Page 1

SERVICE MANUAL

W75 – W100 – W160 – W230

471 1553-51

Page 2

Page 3

NOTICE TO SERVICE PERSONNEL

INSTALLATION

Improper installation of Wascomat laundry and wet cleaning equipment can result in

personal injury and severe damage to the machine.

REFER INSTALLATION TO QUALIFIED PERSONNEL!

RISK OF ELECTRIC SHOCK

The equipment utilizes high Voltages. Disconnect electric power before servicing.

The use of proper service tools and techniques, and the use of proper repair procedures,

is essential to the safety of service personnel and equipment users.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

RISK OF PERSONAL INJURY

This equipment contains moving parts, and some components that may have sharp edges.

Improper or careless service procedures may result in serious injury to service personnel.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

ABOUT THIS MANUAL

This manual is intended to provide service guidance to qualified service personnel.

Wascomat and its authorized dealers make no determination regarding the qualification of

individuals requesting this service manual. The service provider assumes all risks inherent

to the servicing of this equipment and any risks that arise as result of the lack of

knowledge or ability of any person servicing this equipment.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

NOTE:

Improper installation or servicing of Wascomat equipment will void the

manufacturer's warranty!

Page 4

Machine description – Safety regulations

1

Summary

Service-

instruc-

tions

Data

Description of principle components

Programmes

Periodic maintenance

Function sequences – Fault finding

Automatic unit

Timer

Level control

Thermostat

2

3

4

5

11

12

21

22

23

24

25

26

27

Included

units and

components

Door and safety locking device

Motor

Inlet valve, water

Drain valve

Heating

Coin meter

Drum and bearings

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Frame

43

44

45

46

47

48

49

50

Page 5

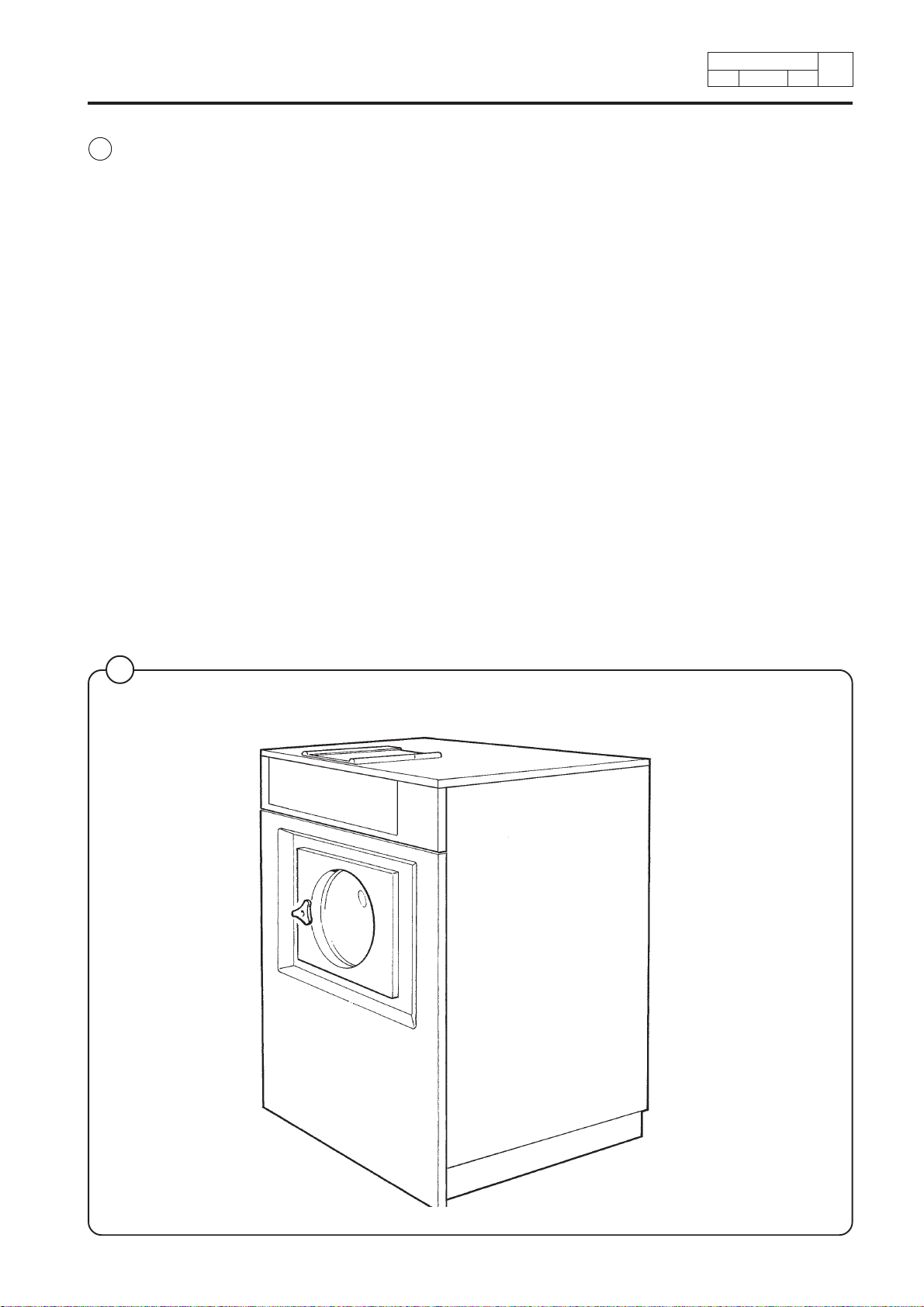

Page 6

Service

Manual

Fig.

The 70 100, 160 and 230 litre washing machines described in this manual

1

are normal spin machines and differ only in size and washing capacity. The

machines are intended for installation in apartment houses, hotels,

laundries, industries, hospitals, smaller institutions and other regular users

who require machines with high reliability, large washing capacity and easy

maintenance.

Because the machines have a washing drum which is solidly mounted in

the frame, they require secure anchoring to the foundation.

The spin speed provides a G-factor of about 80.

The machines are supplied equipped in accordance with customer

specifications for electric, steam, gas heating or non-heating and can be

connected to various combinations of cold, hot and/or cold hard water.

The machines can be supplied with or without coin meter.

The machines are available with two different types of timer:

• Mechanical timer with fixed wash programs. The machine has switches

to select different standard programs.

1. Machine description

9112

91

Type

Edition

Page

1

• Electronic timer with fixed wash programs. The machine has switches to

select different standard programs. The timer also has a built-in troubleshooting program which increases possibilities for rational service.

1

1418

Page 7

1

EditionType

Page

1. Machine description

9112

92

Safety Regulations

• The machine is designed for water washing only.

• The machine must not be used by children.

• Installation and service work may only be carried out by qualified personnel.

• The machine’s door lock may not be bypassed under any circumstances.

• System leakage, such as a worn door gasket, should be repaired

immediately.

• Qualified personnel should study the relevant handbooks and service

manuals before any repairs or service are done.

• This machine may not be sprayed with water.

Service

Manual

Page 8

Service

Manual

2. Data

81

Type

9112

Edition

2

Page

W 75 W 100 W 160 W230

Dry weight capacity

at filling factor 1:13 5.4 kg 7.7 kg 12.3 kg 17.7 kg

at filling factor 1:10 7 kg 10 kg 16 kg 23 kg

Drum volume 70 lit 100 lit 160 lit 230 lit

diameter 520 mm 520 mm 620 mm 700 mm

depth 356 mm 473 mm 520 mm 600 mm

Drum speed wash 52 r/m 52 r/m 52 r/m 45 r/m

spin 530 r/m 530 r/m 500 r/m 455 r/m

G-factor wash 0.8 0.8 0.9 0.8

spin 81 81 87 81

Dimensions width 660 mm 660 mm 745 mm 825 mm

depth 649 mm 766 mm 995 mm 1090 mm

height 1050 mm 1050 mm 1195 mm 1320 mm

Recommended service space

side 250 mm 250 mm 250 mm 250 mm

rear 500 mm 500 mm 500 mm 500 mm

Min. space for moving

machine during servicing

side 50 mm 50 mm 50 mm 50 mm

rear 250 mm 250 mm 250 mm 250 mm

Weight net 107 kg 147 kg 202 kg 265 kg

gross, crate packed 117 kg 158 kg 220 kg 287 kg

gross, box packed 144 kg 185 kg 280 kg 352 kg

Transport volume

crate packed 0.62 m

box packed 0.77 m

3

3

0.65 m

0.8 m

3

3

1.1 m

1.5 m

3

3

1.42 m

1.8 m

3

3

Max floor load during spin 1.2±2.6 kN 1.7±3.4 kN 2.4±4.8 kN 3.1±5.2 kN

Frequency (dynamic load) 9 Hz 9 Hz 8.5 Hz 8.5 Hz

Water valves connection DN20 3/4 DN20 3/4" DN20 3/4'' DN20 3/4''

rec. water pressure 200-600 kPa 200-600 kPa 200-600 kPa 200-600 kPa

pressure limits 40-1000 kPa 40-1000 kPa 40-1000 kPa 40-1000 kPa

capacity at 300 kPa 27 l/min 27 l/min 27 l/min 100 l/min

Drain valve conn. outside diameter 75 mm 75 mm 75 mm 75 mm

capacity 160 l/min 160 l/min 160 l/min 160 l/min

Steam valve connection DN15 1/2" DN15 1/2" DN15 1/2'' DN15 1/2''

