Electrolux GPWBOEOOOO Installation Manual

Thermetic

TILTING BOILING PANS, ROUND, GAS HEATED (GU........, KU........)

TILTING FRYING PANS, RECTANGLE, GAS HEATED (GP........)

US INSTALLATION - INSTRUCTIONS

Doc. 62.9699.01

Edition 1

09.2004

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or

liquids in the vicinity of this or

any other appliance.

WA RN IN G

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating

and maintenance instructions

thoroughly before installing or

servicing this equipment.

INSTRUCTION

Post in a prominent location instructions to be followed if the user smells gas. Consult

the local gas supplier to obtain the information.

Présentez dans des instructions en avant d'un endroit d'être suivi si l'utilisateur sent le

gaz. Consultez le fournisseur local de gaz pour obtenir l'information.

POUR VOTRE SÉCURITÉ

Ne déposez pas ou n'employez pas

l'essence ou d'autres vapeurs ou

liquides inflammables à proximité

de ceci ou d'aucun autre appareil.

AVERTISSEMENT

L'installation inexacte, l'ajustement, le changement, le service ou

l'entretien peuvent causer des blessures matériels, des dommages ou

la mort. Lisez les instructions

d'installation, d'opération et d'entretien complètement avant d'installer ou entretenir cet équipement.

CONTENTS

1. GENERAL REMARKS ........................................................................................................ 3

2. PACKAGING / TRANSPORT ..............................................................................................3

3. TECHNICAL DATA / DIMENSIONED DRAWINGS / INSTALLATION PLANS ................. 3

3.1 TILTING BOILING PANS ................................................................................................................. 3

4. FLOOR GULLIES ................................................................................................................5

5. MOUNTING / POSITIONING / FASTENING IN PLACE / ALIGNMENT .............................5

5.1 POSITIONING ................................................................................................................................... 5

5.2 ACCESS TO INSIDE THE CONSOLES AND SUPPORT ................................................................ 7

5.3 COVERS (PANELS) ......................................................................................................................... 7

6. INSTALLATION ................................................................................................................... 8

6.1 ELECTRICAL CONNECTION ........................................................................................................... 8

6.2 GAS CONNECTION ......................................................................................................................... 9

6.3 UNIVERSAL CONTROL PARAMETER SETTINGS ...................................................................... 10

6.4 THERMACAM / HACCP ................................................................................................................. 13

6.5 INSPECTION PROCEDURES / TEST OF FUNCTIONS ................................................................ 14

7. DECOMMISSIONING / DISMANTLING / DISPOSAL ....................................................... 14

62.9699.01 Page 1

1. GENERAL REMARKS

Responsibility

The setting up, adjustment and initial commissioning of appliances must be carried out in accordance with the manufacturer's instructions and may only be done by authorised

personnel. The installations for the electricity, steam, condensate, hot water, gas and water supplies as well as ventilation

must be laid or fitted by approved installation contractors in

accordance with specific national and local regulations. The

installation contractors are responsible for the correct layouts

and installations in conformity with all safety regulations. The

warning signs and specification plates fitted to the appliances

must be strictly adhered to.

The operator of this appliance is responsible for total observation of the national regulations concerning operating safety.

Validity

These instructions for installation refer to the THERMETIC tilting appliance program with appliances of different sizes: tilting

boiling pans, tilting braising pans and tilting pressure braising

pans.

Dimensioned drawings and installation plans of this document

are only for information purpose to the installers. These plans

may not be used for planning or projecting kitchens.

Tests/certificates

All gas appliances are tested according to the standards

ANSI/NSF 4 - 2002 of Commercial Cooking, Rethermalization,

and Powered Hot Food Holding and Transport Equipment and

ANSI Z83.11-2002 and CSA 1.8-2002 of Gas Food Service

Equipment.

2. PACKAGING / TRANSPORT

Types of packaging

Various types of packaging are used dependent on country of

destination. All versions of these appliances are transported

on a wooden frame or floor, are affixed to these with plastic

straps and located with wooden strips to prevent slipping.

