Page 1

Identification:

Technical Bulletin no:

Date:

Issuer:

Factory:

Subject

Model

Problem

Reason

Action in Factory

ELECTROLUX PROFESSIONAL SPA

MAILING ADDRESS TELEPHONE WEBSITE VAT NO.

VIALE TREVISO, 15

33170 PORDENONE - ITALY

OFFICE ADDRESS TELEFAX E-MAIL ADDRESS

VIALE TREVISO, 15

33170 PORDENONE - ITALY

C08

PDD2005-08 (page 1 of 10), 2nd

23 May 2005

Filippo Fingolo (Ovens Customer Support

Dept.)

PDD Vallenoncello - Italy

New regulations for AOS gas ovens

All AOS gas combi lenghtwise ovens

Possibility of whistling noise during oven working

Differences in LPG mixture

From SN 513 introduced new gas regulations (see table) and

components, also alternative solutions (LPG1 and LPG2) for LPG

installations:

for 6 gas combi ovens:

- new cavity burner (0C1082), replaced pieces In sparepart wharehouse

for 10 1/1 and 20 1/1 gas combi ovens:

- new PWM parameters

- offset regulations with range of values

- new nozzle with diameter 5,50 for cavity burner (spare part code

0C2442) for LPG2/G30 installations

for 10 2/1 gas combi ovens:

- new PWM parameters

- offset regulations with range of values

for 20 2/1 gas combi ovens:

- new PWM parameters

- offset regulations with range of values

- new nozzles with diameter 7,50 (0C2444), 6,00 (0C2445), 5,80

(0C2446) for boiler burners

- new aerator (red one, 0C1045) for boiler burners

- new chimneys for boiler (0C2447)