rec. steam pressure

300-600

Page 9

2

EditionType

Page

2. Data

9112

82

70 LITERS

Heating Voltage Total Fuse Cable crossalternative alternative kW A section mm

No heating 100 V 1 AC 50 Hz 1,4 20 3 x 4

or 100 V 1 AC 60 Hz 1,3 20 3 x 4

Steam heating 120 V 1 AC 60 Hz 1,2 16 3 x 2,5

200 V 3 AC 50 Hz 1,1 10 4 x 1,5

208-240 V 3 AC 60 Hz 1,1 10 4 x 1,5

220-230 V 1 AC 50 Hz 1,4 16 3 x 2,5

220-230 V 3 AC 50 Hz 1,2 10 4 x 1,5

240 V 1 AC 50 Hz 1,4 16 3 x 2,5

380-400 V 3N AC 50 HZ 1,2 10 5 x 1,5

415-440 V 3N AC 50 Hz 1,2 10 5 x 1,5

El 3,0 kW 220-240 V 1 AC 50 Hz 3,5 20 3 x 4

Service

Manual

2

380-400 V 3N AC 50 Hz 3.5 10 5 x 1,5

El 5,4 kW 220-230 V 1 AC 50 Hz 5,8 35 3 x 10

220-230 V 3 AC 50 Hz 5,8 16 4 x 2,5

240 V 1 AC 50 Hz 5,8 35 3 x 10

380-400 V 3N AC 50 Hz 5,8 10 5 x 1,5

415-440 V 3N AC 50 Hz 5,8 10 5 x 1,5

El 6,0 kW 380-415 V 3N AC 50 Hz 6,5 16 5 x 2,5

El 7,5 kW 220-230 V 3 AC 50 Hz 8,0 25 4 x 6

220-230 V 3 AC 60 Hz 8,0 25 4 x 6

240 V 3 AC 60 Hz 8,0 25 4 x 6

380-400 V 3 AC 50 Hz 8,0 16 4 x 2,5

380-400 V 3N AC 50 Hz 8,0 16 5 x 2,5

415-440 V 3 AC 50 Hz 8,0 16 4 x 2,5

415-440 V 3N AC 50 Hz 8,0 16 5 x 2,5

Page 10

Service

Manual

100 LITERS

Heating Voltage Total Fuse Cable crossalternative alternative kW A section mm

No heating 220 V 3 AC 50 Hz 1,6 10 4 x 1,5

or 415-440 V 3 AC 60 Hz 1,6 10 4 x 1,5

Steam heating 380-440 V 3N AC 50 Hz 1,6 10 5 x 1,5

415-440 V 3N AC 50 Hz 1,6 10 5 x 1,5

208-240 V 3 AC 60 Hz 1,6 10 4 x 1,5

120 V 1 AC 60 Hz 1,1 20 3 x 4

220-240 V 1 AC 50 Hz 1,7 16 3 x 2,5

El 7,5 kW 220-230 V 3 AC 50 Hz 8,1 25 4 x 6

380-400 V 3N AC 50 Hz 8,1 16 5 x 25

El 9 kW 415-440 V 3N AC 50 Hz 9,6 16 5 x 2,5

380-400 V 3 NAC 50 Hz 9,6 16 5 x 2,5

2. Data

83

9112

Type

Edition

2

Page

2

160 LITERS

Heating Voltage Total Fuse Cable crossalternative alternative kW A section mm

No heating 208-240 V 1 AC 60 Hz 2,6 16 3 x 2,5

or 208-240 V 3 AC 60 Hz 2,6 10 4 x 1,5

Steam heating 220-230 V 3 AC 50 Hz 2,6 10 4 x 1,5

380-440 V 3N AC 50 Hz 2,6 10 5 x 1,5

415-440 V 3N AC 50 Hz 2,6 10 5 x 1,5

El 12,0 kW 220-230 V 3 AC 50 Hz 12,8 35 4 x 10

380-400 V 3N AC 50 Hz 12,8 20 5 x 4

415-440 V 3N AC 50 Hz 12,8 20 5 x 4

230 LITERS

Heating Voltage Total Fuse Cable crossalternative alternative kW A section mm

No heating 208-240 V 3 AV 60 Hz 2,3 10 4 x 1,5

or 220-230 V 3 AC 50 Hz 2,3 10 4 x 1,5

2

2

Steam heating 380-400 V 3N AC 50 Hz 2,3 10 5 x 1,5

415-440 V 3N AC 50 Hz 2,3 10 5 x 1,5

El 18 kW 208-240 V 3 AC 60 Hz 18,9 50 4 x 16

220-230 V 3 AC 50 Hz 18,9 50 4 x 16

380-400 V 3N AC 50 Hz 18,9 35 5 x 10

415-440 V 3N AC 50 Hz 18,9 35 5 x 10

Page 11

Page 12

Service

Manual

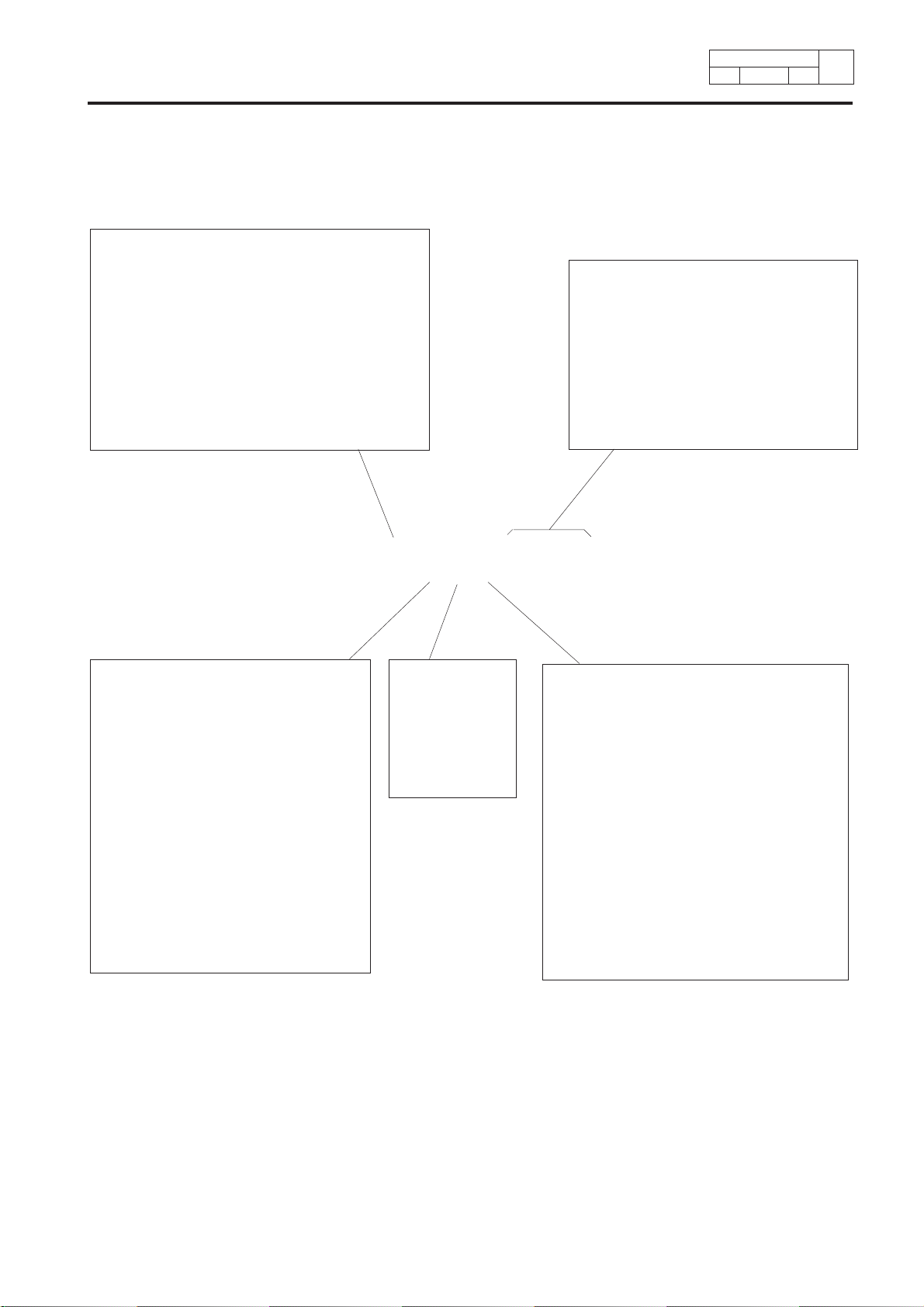

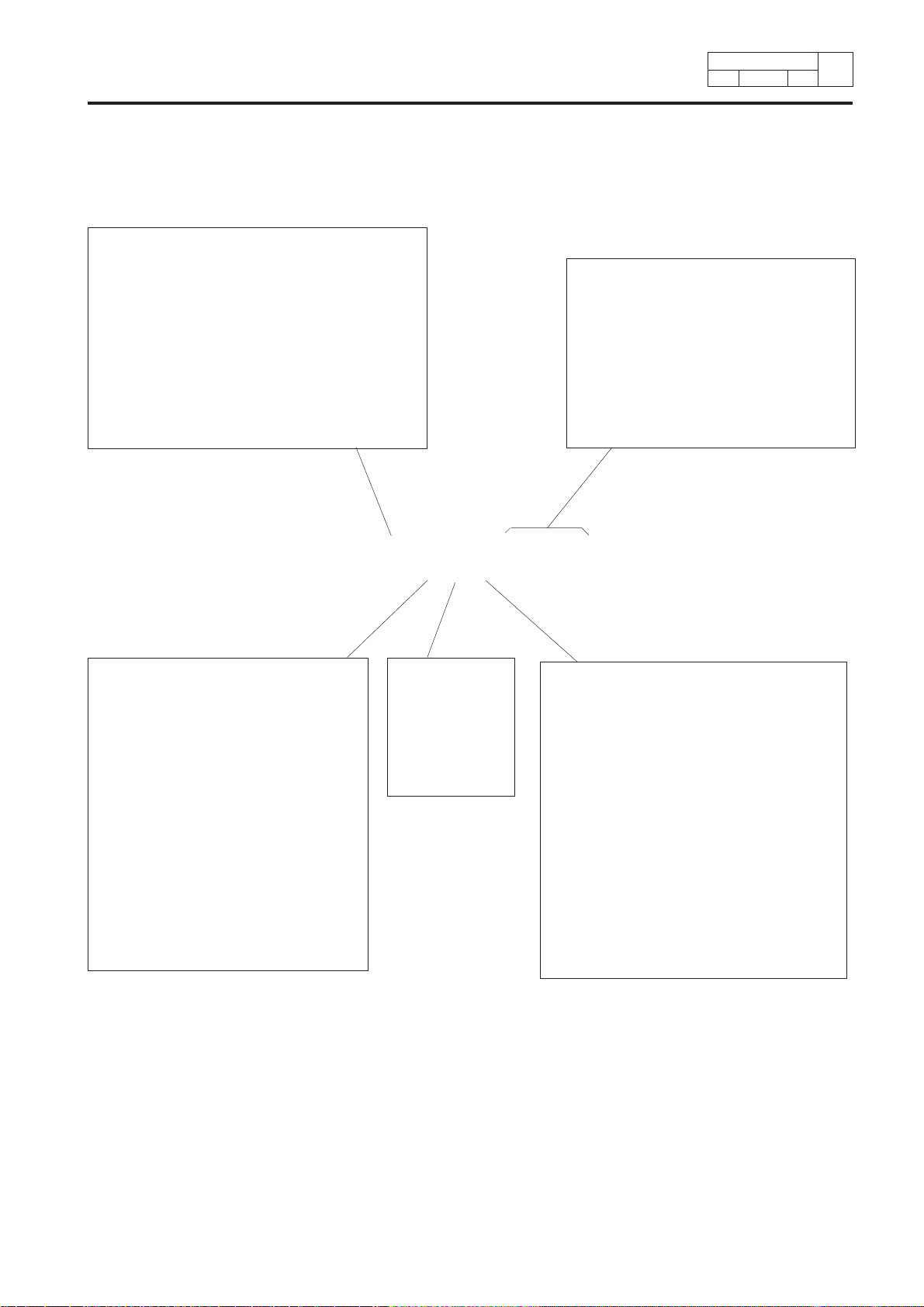

Fig.

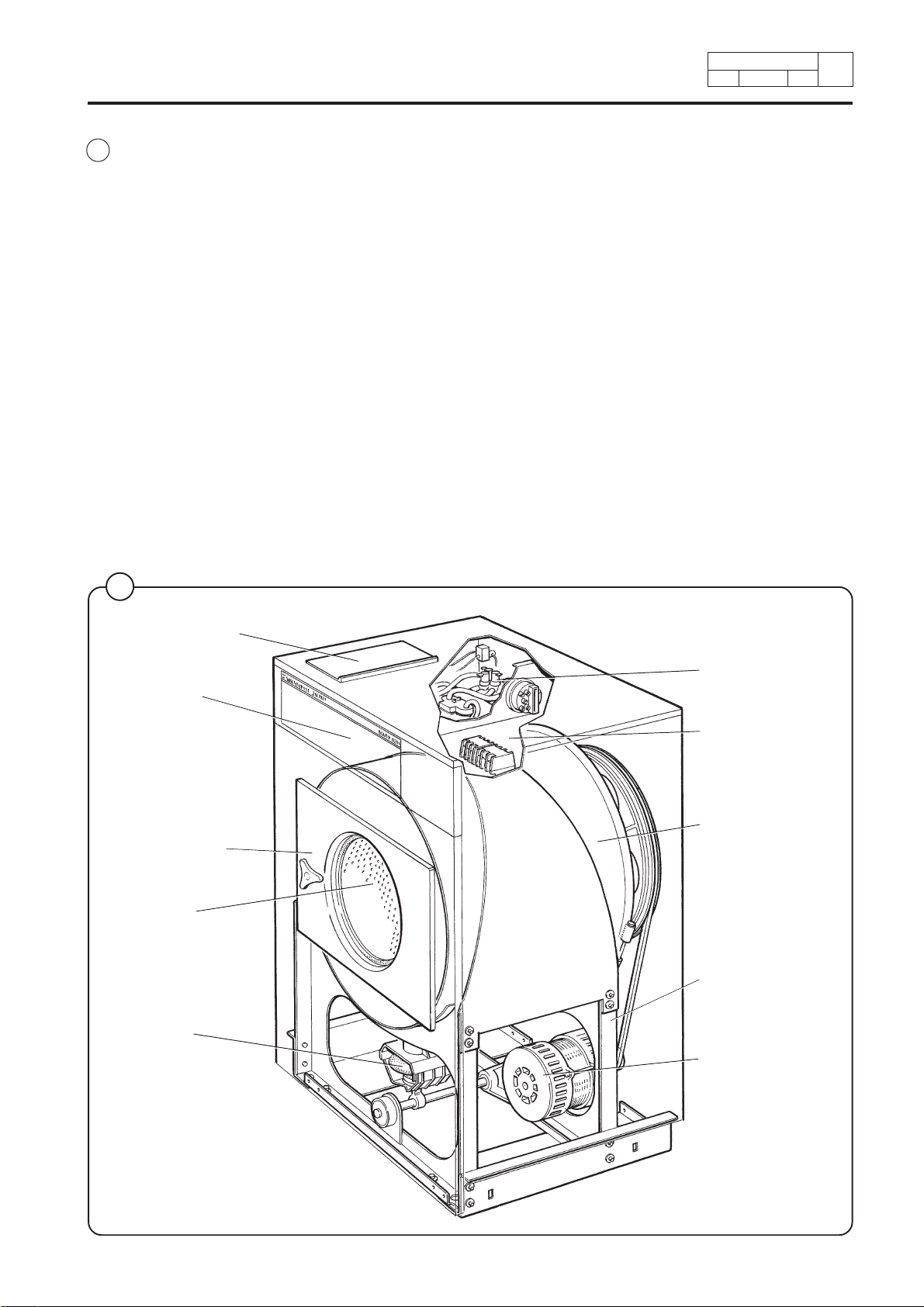

The inner drum drive shaft is mounted in the outer drum with two ball

1

bearings at the back plate. Two neoprene gaskets make the shaft leak

resistant.

The motor is mounted on a rubber-cushioned shaft under the drum.

To prevent transmission of troublesome noises from chassis to the building

frame, the motor’s belt-tensioning device is also rubber-cushioned.

The drain valve is a membrane valve controlled with the help of the water

pressure in the cold water connection.

The door is electrically locked when the machine in running.

Timer, level control, thermostat, motor relays, etc., are located in the

automatic control unit which is easily accessible from the top of the

machine.

The front plate is available in a selection of finishes (galvanised/ painted or

in stainless steel). The side plates are galvanised/ painted, the rear panel is

galvanised/unpainted and the top panel is stainless steel.

5

3. Description of principle components

11 9020 1

9112

Type

Edition

Page

3

1

Detergent compartment

Control panel

Door and Safety lock

Inner drum

Drain valve

Inlet valve, water

Automatic control unit

Outer drum

Chassis

Motor

G119

Page 13

Service

Manual

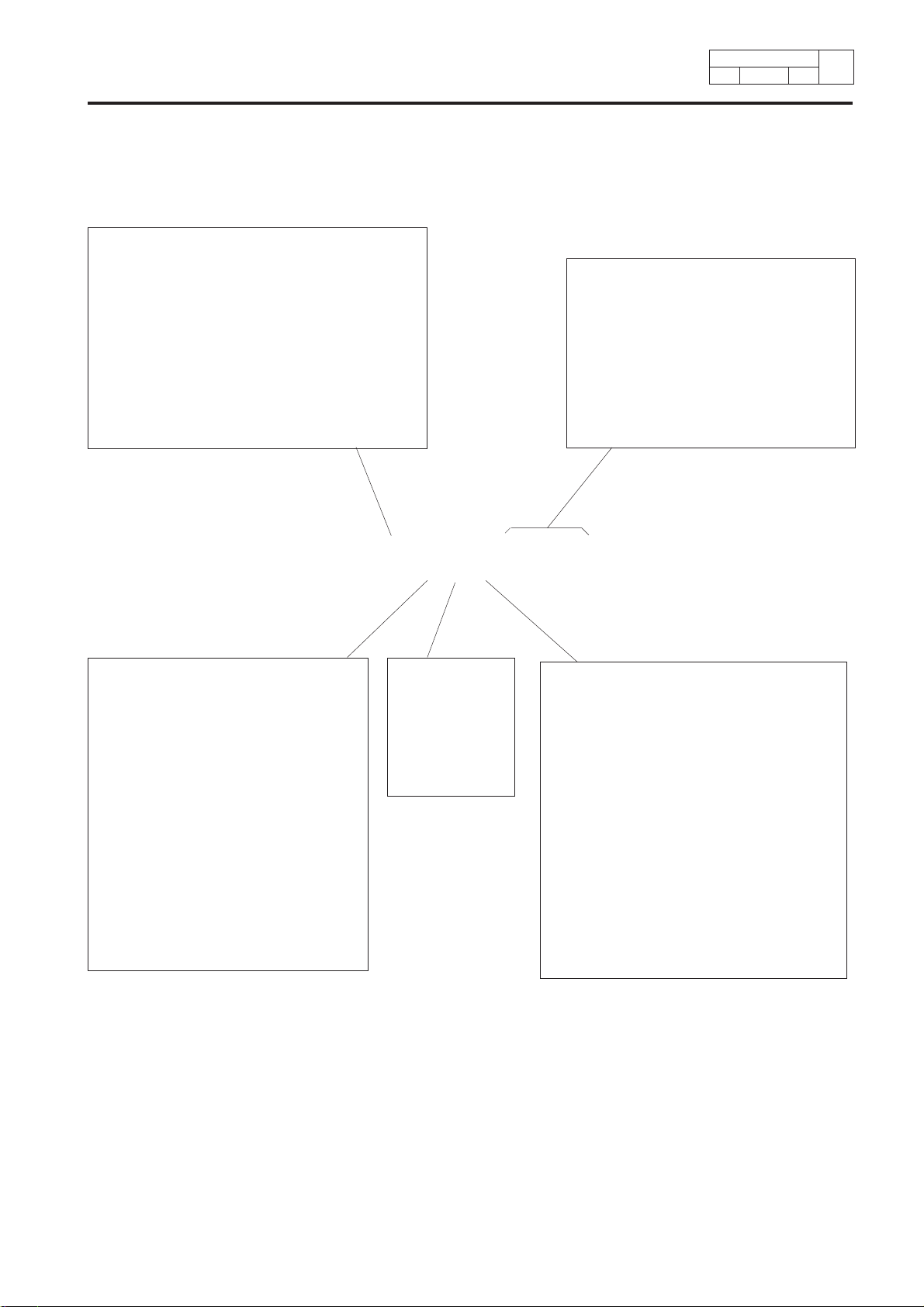

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

10 19002

Edition

Type

Page

4

P = Standard

H = Hygienic and hospital.

These programs follow national

regulations

S = Selecta program. Special OPL-

program.

M = Mop program.

Timer type

E = electronic microprocessor-

controlled timer.

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE11CHd = electronic timer

P11CHd = electromechanical

timer

PE11CHd

Market

0 = Export

1 = Sweden

Machine family

1 = Machine with heating

2 = Machine for laundrettes, Europe

3 = Machine for laundrettes, USA and

4 = Machine for laundrettes,

5 = Machine for OPL, USA

6 = Machine for OPL, Selecta USA

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard water

CHHd = cold, hot and cold hard

water

and Asia

Canada

Denmark and West Germany

8 = Machine for laundrettes, Japan

The symbol PE11CHd used in the example above means:

• for standard user

• with electronic timer

• adapted for Sweden

• equipped with heating

• cold and cold hard water connection.

Page 14

10 2

9002

4

Type

PageEdition

4. Programmes

Program description

The wash programs identified by the symbol P11C are described on the

following pages. They are the programs designed for a regular user using a

heated machine with mechanical timer and intended for cold water

connection only.

