Page 1

0906941

Single and Multi-Channel

EGT, CHT, Carb Temp and OAT Instruments

Operating and Installation Instructions

OII 0906941

You must read this manual before installing or operating the instrument. This

manual contains warranty and other information that may affect your decision

to install this product and/or the safety of your aircraft.

9/6/94

(This manual covers 25 instruments and remote switches)

(Supersedes OI 070781, II 070781, OI 040831 and II 070781-1)

(FAA Approved)

S/N:_____________________

Electronics International Inc. ®

63296 Powell Butte Hwy Bend, OR 97701 (541) 318-6060 Buy-EI.com

Page 2

Important Installation Information

All steps must be read before installing a probe.

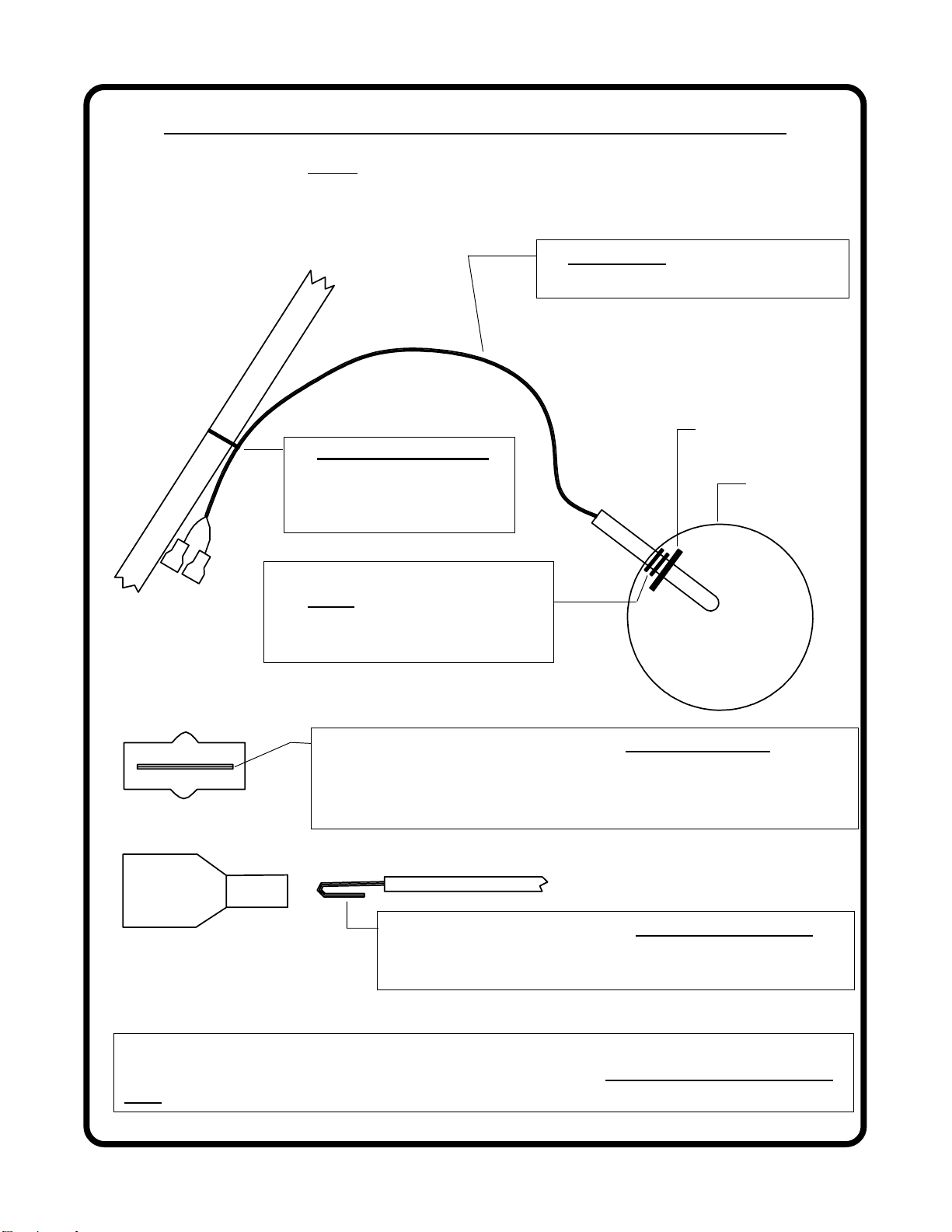

F

1. Leave slack in the cable to allow

for engine movement and vibration.

S.S. Washer.

2. Do Not Overtighten.

Over time, tight wire

wraps will cause the wire

to break.

Hose Clamp.

0720921

E

Male Conn.

3. Both clip rings must be on

the inside of the hose clamp.

The rubber band is used to hold

the washer on during shipping.

4. The tab inside the male connector must be centered (not

bent up or down) to mate properly. Check each connector

before installation. Two drops of oil on the connector will

protect it from corrosion for many years.

5. If you remove a connector, double over the wire

before installing it into a new connector. Each connector must be double crimped very tightly.

6. If connectors have been disconnected several times the female connector may become

loose. If this happens use a pair of needle nose pliers to retighten the female recep-

tacle then mate the connectors.

Page 3

Important Notice

***** MUST READ *****

If you think it is not important to read this manual, you're wrong! This manual

contains important installation information that may affect the safety of your aircraft, delay your installation or affect the operation of your instrument. You

read this manual prior to installing your instrument. Any deviation from these

installation instructions is the sole responsibility of the installer/pilot and may

render the STC invalid.

Read the Warranty / Agreement. There is information in the Warranty / Agreement that may alter

your decision to install this product. If you do not accept the terms of the Warranty / Agreement, do not

install this product. This product may be returned for a refund. Contact Electronics International inc. for

details.

Check that the instrument make and model marked on the side of the instrument and on the invoice are

correct before starting the installation.

Must

It is possible for any instrument to fail thereby displaying inaccurate high, low or jumpy readings.

Therefore, you must be able to recognize an instrument failure and you must be proficient in operating your

aircraft safely in spite of an instrument failure. If you do not have this knowledge, contact the FAA or a

local flight instructor for training.