- new burner for the boiler (0C2190), spare part updated with the new

burner

- introduction of a circular mesh (0C2513) and a circular restriction

(0C2514) on boiler’s

++39 0434 380528 www.electrolux.com 00072220932

++39 0434 380555 filippo.fingolo@electrolux.it

Page 2

Action in Field

- Nozzles, chimneys, aerators, burner, meshes and restrictions available

also in the kit 0C2515

See below the new calibrations and instructions for gas conversion

2

Page 3

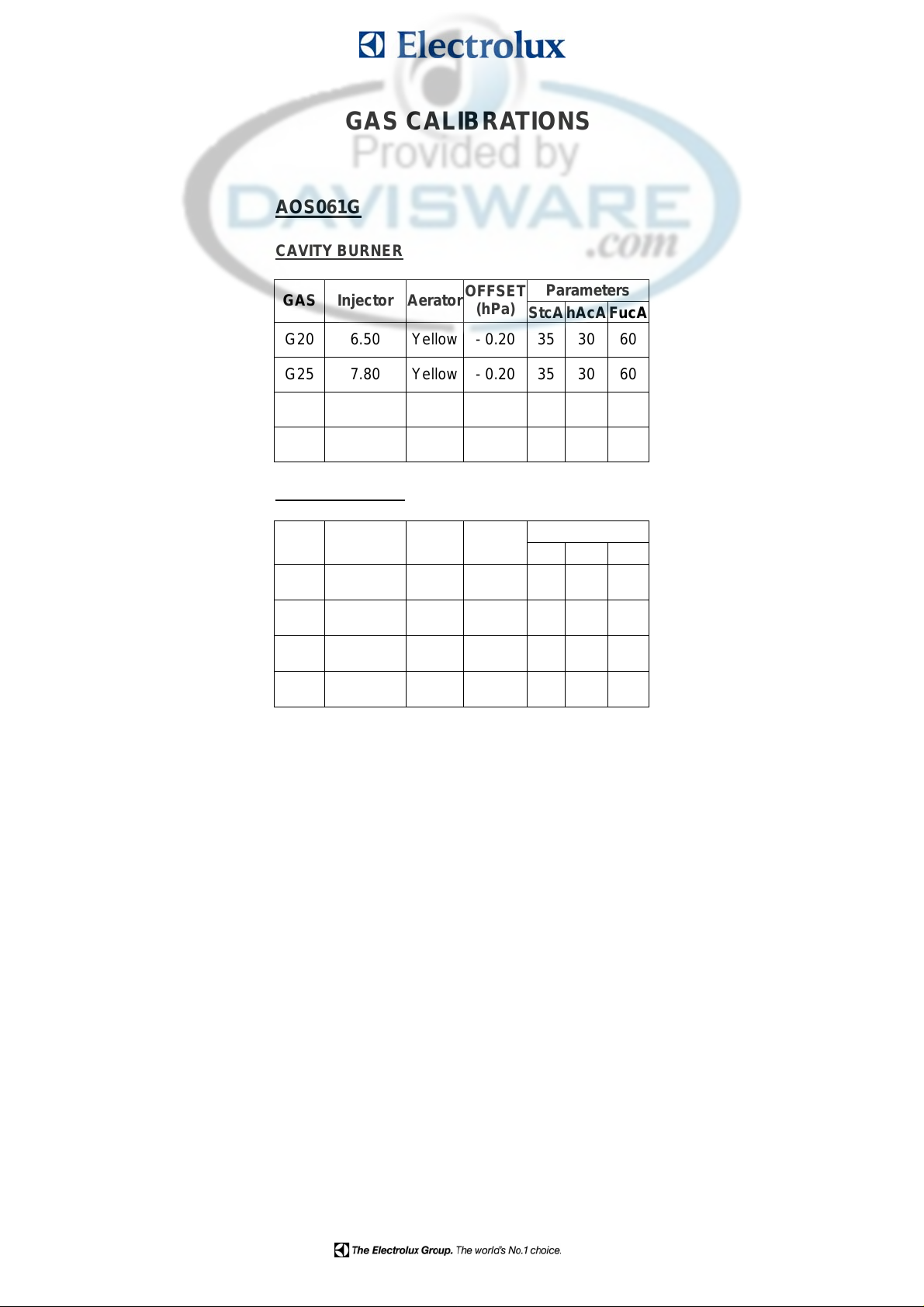

GAS CALIBRATIONS

AOS061G

CAVITY BURNER

GAS Injector Aerator

G20 6.50 Yellow - 0.20 35 30 60

G25 7.80 Yellow - 0.20 35 30 60

G30 5.30 Yellow - 0.25 40 28 43

LPG 5.30 Yellow - 0.13 40 28 43

BOILER BURNER

GAS Injector Aerator

OFFSET

(hPa)

Parameters

StcAhAcAFucA

OFFSET

(hPa)

Parameters

Stbo hAbo Fubo

G20 6.50 Yellow - 0.20 55 35 78

G25 7.80 Yellow - 0.20 55 35 78

G30 5.30 Yellow - 0.28 55 36 66

LPG 5.30 Yellow - 0.18 55 36 66

3

Page 4

AOS101G

CAVITY BURNER

GAS InjectorAerator

OFFSET

(hPa)

Parameters

StcAhAcAFucA

G20 7.00 Red - 0.25 80 26 100

G25 8.00 Red - 0.25 80 26 100

LPG2/G30 5.50 Red - 0.07 ÷ 0.00 23 26 100

LPG1 5.70 Red - 0.15 ÷ - 0.08 23 26 100

BOILER BURNER

GAS InjectorAerator

OFFSET

(hPa)

Parameters

Stbo hAbo Fubo

G20 7.00 Red - 0.10 50 50 100

G25 8.00 Red - 0.10 40 50 100

G30 5.70 Red - 0.28 33 45 74

LPG 5.70 Red - 0.15 33 45 74

LPG conversion for cavity burner for AOS101G

For LPG installations, put the ø 21 flow reducer flange between cavity burner fan and cavity burner. Change the

PWM parameters.

