 3MM TLUR 4401 LED red 3mm

D0057 336399 LED RT 3MM TLUR 4401 LED red 3mm

D0058 336399 LED RT 3MM TLUR 4401 LED red 3mm

D0059 336399 LED RT 3MM TLUR 4401 LED red 3mm

S0020 348874 SCHALTER-TAST 1XEIN SW switch push momentary spst

S0021 348874 SCHALTER-TAST 1XEIN SW switch push momentary spst

S0022 348874 SCHALTER-TAST 1XEIN SW switch push momentary spst

S0023 348874 SCHALTER-TAST 1XEIN SW switch push momentary spst

S0024 348874 SCHALTER-TAST 1XEIN SW switch push momentary spst

S0025 348874 SCHALTER-TAST 1XEIN SW switch push momentary spst

S0026 354891 SCHALTER-INCREMENTALGEBER switch & encoder

new !! *1 357100 SCHALTER-INCREMENTALGEBER switch & encoder

VR020 354890 P-DREH 2X 10KOHM LOG SEMI K pot rotary 2x10k log (K)

VR021 354890 P-DREH 2X 10KOHM LOG SEMI K pot rotary 2x10k log (K)

Part No. Bezeichnung Description

CN001 356589 STIFTLEISTE 26POL connector male 36-pin

CN002 352115 BUCHSE-SUB-D 9POL d-sub connector 9-pin

C0001 301522 KO-KER 22.0PF 500V 10% cap ceramic 22pF

C0002 301522 KO-KER 22.0PF 500V 10% cap ceramic 22pF

C0003 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0004 340520 KO-EL 1.000MF 50V cap electrolytic 1uF/50V

C0005 340520 KO-EL 1.000MF 50V cap electrolytic 1uF/50V

C0006 340520 KO-EL 1.000MF 50V cap electrolytic 1uF/50V

C0007 340520 KO-EL 1.000MF 50V cap electrolytic 1uF/50V

C0008 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0009 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0010 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0011 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

Page 39

Pos. Nr.

Ref. No.

Best. Nr.

112766

NRS 90246

retrofit 90246

contact closure interface

831148

PCB DSP 244 N 6

pcb retrofit 90246

112767

NRS 90247

retrofit 90247

RS-485 interface

831158

PCBAR: DSP244

pcb retrofit 90247

FL001 346765 KO-SO MTB 271 KB FILTER safety component

FL002 346765 KO-SO MTB 271 KB FILTER safety component

IC002 352105 IC MAX 232 CPE IC MAX 232

IC003 331913 IC MC 74 HC 04 N IC MC 74 HC 04 N

X0001 354376 QUARZ 3.6864MHZ HC-49-U crystal 3.6864 mhz

00120 339842 FEDERLEISTE 6POL CE156- connector female 6-pole

00130 344861 FEDERLEISTE 3POL CE156- connector female 3-pole

357762 BLENDE-BED NRS 90246 panel retrofit 90246

CN001 356589 STIFTLEISTE 26POL connector male 36-pin

CN002 348707 STECKER-SUB-D 9POL PRINTB. connector sub-d 9-pin

C0001 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0002 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0003 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0004 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0005 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0006 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0007 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0008 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0009 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0010 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0011 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

IC001 341636 IC SN 74 HC573 N IC SN 74 HC573 N

IC002 341636 IC SN 74 HC573 N IC SN 74 HC573 N

IC003 331920 IC MC 74 HC 00 N IC MC 74 HC 00 N

L0001 339139 FERRITPERLE EXC-ELDR35C coil

RN001 339686 DICKS-NETZW. SILT 09E 103J resistor netw RKL 9S 103J

RN002 339686 DICKS-NETZW. SILT 09E 103J resistor netw RKL 9S 103J

Part No. Bezeichnung Description

357761 BLENDE-BED NRS 90247 front panel retrofit 90247

CN001 356589 STIFTLEISTE 26POL connector male 36-pin

C0001 301522 KO-KER 22.0PF 500V 10% cap ceramic 22pF

C0002 301522 KO-KER 22.0PF 500V 10% cap ceramic 22pF

C0003 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0004 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0005 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0006 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

FL001 346765 KO-SO MTB 271 KB FILTER safety component

FL002 346765 KO-SO MTB 271 KB FILTER safety component

IC002 354175 IC SN 75176 BP RS 485 IC SN 75176

IC003 331913 IC MC 74 HC 04 N IC MC 74 HC 04 N

Page 40

Pos. Nr.