The pilot

to operate the aircraft that does not know the operation of this product. Keep the Operating Manual in the

aircraft at all times.

must understand the operation of this product before flying the aircraft. Do not allow anyone

Page 4

Contents

Warranty --------------------------------------------------------------------------- 2

Operating Instructions: ----------------------------------------------------------- 3

Features ------------------------------------------------------------------------------------------ 3

EGT's --------------------------------------------------------------------------------------------- 4

CHT's -------------------------------------------------------------------------------------------- 7

Carburetor Temperature ----------------------------------------------------------------------- 8

Outside Air Temperature ---------------------------------------------------------------------- 8

Installation Instructions: ---------------------------------------------------------- 9

1. Important Information and Initial Check Out ------------------------------------------ 9

2. CHT Probe Installation ------------------------------------------------------------------- 10

3. EGT Probe Installation -------------------------------------------------------------------- 10

4. Carb. Temp. Probe Installation ---------------------------------------------------------- 10

5. OAT Probe Installation ------------------------------------------------------------------- 11

6. Route the Extension Cables -------------------------------------------------------------- 11

7. Hook Up Connecting Wires -------------------------------------------------------------- 13

8. Connect and Install the Instrument and/or Remote Switch ------------------------- 13

9. System Ground Test ----------------------------------------------------------------------- 13

Troubleshooting Suggestions ---------------------------------------------------- 14

1. Instrument Check Out --------------------------------------------------------------------- 14

2. Probe Check Out --------------------------------------------------------------------------- 14

3. Extension Cable Check Out -------------------------------------------------------------- 14

Specifications and Operating Features ----------------------------------------- 16

Instrument Wiring Diagram ----------------------------------------------------- 17

Remote Switch Diagram

(RS-4-1, RS-4-2, RS-6-1, and RS-6-2) ----------------- 18

Remote Switch Diagram (RS-8-1 and RS-12-1) ---------------------------------- 19

STC Information ------------------------------------------------------------------ 20

1

Page 5

Warranty / Agreement

Electronics International Inc. warrants this instrument and system components to be free from defects in

materials and workmanship for a period of one year from the user invoice date. Electronics International Inc. will repair or replace any item under the terms of this Warranty provided the item is returned

to the factory prepaid.

1. This Warranty shall not apply to any product that has been repaired or altered by any person other

than Electronics International Inc., or that has been subjected to misuse, accident, incorrect wiring,

negligence, improper or unprofessional assembly or improper installation by any person. This warranty

does not cover any reimbursement for any persons time for installation, removal, assembly or repair.

Electronics International retains the right to determine the reason or cause for warranty repair.

2. This warranty does not extend to any machine, vehicle, boat, aircraft or any other device to which the

Electronics International Inc. product may be connected, attached, interconnected or used in conjunction

with in any way.

3. The obligation assumed by Electronics International Inc. under this warranty is limited to repair,

replacement or refund of the product, at the sole discretion of Electronics International Inc.

4. Electronics International Inc. is not liable for expenses incurred by the customer or installer due to

factory updates, modifications, improvements, upgrades, changes, or any other alterations to the product

that may affect the form, fit, function or operation of the product.

5. Personal injury or property damage do to misinterpretation or lack of understanding this product is solely the

pilots responsibility. The pilot must understand the operation of this product before flying the aircraft. Do not

allow anyone to operate the aircraft that does not know the operation of this product. Keep the Operating Manual

in the aircraft at all times.

6. E. I. Inc. is not responsible for shipping charges or damages incurred under this Warranty.

7. No representative is authorized to assume any other liability for Electronics International Inc. in

connection with the sale of Electronics International Inc. products.

8. If you do not agree to and accept the terms of this warranty, you may return the product for a

refund.

This Warranty is made only to the original user. THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOST PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS

EXPRESSLY PROVIDED HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY

TO PURCHASER OR ANY OTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURERS PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN

TORT.

2

Page 6

OPERATING INSTRUCTIONS

Features

1. Instruments:

The Electronics International line of single and multi-channel instruments offer the following features:

A. Digital Display - The digital display allows you to read absolute temperatures at a glance. It does

not require interpretation of dials or tic marks. In a short period of time you will be come familiar with

the normal operating temperatures of your engine. Abnormal temperatures will be easy to spot. The

digital display is easily viewable in direct sunlight. If the instrument backlight has been permanently

powered up (as recommended), the digital display will be easier to see during low ambient light conditions and at night.

B. 1 Degree Resolution - The digital display resolves temperatures to 1 degree. This allows you to

interpret trends quickly. This can be very helpful in diagnosing problems and leaning your engine.

Also, any unit may be ordered to display in degrees F or degrees C.

C. 1/2% Accuracy - Electronics International instruments are not affected by shake, shock, vibration,

tilt, stick-slip, bearing wear, spring wear, lead resistance, probe resistance, magnetic fields or the many

other factors that plague analog instrument accuracy. All E.I. instruments are temperature compensated

to read cabin temperature when a probe is disconnected. E.I. instruments should never need

recalibration. Carburetor and outside air temperatures are measured on precision channels. If a non-

precision channel (i.e., EGT, CHT, etc.) is used to measure Carb. Temp or OAT there can be a

several degree temperature error. A precision channel uses a single yellow connector.

D. Flexibility - Electronics International instruments are compatible with any type K ungrounded

probe. This means any instrument, regardless of what is printed on the front panel (EGT, CHT, OAT,

etc.), will work with any of our probes (i.e., an OAT channel can read EGT or CHT probes accurately).

Also, lead resistance does not affect the accuracy of these units. You may use any length extension

cable between the unit and the probe without affecting the accuracy of the instrument.

E. Upgradable - Any single channel EGT and/or CHT unit may be upgraded to a full multi-channel

analyzer by simply adding a remote switch to the system. The instruments, remote switches, extension

cables and probes were designed in a modular fashion with slip-on connectors. This means a remote

switch may be added to your existing system by simply mounting it into your instrument panel, installing the additional wires and probes and plugging it in. You do not have to buy a new system to upgrade

to a full analyzer.