Then change the injector with the 5.70 one and calibrate the offset in the range - 0.15 ÷ - 0.08 hPa so as to

eliminate possible whistles/noises (row LPG1). After you have found the best working condition, cool down and

verify ignitions with cold burner.

If the previous setting does not eliminate whistles or noise, change the 5.70 injector with the 5.50 one and use the

calibrations of LPG2/G30 row: calibrate the offset in the range - 0.07 ÷ 0.00 hPa so as to eliminate possible

whistles/noises (row LPG1). After you have found the best working condition, cool down and verify ignitions with

cold burner.

4

Page 5

AOS201G

UPPER CAVITY BURNER

GAS Injector Aerator

G20 7.00 Red - 0.25 80 26 100

G25 8.00 Red - 0.25 80 26 100

LPG2/G30 5.50 Red - 0.07 ÷ 0.00 23 26 100

LPG1 5.70 Red - 0.15 ÷ - 0.08 23 26 100

LOWER CAVITY BURNER

GAS Injector Aerator

G20 7.00 Red - 0.25 80 26 100

OFFSET

(hPa)

Parameters

StcA hAcA FucA

OFFSET

(hPa)

Parameters

StcA hAcA FucA

G25 8.00 Red - 0.25 80 26 100

LPG2/G30 5.50 Red - 0.07 ÷ 0.00 23 26 100

LPG1 5.70 Red - 0.15 ÷ - 0.08 23 26 100

BOILER BURNER

GAS Injector Aerator

OFFSET

(hPa)

Parameters

Stbo hAbo Fubo

G20 8.00 Blue 0 42 45 100

G25 8.50 Blue 0 42 45 100

G30 6.15 Blue - 0.15 30 37 72

LPG 6.15 Blue 0 30 37 72

LPG conversion for cavity burner for AOS201G

For LPG installations, put the ø 21 flow reducer flange between cavity burner fan and cavity burner. Change the

PWM parameters.

Then change the injector with the 5.70 one and calibrate the offset in the range - 0.15 ÷ - 0.08 hPa so as to

eliminate possible whistles/noises (row LPG1). After you have found the best working condition, cool down and

verify ignitions with cold burner.

If the previous setting does not eliminate whistles or noise, change the 5.70 injector with the 5.50 one and use the

calibrations of LPG2/G30 row: calibrate the offset in the range - 0.07 ÷ 0.00 hPa so as to eliminate possible

whistles/noises (row LPG1). After you have found the best working condition, cool down and verify ignitions with

cold burner.

5

Page 6

AOS102G

CAVITY BURNER

OFFSET (hPa) Parameters

GAS Injector Aerator

StcA

hAcA FucA

G20 7.00 Red - 0.17 ÷ - 0.10 45 43 100

G25 8.50 Red - 0.17 ÷ - 0.10 45 43 100

G30 5.70 Red - 0.25 ÷ - 0.18 60 43 100

LPG 5.70 Red - 0.10 ÷ - 0.02 60 43 100

BOILER BURNER

GAS Injector Aerator

OFFSET (hPa) Parameters

Stbo hAbo Fubo

G20 7.00 Red 0 43 50 100

G25 8.50 Red 0 43 50 100

G30 5.70 Red - 0.15 35 45 78

LPG 5.70 Red 0 35 45 78

LPG conversion for cavity burner for AOS102G

For LPG installations, put the ø 25 flow reducer flange between cavity burner fan and cavity burner. Change the

PWM parameters.

Then change the injector with the 5.70 one and calibrate the offset in the range - 0.10 ÷ - 0.02 hPa so as to

eliminate possible whistles/noise. After you have found the best working condition, cool down and verify ignitions

with cold burner.

