Electrolux IC4 4821LF, IC4 4819LF, IC4 4825LF, IC4 4828LF, IC4 4832LF Operating Handbook

...Page 1

Operating handbook

Flatwork ironers

IC44819 – 4821 – 4825 – 4828 – 4832

LF/FLF/R/FR

• Flatwork ironer

• Flatwork ironer folder - LF

• Feeder fl atwork ironer folder - FLF

• Flatwork ironer with rear load removal - R

• Feeder fl atwork ironer with rear load removal - FR

Translated from french

01106073/GB

08.18

Page 2

.

Page 3

OPERATING

HANDBOOK

General

Precaution for use ...............................................................................................1/1

General ................................................................................................................1/2

Method of use

Dryer-ironer control panel ....................................................................................1/3

Simplifi ed instructions for using the ironer ...........................................................2/3

Feeder system control panel ...............................................................................3/3

Simplifi ed instructions for using the ironer ...........................................................4/3

Client mode .........................................................................................................7/3

Starting the machine ............................................................................................7/3

Cooling mode ......................................................................................................8/3

Automatic mode ...................................................................................................8/3

Manual mode .......................................................................................................9/3

With or without folding mode ...............................................................................10/3

Select the length of folds .....................................................................................11/3

Select the length of the fi rst fold ..........................................................................11/3

Service screen in automatic mode ......................................................................12/3

Service screen in manual mode ..........................................................................12/3

Additional instructions ..........................................................................................13/3

Precautions for use ..............................................................................................23/3

Stopping the machine ..........................................................................................26/3

Using the handle ..................................................................................................26/3

RABC Option .......................................................................................................27/3

Safety

Locking and tagging procedure ...........................................................................3/4

Safety devices .....................................................................................................4/4

Operating incidents

The linen remains stuck to the cylinder ...............................................................1/5

When the linen comes off the dryer-ironer it is not dry ........................................1/5

The folding system works without stopping .........................................................1/5

The heating does not work or works badly ..........................................................2/5

The folding system is defective ...........................................................................3/5

The machine temperature drops .........................................................................3/5

The machine stops suddenly ...............................................................................3/5

Additional instructions ..........................................................................................3/5

Maintenance

Preventive maintenance ......................................................................................1/6

Replacing ironing bands ......................................................................................7/6

Appendices

Explanation of graphic symbols ...........................................................................1/7

Washing symbols .................................................................................................2/7

Conversion of measurement units .......................................................................3/7

Lubrifi cation table ................................................................................................4/7

Table of contents

01106073

Notice

Date

00209

Page

Pages/Chapters

000

The manufacturer reserves the right to modify construction and equipment characteristics.

Page 4

01106073

0209 111

PageNotice Date

1

1. Precaution for use

OPERATING

HANDBOOK

Precaution for use

• The machine should not be used by children.

• This ironer must be used exclusively for textiles appropriate for machine ironing, which

have been previously and exclusively washed in water.

• Blankets should not be ironed.

• Be careful with synthetic linen and also with printed linen. They can melt and stick on the

cylinder.

• Do not iron articles that contain plastic, foam, sponge rubber or similarly textured rubberlike materials.

• Do not iron linens coated with solvent, paint, wax, grease or any easily infl ammable pro-

ducts.

Page 5

OPERATING

HANDBOOK

You should have found an instruction handbook and keys to open the machine casings, and

a maintenance poster to display in your laundry, inside your machine.

Depending on its destination, the dryer ironer is delivered bare or may be placed on a transport pallet and/or packed with plastic fi lm.

In some cases, it may be delivered in maritime packing (wood crate).

Please refer to the handling chapter in this instruction handbook for a description of handling

operations.

2. General

01106073

Notice

Date

10209

Page

2

Before any use, it is compulsory to read the instruction handbook.

Users must have learnt how to the machine operates.

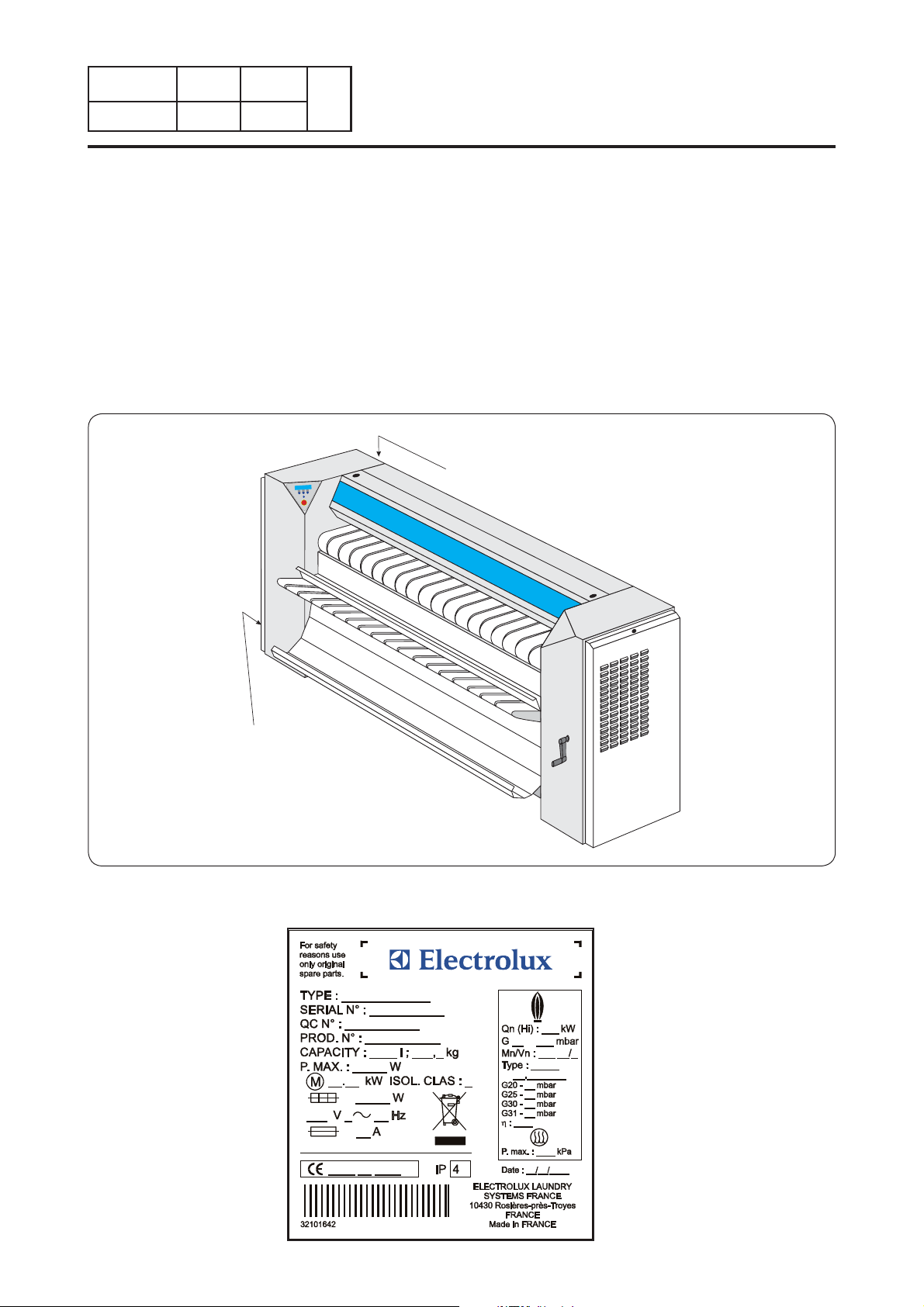

The identifi cation plate is situated on the left side.

This machine should be installed in conformance to the health and safety regulations, and only used in a suffi ciently aerated area.

Check the instructions before installing or using the machine.

Page 6

01106073

The machines described in this hanbook have a ironing capacity of 190, 210, 250, 280, 320

cm wide depending on the type. They are available with steam, electric, gas or thermal fl uide

heating.

A version of the machine with a fully automatic folding system enables one or two persons to

dry, iron and fold sheets longitudinally.

Another version with a mechanical system allows the washing to come out at the back of the

machine.

The ironing speed is adjustable as a function of the density (weight/m²) and humidity of the

washing.

0209 2

PageNotice Date

2

2. General

Adjustment label

(for gas machine only)

%

OPERATING

HANDBOOK

Identifi cation

plate

Identifi cation plate

D1090

Page 7

OPERATING

HANDBOOK

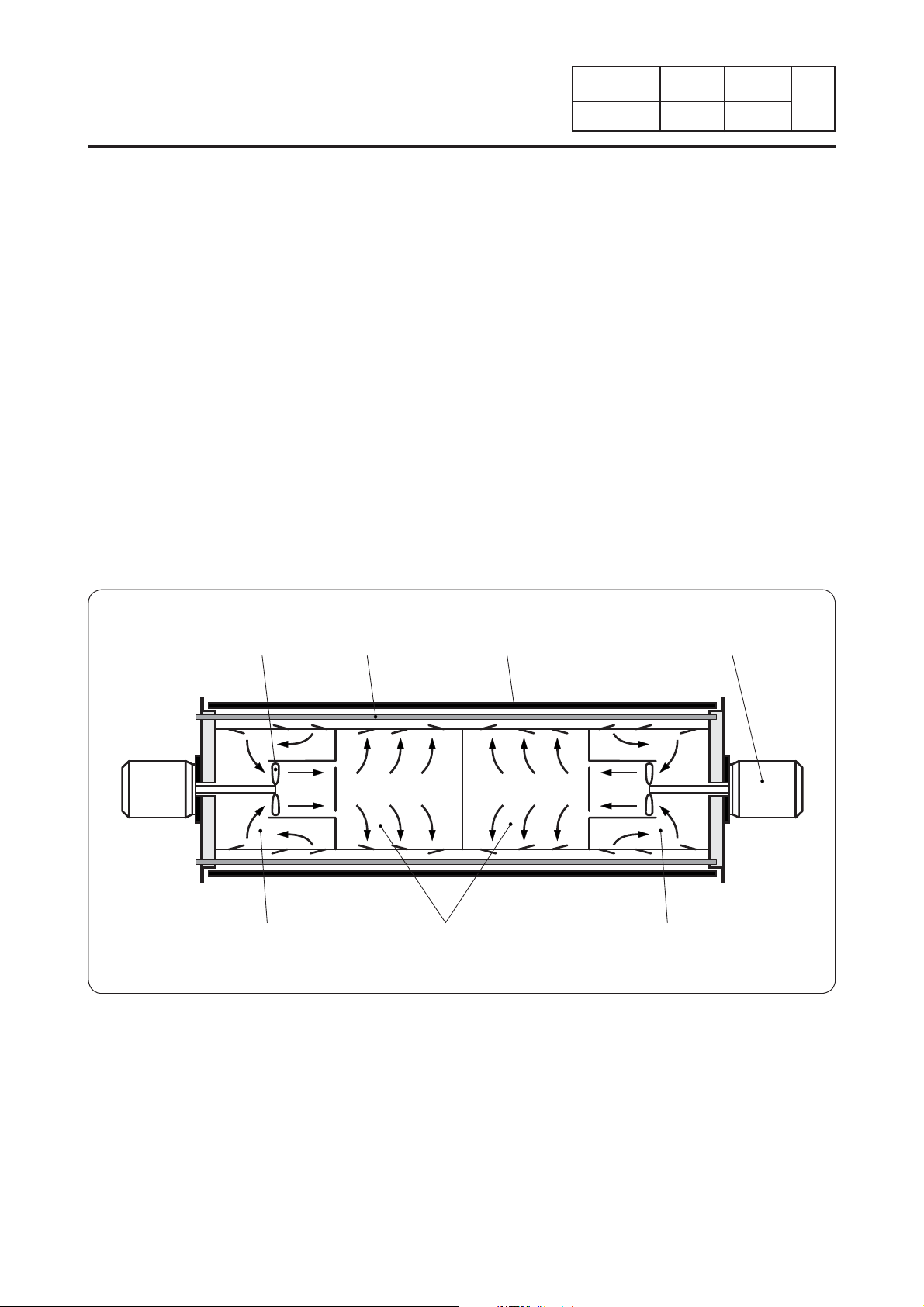

The electrically heated dryers-ironers can be equipped with a temperature regulation system

for the heating cylinder using circulating heat. Machines fi tted with a Dubixium cylinder have

a normal electric heating device.

This system provides an excellent tool to optimise the performance of the dryer-ironer for

those clients who mainly carry out staggered ironing. It prevents suddenly heating cut-outs

caused by partial use of the whole length of the machine (Patent No. 9608471).

The unused calories on the sides of the cylinder are redistributed towards the centre, where

the demand is greatest (please see the diagram below).

In this way, it is possible to limit the rise in temperature on the sides of the cylinder and the

fall in temperature in the centre of the cylinder.

2. General

01106073

Notice

0209

Date

3

2

Page

Ventilation

fan

Vacuum

chamber

Heating

element

Discharge

chambers

Cylinder

Long spindle

motor

Vacuum

chamber

D0572

Page 8

01106073

1741

4

2

PageNotice Date

OPERATING

HANDBOOK

We draw your attention on the following practices. they will have consequences on the quality of your

f nished items and can, in some cases, void the warrantly of your ironer.

RECOMMANDATIONS

AND WARNINGS

REGARDING

Multi layer items :

Worn polycotton Sheets

(cotton washed away) :

Large items

DESCRIPTIONS

(why ant what are the consequences)

sheets folded in two layers and more will be much

longer to dry. A double layer sheet will be longer to dry

than twice the time of a single layer.

