Page 1

Thermaline bratt pans - h = 700 mm

Electric tilting pressure bratt pans CTS

The Electrolux THERMALINE is designed for the very heavy duty requirements of hotels, institutions, hospitals,

central kitchens and in-flight kitchens. The range consists of a wide choice of elements that can be installed as

individual, free-standing units or assembled into a complete cooking suite made virtually seamless by means

of hygienic connecting systems. The electrically heated tilting pressure bratt pan has a multifunctional cooking

surface in compound and is used for browning, braising, preparing sauces, sautéing, poaching, steaming,

boiling, stewing, preparing white sauces, pressure steaming, etc.

Performance features & user

benefits

• Large digits on display can be easily

seen from a distance.

• Multipurpose cooking surface

guarantees great flexibility in the

cooking processes:

- Roasting / Browning / Stewing and

Preparation of sauces / Sautéing and

Boiling

- Pressure cooking / Steaming with

closed or open lid.

• The flat bottom allows an even

distribution of fat. The minimum use

of fat offers optimum grilling results.

• Advantages of pressure cooking

(depending on quality and type of

food) in comparison with a traditional

bratt pan:

- Cooking duration reduced by

approximately 50% compared with

normal cooking.

- Low nutritional properties alteration

- Low weight losses (-13÷15%)

- Lower energy consumption (up to

80 %).

• Optimum heat distribution in the

food provides best cooking results in

terms of taste, colour and

consistency and in terms of

preserving vitamins.

• Overnight cooking possible: saving

electricity and time.

• A complete menu can be prepared

at the same time: vegetables,

potatoes, meat and crème caramel.

• Motorized tilting allows for precise

pouring of any liquid product.

• The pan can be tilted at a variable

speed over 90° to facilitate pouring

and cleaning operations.

• The tilting axis is located at the front

and upper position of the pan to keep

the pouring path short when filling

different types of vessels.

• Insulated and counterbalanced lid.

584701

• The square inner cooking well and

the suspension frames (optional

accessory), make it possible to work

directly with GN containers.

Controls

• Electronic microprocessor control

with digital display consents

pre-selection of cooking temperature

(from 50 to 250°C), duration and start

time, ensuring adherence to

pre-programmed cooking process.

Page 2

Thermaline bratt pans - h = 700 mm

Electric tilting pressure bratt pans CTS

• “Boiling function”: when nominal

temperature is equal or lower than

110°C, the system measures the

temperature on the sides of the well,

as in a boiling pan.

• “Frying function”: when nominal

temperature is equal or higher than

110°C, the system controls the

temperature on the bottom plate as in

a frying pan.

• “Pressure function”: once the

pressure lid is closed the system

automatically regulates itself.

• No overshooting of cooking

temperatures and fast reaction.

• Error display for quick

trouble-shooting.

• A SOFT setting for a gentle heat

input, for delicate products - avoiding

undesired spillage.

• POWER LEVELS setting: possibility

of choosing between 9 available

power levels to adjust to the type of

food being cooked instead of

selecting the temperature.

• On request it can be connected to

an HACCP integrated system for

monitoring, supervision and recording

of all data by means of a computer.

• Prearranged for eventual energy

optimisation or external surveillance

systems.

• The steam condensation function

automatically nullifies the steam

pressure after cooking is completed

at the end of the cooking cycle.

• The Core Temperature Sensor

provides efficient temperature control:

the power is supplied as and when

required to keep the set temperature

value without exceeding it. Once

reached, the food is ready to be

served.

Construction

• Top, front and side panels in AISI

304 stainless steel.

• Pan with all edges rounded.

• Pan bottom with thermo storage

block heating technology: 15 mm in

compound plus 15 mm thick storage

and heating block.

• The high-quality thermal insulation

of the pan saves energy and keeps

operating ambient temperature low

for the comfort of the chefs.

• The water mixing unit (optional

accessory) integrated into the left

console simplifies filling and cleaning

the pan.

• Safety valve on the lid avoids

overpressure in the food

compartment.

• The pressure lid is provided with a

proven fast-acting lock which is

simple and safe in operation.

Hygiene & Safety

• Minimised presence of narrow gaps

for easier cleaning of the sides in

order to meet the highest hygiene

standards.