6

Page 7

AOS202G

UPPER CAVITY BURNER

GAS Injector AeratorOFFSET (hPa)

G20 7.00 Red - 0.20 45 43 100

G25 8.00 Red - 0.20 45 43 100

G30 5.70 Red - 0.20 ÷ - 0.15 40 43 95

LPG 5.70 Red - 0.10 ÷ - 0.05 40 43 95

LOWER CAVITY BURNER

GAS Injector AeratorOFFSET (hPa)

G20 7.00 Red - 0.20 45 43 100

Parameters

StcA hAcA FucA

Parameters

StcA hAcA FucA

G25 8.00 Red - 0.20 45 43 100

G30 5.70 Red - 0.25 ÷ - 0.20 40 43 95

LPG 5.70 Red - 0.15 ÷ - 0.10 40 43 95

UPPER BOILER BURNER

GAS Injector AeratorOFFSET (hPa)

Parameters

Stbo hAbo Fubo

G20 7.50 Red - 0.05 ÷ 0.00 40 50 100

G25 8.50 Red - 0.05 ÷ 0.00 40 50 100

LPG2/G30 5.80 Red - 0.07 ÷ - 0.02 40 45 90

LPG1 6.00 Red - 0.07 ÷ - 0.02 40 45 90

LOWER BOILER BURNER

GAS Injector AeratorOFFSET (hPa)

Parameters

Stbo hAbo Fubo

G20 7.50 Red - 0.05 ÷ 0.00 40 50 100

G25 8.50 Red - 0.05 ÷ 0.00 40 50 100

LPG2/G30 5.80 Red - 0.07 ÷ - 0.02 40 45 90

LPG1 6.00 Red - 0.07 ÷ - 0.02 40 45 90

7

Page 8

LPG conversion for cavity burners for AOS202G

For LPG installations, put the ø 25 flow reducer flange between cavity burner fan and cavity burner. Change the

PWM parameters.

Then change the injector with the 5.70 one and calibrate the offset in the range - 0.10 ÷ - 0.05 hPa (upper cavity

boiler) and - 0.15 ÷ - 0.10 hPa (lower cavity boiler) so as to eliminate possible whistles/noise. After you have found

the best working condition, cool down and verify ignitions with cold burner.

LPG conversion for boiler burners for AOS202G

Change the PWM parameter.

Then change the injector with the 6.00 one and calibrate the offset in the range - 0.07 ÷ - 0.02 hPa (upper and

lower boiler burner) so as to eliminate possible whistles/noise (row LPG1). After you have found the best working

condition, cool down and verify ignitions with cold burner.

If the previous setting does not eliminate whistles or noise, change the 6.00 injector with the 5.80 one and use the

calibration of LPG2/G30 row: calibrate the offset in the range - 0.07 ÷ - 0.02 hPa (upper and lower boiler burner) so

as to eliminate possible whistles/noise. After you have found the best working condition, cool down and verify

ignitions with cold burner.

ONLY FOR AOS202 GAS INSTALLATIONS – from serial number 513

Specified with a label on the roof of 202 gas ovens exact position for boiler’s chimneys, also with a label

on chimney.

For AOS202 gas ovens introduced a new chimney with 3 holes to reduce whistle.

0C2447

8

Page 9

Created a RETROFIT KIT BOILER ASSEMBLY 0C2515 for AOS 202 gas to eliminate noises on ovens

produced before sn 513:

0C2515

The kit includes the following pieces:

- circular mesh 0C2513 2 pieces

- circular restriction 0C2514 2 pieces

- nozzles 7,50 mm 0C2444 2 pieces

- nozzles 8,50 mm 0C1143 2 pieces

- nozzles 5,80 mm 0C2446 2 pieces

- nozzles 6,0 mm 0C2445 2 pieces

- boiler burner 0C2190 1 piece

- boiler chimney ( 3 holes) 0C2447 2 pieces

- red aerator 0C1045 2 pieces

9

Page 10

To use circular restrictions and meshes here you can find explanation:

CIRCULAR RESTRICTION 0C2514

You have to insert on the top of the boiler the mesh (just put it into) and fix the restriction with 3 or 4

welding points or, alternatively, you can fix them by deforming with a hammer and a chisel the edge

of pipe once you have fixed them.

Also on boiler’s fans changed green aerators with red ones:

0C1045

10

Loading...

Loading...