Page 1

Milano

VISUAL DIVISION

graphic project

ELECTROLUX EUROCLEAN ITALIA SPA

Località Novella Terza 20070 Guardamiglio-Italy

Telephon nr. +39 377 451124 Fax nr. +39 377 51443

96 11-96

a

4

N

I

S31E34UK

W 345 B/M

W 355 B/M

W 365 B

W 375 B

MANUAL FOR USE

AND MAINTENANCE

Page 2

INDEX

NOTE

pag.

INTRODUCTION..................................................................1

UNPACKING ......................................................................2

TECHNICAL SPECIFICATION .................................................3

MACHINE CONTROLS .........................................................4

PREPARATION FOR USE ...................................................5-9

SCRUBBING AND DRYING OPERATION ........................10-15

CHANGING BRUSHES..................................................16-17

MAINTENANCE ...........................................................18-19

SAFETY AND FAULTS.........................................................20

TROUBLE SHOOTING ........................................................21

OPTIONALS.................................................................22-24

Page 3

A front splash guard is also available.

OPTIONALS

INTRODUCTION

INTRODUCTION

This manual is a guide to the efficient use of the machine and also contains practical information concerning the

functioning, adjustments and user maintenance of your new scrubber/drier. Your machine has been designed and

constructed to ensure maximum performarnce and ease of operation in a wide variety of applications. Before delivery, the

machine has been tested in our factory and by our distributor to ensure that it is delivered to you in perfect condition. To

maintain the machine in this condition and guarantee functioning without problems, it is essential that the periodic

maintenance operations indicated in this manual are properly carried out. Before using the machine, carefully read this

manual and keep it within easy reach for your future reference. Indications of “LEFT” and “RIGHT” are as seen from the

operators position. If you should need any further information concerning the machine, please do not hesitate to contact

either Electrolux Euroclean or our local distributor.

GENERAL SAFETY RULES

The rules below have to be followed carefully in order to

avoid damages to the operator and to the machine.

- Read the labels carefully on the machine; Do not cover

them for any reason and replace them immediately if

damaged.

- The socket for the power supply must be fitted with a

standard earthing (ground) system.

- With the brushes in working position, avoid touching or

passing over the mains cable. Avoid damaging by

squashing, bending or stressing.

- Where there is damage to the mains cable, stop the

machine, take off the plug from the mains system, and

replace the damaged cable immediately by calling the

Electrolux Service department.

- Do not mix different detergents, avoiding harmful odours.

- Do not place any liquid containers onto the machine.

- The storage temperature has to be between +15°C and +

55°C.

- The perfect operating temperature should be between 0°

C and 40° C.

- The humidity should be between 30 and 95%.

- Do not use the machine in explosive atmosphere.

- Do not use the machine as a means of transport.

- Do not use acid solutions which could damage the

machine.

- Avoid working with the brushes when the machine stands

still, in order to prevent floor damages.

- Do not vacuum iflammable liquids.

- In case of fire, use a powder extinguisher. Do not use

water.

- Do not strike shelvings or scaffoldings, where there is

danger of falling objects.

- Adapt the utilization speed to the adhesion conditions.

- Do not exceed over the limit gradient stated, to avoid

conditions of instability (2% max).

- The machine has to carry out simultaneously the

operations of washing and drying. Different operations

have to be carried out in areas which are not permitted

for the passage of non employed staff. Signal the areas

of moist floors with suitable signs.

- If the machine does not work properly, check by

conducting simple maintenance procedures. Otherwise,

it is better to ask for technical service.

-Where parts are required, ask for ORIGINAL spare parts

to an agent and/or to an authorized dealer.

- For any maintenance operation take off the power supply

from the machine.

- Do not take off the pieces which require the use of tools

to be removed.

- Do not wash the machine with direct water jets or with

high water pressure not with corrosive material.

- Every 200 working hours have a machine check through

a service department.

- The machine should not be abandoned, because of the

presence of toxic-harmful materials (batteries, oil etc.).

This disposal must be subject to the rules which provide

for its scrapping in appropiate centres.

- The machine does not cause any harmful vibrations.

