Electrolux GP Operation Manual

Thermetic

TILTING FRYING PANS, RECTANGLE, ELECTRIC

(GP........)

US SERVICE MANUAL

Electrically and steam heated

TILTING FRYING PANS

Doc. 62.9694.03

Edition 1

09.2006

CONTENTS

1. CONSTRUCTION/ FUNCTIONS......................................................................................... 3

1.1 TECHNICAL DATA 3

2. ELECTRIC DIAGRAMS ...................................................................................................... 4

3. MAINTENANCE CHECK LIST............................................................................................ 6

4. ACCESS TO INSIDE........................................................................................................... 7

5. FUNCTIONAL COMPONENTS.............. .... ... ... ... ... .... ... ... ... .... ............................................ 7

5.1 FU1. OPERATING FOIL ................................................................ .................................... ...............7

5.2 FU2. UNIVERSAL CONTROL .................. ... .................................... ... ... .................................... ....... 8

5.2.1 PARAMETER PROGRAMMING ....................................................................................................................... 8

5.2.2 MANUAL PARAMETER INPUT ........................................................................................................................ 8

5.2.3 PROGRAMMING SPECIFIC APPLIANCE AND USER DATA ........................................................................ 9

5.2.4 TRIMMING OF TEMPERATURE MEASURING ............................................................................................. 11

5.2.5 TEST FUNCTIONS FOR SERVICE APPLICATION ....................................................................................... 11

5.2.6 TROUBLESHOOTING DISPLAY .................................................................................................................... 12

5.2.7 OPERATING PRINT (UP) ............................................................................................................................... 12

5.2.8 CONTROL PRINT (SP) .............................................................. ..................... ................................................ 13

5.2.9 CONTROL SWITCH (S) ............................................................. ..................... ................................................ 13

5.2.10 SAFETY THERMOSTAT (F1) ......................................................................................................................... 14

5.2.11 FOOD SENSOR (B1) ...................................................................................................................................... 14

5.2.12 ELECTRIC HEATING (EI, EA) ........................................................................................................................ 15

5.2.13 END SWITCH (ES) .......................................................................................................................................... 15

5.2.14 TERMINALS .................................................................................................................................................... 16

5.2.15 CONTROL FUSE (X4) ..................................................................................................................................... 16

5.2.16 CONTACTORS (K) ......................................................................................................................................... 16

5.2.17 HEATING RESISTOR (E11) ........................................................................................................................... 16

5.2.18 POWER ISOLATOR (H) .................................................................................................................................. 16

5.3 FU1.3. MOTOR TILTING ...............................................................................................................17

5.3.1 CONTROL SYSTEM (KS) ............................................................................................................................... 17

5.3.2 TILTING MOTOR (AN) .................................................................................................................................... 17

5.3.3 SWITCH (CK) .................................................................................................................................................. 17

5.4 LID (D) ............................................................................................................................................. 19

5.4.1 LID HINGE (DG) .............................................................................................................................................. 19

62.9692.03 Page 1

5.5 MIXING UNIT ................................................................................................................................... 20

5.6 PAN .................................................................................................................................................21

5.6.1 BEARINGS, PIVOTS .......................................................................................................................................21

5.6.2 CASING (MN) ..................................................................................................................................................21

5.7 APPENDIX

UNIVERSAL CONTROL DESCRIPTION OF PARAMETERS .....................................................22

Page 2 62.9692.03

VALIDITY

This document refers to the following tilting frying pans:

Tilting frying pans,

electrically heated

.P.B......

060 E

(15.9 gal)

.P.C......

080 E

(21.1 gal)

.P.E......

100 E

(26.4 gal)

ADDITIONAL DOCUMENTS

Operating instructions 76.9694.01 delivered with the appli-

ance

Installation instructions76.9698 delivered with the appliance

Spare parts list 76.9694.02 distributed by the service

department

Electrical diagrams 91.2046, 91.2048, delivered with the

appliance

SERIAL NUMBER YWWXXXXX

The serial number of the appliance is marked on the type

plate. The 8 digits give following information:

Y last digit of the year of production

WW week of production

XXXXX running number

SAFETY MEASURES

• Maintenance work, adjustments, conversions and repairs

may only be carried out by an authorized technician. These

technicians must be instructed by the manufacturer and

carry out the work in accordance with specific national and

local regulations. Parts requiring replacement are only to

be replaced by original spares.