• Easy to clean cooking surface due

to large-radius edges and corners.

• IPX6 water resistant.

• 98% recyclable by weight &

packing free of toxic substances.

TUET06EEFT

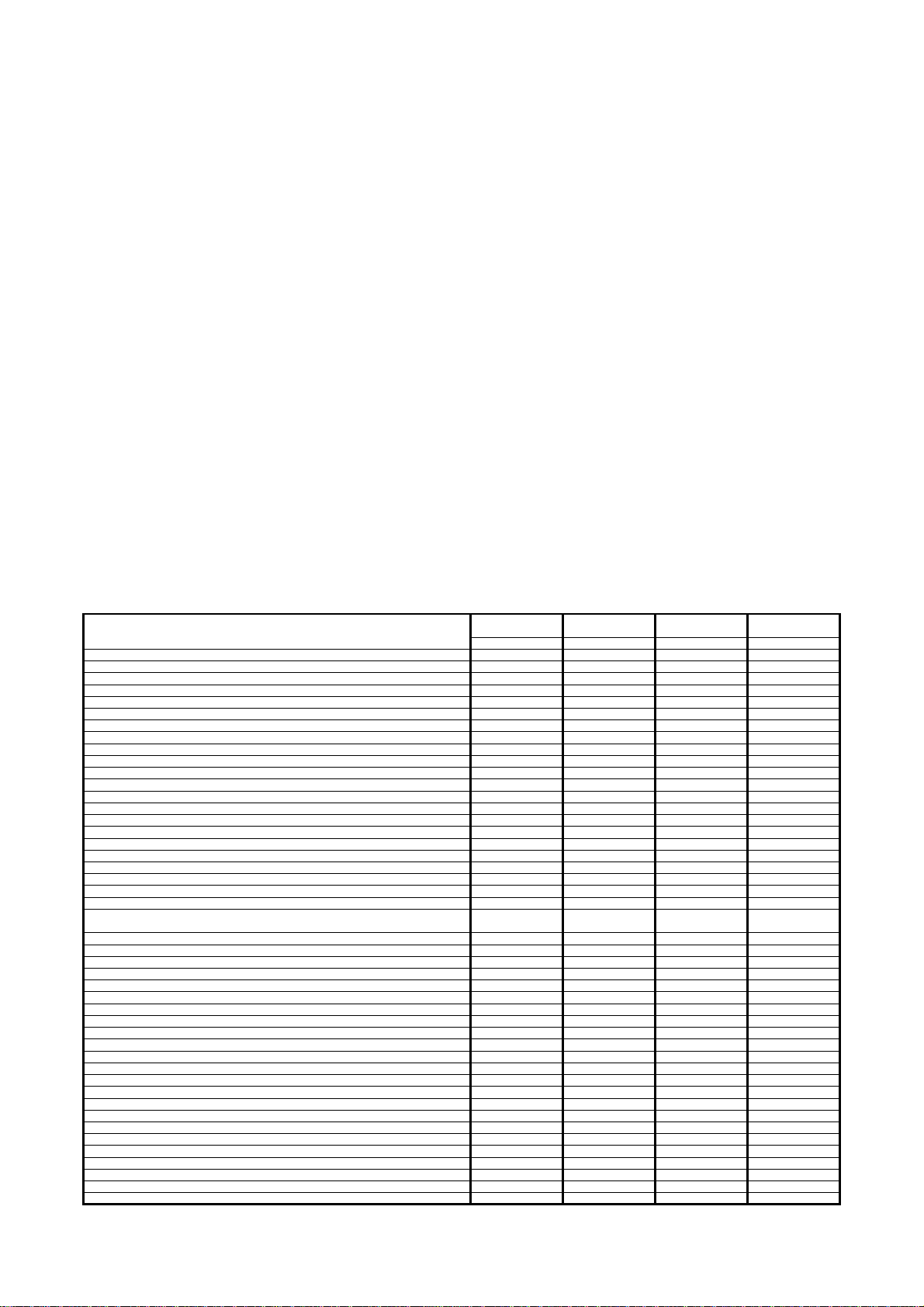

TECHNICAL DATA

Water supply

pressure min. , max. - bar 2, 6 2, 6 2, 6 2, 6

Configuration Rectangular; Tilting Rectangular; Tilting Rectangular; Tilting Rectangular; Tilting

