Page 1

SERVICE MANUAL

COOKERS

© Electrolux Distriparts

Muggenhofer Straße 135

D-90429 Nürnberg

Germany

Fax +49 (0)91 1 323 1022

DGS-TDS-N

Edition:

02.06

Built-in hobs

Induction

„TEIS“

Publ.-Nr.:

599 525 284

685

EN

Page 2

Inhaltsverzeichnis

1. ESD=electrostatic discharge ............................................................................ 3

2. Software specifications, Functions ...................................................................4

2.1 Sample illustration: Induction hob......................................................................4

2.2 Control panel .....................................................................................................4

2.3 Symbol,display and keys explanation ................................................................5

2.3.1 Touch control sensor fields ...............................................................................5

2.3.2 Displays ............................................................................................................5

3. Functions of appliance ......................................................................................6

3.1 Basic functions/Child safety/Power-function.....................................................6

3.2 Safety cutoff ......................................................................................................7

4. Functional parts - Component data, installation situation, .................................8

dismantling ........................................................................................................8

4.1 General view......................................................................................................8

4.2 Contact switch and input electronics (UI)..........................................................9

4.3 Induction coil....................................................................................................10

4.4 The induction module ......................................................................................11

5. Alarm Symptoms ............................................................................................ 12

5.1 Appliance not functioning at all, cannot be switched on ..................................12

5.2 Individual cooking zones do not work (partially) or work incorrectly or

cannot be used................................................................................................13

5.3 Alarm message „E“ .........................................................................................14

5.4 Other Alarmsymptoms .................................................................................... 15

5.5 Connection guideline .......................................................................................16

5.6 Display ............................................................................................................17

5.7 Inductions module test ....................................................................................17

5.8 Pot identification information ...........................................................................18

5.9 Touch Control Cooking Hobs Information........................................................19

5.10 Demo mode / Self test (Service mode) / Alarm Menu.....................................20

6. Wiring diagrams..............................................................................................21

6.1 Example-slotted plan.......................................................................................21

6.2 Example-circuit diagram .................................................................................22

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 2 -

Page 3

1. ESD=electrostatic discharge

As the single electronic interfaces are not protected internally against statical electricity and are

partially open, you must pay attention to that, in case of a repair, there will be a potential

compensation via the housing of the appliance (touch it) in order to neutralize a possible

charging and to prevent a damaging of the affected electronic interface.

You also have to be careful with those electronics delivered as spare parts, which have to be put

out of the ESD protective package only after a potential compensation (discharge of possible

statical electricity).

If a potential compensation with an existing static electricity is not executed, it does not mean

that the electronic is demaged directly. Consequential damages may result due to the damaging

of internal structures which arise only in case of load through temperature and current.

Endangered are all assembly groups which are provided with control entries, wire paths lying

open and free-accessible processors.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 3 -

