© Electrolux

Muggenhofer Straße 135

D-90429 Nürnberg

Germany

Fax +49 (0)911 323 1022

Spares Operation

Publ.-Nr.:

599 518 355 EN

10.2003

DGS-TDS-N - R.Kurzke

Ausgabe:

SERVICE MANUAL

Compact front loaded

Washing Machines

(Timer controlled)

Compact front loaded

Washing Mashines

from Torsvik

Timer controlled

- 2 -

10.2003 R.K. 599 518 355

Table of Contents

General features 3

Programs 4

Timer function 5

Operation principle 6

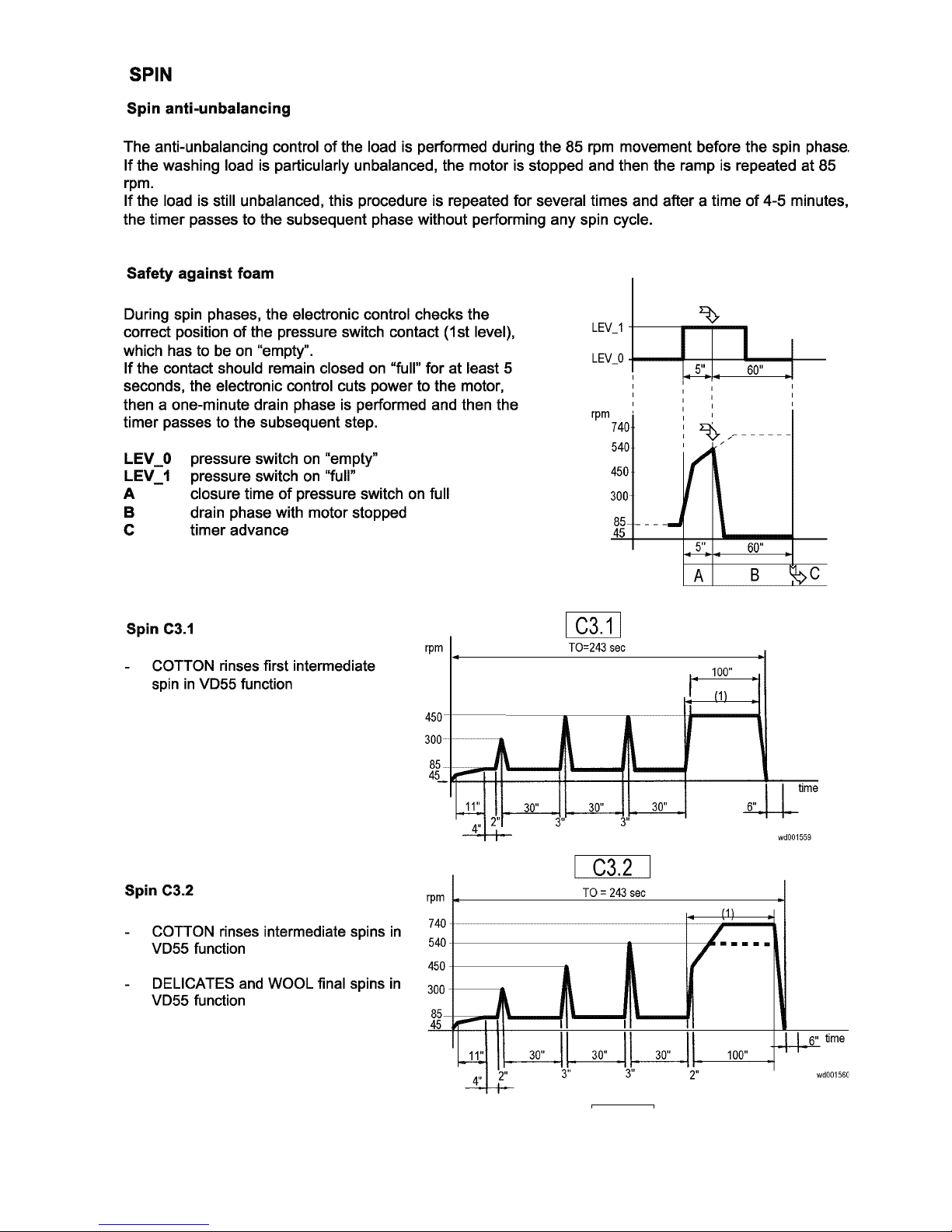

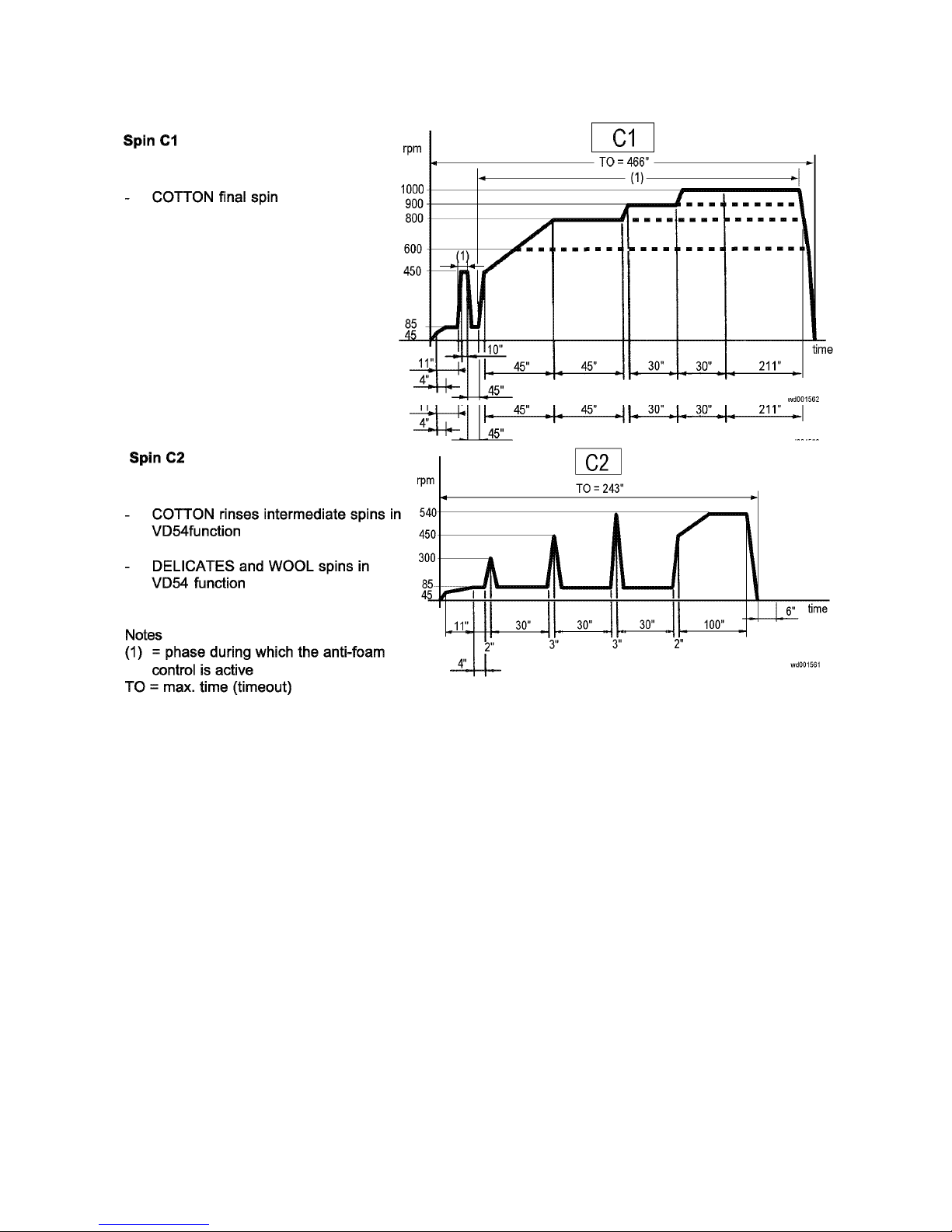