• Follow strictly the attention and warning label indications

on the appliances.

• Cleaning and maintenance may only be carried ou t when

the appliance is cold.

• In case a connection with a sealing is opened, always a

new sealing should be used when installing the connection.

• The manager is responsible for ensuring that all compo-

nents relevant for safety (jacket safety valve, drain valve,

pressure gauge, thermostat, excess-temperature thermostat) are in perfect working order at all times. The operating

condition of these components must be examined by an

authorized technician at least once a year and any defects

remedied if required.

• Before beginning any servicing, all appliances must be dis-

connected from the power supply; the steam, condensate,

hot water and drinking water pipes must also be turned off

or closed. Disconnection from the power supply is effected

by switching off at the main switch or removing the fuses

fitted to the power supply.

• The internal wiring in the appliance as well as the earth

connections must be carried out in accordance with the

complete electrical schematic. Basically, all metal parts on

which electrical connections are located must be earthed.

• Boiling pans of this design and operating function do not

require special acceptance tests. They are subjected to a

pressure and operating test which meets the regulations on

the manufacturer's premises. Recurrent pressure testing is

not compulsory. To ensure the complete operating efficiency and safety of appliances, however, owners should

arrange for personnel authorized by the manufacturer to

check on all safety equipment and to conduct pressure

tests at regular intervals.

• After the appliance has been connected up, the service

agent must carry out a test of all functions in the course of

which all the programs and operating states of all operating

elements as laid down in the operating instructions are

checked.

• The conclusion of a maintenance agreement should be

recommended to the user.

MAINTENANCE INTERVAL

An obligatory service check is required annually.

1. CONSTRUCTION/ FUNCTIONS

The food is heated by the thick base of the pan under which

several electric rod heaters are located. The pans are

equipped with an electronic comfort control unit with regulation

of the bottom resp. food temperature with or without programming of the cooking time and starting time. The control system

is operated via a membrane keyboard. The pan has a variablespeed tilting facility powered by an electric motor. All types can

be fitted with a mixing unit if required.

1.1 TECHNICAL DATA

Pan bottom made of steel or nickel-chrome plated steel.

Floor mounting on feets or wheels.

Electronic control of pan-base and cooking temperature

or process control system of pan-base and cooking tempera-

ture regulation with programmable cooking and starting time

Hoseproof IP X5

Heating up times (see schedule) of an empty pan from 68°F

(20°C) to an average bottom temperature of 446°F (230°C)

.

Electrically heated tilting frying pans

GP.B......

060 E

(15.9 gal)

Wattage kW 12,2 15,2 18,2

Voltage 208V/3~N

Current A

Voltage 240V/3~N

Current A

Voltage 480V/3~N

Current A

Net content in lt (=max.

capacity)

Heating up times, min. 20 20 20

El. tilting motor: Wattage

kWVoltageCurrent A

35.5 31 15.7

43.8 38.1 19.8

43.8 38.1 23

63 84 104

0.2

230V/1*NE, 50 Hz

1

GP.C......

080 E

(21.1 gal)

GP.E......

100 E

(26.4 gal)