The several layers of a sheet may slide against one

another depending on their material and quality. The

consequences can be a poor ironing quality (wrinkles),

will be a poor quality length foldingand most probably

an impossible cross-folding.

Polyester-cotton blended sheets have got a limited lifetime that needs to be considered. Old sheets will have

no cotton left after a certain amount of washes.

The consequences of ironing them on an ironer are :

- Increased electro-static unbearable by the machine

even if this one is equiped with an anti-static bar.

Sheets will stick to parts of the machine creating jams

and disrupting the length folding.

- Photocells may not detect the presence of the sheets,

also disrupting length folding.

Your machine cannot automatically feed items wider

than its width,

For an IC4 4819 the maximum width is : 1910 mm

For an IC4 4821 the maximum width is : 2120 mm

For an IC4 4825 the maximum width is : 2540 mm

For an IC4 4828 the maximum width is : 2750 mm

For an IC4 4832 the maximum width is : 3170 mm

Type of product concerned

Basic R LF FLF F-R FFS

XXXXXX

XXXXXX

XX X X

Size of items in general

Your machine cannot fold items longer than 3

meters

Your ironer will deliver optimum results when processing items which width is closest to the maximum

acceptable width.

Processing smaller items will alter the performance

of your ironer. In such cases, it's preferable to operate

your ironer in manual mode.

Example of sheets of 1.80 x 2.80m processed on an

IC44825FLF or FFS Gas or Electric heated:

They will have to be fed by the 1.80m width (2.80m

being wider than the machine can feed). The automatic feeding will feed in the middle of the machine leaving 37cm on either side of each sheet. This practice

will quickly lead to an overheating of the sides of the

cylinder and dramatically reduce the production of the

ironer.

You may delay the overheating of sides of the cylinder

by alternating the side through which you feed the

items.

You should always seek to use the maximum width of

your ironer.

XXXXXX

Page 9

OPERATING

HANDBOOK

01106073

Notice

1741 5

Date

Page

2

RECOMMANDATIONS

AND WARNINGS

REGARDING

Size of items for

automatic feeding

Size of items for

automatic folding

Thick items

Thin items

Particular items

Inappropriate materials

DESCRIPTIONS

(why ant what are the consequences)

The minimum size of items to be automatically Length

Folded is 90cm. Smaller sizes will be systematically

dropped or rejected if ironed in folding mode. Note

that it is highly recommended not to automatically

feed items that are much smaller than the width of the

ironer. See "Size of items in general"

The minimum size for items to be automatically cross

Folded is 110. Smaller sizes will be systematically

rejected to the rear of the FFS ironer.

Thick fabrics may lead to very thick folded items

depending on your choice of folding patern. The maximum thickness acceptable by the cross folding unit

is 40mm for the second cross fold and 80mm for the

third cross fold.

You can modify this thickness by modulating the

length folding patern and/or cancelling the third cross

fold (on IC44825FFS or IC44832FFS). Please refer to

the programming manual.

Thin and light fabrics (below 80 gr/m²) may cause

disruption in the length folding and not allow optimum

quality of folding. They may also jam. You can iron

them with precaution.

Your ironer is designed to process f atwork only, such

as sheets, duvet covers, pillow cases, table cloths and

napkins. Any other items may cause malfunctions of

your ironer and may void your warranty. If you are

unsure, refer to your nearest Elecrolux Professional

distributor for advise.

Your ironer is not designed for processing the following items :

- Padded covers : they are too thick and of inapro-

priate material

- Terrycloth : it must be tumble dried. Ironing them

will make them very rough.

- Fitted sheets : elastics may deteriorate following

exposure to excessive heat and possibly melt. Depending on their shape and material, they may be ironed if

fed into the ironer with elastics facing upward so that

they are not in direct contact with the cylinder. In no

case they must be automatically fed as the elastics will

greatly disrupt the feeding. They cannot be automatically folded for the same reason.

- Garments : they are of complex shape (not f at) and

must be ironed with appropriate f nishing equipment.

- Aprons : they are often f at but feature cords and

strings that will jam into moving parts of your ironer.

- Shower curtains : their material will not sustain the

heat and they will melt on the cylinder.

Your ironer is designed to safely process cotton, polyester-cotton and f ax. For any other material, please

refer to your linen supplier and you nearest Electrolux

Professional distributor.

Type of product concerned

Basic R LF FLF F-R FFS

XX X

X

X

XXXXXX

XXXXXX

XXXXXX

Page 10

01106073

1741

6

2

PageNotice Date

OPERATING

HANDBOOK

RECOMMANDATIONS

AND WARNINGS

REGARDING

Ironer maintenance

Reject ratio

PlivitTM Length Folding

DESCRIPTIONS

(why ant what are the consequences)

Your ironer is designed to run 8 hours without interruption. Every 8 hours and at other set intervals there

are a number of required maintenance operations to

be performed by yourself or your service engineer. It

is critical that you strictly follow these requirements

for your ironer to run properly. Please refer to chapter

"Preventive maintenance" of this manual. Should you

run your ironer for more than one shift, you must ensure that these maintenance operations are performed

between shifts.

In addition to these maintenance operations, your

ironer should be stopped, cooled and shut down for at

least one hour every 24 hours.

Because faltwork is only f at and rectangle the day you

buy it and then rapidly changes shape and charateristcs

after each wash, it is normal that 4% to 5% are rejected

by the machine.

Note that the quality of feeding will inf uence the

quality of folding. Items may be rejected because they

have not been fed properly. Static electricity and dirty

photocells will also interfere with the performance of

your ironer. Refer to "Preventive maintenance" chapter

of this manual.

Your ironer performs a Plivit

It is different from an edge to edge folding and from an

accordion folding. Refer to Chapter 03 page 26 for

explanation and illustrations of various folding paterns.

TM

Length Folding patern.

Type of product concerned

Basic R LF FLF F-R FFS

XXXXXX

XX X

XX X

Buttons on Duvet covers

In order to obtain consistent sizes of folded items, sorting f atwork per size before ironing is paramount.

Some duvet covers feature various types of fasteners

that can be buttons, velcro, in plastic, metal or wood

etc… These duvet covers may be ironed making sure

that fasteners are facing up on the feeding table. The

drying in the area of the fasteners will be longer than

the rest of the duvet cover. This is normal due to the

multi-layer of textile in this area and its complex

shape. Lying these layers f at on the feeding table will

help with a more homogeneous drying.

Note that if the thickness of the duvet cover plus the

buttons/fasteners is greater than 8mm, it may interfere

with the f nger guard protection of your ironer and

stop it. This f nger guard is a safety device to protect

operators getting their f ngers caught and driven into

the ironer.

XXXXXX

Page 11

OPERATING

HANDBOOK

Notice

1741 701106073

Date

2

Page

This page is left blank on purpose.

Page 12

01106073

0209

1

3

PageNotice Date

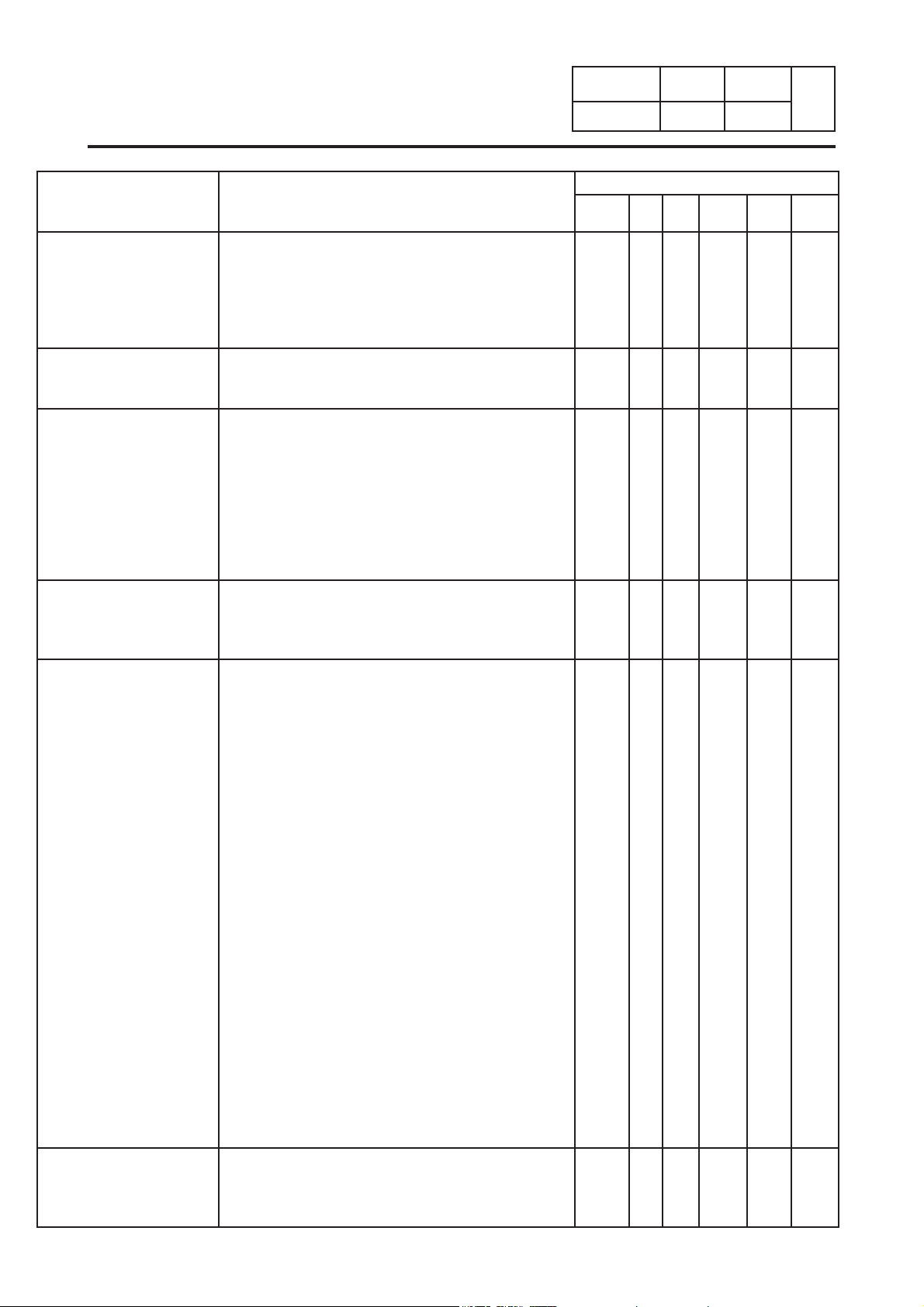

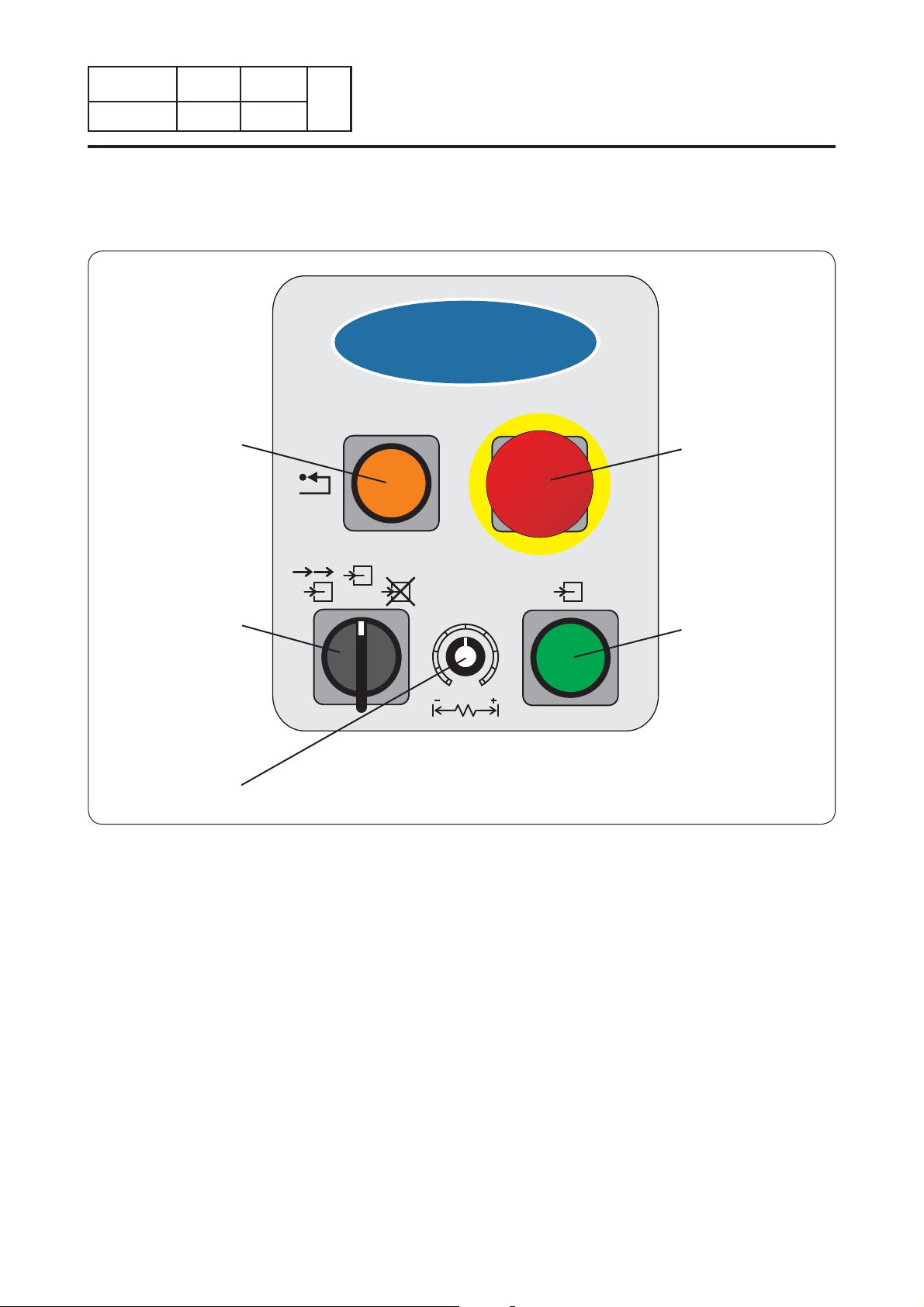

Dryer-ironer control panel

Stand by

START

%

3. Method of use

OPERATING

HANDBOOK

Display screen

Functions keys

Function key assignments vary

according to the menu displayed

on the screen during operation

This indicator lights up when the

linen removed from the dryerironer is not completely dry.

