Page 1

Flight Type Dishwashers

Page 2

General features

• Electrolux, the leading choice for catering

equipment, introduces its new line of flight type

dishwashers.

• Compact, ergonomic design and cost saving,

combined with perfect washing results, make the

Electrolux flight type dishwasher the best choice

for large canteens, in-flight catering, hospitals,

hotels and marine installations.

• Electrolux appliances have been designed using

a modular approach, allowing them to be

tailored to individual requirements.

2

Page 3

• All the new machines have well designed

functions making them easier to work with and

creating a pleasant working environment.

• The working environment in the dishwashing

area is improved with low temperatures, low

noise levels and reduced humidity.

• The new flight type dishwashers feature a

double skinned structure with thermal and

acoustic insulation (less than 70dB).

• Electrolux new generation of flight type

dishwashers has been engineered with tried and

tested technology.

3

Page 4

Reliability

Electrolux flight type dishwashers have

been carefully designed to offer long term

reliability, even in the most arduous

conditions.

Reliability:

• the panels and the inspection doors

have a double skin structure in order to

reduce noise and heat dispersion

• in order to completely avoid any

detergent corrosive action, the tank is

made of AISI 316 stainless steel

• all the main elements are made in AISI 304

stainless steel:

- baring structure

- feet

- internal and external panels

- inspection doors

- washing and rinsing arms

- filter plates and filter boxes

- screws

- side support for dishes

• all electric components, wash and rinse

pumps are tested to guarantee a long

lasting operation of the dishwasher

• Stainless steel washing pumps are

standard on version “A”, optional on “B” &

“C”. As standard, all the units are

equipped with low voltage (24 volt)

control panel to guarantee high safety

standards and long lasting reliability

4

Page 5

Accessibility

Electrolux flight type dishwashers have

been designed to be extremely accessible

and easy to use.

Accessibility:

• easier maintenance, thanks to the

accessibility from the front and sides of

the machine

• all the main working components are

placed on the front of the machine

• adjustments of the tension of the conveyor

belt can be made from the loading side

• the fingers in the conveyor are easily

replaceable

• electrical and water service connections

can be made from above or below

• the electric control box is clearly

organized and centrally located

• the ESD (Energy Saving Device) and

condenser unit are accessible via the

hinged top

5

Page 6

Cleanability

The flight type dishwasher has been

specifically engineered to be easily

cleanable both internally and externally.

Internal cleanability:

• final wash & rinse area behind one large

balanced inspection door to allow an easy

access to the washing area

• drying zone with inspection door for

cleaning and removal of fallen items

• washing chamber without internal pipes

• internal screws in the wash chamber do

not project past the nuts

• the loading end is easily accessible for

cleaning and emptying of the large scrap box

• washing arms in stainless steel, easily

removable for daily control and cleaning

• double tank filters (flat and box) are

easily removable

• tank with round corners to make easy

periodical cleaning, avoiding the stagnation

of food remains

• sloping base to convey the dirty water

towards the drain

• optional cleaning ramp available in

loading sections above 700 mm in length

External cleanability:

• smooth external surfaces

• 200 mm height feet enable ease of

cleaning under the machine

• loading area without feet

• the back is completely closed so that the

machine can be placed against the wall

• IPX 5 water protection

6

Page 7

Total control

Power on

The electronic control panel has been

designed not only to control the

dishwasher, but also to provide the

operator and engineer a host of useful

information that can improve the

efficiency and washing performance.

The new digital control panel with HACCP

integration and fault diagnosis system

is used to read the temperature of all

washing, rinsing and drying sections.