External dimensions - mm

width 1200 1200 1600 1600

depth 900 900 900 900

height 700 700 700 700

Net vessel useful capacity - Lt. 60 90 100 150

Electronic ● ● ● ●

Tilting mechanism Automatic Automatic Automatic Automatic

Double jacketed lid ● ● ● ●

Working temperature - min/max - °C 50, 250 50, 250 50, 250 50, 250

Vessel dimensions - mm

width 680 680 1050 1050

depth 550 550 550 550

height 220 290 220 290

Heating type Direct Direct Direct Direct

Power - kW

auxiliary 0.2 0.2 0.2 0.2

installed-electric 15.5 15.5 20.6 20.6

Net weight - kg. 230 240 320 340

Supply voltage 400 V, 3N, 50/60 400 V, 3N, 50/60 400 V, 3N, 50/60 400 V, 3N, 50/60

ACCESSORIES

AUTOM.WATER FILLING (HOT+COLD) L/H SIDE 912050 912050 912050 912050

AUTOM.WATER FILLING(COLD WATER) L/H SIDE 912048 912048 912048 912048

BACK PANEL SUPPORT BASE-NO PLINTH 912055 912055 912055 912055

BASE PLATE 1/1GN- PRESSURE BRAISING PAN 910201 910201 910201 910201

BOTTOM PLATE+FEET 100MM-TILT.UNIT-D=900 912066 912066 912066 912066

BOTTOM PLATE+FEET 200MM-TILT.UNIT-D=900 912071 912071 912071 912071

C-BOARD FOR WALL INSTALLATION 1200X40 MM 912100 912100

C-BOARD FOR WALL INSTALLATION 1600X40 MM 912104 912104

CONNECT.RAIL(PER MT)BACK-TO-BACK INSTALL 912056 912056 912056 912056

ELECTRO KIT 16A/32A,FOR 912460 NEWTHERMA 912461 912461 912461 912461

FS ISLAND INSTALL.+REAR PANELLING-H=700 912052 912052 912052 912052

MIXING TAP (1 HAND)L/H SIDE-TILTING PANS 912047 912047 912047 912047

MIXING TAP (2 HAND)L/H SIDE-TILTING PANS 912046 912046 912046 912046

MIXING TAP(SWIVEL)L/H SIDE-AUTOM.FILLING 912074 912074 912074 912074

MOBILE KIT NEWTHERM (VAR.WIDTH = S-CODE) 912460 912460 912460 912460

PERFORATED CONTAINER+HANDLES 1/1GN H=100 910211 910211 910211 910211

PERFORATED CONTAINER+HANDLES 1/1GN H=200 911673 911673 911673 911673

S/S PLINTHS(L+R) 900X200MM-TILTING UNITS 912059 912059 912059 912059

S/S PLINTHS(L+R)900X100MM-TILT.UNIT-WALL 912058 912058 912058 912058

SPRAY GUN - LEFT HAND SIDE 912051 912051 912051 912051

STRAINER F.DUMPLINGS-BOIL.PANS 80/100LT 910053 910053 910053 910053

SUSPENS.FRAME1/1,RECT.BOIL&BRAISING PANS 910191 910191 910191 910191

WATER CONNECTION KIT,FOR 912460 NEWTHERM 912462 912462 912462 912462

584699

TUET09EEFT

584701

TUET10EEFT

584703

TUET15EEFT

584705

DAIA0152010-05-28Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Page 3

584701

Thermaline bratt pans - h = 700 mm

Electric tilting pressure bratt pans CTS

TUET09EEFT

LEGEND

CWI - Cold water inlet 1/2"

EI - Electrical connection 400 V, 3N, 50/60

584701

DAIA0152010-05-28Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Page 4

584705

Thermaline bratt pans - h = 700 mm

Electric tilting pressure bratt pans CTS

TUET15EEFT

LEGEND

CWI - Cold water inlet 1/2"

EI - Electrical connection 400 V, 3N, 50/60

584705

DAIA0152010-05-28Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Loading...

Loading...