Page 1

PROFESSIONAL LAUNDRY

Multi-Form Finishers

FFM1, FFM2

Features and benefits

• Even distribution of steam moistens the fabric to

remove creases

• For shirts and jackets/coats/labcoats/whitecoats

processing

• Hot air blowing presses and dries the fabric

• Pneumatic front clamp holds the garment in place

• Adjustable air blowing baffle, suitable for various

fabric types

• Available either for central steam (FFM1) or with

built-in boiler (FFM2)

• Self-contained and integral steam boiler simplifies

the installation (FFM2) and can operate a collar &

cuffs press too, for a complete shirts group

• Air operated cuff clamp improves the sleeve finish

Main options

• Water spray gun with support (FFM2)

• Water spray gun with support and condenser

(FFM1)

Page 2

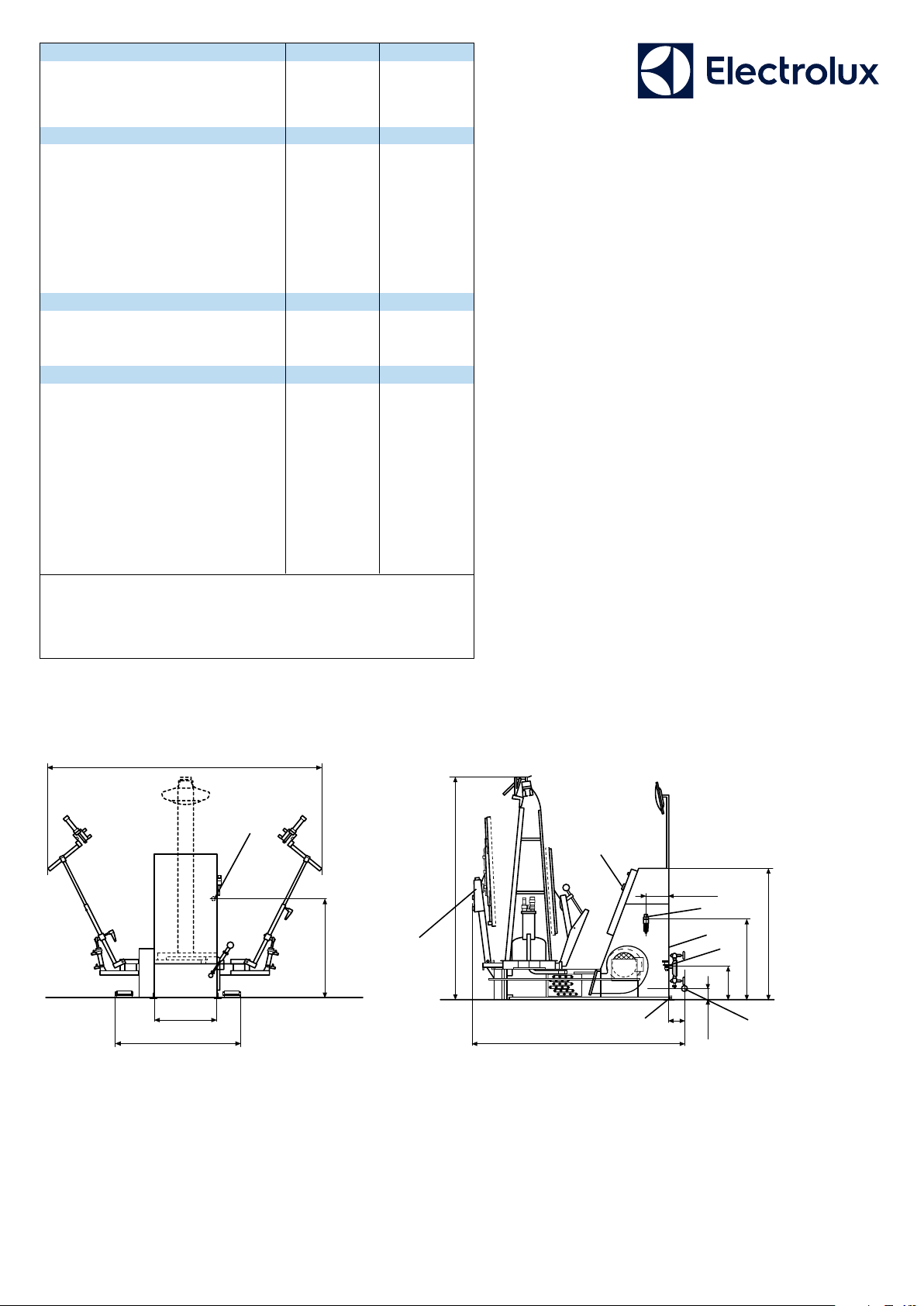

A

Electrical connections FFM1 FFM2

Voltage

208-240V 3 AC 50/60 Hz kW 2 29

400-415V 3N AC 50 Hz kW 2 29

Steam and Air connection

Steam DN 15 Rec. steam pressure kPa 500 Steam consumption kg/h 25-30 Condensate DN 15 Compressed air DN 8 8

Rec. air pressure kPa 700 700

Air consumption l/h 150 150

Water supply mm - Ø13

Boiler drain DN - 15

Shipping data

net, kg 196 218

crated, kg 238 260

boxed, kg 286 308

Dimensions in mm

A Width max 2000 2000

B Depth 1600 1600

C Height 1700 1700

D 455 455

E 780 780

F 490 490

G 60 60

H 130 130

I 215 215

K 570 570

L 170 170

M 1000 1000

1 Control panel

2 Electrical connection

6 Water drain (built-in boiler only)

7 Water supply (built-in boiler only)

3 Steam connection

4 Condensate

5 Air connection

2

D

E

Front Right side

www.electrolux.com/professional

Share more of our thinking at www.electrolux.com

F

6023 B

1

C

1

B

L

5

3

7

4

H

G

M

K

I

6023 C

6

Art. No. 438918911/2015.01.14

We reserve the right to alter specifications without notice.

Loading...

Loading...