Electrolux EIGD55H, EIED55H, EWMGD65H, EWED65H, EWGDS65H Technical & Service Manual

...

DRYER SERVICE MANUAL #5995523544 2008 ALL RIGHTS RESERVED

WWaavvee--TToouucchh™™ && IIQQ--TToouucchh™™

FFrroonntt--LLooaadd DDrryyeerr

MMooddeellss

EEIIGGDD5555HH,, EEIIEEDD5555HH,, EEWWEEDD6655HH,, EEWWGGDDSS6655HH

EEWWMMEEDD6655HH && EEWWMMGGDD6655HH

TTeecchhnniiccaall SSeerrvviiccee MMaannuuaall

1-1

SSeeccttiioonn 11

BBaassiicc IInnffoorrmmaattiioonn

BBaassiicc IInnffoorrmmaattiioonn

BBaassiicc IInnffoorrmmaattiioonn

1-2

SSeeccttiioonn 11 -- BBaassiicc IInnffoorrmmaattiioonn

................................

11--11

Table of Contents.................................................... 1-2

Safe Servicing Practices ........................................ 1-4

Protect Children...................................................... 1-4

Prevent Fire ............................................................ 1-5

Product Specifications Wave-Touch™.................. 1-6

Product Specifications IQ-Touch™ ...................... 1-6

Serial Number Breakdown...................................... 1-6

Quick Reference Sheet .......................................... 1-7

Language of Laundry.............................................. 1-8

SSeeccttiioonn 22 -- IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

................................................ 22--11

Important Safety Instructions ................................ 2-2

Safety Precautions.................................................. 2-2

Tools and Materials Needed for Installation .......... 2-3

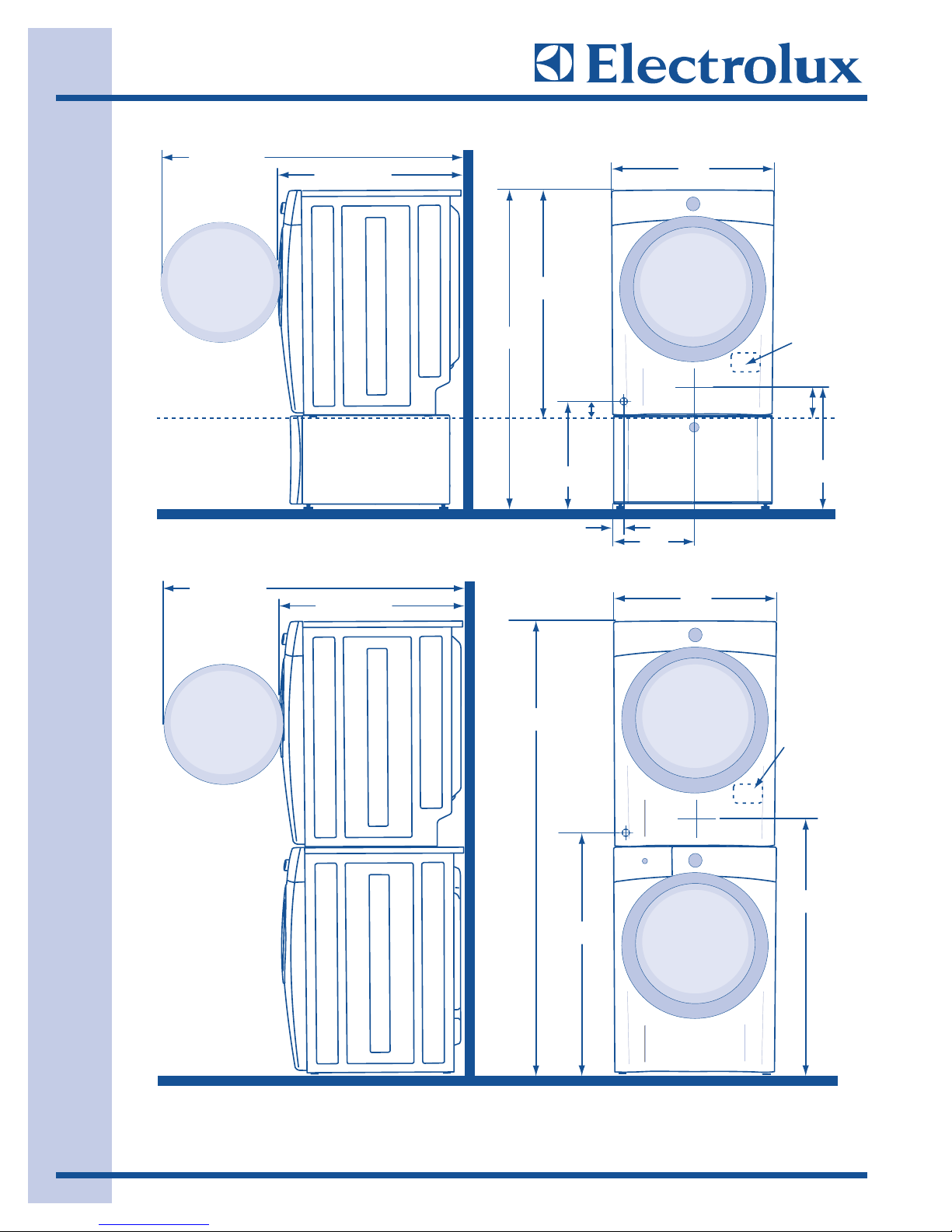

Dryer Installation Dimensions ................................ 2-4

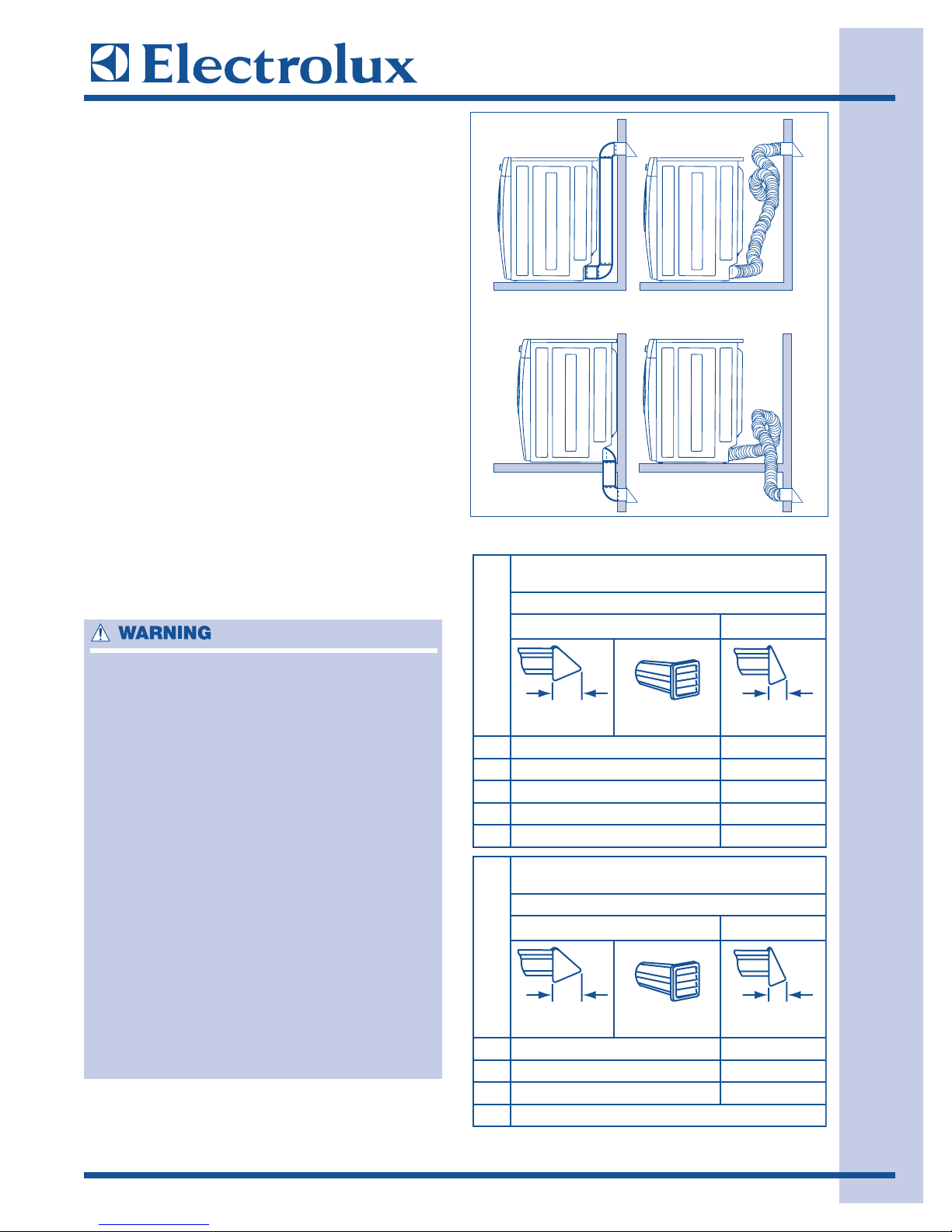

Exhaust System Requirements .............................. 2-5

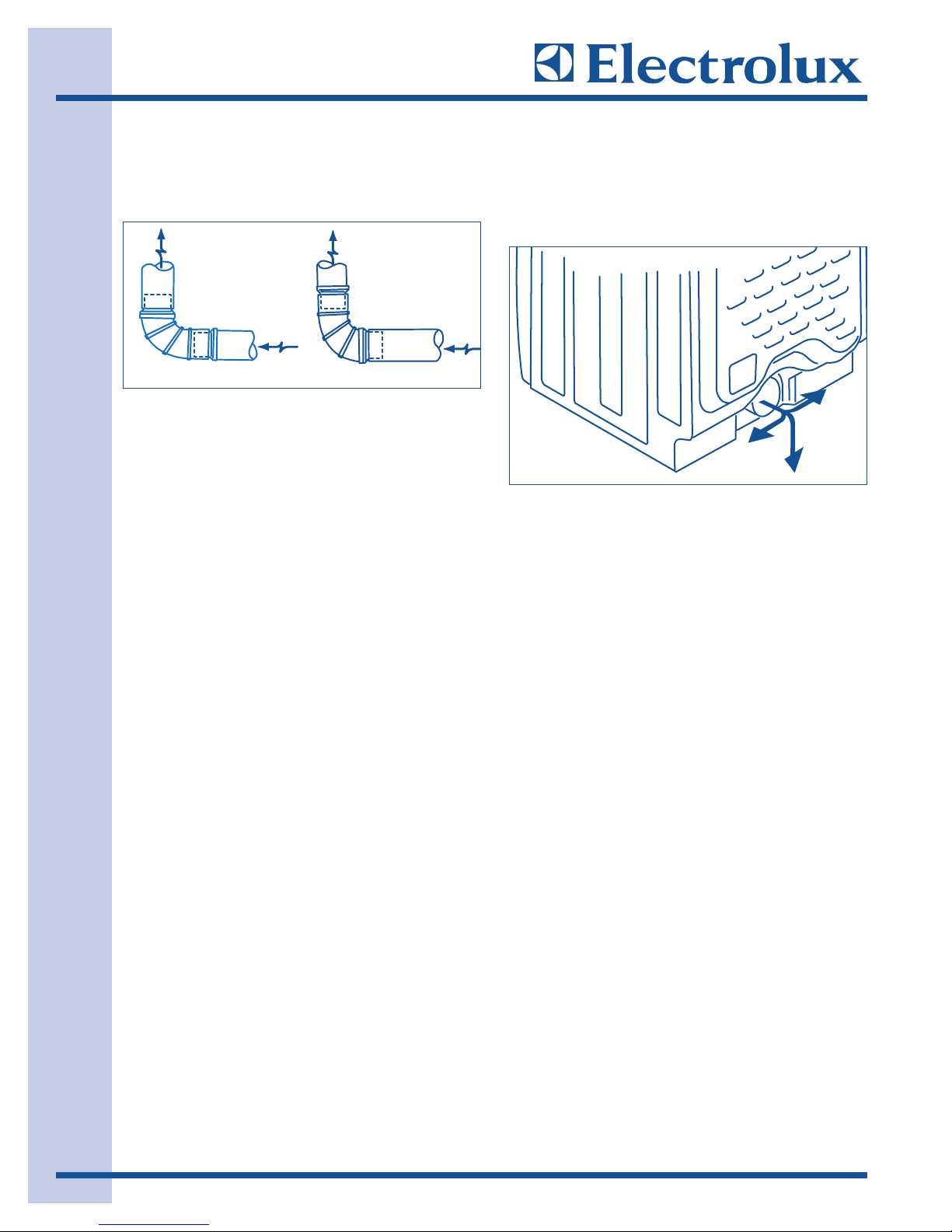

Install Male Fittings in Correct Direction ................ 2-6

Exhaust Direction.................................................... 2-6

Manufactured or Mobile Home Installation ............ 2-6

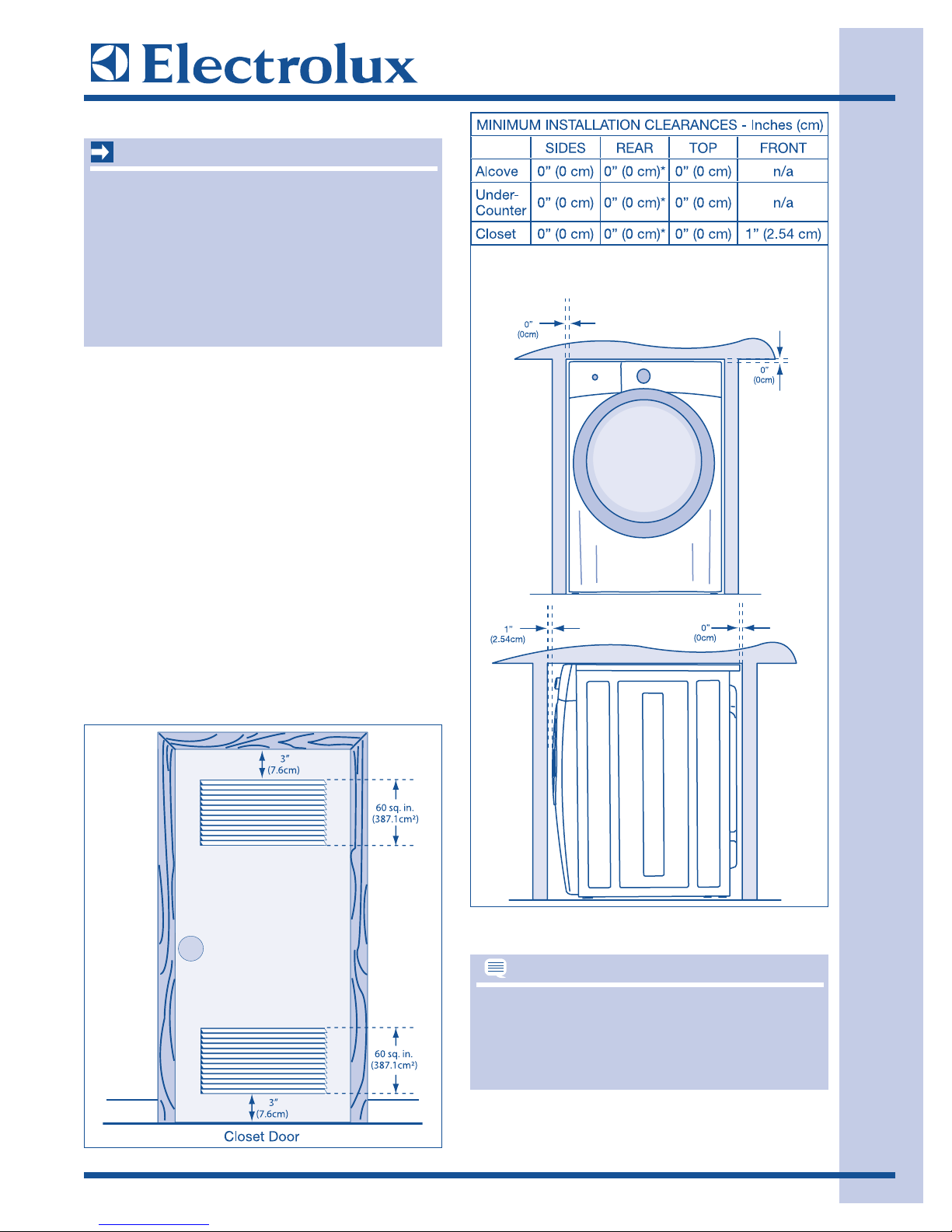

Clearance Requirements ........................................ 2-7

Installation in a Recess or Closet .......................... 2-7

Electrical System Requirements ............................ 2-8

3-Wire Power Supply Cord Kit .............................. 2-8

4-Wire Power Supply Cord Kit .............................. 2-8

Outlet Receptacle .................................................. 2-8

Electrical Requirements for Gas Dryer .................. 2-8

Electrical Installation .............................................. 2-9

For a Grounded, Cord-connected Dryer:

(U.S.A. Electric Dryer) ............................................ 2-9

For a Grounded, Cord-connected Dryer:

(Canada Electric Dryer) .......................................... 2-9

Gas Dryer................................................................ 2-9

Electrical Connection (non-Canada) 3 Wire Cord .. 2-10

Electrical Connection (non-Canada) 4 Wire Cord .. 2-11

Gas Supply Requirements...................................... 2-12

Gas Connection ...................................................... 2-12

Water Connection (Steam Model Only).................. 2-13

General Installation ................................................ 2-14

Wave-Touch™ Installation Cycle ............................ 2-15

IQ -Touch™ Installation Cycle ................................ 2-15

Reversing Door ...................................................... 2-16

Preparing to Reverse Door Swing .......................... 2-16

Removing Trim Ring .............................................. 2-16

Removing Door from Hinge.................................... 2-16

Removing Hinge from Front Panel ........................ 2-17

Removing Door Lock from Front Panel.................. 2-17

Reattaching Door Lock to Font Panel .................... 2-18

Reattaching Hinge to Front Panel .......................... 2-18

Removing Striker Plate .......................................... 2-19

Removing Latch Indicator .................................... 2-19

Removing Hole Plug .............................................. 2-20

Reinserting Latch Indicator .................................... 2-20

Reattaching Striker Plate........................................ 2-21

Reinserting Hole Plug ............................................ 2-21

Reattaching Door Assembly .................................. 2-21

Reversing Trim Ring................................................ 2-22

Reinstalling Trim Ring ............................................ 2-22

Reinstalling Trim Plug ............................................ 2-22

Accessories ............................................................ 2-23

Matching Storage Pedestal .................................... 2-23

Dryer Stacking Kit .................................................. 2-23

Dryer Stacking Instructions .................................. 2-24

Kit Components...................................................... 2-24

Preparing to Stack.................................................. 2-24

Preparing Dryer for Stacking .................................. 2-24

Preparing Washer for Stacking .............................. 2-25

Prepare Top Surface of Washer ............................ 2-25

Stacking Dryer ........................................................ 2-25

Removing Stacked Dryer........................................ 2-26

SSeeccttiioonn 33 -- EElleeccttrroonniicc CCoonnttrrooll

................................................................ 33--11

Control Panel (User Interface Layout)

Wave-Touch™ ........................................................ 3-2

Selecting the Appropriate Cycle and Settings

Overview ................................................................ 3-2

Demo Mode ............................................................ 3-2

Wave-Touch™ Dryer Options Chart ...................... 3-3

Wave-Touch™ Dryer Options Chart

(Steam Model) ........................................................ 3-4

Control Panel (User Interface Layout)

IQ-Touch™ .............................................................. 3-5

Selecting the Appropriate Cycle and Settings

Overview ................................................................ 3-5

Demo Mode ............................................................ 3-5

IQ-Touch™ Dryer Options Chart ............................ 3-6

Cycle Selection ...................................................... 3-7

Auto Dry Cycles ................................................ 3-7

Normal .............................................................. 3-7

Towels................................................................ 3-7

Mixed Load........................................................ 3-8

Heavy Duty ........................................................ 3-8

Bulky/ Bedding.................................................. 3-8

Casual................................................................ 3-8

Active Wear ...................................................... 3-8

Delicate.............................................................. 3-8

Time Dry Cycles...................................................... 3-8

Time Dry ............................................................ 3-8

Fast Dry ............................................................ 3-8

Touch Up (non-steam models only) .................. 3-8

Perfect Steam (steam models only) .................. 3-8

My Favorites (Wave-Touch™) .......................... 3-9

Drying Temperature ................................................ 3-10

Auto Dry ............................................................ 3-10

Maximum Temp ................................................ 3-10

High Temp ........................................................ 3-10

Med High Temp ................................................ 3-10

Medium Temp.................................................... 3-10

Med Low Temp.................................................. 3-10

Low Temp .......................................................... 3-10

Air Fluff Temp .................................................... 3-10

Time Dry ............................................................ 3-10

Options .................................................................. 3-11

Add Steam (steam models only) ...................... 3-11

Extended Tumble .............................................. 3-11

Wrinkle Release (IQ-Touch™)............................ 3-11

Wrinkle Release (Wave-Touch™ ) .................... 3-11

1-3

SSeeccttiioonn 33 -- EElleeccttrroonniicc CCoonnttrrooll

Gentle Tumble .................................................. 3-12

Delicate Heat .................................................... 3-12

Sanitize .............................................................. 3-12

Chime ................................................................ 3-12

Delicate Heat .................................................... 3-12

Damp Alert ........................................................ 3-12

Shrink Guard .................................................... 3-12

User Interface Features .......................................... 3-13

Save as Favorite................................................ 3-13