These machines have eight fixed programs, which are selected by using the

knob on the control panel.

Program Wash type

Normal 95° white wash

Normal 60° colour wash

Normal 40° colour wash

Mild 30° delicate wash

Wool separate wool garments

Permanent press 40° fine wash

Service

Manual

Permanent press 60° coloured

Permanent press 95° white

By pushing the selector button HEAVILY SOILED a prewash and rinse will

be added to the three standard programs.

During cool-down, water filling and heating, the timer does not move. This

time is not included in the stated program times.

Page 15

Service

Manual

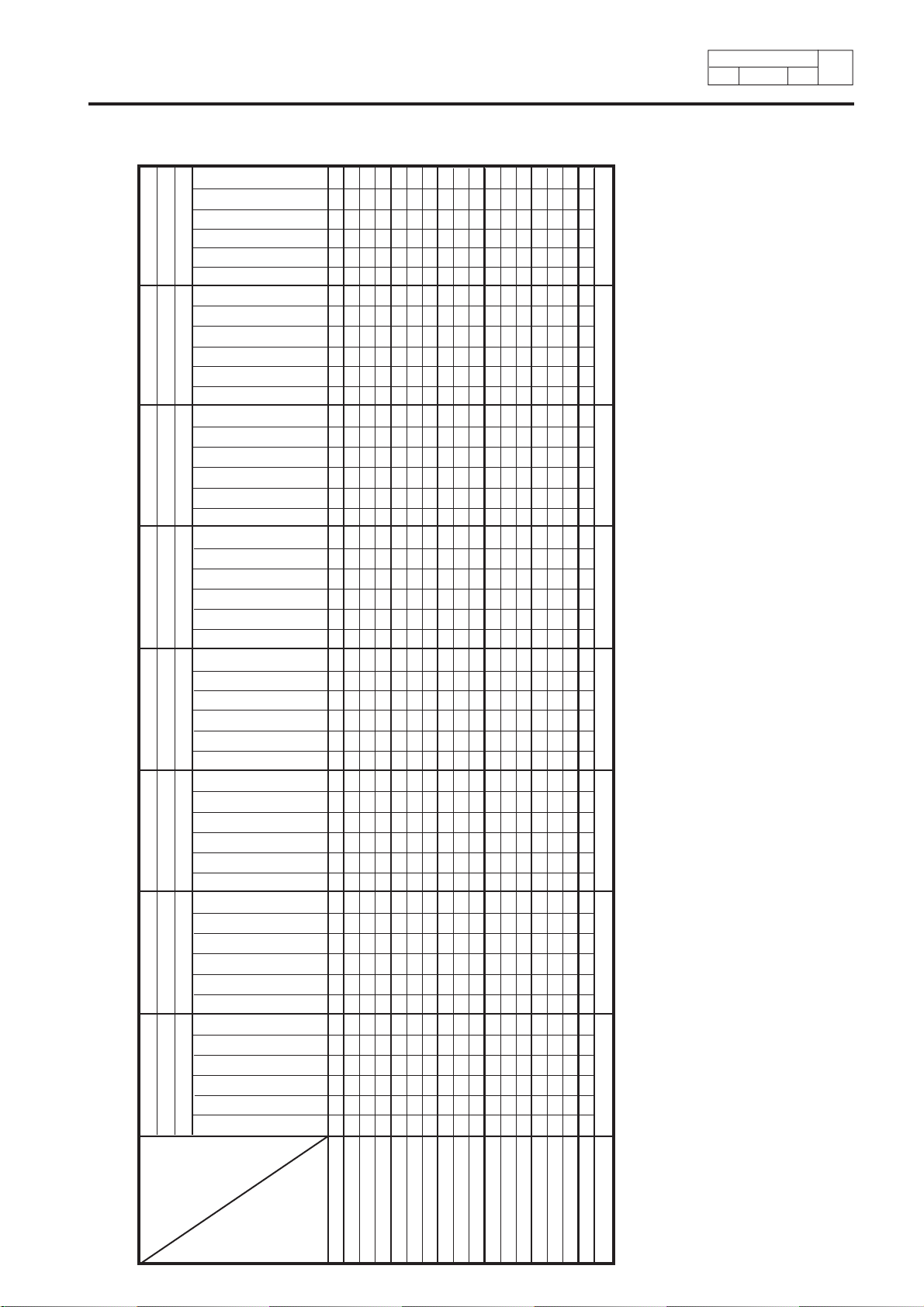

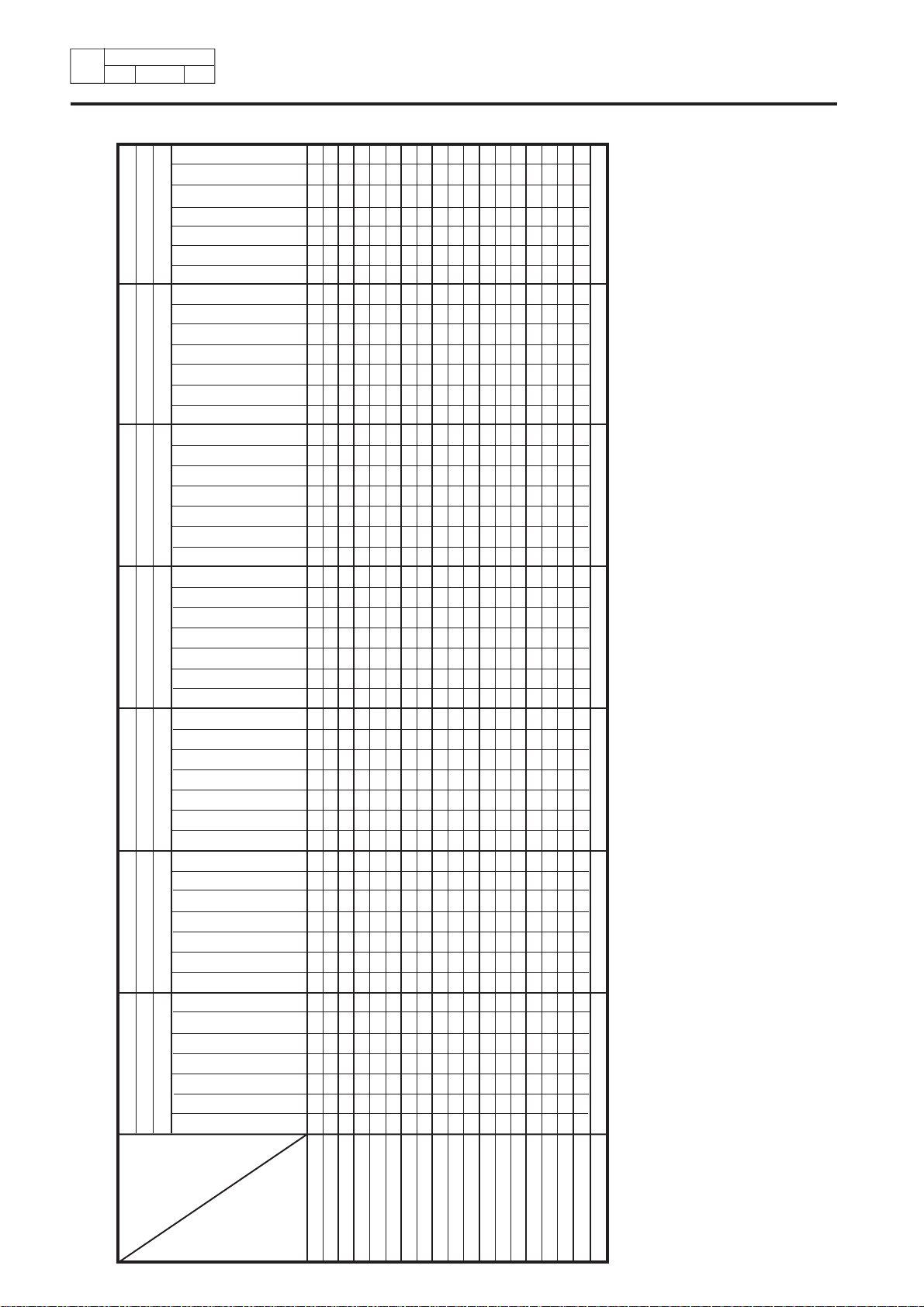

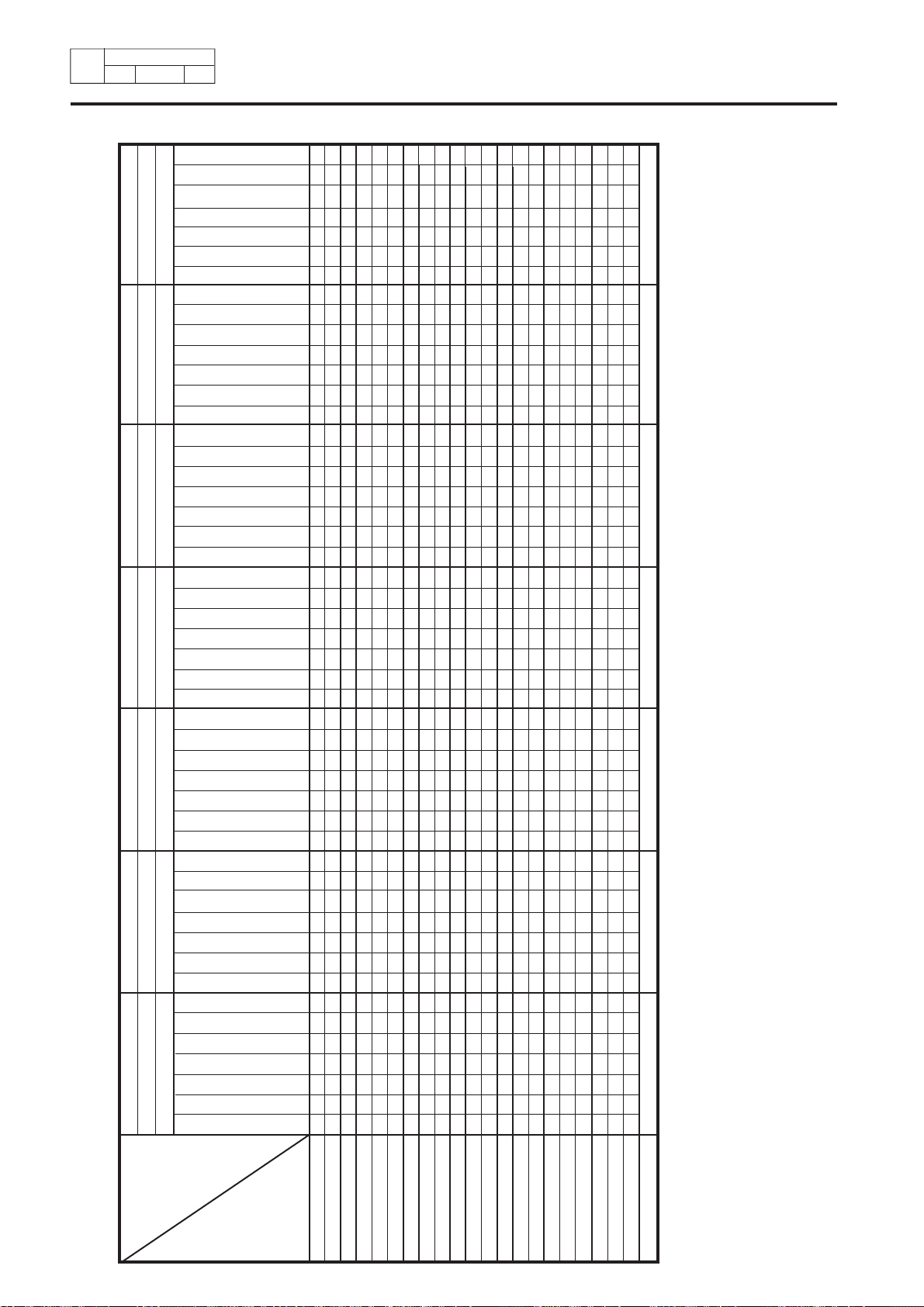

Program P11C

12 34 5 6 78

STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60° PERM. PRESS 95°

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-LL2N

3C-LL2N

3C-LL2N

3C-HL2G

3C-HL2G

3C-LL2N

3C-LL2N

3C-LL2N

C56

12 C 90 LL 2 N

C56

12 C 60 LL 2 N

---

12 C 40 LL 2 N

---

2C40HL-G

---

2C30HL-G

---

12 C 40 LL 2 N

C56

12 C 60 LL 2 N

C56

12 C 90 LL 2 N

4. Programmes

1N

1N

1N

1-

1-

1N

1N

1N

1C-HL-N

1N

2C-HL-N

1N

2C-HL3N

1N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

--

1C-HL-G

1-

2C-HL-G

1-

--

1C-HL-G

1-

2C-HL-G

1-

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1E

0.5 E

2C-HL3N

1N

1E

0.5 E

2C-HL3N

1N

1E

0.5 E

--

2C-HL3G

1G

1E

--

2C-HL3G

1G

1E

2C-HL3N

1N

0.5 E

0.5 E

0.5 E

1E

2C-HL3N

1N

1E

2C-HL3N

1N

1E

1.5 N

1.5 N

1.5 N

1.5

1.5 -

1.5 N

1.5 N

1.5 N

27.5 27.5 27.5 16.5 16.5 27.5 27.5 27.5

10 9002 3

Type

Edition

E = EXTRACTION

D = DISTRIBUTION

N = NORMAL ACTION 12/3 SEC

G = GENTLE ACTION 3/12 SEC

Page

4

PROGRAM

WITHOUT PRE WASH

PROGRAM

MAIN WASH

SEQUENCE

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

TOTAL TIME

SHAKE OUT

C = COLD WATER

LL = LOW LEVEL

HL = HIGH LEVEL

Page 16

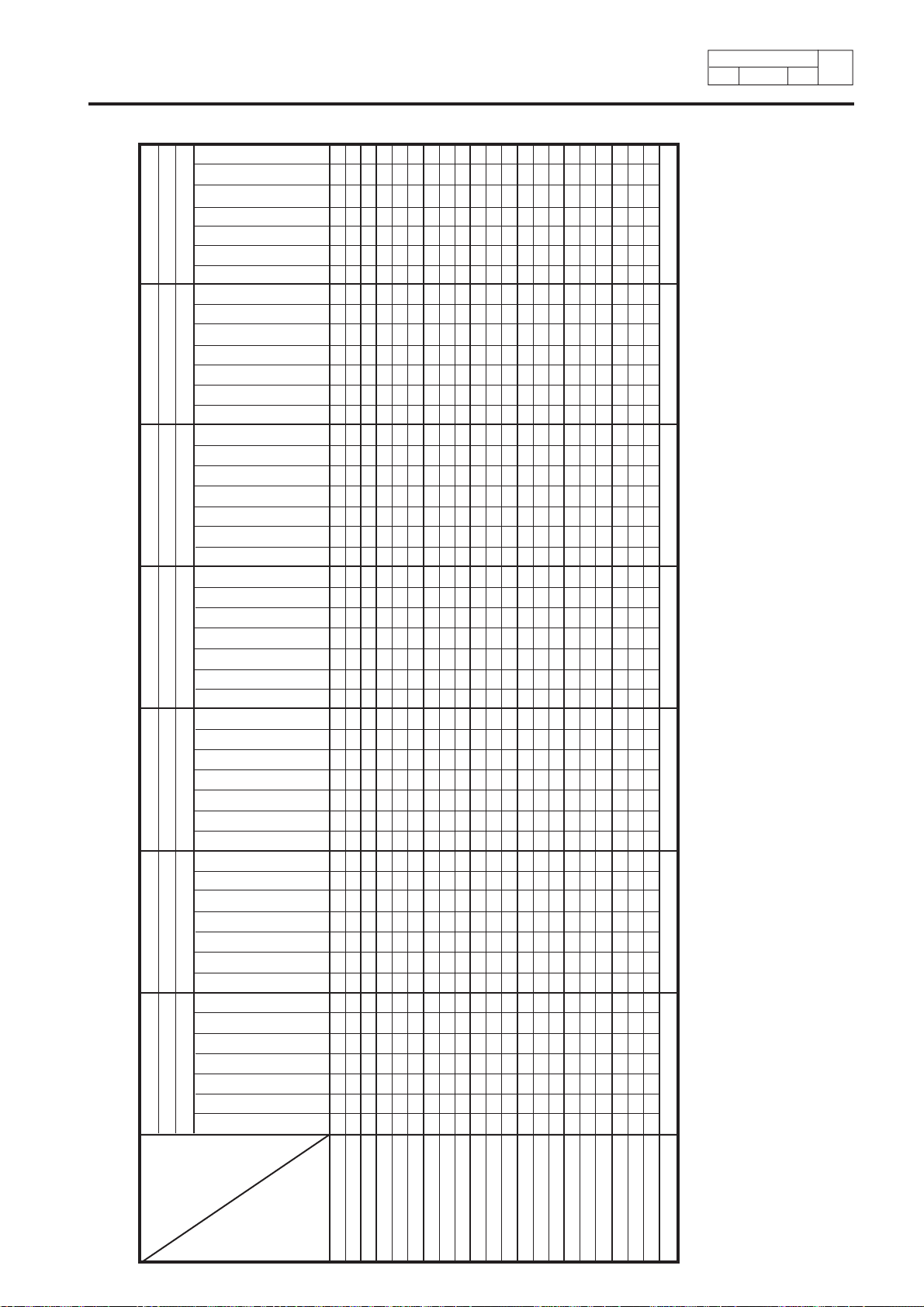

10 9002 4

4

Type

Edition

Page

4. Programmes

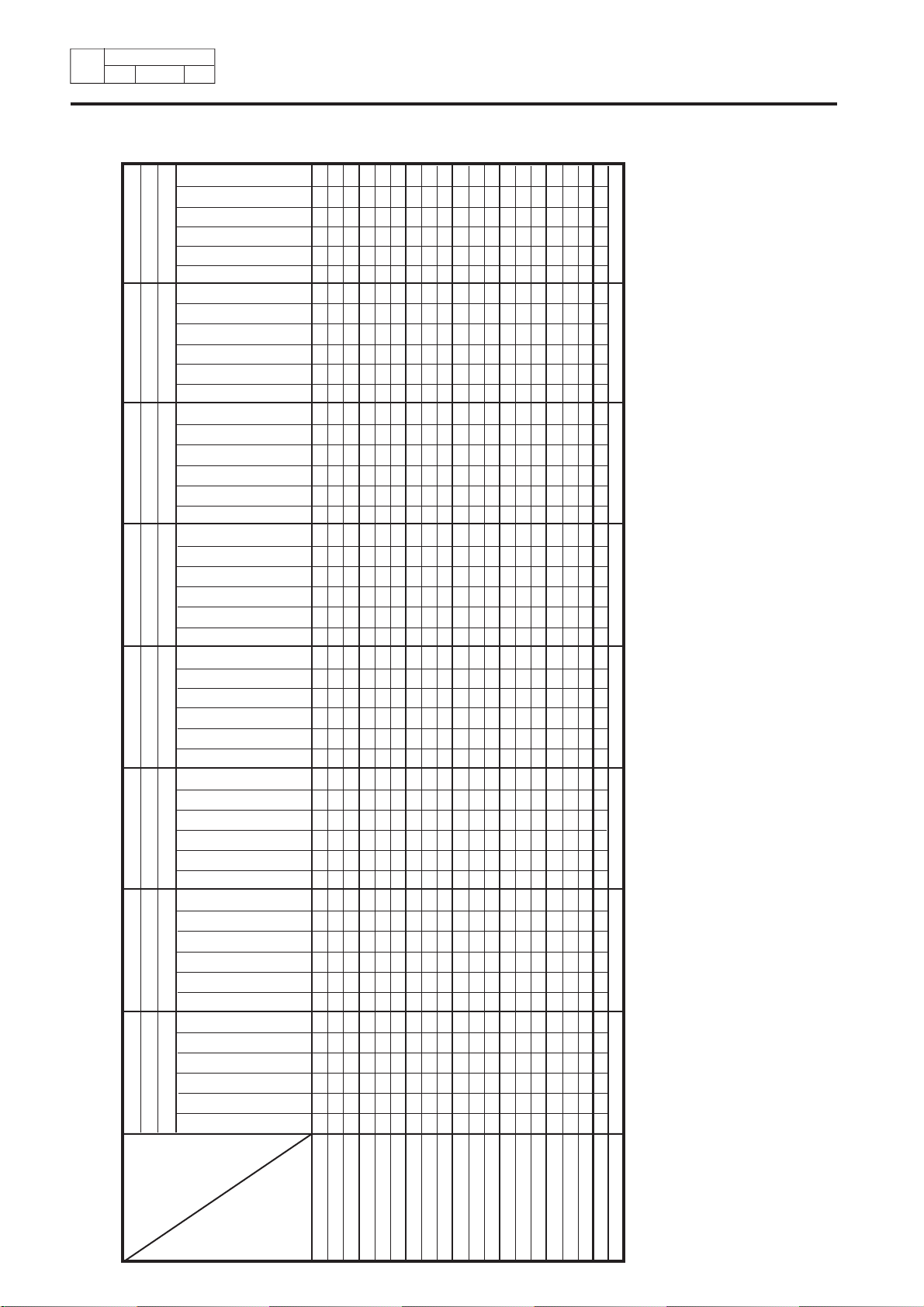

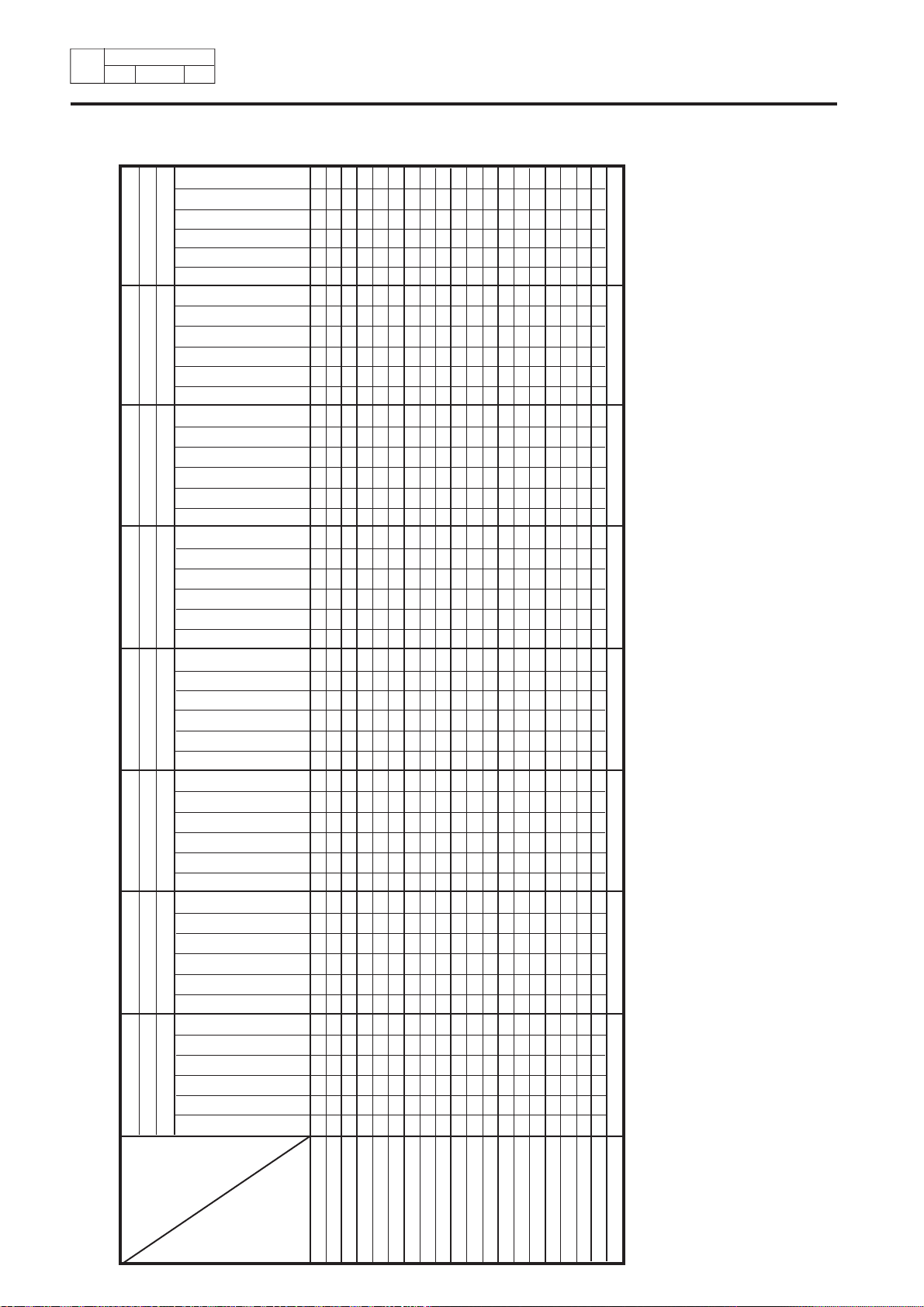

Program P11C with prewash

ACTION

DETERGENT

LEVEL

TEMP

910111213141516

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60° PERM. PRESS 95°

HEAVY SOILED HEAVY SOILED HEAVY SOILED

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N

0.5 N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N

0.5 N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N

0.5 N

3C-LL2N

3C-LL2N

3C-LL2N

3C-HL2G

3C-HL2G

C56

12 C 90 LL 2 N

C56

12 C 60 LL 2 N

---

12 C 40 LL 2 N

---

2C40HL-G

---

2C30HL-G

---

12 C 40 LL 2 N

C56

12 C 60 LL 2 N

C56

12 C 90 LL 2 N

1N

1N

1N

1-

1-

1N

1C-HL-N

1N

1C-HL-N

1N

