Page 1

Identification:

Technical Bulletin:

Date:

Issuer:

Factory:

Subject

Model

Problem

Reason

Action in

Factory

C8 alarm in UC / FL / HT with CWS

Undercounter double skin, Front Loading and Hood Type high capacity with

water softener built-in (LS6EADPWS / WT38WS, LU7ADPWS /

WTU40ADPWS and LS14EAWS / WT65WS).

C8 alarm within few hours of working after installation.

In machine made during year 2007 (serial number starting with 7) we have

found 2 possible reasons:

1. loose cable to reed switch connector. This may give false contact and then

the circuit is open (not emptied boiler) even if the circuit is closed (emptied

boiler).

2. deflected magnetic field of floater magnet by rear panel in stainless steel

430 (only Undercounter LS6EADPWS / WT38WS and only for machines

with serial number from 72400001 to 80500001) whereas the rear panel is

very close to the water softener device.

In these installations the floater magnet cannot close the reed switch even

if the floater goes down regularly with the water.

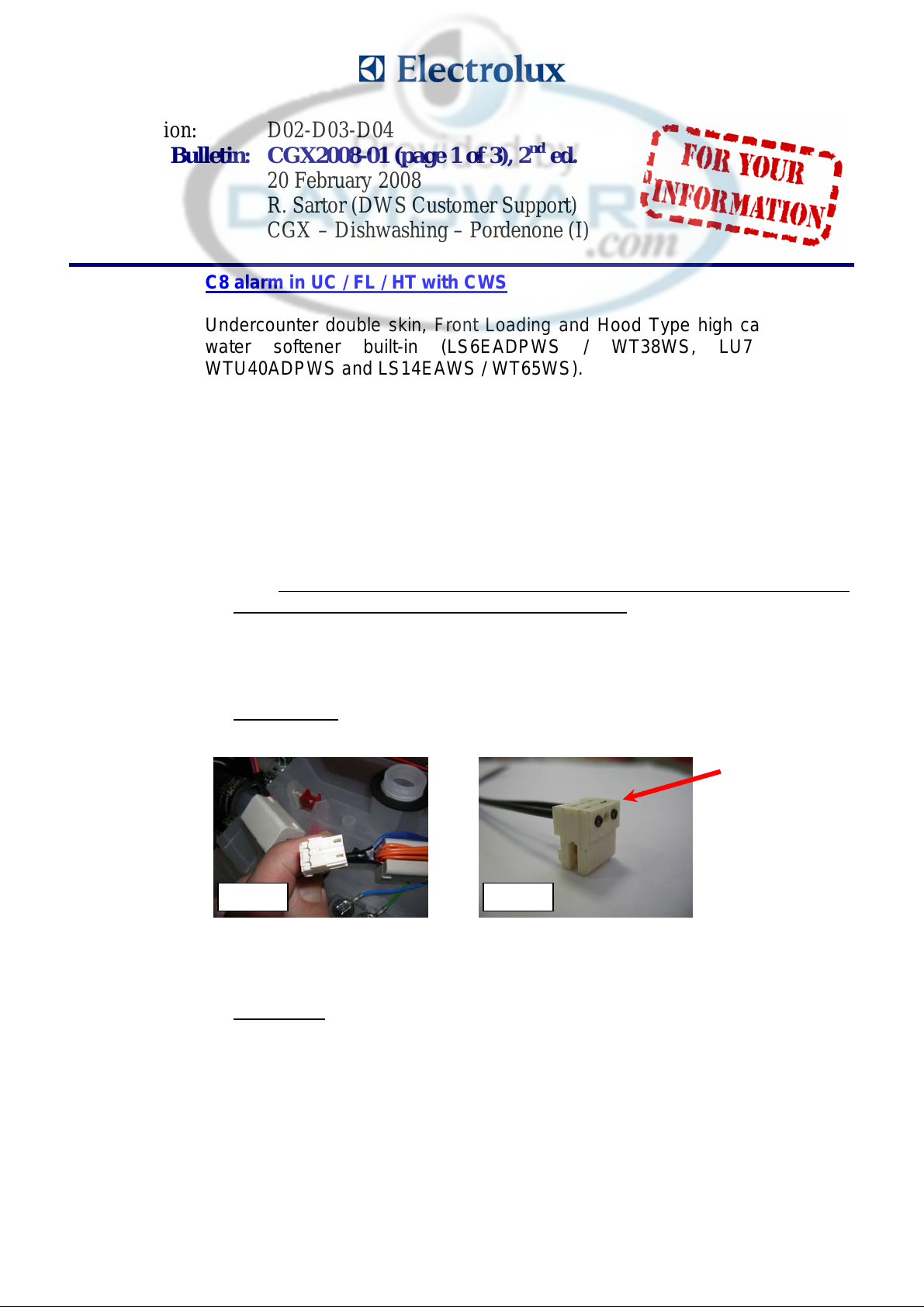

1) Loose cable: from serial number 80300001 we have introduced a new

connector with more reliable cables fixing.

OLD

D02-D03-D04

nd

CGX2008-01 (page 1 of 3), 2

ed.

20 February 2008

R. Sartor (DWS Customer Support)

CGX – Dishwashing – Pordenone (I)

NEW

Furthermore on January 12th, 2008 we made a recall of all CWS machines in

CWH. All those machines have been updated.

2) Rear panel: from serial number 80600001 we have re-introduced stainless

steel 304 keeping the same spare part code 0L1420.

ELECTROLUX PROFESSIONAL SPA

MAILING ADDRESS TELEPHONE WEBSITE VAT NO.