Set Prefs............................................................ 3-13

User Guides ...................................................... 3-13

Stain Guides ...................................................... 3-13

Control Lock (Wave-Touch™) .......................... 3-13

Control Lock (IQ-Touch™) ................................ 3-13

My Favorites (Wave-Touch™) .......................... 3-13

Save as Favorite .................................................... 3-14

Setting Preferences ................................................ 3-15

Custom Mode.................................................... 3-15

Install Cycle (Wave-Touch™) ............................ 3-16

Install Cycle (IQ -Touch™) ................................ 3-16

Reset (Wave-Touch™) ...................................... 3-17

Reset (IQ-Touch™) ............................................ 3-17

Contrast ............................................................ 3-17

Brightness ........................................................ 3-18

Volume .............................................................. 3-18

Language .......................................................... 3-18

Cycle Description .............................................. 3-18

Status Display .................................................. 3-18

Drum Light ........................................................ 3-18

Diagnostics and Error Codes ................................ 3-19

Reading Error Codes .............................................. 3-19

To Clear Latest Stored Error Code ........................ 3-19

Exiting Diagnostic Mode ........................................ 3-19

Diagnostic Mode .................................................... 3-20

To Start the Diagnostic Mode ................................ 3-20

Error Code Chart .................................................... 3-21

IQ-Touch™ Available Cycle Settings, Pre-Sets

and Options Chart .................................................. 3-23

Wave-Touch™ Available Cycle Settings,

Pre-Sets and Options Chart .................................. 3-24

Wave-Touch™ with Steam, Available Cycle

Settings, Pre-Sets and Options Chart.................... 3-25

SSeeccttiioonn 44-- CCoommppoonneenntt TTeeaarrddoowwnn

.................................................... 44--11

Warnings and Cautions .......................................... 4-2

Door Components .................................................. 4-3

Door Trim Ring .................................................. 4-3

Door Assembly .................................................. 4-3

Latch Plate and Door Latch .............................. 4-4

Inner Door Glass .............................................. 4-4

Door Latch Assembly........................................ 4-4

Latch Indicator .................................................. 4-5

Door Strike ...................................................... 4-5

Outer Door Glass .............................................. 4-5

Door Hinge ........................................................ 4-6

Lint Trap .................................................................. 4-6

Air Duct Cover ........................................................ 4-6

Top Panel ................................................................ 4-7

Console and User Interface.................................... 4-7

Front Panel.............................................................. 4-8

Door Switch ............................................................ 4-8

Control Assembly .................................................. 4-9

Control Box Bracket .............................................. 4-9

Interior Light............................................................ 4-10

Top Rear Brace ...................................................... 4-10

Rear Panel .............................................................. 4-10

Inlet Thermistor ...................................................... 4-11

Moisture Sensing Bar ............................................ 4-11

Belt Removal (Wave Touch™) ................................ 4-12

Belt Removal (IQ Touch™)...................................... 4-12

Front Inner Panel and Drum .................................. 4-12

Roller Assembly ...................................................... 4-13

Front Air Duct ........................................................ 4-13

Exhaust Thermal Limiter ........................................ 4-14

Exhaust Tube .......................................................... 4-14

Outlet (Exhaust) Thermistor .................................. 4-14

Belt Tensioner (Wave Touch™) .............................. 4-15

Belt Tensioner (IQ Touch™) .................................. 4-15

Motor and Blower Assembly .................................. 4-16

Motor and Blower Assembly Separation................ 4-17

Drum Vane .............................................................. 4-18

Rear Heat Duct ...................................................... 4-18

Heat Shield ............................................................ 4-18

Electric Heater Function ........................................ 4-19

Heater Assembly .................................................... 4-19

Thermal Limiter and Safety Thermostat ................ 4-19

Gas Heater Assembly Breakdown.......................... 4-20

Thermal Limiters .................................................... 4-20

Gas Valve Wire Harness Connections.................... 4-20

Gas Valve Coil ........................................................ 4-20

Manifold and Burner Assembly Breakdown .......... 4-21

Combustion Tube .................................................. 4-22

SSeeccttiioonn 55-- TTrroouubblleesshhoooottiinngg

........................................................................ 55--11

Troubleshooting Chart ............................................ 5-2

Electrical Tests For Gas And Electric Dryers .......... 5-4

Electrical Tests For Electric Dryers ........................ 5-5

Electrical Tests For Gas Dryers .............................. 5-6

SSeeccttiioonn 66-- WWiirriinngg DDiiaaggrraammss

.................................................................... 66--11

Wiring Diagram Model EIED55H ............................ 6-2

Wiring Diagram Model EIGD55H ............................ 6-3

Wiring Diagram Model EWED65H .......................... 6-4

Wiring Diagram Model EWGD65H.......................... 6-5

Wiring Diagram Model EWMED65.......................... 6-6

Wiring Diagram Model EWMGD65 ........................ 6-7

BBaassiicc IInnffoorrmmaattiioonn

BBaassiicc IInnffoorrmmaattiioonn

1-4

SSaaffee SSeerrvviicciinngg PPrraaccttiicceess

AAvvooiidd ppeerrssoonnaall iinnjjuurryy aanndd//oorr pprrooppeerrttyy ddaammaaggee bbyy oobbsseerrvviinngg iimmppoorrttaanntt SSaaffee SSeerrvviicciinngg PPrraaccttiicceess..

FFoolllloowwiinngg aarree ssoommee lliimmiitteedd eexxaammpplleess ooff ssaaffee pprraaccttiicceess::

1. DO NOT attempt a product repair if you have any doubts as to your ability to complete the repair in a

safe and satisfactory manner.

2. Always Use The Correct Replacement Parts as indicated in the parts documentation. Substitutions

may defeat compliance with Safety Standards Set For Home Appliances.

3. Before servicing or moving an appliance:

• Remove power cord from the electrical outlet, trip circuit breaker to OFF position, or remove fuse.

• Turn off water supply for steam models.

• Turn off gas supply for gas dryers.

4. Never interfere with the proper operation of any safety device.

5. Use ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE. Substitutions may defeat

compliance with Safety Standards Set For Home Appliances.

6. GROUNDING: The standard color coding for safety ground wires is GREEN, or GREEN with YELLOW

STRIPES. Ground leads are not to be used as current carrying conductors.

It is EXTREMELY important that the service technician reestablish all safety grounds prior to

completion of service. Failure to do so will create a hazard.

7. Prior to returning the product to service, ensure that:

• All electrical connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high temperature

components, and moving parts.

• All non-insulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all

metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely connected.

• All panels are properly and securely reassembled

• Gas and water supplies are turned ON if shut off prior to service.

PPrrootteecctt CChhiillddrreenn

Do not allow children to play on or in the dryer.Close supervision of children is necessary when the dryer

is used near children. As children grow, teach them the proper, safe use of all appliances.

Destroy the carton, plastic bag and other packing materials after the dryer is unpacked.

Children might use them for play. Cartons covered with rugs, bedspreads or plastic sheets can become

airtight chambers.

Keep laundry products out of children’s reach. To prevent personal injury, observe all warnings on product

labels.

Before the dryer is removed from service or discarded, remove the dryer door to prevent accidental

entrapment.

Failure to comply with these warnings could result in serious personal injuries.