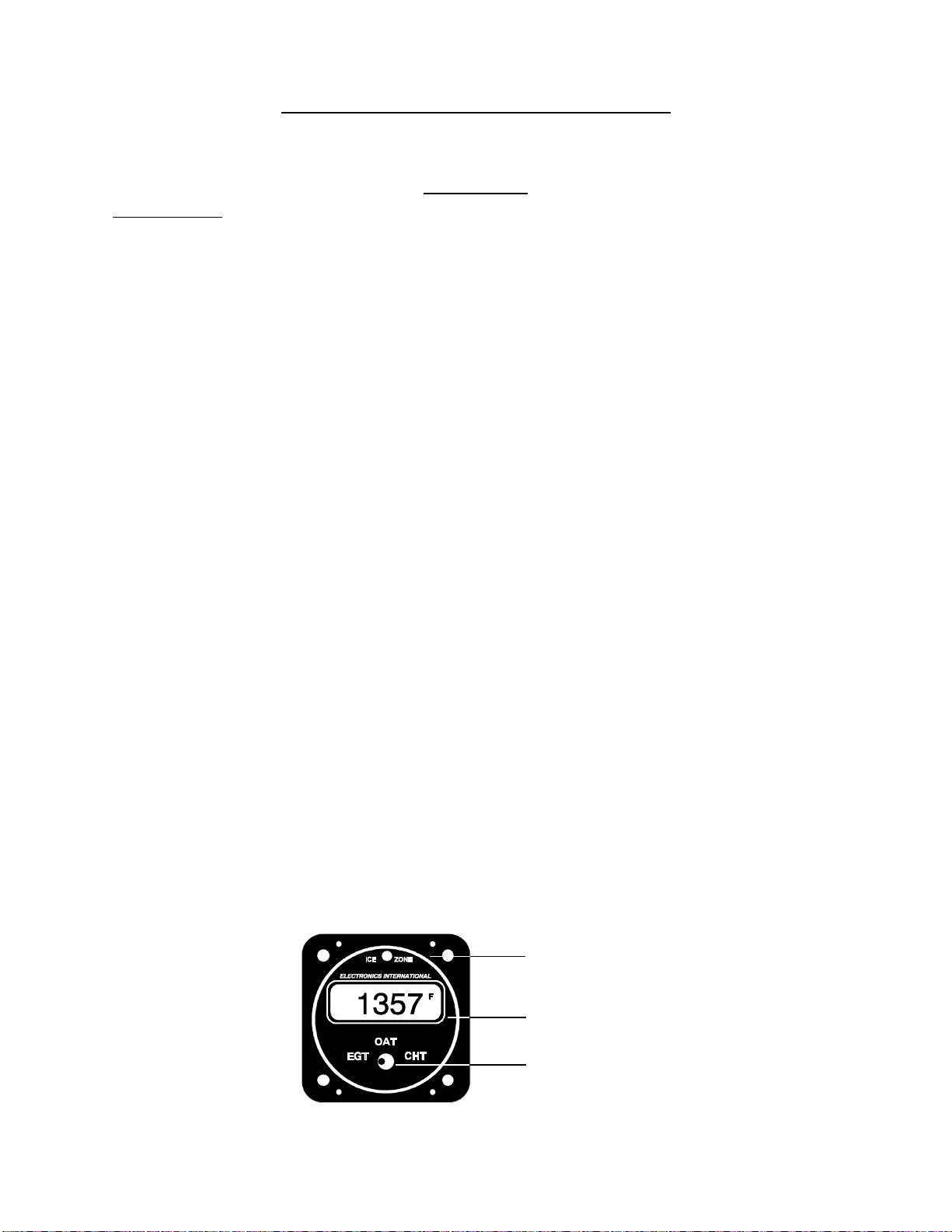

Ice Zone Warning Light. Only available on

the Carb. Temp/OAT instruments.

Digital Display.

Selector Switch.

3

Page 7

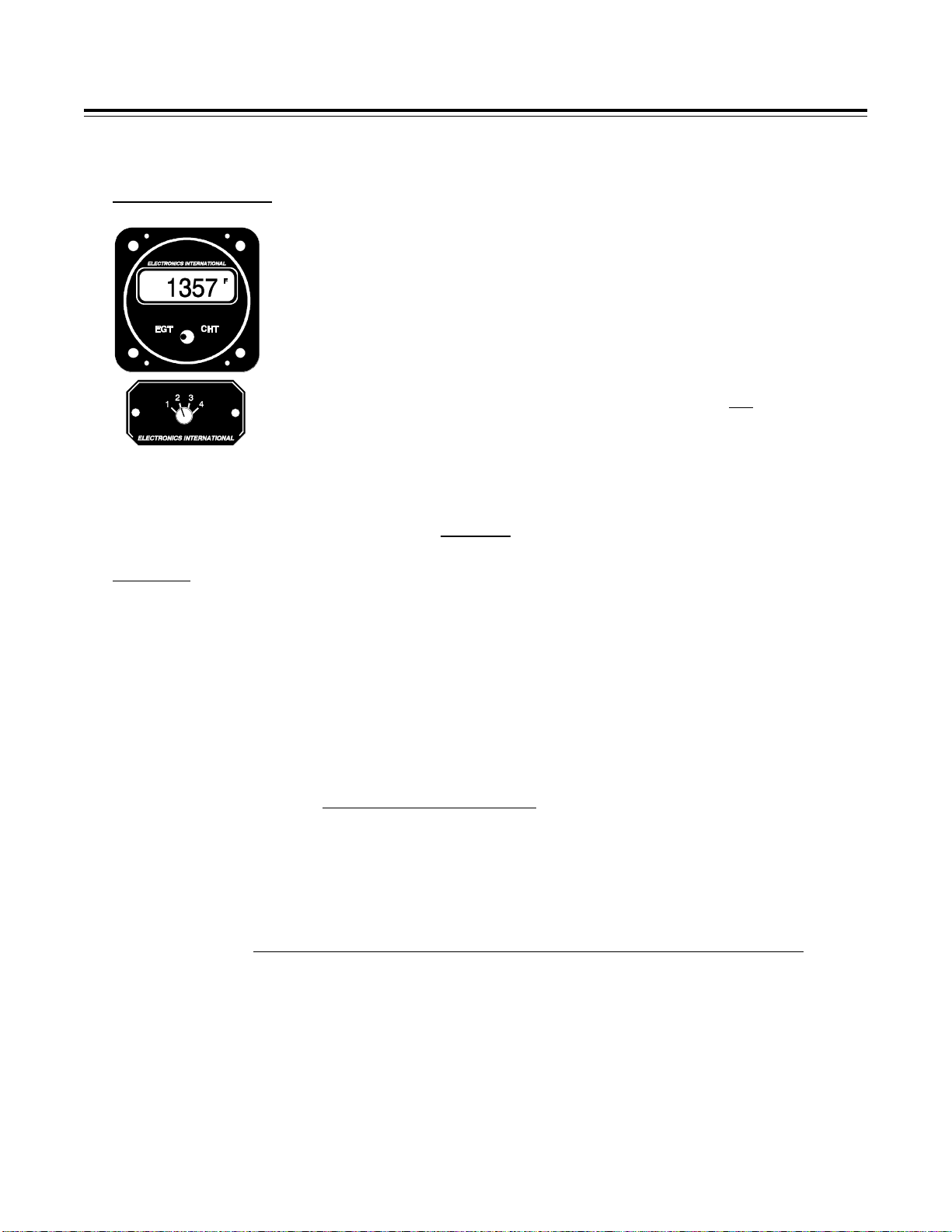

2. Remote Switches:

Instrument displaying

EGT for channel #2.