Page 4

2. Software specifications, Functions

2.1 Sample illustration: Induction hob

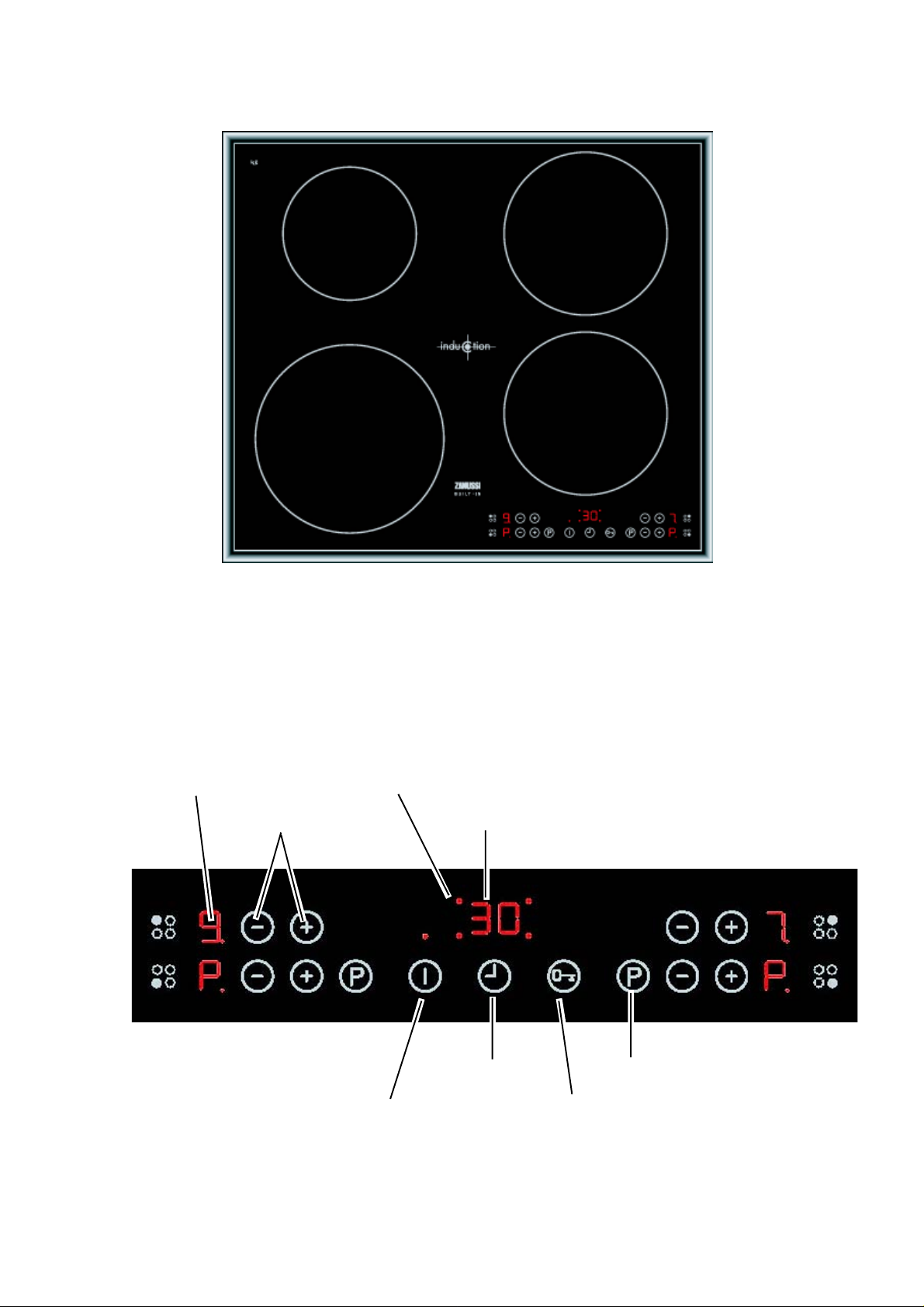

2.2 Control panel

The symbol of the Touch control sensor field depend on the various brands, however their

functions are the same.