Types of Spin 7

Construction

Enclosure 9

Upperframe 9

Lowerframe 9

Rear of machine 10

Front panel 11

Detergent dispenser 11

Front hatch 12

Hatch locking switch 12

Washing unit with outer drum 13

Function

Monitoring of spin phase for imbalance 14

Water supply valve 15

Level regulator 15

Heating element 16

NTC-Thermistor 16

Drainage pump 17

Service/Accessibility

Top plate 18

Panel 19

Hatch 20

Hatch hinge 21

Rear ot machine 22

Drum unit 23

Shockabsorbers 23

Outer drum with drum bearing 24

Troubleshootings 25

Motor check 27

Diagrams 28

Washing programs table 30

Timer diagram 31

Timer connectors 32

- 3 -

10.2003 R.K. 599 518 355

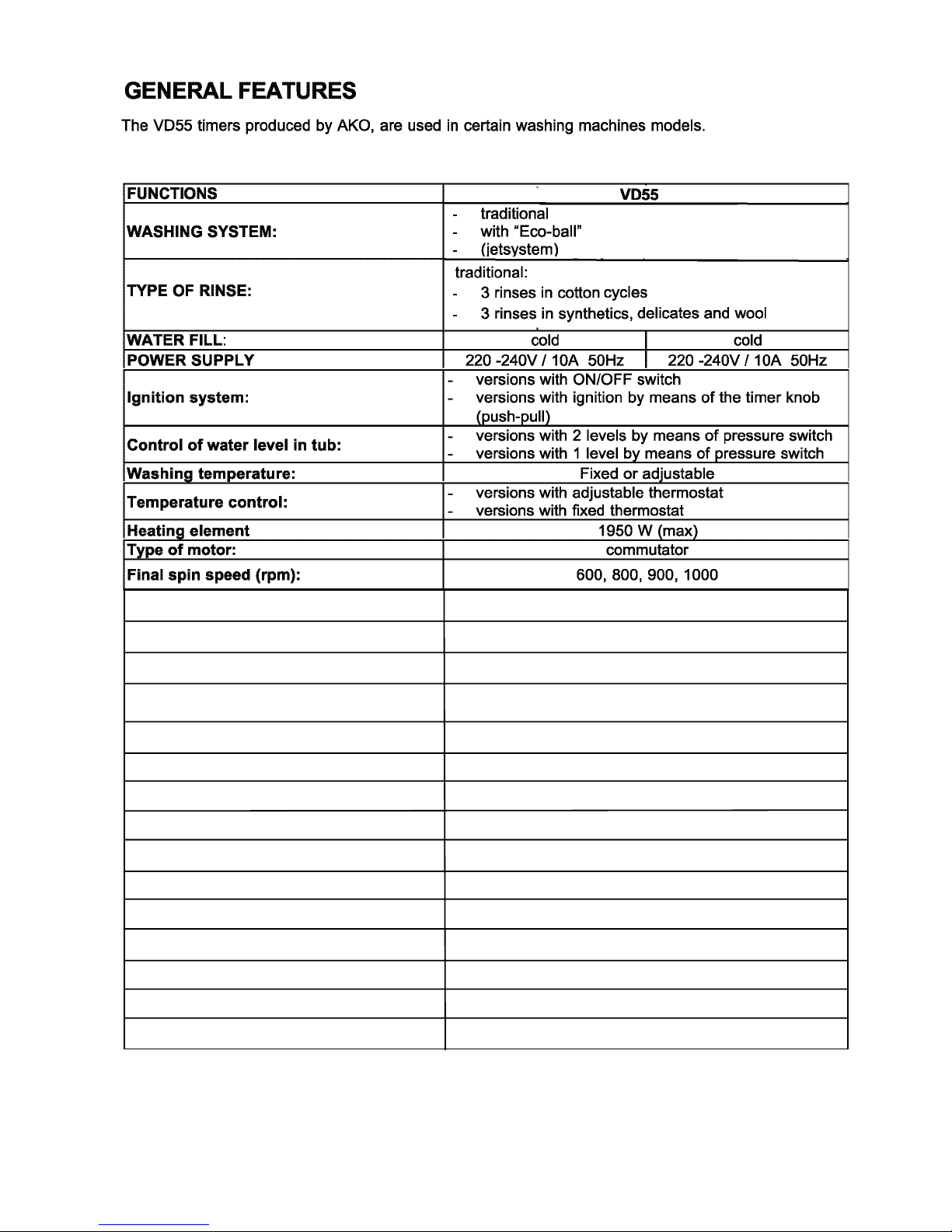

Controls

Timer type VD55

Push button functions On/off, Rinse hold

Knob/Command func. Program, Temperature

Dimensions

Height 670 mm

Width 495 mm

Depth 515 mm

Tub material Carboran

Drum volume 27 l

Washing capacity 3.00 kg

Inlet hose length 130 cm

Outlet hose length 160 cm

Det. dispenser type of Two chambers

Cord length 170 cm

- 4 -