Low speed

DIN 50110

• if a fault occurs it will be indicated on

the control panel

• as an option it is possible to measure

the consumption of water and energy

• in the “Washing mode” pumps and drier

stop after one minute if no dishes are loaded

in the conveyor and start automatically

when dishes enter into the machine

• on request an integrated printer can be

installed on the machine, in order to print

out all the data about the washing

processes, displayed on the window

Window

2x16 digits

Up/

down

Info StopPower off High speed

Start

Stand by mode

The following information can be selected

and displayed in the window:

• temperatures: actual and set values

• flow limit settings • statistics-today’s

washing • alarms-today’s washing • time

left to service • HACCP protocol • print

protocol • clear protocol

Washing mode

The following information can be selected

and displayed in the window:

• washing efficiency • current alarms

• temperatures-actual and set values

• flow/speed/electrical power-actual

values (if measuring devices are installed)

• statistics-today’s washing • current

alarms-today’s washing

7

Setup mode

In the setup mode the following fields can

be set: For the user • date and time

• choice of 12 languages • For the technician

with access code • temperatures can be

altered • timer • HACCP protocols (how

to print) • Water flows (option) • contact

time (between water and items)

Page 8

The product range

WTF2 2 tank (standard pre-wash)

4500 mm length

3600 plates/hour

WTF3 3 tank (standard pre-wash)

5800 mm length

5000 plates/hour

WTF4H 4 tank (heavy duty pre-wash)

7400 mm length

7200 plates/hour

WTF2H 2 tank (heavy duty pre-wash)

4800 mm length

3600 plates/hour

WTF3H 3 tank (heavy duty pre-wash)

6100 mm length

5000 plates/hour

880

1024

Optional wideGeneral purpose

8

Page 9

The product range consists of 5 different sized

models available in 3 specificational levels to

provide the customer a wide range of machines

that can be even further personalized.

Version “A” – suitable for installations where

incoming water temperature is below 15 °C and

where usage is going to be particularly heavy

and incorporates energy saving device to reduce

power requirements by 20/30 kW/h.

No ventilation hood is required.

Version “A” Version “B” Version “C”

Drying Tunnel Drying Tunnel Drying Tunnel

Energy Saving Device Energy Saving Device

Heavy Duty Pump in stainless steel

Eco pre-scrap arm in prewash tank

Version “B” – and suitable for installations

where incoming water temperature is below 15 °C

but where usage is going to be normal. No ventilation

hood required.

Version “C” – suitable for installations where

incoming water temperature is 55 °C. Ventilation

hood is required.

• All models include a 1100 mm long

drying tunnel that incorporates an

inspection door to collect items that may

fall onto the belt

• The standard range is ideal for washing

items measuring up to 600 x 400 mm

wheareas the wide and high version can

wash 744 x 550 mm items

• The wide’n’high versions can take 3

plates instead of 2 for the standard version,

so the capacity is increased by 50%

• Version "A" incorporates an eco-scrap

arm that uses water from the ESD device

to immediately start to “soften” & “wet”

items immediately as they enter the

machine to wash items that have not

been pre-scrapped or when the machine is

used mainly on the fast speed

• Version “A” also incorporates as standard

high performance stainless steel wash

pumps to provide a stronger washing

action usually required to wash a lot of

gastronorm containers or when the

machine is used during heavy conditions

• All Flight type dishwashers are supplied

with a multipurpose belt.

Version “A” Version “A”

9

Page 10

Technical data

2 3 5

1

6

1 Loading section All models + versions

Standard length

Optional lengths

700 mm

1200 mm

1500 mm

1800 mm

2400 mm

3000 mm

4000 mm

2 Pre wash

Tank capacity l

Temperature °C

Pump power versions “B” and “C”

Pump power versions “A”

Options: Lateral strainer and "Cross-over" loading section L = 2900 mm

3 Wash with detergent

Tank capacity l

Heating element kW

Temperature °C

Pump power versions “B” and “C”

Pump power versions “A”

WTF2

55 - 65

125

15

2,7

4

WTF2H

Heavy

duty

125

15

55 - 65

2,7

4

119

15

55 - 65

2,7

WTF3HWTF3 WTF4H

Heavy

duty

119

55 - 65

2,7

Heavy

duty

113

15

15

55 - 65

2,7

444

Heavy duty

71

30 - 50

0,88

0,88

4 Wash with detergent

Tank capacity l

Heating element kW

Temperature °C

Pump power versions “B” and “C”