Display

Cooking level selection Timer Display

Cooking Zone displays, Timer Function

Timer

On/Off with control lamp

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 4 -

Power function

Interlock

Page 5

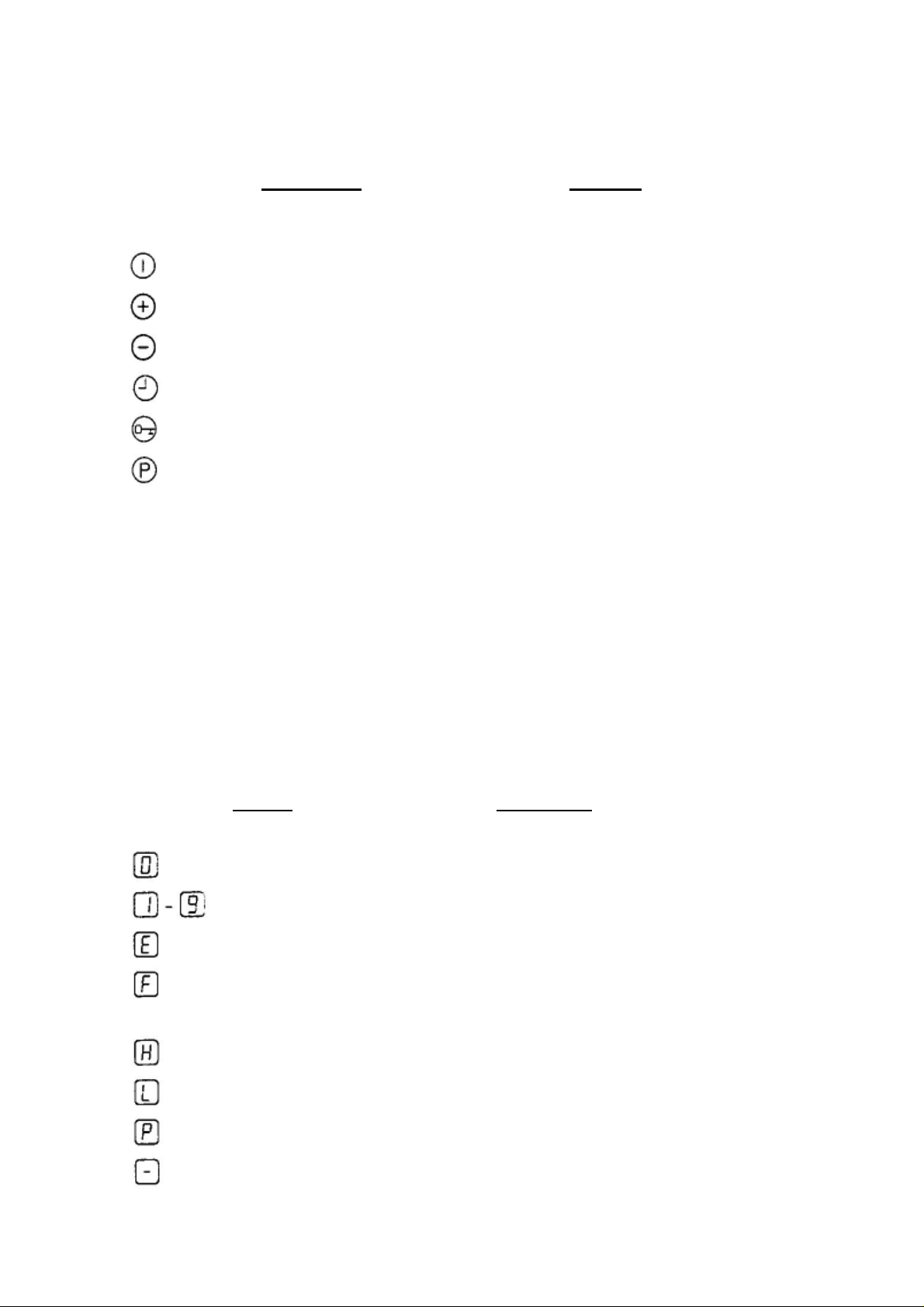

2.3 Symbol,display and keys explanation

2.3.1 Touch control sensor fields

Sensor field Function

On/Off Appliance On and Off connection

increase settings Increase cooking level/time

reduce settings Reduce cooking level/time

Timer Timer choice

Interlock Control panel lock/unlock

Power Power function Switch on/off

2.3.2 Displays

Display Description

Cooking area is switched off

Cooking levels Cooking levels are set

Fault Function failure occurs

Pot detection Cooking tablewear is unsuitable or too

small and/or it is not put on.

Residual heat Cooking area is still warm

Child safety function Interlock/Child safety is on

Power Power-function is switched off

Safety cutoff Safety cutoff is active

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 5 -

Page 6

3. Functions of appliance

e

e

3.1 Basic functions/Child safety/Power-function

Control panel Display/signal

Switch on/off the appl i a nce

Swit ch on ( I ) Touch for 2 sec onds "0"/"H", Control la m p l i ghts up

Swit ch off ( I ) Touch for 1 sec ond "H"/none, Control lamp turns off

After s wi tching on, a cook i n g l evel or a function has t o b e set wit h in 10 seconds ,

otherwise the appli ance switches off autom a ticall y.

Set cooking level

Boos t ( + ) Touch "1" t o "9"/"P"

Minim ise ( - ) Touch "9" t o " 0 "

Swit ch off Touch ( + ) and ( - ) simultaneously "0"

Locked/unlocked control panel

Swit ch on Touch (loc k) "L" (for 3 s econds)

Switch off Touch (lock) Pre-set cooking level

When switc hi ng off the app l i ance, the lock wi l l switc h off autom atical l y.

Switch on the chil dproof lock

Step 1 ( I ) Switch on the appli a nce "0"

Step 2 Touch (loc k) until the signa l s oun ds Acoustic signal

Step 3 ( + ) Touch "L"

Appli ance swiches off. The chi l dproof lo ck is switc he d on.