62.9694.03 Page 3

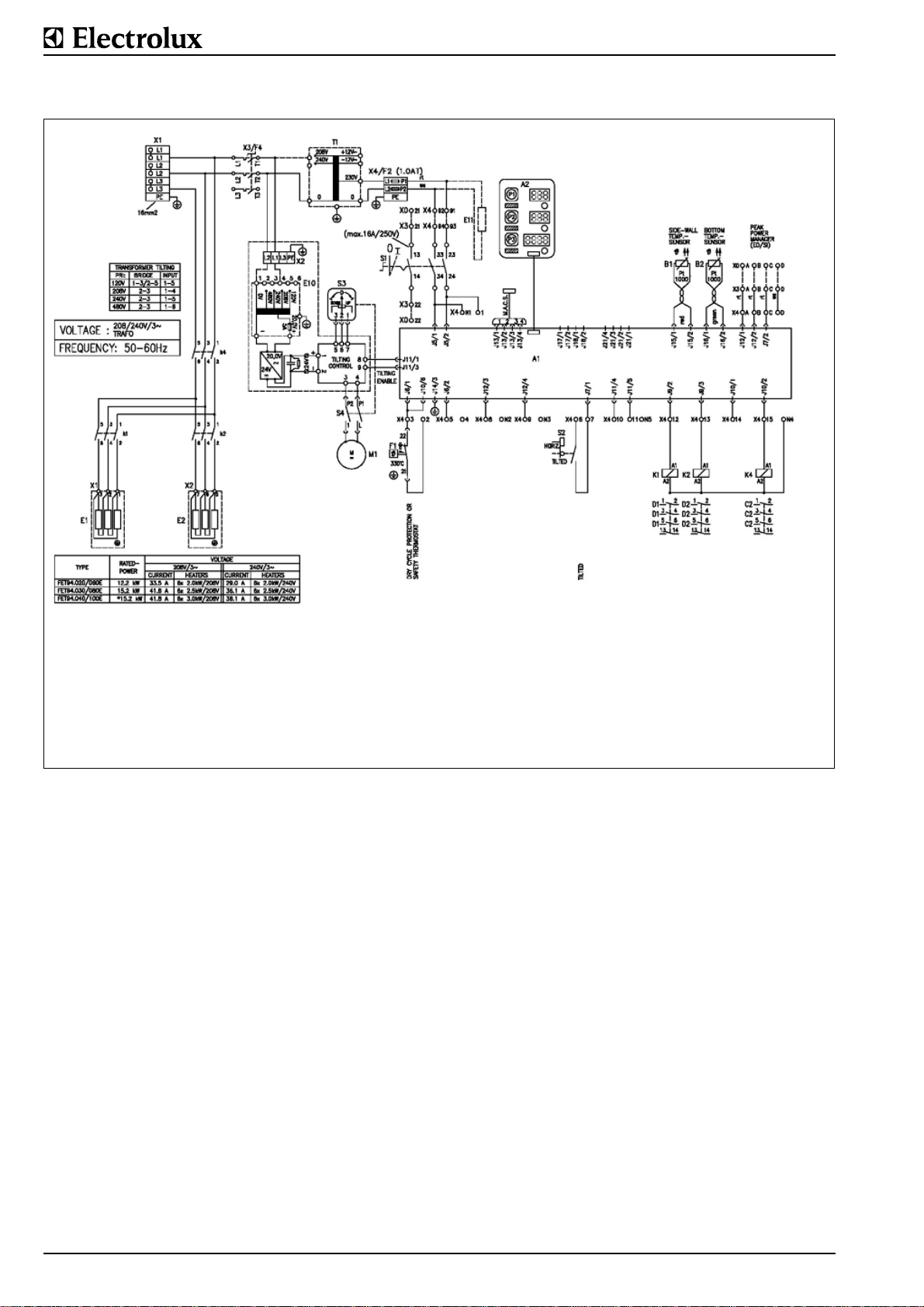

2. ELECTRIC DIAGRAMS

A1 Control print

A2 Operating print

B1 Food temperature sensor

B2 Bottom temperature sensor

E Heating elements

E10 Tilting control

E11 Heating resistor

Fig. 1 Electric diagram, electrically heated frying pan60 LT - 100 LT (15.9 gal - 267.4 gal) 208 V and 240 V

F1 Excess-temperature thermostat

K1.2 Contactors

K4 Safetycontactor

M1 Tilting motor

Q1 Power isolator, optional

S1 Control switch

S2 End switch for horizontal position of

the pan

S1 Tilting switch

X0-.. Terminals

X4 Control fuse

T1 Single- phase transformer (only for

voltage 230V)

EO/SI Connection for energy optimizing

system

The precise specifications of the individual electric components are given in the corresponding parts list. These must be

used in conjunction with the electrical schematic valid for the

appliance.