1C-HL-N

1C-HL-N

1N

2C-HL-N

1N

2C-HL3N

1N

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-N

1N

0.5 E

--

1C-HL-G

1-

--

1C-HL-G

1-

1N

1C-HL-N

1N

0.5 E

1N

1C-HL-N

1N

0.5 E

1N

1C-HL-N

1N

0.5 E

0.5 E

2C-HL-N

1N

0.5 E

2C-HL-N

1N

0.5 E

--

2C-HL-G

1-

--

2C-HL-G

1-

2C-HL-N

1N

0.5 E

2C-HL-N

1N

0.5 E

2C-HL-N

1N

0.5 E

1E

2C-HL3N

1N

1E

2C-HL3N

1N

1E

2C-HL3G

1G

1E

2C-HL3G

1G

1E

2C-HL3N

1N

1E

2C-HL3N

1N

1E

2C-HL3N

1N

1E

1.5 N

1.5 N

1.5 N

1.5

1.5

1.5 N

1.5 N

1.5 N

33 33 33 16.5 16.5 27.5 27.5 27.5

Service

Manual

E = EXTRACTION

D = DISTRIBUTION

N = NORMAL ACTION 12/3 SEC

G = GENTLE ACTION 3/12 SEC

PROGRAM

PROGRAM

SEQUENCE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SPIN DOWN

TOTAL TIME

C = COLD WATER

LL = LOW LEVEL

HL = HIGH LEVEL

Page 17

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

P = Standard

H = Hygienic and hospital.

These programs follow national

regulations.

S = Selecta program. Special OPL-

program.

M = Mop program.

11 1

Type

9002

Edition

Page

4

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard water

CHHd = cold, hot and cold hard

water

PE11CHd

Timer type

E = electronic microprocessor-

controlled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE11CHd = electronic timer

P11CHd = electromechanical

timer

The symbol PE11CHd used in the example above means:

Market

0 = Export

1 = Sweden

Machine family

1 = Machine with heating capacity

2 = Machine for laundrettes,

Europe and Asia

3 = Machine for laundrettes,

USA and Canada

4 = Machine for laundrettes,

Denmark and West Germany

5 = Machine for OPL, USA

6 = Machine for OPL, Selecta USA

8 = Machine for laundrettes, Japan

• for standard

• with electronic timer

• adapted for Sweden

• equipped with heating

• cold and cold hard water connection

Page 18

11 2

Type

4

9002

Service

PageEdition

4. Programmes

Manual

Program description

The wash programs identified by the sybol P11C

are described on the following pages. They are the

programs for a regular user in Sweden using a

heated machine with mechanical timer and

intended for cold water connection only. There are

more program variations available for machines

with electronic timer.

Machines with wash program PE11C have seven

fixed programs which are selected by pushing the

program buttons on the panel.

Program Wash type

Normal 95° white wash

Normal 60° colour wash

Normal 40° colour wash

Mild 30° delicate wash

Wool separate wool garments

Permanent press 40° fine wash

1

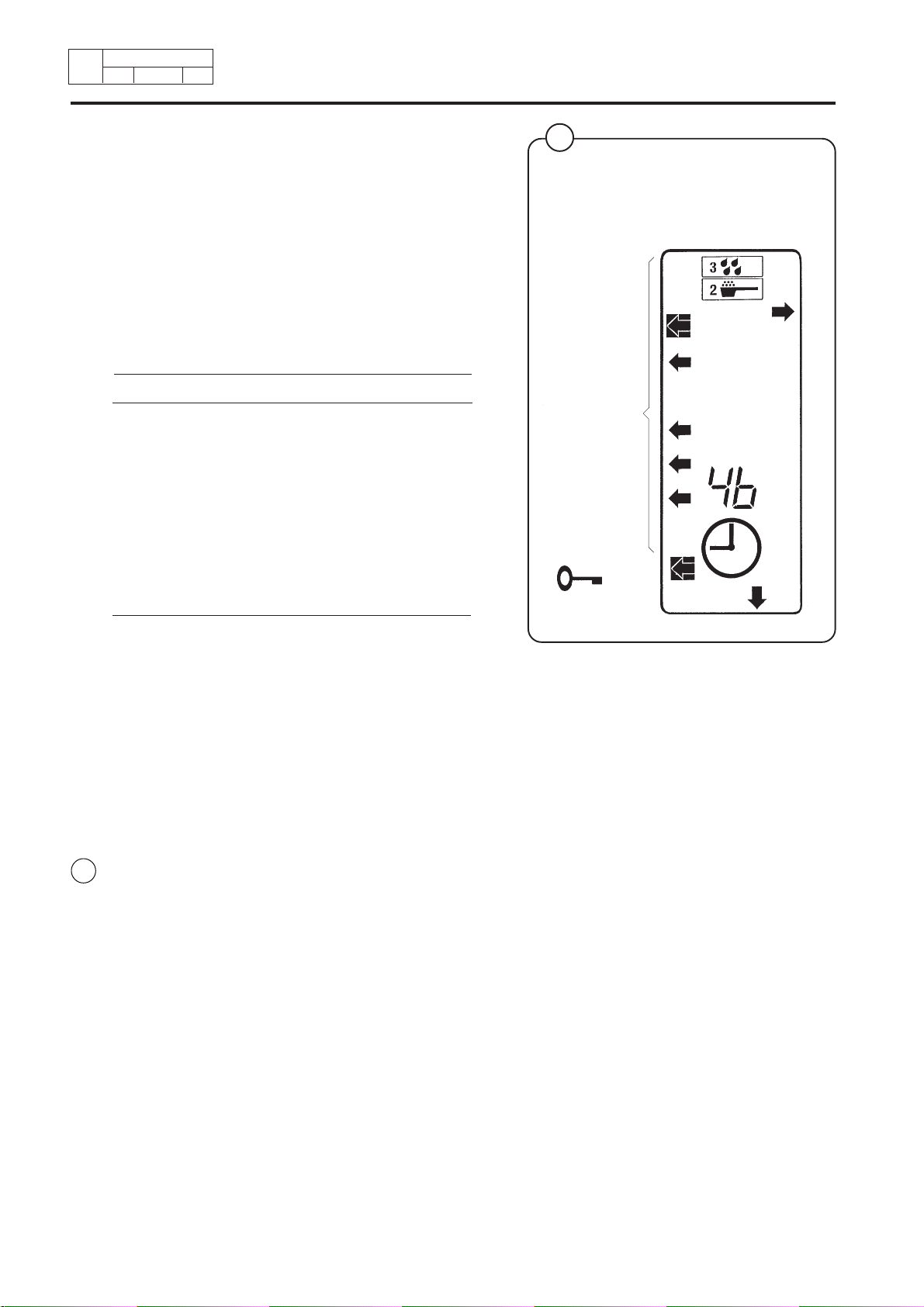

Nine arrow and

square

symbols

indicate

different

program steps

(shown here is

a program

example with

arrows 3, 4, 6,

7 and 8 in

use).