TThhiiss sseerrvviiccee mmaannuuaall iiss iinntteennddeedd ffoorr uussee bbyy ppeerrssoonnss hhaavviinngg eelleeccttrriiccaall aanndd mmeecchhaanniiccaall ttrraaiinniinngg aanndd aa

lleevveell ooff kknnoowwlleeddggee ooff tthheessee ssuubbjjeeccttss ggeenneerraallllyy ccoonnssiiddeerreedd aacccceeppttaabbllee iinn tthhee aapppplliiaannccee rreeppaaiirr ttrraaddee..

EElleeccttrroolluuxx HHoommee PPrroodduuccttss,, IInncc.. ccaannnnoott bbee rreessppoonnssiibbllee,, nnoorr aassssuummee aannyy lliiaabbiilliittyy,, ffoorr iinnjjuurryy oorr ddaammaaggee ooff

aannyy kkiinndd aarriissiinngg ffrroomm tthhee uussee ooff tthhiiss mmaannuuaall..

BBaassiicc IInnffoorrmmaattiioonn

1-5

PPrreevveenntt FFiirree

Do not dry items that have been previously cleaned in, soaked in, or spotted with gasoline, cleaning

solvents, kerosene, waxes, etc. Do not store these items on or near the dryer. These substances give off

vapors that could ignite or explode.

Do not place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a load to catch fire.

To prevent fire, do not use heat to dry items containing plastic, foam rubber or similarly textured rubberlike materials, or items containing feathers or down. Use Air Fluff (No Heat) only.

Clean the lint screen before or after each load. The interior of the dryer, lint screen housing and exhaust

duct should be cleaned approximately every 18 months by qualified service personnel. An excessive

amount of lint buildup in these areas could result in inefficient drying and possible fire.

Do not operate the dryer if the lint screen is blocked, damaged or missing. Fire hazard, overheating and

damage to fabrics can occur. If your dryer has a drying rack, always replace the lint screen when finished

using the drying rack.

Keep area around exhaust opening and surrounding areas free from the accumulation of lint, dust and dirt.

Do not obstruct the flow of ventilating air. Do not stack or place laundry or throw rugs against the front or

back of the dryer.

Do not spray any type of aerosol into, on or near dryer at any time.

Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of

the fabric softener or product.

Failure to comply with these warnings could result in fire, explosion, serious bodily injury and/or damage

to the rubber or plastic parts of the dryer.

TTOO PPRREEVVEENNTT PPEERRSSOONNAALL IINNJJUURRYY OORR DDAAMMAAGGEE TTOO TTHHEE DDRRYYEERR,, TTHHEE EELLEECCTTRRIICCAALL PPOOWWEERR CCOORRDD

OOFF AA GGAASS DDRRYYEERR MMUUSSTT BBEE PPLLUUGGGGEEDD IINNTTOO AA PPRROOPPEERRLLYY GGRROOUUNNDDEEDD AANNDD PPOOLLAARRIIZZEEDD 33--PPRROONNGG

OOUUTTLLEETT.. TTHHEE TTHHIIRRDD GGRROOUUNNDDIINNGG PPRROONNGG MMUUSSTT NNEEVVEERR BBEE RREEMMOOVVEEDD..

NNEEVVEERR GGRROOUUNNDD TTHHEE DDRRYYEERR TTOO AA GGAASS PPIIPPEE..

DDOO NNOOTT UUSSEE AANN EEXXTTEENNSSIIOONN CCOORRDD OORR AANN AADDAAPPTTEERR PPLLUUGG..

AALLWWAAYYSS DDIISSCCOONNNNEECCTT TTHHEE DDRRYYEERR FFRROOMM TTHHEE EELLEECCTTRRIICCAALL SSUUPPPPLLYY BBEEFFOORREE AATTTTEEMMPPTTIINNGG AANNYY

SSEERRVVIICCEE OORR CCLLEEAANNIINNGG.. FFAAIILLUURREE TTOO DDOO SSOO CCAANN RREESSUULLTT IINN EELLEECCTTRRIICCAALL SSHHOOCCKK OORR IINNJJUURRYY..

DDOO NNOOTT UUSSEE AANNYY TTYYPPEE SSPPRRAAYY CCLLEEAANNSSEERR WWHHEENN CCLLEEAANNIINNGG DDRRYYEERR IINNTTEERRIIOORR.. HHAAZZAARRDDOOUUSS

FFUUMMEESS OORR EELLEECCTTRRIICCAALL SSHHOOCCKK CCOOUULLDD OOCCCCUURR..

TTOO PPRREEVVEENNTT IINNJJUURRYY,, DDOO NNOOTT RREEAACCHH IINNTTOO TTHHEE DDRRYYEERR IIFF TTHHEE DDRRUUMM IISS MMOOVVIINNGG.. WWAAIITT UUNNTTIILL

TTHHEE DDRRYYEERR HHAASS SSTTOOPPPPEEDD CCOOMMPPLLEETTEELLYY BBEEFFOORREE RREEAACCHHIINNGG IINNTTOO TTHHEE DDRRUUMM..

TTOO PPRREEVVEENNTT IINNJJUURRYY AANNDD DDAAMMAAGGEE TTOO TTHHEE DDRRYYEERR::

•• AALLLL RREEPPAAIIRRSS AANNDD SSEERRVVIICCIINNGG MMUUSSTT BBEE PPEERRFFOORRMMEEDD BBYY AANN AAUUTTHHOORRIIZZEEDD SSEERRVVIICCEERR

UUNNLLEESSSS SSPPEECCIIFFIICCAALLLLYY RREECCOOMMMMEENNDDEEDD IINN TTHHIISS OOWWNNEERR’’SS GGUUIIDDEE..

UUSSEE OONNLLYY AAUUTTHHOORRIIZZEEDD FFAACCTTOORRYY PPAARRTTSS..

•• DDOO NNOOTT TTAAMMPPEERR WWIITTHH CCOONNTTRROOLLSS..

•• DDOO NNOOTT IINNSSTTAALLLL OORR SSTTOORREE TTHHEE DDRRYYEERR WWHHEERREE IITT WWIILLLL BBEE EEXXPPOOSSEEDD TTOO TTHHEE

WWEEAATTHHEERR..

BBaassiicc IInnffoorrmmaattiioonn

1-6

PPrroodduucctt SSppeecciiffiiccaattiioonnss WWaavvee TToouucchh

™

DDrryyeerr

2 Premium Colors

Enhanced LCD Controls (with larger trilingual display)

Reversing Drum

Quiet (56 dBA maximum)

11 Standard and 3 Favorite Cycles with custom

settings to reach 42 Total Cycles

Multiple User Mode – 3 User Modes with Favorite

and Custom Cycles

8 Timed Dry Options

Shrink Guard

Drum Light with manual switch

2 Temperature Selections (7 total)

Steam

Fastest Cycle Time

CCyycclleess

NSF Certified

Heavy Duty

Bulky/Bedding

Mixed Load

Towels

Normal

Active Wear – Use for sports/workout gear

Quick Dry – The fastest cycle in the industry

Casual – Use for Permanent Press items

Delicate – Gentler than any cycle available

Touch Up

Time Dry – Up to 90 minutes

My Favorite – Programmable by consumer

AAddddiittiioonnaall OOppttiioonnss

Damp Alert – For items that will be ironed.

Control Lock – to prevent accidental operation by

children

7 Temperature Selections

Wrinkle Rid – Extends tumble time so wrinkles do

not set.

Soft Heat – Reduces the temperature as the cycle

progresses to prevent damage.

PPrroodduucctt SSppeecciiffiiccaattiioonnss IIQQ TToouucchh™DDrryyeerr

White and 1 Premium Color

Superior drying – Even & Gentle

Reversible Door

Push2Open: Door & Pedestal

Large Capacity (8 cu. ft.)

Intelligent and Adaptive LCD Controls

Electrolux Blue LEDs

Custom Cycles Including My Favorite

Quiet (59 dBA maximum)

Top CU Rating

11 Cycles with 4 Dryness levels and 5

Temperature Selections

NSF Rated Sanitary Cycle

Fastest Cycle Time

CCyycclleess

NSF Certified

Heavy Duty

Bulky/Bedding

Mixed Load

Towels

Normal

Quick Dry – The fastest cycle in the industry

Casual – Use for Permanent Press items

Delicate – Gentler than any cycle available

Touch Up

Time Dry – Up to 90 minutes

My Favorite – Programmable by consumer

AAddddiittiioonnaall OOppttiioonnss

Damp Alert – For items that will be ironed.

Control Lock – to prevent accidental operation by

children

5 Temperature Selections

Wrinkle Rid – Extends tumble time so wrinkles do

not set.

Soft Heat – Reduces the temperature as the cycle

progresses to prevent damage.

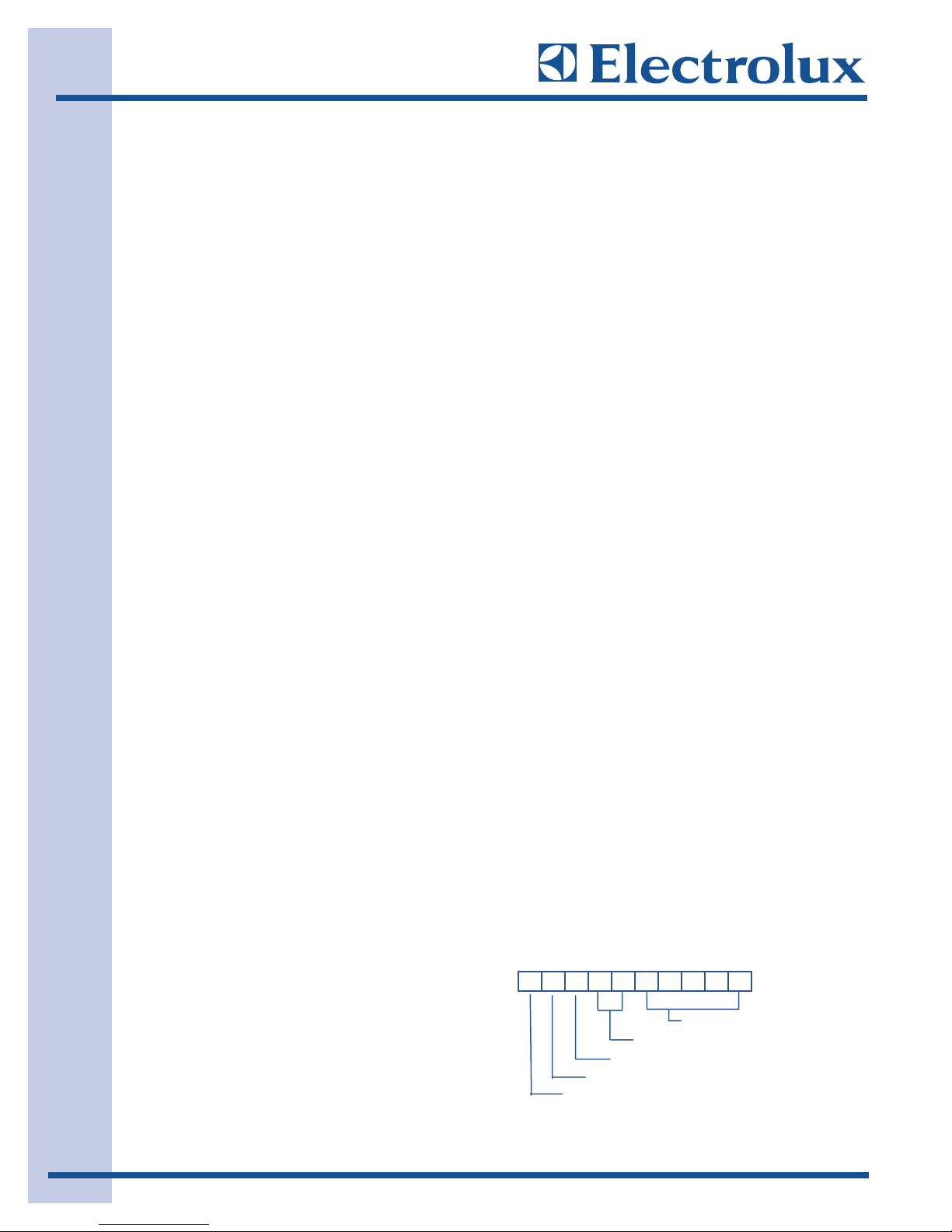

MMooddeell NNuummbbeerr BBrreeaakkddoowwnn

Each model follows the following nomenclature:

E ..................for Electrolux

I ..................for IQ Touch

W ..................for Wave Touch

FLW ..............for Front Load Washer

ED ................for Electric Dryer

GD ................for Gas Dryer

MED/MGD ....Steam Electric/Steam Gas Dryer

P ....................for Pedestal

SSeerriiaall NNuummbbeerr BBrreeaakkddoowwnn

Serial Number Breakdown

4D82812345

Production Week

Last Digit of Production Year

Product Identication

Manufacturing Facility

Incremented unit number

BBaassiicc IInnffoorrmmaattiioonn

1-7

QUICK REFERENCE SHEET

SPECIFICATION

Electrical

Vol ts 120/208 or 120/240

Amps (circuit)

Motor wattage

Heat input (Watts @ 240 VAC)

Heat input (BTU/Hr.)

Auto. Elec. Ignition

Drum

Size (Cu. Ft.)

Finish

R.P.M.

Airow CFM

DRUM TEMPERATURES

(Max. opening on 3rd cycle)

Maximum

Medium

Low

Dimension (Inches)

Height

Width

Depth

ELECTRIC MODELS

120/208 or 120/240

30

200-290 Watts

4300/5500

---

---

8.0

Powder Paint Epoxy

48 - 54

200

120° - 160°

110° - 140°

95° - 130°

38”

27”

31.5”

GAS MODELS

120

15

200-290 Watts

---

22,000

Ye s

8.0

Powder Paint Epoxy

48 - 54

200

120° - 180°

105° - 145°

95° - 130°

38”

27”

31.5”

Vent Capability

Top Finish

Port Opening (Sq.In.)