Emergency stop button

Emergency stop

The emergency stop must be unblocked, if not the machine will not work (to unblock, turn the

red button to the right).

If the machine for some reason has to be stopped, abnormal or dangerous running, press

emergency stop button.

Release the emergency stop, by turning it clokwise only after checking what motivated this

stop.

D1094

D0543

D0544

Page 13

OPERATING

HANDBOOK

3. Method of use

01106073

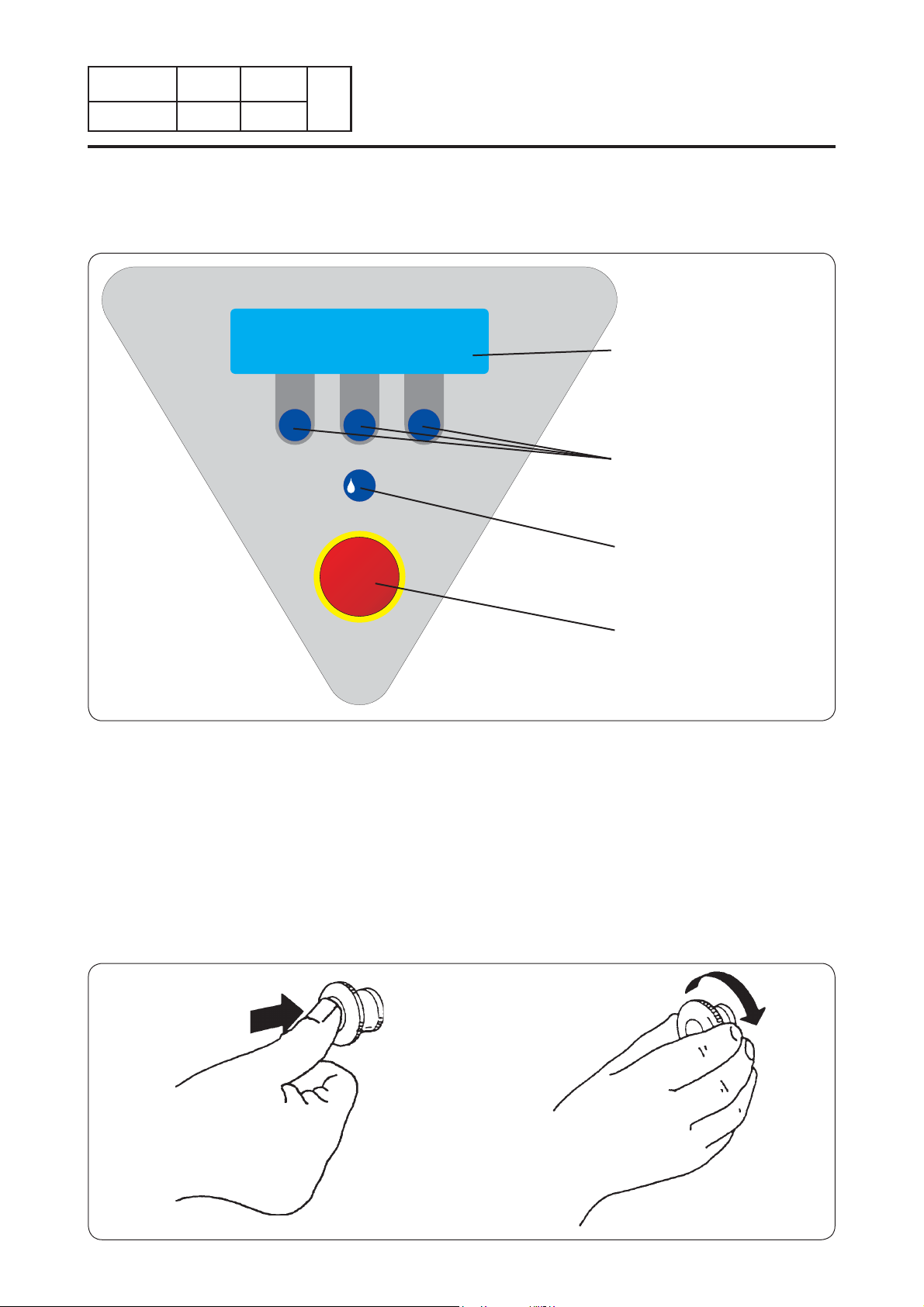

Simplifi ed instructions for using the ironer

Notice

0209 2

Date

Page

3

1

2

3

Switch

on the

main

switch,

open

the gas stop

valve or the steam

valve.

Manual Mode : Adjust the order temperature on the wished value thanks to keys (-)

or (+) and push on OK.

Set Temp : 180°C

- + OK

Folding : You should choose from the NO

folding, FIX folding (manual) or PLIVIT

(automatic) modes and move the reception

tank upwards.

NO FIX PLIVIT

Wait for displaying of the following message and press the

central key.

Stand by

START

Folding

When it begins operating, the

machine is set to "automatic

mode". You can now insert

sheets.

Dx °C 2.5m/mn 000

MANU PLI NEXT

Manual Mode : Adjust the ironing speed

on the wished value thanks to keys (-) and

(+) and push on OK.

Set Speed : 2.0 m/mn

- + OK

4

5

6

Safety : The machine must stop when the

mobile safety protector (hand safety) is

switched on.

Check operation

of this protection

every day.

Ironing :

Place the washing to be ironed on the

feeding table.

Stopping the machine : Push on any key to display "Select

Running Mode" and push on STOP.

Do not use the folding function during the cooling phase.

Leave the machine cool down until the following message has

disappeared.

In an emergency, pressing the

hand safety bar will stop the

machine.

Ignition fault on gas heating machine :

This message keeps on fl ashing over 30

seconds if a fault occurs when igniting the

gas burner.

Gas Ignition

Cool-Down : xx°C

START

Error

Switch

the

main

switch

off,

close the

gas stop valve or

the steam valve.

Page 14

01106073

0209

3

3

PageNotice Date

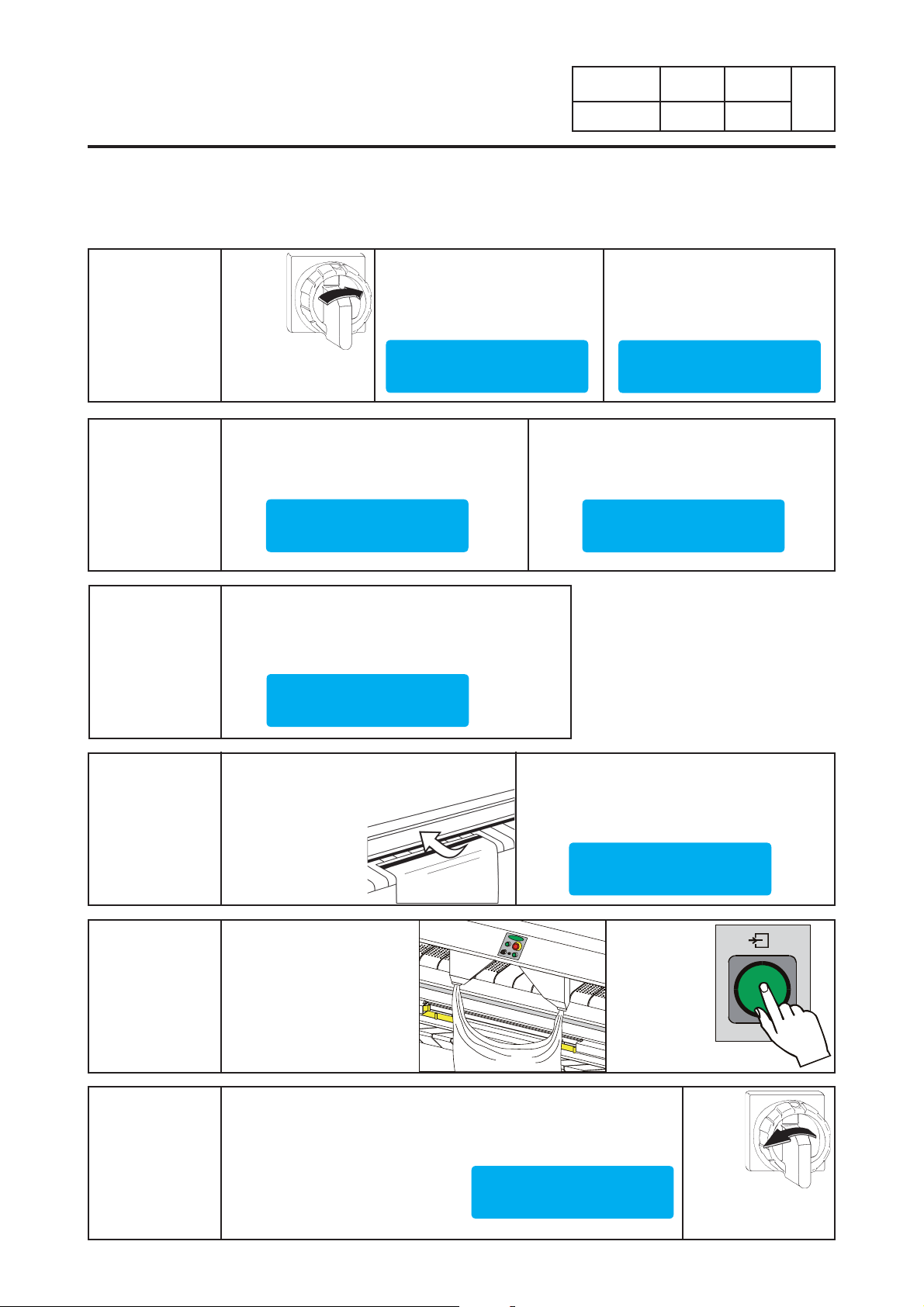

Feeder system control panel

Feeder system start

button and fl ashing

fault indicator light

3. Method of use

OPERATING

HANDBOOK

Emergency stop

button

Selector button With

feed, Semi-automatic

feed, or Without feed.

Gripper tension

adjustment button.

3

2

1

4

5

Feedind start pushbutton

D1118

Page 15

OPERATING

HANDBOOK

3. Method of use

01106073

Simplifi ed instructions for using the ironer

Notice

0209 4

Date

Page

3

1

2

3

Switch

on the

main

switch,

open

the gas stop

valve or the steam

valve.

Manual Mode : Adjust the order temperature on the wished value thanks to keys (-)

or (+) and push on OK.

Set Temp : 180°C

- + OK

Folding : You should choose from the NO

folding, FIX folding (manual) or PLIVIT

(automatic) modes and move the reception

tank upwards.

NO FIX PLIVIT

Wait for displaying of the following message and press the

central key.

Stand by

START

Folding

When it begins operating, the

machine is set to "automatic

mode". You can now insert

sheets.

Dx °C 2.5m/mn 000

MANU PLI NEXT

Manual Mode : Adjust the ironing speed

on the wished value thanks to keys (-) and

(+) and push on OK.

Set Speed : 2.0 m/mn

- + OK

4

5

6

Safety : The machine must stop when the

mobile safety protector (hand safety) is

switched on.

Check operation of

this protection every

day.

In Automatic mode :

- First select the mode

With feeding.

- Pinch both edges of a

sheet length in the clips.

Stopping the machine : Push on any key to display "Select

Running Mode" and push on STOP.

Do not use the folding function during the cooling phase.

Leave the machine cool down until the following message has

disappeared.

In an emergency, pressing the

hand safety bar will stop the

machine.

Ignition fault on gas heating machine :

This message keeps on fl ashing over 30

seconds if a fault occurs when igniting the

gas burner.

Gas Ignition

Feeding:

Push on the

button Start

Feeding.

Cool-Down : xx°C

START

Error

Switch

the

main

switch

off,

close the

gas stop valve or

the steam valve.