Permanent press 60° coloured

The programmer has two selector buttons,

HEAVILY SOILED and NO SPIN. By pushing in

one or the other or both simultaneously, a total of

28 different program variations are accessible.

During cool-down, water filling and heating, the

timer does not move. This program time is not

included in the stated program times.

Program indicator

Fig.

To the left in the display window, there are ten

1

arrow symbols which can be illuminated. A square

surrounding each arrow can also be illuminated.

The arrows light up when a program is selected in

order to indicate which program step is in progress.

During program operation, the squares around the

arrows light up when each program step is

completed.

In the following program schedule, there are

columns titled "PROG. INDIC." for each program.

The numbers included in the columns indicate

which squares should light. Squares which are

already illuminated remain lit throughout the

program operation.

1445

Page 19

Service

Manual

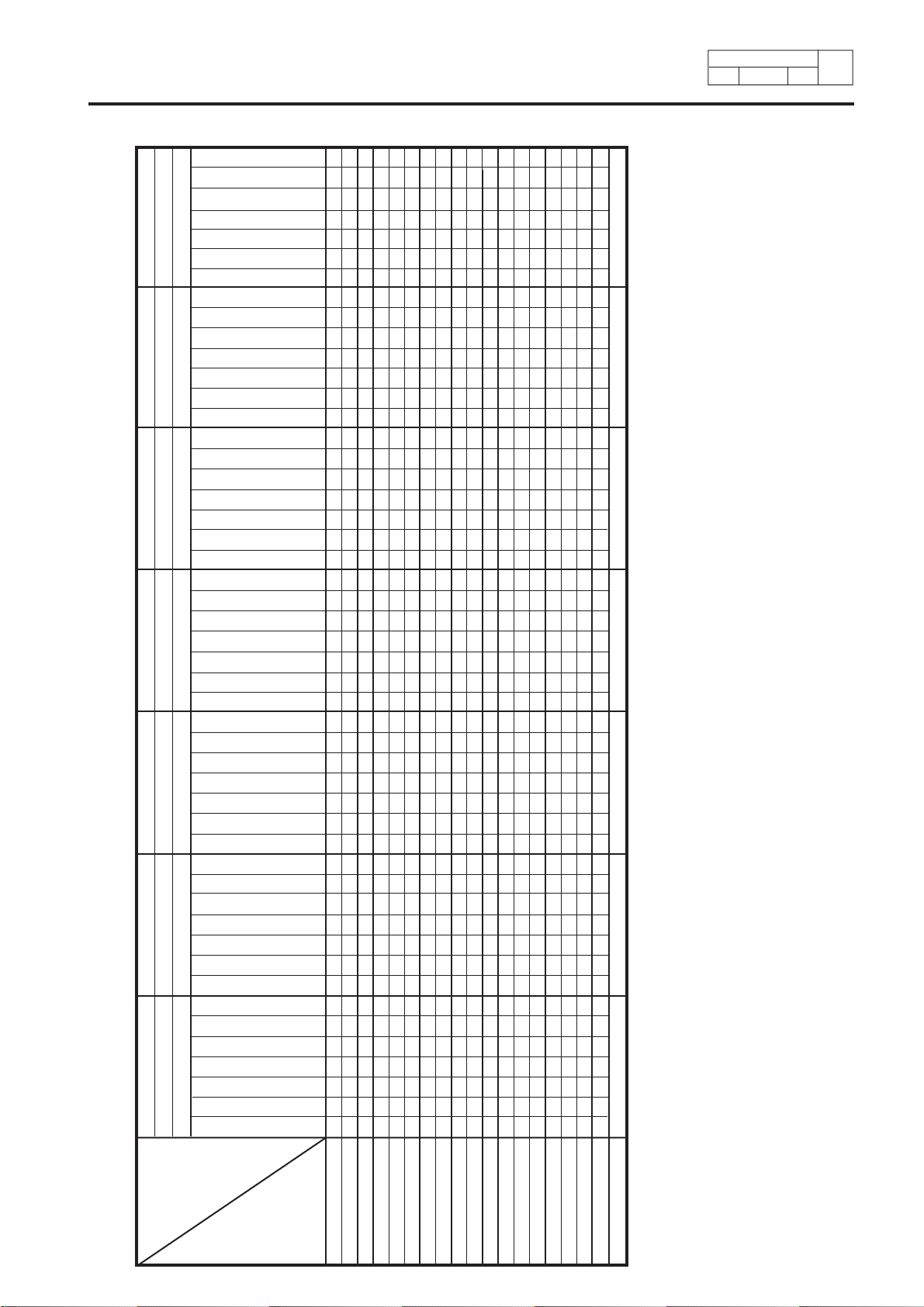

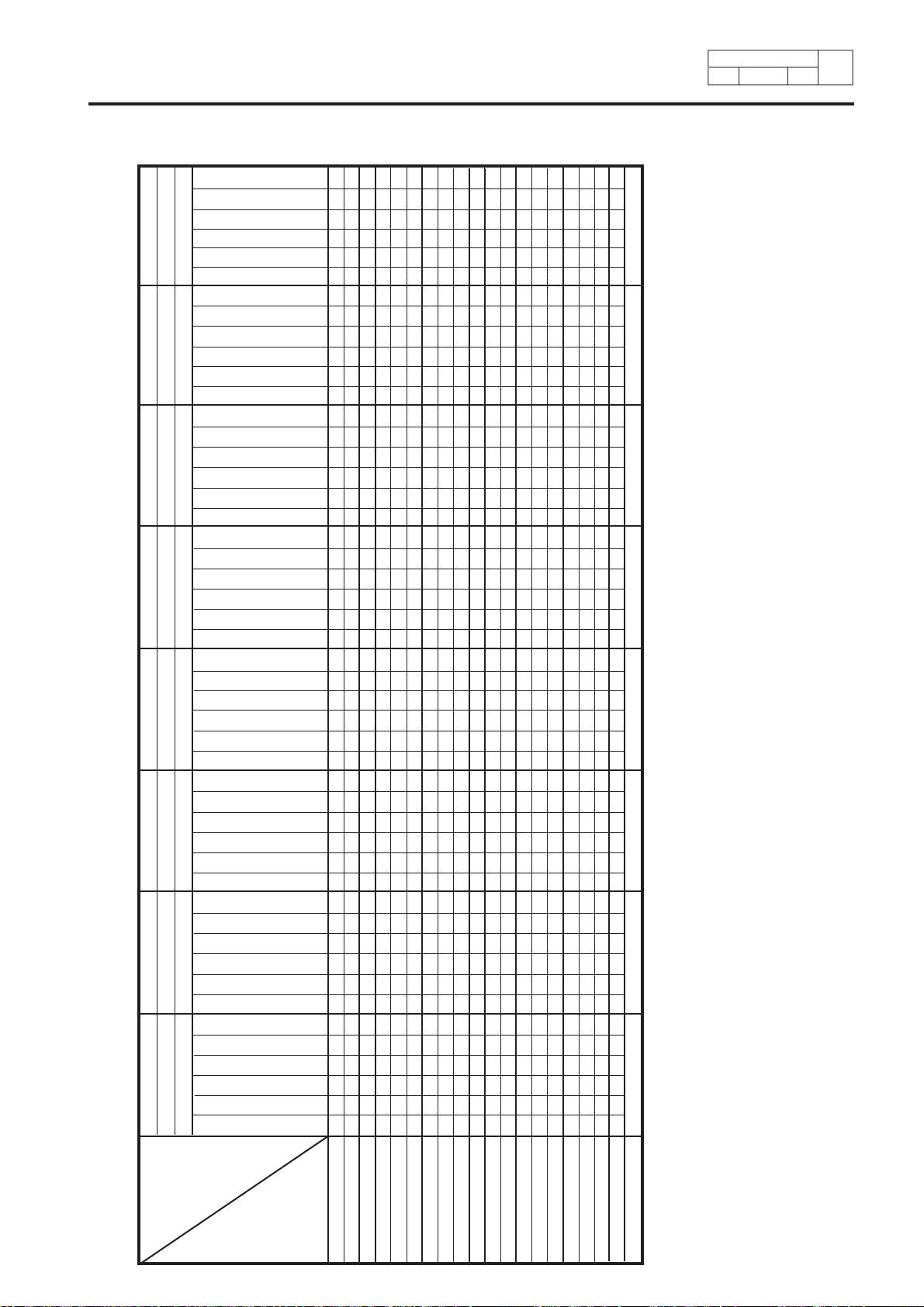

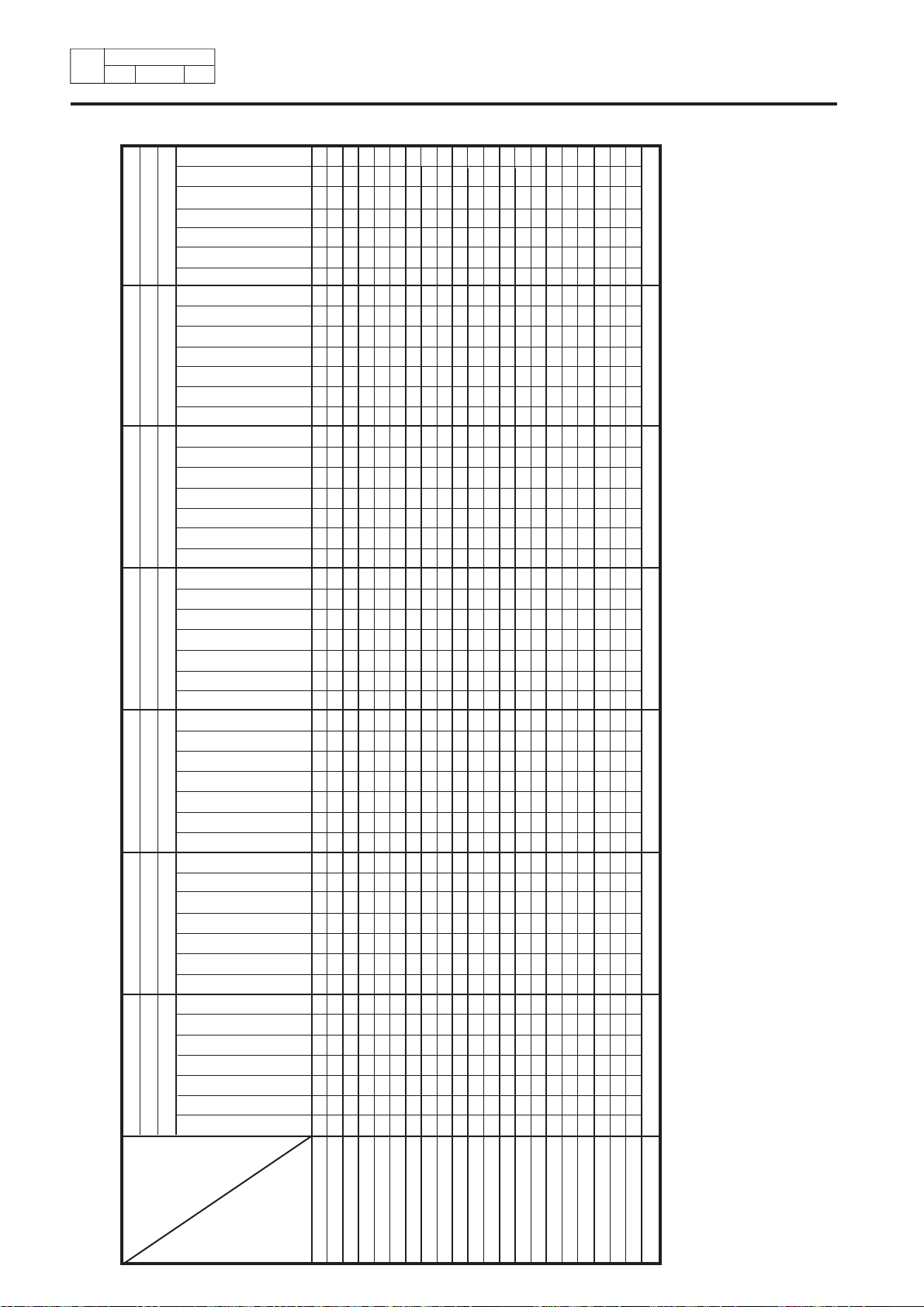

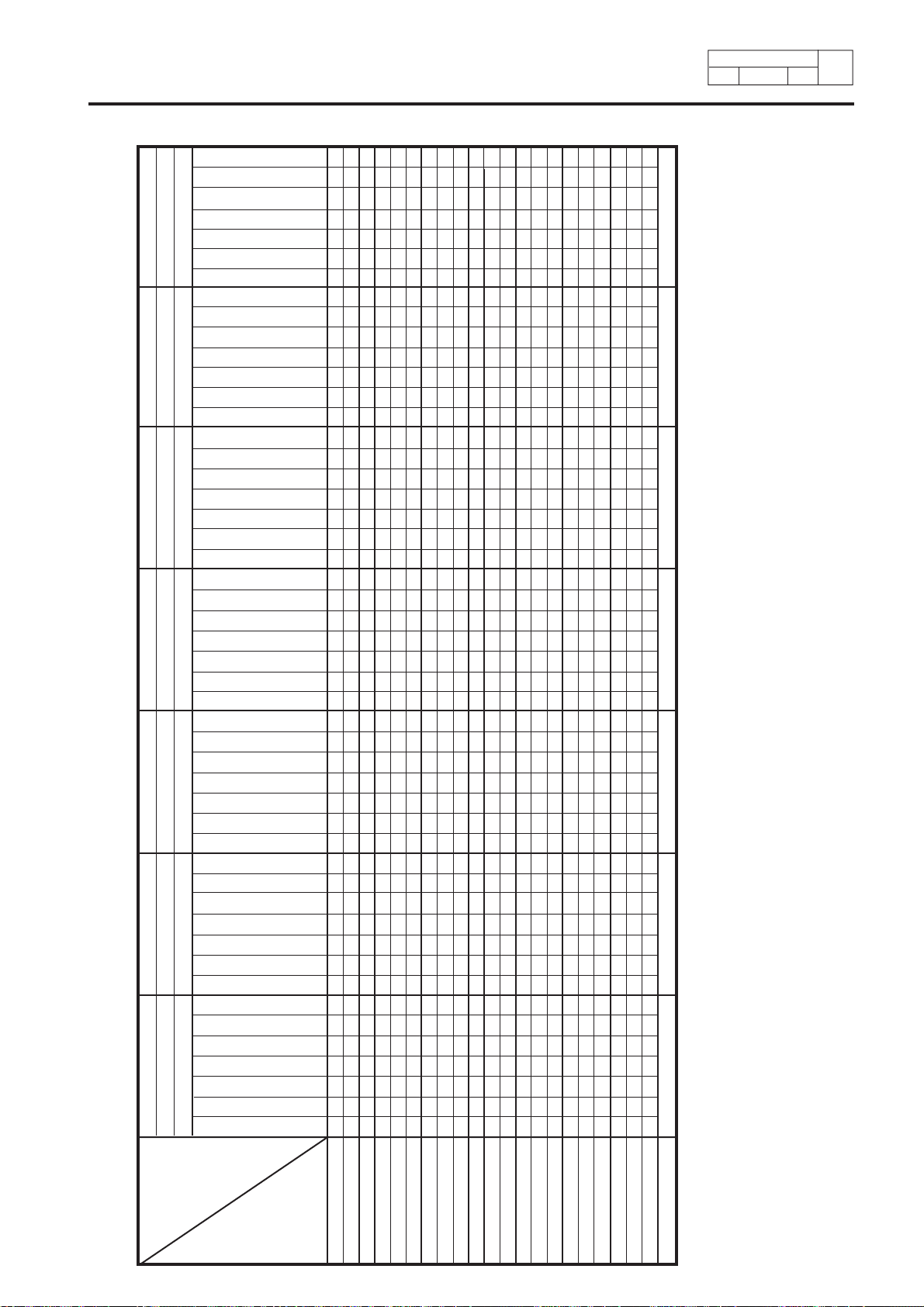

Program PE11C

12 3 4 5 6 7

STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60°

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-LL2N3

3C-LL2N3

3C-HL2G3

3C-HL2G3

3C-LL2N3

3C-LL2N3

3C-LL2N3

4. Programmes

10 C 55 LL 2 N 3

10 C 40 LL 2 N 3

2C40HL2G3

2C30HL2G3

12 C 40 LL 2 N 3

12 C 55 LL 2 N 3

12 C 85 LL 2 N 3

0.5 N 4

0.5 N 4

0.5 4

0.5 4

0.5 N 4

0.5 N 4

CHLN4

0.5 N 4

1.5 C - LL - N 6

1.5 C - LL - N 6

1C-HL-G6

1C-HL-G6

1.5 C - LL - N 6

1.5 C - LL - N 6

1.5 C - LL - N 6

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

2C-HL-G7

0.5 6

2C-HL-G7

0.5 6

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

11 9002 3

Type

Edition

2C-HL3N8

0.3 N 7

0.5 E 7

0.3 N 7

0.5 E 7

0.5 7

0.5 7

0.3 N 7

0.5 E 7

0.3 N 7

0.5 E 7

0.3 N 7

0.5 E 7

1E9

0.3 N 9

0.5 N 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3G8

1E9

0.5 G 9

0.2 G 9

2C-HL3G8

1E9

0.5 G 9

0.2 G 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

24 24 24 13.2 13.2 22 22

E = EXTRACTION

D = DISTRIBUTION

N = NORMAL ACTION 12/3 SEC

G = GENTLE ACTION 3/12 SEC

Page

4

PROGRAM

PROGRAM

SEQUENCE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

SPIN DOWN

TOTAL TIME

EXTRACTION

C = COLD WATER

LL = LOW LEVEL

HL = HIGH LEVEL

Page 20

11 9002 4

4

Type

Edition

Page

4. Programmes

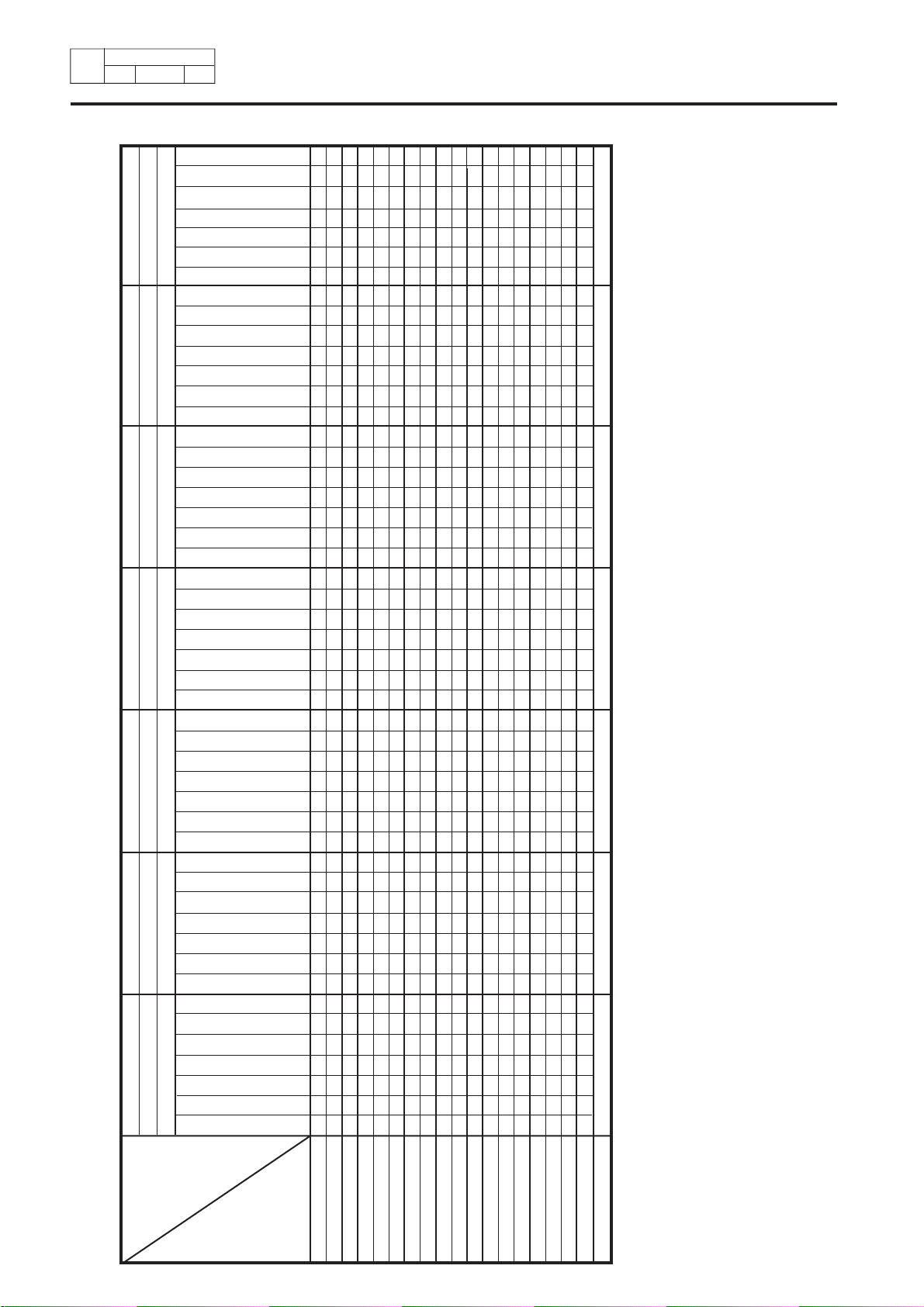

Program PE11C with "HEAVILY SOILED"

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

8 9 10 11 12 13 14

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60°

HEAVY SOILED HEAVY SOILED HEAVY SOILED STANDARD STANDARD HEAVY SOILED HEAVY SOILED

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N1

0.3 N 2

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N1

0.3 N 2

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N1