EGT'sOperating Instructions

A remote switch may be connected to any channel on any Electronics International

Instrument. This gives the instrument multi-channel capability. There are two types

of remote switches available, single deck and double deck. If a single deck four

channel remote switch (RS-4-1) is connected to the EGT channel on an EC-1, the

instrument would be capable of measuring four EGT's and one CHT. The remote

switch will select which EGT channel would be displayed on the EC-1 instrument

when the instruments selector switch is placed in the EGT position. If a double deck

four channel remote switch (RS-4-2) is connected to the EGT and CHT channels on

an EC-1, the instrument will be capable of measuring four EGT's and four CHT's.

The EC-1 will select wether EGT or CHT will be displayed. The Remote Switch will

select which channel will be displayed.

EGT's

1. Leaning:

You will want to lean your engine in cruise. A rich running engine wastes fuel needlessly and tends to run

rough. This creates vibration, which causes deterioration of engine accessories and engine mounts. Also,

proper leaning at cruise and during descent means less spark plug fouling, longer life for the plugs, reduced

maintenance costs and considerable fuel savings. Furthermore, good leaning techniques result in cleaner

combustion chambers with fewer lead salt deposits on the pistons and exhaust valves. Under certain conditions, these deposits invite preignition and higher maintenance costs. Proper leaning at cruise during cool or

cold weather aids in raising engine and oil temperatures to desirable minimums in order to evaporate the

water and acids out of the oil. Water and acids attack the insides of an engine, causing rust and corrosion.

To properly lean your engine using a multi-channel analyzer perform the following steps:

A. Rough Leaning: Select the hottest EGT cylinder. Adjust the mixture control from the full rich

position to a leaner setting that results in a slight drop in engine RPM or to a setting near peak EGT, as

dictated by experience. The mixture control should be left at this setting until the EGTs stabilize. It

will take about 20 seconds for the temperatures to stabilize within 1`F. This lag is due to the combustion walls and piston domes increasing in temperature, which affect the combustion and exhaust gas

temperatures. To correctly lean an engine you must wait for the engine to thermally stabilize. Less

sensitive gauges will not pick up these subtle changes, which are important in leaning and diagnosing

problems.

B. Precision Leaning: Again select the hottest EGT cylinder. This cylinder may be different than the

one you started with. This is the cylinder on which you should perform your precision leaning. Again,

start leaning, making only very small adjustments and waiting 3 to 5 seconds between adjustments. As

4

Page 8

EGT'sOperating Information

you approach peak, the exhaust gas temperature will rise much slower until it starts to decrease. When

this happens you have reached peak EGT. The 1`F resolution of the digital display will be invaluable in

helping you precisely detect peak EGT.

C. Finding The Cylinder That Peaks First: For most engines Step B (Precision Leaning) will result in a

properly leaned engine. If you find this to be the case with your engine, this step will not be necessary.

But if you want to verify that you have leaned to the cylinder that peaked first and your engine is

operating properly, perform the following with the cylinder found in step B at peak EGT. Slightly

enrich the mixture and quickly step through each cylinder. Any cylinder that shows a rising temperature

is a leaner cylinder. Check that this cylinder does not rise more than 15F before it starts decreasing in

temperature. If a cylinder rises more than 15F it may have a problem.

When installing a single channel EGT instrument in an aircraft there is no guarantee that the probe is installed on the leanest cylinder. Every engine operates a little differently. For the same make and model of

engine installed in the same type of aircraft there can be differences between the leanest cylinders. Furthermore, there can be a difference between operating temperatures and the temperature spread between cylinders. Every engine has its own unique operating temperatures. To properly lean your engine using a single

channel EGT unit perform the following steps:

A. Rough Leaning: Adjust the mixture control from the full rich position to a leaner setting that results

in a slight drop in engine RPM or to a setting near peak EGT, as dictated by experience. The mixture

control should be left at this setting until the EGTs stabilize. It will take about 20 seconds for the

temperatures to stabilize within 1`F. This lag is due to the combustion walls and piston domes increasing in temperature and, therefore, affecting the combustion and exhaust gas temperatures. To correctly

lean an engine you must wait for the engine to thermally stabilize. Less sensitive gauges will not pick

up these subtle changes, which are important in leaning and diagnosing problems.

B. Precision Leaning: Again, start leaning, making only very small adjustments and waiting 3 to 5

seconds between adjustments. As you approach peak the exhaust gas temperature will rise much slower

until it starts to decrease. When this happens you have reached peak EGT. The 1`F resolution of the

digital display will be invaluable in helping you precisely detect peak EGT. You will then need to

enrichen the mixture for an EGT reading 30 'F lower than peak to insure there is no cylinder operating

on the lean side of peak EGT.

If your engine runs rough before peak EGT is reached, note the temperature reading on the EGT

instrument. When an engine starts to run rough (not when it loses power, but actually runs rough) the

leanest cylinder has gone past peak EGT by 30 to 50 degrees F. The leanest cylinder is lean misfiring

causing the engine to run rough. From this point enrichen the mixture to obtain a 50 degrees F lower

EGT from the noted temperature. This will set the leanest cylinder slightly on the rich side of peak

EGT. The rest of the cylinders will be running richer than the leanest by an amount dictated by the

temperature spread for your engine. With this method you can reasonably lean an engine even when the

probe has not been mounted on the leanest cylinder.

Electronics International's unique stable display allows you to precisely lean to peak EGT or to a specific

temperature below peak for most engines. Peak EGT with a float-type carbureted engine is frequently a

vague point because of the fuel/air distribution issues in these lower horsepower engines. As a result, these

5

Page 9

Operating Information

engines tend to operate smoother at 25F on the rich side of peak EGT. Fuel-injected engines will provide a

more precise peak. Most engines normally operate within an EGT range of 1300F to 1600F at cruise

power.

Some engine manufacturers allow leaning to peak EGT at 75% power and below on their direct drive normally aspirated engines. For your engine, check the engine manufacturers recommended procedures. It

is not recommended to lean to peak EGT above 75% power settings. The richer mixture is needed to cool

the combustion temperatures and keep the anti-knock capability of the fuel high enough to prevent detonation

from occurring at the higher power settings.