24

MODIFICATIONS AND IMPROVEMENTS

Electrolux Euroclean aim toward continuous improvement of its machines and reserves the right to carry out modifications

and improvements whenever necessary without being obliged to update machines which have been sold previously.

SAFETY

You too can avoid accidents.

No accident prevention programme is effective without the total co-operation of the person directly responsible for the

functioning of the machine. The majority of accidents which may occur either during work or transferring the machine from

site to site are caused by the non-observance of the most elementary safety rules. An alert and cautious operator is the best

guarantee against accidents and is more effective than any other part of an accident prevention programme.

The machine must be switched off and disconnected from either its battery or mains supply before any servicing or

adjustment of operational parts are carried out. Ensure that any assistant is clear of the machine and that covers are closed

before switching on.

1

Page 4

1

2

3

4

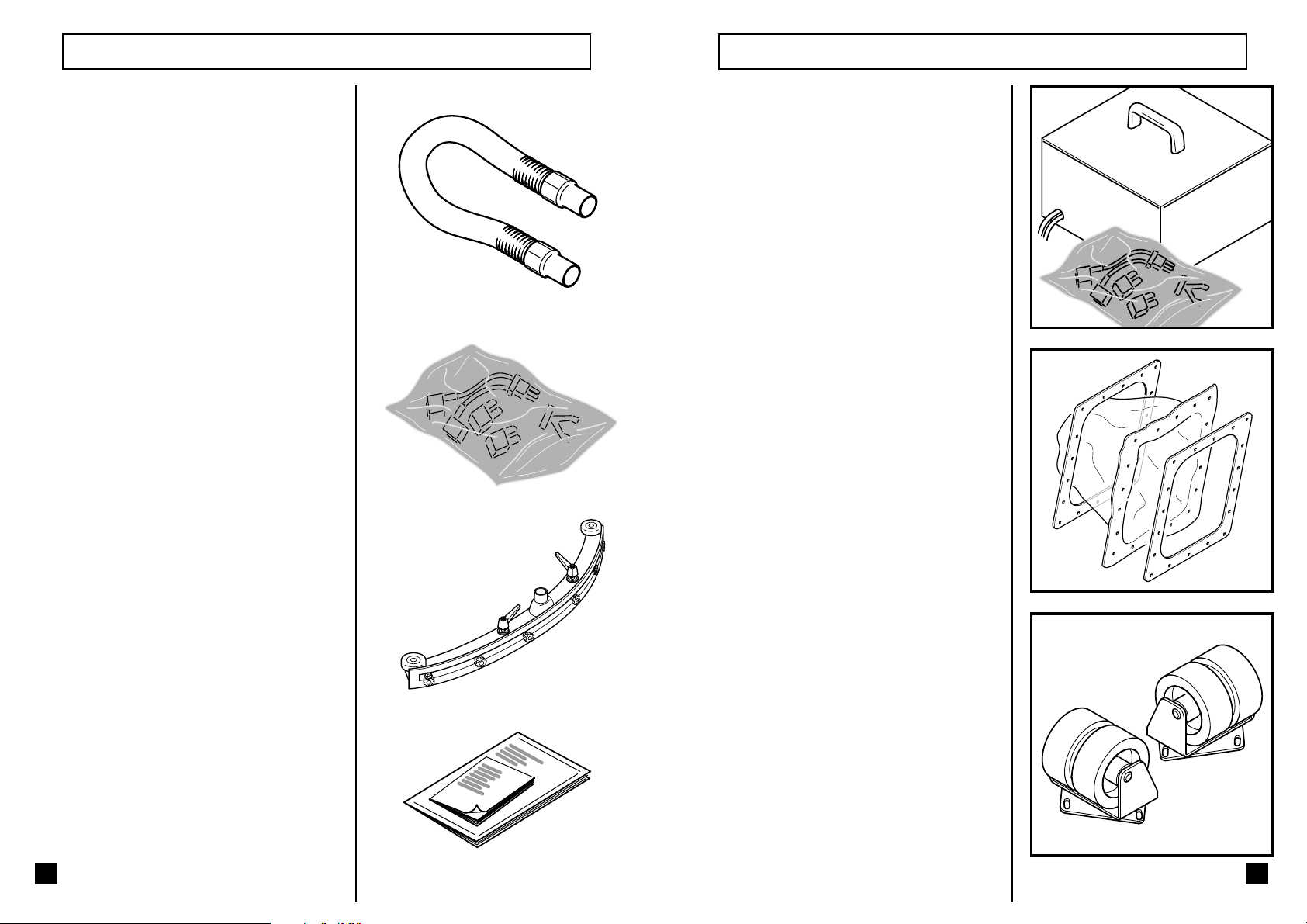

UNPACKING OPTIONALS

Check that you have received following parts

together with the machine:

- Connecting hose for squeegee

- Plastic bag with cables

Kit of cable to transform machine from mains

version to battery operated version.

Mains unit (or transformer) to change the machine

from the battery operated version to the mains

version.

For the models W345 and W355 a kit is

available to equip the machine with the

membrane.

- Squeegee

- Documents

2

In order to reduce the pressure of the machine on

the floor (according to norm DIN 18032) two rear

twin wheels can be mounted.

W345 and W355 cod. D00.06630

W365 and W375

cod. D00.06640

23

Page 5

O)

OPTIONALS

In addition to the normal accessories supplied

with the machine the following optionals are

available:

Batteries:

- For models 345/355 two 12 V batteries 140

amp hours.

- For models 365/375 four 6V batteries 240

amp hours.

Battery chargers:

- For models 345/355/365/375 two different

battery chargers are available with different

specifications according to the country where

there will be used: a) 24 Volts 30 A 50 Hz

b) 24 Volts 30 A 60

Hz

Different types of brushes and pad holders are

available. For a complete list consult your nearest

dealer.