Override the chi l dproof lock

Step 1 ( I ) Switch on the appli a nce "L"

Step 2 Touch ( + ) and ( - ) simultaneously "0"/Aco ustic signal

Appli ance can be us ed regularly t ill the next deactivation of the appl i an c e.

The childproof l oc k can t h erewi t h be switc he d off for an is ol a t ed cookin g act;

afterwards i t remains active.

Switch off the childproof lock

Step 1 ( I ) Switch on the apparat "L"

Step 2 Touch (loc k) until the signa l s oun ds Acoustic signal

Step 3 ( - ) Touch

Appli ance swit ches off. The ch il dpro of lo c k is switc he d off.

Switch on/off power function

The power function ( P ) provides addit i onal capac i t y for the leading induct ion cook i ng zone, e. g. to bring water to boil qui ckly.

The power function wi ll be activated at the cooki ng z o ne, u front a nd t o the left, i n 8 minutes, and at th

After this t he i nd uction, the cooking zo ne switc hes automa ticall y back to cook i ng l e vel 9. If the po wer function s tops,

the c oo king zones change back aut om atical l y to the pre-set c oo king level.

Swit ch on ( P ) Touch "P"

Swit ch off ( P ) Touch "P"

Powe r Managem ent

The cooki n g zones have a maxi m al capaci ty. If t hi s service t ype exc eeds by s wi tching on t he po wer function, the power managem en t

reduces the c ooking levels t o a not he r cooking zone. The dis pl a y of t h i s cook i ng zone changes betwe

poss ible cooking level for one minut e. Afterwards the ac t ua l cooking l evel wil l be i ndi cated.

Example:

Cooking zone most recently switched on Other cooking zones

Set cooki ng l evel Set cooking level Displ ay/ac t ual cooki ng l evel

"P" 9 6 al ternately with 9/6

If the power funct i on stops , the cook i n g zones ch ange bac aut omatic a l l y to the pre-set cooking levels.

( - ) Touch "9"

cook i ng zone, up front and to the right , in 5 min ut es.

the pre-s et and max im u m

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 6 -

Page 7

3.2 Safety cutoff

Cooking field: - If you do not set a cooking level in a cook zone within approx. 10 seconds

after switching on of the cook field, the cook field switches off

automatically.

- If one or more sensor fields are covered longer than 10 seconds, e.g. by

a pot placed on it, a signal sounds and the cook field switches off

automatically.

- If all cook zones are switched off, the cook field switches off

automatically approximately 10 seconds later.

Control panel: Humidity (e.g. a wet cloth) or over-cooking liquid on the control panel switches all

cook zones off immediately.

Induction cooking zones: - During overheating (e.g. an empty-cooked pot) the cook zone switches

off automatically. „- “is displayed. Before renewed use the cook zone

must be set to „0 “and be cooled down.

- If suitable table-ware is used, „F“ flashes in the display and after 10

minutes the display of the cook zone switches off.

- If one of the cook zones is not switched off after a certain time or if the

cook stage is not changed, the appropriate cook zone switches off

automatically.

cooking level The cooking zones are disconnected with:

1-2 6 Hours

3-4 5 Hours

5 4 Hours

6-9 1,5 Hours

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 7 -

Page 8

4. Functional parts - Component data, installation situation,

dismantling

4.1 General view

Contact switch and

holding frame UI

Input electronic (UI)

Insulation

Induction coil

Module of induction

Insulation

Sensor plate aluminium

Sensor

Support spring

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 8 -

Page 9

4.2 Contact switch and input electronics (UI)

The contact switch is glued directly on the glass ceramic and over a foil conductor connected

with input electronics. The UI is fixed in a plastic framework, which is also glued directly onto on

the glass ceramic.

Fig. 1 Fig. 2

The trough framework is screwed onto the trough bath with star Torx TX20 screws. Before the

glass ceramic can be removed after the complete loosening of the star screws, it must be lightly

raised at the front, so that both 3-pole connection cable input electronics/ induction module can

be taken off (fig. 1).