Ref. No.

Best. Nr.

JS001 354555 BUCHSE-FL. XLR 3POL connector xlr female 3-pole

JS002 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male 3-pin

X0001 354376 QUARZ 3.6864MHZ HC-49-U crystal 3.6864 mhz

Part No. Bezeichnung Description

Notes:

*1 please see service informations

Page 41

Stücklisten - Bill of materials

112767

NRS 90247 RS-485 INTERFACE

retrofit 90247

Pos. Nr.

Best. Nr.

Zubehör

Accessories

Mechanische Teile

Metal work

Platinen

Printed circuit boards

831158

PCBAR:DSP 244 N 6

pcb assy retrofit 90247

Ref. No.

CN001 356589 STIFTLEISTE 26POL connector male 36-pin

C0001 301522 KO-KER 22.0PF 500V 10% cap ceramic 22pF

C0002 301522 KO-KER 22.0PF 500V 10% cap ceramic 22pF

C0003 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0004 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0005 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0006 343532 KO-EL 100.000MF 25V cap electrolytic 100uF/25V

C0007 340523 KO-EL 22.000MF 16V cap electrolytic 22uF/16V

C0008 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0009 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0010 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

C0011 329021 KO-KER 0.10MF 100V 20% cap ceramic 100nF

FL001 346765 KO-SO MTB 271 KB FILTER safety component

FL002 346765 KO-SO MTB 271 KB FILTER safety component

IC002 331937 IC MC 74 HC 86 N IC MC 74 HC 86 N

IC004 354486 IC MAX 1480 BCPI IC MAX 1480

JS001 354555 BUCHSE-FL. XLR 3POL xlr connector female 3-pole

JS002 351816 STECKER-FL. XLR 3POL PRINTB xlr connector male 3-pin

X0001 354376 QUARZ 3.6864MHZ HC-49-U crystal 3.6864 mhz

Part. No. Bezeichnung Description

334989 SCHRGEWF C M3 X 6-ST-H screw M3x6

336245 KRT. L 2100 160X88X64 carton

347529 SCHUTZBEUTEL 127X305 poly bag

357761 BLENDE-BED NRS 90247 front panel retrofit 90247

Page 42

Service Information January 2000

Part No. 357007

Replacing the power supply board on DX 38

The switching Power supply board has been changed to a new one with part number 357007.

If the seria lnumber on your Dx38 is lower than 11099, you have to replace the old cable

harness by the provided cable harness (see drawing).

By checking the colours of the cables you can see, if there is the old or the new cable harness

built in.

80448

80449

blue red black

orange

grey

red ora

nge

greyblackblu

e

PSU

Page 43

Service Information February 2000

Replacing the Data-Encoder on DX 38

If you have to replace the data-encoder, you have to use the old one ( part-# 354891 ) as long

the serial number of your unit is below 11229.

All units with serial numbers 11229 and higher use the new encoder ( part-# 357100 ).

In case you want to use the new encoder on units with serial numbers below 11229 you have

to replace the complete front pcb: #86247 and to update the software to enable the new

encoder.

The current firmware version can be downloaded from our website::

www.electro-voice.de

To enable the new encoder you have to go to the service mode of the DX38:

- Press the SELECT-button to the right side and the EDIT-button simultaneously while

switching power on.

- The unit will start in SERVICE MODE

- Step through test menu with the SELECT button until you reach “ENCODER TYPE“.

- Push RECALL, the unit will show „STEPS/DETEND 2“

- Change with encoder to „STEPS/DETEND 1“

- Press RECALL again, then you can switch off the unit

- Your unit has stored the usage of the new encoder

Wrong encoder behavior

In some cases, especially on units which have a serial number below 10060 there could be a

problem when upgrading to a firmware revision higher than 1.02.

If the encoder reacts wrong while turning and takes two steps instead of one, use the above

service procedure and set the ENCODER TYPE to „STEP/DETEND 2“

Warning:

Never use any other service program on the unit !

Loading...

Loading...