0.3 N 2

3C-LL2N3

12 C 60 LL 2 N 3

3C-LL2N3

12 C 40 LL 2 N 3

3C-HL2G3

2C40HL2G3

3C-HL2G3

2C30HL2G3

12 C 40 LL 2 N 3

12 C 60 LL 2 N 3

12 C 90 LL 2 N 3

C55 N 4

0.5 N 4

0.5 N 4

0.5 4

0.5 4

0.5 N 4

0.5 N 4

CHLN4

0.5 N 4

1.5 C - LL - N 6

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

0.3 N 7

0.5 E 7

1.5 C - LL - N 6

0.3 N 6

0.5 E 6

1.5 C - HL - N 7

0.3 N 7

0.5 E 7

1C-HL-G6

1C-HL-G6

0.5 N 5

1.5 C - LL - N 6

1.5 C - LL - N 5

0.5 N 5

1.5 C - LL - N 6

1.5 C - LL - N 5

0.5 N 5

1.5 C - LL - N 6

1.5 C - LL - N 5

2C-HL-G7

0.5 6

0.5 6

0.3 N 6

0.3 N 6

0.3 N 6

0.5 7

2C-HL-G7

0.5 7

0.5 E 6

1.5 C - HL - N 7

0.3 N 7

0.5 E 7

0.5 E 6

1.5 C - HL - N 7

0.3 N 7

0.5 E 7

0.5 E 6

1.5 C - HL - N 7

0.3 N 7

0.5 E 7

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3G8

1E9

0.5 G 9

0.2 G 9

2C-HL3G8

1E9

0.5 G 9

0.2 G 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

2C-HL3N8

1E9

0.3 N 9

0.5 N 9

29.3 29.3 29.3 13.2 13.2 24 24

D = DISTRIBUTION

Service

Manual

E = EXTRACTION

N = NORMAL ACTION 12/3 SEC

G = GENTLE ACTION 3/12 SEC

PROGRAM

PROGRAM

SEQUENCE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

TOTAL TIME

EXTRACTION

SPIN DOWN

C = COLD WATER

LL = LOW LEVEL

HL = HIGH LEVEL

Page 21

Service

Manual

4. Programmes

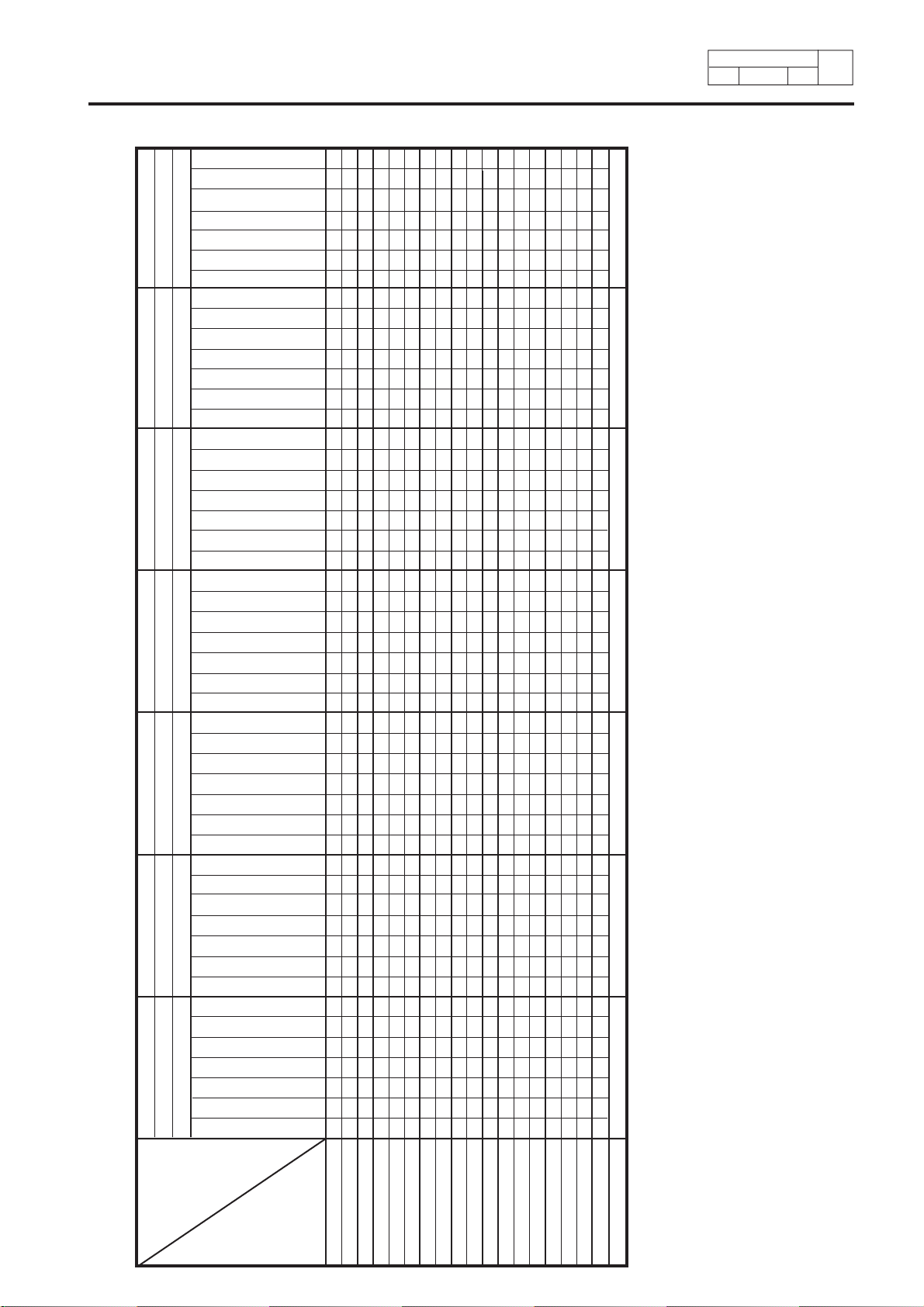

Program PE11C with "NO SPIN"

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

15 16 17 18 19 20 21

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60°

NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-LL2N3

10 C 55 LL 2 N 3

3C-LL2N3

10 C 40 LL 2 N 3

3C-HL2G3

2C40HL2G3

3C-HL2G3

2C30HL2G3

3C-LL2N3

12 C 40 LL 2 N 3

3C-LL2N3

12 C 55 LL 2 N 3

3C-LL2N3

12 C 85 LL 2 N 3

0.5 N 4

0.5 N 4

0.5 4

0.5 4

0.5 N 4

0.5 N 4

CHLN4

0.5 N 4

1.5 C - LL - N 6

1.5 C - LL - N 6

1C-HL-G6

1C-HL-G6

1.5 C - LL - N 6

1.5 C - LL - N 6

1.5 C - LL - N 6

11 9002 5

Type

Edition

0.3 N 6

1.5 C - HL - N 7

0.3 N 6

1.5 C - HL - N 7

2C-HL-G7

0.5 6

2C-HL-G7

0.5 6

0.3 N 6

1.5 C - HL - N 7

0.3 N 6

1.5 C - HL - N 7

0.3 N 6

1.5 C - HL - N 7

2C-HL3N8

0.3 N 7

0.3 N 7

0.5 7

0.5 7

0.3 N 7

0.3 N 7

0.3 N 7

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3G8

0.5 G 8

2C-HL3G8

0.5 G 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

21.5 21.5 21.5 12 12 19.5 19.5

E = EXTRACTION

D = DISTRIBUTION

N = NORMAL ACTION 12/3 SEC

G = GENTLE ACTION 3/12 SEC

Page

4

PROGRAM

PROGRAM

SEQUENCE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

TOTAL TIME

SPIN DOWN

C = COLD WATER

LL = LOW LEVEL

HL = HIGH LEVEL

Page 22

11 9002 6

4

Type

Edition

Page

4. Programmes

Program PE11C with "HEAVILY SOILED" and " NO SPIN"

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

22 23 24 25 26 27 28

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60°

H. SOIL + NO EXTR. H. SOIL + NO EXTR. H. SOIL + NO EXTR. H. SOIL + NO EXTR. H. SOIL + NO EXTR. H. SOIL + NO EXTR. H. SOIL + NO EXTR.