Page 16

01106073

0209

5

3

PageNotice Date

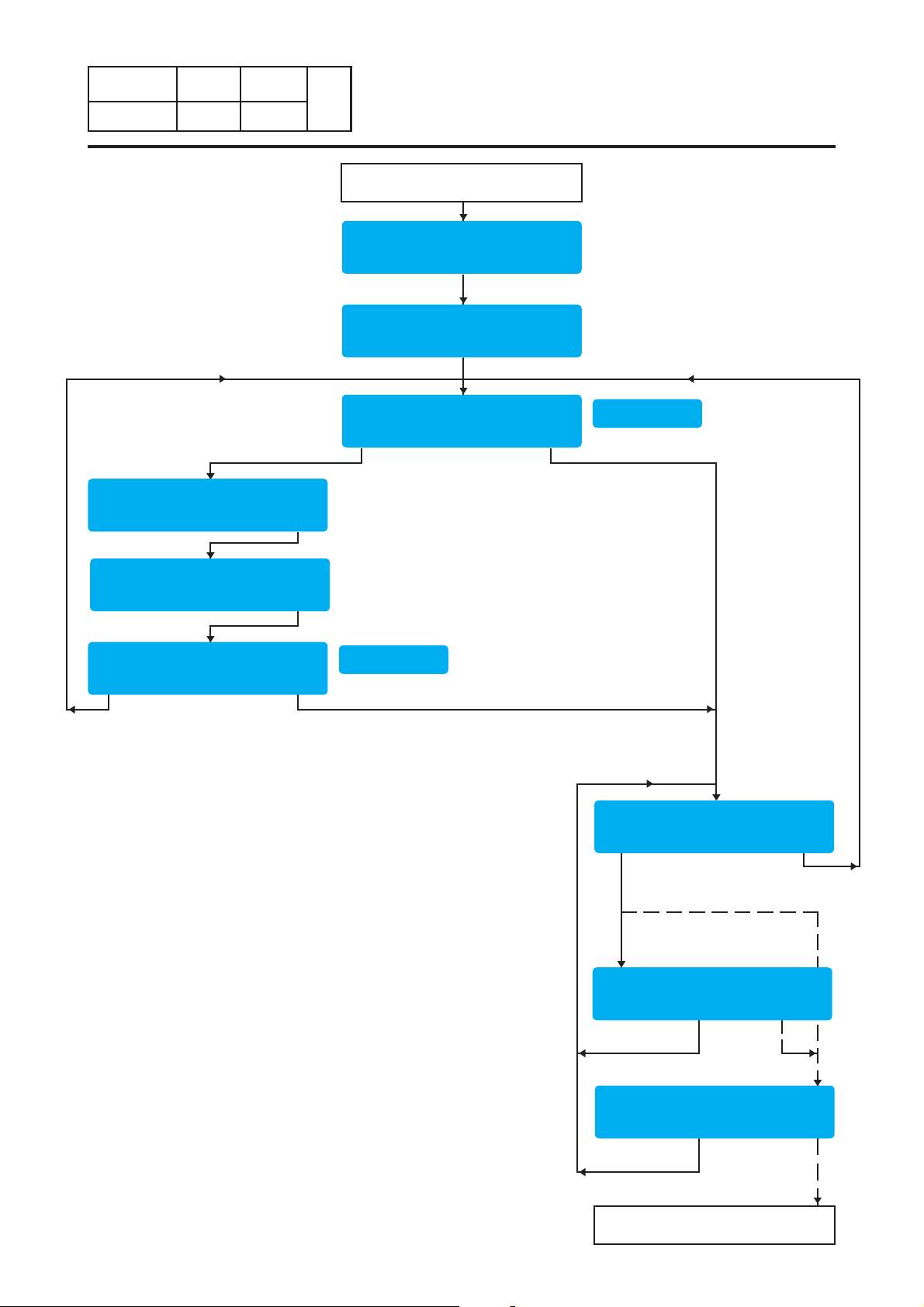

3. Method of use

OPERATING

HANDBOOK

Without folding

emp : 180°C

Set T

- + OK

Set Speed : 2.0m/mn

- + OK

ON

DIAMMS V xx.xx

Stand-by

START

Dx °C 2.5m/mn 000

MANU NEXT

T<100°C

Warm-up

Mx 160°C 2.5m/mn 000

DIAMMS NEXT

T<100°C

Warm-up

Warm-up

STOP RST-CNT NEXT

T<100°C

T>100°C

Cool-Down : xx°C

START

T<100°C

Stand-by

START

OFF

Page 17

OPERATING

HANDBOOK

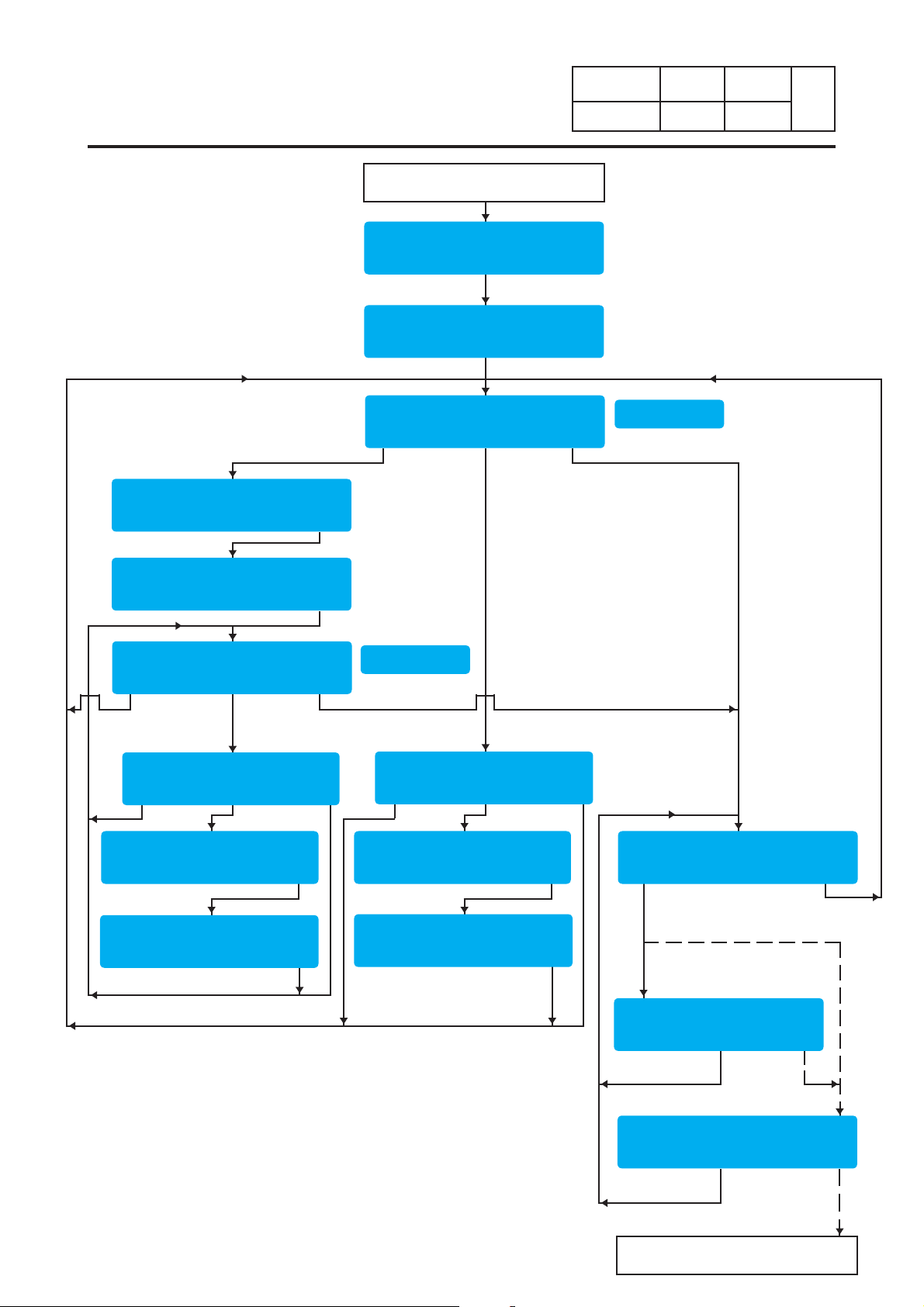

3. Method of use

01106073

Notice

0209 6

Date

Page

3

With folding

Set Temp : 180°C

- + OK

Set Speed : 2.0m/mn

- + OK

ON

DIAMMS V xx.xx

Stand-by

START

Dx °C 2.5m/mn 000

MANU PLI NEXT

T<100°C

Warm-up

Mx 160°C 2.5m/mn 000

DIAMMS PLI NEXT

Folding

NO FIX PLIVIT

Size of folds : 20

- + OK

Offset 1st Fold : 00

- + OK

T<100°C

Warm-up

Folding

NO

FIX PLIVIT

Size of folds : 20

- + OK

Offset 1st Fold : 00

- + OK

Warm-up

STOP RST-CNT NEXT

T<100°C

T>100°C

Cool-Down : xx°C

START

Stand-by

START

OFF

T<100°C

Page 18

01106073

0209

7

PageNotice Date

Client mode

Starting the machine

3

3. Method of use

OPERATING

HANDBOOK

DIAMMS V: xx.xx

EMERGENCY STOP

RESET PUSH BUTTON

Start-up screen

Turn on the power to the machine using the

machine’s main switch.

appear on the screen for 4 seconds.

"Emergency stop" warning message

If the screen displays this message, check whether

the emergency stop button has been operated.

The software version will

EMERGENCY STOP

START

Stand by

START

Reset the emergency stop button and confi rm by

pressing the central key

In all cases, you will return to the previous menu.

Accessing the start-up menu

The machine now asks you to press the central key

to exit standby mode so as to display the pull-down

menus and select the machine’s operating modes.

.

Page 19

OPERATING

HANDBOOK

Warm-up

MANU NEXT

3. Method of use

01106073

0209 8

3

Notice

Warm-up

As soon as the machine is turned on, the "Start

heating" command is given. The cylinder temperature

begins to rise.

By default, the machine is set for automatic mode.

The service screen appears as soon as the sheets

have been inserted or when the required temperature

is reached.

Date

Page

Cooling mode

Warm-up

STOP RST-CNT NEXT

Cool-Down : xx°C

START

Automatic mode

Mx 160°C 2.0m/mn 000

DIAMMS NEXT

Cooling mode

When the STOP

operation, the machine will switch to standby and the

heating system will be switched off.

The screen will remain in this mode as long as the

temperature of the cylinder remains above 100°C

(212°F).

The screen then displays the following message.

function is requested during

Stand by

START

You can now switch off the machine.

RST-CNT resets the sheet counter.

Selection of the automatic mode

When it starts up, the machine is set for automatic

mode by default. However, you can switch over to

manual mode at any time.

The "

M" in the upper left-hand corner shows that you

are in manual mode. To return to automatic mode,

all you need to do is to press once on the "DIAMMS"

button.

The "X" behind the letter "M" can take several forms:

• "F" if you have chosen the "FIX" folding mode.

• "P", if you have chosen the "PLIVIT" folding mode.

• If nothing is shown, this means that folding is

deactivated.

Page 20

01106073

0209

Manual mode

9

3

PageNotice Date

3. Method of use

OPERATING

HANDBOOK

Dx °C 2.5m/mn 000

MANU NEXT

Set Temp : 180°C

- + OK

Selection of Manual mode

If you press MANU, you will switch to manual mode.

In this mode you use the following menus to select

the temperature and the ironing speed you wish to

apply to the machine.

The "X" behind the letter "D" can take several forms:

• "F", if you have chosen the "FIX" folding mode.

• "P", if you have chosen the "PLIVIT" folding mode.

•

If nothing is shown, this means that folding is

deactivated.

Each changeover from manual mode to automatic

mode automatically resets the sheet counter

Temperature setting

This screen does not appear on machines

equipped with a steam heating mode.

The screen will now ask you to set the ironing

temperature.

The ironing temperature can be adjusted in

increments of 5 degrees Celsius (or 9 degrees

Fahrenheit) by pressing.

Press

OK to confi rm the temperature.

Note: if you request a temperature lower than

120°C (248°F), the screen will display a (-) sign to

indicate that the heating has been switched off

and allow the machine to operate without heating.

.

Set Speed : 2.0m/min

- + OK

Ironing speed

The screen now asks you to select the ironing speed.

The ironing speed can be set between and minimum

and a maximum value specifi ed in the Settings menu.

The value can be adjusted in increments of 1/10 of a

metre (or 3/10 of an inch) by pressing.

Press

OK to confi rm the ironing speed.

It should be noted that the minimum and maximum

ironing values depend on the converter adjustment

settings.

Page 21

OPERATING

HANDBOOK

3. Method of use

With folding or without folding mode

Dx °C 2.5m/mn 000

MANU PLI NEXT

01106073

0209 10

3

Notice

Selection of With folding or Without

folding mode

This screen will only appear if you have replied

YES when setting the machine's starting

parameters.

The screen now asks you to select the with folding or

without folding mode.

Date

Folding

NO FIX PLIVIT

Page

If you do not want to fold, press "NO".

If you wish to use the manual folding function, (in

other words by adjusting the length of the desired

folds), press on "FIX".

In the opposite case, press on "PLIVIT" in order to

have the machine carry out automatic folding.

It should be noted that by returning to this screen

and reselecting one of the two options, you can

reinitialise the folding system in the event of

incorrect operation.

Page 22

01106073

0209

11

3

PageNotice Date

3. Method of use

OPERATING

HANDBOOK

Following screens are displayed only if your machine includes the folding option and the manual

fold adjusting.

Select the length of folds

Size of folds : 20

- + OK

Lenght of fold

This screen enables to manually select the fold length

while folding.

Before feeding in a sheet, choose the desired fold

length according to the length of the sheet.

To calculate the length of the folds, you should

measure the length of the sheet and then estimate a

fold length, bearing in mind that you should always

divide by an even number of folds (minimum four).

an example :

• Sample values : for a sheet of 240 cm, we obtain

6 folds of 40 cm or 8 folds of 30 cm. On the other

hand, it is not possible to have 4 folds of 60 cm.

After an initial trial, you should then fi ne-tune the

folding function by increasing or reducing the fold

length: for example by increasing an initial fold value

of 40 cm to 41 cm or reducing it to 39 cm.