2. EGT Diagnostics:

Since the EGT is directly related to the combustion temperature, it is an indication of the engines ability to

produce power. If the engine is not producing the correct amount of power, the EGT instrument can be a

very valuable troubleshooting tool as well an early warning system before engine failure occurs. With 1F

resolution, our digital EGT instruments will react to the slightest changes in the combustion process. To

detect a problem, become familiar with your engines normal EGT readings during run-up, climb, cruise and

descent. Any difference from the norm can be a sign of trouble.

During normal operation the EGT will stabilize to 1F for a given throttle and mixture setting. If it does not

stabilize, this can also be the first sign of trouble. With rate and trend information being displayed instantaneously and with temperatures being read to 1F, few problems can escape the pilot flying one of Electronics

Internationals analyzer systems. The following is a list of EGT/CHT symptoms and possible problems:

EGT's

Symptom

One EGT reads abnormally high. The corresponding CHT reads lower than normal.

One EGT reads abnormally high. The corresponding CHT reads higher than normal.

One EGT reads abnormally low.

High CHTs and/or high EGTs on all cylinders.

High EGTs and/or low CHTs on all channels.

Jumpy readings on one channel.

Possible Problem

Burned valve or broken ring, defective plug, plug

wire or mag.

Plugged injector, intake leak.

Over-sized injector, restricted exhaust, broken or

leaky exhaust header.

Excessive leaning with power settings over 75%.

Detonation due to bad fuel. Closed or restricted

cowl flaps. Missing or loose baffling.

Timing problem or defective mag.

This is not an engine problem. Check all connections and the probe for proper operation. See

Troubleshooting Section of this manual.

6

Page 10

Operating Information

It is not necessary to continually monitor the EGTs in order to detect a problem. Most problems worsen

over a period of time and can be easily detected before they become a safety hazard by thoroughly checking

the EGT readings at run-up and once or twice during a flight.

CHT's

1. CHT Operation:

The Cylinder Head Temperature (CHT) instrument helps the pilot protect his engine against the threat of

excessive heat. Most general aviation aircraft monitor the hottest CHT, as determined by extensive flight

tests done by the airframe manufacture. Minimum in-flight CHT should be 150F, and maximum in most

direct drive normally aspirated Avco Lycoming engines is 500F. Some of the higher powered, more complex engines have a limit of 475F. Although these are minimum and maximum limits, the pilot should

operate the engine at more reasonable temperatures in order to achieve the expected overhaul life of the

powerplant. It would be normal during all-year operations in climb and cruise to see cylinder head temperatures in the range of 350F to 435F.

CHT's

Sudden cooling of the CHT (known as shock cooling) is a problem that is common with aircraft engines.

This is caused by fast descents with little or no power and rich mixtures. This may result in bent pushrods

due to exhaust valves sticking, burned valves, spark plug fouling, broken piston rings, cracked cylinders at

the spark plug and valve ports and warped exhaust valves. To avoid these problems, do not allow the CHT to

cool more rapidly than 1F every 3 seconds during in-flight operation. This can be easily detected with our

1F digital display.

During climbs, the cylinder head temperatures will rise rapidly until the heat absorbed by the combustion

walls is dissipated out the engines cooling fins. At this point, the CHT will stabilize. Any change in

throttle, mixture, cowl or airspeed will affect the CHT and the rate at which it will change. Since rate and

trend information can be easily interpreted from our digital display, changing any one of these parameters to

stabilize, slow or reduce the CHT is possible with almost immediate results. Our digital instrument takes the

guesswork out of controlling your CHT.

2. CHT Diagnostics:

The source of heat in an engine is from the combustion of the fuel/air mixture producing temperatures of

approximately 4000F. Some of this heat energy goes into heating the cylinder heads through radiation and

conduction. This heat is sinked away from the engine by the air flow over the cylinder heads. When the heat

being generated in the cylinder heads equalizes with the heat being sinked away, the cylinder head temperature will stabilize. If a problem arises in the combustion chamber or in the ability of the cooling system to

sink away heat, the CHTs will be affected. To detect a problem, become familiar with your engines CHT

operating temperatures during run-up, climb, cruise and descent. Any differences from normal can be a sign

of trouble.

7

Page 11

Carburetor TemperatureOperating Information

Continuous change in the CHT can also be a sign of trouble. Because of the large thermal mass of the

engine, the CHTs change slowly after the initial climb. Any continuous change in one or all of the CHTs

after this initial climb can be the sign of trouble. The rate and trend of this change can easily be detected

with Electronics Internationals 1F resolution digital display. This information allows the pilot to make

changes in flight attitude or engine operation and see the effects almost instantaneously.

Carburetor Temperature

Venturi affect and atomization of fuel can cause temperatures in the carburetor to drop 30F or more. When

the atmospheric conditions are right for the aircrafts current flight altitude (moderate to high humidity), the

moisture in the carburetor venturi can freeze quickly. Within minutes ice can choke off the venturi and the

engine will stop with little warning.

When Carb. Temp. is selected on the Electronics International Carb. Temp. instrument, the carburetor

temperature is continuously monitored and the Ice Zone warning light over the display is activated for that

channel. The Ice Zone warning light is only active for the channel selected. At 39F (before ice can form

in the venturi of the carburetor) the Ice Zone warning light will light up. When this happens, apply carburetor heat, making small adjustments to bring the carburetor temperature above 39F, thereby avoiding any

possible carburetor icing condition. An additional benefit of running carburetor temperatures 9F above

freezing is improved atomization of the fuel which results in fewer lead deposits, cleaner plugs and better

economy. If the carburetor temperature is below 10F the Ice Zone warning light will go off. Below 10F

there is not enough moisture in the air to form ice in the carburetor.

The Ice Zone warning light has the advantage of catching your attention without having to continuously

monitor the unit. At night this light may be too bright. An LED Intensity Control Line is provided which

may be connected to the aircraft panel rheostat. When the instrument panel lights are turned up the Ice

Zone warning light will dim.

Monitoring carburetor temperature to 1F can also help with hard to start engines. If the engine becomes

flooded and fuel starts to drip from the carburetor, the unit will display a drop in carburetor temperature as

the fuel starts to evaporate. If the engine backfires and a fire starts in the venturi, the unit will display a rapid

rise in the carburetor temperature. The carburetor probe is rated for 700F, so probe damage is not likely.

