Page 1

Identification:

Technical

Bulletin no:

Date:

Issuer:

Factory:

Subject

Model

Reason

Action in

Factory

D06

CGX2007-08 (page 1 of 4), 2nd ed.

29 March 2007

R. Sartor (DWS Customer Support)

DW Vallenoncello - Italy

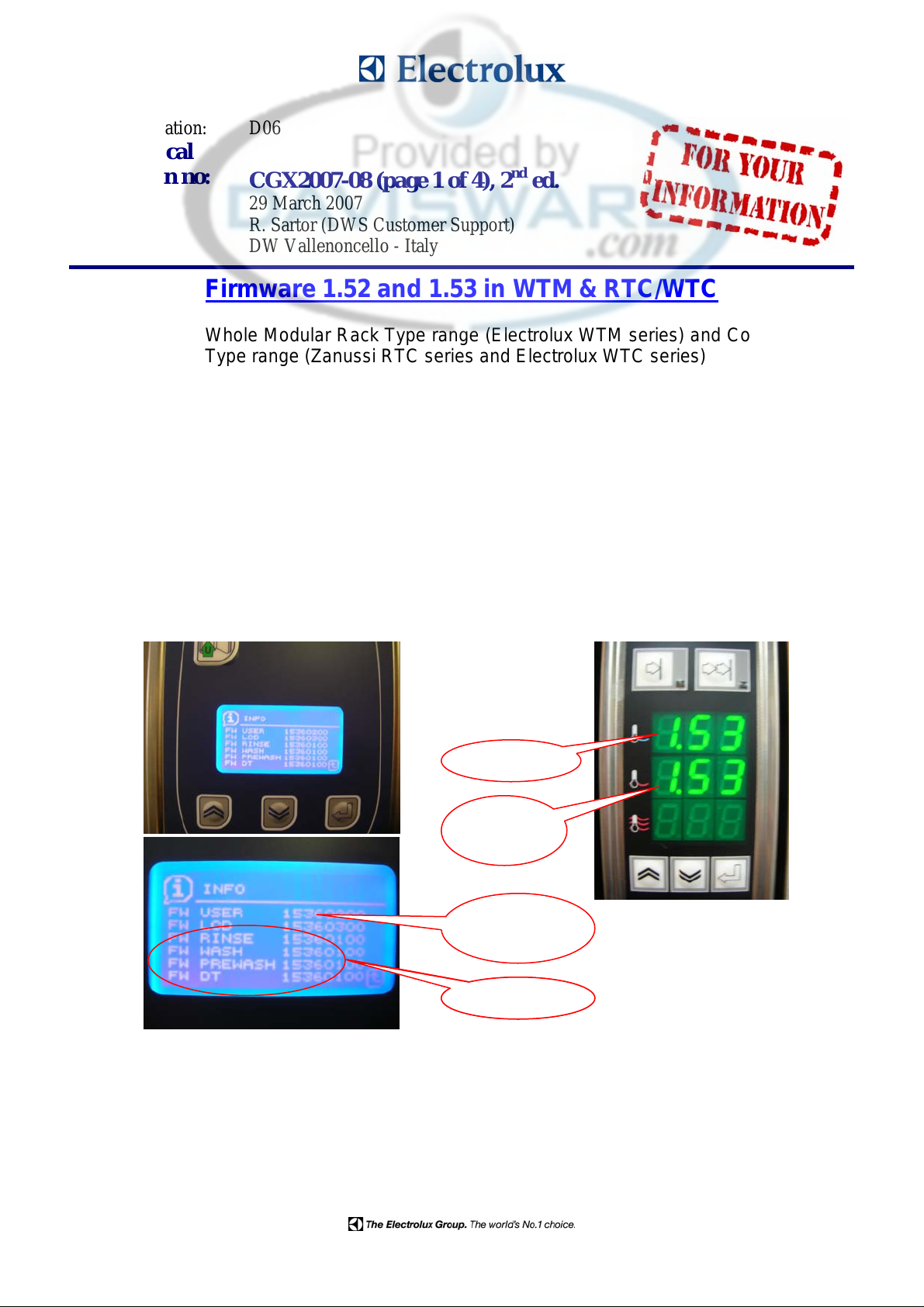

Firmware 1.52 and 1.53 in WTM & RTC/WTC

Whole Modular Rack Type range (Electrolux WTM series) and Compact Rack

Type range (Zanussi RTC series and Electrolux WTC series)

New features and new procedures to avoid alarms 72, 73 and 78.