The fold length can be adjusted from 20 to 48 cm per

steps of 1 by pressing the two left keys.

Valid by pressing the key OK.

As

Select the offset of the fi rst fold

Offset 1st Fold : 00

- + OK

Length of

folds

Shrinkage

of the fi rst

fold

Sheet with

6 folds

D1068

Length of the fi rst fold

This screen makes it possible to manually select the

length of the fi rst folds during the folding process in

order to adjust the length of the sheet tail with the

other folds.

•

Sample values: with a sheet of 265 cm and 8 x 35

cm folds, you can set the fi rst fold at 20 cm (with

an edge margin of 15 cm) followed by 6 folds of

35 cm.

• Sample values: with a sheet of 265 cm and 6 x 45

cm folds, you can set the fi rst fold at 40 cm (with

an edge margin of 5 cm), followed by 4 folds of 45

cm.

Feed problems or problems concerning the shape of

the sheets (which can sometimes be irregular), may

lead to the last fold "overshooting".

• Sample values: if you have selected folds of 45

cm and if after having modifi ed the edge margin

setting, the fi nal folds exceed 10 cm, you should

increase the fold length to 47 cm :

[45 cm + (10 cm / no. of folds)] = [45 + (10 / 5)]

in order to adjust the tail of the sheet.

By pressing the two buttons on the left, the value

for the fi rst fold can be adjusted from 0 up to half of

the "fold length" value previously set (with the value

increasing by 1 each time you press the button).

Valid by pressing the key OK.

Page 23

OPERATING

HANDBOOK

3. Method of use

Service screen in Automatic mode

Dx °C 2.5m/mn 000

MANU NEXT

01106073

0209 12

3

Notice

Service screen in automatic mode

The values for the current use of the machine are

shown on the fi rst line of the screen.

• The

The two following values show:

• The ironing speed

• The sheet counter information

In automatic mode (DIAMMS), the cylinder

temperature will not be displayed. This is managed by

the machine itself. Only the fl ashing "°C" indicator is

shown.

The second line displays the commands accessible

from the buttons on the panel.

"D" shows that you are in automatic mode

(DIAMMS).

Date

Page

Service screen in Manual mode

Mx 160°C 2.0m/mn 000

DIAMMS NEXT

Service screen in Manual mode

The fi rst line of the screen displays the values for the

current use of the machine.

• The

The following three values show:

• The current cylinder temperature

• The ironing speed

• The sheet counter information.

Various indications regarding the temperature of the

ironing cylinder are displayed:

"M" shows that you are in manual mode.

• If the temperature indicator blinks, this means the

machine is preheating.

• A (-) sign indicates that the temperature of the

cylinder is below 100°C (212°F).

• The current temperature is displayed when the

temperature of the cylinder is between 101°C and

245°C (213°F and 470°F)).

Note: values 101-245°C are minimum and

maximum temperature that the electronic

programmer can display. The maximum ironing

temperature cannot reach 245°C (470°F), a

safety thermostat automatically cuts off heating

before reaching this value.

• A (+) sign indicates that the temperature of the

cylinder is above 245°C (470°F).

At this point, press one of the three keys to return to

the manual/automatic mode selection display. Use

this function to change the set temperature or ironing

speed.

The second-line displays the commands accessible

from the buttons on the panel.

Page 24

01106073

0209

13

3

PageNotice Date

3. Method of use

OPERATING

HANDBOOK

Complementary instructions for starting up a machine with gas

heating.

The ignition of the burner is delayed by 30 seconds following the start command in order to

allow for the pre-ventilation of the combustion chamber.

The machine will be ready to be used after the following message disappears :

"Error Gas Ignition".

NOTE: the noise at the inter-ignition is not an explosion. It is a normal phenomenon.

Complementary instructions for starting up a machine with

electrical heating.

The typical ironing temperature is 150 to 180 °C (300 °F to 356 °F). You just have to set the

electronic thermostat to the required temperature.

In automatic mode, the ironing temperature is defi ned and managed by the machine.

Complementary instructions for starting up a machine with

steam heating.

Note that the temperature is directly related to the steam pressure (see table bellow).

The typical ironing temperature is 150 to 180 °C (302 °F to 356 °F).

On the contrary of a gas or electric heated machine, for a steam heated machine, you just

have to adjust the ironing speed regardingthe linen and its water retention.

Correspondence between Steam pressure / Temperature

Manometric pres-

sure in bars

300 400 500 600 700 800 900 1000

(3) (4) (5) (6) (7) (8) (9) (10)

Temperature in

°C

143 151 158 164 169 174 179 183

Page 25

OPERATING

HANDBOOK

3. Method of use

01106073

Notice

Date

140209

Page

Additional instructions for using an ironer with rear delivery

Two emergency push buttons are located at the rear of the machine in order to

ensure the safety of the employees.

To underline that a sudden stop of the ironing cylinder with temperature above 120

°C (248 °F) can damage the ironing belts.

After an action on the emergency push

button, re-starting the ironer is only possible after pushing the ON key and then the

heating ON key.

D1091

3

Page 26

01106073

0209

15

3

PageNotice Date

3. Method of use

OPERATING

HANDBOOK

Additional instructions for using a machine with automatic folding

Even if your ironer is equipped with the automatic folding function, a "With folding/Without

folding" mode makes it possible for you to use your ironer without the automatic folding

function. In this case, you simply need to move the reception tank upwards in order to enable

the linen to leave the machine unfolded, and then select the "Without folding" function on the

command panel.

Ironing of small items of linen, without using the feeding system or the

automatic folding system.

• Close the fl ap (A) so as to be able to

stand as close as possible to the machine.

B

• Leave the linen collector (B) in the

horizontal position to receive the small

items of linen as they are ironed.

If the tank is in the wrong position to receive unfolded linen, an electronic device prevents

you from using the ironer in the folding mode, even if you have selected the folding mode via

the command panel. The message "Warning: tank position error" is then displayed on the

command panel.

To return to the automatic folding mode, you should select the "with folding" mode and then

lower the reception tank. The linen will then be released directly on to the reception table.

Ironing with the automatic feeding

system and the automatic folding system

A

D1099

• Open the fl ap (A) to allow the linen to

hang correctly during smoothing.

• Swing the linen collector (B) into the

vertical position to form a box with the

fl ap.

NOTE: to ensure easy handling of the reception tank, it is recommended that you

operate this manually from its centre (between the two arrows inlaid on the front

edge of the tank).

A

B

D1100

Page 27

OPERATING

HANDBOOK

3. Method of use

01106073

Notice

0209 16

Date

Folding characteristics (machine with folding function only)

• Dimension of sheets compatible with folding:

Min. length : 90 cm (35")

Max. length : 355 cm (140")

• Fold dimensions :

Min. length: 20 cm (8")

Max. length : 50 cm (24")

• Number of folds :

4 folds min.

10 folds max.

• Minimum feeding separation distance between two sheets : 10 cm (4")

• Dimension of the fi rst fold before the complete sheet measurement (advance folding) :

25 cm (10")

• Dimension of the second fold before the complete sheet measurement (advance folding) :

35 cm (14")

Page

3

• When a sheet is too long, folding starts before the complete sheet measurement, this is

advance folding. The machine then automatically adjusts the folds as a function of the

measurement made.

Automatic feed characteristics (machine with feed function only).

• Gripper movement speed

• The sheet size must be between 85% and 100% of the usable width of the dryer-ironer.

Page 28

01106073

0209

17

3

PageNotice Date

Table for adjustment of folding values

Note : Only the following values garantee a correct folding.

3. Method of use

OPERATING

HANDBOOK

L

100

105

110

115

120

125

130

135

140

145

150

155

cm

90

95

N

=25 - -

X

26

28

29

30

31 21 -

33 22 -

34 23 -

35 23 -

36 24 -

38 25 -

39 26 -

40 27 -

41 28 21

--

--

--

--

N

L

cm

185 X

190

195

200

205

210

215

220

225

230

235

240

245

250

6 8 10 12 8 10 1246 8

=33 24 - -

33 25 - -

34 26 21 -

35 26 21 -

36 27 22 -

37 28 22 -

38 28 23 -

38 29 23 -

39 29 24 -

40 30 24 -

41 31 25 20

42 31 25 21

43 32 26 21

43 33 26 22

N

L

cm

280 X

=36 29 24

285 37 30 25

290

295

300

305

310

315

320

325

330

335

340

345

38 30 25

38 31 25

39 31 26

39 32 26

40 32 27

41 33 27

41 33 28

42 34 28

43 34 28

43 35 29

44 35 29

44 36 30

N

32007985

L (cm)

255160

260165

265170

270175

275180

44 33 27 2243 28 21

45 34 27 2344 29 22

46 34 28 2345 30 23

47 35 28 2346 31 23

48 36 29 2448 32 24

350

45 36 30

R=5

20< <48X

(cm)

Page 29

OPERATING

HANDBOOK

3. Method of use

01106073

Notice

Instructions for using the feeding system

The feed device includes a command panel with fi ve buttons or indicators.

The feeder operates independently of the automatic folding system.

The ironer can be used in a variety of ways:

• ironer on its own for small items of linen,

• the ironer together with the feeding system,

• the ironer together with the automatic folding system,

• ironer together with the feeding system and the automatic folding system.

0209 18

Date

Page

3

Ironing of small items of linen, without using the feeding system or the

automatic folding system.

• Close the fl ap (A) so as to be able to

stand as close as possible to the machine.

• Leave the linen collector (B) in the

horizontal position to receive the small

items of linen as they are ironed.

• Leave the shelf (C) in a vertical posi-

tion to allow access to the container of

the feeding table in order to store the

linen in it.

B

A

D1101

C

D1102

Page 30

01106073

0209

19

3

PageNotice Date

Ironing with the automatic feeding

system and the automatic folding system

• Open the fl ap (A) to allow the linen to

hang correctly during smoothing.

• Swing the linen collector (B) into the

vertical position to form a box with the

fl ap.

3. Method of use

A

OPERATING

HANDBOOK

B

D1103

• Raise the shelf (C) as shown in the

diagram opposite to cover the container of the feeding table so that it rests

on the stop (4).

• If you wish to lower the shelf (C), pro-

ceed as shown in the diagram opposite.

C

4

1

3

2

D1104

C

1

2

D1105

Page 31

OPERATING

HANDBOOK

• Turn the selection button to select the

mode :

- Automatic feed

- Semi-automatic feed

3. Method of use

• Press the initialisation button to po-

sition the clamps in operating mode

(clamps in the centre of the machine).

01106073

Notice

0209 20

Date

Page

3

Note: in the event of blockage or

stoppage of the machine, of restarting,

power failure or if this indicator begins

fl ashing, you must press this same

button again to reinitialise the feeder.

• Take a large edge of the sheet in your

hands and place one corner in one

clamp and the other corner in the other

clamp. Do not leave over 3 to 4 cm

outside the clamp.

3-4 cm

D1119

Page 32

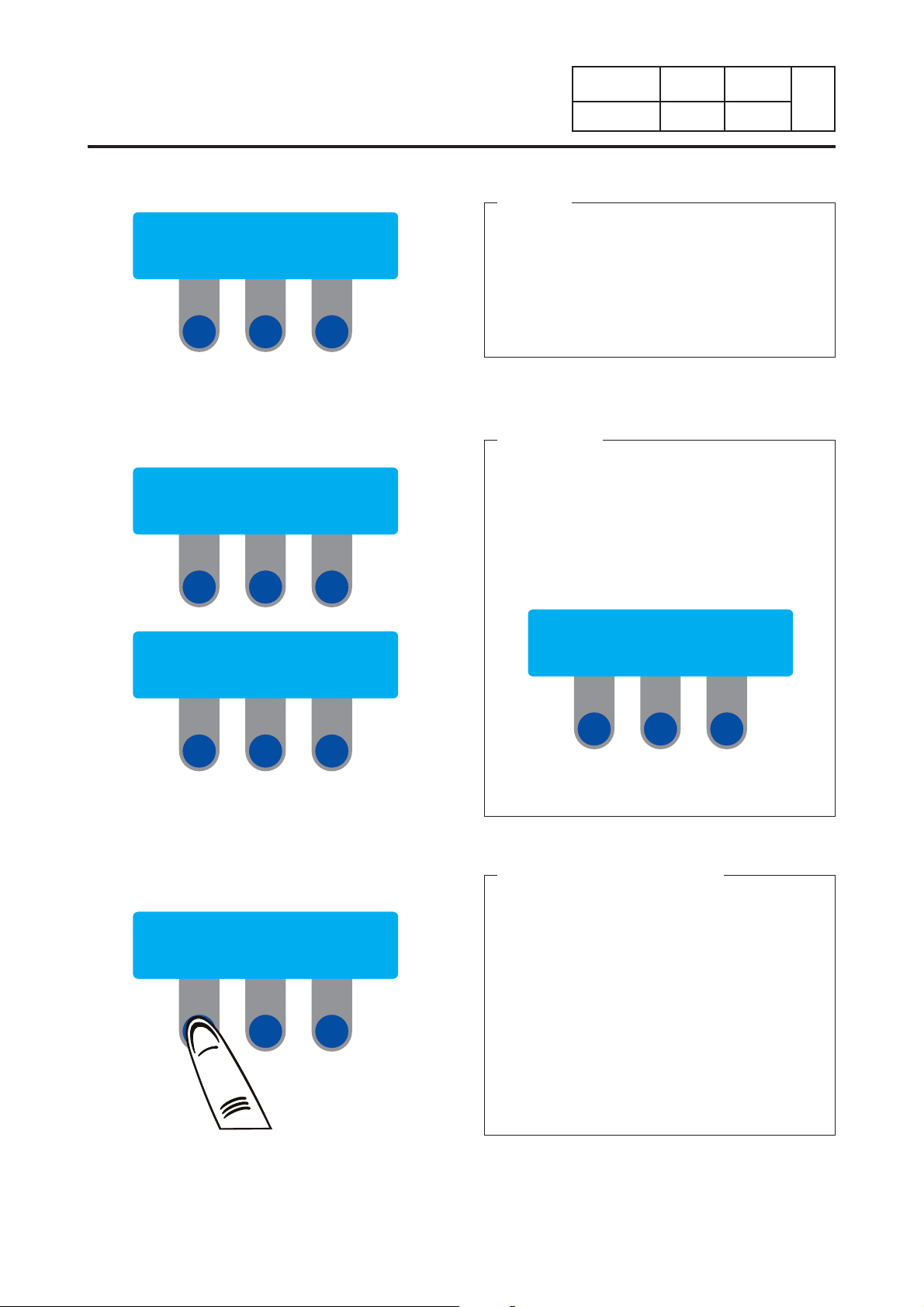

1

2

3

4

5

01106073

0209

21

3

PageNotice Date

• Press the feeder start button.