Outside Air Temperature

The Electronics International OAT instrument has three features that make it a valuable tool when measuring

outside air temperatures. The first of these features is its superior accuracy and linearity over conventional

gauges. Outside air temperatures have a big affect on your aircrafts ability to lift and on engine horsepower.

Accurate OAT readings are essential if you are looking for maximum performance from your aircraft.

8

Page 12

The second valuable feature is the instrument's ability to detect small temperature changes (1F). This gives

the pilot rate and trend information (in what direction and how fast the temperatures are changing) at a

glance. This is valuable for detecting changing atmospheric conditions and avoiding thunderstorms and icing

conditions. It can also help to find cooler flying conditions in warm weather.

The third feature is the instrument's Ice Zone Warning Light. This light will come on when the OAT drops to

39F and stays above 10F. This feature can be very useful to a pilot by warning him of the possibility of

structural ice if weather conditions are right.

The Electronics International OAT instrument resolves outside air temperatures to 1F and is very sensitive

to air temperatures changes. For this reason, when the OAT probe is in still air and near a heat source, such

as hot asphalt, a hangar heater, etc., the unit will read the actual temperature to which the probe is subjected.

When the engine starts and there is a flow to air over the probe, the unit will read the air temperature accurately and display changes quickly.

INSTALLATION INSTRUCTIONS

1. Important Information and Initial Check Out:

A. The installer and aircraft owner must read the Warranty before starting the installation. There is

information in the Warranty that may alter your decision to install this instrument. If you do not accept the

terms of the Warranty, do not install this instrument.

B. If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft EGT,

CHT, Carb Temp and/or OAT instruments, Do Not attempt to install this instrument. The installer should

use current aircraft standards and practices to install this instrument (refer to AC 43.13).

C. Check that any necessary FAA Approvals (STC's, etc.) are available for your aircraft before starting

the installation. STC's are located at the back of this manual.

D. Read the entire Installation Instructions and resolve any issues you may have before starting the installa-

tion. This may eliminate any delays once the installation is started.

E. THIS INSTALLATION MAY REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFT THAT

ARE NOT SUPPLIED IN THE KIT. Acquire all the parts necessary to install this instrument before

starting the installation.

F. Check that the instrument make and model are correct before starting the installation.

G. Before starting the installation make sure the unit will fit in the location you intend to install it without

obstructing the operation of any controls.

9

Page 13

Installation Instructions

H. If this instrument is to replace an existing unit in the aircraft, it is the installer's responsibility to move or

replace any existing instruments or components in accordance with FAA approved methods and procedures.

The following Installation Instructions do not cover moving or the removal of any existing instruments or

components.

2. CHT Probe Installation

2. CHT Probe Installation:

A single CHT probe should be placed on the hottest cylinder. In a 6-cylinder engine this would be one of the

center cylinders. On a 4-cylinder engine this would be one of the back cylinders.

If a second CHT probe is to be installed it should be placed on one of the front unobstructed cylinders. This

will allow the unit to detect shock-cooling.

Most engines have a port just below the lower spark plug for the CHT probe.

CHT probe in one of the cylinders, do not remove it. Select another cylinder for your probe. If youre

putting a CHT probe on every cylinder use our P-102 Gasket CHT Probe for secondary readings on your

primary cylinder.

If your engine has a primary

3. EGT Probe Installation:

A single EGT probe should be installed in the exhaust stack of the leanest cylinder. Each engine has its own

characteristics and the leanest cylinder can be different from aircraft to aircraft. As a general rule, the leanest

cylinder is one of the back cylinders on a carbureted engine and one of the center cylinders on a fuel-injected

engine.

Look at each exhaust stack and determine the best location at which all of the EGT probes can be mounted at

the same distance down from the exhaust ports. The ideal location is 1 1/2", but ease of installation should

prevail. Drill a 13/64" diameter hole in each exhaust stack. Insert the probe and tighten the hose clamp. As

the hose clamp is heated and cooled, it will become loose as it conforms to the exhaust stack. After the first

10 hours of operation, each hose clamp should be retightened.

IMPORTANT NOTE: For Cessna 210s or any aircraft using a slip joint in the exhaust system, install the

EGT probes ABOVE OR BELOW THE SLIP JOINT. Installing a EGT probe in the slip joint can damage

the probe.

4. Carb Temp Probe Installation:

Remove the threaded plug located in the carburetor housing just below the throttle valve. Install the Carburetor Temperature Probe in this hole using a lock washer. Care should be taken not to over-tighten the probe

and strip the threads in the carburetor housing.

If your carburetor does not have a factory tapped hole, remove the carburetor from the engine. Drill out the

lead plug located just below the throttle valve with a 7/32 drill and tap this hole with a 1/4 x 28 tap. Remove

all burrs and metal shavings from the interior and exterior of the carburetor. Install the carburetor temperature probe as outlined above. Reinstall the carburetor on the engine.

10

Page 14

5. OAT Probe InstallationInstallation Instructions

NOTE: A Carb Temp Probe should be connected to the precision channel on a CA-1, A-1 or EAC-1 unit. A

three to four degree F error can occur in some instances if the Carburetor Probe is not connected to a precision channel.

5. OAT Probe Installation:

Mount the OAT Probe in an appropriate location on the aircraft, using the hardware supplied. The OAT

Probe is sensitive to air temperature changes. For this reason, do not mount the OAT probe in the path of the

cowl or engine exiting air (i.e., on the belly of the aircraft). Also, the probe should not be mounted within 8

inches of an exhaust pipe. The radiant energy from the exhaust pipe can cause the probe to read slightly

high. Other than these considerations the OAT Probe may be mounted in an air intake vent, on the side of

the cowling or anywhere else on the aircraft.

NOTE: An OAT Probe should be connected to the precision channel on a CA-1, A-1 or EAC-1 unit. A three

to four degree F error can occur in some instances if the OAT Probe is not connected to a precision channel.

6. Route the Extension Cables:

Mark both ends of each cable with the appropriate cylinder and/or probe type. Plug each probe into its

associated extension cable. Be sure the connectors mate properly. When tie wrapping these cables down,

be sure there is no strain or pulling on the cable against the probe housing. Each probe should have 3 to 4

inches of slack to allow the engine to move in its mount without breaking any wires. Also, there should be a

tie wrap near the probe connectors. Dress each cable up to the instrument or remote switch keeping them

away from any hot areas (exhaust stacks, cylinder heads, etc.).