W345 430mm (17 “) 1 required

Union mix scrub brush cod.145 00 42-00

Polypropylene scrub brush cod.145 00 96-00

Silicon Carbide scrub brush cod.140 00 63-00

Pad holder cod.145 00 43-00

W355 280mm (11 “) 2 required

Union mix scrub brush cod.145 00 45-00

Polypropylene scrub brush cod.145 00 97-00

Silicon Carbide scrub brush cod.145 00 64-00

Pad holder cod.145 00 46-00

W365 320mm (12,5 “) 2 required

Union mix scrub brush cod.145 01 02-00

Polypropylene scrub brush cod.145 01 00-00

Silicon Carbide scrub brush cod.140 01 03-00

Pad holder cod.145 01 04-00

W375 370mm (14,5 “) 2 required

Union mix scrub brush cod.145 01 07-00

Polypropylene scrub brush cod.145 01 05-00

Silicon Carbide scrub brush cod.140 01 08-00

Pad holder cod.145 01 09-00

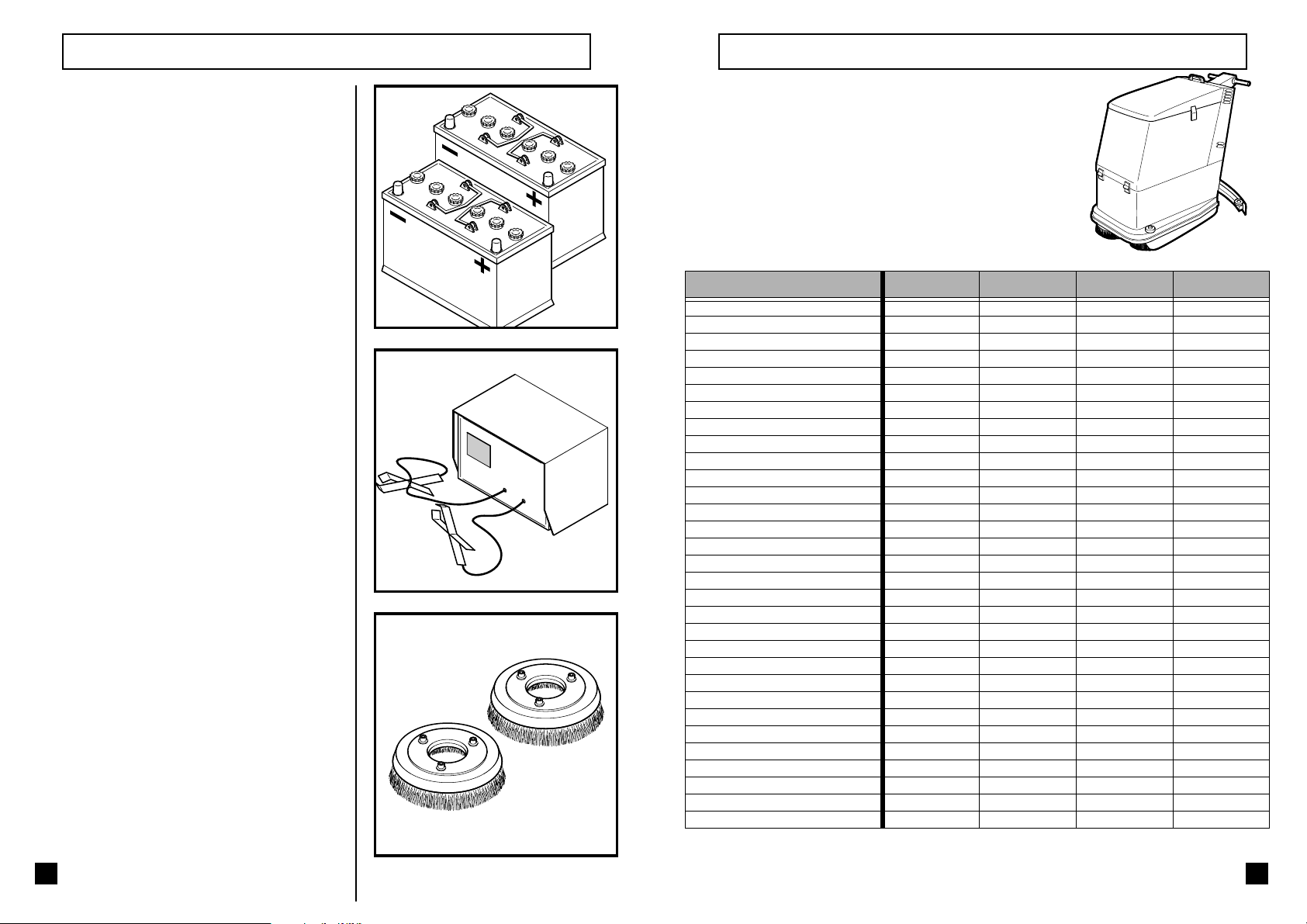

TECHNICAL SPECIFICATION

MODELS

Working width (mm)

Width of squeegee (mm)

N° of brushes

Brush/s diameter (mm)

Brush speed (rpm)

Brush motor (watts)

Brush pressure (Kg)

Clean liquid tank (ltr)

Recovery tank (ltr)

Vacuum motor type

Vacuum motor (watts)

Vacuum depression (mm/H

Run time hour meter

Battery condition indicator

Traction motor (watts)

Forward speed (Km/H)

Reverse speed (Km/H)

Drive wheel diameter (mm)

Castor wheel diameter (mm)

Operating voltage (volts)

Length (mm)

Width (mm)

Height (mm)

Weight without batteries (kg)

Weight with mains unit (kg)

Standard wet batteries

Capacity 20 at hr rate (Ah)

Charger - taper current

Low maintenance dry batteries

Capacity 5 at hr rate (Ah)

Charger - constant voltage

(*) with the membrane (optional)

2

TECHNICAL SPECIFICATION

W345B/M

430 538 628 728

700 800 920 1010

1222

430 280 320 370

180 270 270 180

1x250 2x200 2x200 2x375

13-27 20-31 21-36 30-45

34/50 (*) 38/54 (*) 72 72

35/51 (*) 39/55 (*) 74 74

2 stages. 3 stages. 3 stages. 3 stages.