Since serial number 71300001 we have introduced the firmware release 1.52

in User Interface 0L1285 and MEC board 0L1284 for WTM and the firmware

release 1.53 in User Interface 0L1196 and MEC board 0L1291 for RTC/WTC

(spare part codes are not changed).

The new firmware has new features/procedures as listed here below.

Most of them can be implemented just replacing the Master board (either

User Interface in WTM or MEC board in RTC/WTC). Remaining ones can be

implemented only replacing both Master board and Slave boards.

MEC board

User

interface

User

interface

MEC boardsMEC boards

ELECTROLUX PROFESSIONAL SPA

MAILING ADDRESS TELEPHONE WEBSITE VAT NO.

VIA SEGALUZZA, 30

33170 PORDENONE - ITALY

OFFICE ADDRESS TELEFAX E-MAIL ADDRESS

VIA SEGALUZZA, 30

33170 PORDENONE - ITALY

++39 0434 380650 www.electrolux.com 00072220932

++39 0434 380636

++39 0434 385646

riccardo.sartor@electrolux.it

Page 2

(

)

(

)

(

)

(

)

(

)

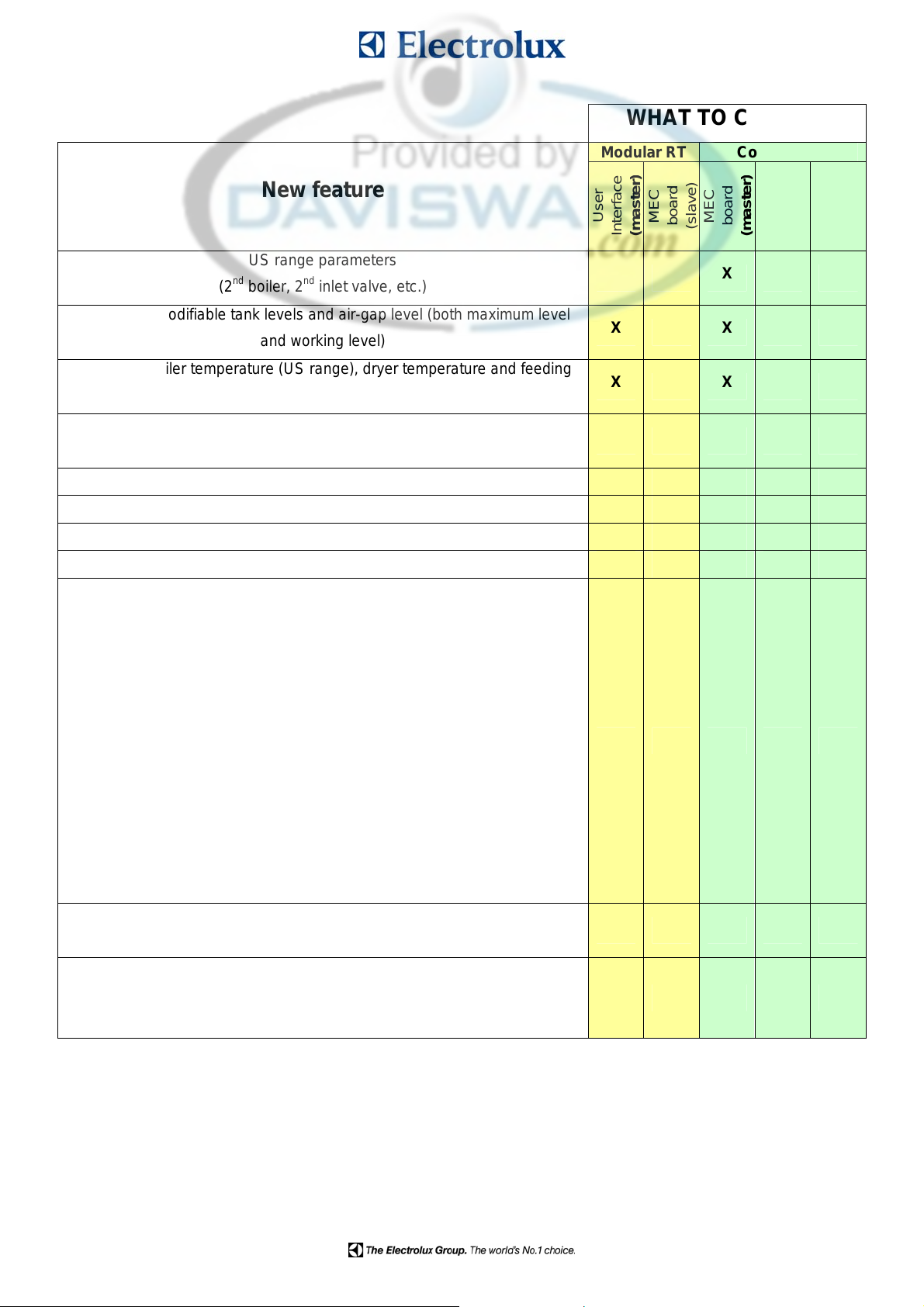

New feature

WHAT TO CHANGE

Modular RT Compact RT

User

Interface

master

MEC

board

slave

MEC

board

master

User

Interface

slave

MEC

board

slave

US range parameters

nd

boiler, 2nd inlet valve, etc.)