Destination Overseas:

Version: Heavy, crate closed

Floor: Wooden floor

Floor fixing:

Side and cover frame:

Water and dust protection: Plastic film

Physical outer protection: Closed crate

Held together by: External steel banding

Transport: Forwarder

Stack ability: max. 4 appliances

Packaging markings

The external surfaces of the packaging have the following

markings which must be strictly adhered to:

• Forwarding label with the following information:

- Delivery company

- Delivery company's order number

- Customer's order number if available

- Delivery address

- Package number

- Net weight in kg

- Gross weight in kg

- External dimensions of the packaging

• Handling stickers with pictograms

- Umbrella = Keep dry; the packaged appliance

may not be stored outdoors

- Glass = Contents fragile

- Arrow pointing up = Only transport and store the

appliance in this position

- Stacking number = Number of appliances that can be

stacked (1 = cannot be stacked)

- Ice crystal and roof = Protect against frost

Transport weights

The precise gross and net weight is given on the forwarding

label:

Tilting boiling pans max. gross weight max. net weight

.U........ kg lb. kg lb.

080 LT (21.1 gal) 215 474 195 430

100 LT (26.4 gal) 250 551 230 507

150 LT (39.4 gal) 290 639 270 598

300 LT (79.3 gal) 410 904 390 860

Tilting braising pans max. gross weight max. net weight

.P........ kg lb. kg lb.

060 LT (15.9 gal) 230 507 210 463

080 LT (21.1 gal) 260 573 240 529

100 LT (26.4 gal) 290 639 270 595

Packaging dimensions

The precise external dimensions of the packaging are given on

the forwarding label attached to the outside of the packaging.

The maximum dimensions of the "European light" style of

packaging are given below:

Appliance size

LT

Tilting boiling pans 80, 100 1200 47.2 900 35.4

Tilting boiling pans 150 1300 51.2

Tilting boiling pans 300, 400 1500 59.1

Tilting braising pans 60 1200 47.2

Tilting braising pans100 1600 66.9

Width Depth Height

mm inch mm inch mm inch

1000 39.4

900 35.4

900 35.4Tilting braising pans 80 1400 55.1

Handling

Both packaged as well as unpacked appliances are best lifted

and transported whenever required with a pallet truck which is

inserted into the wooden frame or under the wooden base.

This applies to both the loading and unloading of trucks as well

as to handling operations on the installation site.

For handling by a crane, the unpacked appliances do not have

any specific lifting points to which they can be attached. It is

necessary to wrap two straps or ropes around the appliance

when lifting is required. Wrapping straps or ropes around the

appliance may only be done at the sides and not round the

front and the rear. The straps or ropes should be arranged

approximately 150 mm (5.9“) from the outer edges.

3. TECHNICAL DATA / DIMENSIONED DRAWINGS / INSTALLATION PLANS

These illustrations are not intended for the planning and laying

of the supply lines in the building.

3.1 TILTING BOILING PANS

Style of mounting Floor mounting with feed

Tilting Motor tilting with lifting motor

PROCESS COMFORT control system with cooking tem-

Control system

Protective system hose proof IP X5

perature control and

programmable cooking and

starting time.

Manual control for steam

heated boiling pans.