420 540 540 540

1150 1700 1700 1700

yes yes yes yes

yes yes yes yes

120 120 200 200

0-4,5 0-4,5 0-5 0-5

0-2,5 0-2,5 0-2,5 0-2,5

150 150 200 200

80 80 100 100

24 24 24 24

1235 1235 1330 1330

460 580 685 775

1050 1050 1095 1095

97 112 125 135

132 146 n/a n/a

2 x12v 2 x12v 4 x 6v 4 x 6v

140 140 240 240

12 cells 25 A 12 cells 25 A 12 cells 25 A 12 cells 25 A

2 x 12v 2 x 12v 4 x 6v 4 x 6v

70 70 160 160

24v. 25 A 24v. 25 A 24v. 25 A 24v. 25 A

W355B/M W365B W375B

22

3

Page 6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

MACHINE CONTROLS

1324

56 7 8 9

- Scrubbing detergent flow adjustment

push button

- Suction on/off push button

- Brush motor on/off push button

- Run-time hour meter

- Scrubbing detergent flow boost pump

on/off push button

- Recovery tank full warning indicator

- Brush release push button

- Battery condition voltmeter

- Master key-switch

- Drive function control

- Switch for the speed selection

- Scrubbing detergent tank emptying

hose

- Handle height adjustment locking handwheel

- Drive motor on/off switch

- Squeegee control lever

- Recovery tank emptying hose

- Squeegee

- Brush pressure control hand-wheel

- Squeegee pressure control

- Squeegee rake angle control

- Brush lift/lower pedal

10

11

12

13

14

15

16

17

18

19

20

21

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE CHECK

Nothing works.

No liquid supply to the

brushes.

Squeegee is not drying the

floor well.

All indicators flashing when

key switched on.

All 3 indicators of the battery

condition meter flashing.

3 indicators of battery

condition meter flashing in

sequence

No power.

Is the tank empty.

Are the brushes revolving and

the machine moving as well

as the flow control activated.

Is the tank filter blocked.

Are the solenoid valves

blocked.

Are the pipes blocked.

Blockage in hose.

Worn sgueegee not sitting

fully on floor.

Torn tank lid gasket.

Traction control not in neutral

position.

Traction drive electronics

faulty.

Overload in electrical circuit. Will reset when cooled

Is the battery plugged in.

Is the mains lead plugged in

and switched on.

Is the mains socket live.

Fill the tank.

Try this sequence.

Remove and clean.

Remove and clean.

Flush through with clean hot

water.

Remove and flush through

with water.

Adjust pressure and rake.

Replace

Centre the traction control

then switch the key on.

Call Service Engineer. or

Replace P.C.B.

down. Check motor currents

for overload, or tight

bearings etc.

4

21

Page 7

SAFETY AND FAULTS

Keyswitch/accelerator sequence:

This safety feature prevents the machine from

moving if the machine is accidentally switched on

with either forward or reverse function engaged

(due to machine fault or an operator error).

When this happens the leds on display panel

begin flashing.

Mosfet short circuit:

This safety feature prevents the machine from

moving if the machine is switched on with the the

part of the electronic print card controlling drive

power is in short circuit (in this case the machine

would move immediately at full speed). This

condition is signalled by the 3 voltmeter leds

which start flashing.

Overheating of the electronic print card

cooling vents:

This protection device of the electronic print card

prevents damage to the card itself during

prolonged use of the machine when one of its

functions is overloaded. In this condition the

machine automatically cuts off all its functions

which are then only restored when temperature

returns to normal value. This condition is signalled

by the lighting up in sequence of the 3 voltmeter

leds.