We do not recommend removing the connectors when installing the extension cables but if you must shorten

the cable, pull any excess cable length through the fire wall and cut it off at this time. However, it is recommended you leave some extra wire length under the instrument panel for later modifications. Varying cable

lengths will not affect the accuracy of this instrument so cables of any length may be ordered from the

factory. The Extension Cables and probe wires are made of type K thermocouple wire that must not be

substituted or extended with regular copper wire. Also, it is important these wires not be kinked (i.e., do not

bend the wires on a radius less than 1 inch).

Attach the appropriate connectors to the ends of each of the Extension Cables as described below:

Red Slip-on Connectors

A) Strip the overbraid back 3 1/2". Be careful not to nick the wires.

B) Shrink a piece of 1" heat shrink over the cut portion of the overbraid.

C) Split the two wires back 3". Be careful not to nick the wires.

11

Page 15

Installation Instructions

D) Strip each wire and double the wires over. These wires must be doubled over.

E) Place a male connector on the red wire and a female connector on the yellow wire. Double crimp

these connectors. A good crimp is very important. Poor crimps will cause jumpy readings and are the

biggest source of problems.

6. Route the Extension Cables

Red Slip-on Connector

Male Connector

Keep the tab straight.

Yellow Precision Connector

A) Strip the overbraid back 3 1/2". Be careful not to nick the wires. Shrink a piece of 1" heat shrink

over the cut portion of the overbraid.

B) Remove the yellow cap on the Precision Female Connector.

C) Strip back the wire insulation 1/2".

D) Connect the yellow lead of the Extension Cable to the terminal marked + and the red lead to the

other terminal.

yellow cap on the Female Precision Connector. Be careful not to overtighten any screws or twist the

wires when installing the connector.

The insulation on these wires should almost touch the mounting screws. Replace the

Double Crimp

Double the wires.

Yellow Precision Connector

Red Wire

Yellow Wire

Tie off any excess cable under the instrument panel. Be sure these cables do not obstruct the freedom of

travel of any controls. Cable length does not affect the accuracy of our units, so cables of any length may be

ordered from the factory.

12

Page 16

Installation Instructions

7. Hook-Up Connecting Wires

7. Hook-Up Connecting Wires:

Connect the red wire supplied in the kit to the 12 or 24 volt bus via a 1 amp fuse or circuit breaker (see the

Wiring Diagram at the back of this manual). Connect the black wire supplied in the kit to ground. Connect

the white/violet to the 12V bus (leave it open for a 24V system). Connect the white/gray wire to the 24V bus

(

connect to ground for a 12V system). If this unit has an "Ice Zone" warning light, connect the white/orange

wire to the Panel Light Rheostat to dim the "Ice Zone" warning light at night.

Tie off any excess cable under the instrument panel.

travel of any controls.

Be sure these cables do not obstruct the freedom of

8. Connect and Install the Instrument and/or Remote Switch:

Connect the extension cables and all other wires to the instrument and/or remote switch as shown in the

appropriate wiring instructions at the back of this manual. Be sure the connectors mate properly. Install the

unit from behind the instrument panel using 6 x 32 screws. These screws must not be longer than .4 inches.

Install the remote switch through a 1" square hole cut into the aircraft instrument panel. Tie wrap cables as

needed. Be sure these cables do not obstruct the freedom of travel of any controls.

9. System Ground Test:

A. Turn the master switch on and look for a near ambient temperature reading on each channel. If the

instrument does not power-up (display a reading), check the power and ground leads (red and black leads)

for an open, loose or poor connection.

If you suspect any channel is not receiving a signal remove the probe from the engine (leaving it connected

to the Extension Cable) and apply a temperature to it. Look for an increase in reading on the display for that

channel. Check the other channels for an increase in reading. You may have connected the probe to the

wrong Extension Cable. If the reading is decreasing, you may have reversed the connectors on the Extension

Cable leads (the yellow wire on the probe must connect to the yellow wire on the Extension Cable).

B. Start the engine and check each channel for a proper reading. On the ground EGTs will read around

900F and CHTs will read around 200F. If you suspect any channel is not receiving a signal properly, see

the Troubleshooting section of this manual.

13

Page 17

TROUBLESHOOTING SUGGESTIONS

Because high reliability is designed into Electronics Internationals equipment, there is no reason to put up with

poor operation. We have few problems with our probes, cables and units and installation is simple. Usually

fixing a problem is just a matter of inspecting the installation at a few key points.

Strategy:

If you have more than one problem, FIX ONE PROBLEM AT A TIME. Trying to fix all of them at once

can be confusing and misleading. In many cases fixing one problem first will lead you to the solution for

fixing all of the problems. Therefore, take one problem on one channel and proceed with the following:

1. Instrument Check Out:

If there is an identical symptom on each channel, then the instrument may have a problem. But if even one

channel of the instrument is operating properly, the instrument probably does not have a problem. A good

method to test the instrument is to remove all the Extension Cables. Then look for a reading on all channels

to be near cabin temperature. The only inputs a unit requires to operate properly and measure cabin temperature is power (red lead) and ground (black lead). Check the power and ground leads for proper connection

(pull on the wire at each connector).

NOTE: Few problems turn out to be the instrument.

2. Probe Check Out:

There are two good methods of testing a probe. Perform one or both of the following:

A. A probe can be tested with an ohmmeter. Disconnect the probe from the Extension Cable. When

testing the resistance between the connectors, the probe should measure a short (less than 5 ohms).

When measuring from one lead (either lead) of the probe to the probe sheath (metal tip), there should be

an open (10k or greater).

B. Another method of checking a probe is to plug the suspected bad probe into a channel that is working properly. If the problem follows the probe, you have a defective probe.

3. Extension Cable Check Out:

With the Extension Cable connected to the unit, remove the probe from the suspected bad Extension Cable.

Set the unit to the proper channel and look for a near cabin temperature reading on the display. A very high

or low reading indicates a short to ground in the cable. Next, connect an ohmmeter, set to 10K range, to the

open probe ends of the suspected bad Extension Cable. Set the unit to the proper channel and look for a very

high (+ or -) reading on the digital display. A near cabin temperature reading or no change in reading

indicates an open in the cable or its connectors. Also, look for a reading on the ohmmeter around 12K ohms.

Most problems of this kind are usually one of the following:

14

Page 18

3. Extension Cable Check OutTroubleshooting Suggestions

A. Poor Connections: When plugging the probe into the extension cable it is possible to get the tab on

the male connector to wedge between the red nylon and metal receptacle in the female connector. This

connection may work for a few weeks or even months and then you will start to see jumpy readings.