Pump power versions “A”

107

30 - 50

2,7

4

71

30 - 50

0,88

0,88

WTF3WTF3WTF2HWTF2 WTF4H

Heavy duty

107

30 - 50

2,7

Heavy duty

4

Heavy duty

107

30 - 50

2,7

4

WTF4H

119

12

55 - 65

2,7

4

Options: heavy duty stainless steel pump 4.1 kW available for the standard pre-wash and wash tanks

10

Page 11

7

8 Unloading section

4 Power Rinse without detergent

Tank capacity l

Heating element kW

Temperature °C

Pump power versions “B” and “C”

Pump power versions “A”

125

15

65 - 75

2,7

8

WTF3HWTF3 WTF4H

Heavy duty

125

65 - 75

2,7

Heavy duty

15

65 - 75

125

15

2,7

444

WTF2

WTF3

WTF4

Special length

700 m m

110 0 m m

1500 mm

1800 mm

2400 mm

3000 mm

4000 mm

7 Drying section

All models and versions

Module length mm

Temperature °C

Air circulating m

3

/h

Fan motor kW

Heating elements kW

Standard

1100

40 - 60

2400

0,55

9

Options: Double drying tunnel for plastic items that requires long drying time

Total power Electric and Steam models

Electric kW - Duo Rinse 47

models

Electric kW - Twin Rinse

Electric

Electric kW

Steam kg/h - Duo Rinse

Steam

models

Steam kg/h - Twin Rinse

Electric kW - Duo Rinse

models

Electric kW - Twin Rinse

Electric

Electric kW

Steam

Wide models Standard models

models

WTF2 WTF2H WTF3 WTF3H WTF4H

49 65 67 82

61

4,9

66

85

53

61

61 79 79 94

6,8 7,8 9,7 12,5

66 91 91 110

85 111 111 130

53 71 71 86

61 79 79 94

7,5 7,5 10,2 10,2 12,8

72 72 97 97 116Steam kg/h - Duo Rinse

85 85 111 111 130Steam kg/h - Twin Rinse

11

Page 12