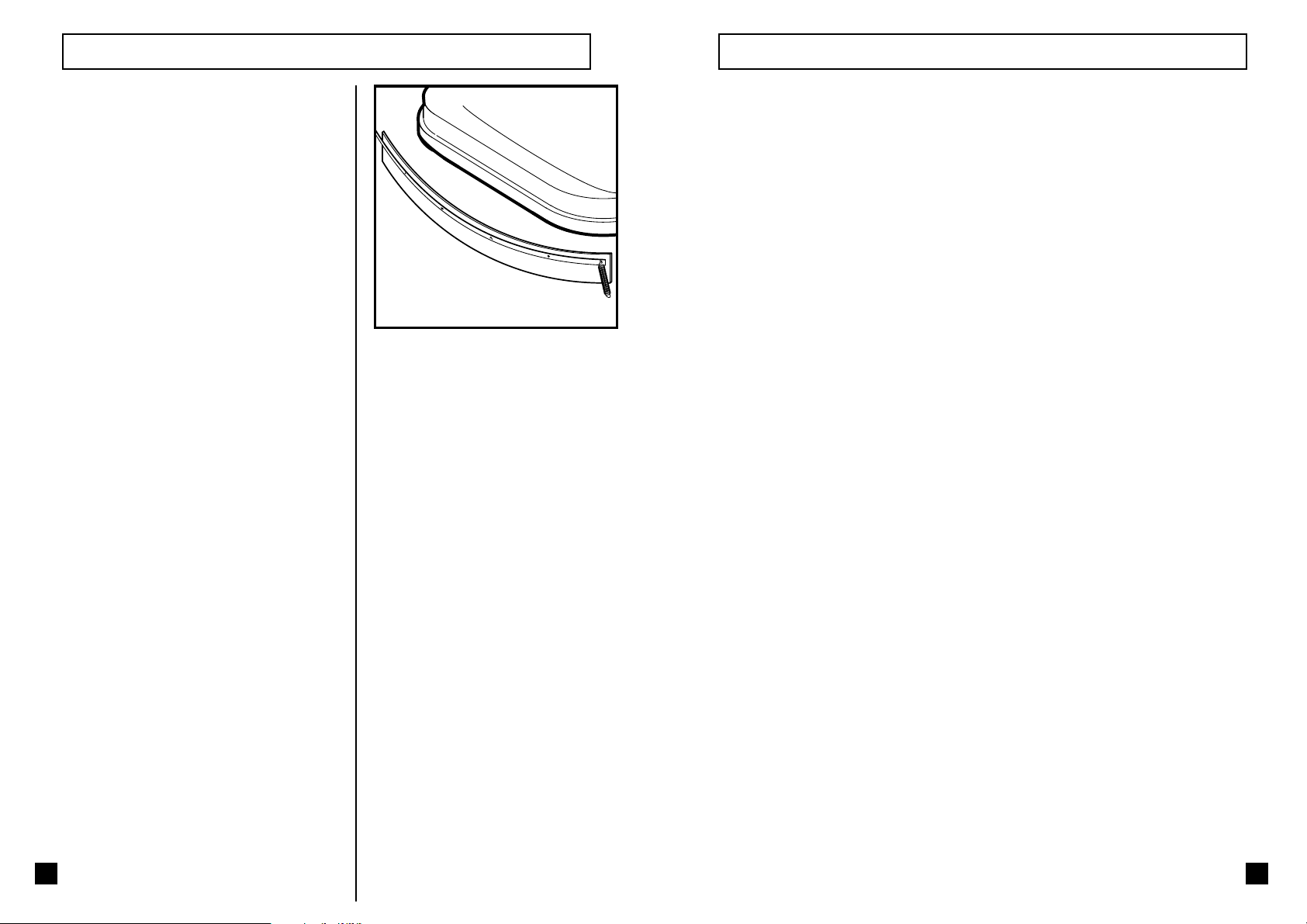

PREPARATION FOR USE

Partially unscrew the two middle levers on the

squeegee. Push the squeegee into the locating

lugs as illustrated and fully tighten the levers.

(pull the lever up to disingage it and make its

rotation free).

Push the coiled end of the squeegee hose fully

home onto the tubular spigot in the centre of the

squeegee.

Micro switch:

Micro switch to shut off all the functions when the

tank is in the upright position.

(SEMKO APPROVAL)

20

Push the straight end of the squeegee hose onto

the tank inlet pipe which protrudes through a slot

in the lower rear panel.

5

Page 8

PREPARATION FOR USE

For models working with batteries follow

instructions below, whereas in the case of mains

operated models the transformer has already

been placed inside the machine and needs no

further installation.

The batteries are supplied without liquid,

therefore they must be filled up with the

appropriate acid before they can be used.

Take special care when handling the

acid as it is corrosive, If it should come

into contact with skin or eyes, wash

abundantly with water and consult a

doctor.