Component Resistances*

Drive motor (120 volt, 60 Hz, 1/4 h.p. 1725 rpm)

Motor Start Winding

Motor Run Winding

Heating Element

Control Thermistor

Burner Assembly

Ignitor

Secondary Coil

Booster Coil

Powder Paint Enamel

4-Way

235

Electric Models

4.5 Ohms

3.8 Ohms

26.4 Ohms

50K Ohms

+/- 5% @ 77° F

---

---

---

4-Way

Powder Paint Enamel

235

Gas Models

4.5 Ohms

3.8 Ohms

50K Ohms

+/- 5% @ 77° F

50 - 400 Ohms

1200 Ohms

1320 Ohms

* +/- 10% @ 77° F

BBaassiicc IInnffoorrmmaattiioonn

1-8

The Language of Laundry

Machine Wash

Instructions

Normal

Wash

Permanent

Press

Gentle

Cycle

DO NOT

Machine Wash

Cold

(<85ºF)

Special

Care

Hand

Wash

DO NOT

Wring

Bleaching

Instructions

Bleach

as Needed

Non-chlorine

Bleach as Needed

DO NOT

Bleach

Instructions

Normal

Dry

Permanent

Press

Gentle

Setting

DO NOT

Tumble Dry

No Heat

Dryer

Machine Dry

DO NOT

Line Dry

Drip Dry

Dry Flat

Dry in

Shade

Ironing

Instructions

Low Heat

Med. Heat

High Heat

DO NOT

Steam

DO NOT

Iron

Dry

Cleaning

Dry Clean

Dry Clean

w/ Any

Solvent

Dry Clean

w/Petroleum

Solvent

Dry Clean

w/Solvents

Other Than

Trichloroethylene

DO NOT

Dry Clean

Warm

(<105ºF)

Hot

(<120ºF)

Hot

(<140ºF)

Low Heat

Normal/

Med. Heat

High

Heat

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-1

SSeeccttiioonn 22

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-2

IIMMPPOORRTTAANNTT SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS

SSaaffeettyy PPrreeccaauuttiioonnss

Do not attempt to install or operate this appliance until you read the safety precautions in this guide.

Safety items throughout this guide are labeled with a Warning or Caution based on the risk type.

WWAARRNNIINNGG

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CCaauuttiioonn

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

EELLEECCTTRROOLLUUXX CCAANNNNOOTT BBEE HHEELLDD RREESSPPOONNSSIIBBLLEE FFOORR DDAAMMAAGGEE TTOO PPRROOPPEERRTTYY OORR IINNJJUURRYY TTOO

PPEERRSSOONNSS CCAAUUSSEEDD BBYY FFAAIILLUURREE TTOO CCOOMMPPLLYY WWIITTHH TTHHEE IINNSSTTAALLLLAATTIIOONN,, MMAAIINNTTEENNAANNCCEE AANNDD

SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS CCOONNTTAAIINNEEDD IINN TTHHIISS SSEERRVVIICCEE MMAANNUUAALL..

TTOO RREEDDUUCCEE TTHHEE RRIISSKK OOFF FFIIRREE,, EELLEECCTTRRIICCAALL SSHHOOCCKK,, OORR IINNJJUURRYY WWHHEENN UUSSIINNGG AA

WWAAVVEE--TTOOUUCCHH™™ OORR IIQQ--TTOOUUCCHH™™ DDRRYYEERR,, FFOOLLLLOOWW BBAASSIICC SSAAFFEETTYY PPRREECCAAUUTTIIOONNSS IINNCCLLUUDDIINNGG

TTHHEE FFOOLLLLOOWWIINNGG::

-- RREEAADD AALLLL IINNSSTTRRUUCCTTIIOONNSS BBEEFFOORREE OOPPEERRAATTIINNGG TTHHEE DDRRYYEERR..

-- BBEEFFOORREE PPEERRFFOORRMMIINNGG AANNYY TTYYPPEE OOFF SSEERRVVIICCEE OORR IINNSSTTAALLLLAATTIIOONN,, MMAAKKEE SSUURREE TTHHAATT

EELLEECCTTRRIICC PPOOWWEERR TTOO TTHHEE DDRRYYEERR IISS DDIISSCCOONNNNEECCTTEEDD..

-- TTOO AAVVOOIIDD TTHHEE PPOOSSSSIIBBIILLIITTYY OOFF EEXXPPLLOOSSIIOONN OORR FFIIRREE,, DDOO NNOOTT SSTTOORREE OORR UUSSEE

CCOOMMBBUUSSTTIIBBLLEE,, FFLLAAMMMMAABBLLEE,, OORR EEXXPPLLOOSSIIVVEE LLIIQQUUIIDDSS OORR VVAAPPOORRSS ((SSUUCCHH AASS GGAASSOOLLIINNEE))

IINNSSIIDDEE OORR IINN TTHHEE VVIICCIINNIITTYY OOFF TTHHIISS OORR AANNYY OOTTHHEERR AAPPPPLLIIAANNCCEE..

-- TTHHIISS AAPPPPLLIIAANNCCEE IISS EEQQUUIIPPPPEEDD WWIITTHH AA TTHHRREEEE--PPRROONNGG GGRROOUUNNDDIINNGG PPLLUUGG FFOORR

PPRROOTTEECCTTIIOONN AAGGAAIINNSSTT PPOOSSSSIIBBLLEE EELLEECCTTRRIICC SSHHOOCCKK HHAAZZAARRDDSS.. PPLLUUGG IITT OONNLLYY IINNTTOO AA

DDEEDDIICCAATTEEDD,, GGRROOUUNNDDEEDD EELLEECCTTRRIICCAALL OOUUTTLLEETT.. WWHHEENN OONNLLYY AA SSTTAANNDDAARRDD TTWWOO--PPRROONNGG

EELLEECCTTRRIICCAALL OOUUTTLLEETT IISS AAVVAAIILLAABBLLEE,, TTHHEE CCUUSSTTOOMMEERR MMUUSSTT HHAAVVEE IITT RREEPPLLAACCEEDD WWIITTHH AA

DDEEDDIICCAATTEEDD,, PPRROOPPEERRLLYY GGRROOUUNNDDEEDD TTHHRREEEE--PPRROONNGG EELLEECCTTRRIICCAALL OOUUTTLLEETT BBEEFFOORREE UUSSIINNGG

TTHHIISS AAPPPPLLIIAANNCCEE.. DDOO NNOOTT UUNNDDEERR AANNYY CCIIRRCCUUMMSSTTAANNCCEESS,, CCUUTT OORR RREEMMOOVVEE TTHHEE TTHHIIRRDD

((GGRROOUUNNDD)) PPRROONNGG FFRROOMM TTHHEE PPOOWWEERR CCOORRDD.. DDOO NNOOTT UUSSEE AANN AADDAAPPTTEERR PPLLUUGG.. DDOO NNOOTT

UUSSEE AANN EEXXTTEENNSSIIOONN CCOORRDD.. DDOO NNOOTT UUSSEE AA PPOOWWEERR CCOORRDD TTHHAATT IISS FFRRAAYYEEDD OORR DDAAMMAAGGEEDD..

TTHHEE UUSSEE OOFF AA GGRROOUUNNDD FFAAUULLTT IINNTTEERRRRUUPPTTEERR ((GGFFII)) IISS NNOOTT RREECCOOMMMMEENNDDEEDD..

-- DDOO NNOOTT IINNSSTTAALLLL OORR UUSSEE AA DDAAMMAAGGEEDD AAPPPPLLIIAANNCCEE.. IIFF YYOOUU RREECCEEIIVVEE AA DDAAMMAAGGEEDD

AAPPPPLLIIAANNCCEE,, IIMMMMEEDDIIAATTEELLYY CCOONNTTAACCTT YYOOUURR DDEEAALLEERR OORR BBUUIILLDDEERR..

-- DDOO NNOOTT UUSSEE TTHHEE DDRRYYEERR UUNNTTIILL IITT HHAASS BBEEEENN PPRROOPPEERRLLYY IINNSSTTAALLLLEEDD BBYY AA QQUUAALLIIFFIIEEDD

IINNSSTTAALLLLEERR AACCCCOORRDDIINNGG TTOO TTHHEESSEE IINNSSTTAALLLLAATTIIOONN IINNSSTTRRUUCCTTIIOONNSS.. TTHHEE IINNSSTTAALLLLEERR MMUUSSTT

SSHHOOWW TTHHEE CCUUSSTTOOMMEERR TTHHEE LLOOCCAATTIIOONN OOFF TTHHEE PPOOWWEERR PPLLUUGG SSOO TTHHAATT TTHHEEYY KKNNOOWW WWHHEERREE

AANNDD HHOOWW TTOO DDIISSCCOONNNNEECCTT PPOOWWEERR TTOO TTHHEE DDRRYYEERR..

-- DDOO NNOOTT IINNSSTTAALLLL,, RREEPPAAIIRR,, OORR RREEPPLLAACCEE AANNYY PPAARRTT OOFF TTHHEE DDRRYYEERR UUNNLLEESSSS

SSPPEECCIIFFIICCAALLLLYY RREECCOOMMMMEENNDDEEDD IINN TTHHEE LLIITTEERRAATTUURREE AACCCCOOMMPPAANNYYIINNGG IITT.. AA QQUUAALLIIFFIIEEDD

SSEERRVVIICCEE TTEECCHHNNIICCIIAANN SSHHOOUULLDD PPEERRFFOORRMM AALLLL OOTTHHEERR SSEERRVVIICCEE..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-3

WWHHAATT TTOO DDOO IIFF YYOOUU SSMMEELLLL GGAASS::

•• DDoo nnoott ttrryy ttoo lliigghhtt aannyy aapppplliiaannccee..

•• DDoo nnoott ttoouucchh aannyy eelleeccttrriiccaall sswwiittcchh;; ddoo nnoott uussee aannyy pphhoonnee iinn yyoouurr bbuuiillddiinngg..

•• CClleeaarr tthhee rroooomm,, bbuuiillddiinngg oorr aarreeaa ooff aallll ooccccuuppaannttss..

•• IImmmmeeddiiaatteellyy ccaallll yyoouurr ggaass ssuupppplliieerr ffrroomm aa nneeiigghhbboorr’’ss pphhoonnee.. FFoollllooww tthhee ggaass ssuupppplliieerr’’ss iinnssttrruuccttiioonnss..

•• IIff yyoouu ccaannnnoott rreeaacchh yyoouurr ggaass ssuupppplliieerr,, ccaallll tthhee ffiirree ddeeppaarrttmmeenntt..

PPrree--iinnssttaallllaattiioonn RReeqquuiirreemmeennttss

TToooollss aanndd mmaatteerriiaallss nneeeeddeedd ffoorr iinnssttaallllaattiioonn::

DDEESSTTRROOYY CCAARRTTOONN,, PPLLAASSTTIICC BBAAGGSS,, AANNDD AANNYY EEXXTTEERRIIOORR WWRRAAPPPPIINNGG MMAATTEERRIIAALL IIMMMMEEDDIIAATTEELLYY

AAFFTTEERR TTHHEE DDRRYYEERR IISS UUNNPPAACCKKEEDD.. CCHHIILLDDRREENN SSHHOOUULLDD NNEEVVEERR UUSSEE TTHHEESSEE IITTEEMMSS FFOORR PPLLAAYY..

CCAARRTTOONNSS CCOOVVEERREEDD WWIITTHH RRUUGGSS,, BBEEDDSSPPRREEAADDSS,, PPLLAASSTTIICC SSHHEEEETTSS OORR SSTTRREETTCCHH WWRRAAPP MMAAYY

BBEECCOOMMEE AAIIRR TTIIGGHHTT CCHHAAMMBBEERRSS AANNDD CCAANN QQUUIICCKKLLYY CCAAUUSSEE SSUUFFFFOOCCAATTIIOONN..

KKEEEEPP LLAAUUNNDDRRYY PPRROODDUUCCTTSS OOUUTT OOFF CCHHIILLDDRREENN’’SS RREEAACCHH.. TTOO PPRREEVVEENNTT PPEERRSSOONNAALL IINNJJUURRYY,,

OOBBSSEERRVVEE AALLLL WWAARRNNIINNGGSS OONN PPRROODDUUCCTT LLAABBEELLSS..

CCUUTT HHAAZZAARRDD.. TTOO PPRREEVVEENNTT SSEERRIIOOUUSS IINNJJUURRYY FFRROOMM SSHHAARRPP EEDDGGEESS,, WWEEAARR WWOORRKK GGLLOOVVEESS

WWHHEENN HHAANNDDLLIINNGG,, UUNNPPAACCKKIINNGG OORR DDIISSAASSSSEEMMBBLLIINNGG UUNNIITT..

EEXXCCEESSSSIIVVEE WWEEIIGGHHTT HHAAZZAARRDD

TToo aavvooiidd bbaacckk oorr ootthheerr iinnjjuurryy,, hhaavvee mmoorree tthhaann oonnee ppeerrssoonn mmoovvee oorr lliifftt tthhee ddrryyeerr..

TThhee eelleeccttrriiccaall sseerrvviiccee ttoo tthhee ddrryyeerr mmuusstt ccoonnffoorrmm wwiitthh llooccaall ccooddeess aanndd oorrddiinnaanncceess aanndd tthhee llaatteesstt

eeddiittiioonn ooff tthhee NNaattiioonnaall EElleeccttrriiccaall CCooddee,, AANNSSII//NNFFPPAA 7700,, oorr iinn CCaannaaddaa,, tthhee CCaannaaddiiaann eelleeccttrriiccaall ccooddee

CC2222..11 ppaarrtt 11..

CAUTION

NOTE

or

Adjustable

pliers

semi-rigid metal exhaust duct work

Phillips, straight, &

square bit screwdrivers

4 inch, rigid metal or

Adjustable

wrench

3-wire or 4-wire

240 volt cord kit

(electric dr yer)

Pipe wrench

for gas

supply

4 in.

(10.2 cm)

clamp

LP-resistant

thread tape

(for natural gas

or LP supply)

gas line

shutoff valve

(gas dr yer)

Carpenter’s level

½” NPT union are

adapters (x2) and

exible gas supply line

(gas dr yer)

External

vent hood

Metal foil tape

(not duct tape)

or

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-4

DDrryyeerr IInnssttaallllaattiioonn DDiimmeennssiioonnss

FFiigguurree 22--11..

50.6” (128.5cm)*

To clear open door

Freestand dryer

on oor

Floor line

31.50” (80cm)*

To front of closed door

53.00”

(134.5cm)

38.00”

(96.5cm)

Gas supply

pipe on rear

of gas unit

1.4”

(3.5cm)

27.00”

(68.5cm)

Electrical

supply on

rear of unit

Centerline

height for

rear vent

3.40”

(8.5cm)

Dryer mounted on

optional pedestal

Floor line

* To obtain these minimal depth dimensions, dryer must either be vented straight back

or with a quick-turn90° elbow. Connection of water inlet hose on Steam Models

adds 3/4 in. (2 cm) to installation depth.