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N1

0.3 N 2

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N1

0.3 N 2

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N1

0.3 N 2

3C-LL2N3

12 C 60 LL 2 N 3

3C-LL2N3

12 C 40 LL 2 N 3

3C-HL2G3

2C40HL2G3

3C-HL2G3

2C30HL2G3

12 C 40 LL 2 N 3

12 C 60 LL 2 N 3

12 C 90 LL 2 N 3

C55 N 4

0.5 N 4

0.5 N 4

0.5 4

0.5 4

0.5 N 4

0.5 N 4

CHLN4

0.5 N 4

1.5 C - LL - N 6

0.3 N 6

1.5 C - HL - N 7

1.5 C - LL - N 6

0.3 N 6

1.5 C - HL - N 7

1C-HL-G6

1C-HL-G6

0.5 N 5

1.5 C - LL - N 6

1.5 C - LL - N 5

0.5 N 5

1.5 C - LL - N 6

1.5 C - LL - N 5

0.5 N 5

1.5 C - LL - N 6

1.5 C - LL - N 5

2C-HL-G7

0.5 6

2C-HL-G7

0.5 6

0.3 N 6

1.5 C - HL - N 7

0.3 N 6

1.5 C - HL - N 7

0.3 N 6

1.5 C - HL - N 7

2C-HL3N8

0.3 N 7

0.3 N 7

0.5 7

0.5 7

0.3 N 7

0.3 N 7

0.3 N 7

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3G8

0.5 G 8

2C-HL3G8

0.5 G 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

26.8 26.8 26.8 12 12 21.5 21.5

E = EXTRACTION

D = DISTRIBUTION

G = GENTLE ACTION 3/12 SEC

Service

Manual

N = NORMAL ACTION 12/3 SEC

PROGRAM

PRE WASH

PROGRAM

DRAIN

SEQUENCE

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

SPIN DOWN

TOTAL TIME

EXTRACTION

C = COLD WATER

LL = LOW LEVEL

HL = HIGH LEVEL

Page 23

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

9002

12 1

Type

Edition

Page

4

P= Standard

H= Hygienic and hospital.

These programs follow national

regulations.

S= Selecta program. Special OPL-

program.

M= Mop program.

Timer type

E= electronic microprocessorcontrolled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE01CH = electronic

timer

P01CH = electromechanical

timer

PE01CH

Market

0= Export

1= Sweden

Machine family

1= Machine with heating

2= Machine for laundrettes, Europe

and Asia

3= Machine for laundrettes, USA

and Canada

4= Machine for laundrettes, Denmark

and West Germany

5= Machine for OPL, USA

6= Machine for OPL, Selecta USA

8= Machine for laundrettes, Japan

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard

water

CHHd = cold, hot and cold hard

water

The symbol PE01CH used in the example above means:

• for standard user

• with electronic timer

• equipped with heating

• cold and hot water connection

Page 24

12 9002 2

4

Type

Edition

Page

Program P01CH

12 34 5 6 78

STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL 40° PERM. PRESS 40° PERM. PRESS 60° PERM. PRESS 95°

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-HL2G

3C-HL2G

4. Programmes

C56

1N

12 W 90 LL 2 N

C56

1N

12 W 60 LL 2 N

-1N

12 W 40 LL 2 N

--

2C40HL-G

1-

--

2C30HL-G

1-

-1N

12 W 40 LL 2 N

-1N

12 W 60 LL 2 N

-1N

12 W 90 LL 2 N

1C-HL-N

1N

2C-HL-N

0.5 E

1C-HL-N

1N

2C-HL-N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

--

1C-HL-G

1-

2C-HL-G

1-

--

1C-HL-G

1-

2C-HL-G

1-

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

1N

2C-HL3N

1N

1E

0.5 E

1N

0.5 E

0.5 E

--

2C-HL3G

--

2C-HL3G

2C-HL3N

0.5 E

2C-HL3N

0.5 E

0.5 E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3N

1N

1E

1.5 N

1G

1E

1.5 -

1G

1E

1.5 -

1N

4E

1.5 N

1N

4E

1.5 N

27.5 27.5 27.5 16.5 16.5 24.5 24.5 24.5

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

2C-HL3N

1N

4E

1.5 N

Service

Manual

PROGRAM

PRE WASH

CYCLE

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SHAKE OUT

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 25

Service

Manual

4. Programmes

Program P01CH with "HEAVY SOILED"

ACTION

DETERGENT

LEVEL

TEMP

910111213141516

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL 40° PERM. PRESS 40° PERM. PRESS 60° PERM. PRESS 95°

HEAVY SOILED HEAVY SOILED HEAVY SOILED

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6W-LL1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6W-LL1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6W-LL1N

C56

1N

12 W 90 LL 2 N

C56

1N

12 W 60 LL 2 N

-1N

12 W 40 LL 2 N

--

3C-HL2G

2C40HL-G

1-

--

3C-HL2G

2C30HL-G

1-

-1N

12 W 40 LL 2 N

0.5 N

-1N

12 H 60 LL 2 N

0.5 N

-1N

12 H 90 LL 2 N

0.5 N

1C-HL-N

1N

2C-HL-N

0.5 E

1C-HL-N

1N

2C-HL-N

0.5 E

1C-HL-N

1N

2C-HL-N

0.5 E

--

1C-HL-G

1-

2C-HL-G

--

1C-HL-G

1-

2C-HL-G

--

1C-HL-N

1

1C-HL-N

1N

2C-HL-N

0.5 E

--

1C-HL-N

1

1C-HL-N

1N

2C-HL-N

0.5 E

--

1C-HL-N

1

1C-HL-N

1N

2C-HL-N

0.5 E

12 9002 3

Type

1N

2C-HL3N

1N

1E

0.5 E

1N

0.5 E

1N

0.5 E

--

1-

--

1-

1N

0.5 E

1N

0.5 E

1N

0.5 E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3G

1G

1E

1.5 -

2C-HL3G

1G

1E

1.5 -

2C-HL3N

1N

4E

1.5 N

2C-HL3N

1N

4E

1.5 N

36 36 36 16.5 16.5 24.5 24.5 24.5

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

2C-HL3N

1N

4E

1.5 N

Edition

Page

4

PROGRAM

PRE WASH

CYCLE

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SHAKE OUT

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 26

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

9002

13 1

Type

Edition

Page

4

P= Standard

H= Hygienic and hospital.

These programs follow national

regulations.

S= Selecta program. Special OPL-

program.

M= Mop program.

Timer type

E= electronic microprocessorcontrolled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE01CH = electronic

timer

P01CH = electromechanical

timer

PE01CH

Market

0= Export

1= Sweden

Machine family

1= Machine with heating

2= Machine for laundrettes, Europe

and Asia

3= Machine for laundrettes, USA

and Canada

4= Machine for laundrettes, Denmark

and West Germany

5= Machine for OPL, USA

6= Machine for OPL, Selecta USA

8= Machine for laundrettes, Japan

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard

water

CHHd = cold, hot and cold hard

water

The symbol PE01CH used in the example above means:

• for standard user

• with electronic timer

• equipped with heating

• cold and hot water connection

Page 27

13 9002 2

4

Type

Edition

Page

Program PE01CH

01 02 03 04 05 06 07

STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL PERM. PRESS 40° PERM. PRESS 60°

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-HL2G3

3C-HL2G3

4. Programmes

10 W 55 LL 2 N 3

0.5 N 4

10 W 40 LL 2 N 3

0.5 N 4

2C40HL2G3

0.5 - 4

2C30HL2G3

0.5 - 4

1N4

16 W 40 LL 4 N 3

1N4

14 W 55 LL 4 N 3

1N4

14 W 85 LL 4 N 3

1.5 C - LL - N 6

1.5 C - LL - N 6

1C-HL-G6

1C-HL-G6

1.5 C - LL - N 6

1.5 C - LL - N 6

1.5 C - LL - N 6

0.3 N 6

0.5 6

0.3 N 6

0.5 6

0.5 - 6

0.5 - 6

0.3 N 6

0.5 6

0.3 N 6

0.5 6

0.3 N 6

0.5 6

1.5 C - HL - N 7

1.5 C - HL - N 7

2C-HL-G7

1C-HL-G7

1.5 C - HL - N 7

1.5 C - HL - N 7

1.5 C - HL - N 7

Service

Manual

N

N

2C-HL3N8

0.3 N 7

0.5 7

0.3 N 7

0.5 7

0.5 - 7

0.5 - 7

0.3 N 7

0.5 7

0.3 N 7

0.5 7

0.3 N 7

0.5 7

19

0.3 N 9

0.5 N 9

N

N

2C-HL3N8

19

0.3 N 9

0.5 N 9

-

G

2C-HL3G8

19

0.5 G 9

0.2 G 9

-

G

2C-HL3G8

19

0.5 G 9

0.2 G 9

N

N

2C-HL3N8

69

0.3 N 9

0.5 N 9

N

N

2C-HL3N8

49

0.3 N 9

0.5 N 9

N

N

26.4 26.4 30.4 12.2 13.2 18.9 18.9

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

2C-HL3N8

49

0.3 N 9

0.5 N 9

PROGRAM

PROGRAM

SEQUENCE

PRE WASH W 1

DRAIN

MAIN WASH W 1

MAIN WASH W 1

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

SHAKE OUT

DRAIN

EXTRACTION

FILLING

HEATING

- = NO ACTION

TOTAL TIME

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 28

Service

Manual

4. Programmes

Program PE01CH with "HEAVY SOILED"

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

08 09 10 11 12 13 14

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE WOOL PERM. PRESS 40° PERM. PRESS 60°

HEAVY SOILED HEAVY SOILED HEAVY SOILED STANDARD STANDARD HEAVY SOILED HEAVY SOILED

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6 W 30 LL 1 N 1

0.5 N 2

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6 W 30 LL 1 N 1

0.5 N 2

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6 W 30 LL 1 N 1

0.5 N 2

3C-HL2G3

3C-HL2G3

C55 N 4

14 W 60 LL 2 N 3

0.5 N 4

1.5 C - LL - N 5

16 W 40 LL 2 N 3

0.5 N 4

1.5 C - LL - N 5

2C40HL2G3

0.5 - 4

2C30HL2G3

0.5 - 4

1N4

16 W 40 LL 4 N 3

1.5 C - LL - N 5

1N4

16 H 60 LL 4 N 3

1.5 C - LL - N 5

1N4

16 H 90 LL 4 N 3

1.5 C - LL - N 5

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 6

1.5 C - HL - N 7

0.3 N 7

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 6

1.5 C - HL - N 7

0.3 N 7

1C-HL-G6

2C-HL-G7

0.5 - 6

0.5 - 7

1C-HL-G6

2C-LL-G7

0.5 - 6

0.5 - 7

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 6

1.5 C - HL - N 7

0.3 N 7

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 6

1.5 C - L - N 7

0.3 N 7

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 6

1.5 C - HL - N 7

0.3 N 7

0.5 7

0.5 7

0.5 7

0.5 7

0.5 7

13 9002 3

Type

Edition

N

N

2C-HL3N8

19

0.3 N 9

0.5 N 9

N

N

2C-HL3N8

19

0.3 N 9

0.5 N 9

-

G

2C-HL3G8

19

0.5 G 9

0.2 G 9

-

G

2C-HL3G8

19

0.5 G 9

0.2 G 9

N

N

2C-HL3N8

49

0.3 N 9

0.5 N 9

N

N

2C-HL3N8

49

0.3 N 9

0.5 N 9

N

N

36.9 36.9 36.9 13.2 13.2 26.9 24.9

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

2C-HL3N8

49

0.3 N 9

0.5 N 9

Page

4

PROGRAM

PROGRAM

SEQUENCE

PRE WASH W 1

DRAIN

MAIN WASH W 1

MAIN WASH W 1

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

SHAKE OUT

DRAIN

EXTRACTION

FILLING

HEATING

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 29

13 9002 4

4

Type

Edition

Page

4. Programmes

Program PE01CH with "NO EXTRACTION"

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

15 16 17 18 19 20 21

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE WOOL PERM. PRESS 40° PERM. PRESS 60°

NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION NO EXTRACTION

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

10 W 55 LL 2 N 3

0.5 N 4

10 W 40 LL 2 N 3

0.5 N 4

3C-HL2G3

2C40HL2G3

0.5 - 4

3C-HL2G3

2C30HL2G3

0.5 - 4

1N4

16 W 40 LL 4 N 3

1N4

14 W 55 LL 4 N 3

1N4

14 W 85 LL 4 N 3

1.5 C - LL - N 6

1.5 C - LL - N 6

1C-HL-G6

1C-HL-G6

1.5 C - LL - N 6

1.5 C - LL - N 6

1.5 C - LL - N 6

0.3 N 6

1.5 C - HL - N 7

0.3 N 7

0.3 N 6

1.5 C - HL - N 7

0.3 N 7

2C-HL-G7

0.5 - 6

0.5 - 6

0.3 N 6

0.3 N 6

0.3 N 6

2C-HL-G7

1.5 C - HL - N 7

1.5 C - HL - N 7

1.5 C - HL - N 7

0.5 - 7

0.5 - 7

0.3 N 7

0.3 N 7

0.3 N 7

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3G8

0.5 G 8

2C-HL3G8

0.5 G 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

Service

Manual

N

N

N

N

-

G

-

G

N

N

N

N

N

N

20.9 20.9 22.9 12.0 12.0 16.4 16.4

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

PROGRAM

PROGRAM

SEQUENCE

PRE WASH W 1

DRAIN

MAIN WASH W 1

MAIN WASH W 1

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

SHAKE OUT

DRAIN

EXTRACTION

FILLING

HEATING

- = NO ACTION

TOTAL TIME

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 30

Service

Manual

4. Programmes

13 9002 5

Type

Edition

Page

4

Program PE01CH with "HEAVY SOILED" and "NO EXTRACTION"

PROGIND

22 23 24 25 26 27 28

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE WOOL PERM. PRESS 40° PERM. PRESS 60°

H. SOIL + NO EXTR. H. SOIL + NO EXTR. H. SOIL + NO EXTR. NO EXTRACTION NO EXTRACTION H. SOIL + NO EXTR. H. SOIL + NO EXTR.

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-HL2G3

3C-L 2G3

6 W 30 LL 1 N 1

0.5 N 2

6 W 30 LL 1 N 1

0.5 N 2

6 W 30 LL 1 N 1

0.5 N 2

C55 N 4

14 W 60 LL 2 N 3

0.5 N 4

1.5 C - LL - N 5

16 W 40 LL 2 N 3

0.5 N 4

1.5 C - LL - N 5

2C40HL2G3

0.5 - 4

2C30HL2G3

0.5 - 4

1N4

16 W 40 LL 4 N 3

1.5 C - LL - N 5

1N4

16 H 60 LL 4 N 3

1.5 C - LL - N 5

1N4

16 H 90 LL 4 N 3

1.5 C - LL - N 5

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

1C-HL-G6

2C-HL-G7

0.5 - 6

1C-HL-G6

0.5 - 6

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

0.5 N 5

1.5 C - LL - N 6

0.3 N 6

1.5 C - HL - N 7

1.5 C - HL - N 7

2C-HL-G7

1.5 C - HL - N 7

1.5 C - L - N 7

1.5 C - HL - N 7

2C-HL3N8

0.3 N 7

0.3 N 7

0.5 - 7

0.5 - 7

0.3 N 7

0.3 N 7

0.3 N 7

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3G8

0.5 G 8

2C-HL3G8

0.5 G 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

2C-HL3N8

0.3 N 8

N

N

N

N

-

G

-

G

N

N

N

N

N

N

31.4 31.4 31.4 12 12 24.4 22.4

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

PROGRAM

PROGRAM

SEQUENCE

PRE WASH W 1

DRAIN

MAIN WASH W 1

MAIN WASH W 1

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

SHAKE OUT

DRAIN

EXTRACTION

FILLING

HEATING

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 31

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

9002

14 1

Type

Edition

Page

4

P= Standard

H= Hygienic and hospital.