Fig. 3

Input electronics are configured and provided with a standard software. After extracting from the

holding frame and taking the foil conductor off input electronics can be removed.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 9 -

Page 10

4.3 Induction coil

The spare part induction coil consists of the coil body, the white insulation and a coil holder.

Fig. 1

Fig. 2 Fig. 3

The induction coils are held with springs, which must be locked into the induction module carrier

(fig. 1). The nominal reduction rates in the trough (fig. 3) serve as position indicators.

Performance table

Chosen % of the m aximum Cooking z one Cooking zone Cooki ng zone

cooking level performance 140mm 180mm 210m m

13.0%425466

2 5.5% 77 99 121

3 10.5% 147 189 231

4 15.5% 217 279 341

5 21.0% 294 378 462

6 31.0% 434 558 682

7 45.0% 630 810 990

8 64.0% 896 1152 1408

9 100.0% 1400 1800 2200

P 2800 2800

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 10 -

Page 11

4.4 The induction module

With this series the induction modules are implemented as double modules, i.e. an induction

trough with four induction cook places has 2 induction modules (fig. 1). The induction module is

provided with a standard software and does not have not to be programmed.

Fig. 1

Fig. 2 Fig. 3

The induction module of the trough is held with four sheet metal noses (fig. 2), in each case two

above and below, which are led through the induction module carrier and interlocked afterwards.

Technical data

Main voltage: 230V

Rated frequency: 50/60Hz

Max. output: 3.6kW

Output per cooking area max.: 2.8kW

Total output: 3.6kW

Ambient temperature max.: T 85

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 11 -

Page 12

5. Alarm Symptoms

5.1 Appliance not functioning at all, cannot be switched on

Alarm

Symptom

House fuse

triggered

Cooking

field cannot

be switched

on.

Connector of the cable to

Fuse strip conductor burnt

Touch control defect. If 5VDC exist and power

Cooking

Hob

Display

None

No mains voltage or

Possible Alarm

Cause

Incorrect connection at

the power connection

terminal.

Final induction phase

defect.

incorrect connection (1

phase missing ->no

control voltage; N not

connected to terminal 4

and 5 not connected)

the Touch Control

/Display not inserted.

out and/or final induction

phase defect

Alarm Remedying

Test the pin assignment and

230VAC between N , Lines and

earth on the supply line.

See chapter Testing Power

Component

Test the pin assignment and

230VAC , Neutral, Line(s) and

earth. Both of the "N“s should be

connected to wall terminals.

Test connector at the filter and

Touch Control. Reapply the mains

voltage.

See Chapter Testing Power

Component

component already replaced:

replace the UI. Ensure that the

Touch pcb is well glued to the

glass, and that the connection wire

is well inserted.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 12 -

Page 13

5.2 Individual cooking zones do not work (partially) or work incorrectly or cannot be used

Alarm Symptom Cooking

Hob

Display

Pan does not

heat up.

No power on all

hobs

Individual buttons

cannot be used

or cannot always

be used.

Cooking hob

power too low or

not provided for a

longer duration.

"H" in display

when cooking

hob and oven

cold and

switched off.

Normal cooking

phase

Flashing

"F“

Normal cooking

phase

Touch Control defect. 1) See Chapter 5. Touch

Normal cooking

phase

"H“

Possible Alarm

Cause

Pan in the border area of the pan

detection and only works with low

power

Pan not detected. Check whether t he pots or

Coil not correctly connected. Check whether the coil lines

Distance between coil and glass

ceramic too large.

Demo mode activat ed. See Chapter demo mode

Incorrectly installed, exhaust not

possible to the front.

Unsuitable pots (bottom bent) See Chapter Pot De tection

Induction coi l i s not applied to the glass

ceramic

Fan does not start. 1) When setting a cooking

Temperature sensor defect. Replace corresponding coil

Alarm Remedyi ng

Use different pot or this pot

on a smaller hob. See

Chapter Pot Detection

Information

pans are suita ble for

induction. See Pot Detection

Information

are connected and the torque

has been adhered to.

Check whether the coil is

applied to the glass ceramic

and whether the glass was

pushed was pushe d down

when screwing in position.

Control Cooking Hobs

Information.

2) Should this not help,

replace Touch Con trol.

See chapter installation

situation.