The W345B & W355B machines use two 12 volt

batteries, the W365B & W375B machines use

four 6 volt batteries.

Study the

illustrations then fit

the batteries and

connect the links

supplied as

indicated.

Plug the battery

socket into the

machine as shown.

Fold over the flaps

to cover the battery

tops, then lower the

tank unit to safely

cover exposed

working parts.

+

MAINTENANCE

The three solenoid valve bodies may be removed

by turning them through 45 degrees and lifting

them away to reveal the plunger and seating of

each valve. These should be cleaned of scale and

of any other foreign matter.

Regularly inspect the squeegee for damage or

wear to the lips. The lips may be easily replaced

by unscrewing the retaining strips, remove the

lips, replace with new, then screw the cover strips

back again to retain them.

-

Important:periodically clean the suction

filters; this is very important not to

+

reduce the suction capability of the

squeegee.

-

6

19

Page 9

MAINTENANCE

BEFORE ANY MAINTENANCE IS CARRIED

OUT THE BATTERY MUST BE UNPLUGGED

OR THE MAINS LEAD UNPLUGGED.

Periodically unscrew the filter inside the scrubbing

detergent tank, scrub whit a stiff brush under

running water to remove any accumulated foreign

matter.

Note: for the models 345-355 it is enough to pull

the filter to remove it. Press the filter to mount it.

For the battery operated models, the level of the

liquid inside batteries must be checked

periodically, and topped up with distilled water

if necessary.

Raise the bonnet, uncover the battery

compartment, remove caps and check level.

Special care should be taken

when handling battery liquid

as it is corrosive. If it should

come into contact with skin

or eyes, wash abundantly

with water and consult a

doctor.

365-375

345-355

PREPARATION FOR USE

The machine may now be run for trial purposes

but before putting it into service the batteries

should be charged to bring them up to their

maximum capacity.

New batteries will gradually “run in” and

increase in capacity to a maximum in about the

first 10 charge/discharge cycles.

-

+

If necessary the batteries should

be charged using an appropriate

battery charger. Remove the

battery caps during the charging

operation.

+

-

-

+

-

+

Recharge batteries when necessary with an

appropriate battery charger.

18

Check that the Hertz and Voltage

readings of the mains supply

correspond to those of the battery

charger.

7

Page 10

PREPARATION FOR USE

Drop the brushes (one or two depending on the

model) roughly side by side in front of the

machine, the actual position does not matter.

Switch the machine on by turning the key in the

key-switch a quarter turn clockwise. Wait

momentarily until the battery condition indicator

above the switch lights.

Note :

The mains machine will have to be plugged in,

the indicator then only shows that power is

available.

CHANGING BRUSHES

Position the new brushes roughly side by side on

the floor in front of the machine.

Move the machine forward until the brushes are

pushed along the floor. Release the brush lift/

lower pedal and allow it to settle at its highest

point. Rock the machine forward and back about

50mm (2”) to settle the drive plates into the brush

centers.

Drive the machine forward by holding the handgrips, then rolling the thumb wheels forward until

the machine moves completely over the brushes.

To stop release the thumb wheels and they will

return to a neutral position. This will ensure the

brushes are fully located under the drive plates.

8

Press the brush motor on/off push button to

engage the brushes. Press the brush pedal down

and latch it into its lower position, press the brush

push button again to stop the motors.

The machine is now ready for use again.

17

Page 11

CHANGING BRUSHES

To replace brushes carry out the following

sequence of operations:

The machine should be switched on but all

functions switched off.

Raise the brush unit by pressing down the brush

lift/lower pedal and latching in its lowest position.

Press the brush release push button momentarily

and the brushes at present fitted will be unloaded

from the machine.

PREPARATION FOR USE

Lower the brush unit by pushing the pedal to the

right to unlatch it. Then allow it to rise as far as it

will go. Push the machine forward then back

about 50mm (2”) to ensure the drive has located

in the brushes.

Press the brush “on/off” push button: the indicator

will light and the brush motors will engage the

brushes.

Move the machine backward by rolling the

traction control rearward until the brushes are

visible in front of the machine.