Note : If the machine is set on the

semiautomatic feeding mode, you must

push this start button to move the clamps

in front position.

• Turn this button to adjust the sheet

tension using the grippers before it is

released on to the feeder table.

3. Method of use

OPERATING

HANDBOOK

• In the event of a problem, press the

emergency stop button.

Page 33

OK OKOK

3

2

1

OPERATING

HANDBOOK

3. Method of use

01106073

Notice

0209 22

Date

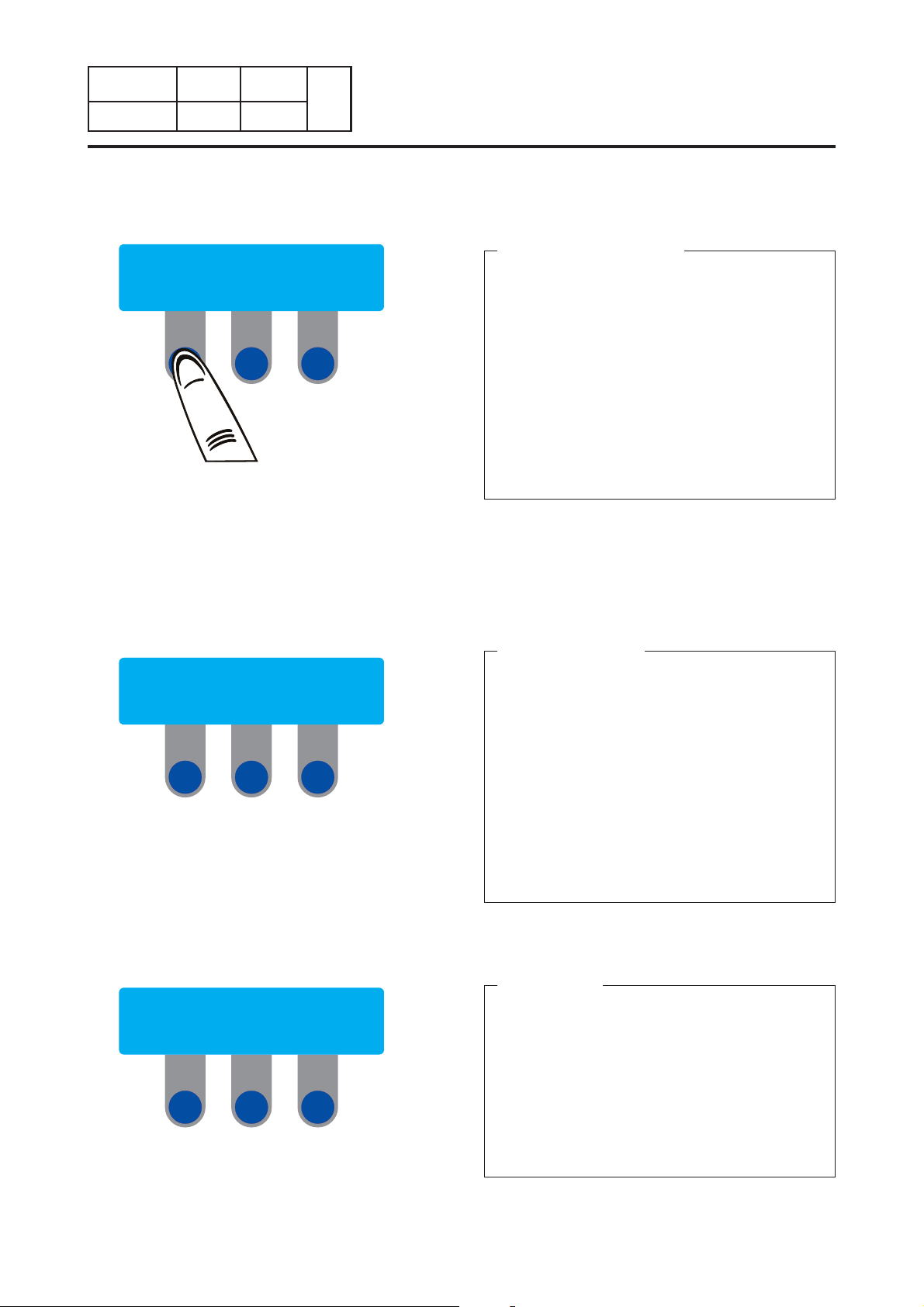

Additional instructions to optimise a dryer-ironer.

When ironing small sheets or small washing, pass abreast the washing of the heating cylinder to provide correct regulation of the cylinder temperature.

As a general rule, the whole of the cylinder should be used (1). Either iron the linen from the

front (2) or iron alternately (3), which makes maximum use of the heat units available over

the surface of the cylinder. It also overcomes diffi culties arising from random control values

caused by partial use of the cylinder.

Page

3

Cylinder

Linen

D1097

Page 34

01106073

0910

23

3

PageNotice Date

Precautions for use

Please respect the following usage recommendations to get the best out of your ironer:

In manual mode

• Avoid when running, too low or badadjusted temperatures as consequence of :

- a too high ironing speed with high moisture content in sheets : bad sliding on metallic sparts.

- a partial use of the ironing lenght of the cylinder : creating overheating (be carreful

especially, to the risk for the polycotton sheets to loose their shape, generally stabilised at

200 °C (392 °F).

• You should begin ironing when the "Warming up" message disappears.

• Check that the washing can be ironed and check the temperature at which it is to be iro-

ned.

The productivity and quality of ironing / folding depend on the washing quality ; make sure

that all these conditions are satisfi ed.

3. Method of use

OPERATING

HANDBOOK

• We recommend as far as possible, that you should feed pieces of fl at washing (towels,

sheets, etc.) by their hem, with the seam facing top, to obtain maximum ironing quality.

• Carefully engage the washing to be ironed, because it is impossible to disengage a badly

engaged washing.

• Allow 10 cm between washing to be ironed when using a machine with an automatic folding system

• Do not iron washing folded in four, because it will be too thick to achieve the

drying/ironing/folding quality that you are entitled to expect from your machine.

• If possible, use the entire ironing width of the dryer ironer.

CAUTION

Do not push small pieces of laundry in

front of the DIAMMS turners to avoid

jamming.

74032535

Page 35

OPERATING

HANDBOOK

3. Method of use

01106073

Notice

0209 24

Date

Practices to avoid

• Make sure that the width of the washing does not exceed the useful width of the machine.

• Linen units under 0,90 m (machine with the automatic folding or/and feeding option).

• Sizes not fi tting the cylinder working length, partial use of the cylinder.

• Draw-sheets or any other double-layer sheet or sheet pulled into the machine

side by side.

Practices not recommended

• Folding of tableclothes (of poor quality).

• Folding of tablesclothes (of poor quality).

• Worn polycotton sheets (cotton worn away) : uneven fi nish look when folded, high static

electricity.

Page

3

• Large cotton or fl ax-made sheets > 200 g/m².

Cautions

• Prepare the large sheets before feeding : ironing and longitudinal folding defects.

• Avoid the torn, worn or holed sheets, that may hook and alter the measurements and the

longitudinal folding.

• Comply with the mini-maxi sizes of sheets (machine with automatic feeding).

In all cases, you should ensure that the folding characteristics are respected.

Page 36

01106073

0209

25

3

PageNotice Date

3. Method of use

OPERATING

HANDBOOK

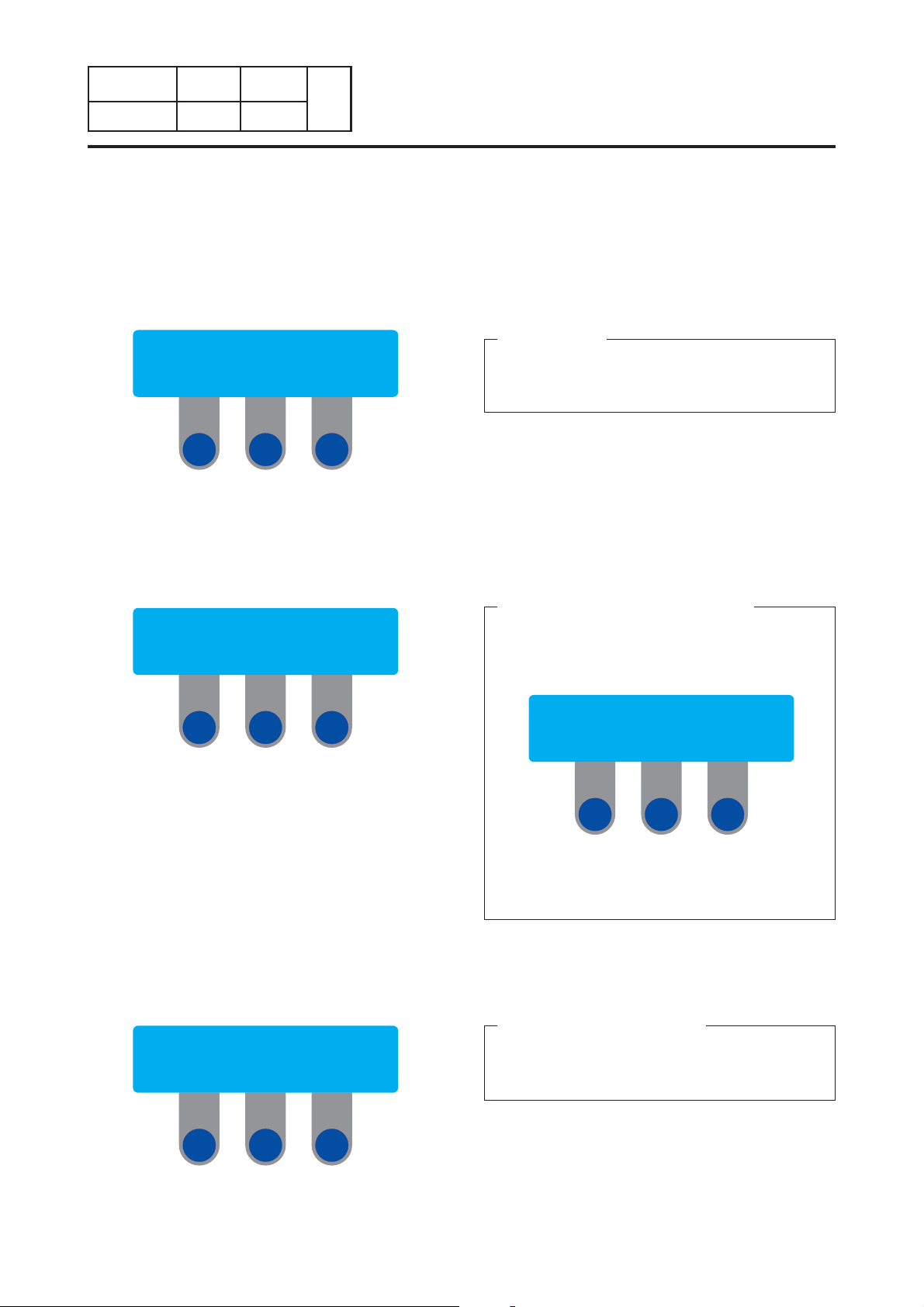

1

1 Fitted-sheet 2 Comforter cases with fl ap 3 Butcher's apron

Draw- Fitted- Comforter Butcher's Linen Linen

sheets sheets cases apron < 200 g/m² > 200 g/m²

Flatwork ironer

Flatwork ironer

+ Folder

Flatwork ironer featuring

rear load removal

2

3

D0411

Flatwork ironer

with feeding

+ Folder

Flatwork ironer with

feed device featuring

rear load removal

Yes Cautions Practices to avoid

• Fitted-sheet (1) : might cause folding problems, measurements altered.

• Comforter cases with fl ap (2) (folding problems).

• Linen other than fl atwork (butcher's apron (3) : watch that the cords do not slide between

the feeding strips).

• Linen < or = 80 g/m² : gravitational pull diffi cult at lengthwise folding.

Page 37

OPERATING

HANDBOOK

3. Method of use

01106073

Notice

1010 26

Date

Stopping the machine

To avoid potentially serious damage to the ironing belts and other components, follow these

instructions when shutting down the machine :

• On steam heated machines, turn off the steam supply to stop the heating and slowly open

the trap-bypass valve to bleed.

• Use the STOP function on control panel to begin the shut-down cooling process.