Information

Check whether the glass

ceramic was pushed down

when being screwed in

position and the coil has

been correctly posit ion ed.

phase >0, the fan ru ns at a

slow speed. If not, check the

fan for foreign bodies,

remove these where

appropriate.

2) If necessary, replace fan.

3) Should this not succeed,

replace power component.

with temperat ure sensor.

Also see Instructions "E4“.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 13 -

Page 14

5.3 Alarm message „E“

When the appliance is switched on, „E“ / „xx“ Alarm Number is displayed in the timer display.

The affected zones are subsequently displayed with an „E“ in the cooking phase display and are

thereby disabed. The other zones can still be used.

Example:

1) Error code 8 for the left board

Alarm

Symptom

Alarm display

in the Touch

Control.

"E3“ 400 VAC detected, instead

"E4“ Coil temperature sensor

"E5“ Coil temperature sensor

Display in

the Cooking

Hob Timer

"E2“ User interface temperature

Possible Alarm

Cause

too high

of 230VAC, on left or right

module or both

defect, not correctly

connected, or broken,

display in the corresponding

zone.

defect, short, display in the

corresponding zone.

Alarm Remedying

Temperature too high due to

installation, or UI defect.

1) verify power lines connection,

on the wall

2) Should alarm still be

displayed, verify internal

connection in the hob,

3) Should alarm still be

displayed, See Chapter Testing

Power Component

1) Inspecting the contacts on

the power board. Is the

connector inserted?

2) The resistance at room

temperature (25°C) amounts to

100 kOhm. If not in this range,

replace affected temperature

sensor.

3) Should above not succeed,

replace power component

concerned.

1) Inspecting the contacts on

the power board.

2) The resistance at room

temperature (25°C) amounts to

100 kOhm.If not in this range,

replace affected temperature

sensor.

3) Should above not succeed,

replace power component

concerned.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 14 -

Page 15

Alarm

Symptom

"E6“ Communication defect

"E7“ “7.” Alarm Temperature

"E8“ Communication

"E9“ Communication defect

Display in

the

Cooking

Hob Timer

Possible Alarm

Cause

inside power board

sensor heat sink power

component E7 open

E7. short

interference between

power and User

interface.

inside user interface

Alarm Remedying

Replace identified power board.

E7, verify connector, if not OK,

Replace affected power component.

E7. Replace affected power component.

1) if left, Verify the power wiring in the

wall. If OK, Reinsert connector of UI,

Or replace cable. If not OK go to 3)

2) if Right, Verify middle connection of

cable of UI, replace cable, if not OK go to

3),

3) take cable of left power board and

connect to right power board, with a test

cable longer connect UI right to power

board left. A) same as before change

User interface, “E6” crossed change the

power board identified.

Replace User interface.

5.4 Other Alarmsymptoms

Alarm Symptom Display Possible

Buzzer defect Touch

Individual display

elements do not

illuminate or do not

do so continuously.

Pots cause noises Unsuitable

Normal

Alarm Remedying

Alarm

Cause

Replace User interface.

control

defect.

Defective

display

elements

pots.

sound level

Replace User interface.

See Chapter Pot Detection Information.

Interference noises result from the high

working frequency of the induction. This can

vary from pan to pan. When measured in

operation pursuant to EN60335 §11-3

pursuant to EN60704 with 4 pots <47dBA. A

pot with boiling water has approx. 60-62dBA.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 15 -

Page 16

5.5 Connection guideline

Power cords inside the hob

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 16 -

Page 17

5.6 Display

For details, refer to Instruction Manual - Cool top platform

Symbol Comment

„.“ Intermediate cooking levels

„-“ Induction – zone switched off because of over temperature at the coil sensor

(empty pot)

„A“ Fast heating up function („Ankochstoss“)

„E“ On alarm display see error!

„F“ Pot detection – no pot detected

„H“ Residual heat indication

„L“ Lock – Function or key lock

„P“ Power (booster) function for induction

5.7 Inductions module test

1. When alarm messages and disabled zones exist (“E“ in cooking phase display), please

make a note of the power component which is affected.

2. Check power lines and connection to user interface is connected,

3. If IGBT has become shorted, this normally means that the IGBT housing is damaged.

Replace power component.

4. Measure resistance at the IGBTs

Pin1-Pin2 or Pin2-Pin3 >50kOhm f Okay

<50Ohm f power component defect & replace

Only replace the affected power component.