10.2003 R.K. 599 518 355

- 5 -

10.2003 R.K. 599 518 355

- 6 -

10.2003 R.K. 599 518 355

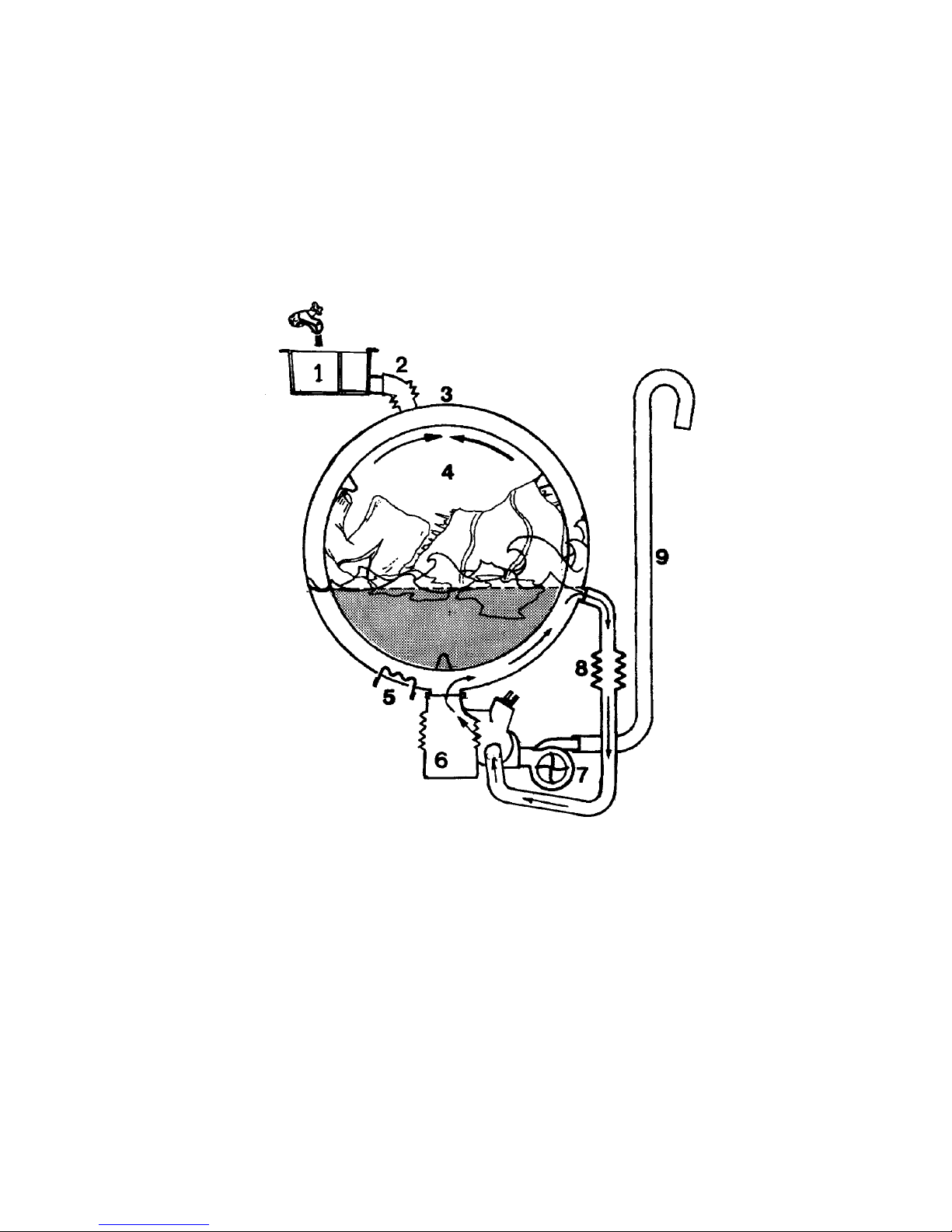

5 Heating element

6 Rubber bottom, fixed to outer drum

7 Drainage pump

8 Circulation hose

9 Drainage hose

OPERATION PRINCIPLE

Traditional washing Operation

1 Detergent hatch

2 Hose between detergent dispenser and outer drum

3 Outer drum

4 Inner drum

- The partides of soiling substances which are freed from the textile fibres by the chemical action of the detergent

at the temperature of the washing water are re-moved by the flow of water through the fibres.

- The reversing rotation ofthe drum causes mechamcal interaction between the parts ofthe load and the

detergent solution which separates the partides from the textlies.

- The water level is at such a height that the load is successively lifted from the solution by the ridges formed

in the inner drum and then falls back into the solution.

- The Circulation ofthe solution during the rotation ofthe drum prevents the accumulation of detergent in the

rubber bottom.