16

Once the brushes have locked on, raise the brush

unit by pushing the pedal down and latching it at

its lower position.

Press the brush “on/off” push button again (see

previous picture); the green indicator will wait for

the motors to spin down to stop before going out.

Note : The motors do not stop immediately.

The brushes are now loaded onto the machine.

9

Page 12

SCRUBBING AND DRYING OPERATION

Open the tank lid.

Fill the left tank with water to within about 75mm

(3”) from the top edge then add the scrubbing

detergent in a quantity to make a dilution

according to its instruction.

Too strong a mix wastes detergent, too weak a

mix will not work efficiently.

The machine is now ready for use so move off to

the site to be cleaned.

SCRUBBING AND DRYING OPERATION

Unclip the recovery tank emptying hose and

remove the drain plug whilst holding the pipe at

its highest extent, then lower it carefully into a

gully or drain.

Note:

It is against Water Regulations to discharge

detergents into a surface drain, only use a foul

gully or drain.

At the same time as emptying the recovery tank

check if the clean tank requires refilling.

If the clean liquid runs out then it is recommended

that to save time the recovery tank be emptied at

the same time as the clean tank is refilled.

Switch the machine on by turning the key in the

key-switch a quarter turn clockwise.

10

A switch is fitted on the rear panel to the right of

the control handle which controls the drive motor

power. With the switch lever in the up position the

traction motor is disconnected and the machine

may be pushed easily from site to site when the

mains lead is unplugged or when the batteries are

not available.

OFF

ON

15

Page 13

SCRUBBING AND DRYING OPERATION

Push the machine slowly forward, and adjust the

squeegee pressure control until the lips bend over

evenly as illustrated below. Then re-adjust the rake

control to make the radius of the squeegee sit

parallel to the floor and the lips bend evenly.

TRAVEL DIRECTION

FLOOR LEVEL

The lips must be replaced when they become

feather edged or torn.

Fully lift the squeegee control lever (just below and

to the right of the machine handle) to lower the

squeegee to a flat floor surface.

SCRUBBING AND DRYING OPERATION

Press the brush “on/off” push button: the indicator

will light and the brush motors will start.

Lower the brush unit by pushing the pedal to the

right to unlatch it.

If the recovery tank full indicator lights continuosly

for a period of 6 seconds the suction motor will

switch off and the tank will have to be emptied

before continuing the operation.

Note:

Lift the brushes whilst still moving forward then

stop traction, in that order, to avoid “polo rings”.

Lift the squeegee and stop the suction motor. Drive

the machine to an emptying point or use a transfer

trolly to empty the recovery tank.

14

Drive the machine forward by holding the handgrips. And turning the thumb wheels.

11

Page 14

SCRUBBING AND DRYING OPERATION

When the machine is ready for scrubbing select

the estimated amount of clean liquid required by

pressing the detergent flow control on/off push

button; an indicator will light which can be

increased in three steps for varying the quantity of

liquid delivered to the brushes.

If more liquid is required press the boost pump

on/off push button which will double the amount

of flow; this will be shown by the indicator.

Note:

The liquid will be delivered to the brushes only

when the machine is moving forward and the

brushes are rotating. If either the brushes or the

forward traction are stopped the liquid flow

will stop.

SCRUBBING AND DRYING OPERATION

Press the suction on/off push button.

Start the brushes rotating, move the machine

slowly forward, then immediately lower the

brushes to the floor by lifting the foot pedal. (If the

brushes are allowed to rotate in contact with the

floor without the machine moving then it is likely

to cause “polo rings” on the floor).

Whilst moving forward observe the cleaning

effect on the floor and adjust the detergent flow to

the minimum required whilst being liquid enough

to be picked up by the squeegee. This allows the

liquid to last longer before having to refill the

tank. If too little liquid is used the floor will dry

with a “sludgy” grey look to it.

The height of the drive handle can be adjusted by

turning the knob A.

The speed range can be selected by means of

switch B.

A

B

Lower the squeegee to the floor.

12

+

Adjust the brush pressure to the minimum

required; this will assist in using the least amount

of power necessary from the battery which will

then last longer before requiring recharge.

13

Loading...

Loading...