62.9699 Page 3

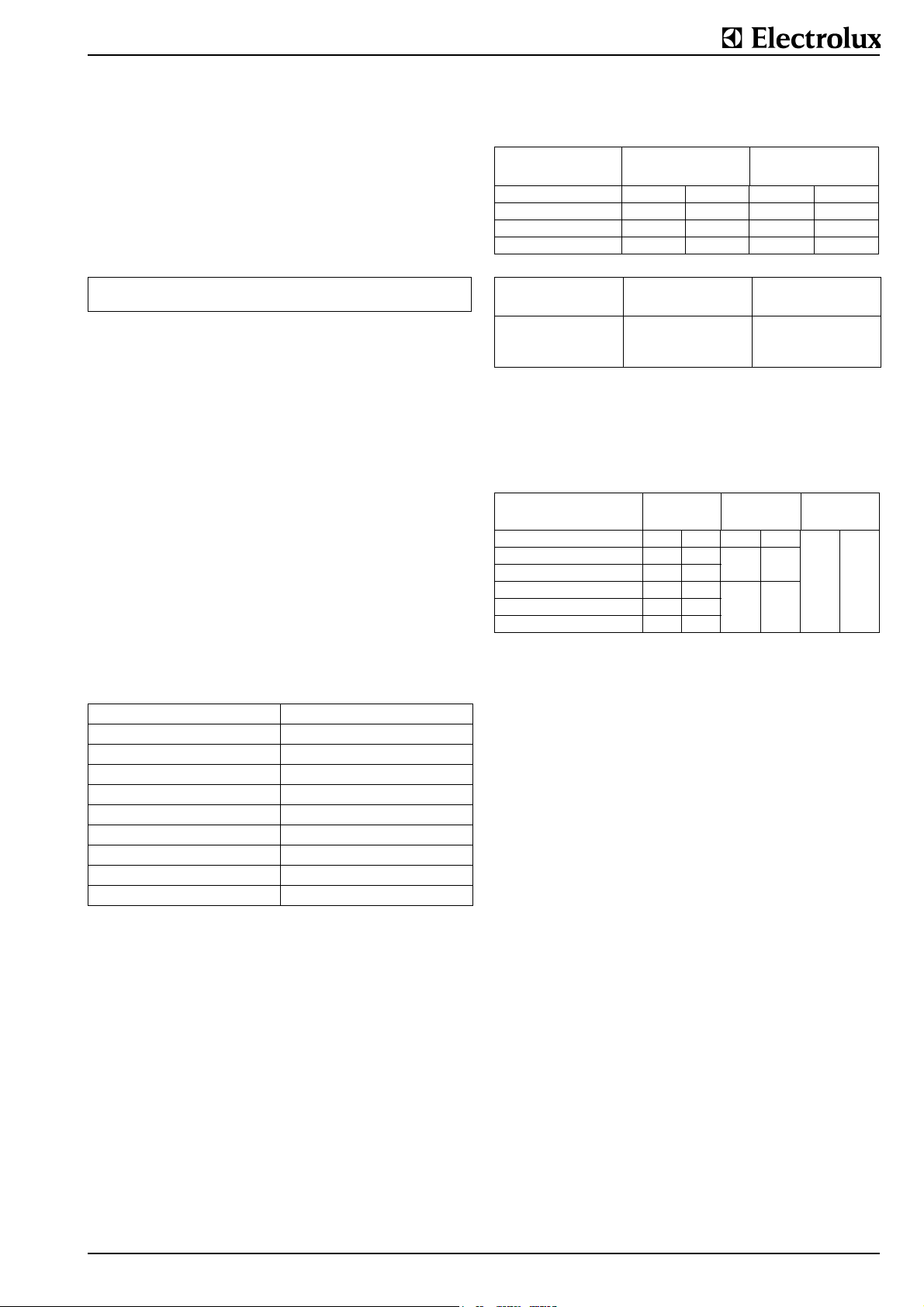

3.1.1 Gas heated tilting boiling pans (.U........))

80 LT,

gas heated

Heating capacity (gas) kW 18 21 27 45

Elect. motor tilting

Wattage in kW

Voltage (V), Current in A

0,2

230V/1~N,60 Hz, 0,7 A

100 LT, g

as heated

150 LT,

gas heated

300 LT,

gas heated

Mains connection 120V/1~N/60Hz

Necessary gas flow per appliance:

80 LT,

gas heated

Natural gas H m3/h 1.87 2.18 2.80 4.67

Natural gas L m3/h 2.16 2.53 3.25 5.42

Propane kg/h 1.50 1.74 2.24 3.73

Butane kg/h 1.52 1.77 2.27 3.79

100 LT, g

as heated

150 LT,

gas heated

300 LT,

gas heated

Dimensioned drawings for tilting boiling pans (.U........)

L Length to floor gully

N Depth of floor gully

Installation plans for tilting boiling pans (.U........), tilting

frying pans (.P........), tilting braising pans (.X........)

Fig. 1 Dimensioned drawings for tilting boiling pans

Pan size in litres

80 100 150 300

Dimensions mm

A

B

C

D

E

F

G

H

J

K

L

M

N

1200 1200 1300 1500

1073 1096 1224 1352

1034 1060 1190 1290

579 640 710 900

385 395 465 570

900 900 900 900

476 450 420 320

80 88 97 110

680 680 780 780

900 900 1000 1000

710 710 710 810

330 330 330 430

1000 1000 1000 1200

A Width of appliance (see

dimensioned drawing)

E Electrical cable protruding

from wall

W Hot water connection G

1/2", NW15

K Cold water connection G

1/2", NW15

G Gas connection 1"

Fig. 2 Installation plans for tilting boiling pans, tilting

frying pans, tilting braising pans

3.1.2 TILTING FRYING PANS (.P........)

Model (optional) Pan bottom made of steel or chrome-nickel

plated steel

Style of mountingFloor mounting with floor support with con-

sole.