- 7 -

10.2003 R.K. 599 518 355

- 8 -

10.2003 R.K. 599 518 355

- 9 -

10.2003 R.K. 599 518 355

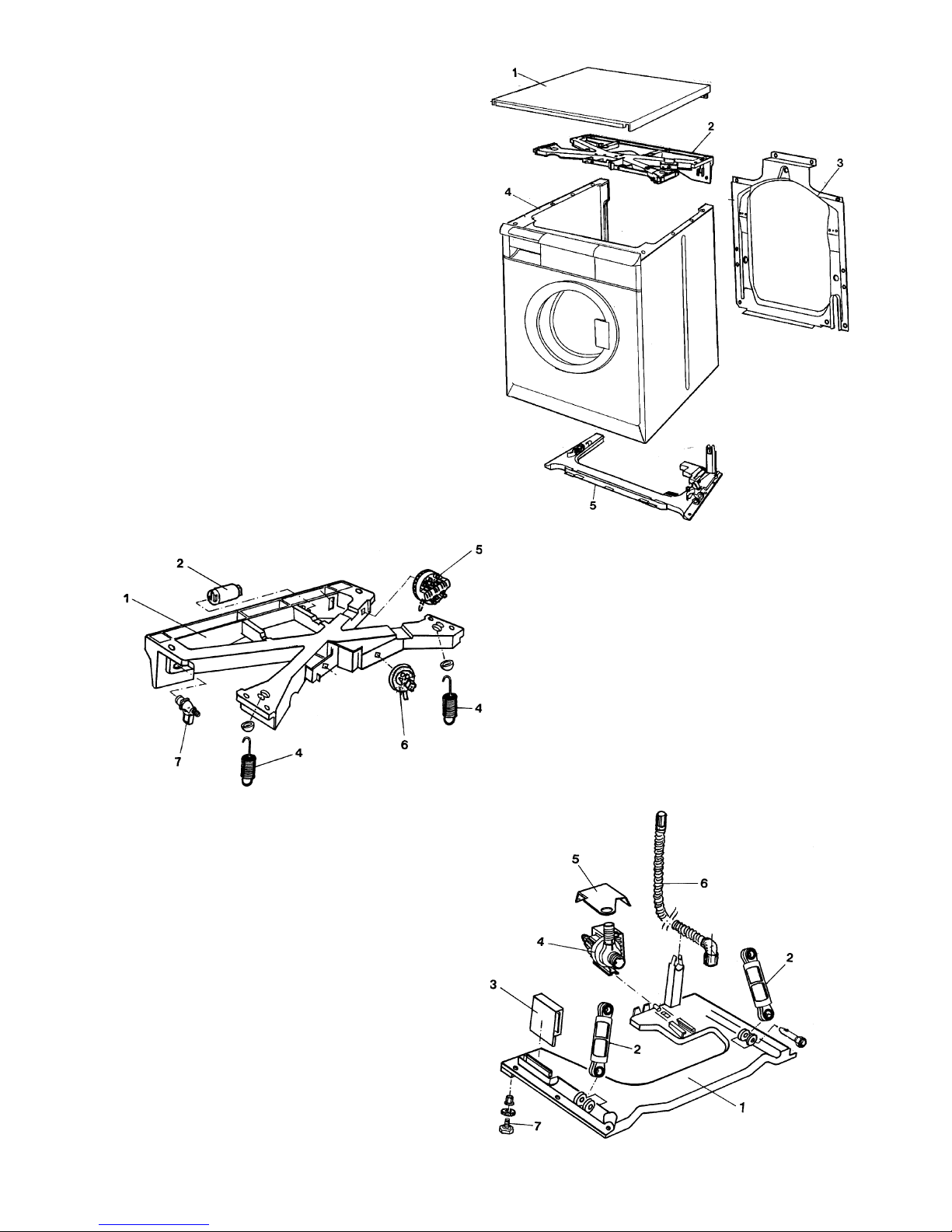

CONSTRUCTION

Enclosure

The enclosure consists of: - a lacquered steel sheet

pressing forming the front and both sides, fixed

between upper and lower CARBORAN frames

- a removabie galvanized sheet steel back plate

- a top of lacquered steel sheet, fixed to the rear of

the upper GARBORAhOframe.