50.6” (128.5cm)*

To clear open door

31.50” (80cm)*

To front of closed door

75.75”

(192.5cm)

16.25”

(41.5cm)

3.75”

(9.5cm)

Gas supply

pipe on rear

of gas unit

39.00”

(99cm)

13.50”

(34.5cm)

To center of rear vent

27.00”

(68.5cm)

18.25”

(46.5cm)

Electrical

supply on

rear of unit

Centerline

height for

rear vent

41.00”

(104cm)

* To obtain these minimal depth dimensions, dryer must either be vented straight back or with a quick-turn 90° elbow.

Connection of water inlet hose on Steam Models adds 3/4 in. (2 cm) to installation depth.

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-5

EExxhhaauusstt SSyysstteemm RReeqquuiirreemmeennttss

Use only 4 inch (10.2 cm) diameter (minimum) rigid

or flexible metal duct and approved vent hood

which has a swing-out damper(s) that open when

the dryer is in operation. When the dryer stops,

the dampers automatically close to prevent drafts

and the entrance of insects and rodents. To avoid

restricting the outlet, maintain a minimum of 12

inches (30.5 cm) clearance between the vent hood

and the ground or any other obstruction.

If the present system is made up of plastic duct or

metal foil duct, replace it with a rigid or semi-rigid

metal duct. In Canada and the United States if

metal (foil type) duct is installed, it must be of a

specific type identified by the appliance manufacturer as suitable for use with clothes dryers and in

the United States must also comply with the

Outline for Clothes Dryer Transition Duct, UL

standard 2158A. Also, ensure the present duct is

free of any lint prior to installing dryer duct.

The dryer must be connected to an exhaust

outdoors. Regularly inspect the outdoor exhaust

opening and remove any accumulation of lint

around the outdoor exhaust opening and in the

surrounding area. (See Figure 2-2 & 2-3)

DDOO NNOOTT AALLLLOOWW CCOOMMBBUUSSTTIIBBLLEE MMAATTEERRIIAALLSS

((FFOORR EEXXAAMMPPLLEE:: CCLLOOTTHHIINNGG,, DDRRAAPPEERRIIEESS AANNDD

CCUURRTTAAIINNSS,, PPAAPPEERR)) TTOO CCOOMMEE IINN CCOONNTTAACCTT

WWIITTHH EEXXHHAAUUSSTT SSYYSSTTEEMM.. TTHHEE DDRRYYEERR MMUUSSTT

NNOOTT BBEE EEXXHHAAUUSSTTEEDD IINNTTOO AA CCHHIIMMNNEEYY,, WWAALLLL,,

CCEEIILLIINNGG,, OORR AANNYY CCOONNCCEEAALLEEDD SSPPAACCEE OOFF AA

BBUUIILLDDIINNGG WWHHIICCHH CCAANN AACCCCUUMMUULLAATTEE LLIINNTT,,

RREESSUULLTTIINNGG IINN AA FFIIRREE HHAAZZAARRDD..

DDOO NNOOTT SSCCRREEEENN TTHHEE EEXXHHAAUUSSTT EENNDDSS OOFF TTHHEE

VVEENNTT SSYYSSTTEEMM,, OORR UUSSEE AANNYY SSCCRREEWWSS,, RRIIVVEETTSS

OORR OOTTHHEERR FFAASSTTEENNEERRSS TTHHAATT EEXXTTEENNDD IINNTTOO

TTHHEE DDUUCCTT TTOO AASSSSEEMMBBLLEE TTHHEE EEXXHHAAUUSSTT

SSYYSSTTEEMM.. LLIINNTT CCAANN BBEECCOOMMEE CCAAUUGGHHTT IINN TTHHEE

SSCCRREEEENN,, OONN TTHHEE SSCCRREEWWSS OORR RRIIVVEETTSS,,

CCLLOOGGGGIINNGG TTHHEE DDUUCCTT WWOORRKK AANNDD CCRREEAATTIINNGG

AA FFIIRREE HHAAZZAARRDD AASS WWEELLLL AASS IINNCCRREEAASSIINNGG

DDRRYYIINNGG TTIIMMEESS.. UUSSEE AANN AAPPPPRROOVVEEDD VVEENNTT

HHOOOODD TTOO TTEERRMMIINNAATTEE TTHHEE DDUUCCTT OOUUTTDDOOOORRSS,,

AANNDD SSEEAALL AALLLL JJOOIINNTTSS WWIITTHH DDUUCCTT TTAAPPEE.. AALLLL

MMAALLEE DDUUCCTT PPIIPPEE FFIITTTTIINNGGSS MMUUSSTT BBEE

IINNSSTTAALLLLEEDD DDOOWWNNSSTTRREEAAMM WWIITTHH TTHHEE FFLLOOWW

OOFF AAIIRR..

FFiigguurree 22--33..

FFiigguurree 22--22..

Correct Incorrect

Correct Incorrect

MAXIMUM LENGTH

of 4” (10.2cm) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

snrut °09 fo rebmuN

4”

(10.2cm) louvered

0 125 ft. (38.10m) 110 ft. (33.53m)

1 115 ft. (35.05m) 100 ft. (30.48m)

2 105 ft. (32.00m) 90 ft. (27.43m)

3 95 ft. (28.96m) 80 ft. (24.38m)

4 85 ft. (25.91m) 70 ft. (21.34m)

MAXIMUM LENGTH

of 4” (10.2cm) Semi-Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

snrut °09 fo rebmuN

4”

(10.2cm)

0 60 ft. (18.29m) 45 ft. (13.72m)

1 50 ft. (15.24m) 35 ft. (10.67m)

2 40 ft. (12.19m) 25 ft. (7.62m)

3 NOT RECOMMENDED

louvered

2.5”

(6.35cm)

2.5”

(6.35cm)

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-6

IInnssttaallll MMaallee FFiittttiinnggss iinn CCoorrrreecctt DDiirreeccttiioonn::

In installations where the exhaust system is not

described in the charts, the following method

must be used to determine if the exhaust system

is acceptable: (See Figure 2-4)

EExxhhaauusstt SSyysstteemm RReeqquuiirreemmeennttss

1. Connect an inclined or digital manometer

between the dryer and the point the exhaust

connects to the dryer.

2. Set the dryer timer and temperature to air fluff

(cool down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be

higher than 1.0 inch of water column. If the

system back pressure is less than 1.0 inch of

water column, the system is acceptable. If the

manometer reading is higher than 1.0 inch of

water column, the system is too restrictive and

the installation is unacceptable.

Although vertical orientation of the exhaust system

is acceptable, certain extenuating circumstances

could affect the performance of the dryer:

1. Only the rigid metal duct work should be used.

2. Venting vertically through a roof may expose

the exhaust system to down drafts causing an

increase in vent restriction.

3. Running the exhaust system through an

uninsulated area may cause condensation and

faster accumulation of lint.

4. Compression or crimping of the exhaust

system

will cause an increase in vent restriction.

5. The exhaust system should be inspected and

cleaned a minimum of every 18 months with

normal usage. The more the dryer is used,

the more often you should check the exhaust

system and vent hood for proper operation.

EExxhhaauusstt DDiirreeccttiioonn

Directional exhausting can be accomplished by

installing a quick-turn 90° dryer vent elbow directly

to exhaust outlet of dryer. Dryer vent elbows are

available through your local parts distributor or

hardware store. (See Figure 2-5)

MMaannuuffaaccttuurreedd oorr MMoobbiillee HHoommee IInnssttaallllaattiioonn

1. Installation MUST conform to current

Manufactured Home Construction & Safety

Standard, Title 24 CFR, Part 32-80 (formerly

the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part

280) or Standard CAN/CSAZ240 MH.

2. Dryer MUST be exhausted outside (outdoors,

not beneath the mobile home) using metal

ducting that will not support combustion.

Metal ducting must be 4 inches (10.16 cm) in

diameter with no obstructions. Rigid metal

duct is preferred.

3. If dryer is exhausted through the floor and area

beneath the mobile home is enclosed, the

exhaust system MUST terminate outside the

enclosure with the termination securely

fastened to the mobile home structure.

4. Refer to previous sections in this guide for

other important exhaust venting system

requirements.

5. When installing a gas dryer into a mobile

home, a provision must be made for outside

make up air. This provision is to be not less

than twice the area of the dryer exhaust outlet.

6. Installer MUST anchor this (1) dryer or (2)

dryer mounted on pedestal to the floor with

approved Mobile Home Installation Kit.

FFiigguurree 22--44..

FFiigguurree 22--55..

CORRECT

INCORRECT

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-7

CClleeaarraannccee RReeqquuiirreemmeennttss

IInnssttaallllaattiioonn iinn aa RReecceessss oorr CClloosseett

1. A dryer installed in a bedroom, bathroom,

recess or closet, MUST be exhausted out

doors.

2. No other fuel burning appliance shall be

installed in the same closet as the gas dryer.

3. The dryer needs the space around it for proper

ventilation.

DDOO NNOOTT

install dryer in a closet

with a solid door.

4. Closet door ventilation required: A minimum of

120 square inches (774.2 cm²) of opening,

equally divided at the top and bottom of door,

is required. Openings should be located 3

inches (7.6 cm) from bottom and top of door.

Openings are required to be unobstructed

when a door is installed. A louvered door with

equivalent air openings for the full length of

door is acceptable. (See Figure 2-6 & 2-7)

DDOO NNOOTT IINNSSTTAALLLL TTHHEE DDRRYYEERR::

11.. IInn aann aarreeaa eexxppoosseedd ttoo ddrriippppiinngg wwaatteerr oorr oouutt

ssiiddee wweeaatthheerr ccoonnddiittiioonnss..

22.. IInn aann aarreeaa wwhheerree iitt wwiillll ccoommee iinn ccoonnttaacctt wwiitthh

ccuurrttaaiinnss,, ddrraappeess,, oorr aannyytthhiinngg tthhaatt wwiillll oobbssttrruucctt

tthhee ffllooww ooff ccoommbbuussttiioonn aanndd

vveennttiillaattiioonn aaiirr..

33.. OOnn ccaarrppeett.. FFlloooorr MMUUSSTT bbee ssoolliidd wwiitthh aa

mmaaxxiimmuumm ssllooppee ooff 11 iinncchh ((22..5544 ccmm))..

TToo aacchhiieevvee aann iinnssttaallllaattiioonn wwiitthh 00”” ((00ccmm))

cclleeaarraannccee ffoorr tthhee bbaacckk ooff tthhee ddrryyeerr ((ffoorr ootthheerr

tthhaann ssttrraaiigghhtt bbaacckk vveennttiinngg)),, aa qquuiicckk--ttuurrnn 9900°°

ddrryyeerr vveenntt eellbbooww mmuusstt bbee iinnssttaalllleedd aass ddeessccrriibbeedd

pprreevviioouussllyy iinn tthhiiss mmaannuuaall..

FFiigguurree 22--66..

FFiigguurree 22--77..

IMPORTANT

NOTE

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-8

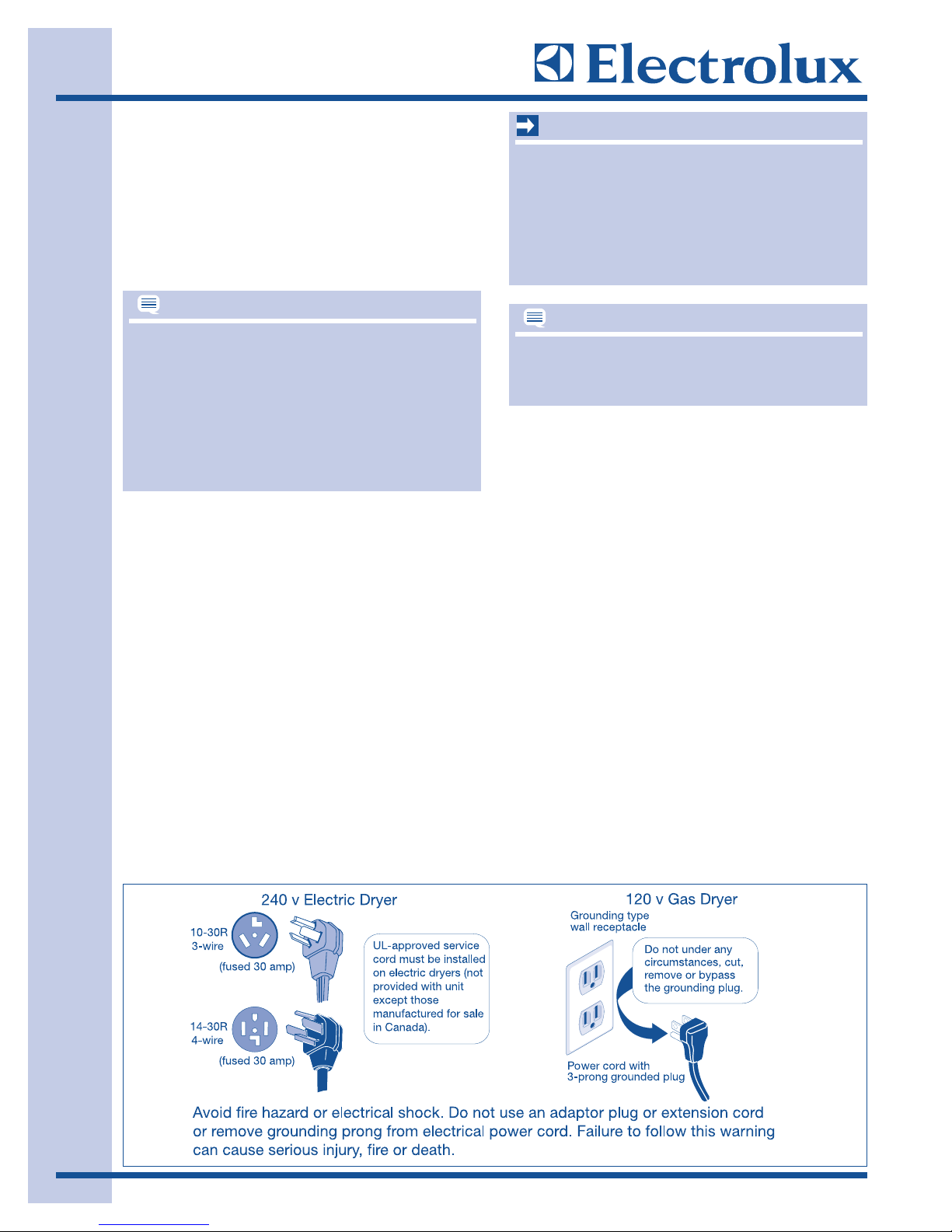

EElleeccttrriiccaall SSyysstteemm RReeqquuiirreemmeennttss

Circuit - Individual 30 amp. branch circuit fused

with 30 amp. time delay fuses or circuit breakers.