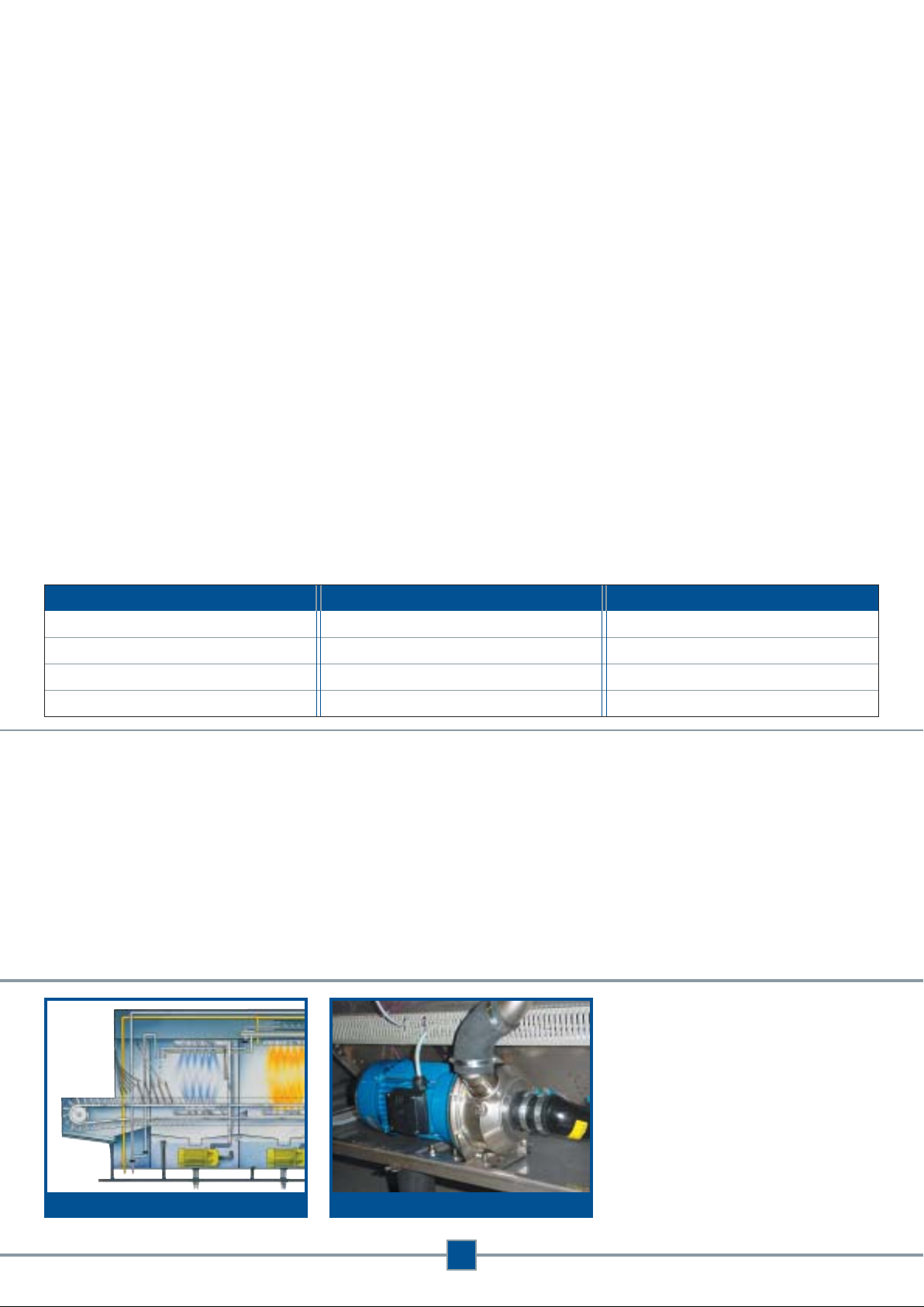

Incoming cold water 10°C

Energy savings

Air temperature 25 °C

Used water 40°C from ESD

to pre-wash tank

Fresh water from CU 35°C

to pre-wash tank

Electrolux energy saving system, as

standard on versions “A” & “B”, cuts

heating costs by half and saves

between 20 to 30 kW/h:

• The energy saving device reduces the

electric consumption by pre-heating the

incoming cold water using the steam from

the dishwasher and part of the used

rinsing water, without increasing the

heating elements in the boiler

• During the dishwashing process, the

machine is taking in cold water via the

condenser and at the same time the

exhaust fan is extracting the steam,

generated in the rinsing and washing

zones, forcing it to pass through the

aluminium lamellas of the condensing

unit. The steam condenses on the cold fins

and the heat is transferred to the cold

incoming water. The water temperature is

increased from ~ 10 °C to ~ 50 °C, that

means an initial energy saving by heating

up the incoming water of ~ 40 °C.

Steam 68°C

Used water 68°C from DUO

Fresh water 54°C to booster

• The extra price of an “A” or “B” version

compared to a “C” version will normally

be repayed within one year of use, taking

in consideration energy savings and the

fact that a ventilation hood is not

required

12

Page 13

Thanks to the condensing unit, the

outgoing air from the machine will be

cooled down to ~ 25 °C and have a

humidity of 75-80%, so no additional

hood is needed over the machine.