1 Top, lacquered steel sheet

2 Upper frame, CARBORAN

3 Back plate,

4 Front and sides, lacquered steel sheet

5 Lower frame, CARBORAN

Upper frame

1. Upper frame of CARBORAN®

2. Interference suppressor

4. Spring, drum suspension

5. Level regulator, level 1

level 2, and

anti-foam function

6. Level regulator, overflow protection

7. Water supply valve

Lower Frame

1. Lower frame, of CARBORANO

2. Shock absorber, fixed to frame with plastic pin

3. Electronics unit

4. Drainage pump, inserted in track and locked to

lower frame with plastic snap fixing

5. Plastic protection for drainage pump

6. Drainage hose, fixed with two plastic clamps

7. Adjustable rear foot with lock nut

- 10 -

10.2003 R.K. 599 518 355

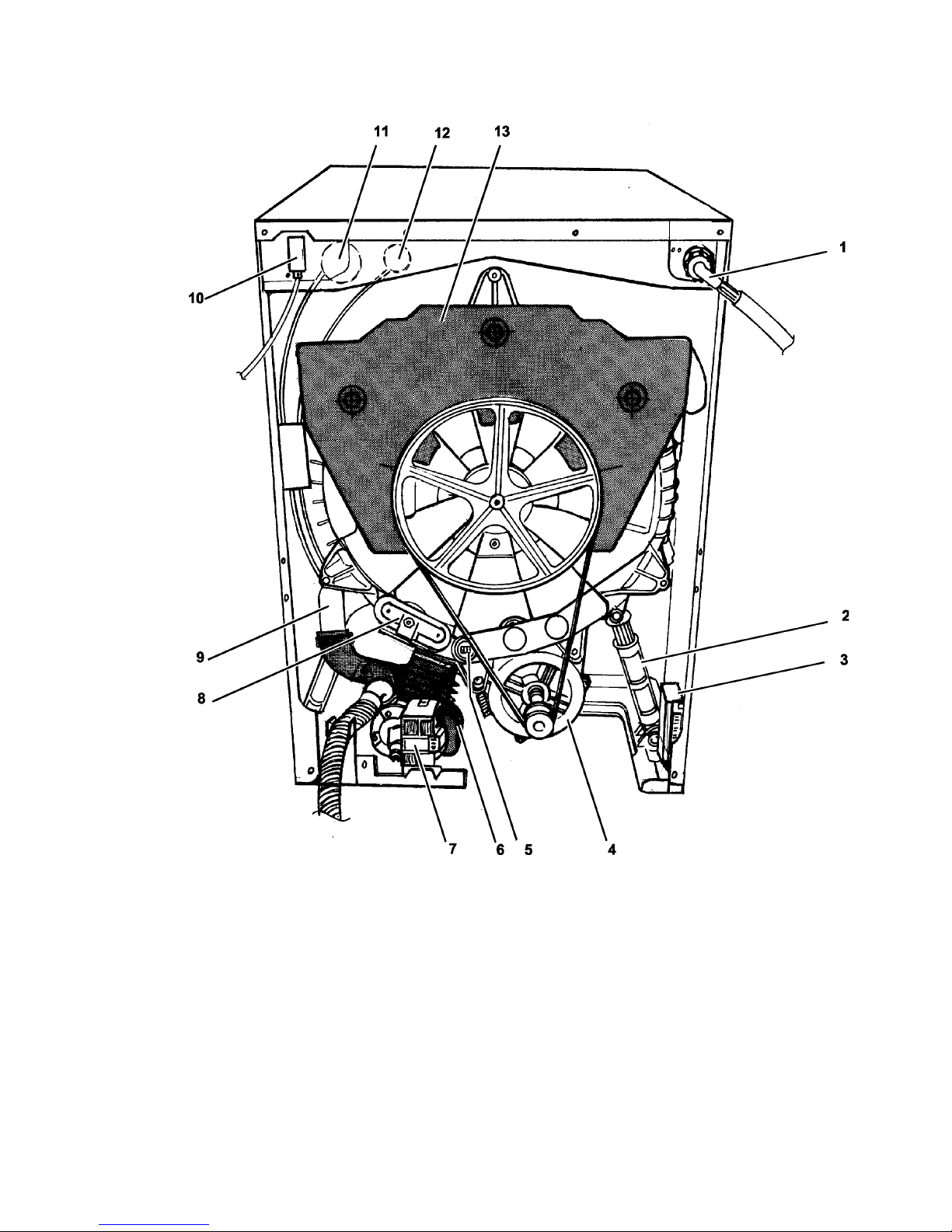

1 Water supply hose

2 Shock absorber

3 Electronics unit 4 Motor

5 Temperature sensor, NTC thermistor

6 Rubber bottom with "pin trap" (filter not provided)

7 Drainage pump

8 Heating element, 1600 W.

9 Pressure chamber

10 Connection terminal block

11 Level regulator, level and anti-foam function

12 Level regulator, overflow protection

13 Rear counterweight

Rear of machine

Loading...

Loading...