• When the screen displays "Stand by/Start", switch the main switch to the "OFF" position.

• On gas heated machines, close the gas supply valve.

You can switch the machine off at any time by pressing on the machine stop switch; but

note that if the ironing cylinder is too hot (above 120 °C (248 °F), it can damage the

bands.

Page

3

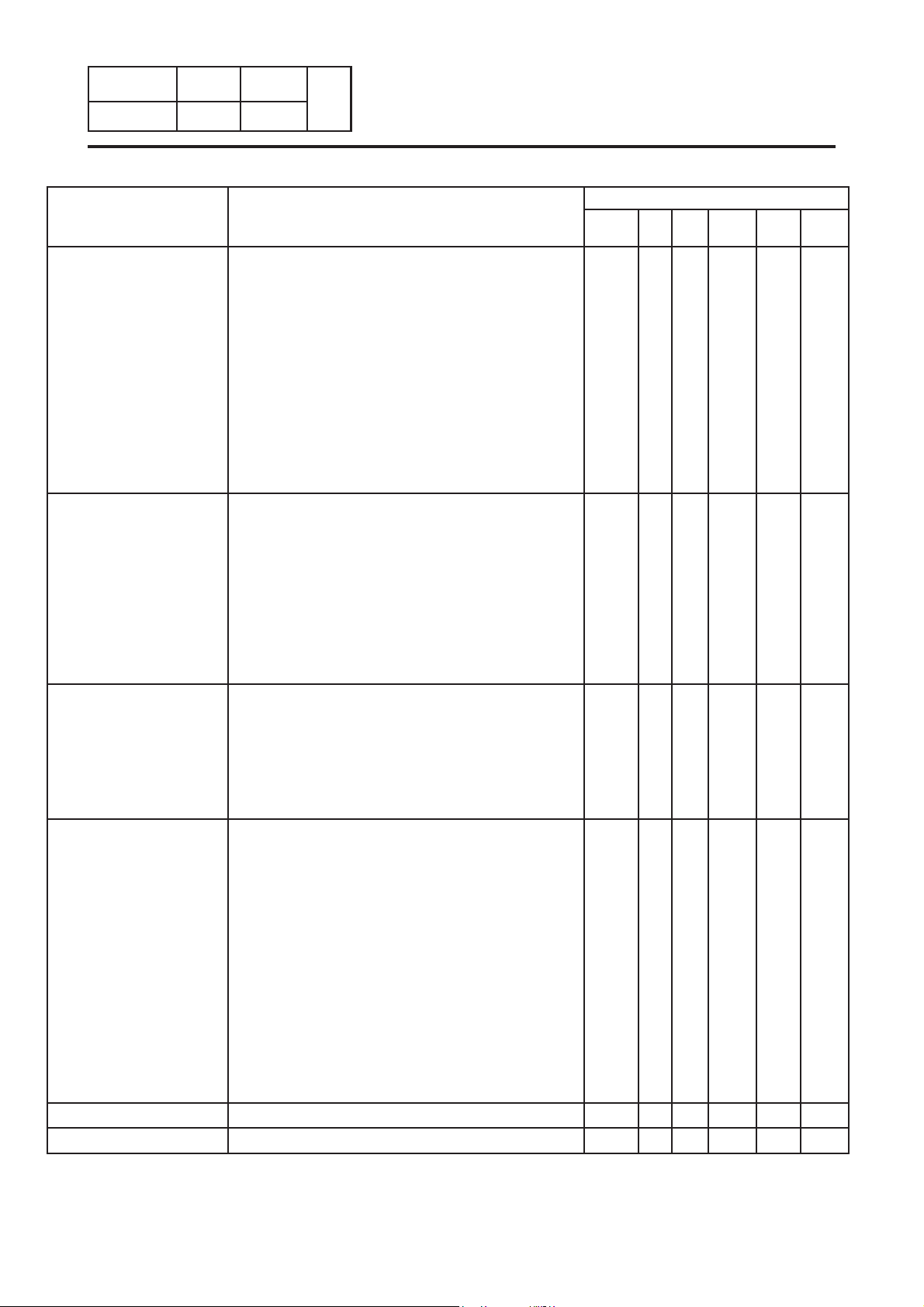

Using the handle

The dryer ironer is fi tted with a handle.

This is very useful to take out the washing

if there is a power failure while you are

ironing; or you can use it to feed a piece

of wet washing to protect the ironing

bands when the ironing temperature is too

high.

Lift the safety plate (1) then push (2) and

turn the handle in the clockwise direction

(3) to rotate the cylinder and take out the

washing.

3

Handle

2

1

D1092

Page 38

01106073

0209

27

3

PageNotice Date

3. Method of use

OPERATING

HANDBOOK

RABC option (Risks Analysis Biocontamination Control)

RABC (Risks analysis and bio contamination control) is a method used for checking hygiene

in laundry shops. It records vital data to ensure processing is performed according to procedures.

Traceability for quality control :

All of the dryer-ironers are compatible with the traceability systems corresponding to the

RABC method.

• CMIS software

• RABC printer

Page 39

OPERATING

HANDBOOK

01106073

4. Safety

CAUTION

Disconnect the machine electrical power

supply before doing any repair or servicing

work.

CAUTION

Do not use the machine unless it is plugged

into a correctly earthed power socket

complying with standards in force.

Notice

4011 1

Date

Page

4

WARNING

The presence of dangerous mechanims

inside the machine can cause serious

injuries. Respect all safety instructions

before doing any work on the machine.

Replace protective casings after doing any

work.

CAUTION

For your personal safety, never use the

machine without the protective housings.

CAUTION

For your own safety, it is prohibited and dangerous to solder the ironing cylinder. If a leak

occurs, never try to repair it yourself.

Ask our technical departments for advice

.

Page 40

01106073

0209

2

4

PageNotice Date

CAUTION

The temperature of the ironing cylinder

after use can reach 200 °C (392 °F) and

can cause serious burns if you touch it.

Allow the machine to cool down before

doing any repair or servicing work.

SAFETY

Never iron if the mobile safety protec-

tor (hand protection bar) is not operating.

4. Safety

OPERATING

HANDBOOK

CAUTION

Never open the Dubixium cylinder’s fi l-

ling cap. This may void the guarantee.

IMPORTANT

To ensure optimal operation of the ma-

chine (gas heating, electronic boards,

etc.), ensure that the ambient temperature does not fall below 15°C.

All repair and servicing work must be undertaken by a competent person.

Never wear full clothes during work (wide sleeves, ties, scarves, etc.).

Disconnect all energy sources and let the ironing cylinder cool down before doing any work

on the machine.

In order to avoid any danger of fi re or explosion, never use infl ammable products to clean the

machine.

If you smell gas, turn off the gas supply, open the windows, do not touch any switches and

inform the maintenance service.

Evacuation of vapour from a dryer ironer with gas heating must never be connected to the

evacuation used for a gas heating machine and a dry cleaning machine or other machine of

the same type.

Page 41

OPERATING

HANDBOOK

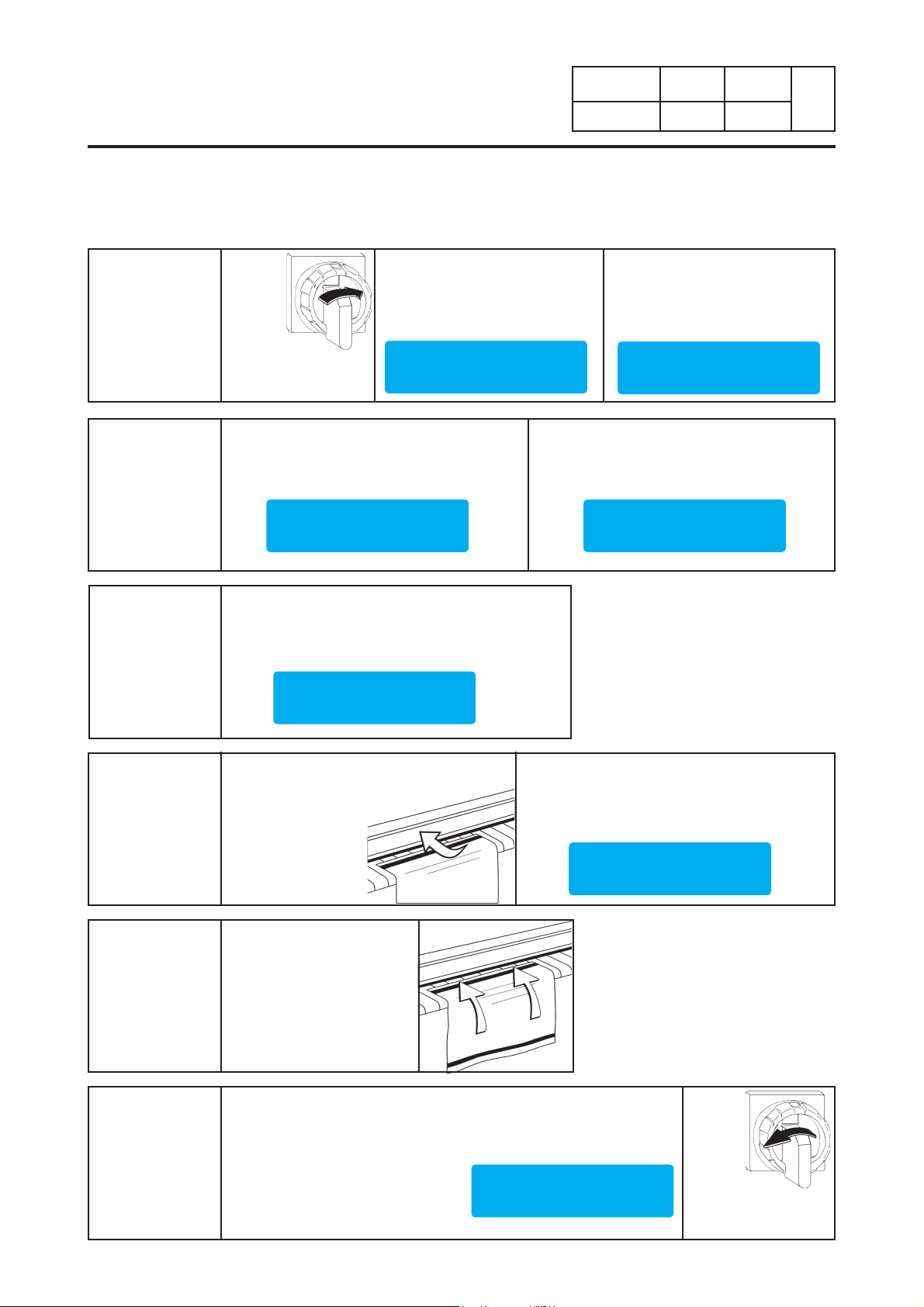

Locking and tagging procedure

A red insert at the beginning of this instruction handbook schematically shows the locking

and tagging procedure described below. If you wish, you can detach this insert and display it

close to the machine to remind maintenance personnel of the safety instructions.

1

2

2

4. Safety

Always respect items

2, 3 and 4 carefully

before doing any repair or maintenance

work on the machine.

Put the main switch

to Off and lock the

handle with a padlock

in one of the three

holes provided for this

purpose.

01106073

Notice

Close the stop valves for

0209 3

Date

the other supplies

(steam,gas, thermal fl uid, com-

pressed air) to stop

and lock their handle with a padlock.

Page

4

3

3

4

4

Open the fi xed protec-

tors (casings, doors)

with the key provided

or a special tool.

Close and carefully

lock the fi xed protec-

tors.

Do the maintenance.

Unlock the stop

valves and the

main switch.

Page 42

01106073

0209

4

4

PageNotice Date

4. Safety

OPERATING

HANDBOOK

Safety devices

Feed safety device

The space between the feed safety fl ap and the drive bands is too small for you to enter your

fi ngers. The machine stops automatically as soon as the fl ap is pushed in.

Protection of motors

The motors have overload protection :

• by thermomagnetic circuit breakers and

• by the electrical selector (for movement).

Restarting the machine

You will not be able to restart the machine after it has stopped (power failure, emergency

stop, action on the feed safety device), until you have pressed one of the keys on the control

panel.

Gas heating

The gas burner is ignited and the fl ame is controlled by an electronic box that provides inte-

gral safety, for example if the fl ue draft is poor or if the gas supply is cut off.

An message on the control panel shows that the system has been put in a safe condition.

A pressure switch connected to the combustion products outlet turns off the machine’s hea-

ting function should extraction problems arise.

Accessibility

All casings can be disassembled using a special tool.

Heating safety device

The control panel applies an initial safety level at the time the machine starts up.

If the temperature is not reached after a given time, the heating command is deactivated.

The operation of the heating function is linked to the rotation of the cylinder. If the cylinder

should stop rotating for any reason, the machine stops heating.

A safety thermostat, which is independent of all electronic systems, limits the heating temperature of the ironing cylinder in all circumstances, (except in the case of a steam heating

machine).

Power supply failure

If there is a mains power supply failure, use the handle to remove any washing engaged in

the machine. If the temperature is too high, use the handle to feed some wet washing and

protect the ironing bands.

Page 43

OPERATING

HANDBOOK

01106073

4. Safety

SAFETY

Make sure that the protection casings are in position before use.

Notice

0209

Date

Complementary instructions for operation

Check daily that the hand safety bar is working correctly, the machine must stop when you

press it. The screen on control panel displays "Emergency Stop/ Reset Push Button". Press

any key to resume ironing.

Ironing Temperature Display

The control enclosure includes an electronic thermostat panel which shows in real time the

temperature of the ironing cylinder.