„IGBT“

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

Pin 1 2 3

- 17 -

Page 18

5.8 Pot identification information

Suitable pot materials:

- Steel enamel

- Stainless steel (with magnet. bottom)

- Aluminium (with magnet. bottom)

- Cast iron

Unsuitable materials:

- Aluminium (à too much power)

- Copper

- Stainless steel (not magnetic)

- Glass

- Ceramic

The pot detection is designed for the following diameters:

Nominal burner ∅ [mm] Minimum pot bottom ∅

instruction manual [mm]

145 125 100

180 145 120

210 180 140

With regard to Ind. G4, the same diameter is stipulated in the

instruction manuals as for the previous model. However, the

real diameter which still functions is much smaller.

The performance for different pots can very by as much as +/

- 10-15%.

- As reference pots, we recommend enamelled steel pots

(e.g. Silit).

Minimum pot bottom ∅

adjusted with steel plate

[mm]

- 2-3 mm thick round steel plates in various diameters are

very suitable for testing the pot detection function.

- Sandwich bottoms can cause very unpleasant noises if

they are not correctly pressed. The same is the case

with regard to handles which are a little loose.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 18 -

Page 19

5.9 Touch Control Cooking Hobs Information

- The Touch Control works on the basis of the capacitive principle, an amortizing mass is

detected, the signal modified is treated with some rules and validated as an action.

- If the user interface is not applied to the glass ceramic, the signal for the button evaluation

is much smaller and the buttons can no longer be used, i.e. always ensure that the plastic

supports are always intact.

- Should the appliance switch itself off without the glass ceramic having been touched, this

is due to a button being activated. Either external water or material on the glass.

Instructions on the operation / possible operation errors if the buttons do not function:

- Please do not approach slowly, especially not from the side, it is better to approach the

button faster. A signal change is above all evaluated.

- Applying excessive pressure to the cooking hob will not make a difference. It is better to

release it for 5 sec. and then press the button again.

- If the adjustment of the cooking stage/timer does not continue after the button has been

released, this is due to the fact that the Touch Control receives a „Button Pressed“ signal

even from a distance of some mm.

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 19 -

Page 20

5.10 Demo mode / Self test (Service mode) / Alarm Menu

To enter the Demo mode / service mode / factory test menu , the following sequence of buttons

must be pressed:

1. Hob is off. Press main switch continuously until display is going off (without beep).

2. Press the „+“ and „ -“ buttons (2a) of both front zones together (all 4 keys togehter ) for

about 3 seconds (-> short beep).

3. Press the timer selection key (-> again short beep).

4. The display (C) shows a “d” for demo mode. If you press the timer select key again you

switch to “S” for service mode, another presee gets you to “E” the alarm menu!

5. By pressing the button “+” of a cooking zone you activate the menu.

6. By pressing the button “-“ of a cooking zone you deactivate the menu.

Demo Mode:

If demo mode is activated the display with the „d“ shows additionally a dot. After selecting the

demo mode, the electronic goes to off. Now it can be used like usual but only without heater

activation. The deactivation of the demo mode is done in the same procedure as activating. After

deactivating the demo mode the electronic must go off. Now the hob can be used in normal

mode.

Service Mode “S”

Routine:

1. Show user interface SW version

2. Show control SW version

3. Show power SW version

4. 400V detection test: “400U” blink on displays until 400V is not applied. When 400V is

detected, the buzzer ring and “OU” is shown on display until 230V is not applied.

5. Test all LEDs / Displays for 7 sec; during this time, booster is set on rear zones to test

sensors. When the time is elapsed, if the sensor are OK the test jump to the following step

otherwise “S” is shown alternatively on zones where the error occurred.

6. Zone power test: a different power level is set on each zone for 2 seconds

Alarm Mode “E”

The last 5 stored alarm codes (if >o) are displayed like an actual alarm, each for 5 sec., starting

with the oldest (read request ‘5’ Alarm code message) to the newest (read request ‘1’).

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 20 -

Page 21

6. Wiring diagrams

6.1 Example-slotted plan

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 21 -

Page 22

6.2 Example-circuit diagram

DGS-TDS-N 02.06 U. H. / A. B. © Electrolux 599 525 284 EN

- 22 -

Loading...

Loading...