(2

Visible and modifiable tank levels and air-gap level (both maximum level

and working level)

Visible 2nd boiler temperature (US range), dryer temperature and feeding

motor current load

Boiler thermoregulation only during warm-up and wash/rinse (it avoids

boiler overheating during the stand-by

Parameters reset (the default is a WTM165 without dryer)

Pressure sensors calibration

Peak energy control (timeout alarms about all heaters are disabled)

Boiler temperature timeout alarm disablement

Dryer temperature cool-down procedure (to avoid alarms 72 and 73)

• the fan works even when machine switches from ready/wash to warm-

up;

• the fan works for 1 minute after switching-off (by control panel) if the

dryer temperature is over 60°C. Then it stops automatically;

X

X X

X X

X X

X X

X X X X X

X X

X X

• the alarm 72 appears only if the dryer temperature is over 80°C for 2

minutes while the fan is working

Alarm 72 and 73 may still appear if the machine is off/on by the main

switch instead of control panel because in that case the fan motor has to

stop working straight after switching-off if (for safety reasons).

See “Action in Field” below for more details about the “DT fan delay” /

“AFd” parameter and the cool-down procedure.

Reviewed air-gap draining procedure to avoid cavitation in case the air-

gap is already empty

Wash temperature and Prewash temperature timeout alarm (only during

warm-up and sanitization cycle for the Wash module, only the sanitization

cycle for the Prewash module)

X X

X X

X X

2

Page 3

(

)

(

)

(

)

(

)

(

)

New feature

Reviewed hysteresis for air-gap working level to avoid frequent on/off

during first air-gap filling

Visible alarms on the inverter display even in case of alarm 27 (the safety

chain - 24V circuit - is kept supplied)

Delay between door closing/emergency switch activation and the status

“ready” (the inverter needs few seconds for switching on otherwi se the

alarm 27 may appear)

Message “see items inside” in Compact RT or “crockery stuck” in Modular

RT instead of alarm 78 in case of items get stuck into the machine

Entry level Hot Air Blower (HAB) control

This HAB is not in production yet

WHAT TO CHANGE

Modular RT Compact RT

User

Interface

master

MEC

board

slave

X X

X X

X X

X X

X X X X X

MEC

board

master

User

Interface

slave

MEC

board

slave

Reviewed “Low power” heating mgt (both tank heaters work during warm-

up). Available only in WTM165 and WTM200

The duo rinse heater can work separately (it’s needed in steam versions

where there are neither tank heaters nor boiler heaters)

User menu accessibility even in case of communication alarm

Action in

Field

The new firmware 1.52 for Modular Rack Type (Electrolux WTM series) and

1.53 for Compact Rack Type (Zanussi RTC series and Electrolux WTC series)

is compatible towards previous firmware versions from 1.40 onwards.

See Service Manual – edition 02.2007 for more details about new

features and new parameters.

MEC board 0L1284

WTM

User interface 0L1285

MEC board 0L1291

RTC / WTC

User interface 0L1196

spare part

code

production

673610100

673610000

673610200

673608201

OLD NEW

code

X

X

X

firmware

release

1.46

1.46

1.47

1.29

n.a. n.a. n.a.

n.a. n.a. n.a.

n.a. n.a. n.a.

production

code

673610101

673610001

673610201

673608202

firmware

release

1.52

1.52

1.53

1.53

3

Page 4

About alarms 72 and 73, the “DT fan delay” / “AFd” parameter we introduced from firmware

release 1.24 onwards does NOT affect the new cool-down procedure.

The “DT fan delay” / “AFd” sets how long the fan motor works after that dryer heater stops

working when the machine is on:

In any case, both dryer fan delay function and new cool-down procedure above can be

implemented in early production dryers just moving the cable from X6:7 to X6:5 so that the

relay RL5 for the dryer fan is connected 24V to the transformer, at the end of safety devices

chain (this change has been introduced in corner dryer since serial number 61800001 and

remaining dryer tunnels since serial number 64600001):

Additional cable for

“DT fan delay” /

“AFd” function

4

Loading...

Loading...