Use separately fused circuits for washer and dryer.

DO NOT operate a washer and a dryer on the

same circuit.

Power Supply - 3-wire or 4-wire, 240 volt,

single phase, 60 Hz, Alternating Current.

33--WWiirree PPoowweerr SSuuppppllyy CCoorrdd KKiitt ((nnoott ssuupppplliieedd))

The dryer MUST employ a 3-conductor power

supply cord NEMA 10-30 type SRDT rated at

240 volt AC minimum, 30 amp, with 3 open end

spade lug connectors with upturned ends or

closed loop connectors and marked for use with

clothes dryers. For 3-wire cord connection

instructions see ELECTRICAL CONNECTIONS

FOR A 3-WIRE SYSTEM.

44--WWiirree PPoowweerr SSuuppppllyy CCoorrdd KKiitt ((nnoott ssuupppplliieedd))

The dryer MUST employ a 4-conductor power

supply cor

d NEMA 14-30 type SRDT or ST (as

required) rated at 240 volt AC minimum, 30 amp,

with 4 open end spade lug connectors with

upturned ends or closed loop connectors and

marked for use with clothes dryers. For 4-wire

cord connection instructions see ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

BBeeccaauussee ooff ppootteennttiiaallllyy iinnccoonnssiisstteenntt vvoollttaaggee

ccaappaabbiilliittiieess,, tthhee uussee ooff tthhiiss ddrryyeerr wwiitthh ppoowweerr

ccrreeaatteedd bbyy ggaass ppoowweerreedd ggeenneerraattoorrss,, ssoollaarr ppooww--

eerreedd ggeenneerraattoorrss,, wwiinndd ppoowweerreedd ggeenneerraattoorrss oorr

aannyy ootthheerr ggeenneerraattoorr ootthheerr tthhaann tthhee llooccaall uuttiilliittyy

ccoommppaannyy iiss nnoott rreeccoommmmeennddeedd..

GGFFII ((GGrroouunndd FFaauulltt IInntteerrrruupptteerr)) rreecceeppttaaccllee iiss

nnoott rreeqquuiirreedd..

DDrryyeerrss mmaannuuffaaccttuurreedd ffoorr ssaallee iinn CCaannaaddaa hhaavvee

ffaaccttoorryy--iinnssttaalllleedd,, 44--wwiirree ppoowweerr ssuuppppllyy ccoorrdd

((NNEEMMAA 1144--3300RR))..

TThhiiss ddrryyeerr iiss iinntteerrnnaallllyy ggrroouunnddeedd ttoo nneeuuttrraall

uunnlleessss iitt wwaass mmaannuuffaaccttuurreedd ffoorr ssaallee iinn CCaannaaddaa..

GGrroouunnddiinngg tthhrroouugghh tthhee nneeuuttrraall lliinnkk iiss pprroohhiibbiitteedd

ffoorr:: ((11)) nneeww bbrraanncchh cciirrccuuiitt iinnssttaallllaattiioonnss,, ((22))

mmoobbiillee hhoommeess,, ((33)) rreeccrreeaattiioonnaall vveehhiicclleess,, aanndd ((44))

aarreeaass wwhheerree llooccaall ccooddeess ddoo nnoott ppeerrmmiitt ggrroouunndd--

iinngg tthhrroouugghh tthhee nneeuuttrraall..

OOuuttlleett RReecceeppttaaccllee

NEMA 10-30R or NEMA 14-30R receptacle to be

located so the power supply cord is accessible

when the dryer is in the installed position.

EElleeccttrriiccaall RReeqquuiirreemmeennttss ffoorr GGaass DDrryyeerr::

Circuit - Individual, properly polarized and

grounded 15 amp. branch circuit fused with 15

amp. time delay fuse or circuit breaker.

Power Supply - 2-wire, with ground, 120 volt,

single phase, 60 Hz, Alternating Current.

Power Supply Cord - The dryer is equipped

with a 120 volt 3-wire power cord.

Grounding Connection - See “Grounding

requirements” in Electrical Installation section.

NOTE

IMPORTANT

NOTE

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-9

EElleeccttrriiccaall IInnssttaallllaattiioonn

FFoorr aa GGrroouunnddeedd,, CCoorrdd--ccoonnnneecctteedd DDrryyeerr::

((UU..SS..AA.. EElleeccttrriicc DDrryyeerr))

1. The dryer MUST be grounded. In the event of

a malfunction or breakdown, grounding will

reduce the risk of electrical shock by a path of

least resistance for electrical current.

2. After you purchase and install a 3 wire or 4

wire power supply cord having an equipment

grounding conductor and a grounding plug

that matches your wiring system, the plug

MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and

grounded in accordance with all local codes

and ordinances. If in doubt, call a licensed

electrician.

DDOO NNOOTT

modify the plug you’ve installed on this

appliance.

FFoorr aa ppeerrmmaanneennttllyy ccoonnnneecctteedd ddrryyeerr::

1.

The dryer MUST be connected to a grounded

metal, permanent wiring system; or an

equipment grounding conductor must be run

with the circuit conductors and connected to

the equipment-grounding terminal or lead on

the appliance.

FFoorr aa GGrroouunnddeedd,, CCoorrdd--ccoonnnneecctteedd DDrryyeerr::

((CCaannaaddaa EElleeccttrriicc DDrryyeerr))

1.

The dryer MUST be grounded. In the event of

a malfunction or breakdown, grounding will

reduce the risk of electrical shock by a path of

least resistance for electrical current.

2. Since your dryer is equipped with a power

supply cord having an equipment-grounding

conductor and a grounding plug, the plug

must be plugged into an appropriate outlet

that is properly installed and grounded in

accordance with all local codes and

ordinances. If in doubt, call a licensed

electrician.

DDOO NNOOTT

modify the plug provided with the

appliance.

GGaass DDrryyeerr

1. The dryer is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong

receptacle.

DDOO NNOOTT

cut or remove ground prong from the

plug.

DDOO NNOOTT UUSSEE AANN EEXXTTEENNSSIIOONN CCOORRDD WWIITTHH TTHHIISS DDRRYYEERR.. SSOOMMEE EEXXTTEENNSSIIOONN CCOORRDDSS AARREE NNOOTT

DDEESSIIGGNNEEDD TTOO WWIITTHHSSTTAANNDD TTHHEE AAMMOOUUNNTTSS OOFF EELLEECCTTRRIICCAALL CCUURRRREENNTT TTHHIISS DDRRYYEERR UUTTIILLIIZZEESS AANNDD

CCAANN MMEELLTT,, CCRREEAATTIINNGG EELLEECCTTRRIICCAALL SSHHOOCCKK AANNDD//OORR FFIIRREE HHAAZZAARRDD.. LLOOCCAATTEE TTHHEE DDRRYYEERR WWIITTHHIINN

RREEAACCHH OOFF TTHHEE RREECCEEPPTTAACCLLEE FFOORR TTHHEE LLEENNGGTTHH PPOOWWEERR CCOORRDD TTOO BBEE PPUURRCCHHAASSEEDD,, AALLLLOOWWIINNGG

SSOOMMEE SSLLAACCKK IINN TTHHEE CCOORRDD..

AA UU..LL..--AAPPPPRROOVVEEDD SSTTRRAAIINN RREELLIIEEFF MMUUSSTT BBEE IINNSSTTAALLLLEEDD OONNTTOO PPOOWWEERR CCOORRDD.. IIFF TTHHEE SSTTRRAAIINN

RREELLIIEEFF IISS NNOOTT AATTTTAACCHHEEDD,, TTHHEE CCOORRDD CCAANN BBEE PPUULLLLEEDD OOUUTT OOFF TTHHEE DDRRYYEERR AANNDD CCAANN BBEE CCUUTT BBYY

AANNYY MMOOVVEEMMEENNTT OOFF TTHHEE CCOORRDD,, RREESSUULLTTIINNGG IINN EELLEECCTTRRIICCAALL SSHHOOCCKK..

DDOO NNOOTT UUSSEE AANN AALLUUMMIINNUUMM WWIIRREEDD RREECCEEPPTTAACCLLEE WWIITTHH AA CCOOPPPPEERR WWIIRREEDD PPOOWWEERR CCOORRDD AANNDD

PPLLUUGG ((OORR VVIICCEE VVEERRSSAA)).. AA CCHHEEMMIICCAALL RREEAACCTTIIOONN OOCCCCUURRSS BBEETTWWEEEENN CCOOPPPPEERR AANNDD AALLUUMMIINNUUMM

AANNDD CCAANN CCAAUUSSEE EELLEECCTTRRIICCAALL SSHHOORRTTSS.. TTHHEE PPRROOPPEERR WWIIRRIINNGG AANNDD RREECCEEPPTTAACCLLEE IISS AA CCOOPPPPEERR

WWIIRREEDD PPOOWWEERR CCOORRDD WWIITTHH AA CCOOPPPPEERR WWIIRREEDD RREECCEEPPTTAACCLLEE..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-10

FFiigguurree 22--99..

FFiigguurree 22--88..