Tilting Motor tilting with lifting motor

Control system Electronic control system with pan-base and

cooking temperature control and program-

mable cooking and starting time.

Tilting Frying Pans

Type 060 LT,

electric

Dimension A (mm) 1200 1400 1600

(inch) 47.2 55.1 63

Braising surface (mm)

(inch)

Pan depth in (mm)

T(inch)

Net content (litres)

(gal)

max. capacity

Heating capacity (gas) kW 16 20 26

Elect. motor tilting

Wattage in kW

Voltage (V), Current in A

600 x 600

23.6x23.6

200

7.9

63

16.4

0,2

230V/1~N,60 Hz, 0,7 A

080 LT,

electric

800 x 600

31.5

200

7.9

84

22.2

100 LT,

electric

1000 x 600

39.8

200

7.9

104

27.5

Mains connection 120V/1~N/60Hz

Dimensioned drawings

H Height for all types 900 mm (35.4“)

S Height of feet / wheel 200 mm (7.9“)

Page 4 62.9699

5. MOUNTING / POSITIONING / FASTENING IN PLACE / ALIGNMENT

In principle, the appliance must be installed in its scheduled

location in accordance with the valid plans. The appliance is

scheduled for connection to fixed power- and water supplies.

The installation dimensions are given on the plans.

The appliances are suitable for setting up as single appliances

or as a group of appliances. They can be set up freely in the

room, side by side, at the side and/or at the back against a

wall.

Gas-heated appliances may only be set up in adequately ventilated rooms. A ventilation engineer is responsible for the

assessment or planning of a ventilation system that fulfils

safety regulations.

Fig. 3 Dimensioned drawings

Tilting frying pans

Installation plan see 3.1.

4. FLOOR GULLIES

In the case of tilting appliances, floor gullies with loose gratings

and floor drains which serve as drains when cleaning are provided for near to the outlet. Floor gullies can be designed for a

single appliance or for a whole group of appliances. There is a

very wide variety of types and sizes. Please consult the relevant installation plans for information concerning layout and

type.

In general, the floor gullies with their drains are concreted into

the floor by the builder.

A Pan sizes 80 to

150 litres; Grating 500 x 1000

mm (19.7x39.4“)

B Pan sizes 200 to

400 litres; Grating 600 x 1200

mm (23.6x47.2“)

Fig. 4 Sample dimensions of individual floor gullies for

tilting boiling pans without drain valves.

Distances/walls

These may not be positioned against combustible walls. If an

appliance is set up next to or against temperature-sensitive

furniture or similar, a safety gap of approximately 50 mm (2“)

should be maintained or some form of heat insulation fitted.

When setting up an appliance in the close vicinity of walls, partitions, kitchen equipment, decorative cladding, etc., it is recommended that the latter are made of incombustible material

or that they are clad in a suitable, incombustible material or

tiled. The regulations governing fire protection must be

adhered to as closely as possible.

Preparation for fastening in place

Before the appliance is brought to the correct place and put in

position, the following connection points must be prepared

dependent on the type of appliance:

• Fastening elements, i.e. drilling holes and inserting plugs.

Explanations for this are included in the relevant sections

under "Fastening".

• Prepare the water connections and, possibly, fit a shut-off

valve.

• Prepare the gas connection and, possibly, fit a shut-off

valve and a filter.

Setting up

The appliance should be transported to the place where it is to

be set up in accordance with § 2

.

Removal of the packaging:

The packaging should not be

removed until immediately before

the appliance is to be set up in

place. All side and top packaging

parts as well as the fastening elements must be removed in

sequence. The appliance should

remain on its wooden transport

frame or base until at the site for

installation.

5.1 Positioning

Transport the appliance on its

wooden frame to a point directly in

front of where it is to be set up. The

installation connections protruding

from the floor should be at the side

as close as possible to the wooden

frame.Slide the appliance off the

wooden frame so that all the installation connections are within the

appliance.

Fig. 5 Typical, floor gully for a single appliance with a siphon

(S) made of stainless steel (728 342 984)

62.9699 Page 5

Loading...

Loading...