Page 4 62.9694.03

A1 Control print

A2 Operating print

B1 Food temperature sensor

B2 Bottom temperature sensor

E Heating elements

E10 Tilting control

E11 Heating resistor

Fig. 2 Electric diagram, electrically heated frying pan60 LT - 100 LT (15.9 gal - 267.4 gal) 480 V

F1 Excess-temperature thermostat

K1.2 Contactors

K4 Safetycontactor

M1 Tilting motor

Q1 Power isolator, optio nal

S1 Control switch

S2 End switch for horizontal position of

the pan

S1 Tilting switch

X0-.. Terminals

X4 Control fuse

T1 Single-ph ase transformer (only for

EO/SI Connection for energy optimizing

The precise specifications of the individual electric components are given in the corresponding parts list. The se must be

used in conjunction with the electrical schematic valid for the

appliance.

voltage 230V)

system

62.9694.03 Page 5

3. MAINTENANCE CHECK LIST

Check Fault B Remedy

Connections for protective

conductors

Connections for equipoten-

tiality

Check that all electric con-

nections and contacts to

terminals, coils, switches

and junctions are tight.

Check contactors and

relays.

The contacts must move

freely without sticking or

jamming. Check all contactors for traces of burning.

Measure the individual

phase currents with a

clamp-on ammeter on the

power supply immediately

before the connection terminals with the appliance

switched on full and compare the currents with the

data on the electrical schematic.

Inspect internal wiring. In case of defect cables

Check condition of all oper-

ating foils.

Optical inspection of the

whole control unit.

Test all operating functions

and check that the control

unit works correctly.

Check switches for easy

movement and correct function.

Compare the digital display

of the bottom temperature

with the actual value measured.

Compare the food temper-

ature display with the actual

value.

Inspect fixation and condition of all temperature sen-

sors (jacket, food,

deaeration, excess temperature) and check electrical

connections.

Inspect condition and function of the safety thermo-

stat.

Test if all heating elements

work well by measuring the

indicated heating-up time or

measure the current.

Check all elements of the

display on the operating

panel with service test 1.

Inspect fixation and condition of all switches (power

isolator, control, tilting, stirrer) and check electrical

connections.

In case of loose contacts

B tighten contacts.

In case of defects or faults B

replace contactor or relay.

Identify defective consumers

(heating systems) by carefully measuring the individual currents. If major

deviations are discovered

B Replace.

B replace cables.

Defective foils

B replace.

S If faults are discovered

B repair faulty units or

exchange parts.

S If problems are encountered

B find reason and repair failure.

If the switch is hard to turn or

makes a noise

B replace.

If the deviation is

B trim the display again.

If the deviation is

B trim the display again.

S If sensors, fixation, electrical

connections are found to be

faulty

B replace the parts concerned.

If sensors, fixation, electrical

connections are found to be

S

faulty

B replace the parts concerned.

If larger differences are noted

B exchange the faulty heating element.

If any element of the display

fails

B exchange the whole operating print.

If defects to any fixation or

electrical connections are

discovered

B replace the parts concerned.

5°F

1°F

Check Fault B Remedy

Check function of acoustic

signals.

Check the lid for correct

shape or damage.

Check the lid hinges for

correct function.

Inspect pipework and screw

connections (pans with

external heating) for tight

sealing.

Check function of mixing

unit for function. Check for

leaks of water connections.

S = Part is relevant for safety

If, during servicing, an increased number of failures is

noted for a part that is relevant for safety, a written report

must be sent to the "Aftersales" office responsible without

delay

Measuring the temperature of the pan base

Precise measurement of the temperature of a pan base using

methods in which contact with the base takes place by touching it with a probe (thermocouple, thermometer, etc.) is very

unreliable and generally leads to deviations in the order of

minus 68°F (20°C) to 104°F (40°C). The use of heat-conducting paste does not result in any substantial improvements.