Tanks 2

Total water Consumption l/h

3

Air emission m

Air temperature °C

Air humidity %

Air humidity without ESD %

*Final Rinse consumption l/h

Energy savings ESD twin rinse

*maximum values when m/c working all the time

/h

WTF2 WTF2H Heavy duty WTF3 WTF3H Heavy duty WTF4H Heavy duty

2334

420

500

20 - 25

75 - 85

100

320

30 30 30 30 30

420 450 450 550

500 800 800 800

22 - 25 22 - 30 22 - 30 22 - 30

75 - 85 75 - 85 75 - 85 75 - 85

100 100 100 100

320 350 350 450

13

Page 14

Rinsing system

Standard Duo Rinse Twin High Temperature Duo Rinse

Electrolux offers 2 final rinse methods:

• The Duo rinse system, standard on all

models, which guarantees an excellent

rinsing performance and also saves rinsing

water, rinse aid and energy by using the

same water twice

• The twin high temperature system, as an

optional alternative for customers who

require a higher level of sanitization or

those who need to wash large boxes

6 Final Rinse

Duo Rinse

Temperature °C

Temperature °C

Water consumption l/h

Boiler heating elements kW

Boiler capacity l

Standard Wide

65651^ramp

85852^ramp

420 - 550320 - 450

2218

1616

Twin high temperature

Temperature °C

Water consumption l/h

Boiler heating elements kW

Boiler capacity l

Standard Wide

8585Both ramps

800600

3030

1616

Options: demi-water or reverse-osmosis system to optimize the rinsing result for glasses and cutlery

14

Page 15

Detergent savings

Detergent saving system:

When the dishwasher is running at full

capacity, the water in the tanks is

continuously replaced by a flow of water,

coming from the final rinse zone and, at

the same time, the equivalent amount of

water is drained off via the drain-pipe in

the pre-wash tank. Electrolux FT

dishwasher has been designed to control

this flow system in order to keep the right

rate of detergent in the washing water

longer than the traditional machines.

• In traditional flight type dishwasher all

the water from the final rinse runs over to

the pre-wash via the wash tank. As the

washing water is replaced at the rate of

300-400 litres per hour, new detergent

must be added to maintain the required

concentration

• The equivalent flow in the new Electrolux

flight type dishwashers is only 100 litres

per hour. This means saving approx. 0,5 kg

detergent per hour! The savings, making a

calculation, based on working 7 hours/day

for 300 days, considering that the right

concentration of detergent is 2 grams per

litre, are more than 1 ton of detergent per

year (1479 kg/year with a traditional

machine vs 420 kg/year with the

Electrolux FT dishwasher)