These programs follow national

regulations.

S= Selecta program. Special OPL-

program.

M= Mop program.

Timer type

E= electronic microprocessorcontrolled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE01CH = electronic

timer

P01CH = electromechanical

timer

PE01CH

Market

0= Export

1= Sweden

Machine family

1= Machine with heating

2= Machine for laundrettes, Europe

and Asia

3= Machine for laundrettes, USA

and Canada

4= Machine for laundrettes, Denmark

and West Germany

5= Machine for OPL, USA

6= Machine for OPL, Selecta USA

8= Machine for laundrettes, Japan

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard

water

CHHd = cold, hot and cold hard

water

The symbol PE01CH used in the example above means:

• for standard user

• with electronic timer

• equipped with heating

• cold and hot water connection

Page 32

14 9002 2

4

Type

Edition

Page

4. Programmes

Program P01CH with pre wash

ACTION

DETERGENT

LEVEL

TEMP

12 34 5 6 78

STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL 40° PERM. PRESS 40° PERM. PRESS 60° PERM. PRESS 95°

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-LL2N

3C-LL2N

3C-LL2N

3C-HL2G

3C-HL2G

3C-LL2N

3C-LL2N

3C-LL2N

C56

1N

12 C 90 LL 2 N

C56

1N

12 C 60 LL 2 N

-1N

12 C 40 LL 2 N

--

2C40HL-G

1-

--

2C30HL-G

1-

-1N

12 C 40 LL 2 N

-1N

12 C 60 LL 2 N

-1N

12 C 90 LL 2 N

1C-HL-N

1N

2C-HL-N

1N

2C-HL3N

1N

0.5 E

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

0.5 E

1C-HL-N

1N

2C-HL-N

1N

0.5 E

0.5 E

--

1C-HL-G

1-

1C-HL-G

1-

1C-HL-N

1N

1C-HL-N

1N

1C-HL-N

1N

--

2C-HL-G

1

--

--

2C-HL-G

1-

2C-HL-N

1N

0.5 E

0.5 E

2C-HL-N

1N

0.5 E

0.5 E

2C-HL-N

1N

0.5 E

1E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3G

1G

1E

1.5 -

2C-HL3G

1G

1E

1.5 -

2C-HL3N

1N

4E

1.5 N

2C-HL3N

1N

4E

1.5 N

30.5 30.5 30.5 16.5 16.5 27.5 27.5 27.5

2C-HL3N

1N

4E

0.5 E

1.5 N

C = COLD WATER (15°C)

LL = LOW LEVEL

HL = HIGH LEVEL

Service

Manual

PROGRAM

CYCLE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SHAKE OUT

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 33

Service

Manual

4. Programmes

Program P01CH with "HEAVY SOIL"

ACTION

DETERGENT

LEVEL

TEMP

910111213141516

NORMAL 95° NORMAL 60° NORMAL 40° DELICATE 30° WOOL 40° PERM. PRESS 40° PERM. PRESS 60° PERM. PRESS 95°

HEAVY SOILED HEAVY SOILED HEAVY SOILED

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N

0.5 N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N

0.5 N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

6C-LL1N

0.5 N

3C-LL2N

3C-LL2N

3C-LL2N

3C-HL2G

3C-HL2G

C56

1N

12 C 90 LL 2 N

C56

1N

12 C 60 LL 2 N

-1N

12 C 40 LL 2 N

--

2C40HL-G

1-

--

2C30HL-G

1-

-1N

12 C 40 LL 2 N

12 C 60 LL 2 N

12 C 90 LL 2 N

1C-HL-N

-1N

1C-HL-N

-1N

1C-HL-N

1C-HL-N

1C-HL-N

1C-HL-N

1C-HL-G

1C-HL-G

--

1N

1C-HL-N

--

1N

1C-HL-N

--

1N

1C-HL-N

1N

2C-HL-N

1N

2C-HL3N

1N

0.5 E

1N

2C-HL-N

1N

0.5 E

1N

2C-HL-N

1N

0.5 E

--

1-

--

1-

1N

0.5 E

1N

0.5 E

1N

0.5 E

--

2C-HL-G

1-

--

2C-HL-G

1-

2C-HL-N

1N

2C-HL-N

1N

2C-HL-N

1N

1E

0.5 E

0.5 E

0.5 E

0.5 E

0.5 E

0.5 E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3N

1N

1E

1.5 N

2C-HL3G

1G

1E

1.5 -

2C-HL3G

1G

1E

1.5 -

2C-HL3N

1N

4E

1.5 N

2C-HL3N

1N

4E

1.5 N

36 36 36 16.5 16.5 27.5 27.5 27.5

C = COLD WATER (15° C)

2C-HL3N

1N

4E

1.5 N

14 9002 3

Type

Edition

LL = LOW LEVEL

HL = HIGH LEVEL

Page

4

PROGRAM

CYCLE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SHAKE OUT

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 34

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

9002

15 1

Type

Edition

Page

4

P= Standard

H= Hygienic and hospital.

These programs follow national

regulations.

S= Selecta program. Special OPL-

program.

M= Mop program.

Timer type

E= electronic microprocessorcontrolled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE11CH = electronic

timer

P11CH = electromechanical

timer

PE01CH

Market

0= Export

1= Sweden

Machine family

1= Machine with heating

2= Machine for laundrettes, Europe

and Asia

3= Machine for laundrettes, USA

and Canada

4= Machine for laundrettes, Denmark

and West Germany

5= Machine for OPL, USA

6= Machine for OPL, Selecta USA

8= Machine for laundrettes, Japan

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard

water

CHHd = cold, hot and cold hard

water

The symbol PE01CH used in the example above means:

• for standard user

• with electronic timer

• cold and hot water connection

Page 35

15 9002 2

4

Type

Edition

Page

Program P02CH

12 34

COLD WARM HOT PERM. PRESS

4. Programmes

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3 W 30* HL 1 N

1N

5 W 40* LL 2 N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3 W 30* HL 1 N

1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3 W 30* HL 1 N

1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3 C 30* HL 1 G

1G

1N

5H90*LL2N

1N

5 W 60* LL 2 N

1N

5 W 30* LL 2 G

1G

1C-HL-N

1N

1C-HL-N

1N

2C-HL3N

1N

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-G

1G

0.5 E

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-G

1G

0.5 E

1E

1.5 N

2C-HL3N

1N

4E

1.5 N

2C-HL3N

1N

4E

1.5 N

23.5 23.5 23.5 20.5

2C-HL3G

1G

4E

1.5 G

Service

Manual

ELECTRICAL HEATED MACHINES.

* TEMPERATURES ON STEAM- AND

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

PROGRAM

CYCLE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SHAKE OUT

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 36

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

9002

16 1

Type

Edition

Page

4

P= Standard

H= Hygienic and hospital.

These programs follow national

regulations.

S= Selecta program. Special OPL-

program.

M= Mop program.

Timer type

E= electronic microprocessorcontrolled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE11CH = electronic

timer

P11CH = electromechanical

timer

PE01CH

Market

0= Export

1= Sweden

Machine family

1= Machine with heating

2= Machine for laundrettes, Europe

and Asia

3= Machine for laundrettes, USA

and Canada

4= Machine for laundrettes, Denmark

and West Germany

5= Machine for OPL, USA

6= Machine for OPL, Selecta USA

8= Machine for laundrettes, Japan

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard

water

CHHd = cold, hot and cold hard

water

The symbol PE01CH used in the example above means:

• for standard user

• with electronic timer

• cold and hot water connection4. Programmes4 13 5Program

Page 37

16 9002 2

4

Type

Edition

Page

Program P03CH

12 34

COLD WARM HOT PERM. PRESS

4. Programmes

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3W-HL1N

1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3W-HL1N

1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3W-HL1N

1N

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

3C-HL1N

1N

--

6W-HL2N

1N

1C HL-N

1N

0.5 E

--

6H-HL2N

1N

1C-HL-N

1N

0.5 E

--

6W-HL2N

1N

1C-HL-N

1N

0.5 E

--

6C-HL2N

1N

1C-HL-N

1N

0.5 E

1C HL-N

1N

2C HL3N

1N

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-N

1N

0.5 E

1C-HL-N

1N

0.5 E

1E

2C-HL3N

1N

4E

2C-HL3N

1N

4E

2C-HL3N

1N

4E

1.5 N

1.5 N

1.5 N

24.5 24.5 24.5 21.5

1.5 N

C = COLD WATER (15° C)

W = WARM WATER (35° C)

H = HOT WATER (65° C)

Service

Manual

LL = LOW LEVEL

HL = HIGH LEVEL

PROGRAM

CYCLE

PRE WASH

DRAIN

WITHOUT PRE WASH

MAIN WASH

COOL DOWN

DRAIN

RINSE 1

DRAIN

EXTRACTION

RINSE 2

DRAIN

EXTRACTION

RINSE 3

DRAIN

EXTRACTION

RINSE 4

DRAIN

EXTRACTION

SHAKE OUT

TOTAL TIME

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 38

Service

Manual

4. Programmes

Identification of wash programs

The wash programs are identified by a combined letter and number symbol.

Identification occurs as described in the example below.

User catagory

17 1

9002

Type

Edition

Page

4

P= Standard

H= Hygienic and hospital.

These programs follow national

regulations.

S= Selecta program. Special OPL-

program.

M= Mop program.

Timer type

E= electronic microprocessorcontrolled timer

Electromechanical timer do not

have a letter positioned here in

the program name.

Example:

PE11CH = electronic

timer

P11CH = electromechanical

timer

HE02CH

Market

0= Export

1= Sweden

Machine family

1= Machine with heating

2= Machine for laundrettes, Europe

and Asia

3= Machine for laundrettes, USA

and Canada

4= Machine for laundrettes, Denmark

and West Germany

5= Machine for OPL, USA

6= Machine for OPL, Selecta USA

8= Machine for laundrettes, Japan

Water connection

C = cold water

CH = cold and hot water

CHd = cold and cold hard

water

CHHd = cold, hot and cold hard

water

The symbol HE02CH used in the example above means:

• for standard user

• with electronic timer

• equipped with heating

• cold and hot water connection

Page 39

17 9002 2

4

Type

Edition

Page

4. Programmes

Service

Manual

Program HE02CH

01 02 03 04 05 06 07

HOT WARM COLD POLYCOTTON 50 COTTON 71 POLYCOTTON 65 SLUICE PR.

STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD STANDARD

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

2C-HL-N2

1N2

2C-HL-N2

1N2

C55 N 5

3 W 63 LL 1 N 3

1N3

3 W 63 LL 1 N 3

1N3

1N5

10 W 68 LL 4 N 4

1N5

10 H 74 LL 4 N 4

6 W 50 LL 4 N 4

1N5

6 C 30 LL 2 G 4

1G5

6 H 60 LL 4 N 4

1N5

6 H 90 LL 4 N 4

1N5

1C-HL-N6

0.5 N 6

1C-HL-N6

0.5 N 6

1C-HL-N6

0.5 N 6

1C-HL-G6

0.5 G 6

1C-HL-N6

0.5 N 6

1C-HL-N6

0.5 N 6

0.5 E 6

0.5 E 6

0.5 E 6

0.5 E 6

0.5 E 6

0.5 E 6

2C-HL-N7

0.5 N 7

2C-HL-N7

0.5 N 7

2C-HL-N7

0.5 N 7

2C-HL-G7

0.5 G 7

2C-HL-N7

0.5 N 7

2C-HL-N7

0.5 N 7

0.5 E 7

0.5 E 7

0.5 E 7

0.5 E 7

0.5 E 7

0.5 E 7

N

N

2C-HL3N8

5E9

0.5 N 9

N

2C-HL3N8

5E9

0.5 N 9

N

2C-HL3N8

2E9

0.5 N 9

G

2C-HL3G8

2E9

0.5 G 9

N

2C-HL3N8

5E9

0.5 N 9

N

2C-HL3N8

5E9

0.5 N 9

N

N

N

N

G

N

N

19.5 19.5 16.5 16.5 27.5 24.5 6.0

C = COLD WATER (15° C)

H = HOT WATER (65° C)

W = WARM WATER (35° C)

LL = LOW LEVEL

HL = HIGH LEVEL

PROGRAM

PROGRAM

SEQUENCE

PRE WASH R1

DRAIN

PRE WASH R1

DRAIN

EXTRACTION

PRE WASH R2

DRAIN

PRE WASH R2

DRAIN

EXTRACTION

PRE WASH W1

DRAIN

MAIN WASH W1

DRAIN

RINSE 1

COOL DOWN

DRAIN

RINSE 2

EXTRACTION

EXTRACTION

DRAIN

RINSE 3

DRAIN

FILLING

EXTRACTION

TOTAL TIME

HEATING

- = NO ACTION

E = EXTRACTION

N = NORMAL ACTION

G = GENTLE ACTION

Page 40

Service

Manual

4. Programmes

17 9002 3

Type

Edition

Page

4

Program HE02CH with "SLUICE"

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

2C-HL-N1

1N1

2C-HL-N1

1N1

2C-HL-N2

1N2

2C-HL-N2

2C-HL-N2

2C-HL-N2

2C-HL-N2

2C-HL-G2

2C-HL-N2

08 09 10 11 12 13 14

HOT WARM COLD POLYCOTTON 50 COTTON 71 POLYCOTTON 65 SLUICE PR.

WITH SLUICE WITH SLUICE WITH SLUICE WITH SLUICE WITH SLUICE WITH SLUICE WITH SLUICE

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

PROGIND

ACTION

DETERGENT

LEVEL

TEMP

INLET WATER

TIME

2C-HL-N1

2C-HL-N1

1N1

1E1

1N1

1E1

1N2

C55 N 5

1N2

1E2

3 W 63 LL 1 N 3

1N3

10 W 68 LL 4 N 4

1N2

1E2

3 W 63 LL 1 N 3

1N3

10 H 74 LL 4 N 4

1N2

1G2

1N2

6 W 50 LL 2 N 4

6 C 30 LL 2 G 4

6 H 60 LL 4 N 4

6 H 90 LL 4 N 4

1N5

1C-HL-N6

1N5

1C-HL-N6

1N5

1C-HL-N6

1G5

1C-HL-G6

1N5

1C-HL-N6

1N5

1C-HL-N6

2C-HL-N7

0.5 N 6

0.5 E 6

0.5 N 7

2C-HL-N7

0.5 N 6

0.5 E 6

0.5 N 7

2C-HL-N7

0.5 N 6

0.5 E 6

0.5 N 7

2C-HL-G7

0.5 G 6

0.5 E 6

0.5 G 7

2C-HL-N7

0.5 N 6

0.5 E 6

0.5 N 7

2C-HL-N7

0.5 N 6

0.5 E 6

0.5 N 7

0.5 E 7

0.5 E 7

0.5 E 7

0.5 E 7

0.5 E 7

0.5 E 7

N

N

2C-HL3N8

2E9

0.5 N 9

N

2C-HL3N8

5E9

0.5 N 9

N

2C-HL3N8

2E9

0.5 N 9

G

2C-HL3G8

2E9

0.5 G 9

N

2C-HL3N8

5E9

0.5 N 9

N

2C-HL3N8

5E9

0.5 N 9

N

N

N

N

G

N

N

19.5 19.5 19.5 16.5 35.5 32.5 12.0

C = COLD WATER (15° C)

H = HOT WATER (65° C)