Correct results can be achieved by means of infrared measurement using a pyrometer (e.g. Raytek's Raynger, series

ST2L). To prevent reflection from the pan base, a heat-resistant, fibre-glass tape (e.g. Scotch Brand tape from 3M) must be

bonded to the area to be measured. A surface area of 2 x 2

inch) 5 x 5 cm is enough for this purpose.

If the sound is offkey or no

sound is heard

B exchange the whole control print.

If irreparably damaged

B replace the lid.

If defective

B disassemble, clean,

grease, adjust the hinge.

In case of leakage

B replace seals or pipes.

If the tap drips or if any pipes

leak

B replace seals.

Page 6 62.9694.03

4. ACCESS TO INSIDE

Sheeting of console, support, pan

Remove the connecting rail

(VS)Loosen the front nuts M6

from underneath. Bend the rail

up slightly at the front. Pull the

rail out of the appliance.

Switch panel (F) removal:

Unscrew the two screws at

location (1) underneath the

switch panel and the nuts (MH)

at location (2) on the top, pull

out the switch panel at the tom

and then lift up out of the fixation. The panel is turned up 90°

like a door and hung at the top

on the console.

Cover (A) removal:

If there is a connecting rail

installed to the cover it has to

be removed first. (see 5.3.1.).

Remove the nuts (MU) (two on

a single console, four on a twin

console) at the relevant location (2). Lift the cover at the

front and pull it out of its clip

attachment at the back (3). If a

mixing unit is fitted, this does

not need to be removed from

the cover.

Service panel (V) removal:

Remove the two external nuts

(6) at the front and pull the

panel from its rear attachment

points (5).

Sidewall (S) removal:

To remove this, the switch

panel (F) must be removed

first. Remove the nuts (4) and

(5) inside. The upper internal

wall (W) cannot be disassembled. It must be removed and

refitted together with the pan.

The panels are refitted in the

reverse order to that described

above.

Cover (A). The height of the

cover can be levelled by fitting

more or fewer shims (BE) and

tightening the nuts (MH).

Floor mountingh

Hanging the operating panel

(F) on the console

Removing the pan base

(BD).

Set the pan in the horizontal

position. Remove the screws

(SB) from underneath and

take out the base (BD) from

underneath.

Fitting the base (BD).

Carefully clean any remains

of the old seal from the edge

of the base. Stick a new

sealing strip (DB) on the

edge of the base. Carefully

position the threaded clip

(SM) on the jacket (MK).

Tighten the screws (SB).

Pan jacket. The pan jacket

is not removed during normal

servicing work. Please refer

to § FU1.6 for instructions.

Removing the Front pan

cover (VA):

The front panel of the pan

cover can be removed as follows without removing the

base (BD): remove the front

screws (SB), pull off the

panel underneath the pan,

draw the panel down and out

of the pan flange.

5. FUNCTIONAL COMPONENTS

5.1 FU1. OPERATING FOIL EXCHANGE Removal

Operating foils (FO) are bonded to the sheetmetal surfaces

(cover plates) with self-adhesive coatings. They are removed

with a spatula, a screwdriver or a knife.

Cleaning

The surfaces to which the foil is to be applied

must be clean and dry, i.e., free from dust,

grease, rust, paint, etc. Suitable for cleaning:

toluol or 3M article S-152 stick remover.

Procedure: shake the can thoroughly and

spray evenly on the surface to be cleaned.

(Distance about 6 - 8 inch (15 - 20 cm).) Rub

over with a clean lint-free cloth. If surfaces are

heavily soiled, repeat the process.

Sticking on the foil

Remove the protective backing, taking care

not to touch the adhesive. After positioning

press down well. It is important to apply firm,

even pressure. The ideal working temperature

is approximately 77°F (25°C). Temperatures

below 50°F (10°C) should be avoided since

the adhesive becomes too hard and instantaneous adhesion is reduced. Following application, the foil has a working temperature range

from -40°F (-40°) to +248°F (+120°C) continuous temperature load and 356°F (180°C)

short-time temperature load.

62.9694.03 Page 7

Loading...

Loading...