15

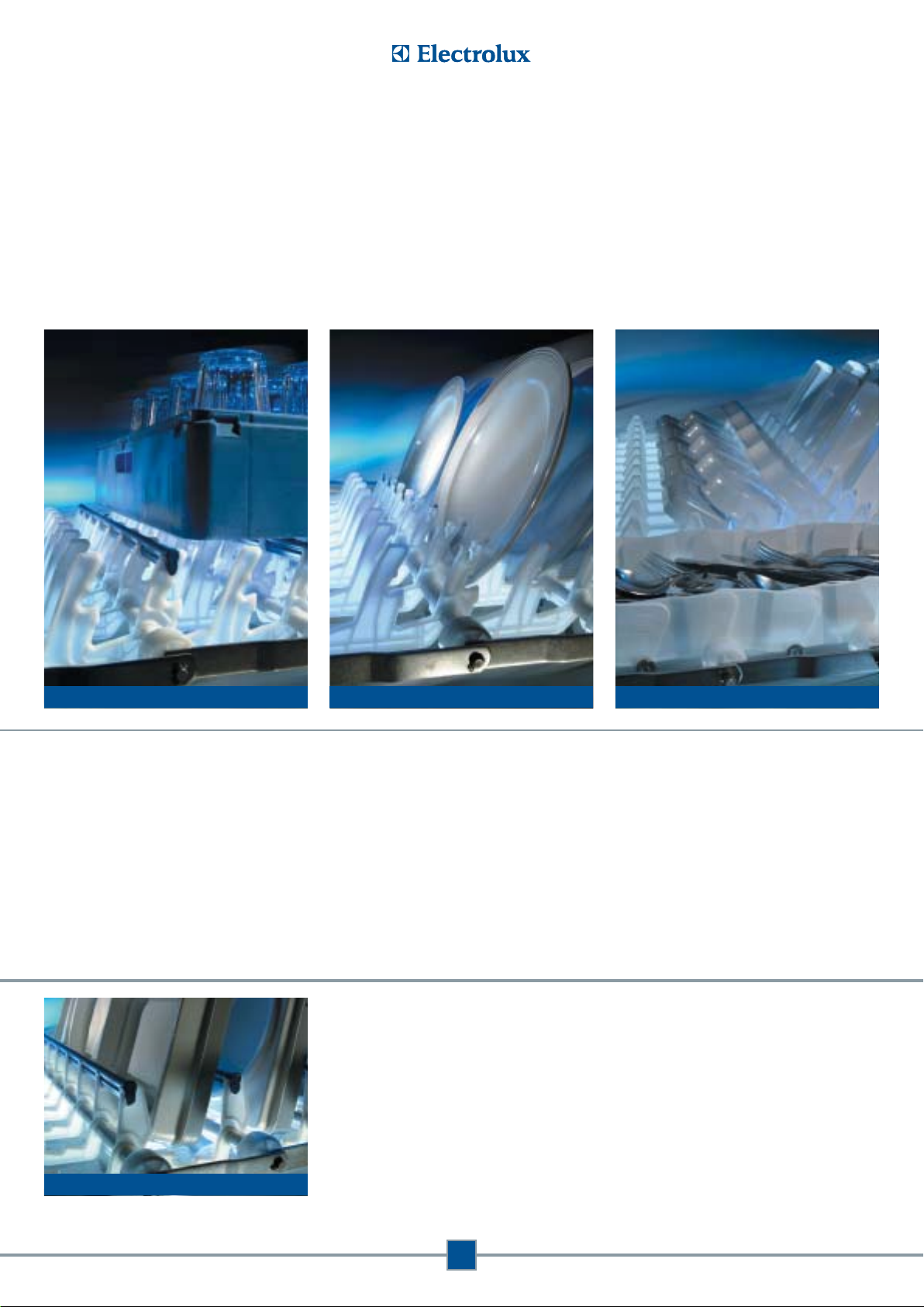

Page 16

Tailor made

customer solutions

Electrolux offers a wide range of options

to tailor the flight type dishwasher

exactly to meet the customers individual

requirements.

• this flexibility has allowed us to satisfy

the needs of large canteens, in-flight

catering establishments, hospitals , hotels

and marine installations

• several types of conveyor belts to wash

different types of trays, racks or boxes are

available

Multipurpose conveyor, (standard and wide

version). Capacity each metre: 32- 48

large plates or 16 trays or 2 dishwashing

racks, distance between fingers 60 mm.

Accessories. Shafts in blue plastic for

easier handling of dishwashing racks.

Conveyor for small items (in-flight

kitchen). For FT dishwasher (standard and

wide version) with manual loading and

unloading of small items, distance

between fingers 60 mm.

Conveyor for serving trays with

insulated lids - standard and wide

version (Temprite, Aladin...).

Capacity each metre:

10 trays or lids, 20-30 large plates or 2

dishwashing racks, distance between

fingers 100 mm.

Conveyor for small items and cutleryMultipurpose conveyorBlue stick for baskets

Combined conveyor for small items (in-flight

kitchen) and cutlery. For FT dishwasher (wide

version) with manual loading and unloading

of small items.

Cutlery can be automatic loaded and

unloaded as an option, distance between

fingers 60 mm.

Conveyor for insulated trays

16

Page 17

Conveyor for larger itemsConveyor for trays and cutlery

Electrolux can offer solutions for washing

a variety of items, such as plastic boxes,

large pots and pans and GN containers.

The machine can be equipped with

specific modules in order to guarantee the

final washing performance.