A running temperature over the selected temperature is normal. This happening is not a

failure of measuring devices but it is due to heating inertia.

In automatic mode, temperature and speed management are handled by the machine itself.

5

4

Page

The use of steam heating machines.

Steam heating machines are designed to operate only using dry saturated steam at a maximum pressure of 1000 kPa (10 bar). You should take care not to exceed this limit in order to

avoid premature damage to pressurised components.

Each time the machine cools down, water vapour is inevitably created. The use of dry saturated steam reduces the risk of erosion and corrosion of the tubes and pressurised components.

There is a risk of deformation, cracking and bursting if pressure levels are used which exceed the recommended 1000 kPa (10 bar). Check that the safety valve operates correctly in

order to avoid the risks of excess pressure building up.

Fire-related risks.

Should a fi re breakout inside the machine, it is recommended that you use a CO2 extin-

guisher.

Note : in the case of a machine using gas heating, it is strictly forbidden to attempt to put

out the fi re before having fi rst turned off the gas inlet valve.

The client must ensure conformity with the Labour Code and his supplier of fi re-fi ghting equi-

pment who issues the Q4 certifi cate to him.

Repair and maintenance work on the machine.

All work on the machine must be carried out by qualifi ed personnel, able to carry out the work

required.

Ensure that the applicable safety conditions for the destination country are fully observed.

Page 44

01106073

0209

1

5

PageNotice Date

Encountered problem Cause of problem Solution

5. Operating incidents

OPERATING

HANDBOOK

The washing remains

stuck to the cylinder

When the linen comes off

the dryer-ironer it is not

dry

Your washing is not rinsed correctly Check rinsing with a 1 %

phenolphthalein solution diluted in

alcohol. If this colorless liquid turns to

pink on the washing as it comes out

of the washing machine, and it still

contains detergents.

if the washing is insuffi ciently rinsed. Increase the number of rinsings if

necessary or reduce product doses.

Check that ironer separating ribbons

are intact.

Check the cylinder temperature.

The washing is not suffi ciently spun.

Your linen is starched There is a risk of starch deposits

forming on the cylinder

Your washer-spin dryer has a spin

rating of below 300G.

Check the drying quality of your

washing machine.

You should plan on a short pre-drying

session in a dryer (5 – 10 mins).

The residual moisture content of the

washing should be about 50 %.

The folding system

works without stopping

The ironing speed is too high.

The ironing temperature is too low.

The linen that you are trying to iron is

too thick.

Check operation of the heating.

Check operation and cleanliness of

the vacuum intake system.

Check the condition of ironing bands

(fi bers containing scale).

Check the pressure of the ironing

roller on the ironing cylinder.

Check that the photoelectric cell is

opposite its refl ector.

The cell is correctly positioned

opposite its refl ector.

Reduce the ironing speed.

Check that these are clean and clean

them if required.

Page 45

OPERATING

HANDBOOK

5. Operating incidents

01106073

Notice

Encountered problem Cause of problem Solution

0209

Date

2

5

Page

The heating does not

work, or works badly

Check the temperature preselection.

Check the safety thermostat.

Check to see if the panel is showing

overheating or a high temperature.

Check the cylinder’s rotation

detection system.

Gas heating

Check the gas inlet.

Clean pressure reducer fi lters.

Check electronic ignition.

Check the position of the ignition

electrodes and fl ame control.

Check operation of the gas solenoid

valve.

The fl ame is yellow Check that the vapour intake fan is

Check the panel’s sensors.

working and is turning in the right

direction.

Check that air inlets are not blocked.

Electrical heating

Check heating contacts KM6, KM7

and KM8.

Check heating resistances.

Check resistance connections.

Check phases.

Steam heating

Check the steam inlet and the boiler

pressure.

Check the steam quality.

Check the non-return valve and the

steam purge.

Check the combustion products

exhaust fl ue.

Check injector calibration.

Clean machine air inlet fi lters.

Page 46

01106073

0209

3

5

PageNotice Date

Encountered problem Cause of problem Solution

5. Operating incidents

OPERATING

HANDBOOK

The folding system is

defective

The machine temperature

drops

The machine stops suddenly

Check that the photoelectric cell and

its refl ector are clean.

Check the folding arm limit switch.

Condensation given off by the linen

when still damp has affected the

operation of the photoelectric cell.

Check the sensor in the thermostat

regulation system.

Check the thermostat by measuring

the cylinder temperature with a

thermometer.

Check that the regulation shoe is in

contact with the cylinder.

Check the electric power supply.

Check the hand safety fl ap switches

S5 and S6.

Check that the linen is perfectly dry

after being ironed.

Check the movement and ventilation

fans.

Check circuit breakers.

Static electricity makes the folding diffi cult to achieve (machine with the folding

system only)

Synthetic textiles are used increasingly in laundry. The low rate of relative moisture on

•

output from drying allows high ironing speeds, which leads to production of harmful static

electricity when the linen is ironed in the machine.

• Use of softening and anti-static products attenuates this phenomenon.

• So, static electricity might cause important diffi culties at folding, especially when ironing

polyester/cotton. It si adviced to add a rincing anti-static liquid at the end of washing cycle

in order to reduce the formation of static elecricity when ironing.

Static electricity

Any friction generates static electricity. Remember the plastic ruler people rub over their

•

pullover to attract little bits of paper. With the same causes producing the same effects,

the linen being subjected to friction in the course of ironing, the rubbing of the linen

against the cylinder generates static electricity. If too much static electricity builds up,

friction has to be reduced, which can be done by removing the driving chain of the presscylinder to reduce the generation of static electricity.

Page 47

OPERATING

HANDBOOK

5. Operating incidents

01106073

Notice

0209

Date

Linen colouring

The brown coloring is due to detergent residues, and will disappear at the next washing.

•

• Colouring caused by the temperature being too high is permanent. Reduce the ironing

temperature or increase the ironing speed.

• The washing should be correctly rinsed so that it does not turn yellow and does not make

the cylinder dirty.

- Check the quality of the washing water (TH/TAC).

- Check the washing and rinsing cycles (see "phenolphthalein" operating incidents).

- Check incrustation of the washing (ash content).

The feed bands are not turning

This type of incident is normal when it only affects a few bands.

•

When washing will not engage any more, adjust the tension of all the bands by changing

the setting of the feed table bearings.

Do not overtighten the bands.

The band must stop turning when you press on it with your fi nger. It must start again

when you remove your fi nger.

4

5

Page

Complementary instructions for starting up a machine with gas heating.

The message "Error Gas Ignition" is fl ashing on display screen during 30 seconds to show

that the gas burner is being ignited. If this message is still displayed after 6 seconds, there

may be an ignition fault, a failure in gas valve opening or a lack of gas.

Switch the machine off and call your local repairman if this occurs regularly.

About 10 minutes is necessary to warm up.

Note :

Do not forget to open the stop valve on the gas supply line before starting to use the

machine, and then close it again after use.

The noise at the inter-ignition is not an explosion. It is a normal phenomenon.

Complementary instructions for starting up a machine with steam heating.

Note : do not forget to open the by-pass or the condensate return valve for about a minute

to purge the pipes so that the cylinders can warm up more quickly; do this before starting to

switch on the machine. Close it afterwards.

Slowly open the steam inlet valve and check the temperature on the control display panel.

Page 48

01106073

0209

5

5

PageNotice Date

Overheating of cylinder sides

Error

Overheating on side

5. Operating incidents

Overheating of cylinder sides (when feeding

is carried out on the centre of the cylinder too

often)

In the event that one of the two sides of the cylinder

overheats due to it being partially used, a fl ashing

message will be displayed on the screen, alternately

with the service screen.

The heating system of the machine will remain shut

down while this fl ashing message is displayed.

T

o continue ironing, allow the cylinder to cool until

the fl ashing display disappears.

OPERATING

HANDBOOK

Overheating of centre of cylinder

Error

Overheating

Overheating of centre of cylinder (when small

linen units are too often fed on the centre of the

cylinder)

In the event that the centre of the cylinder overheats

due to it being used laterally, a fl ashing

will be displayed on the screen alternately with the

operating screen.

The heating system of the machine will remain shut

down while this message continues to be displayed.

To continue ironing, allow the cylinder to cool until

the fl ashing display disappears.

message

Page 49

OPERATING

HANDBOOK

Converter fault

CONVERTER FAILURE

START

5. Operating incidents

01106073

0209

6

5

Notice

"Converter failure" message

If this message appears on the screen, the converter

has developed a fault. Please refer to the converter

manual for information repairing the fault.

The machine will only be able to be restarted once the

fault has been repaired.

To reinitialise the machine, press the central key

If the fault remains, switch off then switch back on the

power supply using the main switch.

Date

Page

.

Fault Emergency stop

EMERGENCY STOP

RESET PUSH BUTTON

Message: "Emergency stop-check button"

If the screen displays this message, one of the

emergency stop buttons has been triggered. The

machine enters safety mode, the heating is turned of

and the cylinder stops.

Check why the button was pressed and then reset it.

The screen should now display this message :

EMERGENCY STOP

START

You can now press on the central button on the panel

to return to the machine operation mode.

If resetting the button does not solve the problem, you

should then check the others.

f

Page 50

01106073

0209 7

5

PageNotice Date

Gas burner ignition fault (only for machines using gas heating)

Error

Gas Ignition

5. Operating incidents

"Gas ignition fault" message

(only on gas-heated machines).

The screen will alternately display this fl ashing

message and the service screen. This means that the

lighting of the gas burners has been requested.

If this message has been displayed over 30 seconds,

the gas burner is not ignited.

into safety state and heating is cut off. Try again and

follow the starting procedure.

Press any key to display the following menu.

After an additional failure, please check the gas

heating running. If the fault remains, consult your

after-sales service.

OPERATING

HANDBOOK

The heating system falls

Reset the igniter (only for machines using gas heating)

Message: "Reset igniter"

The message on the screen will then ask you if you

wish to reset the igniter.

Dx °C 2.5m/min 000

Reset Ignitor STOP

Fault with the heating system

Problem

Fault with the heating system

Press on one of the two buttons on the left to restart

the gas igniter

Press the "STOP" button to stop the machine.

Message: "Problem - fault with the heating

system".

The screen appears if, after a certain time

(approximately 20 minutes) the cylinder temperature

remains below 100°C.

Try to restart the machine.

If the problem continues, please consult your after-

sales service department.

.

Page 51

OPERATING

HANDBOOK

The following three screens will only appear if you have a machine with a folding option and manual fold adjustment.

5. Operating incidents

01106073

Notice

0209

Date

8

Page

Error of communication with the folding option

"Com. Error Folder" message

Error

Com. Error Folder

The screen will alternately display this fl ashing

message and the service screen.

This message means that there is a communication

failure between the control panel and the folding

programmable logic controller.

• Check the link between the control panel and the

programmable logic controller.

• Check the setting of the programmable logic

controller.

• In the Set 2 menu of the service program check

the confi guration for the control panel. The MANU

parameter should be selected.

If the fault remains, consult your after-sales service.

5

Error of the folder running

Error

Folder Error 002

Positioning fault with the reception tank

Error

Reception not ready

"Folder Error 002" message

The screen will alternately display this fl ashing

message and the service screen.

This message followed by a number means a failure

in the folder running.

Switch off then switch back on the power supply using

the main switch. If the fault remains, consult your

after-sales service.

Message: "Problem - tank positioning error".

The screen displays the following fl ashing message,

alternating with the service screen.

This message shows that the reception tank on the

machine is not in the correct position for the folding

option that you have chosen:

•

Raised to use the machine without folding (folding

mode: WITHOUT).

• Lowered to use the machine with folding (folding

mode: FIX or PLIVIT).

Page 52

01106073

2313 1

6

PageNotice Date

Preventive maintenance of the ironer

6. Preventive maintenance

OPERATING

HANDBOOK

Daily (8 h)

1. Check that the machine stops when you press the mobile safety protector (hand safety

2. Check that the "emergency stop button" works correctly.

(at the beginning of each working day)

device).

Weekly (40 h)

3. Clean motor ventilation grills.

4. Clean the drive system of the dewrinkling strips.

5. Clean the separators.

6. Clean the detection cell and its refl ector (on models with the folding function only).

7. Check and clean the fl uff fi lter and the cover fi lter with suction device.

Monthly (170 h)

8. Remove dust from outside the machine.

9. Check the condition of the separating ribbons, and replace them if necessary.

10. Ensure that the thermostatic regulation and overheat safety shoes are always clean and

in contact with the cylinder.

11. Lubricate the steam heater bearings (see lubrication chart in next pages).

Every six months (1000 h)

12. Check for any possible oil seepage, particularly at the fi ller plug (only on Dubixium cylin-

ders).

13. Grease chains (see lubrifi cation table on the following pages).

14. Clean and inspect the cylinder support rollers, along with the stop roller wear indicator

(except on the steam machine). If there is any premature wear, see technical support,

ref. 04102018.

15. Check operation of the handle.

16. Inspect tightness of electrical connections on the power supply terminal block and electrical earthing connections.

17. Clean exhaust system.

18. Inspect heating elements, cables and electrical connections (on electrical heating only).

19. Clean gas fi lter inside the gas valve (on gas heating only).

20. Check the condition of ironing bands and their staples.

21. Check the feed bands and their drive and ejection bands (on models with the folding

funciton only).

22. Clean inside the machine.

Page 53

OPERATING

HANDBOOK

6. Preventive maintenance

01106073

Notice

4311 2

Date

Every year (2000 h)

23. Check if the cylinder is dirty and clean it if necessary.

24. Clean external pipes done by customer.

25. Check that the burner works correctly (gas machines only).