VIA SEGALUZZA, 30

33170 PORDENONE - ITALY

OFFICE ADDRESS TELEFAX E-MAIL ADDRESS

VIA SEGALUZZA, 30

33170 PORDENONE - ITALY

++39 0434 380650 www.electrolux.com 00072220932

++39 0434 380636

++39 0434 385646

Share more of our thinking at www.electrolux.com

riccardo.sartor@electrolux.it

Technical Bulletin (C8 Alarm).doc

Page 2

Action in

Field

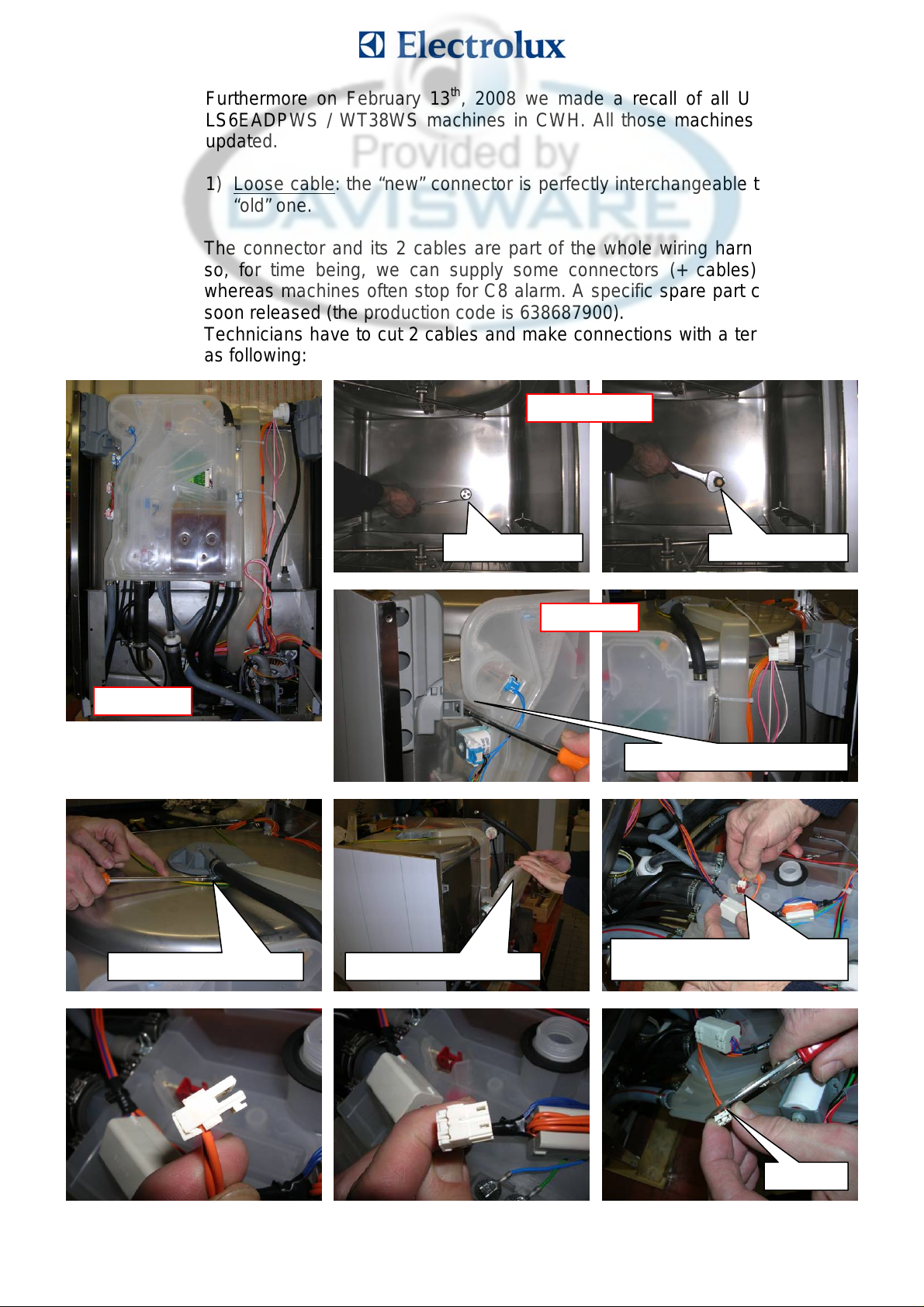

Rear view

Remove clamp for rinse hose Pull the top of the WS device

Furthermore on February 13th, 2008 we made a recall of all Undercounter

LS6EADPWS / WT38WS machines in CWH. All those machines have been

updated.

1) Loose cable: the “new” connector is perfectly interchangeable towards the

“old” one.

The connector and its 2 cables are part of the whole wiring harness 0L0775

so, for time being, we can supply some connectors (+ cables) for retrofit

whereas machines often stop for C8 alarm. A specific spare part code will be

soon released (the production code is 638687900).

Technicians have to cut 2 cables and make connections with a terminal block

as following:

Remove metal cap Remove ring nut

Frontal view

Rear view

Remove screws (left and right side)

Take the connector on the lower part

of the WS device

Cut cables

Share more of our thinking at www.electr olux.c om

2

Page 3

NEW

Take the new connector make connections with a terminal block or by soldering

Fit the connector and then put

the WS device back in its place

Action in

Field

2) Rear panel: it’s not mandatory to replace the rear panel in stainless steel

430.

The magnetic field intensity changes with inverse function of the square of

the distance. Therefore a small gap (10 mm is enough) between the rear

panel and the water softener device can avoid any problem.

Fit a gasket 0L0114 near to upper floater (that detects salt water) and to

lower floater (that detects boiler emptying) / rear window as follow:

Do not fit too thick gasket otherwise the real panel may bulge.

This change will avoid also alarms “SAL 0” that appear seemingly

without any reason (i.e. even if there’s salt in the container and the

machine has already worked for some cycles since the last salt filling).

Front Loading and Hood Type high capacity with water softener built-in

(LU7ADPWS / WTU40ADPWS and LS14EAWS / WT65WS) have never had

rear panel in stainless steel 430 so they do NOT need any spacer between

panel and water softener device.

Share more of our thinking at www.electr olux.c om

3

Loading...

Loading...