The washing and rinsing modules can be

combined with neutral sections, to avoid

water splashing between the different

tanks. A divo-jet system can be inserted

between wash tanks to direct concentrated

detergent onto heavily soiled items.

The conveyor can be inclined up to 4

degrees in order to get the best drying

result. The standard washing arms can be

replaced with side washing arms.

The standard wash pumps on versions “B”

& “C” can be replaced with heavy duty

stainless steel pumps. Loading and

unloading modules can be extended up to

4 metres, and also made for cross over

systems.

The machine can be integrated with waste

management systems such as, waste

disposal units, de-watering units, vacuum

systems.

17

Page 18

Conveyor for trays and cutlery (with automatic loading and unloading)

Combined Flight Type Dishwasher

• The Combined Flight Type WT730 TCW

dishwasher has a

completely automated system that will

take care of both trays and cutlery, thus

eliminating the need for extra workers.

Not only will costs be dramatically cut,

but operational workflow will also be

improved

• The WT730 TCW dishwasher offers the

possibility to process up to 1500 trays/h

• The WT730 TCW dishwasher is made of

a special conveyor belt with two different

tracks – one for trays and one for cutlery.

The trays and cutlery will be fully

automatically loaded from a cord

conveyor

• Both trays and cutlery are collected at

the unloading stage by: a lowerator for

the trays and a trolley with stainless steel

rack for the cutlery

As an option, it is possible to set up the

machines so it collects trays from the

unloading station to two lowerators,

which will give the operator more time to

change the full lowerator.

18

Page 19

Layout

+ 1200

+ 1200

2500 6000

CUTLERY

SORTING

515 200

+ 800

FOOD LEFT-OVERS

FOOD LEFT-OVERS

ADDITIONAL PERSON

IF NEEDED

FLIGHT-TYPE DISHWASHER

RACK DISHWASHER

CUTLERY PICKING

DEVICE

COMBINED TRAY AND CUTLERY WASHER

NAPKIN

BLOWER

+900+900

+900

NAPKIN

BLOWER

+ 1200

+ 1200

+ 800

CUTLERY

SORTING

FOOD LEFT-OVERS

ADDITIONAL PERSON

IF NEEDED

ADDITIONAL PERSON

IF NEEDED

2500 6000

515 200

CUTLERY PICKING

DEVICE

COMBINED TRAY AND CUTLERY WASHER

900 guests /hour 1200 guests /hour

Example of dishwashing layout for 1200

guests/hour kitchen:

• racks with glasses, cups, etc, from the

sorting table on a chain conveyor to a

rack type dishwasher WT 150 HD

• flight type dishwasher with cross over

functions for plates, bowls, etc.

• device for automatic removing of

cutlery from the trays

• combined tray and cutlery dishwasher

(TCW) with automatic loading of trays and

cutlery

Example of dishwashing layout for 900

guests/hour kitchen:

• flight type dishwasher with cross over

function for plates, bowls, etc.

• for racks with glasses, cups, etc. coming

from the sorting table on a chain conveyor

• device for automatic removing of

cutlery from the trays

• automatic unloading of trays in tray

lowerators and of cutlery in a cutlery

trolley

conveyor with the dirty trays & dishes will

cross over the loading section at a height

of 1050 – 1150 mm. The operator can take

the dishes direct from the tray and stack

Dishwashing layout with cross-over

it on the conveyor of the dishwasher.

function

To optimise the function in large

dishwashing systems a cross-over loading

section increase the overall efficiency,

especially when more than one large

dishwasher is used. The cross over loading

section is only 700 mm high, and the

• combined tray and cutlery dishwasher

(TCW) with automatic loading of trays and

cutlery

• automatic unloading of trays in tray

lowerators and of cutlery in a cutlery

trolley

19

Page 20

The Company reserves the right to change specifications without notice.

www.electrolux-professional.com

EFT43EN

Loading...

Loading...