Disturbing the connection, without actually fixing it, may get it to work for a short time and then the

problem will reappear. Physically check your connections at the probe for a proper mate.

Loose Connections: The female slip-on connector between the extension cable and probe can

B.

become loose if the connector has been used many times. This loose connection may work for a few

weeks or even months and then you will start to see jumpy readings. A good connection is difficult to

pull apart. If your connector is loose it can be tightened using a pair of needle nose pliers. Check your

connectors at the probe for a good tight connection.

Poor Crimp: This is usually only a problem if you have removed the connectors and replaced them.

C.

This connection may work for a few weeks or even months and then you will start to see jumpy readings. To check a crimp, give a sharp pull on the wire and connector. The wire should be tight in the

crimp (no movement). When putting a new connector on a wire, double the wire over and put two tight

crimps on the connector.

15

Page 19

SPECIFICATIONS and OPERATING FEATURES

S0908941

Models: (Temperature Monitoring Instruments) E-1, C-1, A-1, CA-1, EAC-1, EAE-1, EC-1, EC-2,

E-2, C-2, E-4, C-4, E-6 and C-6.

Weight: E-1, C-1, A-1, CA-1, EAC-1, EAE-1, EC-1, EC-2, E-2 and C-2 - 7 oz. (unit only)

E-4 and C-4 - 7.6 oz. (unit only)

E-6 and C-6 - 8.3 oz. (unit only)

6' T.C. Cable - 2 oz.

EGT or CHT Probe - 1.6 oz.

Environmental: Meets TSO C43a

Power Requirements: 7.5 to 30 Volts, 1/10 Amp.

Display: LCDs (viewable in direct sunlight), with 12 and 24 volt backlight control wires.

Ice Zone Warning Light: This light comes on when the displayed temperature is between 39'F and 10'F.

An Intensity Control Line is provided to dim this light for night operation.

9/8/94

Display Temperature Range: 1999F to -1999F

Accuracy: 1/2% in accordance with TSO C43a.

Resolution: 1F (with enhanced stability and response circuits).

Probes: Type K, Ungrounded (for improved accuracy, stability and reliability).

Extension Cables: Type K, any length or size (you may use your existing type K cables).

Models: (Remote Switches) RS-4-1, RS-4-2, RS-6-1, RS-6-2, RS-8-1 and RS-12-1

Weight: RS-4-1, RS-4-2, RS-6-1 and RS-8-1 - 3.2 oz. (unit only)

RS-6-2 and RS-12-1 - 4.9 oz. (unit only)

Environmental: Meets TSO C43a

Contacts: Gold

Contact Resistance: <50 milliohms

Angle of Throw: 30 degrees

Rotational Torque: 3.5 to 7.5 ounce-inches

16

Page 20

Instrument

Back Panel

Instrument Wiring Diagram

All Instruments

Red

Black

Description:

Power Lead

Ground Lead

12/24 Volt Bus. via 1 amp fuse.

Ground

Connects To:

Wht/Violet

Wht/Gray

Wht/Org

"Brown" Pair

"Brown" Pair

"Red Stripe" Pair

"Brown" Pair

"Red Stripe" Pair

12V Back Light

24V Back Light

Controls Ice Zone

Warning Light intensity

12 Volt Bus (open for a 24V system).

24 Volt Bus (Gnd for a 12V system).

Panel Light Rheostat (an open line will

cause the light to be at full intensity).

E-1 or C-1 Additional Connections

To Temp. Probe.

E-2 or C-2 Additional Connections

To Left Probe.

To Right Probe.

A-1 or CA-1 Additional Connections

Connector marked "OAT" to OAT Probe.

Connector marked "Carb" to Carb. probe.

EC-1 Additional Connections

To EGT Probe.

To CHT Probe.

"Brown" Pair

"Red Stripe" Pair

"Orange" Pair

"Yellow" Pair

"Brown" Pair

"Orange" Pair

"Brown" Pair

"Red Stripe" Pair

"Orange" Pair

"Yellow" Pair

"Green" Pair

"Blue" Pair

EC-2 Additional Connections

To Left EGT Probe.

To Right EGT Probe.

To Left CHT Probe.

To Right CHT Probe.

EAC-1 Additional Connections

To EGT Probe.

Connector marked "OAT" to OAT Probe.

To CHT Probe.

E-4, C-4, E-6 or C-6 Additional Connections

To Cyl. #1.

To Cyl. #2.

To Cyl. #3.

To Cyl. #4.

To Cyl. #5 (E-6 or C-6 only).

To Cyl. #6 (E-6 or C-6 only).

Page 21

Remote Switch

Back Panel

Remote Switch Wiring Diagram

RS-4-1, RS-4-2, RS-6-1 and RS-6-2

"Wht/Violet and

Wht/Gray" Pair

"Brown" Pair

"Red Stripe" Pair

"Orange" Pair

"Yellow" Pair

"Green" Pair

"Blue" Pair

RS-4-2 and RS-6-2 Only

From the back of the RS-6-2 and RS-4-2 there are two groups of the above wires. Connect one group to the

EGT Probes (or left channel for a twin installation) and connect the other group to the CHT (or right

channel for a twin installation).

To Instrument EGT or CHT Channel.

(For a twin unit, to Instrument Left or Right Channel)

To Cyl. #1.

To Cyl. #2.

To Cyl. #3.

To Cyl. #4.

To Cyl. #5 (RS-6 only).

To Cyl. #6 (RS-6 only)

18

Page 22

Remote Switch

Back Panel

Remote Switch Wiring Diagram

RS-8-1 and RS-12-1

"Wht/Orange" Pair

"Solid Brown" Pair

"Solid Red" Pair

"Solid Orange" Pair

"Solid Yellow" Pair

"Solid Green" Pair

"Solid Blue" Pair

"Violet Stripe" Pair

"Gray Stripe" Pair

"Solid White" Pair

"Solid Black" Pair

To Instrument EGT or CHT Channel.

To Cyl. #1.

To Cyl. #2.

To Cyl. #3.

To Cyl. #4.

To Cyl. #5.

To Cyl. #6.

To Cyl #7.

To Cyl #8.

To Cyl #9 (RS-12-1 only).

To Cyl #10 (RS-12-1 only).

"Brown Stripe" Pair

"Red Stripe" Pair

To Cyl #11 (RS-12-1 only).

To Cyl #12 (RS-12-1 only).

19

Loading...

Loading...