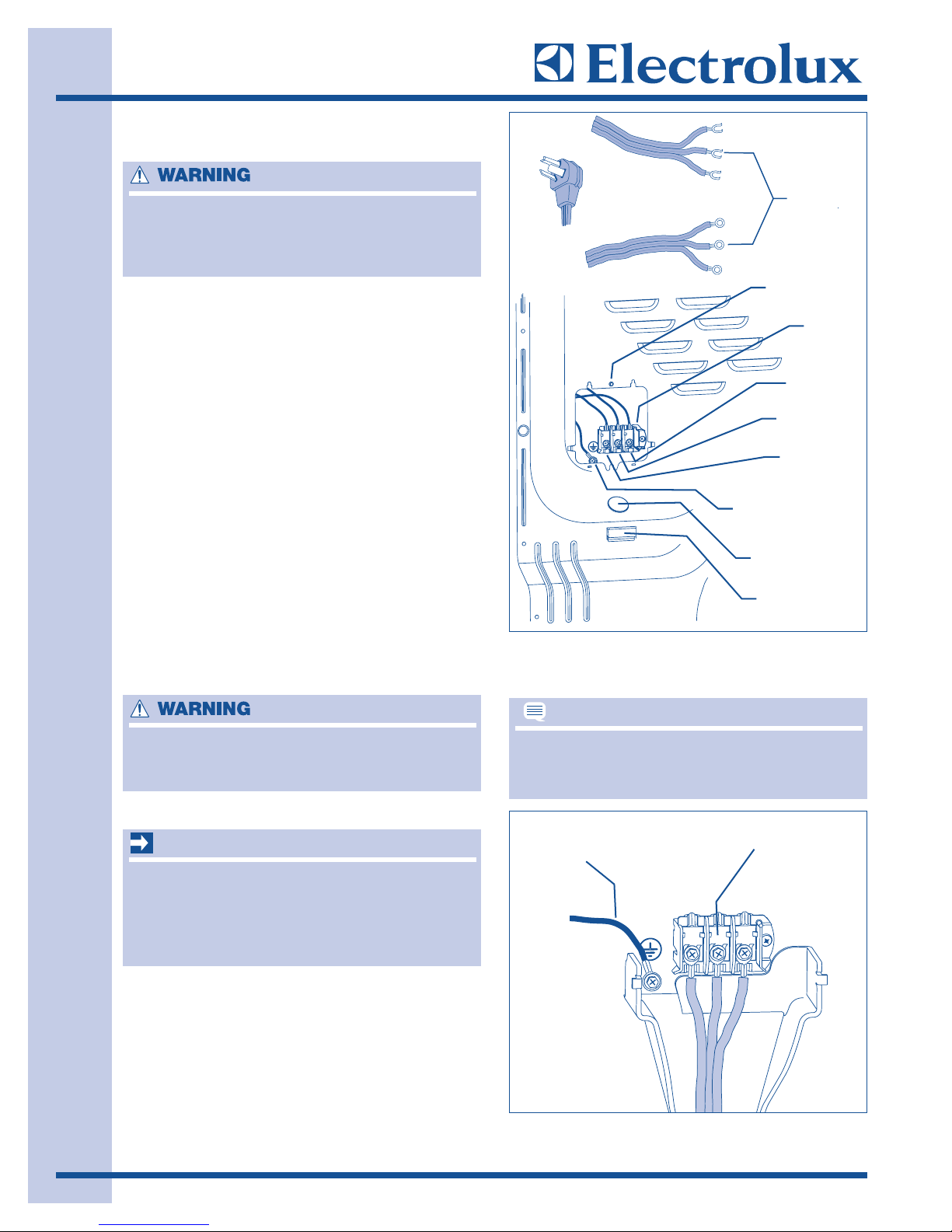

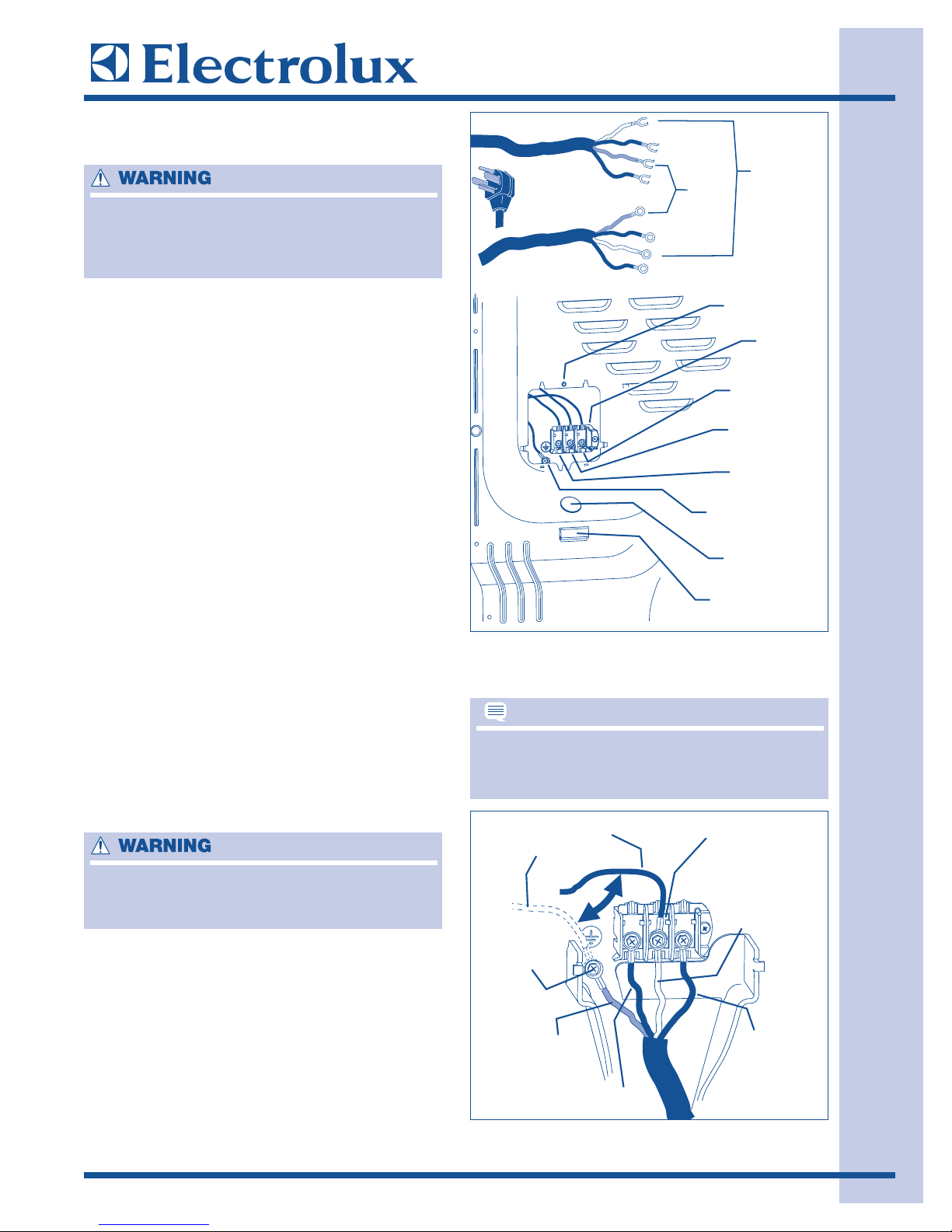

EElleeccttrriiccaall CCoonnnneeccttiioonn ((nnoonn--CCaannaaddaa)) -- 33 WWiirree CCoorrdd

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block

access cover in the lower corner on the back

of the dryer.

3. Install a UL-approved strain relief according

to the power cord/strain relief manufacturer’s

instructions in the power cord entry hole below

the access panel. At this time, the strain relief

should be loosely in place.

4. Thread an UNPLUGGED, UL-approved, 30

amp. power cord, NEMA 10-30 type SRDT,

through the strain relief.

5. Attach the power cord neutral (center wire)

conductor to the SILVER colored center

terminal on the terminal block. Tighten the

screw securely. (See Figure 2-8 & 2-9)

6. Attach the remaining two power cord outer

conductors to the outer, BRASS colored

terminals on the terminal block. Tighten both

screws securely.

7. Follow manufacturer’s guidelines for firmly

securing the strain relief and power cord.

8. Reinstall the terminal block cover.

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD

FFAAIILLUURREE TTOO DDIISSCCOONNNNEECCTT PPOOWWEERR SSOOUURRCCEE

BBEEFFOORREE SSEERRVVIICCIINNGG CCOOUULLDD RREESSUULLTT IINN

PPEERRSSOONNAALL IINNJJUURRYY OORR EEVVEENN DDEEAATTHH..

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD

DDOO NNOOTT MMAAKKEE AA SSHHAARRPP BBEENNDD OORR CCRRIIMMPP

WWIIRRIINNGG// CCOONNDDUUCCTTOORR AATT CCOONNNNEECCTTIIOONNSS..

IIff mmoovviinngg ddrryyeerr ffrroomm aa 44--wwiirree ssyysstteemm aanndd

iinnssttaalllliinngg iitt iinn aa 33--wwiirree ssyysstteemm,, mmoovvee tthhee iinntteerrnnaall

ggrroouunndd ffrroomm tthhee cceenntteerr tteerrmmiinnaall bbaacckk ttoo tthhee

GGRREEEENN ssccrreeww nneexxtt ttoo tthhee tteerrmmiinnaall bblloocckk..

IIff aa tteerrmmiinnaall ssccrreeww ffaallllss dduurriinngg ccoorrdd iinnssttaallllaattiioonn,,

iitt ccaann bbee rreettrriieevveedd iinn tthhee tteerrmmiinnaall ssccrreeww

rreeccoovveerryy sslloott bbeellooww tthhee aacccceessss ppaanneell..

30 Amp

NEMA 10-30

Neutral

(Center Wire)

Access Cover

Screw

Terminal

Block

Line 2

Brass Terminal

Neutral

Silver Terminal

Line 1

Brass Terminal

Internal Ground

Green Screw

Install

UL-approved

strain relief here

Terminal Screw

Recovery Slot

IMPORTANT

NOTE

Do Not remove

internal ground in

a 3-wire system

Neutral terminal

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-11

FFiigguurree 22--1111..

FFiigguurree 22--1100..

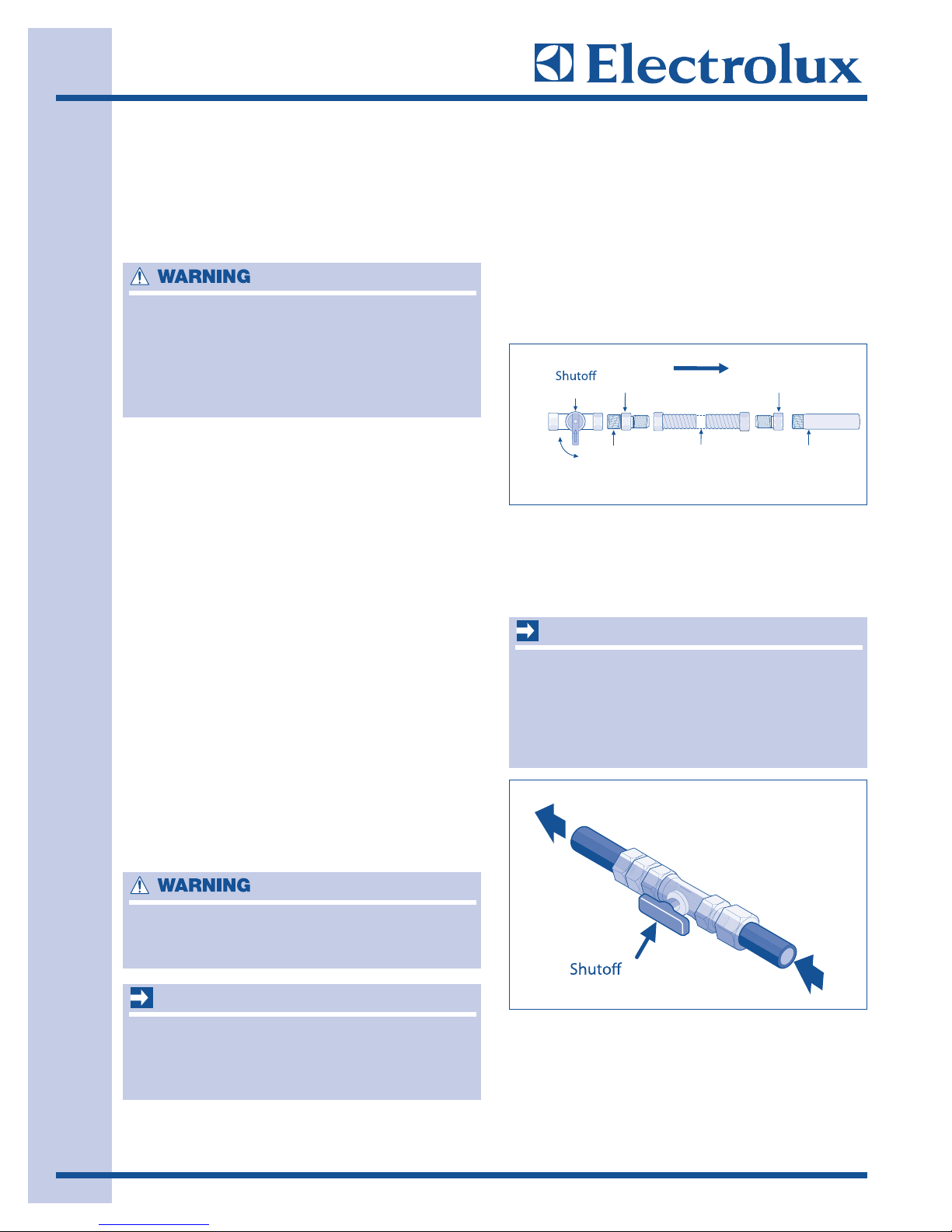

EElleeccttrriiccaall CCoonnnneeccttiioonn ((nnoonn--CCaannaaddaa)) -- 44 WWiirree CCoorrdd

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block

access cover in the lower corner on the back

of the dryer.

3. Install a UL-approved strain relief according

to the power cord/strain relief manufacturer’s

instructions in the power cord entry hole below

the access panel. At this time, the strain relief

should be loosely in place.

4. Thread an UNPLUGGED, UL-approved, 30

amp. power cord, NEMA 14-30 type ST or

SRDT, through the strain relief.

(See Figure 2-10)

5. Disconnect the internal (BLACK) dryer harness

ground wire from the (GREEN) ground screw

next to the terminal block. (See Figure 2-11)

6. Attach the ground (GREEN) power cord wire

to the cabinet with the ground (GREEN) screw.

Tighten the screw securely.

7. Move the internal dryer harness ground

(BLACK) wire to the terminal block and attach

it along with the neutral (WHITE) power cord

wire conductor to the center, SILVER colored

terminal on the terminal block. Tighten the

screw securely.

8. Attach the RED and BLACK power cord

conductors to the outer, BRASS colored

terminals on the terminal block. Tighten both

screws securely.

9. Follow manufacturer’s guidelines for firmly

securing the strain relief and power cord.

10. Reinstall the terminal block cover..

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD

FFAAIILLUURREE TTOO DDIISSCCOONNNNEECCTT PPOOWWEERR SSOOUURRCCEE

BBEEFFOORREE SSEERRVVIICCIINNGG CCOOUULLDD RREESSUULLTT IINN

PPEERRSSOONNAALL IINNJJUURRYY OORR EEVVEENN DDEEAATTHH..

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD

DDOO NNOOTT MMAAKKEE AA SSHHAARRPP BBEENNDD OORR CCRRIIMMPP

WWIIRRIINNGG// CCOONNDDUUCCTTOORR AATT CCOONNNNEECCTTIIOONNSS..

IIff aa tteerrmmiinnaall ssccrreeww ffaallllss dduurriinngg ccoorrdd iinnssttaallllaattiioonn,,

iitt ccaann bbee rreettrriieevveedd iinn tthhee tteerrmmiinnaall ssccrreeww

rreeccoovveerryy sslloott bbeellooww tthhee aacccceessss ppaanneell..

30 Amp

NEMA 14-30

Ground

Green

wire

Neutral

White wire

Access Cover

Screw

Terminal

Block

Line 2

Brass Terminal

Neutral

Silver Terminal

Line 1

Brass Terminal

Internal Ground

Green Screw

Install

UL-approved

strain relief here

Terminal Screw

Recovery Slot

NOTE

Move internal ground (Black)

wire to neutral (Silver)

terminal for 4-wire system

Neutral terminal

Green

ground screw

Green

ground wire

Neutral

White wire

Black or Red

power wire

Black or Red

power wire

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-12

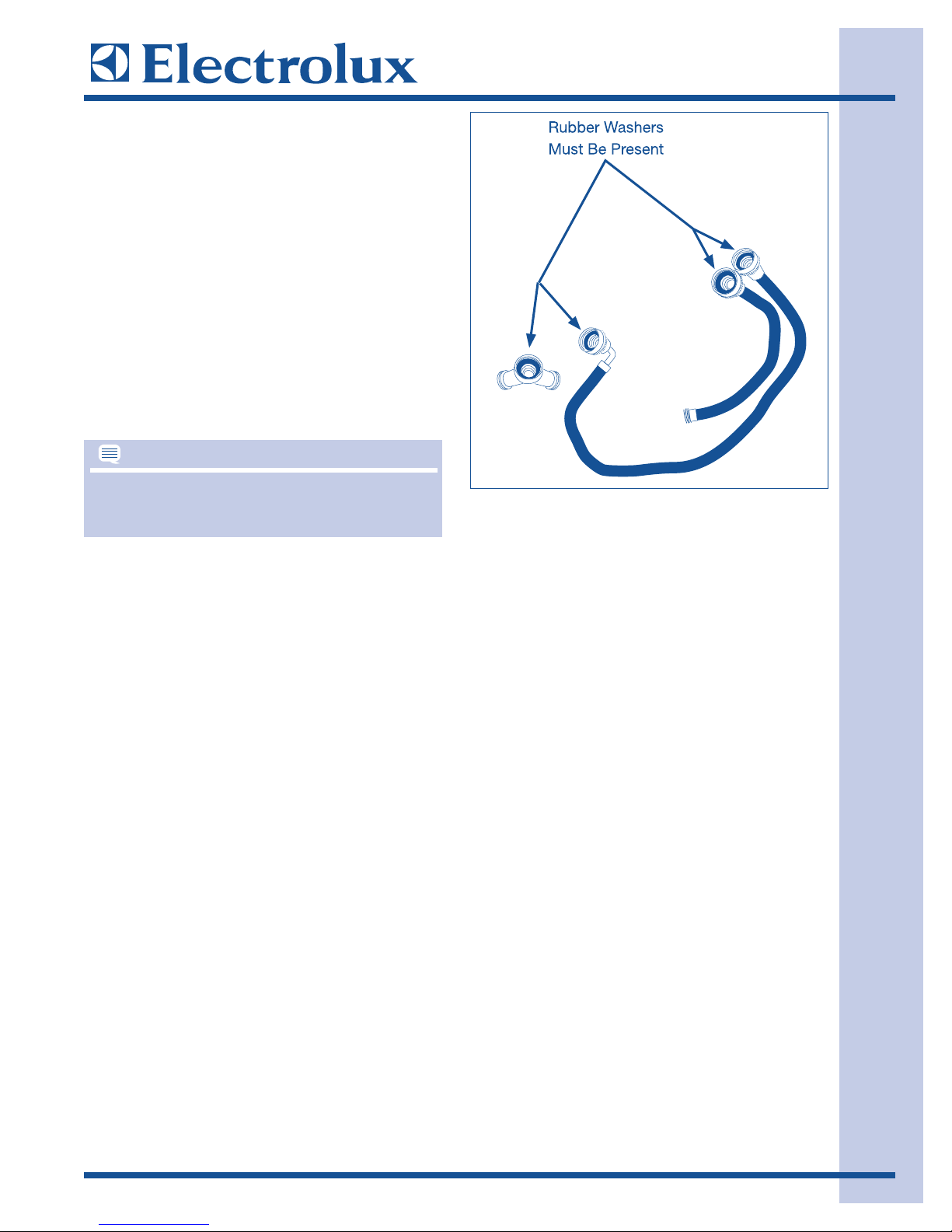

GGaass CCoonnnneeccttiioonn

1. Remove the shipping cap from gas pipe at the

rear of the dryer.

2. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or

approved pipe from gas supply line to the 3/8

inch (0.96 cm) pipe located on the back of the

dryer. Use a 1/2 inch to 3/8 inch (1.27 cm to

0.96 cm) reducer for the connection. Apply an

approved thread sealer that is resistant to the

corrosive action of liquefied gases on all pipe

connections. (See Figure 2-12)

3. Open the shutoff valve in the gas supply line to

allow gas to flow through the pipe. Wait a few

minutes for gas to move through the gas line.

4. Check for gas system leaks with a manometer.

If a manometer is not available, test all

connections by brushing on a soapy water

solution.

GGaass SSuuppppllyy RReeqquuiirreemmeennttss

1. Installation MUST conform with local codes, or

in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (latest

edition).

2. The gas supply line should be 1/2 inch

(1.27cm) pipe.

3. If codes allow, flexible metal tubing may be

used to connect your dryer to the gas supply

line. The tubing MUST be constructed of

stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual

shutoff valve.

5. A 1/8 inch (0.32 cm) N.P.T. plugged tapping,

accessible for test gauge connection, MUST

be installed immediately upstream of the gas

supply connection to the dryer.

6. The dryer MUST be disconnected from the gas

supply piping system during any pressure

testing of the gas supply piping system at test

pressures in excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the gas

supply piping system during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.45 kPa).

8. Connections for the gas supply must comply

with the Standard for Connectors for Gas

Appliances, ANSI Z21.24.

DDOO NNOOTT ccoonnnneecctt tthhee ddrryyeerr ttoo LL..PP.. ggaass sseerrvviiccee

wwiitthhoouutt ccoonnvveerrttiinngg tthhee ggaass vvaallvvee.. AAnn LL..PP..

ccoonnvveerrssiioonn kkiitt mmuusstt bbee iinnssttaalllleedd bbyy aa

qquuaalliiffiieedd ggaass tteecchhnniicciiaann..

TThhee ssuuppppllyy lliinnee mmuusstt bbee eeqquuiippppeedd wwiitthh aann

aapppprroovveedd mmaannuuaall sshhuuttooffff vvaallvvee.. TThhiiss vvaallvvee

sshhoouulldd bbee llooccaatteedd iinn tthhee ssaammee rroooomm aass tthhee ddrryyeerr

aanndd sshhoouulldd bbee iinn aa llooccaattiioonn tthhaatt aalllloowwss eeaassee ooff

ooppeenniinngg aanndd cclloossiinngg.. DDoo nnoott bblloocckk aacccceessss ttoo tthhee

ggaass sshhuuttooffff vvaallvvee..

EEXXPPLLOOSSIIOONN HHAAZZAARRDD

NNEEVVEERR TTEESSTT FFOORR GGAASS LLEEAAKKSS WWIITTHH AANN OOPPEENN

FFLLAAMMEE..

EEXXPPLLOOSSIIOONN HHAAZZAARRDD

UUNNCCOOAATTEEDD CCOOPPPPEERR TTUUBBIINNGG WWIILLLL CCOORRRROODDEE

WWHHEENN SSUUBBJJEECCTTEEDD TTOO NNAATTUURRAALL GGAASS,,

CCAAUUSSIINNGG GGAASS LLEEAAKKSS.. UUSSEE OONNLLYY BBLLAACCKK

IIRROONN,, SSTTAAIINNLLEESSSS SSTTEEEELL,, OORR PPLLAASSTTIICC

CCOOAATTEEDD BBRRAASSSS PPIIPPIINNGG FFOORR GGAASS SSUUPPPPLLYY..

y

FFiigguurree 22--1122..

FFiigguurree 22--1133..

Closed

Manual

Valve

Open

Flare

Union

All connections must be wrench-tightened

elppiN

GAS FLOW

Flexible

Connector

Flare

Union

Inlet Pipe on

Back of Dryer

IMPORTANT

reyrd ot

IMPORTANT

lppus sag morf

Valve -

Open position

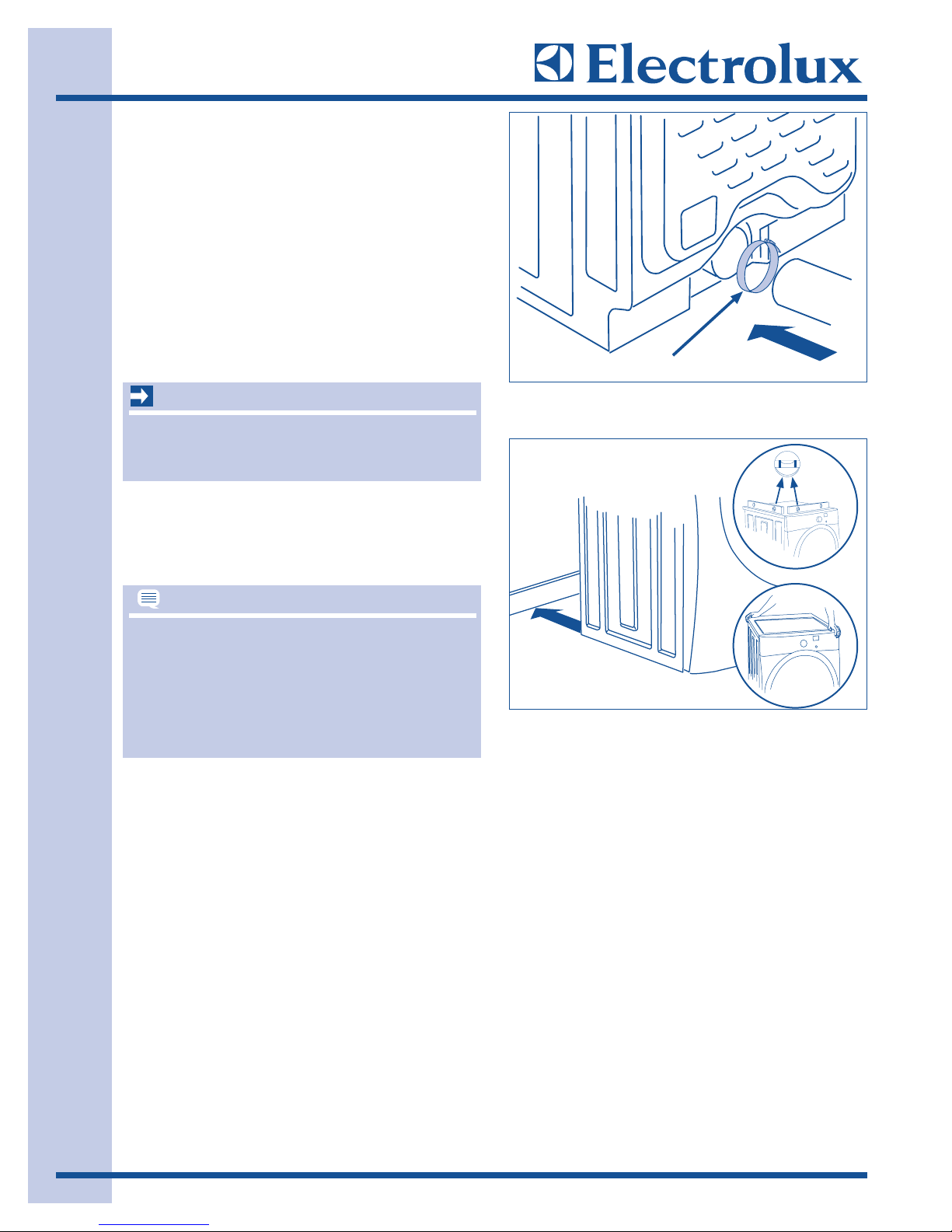

WWaatteerr CCoonnnneeccttiioonn ((SStteeaamm MMooddeell OOnnllyy))

1. Turn off COLD water supply to washer,

2. Remove COLD inlet hose from COLD water

supply and inspect for rubber washer. Replace

washer if it is torn or worn out.

3. Momentarily turn on COLD supply and run

some water into a bucket or container to clear

any contaminants in the line.

4. Remove hose kit from dryer drum and inspect

hose couplings for proper placement of rubber

washers. (See Figure 2-14)

5. If your installation has room for the COLD

water supply to accept the “Y” connector

directly, thread the “Y” connector to the COLD

water supply and snug it by hand; then tighten

it another 2/3 turn with pliers.

6. If there is not room to install the “Y” connector

directly, thread the short extension hose on to

the COLD water supply and snug it by hand;

then tighten it another 2/3 turn with pliers.

7. Thread the “Y” connector to the short

extension hose and snug it by hand; then

tighten it another 2/3 turn with pliers.

8. Connect the COLD inlet hose for the washer

to the “Y” connector and snug it by hand; then

tighten it another 2/3 turn with pliers.

9. Connect the straight end of the long hose from

the kit to the other outlet on the “Y” connector

and snug it by hand. Connect the hose’s 90°

coupling to the brass water inlet on the back

of the dryer and snug it by hand. Tighten each

connection of the dryer inlet hose another 2/3

turn with pliers.

10. Turn on the water and check for leaks at all

connections.

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-13

IIff yyoouu wweerree aabbllee ttoo iinnssttaallll tthhee ““YY”” ccoonnnneeccttoorr

ddiirreeccttllyy ttoo tthhee CCOOLLDD wwaatteerr ssuuppppllyy,, pplleeaassee sskkiipp

ttoo sstteepp 88..

FFiigguurree 22--1144..

NOTE

GGeenneerraall IInnssttaallllaattiioonn

1. Connect the exhaust duct to the outside

exhaust system. Use of a 4” (10.2 cm) clamp

is recommended to connect the dryer to the

exhaust vent system. Use metal foil tape to

seal all other joints. (See Figure 2-15)

2. Carefully slide the dryer to its final position.

Adjust one or more of the legs until the dryer is

resting solidly on all four legs. Place a level on

top of the dryer. The dryer MUST be level and

resting solidly on all four legs. Rock alternating corners to check for stability. Remove and

discard door tape. (See Figure 2-16)

3. Plug the power cord into a grounded outlet.

4. Turn on power at the circuit breaker/fuse box.

5. Perform the “Installation Cycle” to verify proper

installation.

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-14

OOnn ggaass ddrryyeerrss,, bbeeffoorree tthhee bbuurrnneerr wwiillll lliigghhtt,, iitt iiss

nneecceessssaarryy ffoorr tthhee ggaass lliinnee ttoo bbee bblleedd ooff aaiirr.. IIff tthhee

bbuurrnneerr ddooeess nnoott lliigghhtt wwiitthhiinn 4455 sseeccoonnddss tthhee ffiirrsstt

ttiimmee tthhee ddrryyeerr iiss ttuurrnneedd oonn,, tthhee ssaaffeettyy sswwiittcchh wwiillll

sshhuutt tthhee bbuurrnneerr ooffff.. IIff tthhiiss hhaappppeennss,, pprreessss ccaanncceell

aanndd wwaaiitt 55 mmiinnuutteess bbeeffoorree mmaakkiinngg aannootthheerr

aatttteemmpptt ttoo lliigghhtt..

FFiigguurree 22--1155..

FFiigguurree 22--1166..

BBee ssuurree ppoowweerr iiss ooffff aatt aa cciirrccuuiitt bbrreeaakkeerr//ffuussee

bbooxx bbeeffoorree pplluuggggiinngg ppoowweerr ccoorrdd iinnttoo aann

oouuttlleett..

4” Clamp

IMPORTANT

NOTE

WWaavvee--TToouucchh™™ IInnssttaallllaattiioonn CCyyccllee

1. After plugging in the dryer the first time: wake

up the dryer by pressing any button and then

follow the prompts on the LCD User Interface,

including language selection.

2. The Installation Cycle will automatically test for

correct cord connection (on electric models),

presence of gas supply (on gas models) and

free flow of exhaust vent. At cycle completion,

the LCD user interface may display

IINNSSTTAALLLL

PPAASSSS!!

, meaning the dryer is properly installed

and ready for use. If it prompts an action such

as

SSEERRVVIICCEE CCOORRDD, NNOO GGAASS

or

CCaallll SSeerrvviiccee

887777--443355--33228877

, review the installation steps

and make the necessary corrections before

attempting to use the dryer

.

3. The dryer will exit the Installation Cycle and

return to normal operation the next time the

dryer is used.

IIQQ --TToouucchh™™ IInnssttaallllaattiioonn CCyyccllee

1. Empty dryer’s drum and close door.

2. After you plug in the dryer the first time: wake

up the dryer by pressing any button, rotate

cycle knob to touch up cycle, press the start

button and then the cancel button.

3. Wake up the dryer again by pressing any

button, then immediately and simultaneously

press and hold both the sanitize and my

favorite buttons for 5 seconds, or until the LCD

display changes.

4. The LCD window will display

IINNSSTTAALL CCYYCCLLEE

and show estimated time of cycle completion.

Press the start button. The Installation Cycle

will automatically test for correct cord

connection (on electric models) and presence

of gas supply (on gas models). At cycle

completion, the LCD window may display

IINNSSTTAALL PPAASSSS!!

, meaning the dryer is properly

installed and ready for use. If it prompts an

action such as

SSEERRVVIICCEE CCOORRDD,, NNOO GGAASS

or

CCaallll SSeerrvviiccee 887777--443355--33228877

, r

eview the

installation steps and make the necessary

corrections before attempting to use the dryer.

5. The washer will exit the Installation Cycle and

return to normal operation the next time the

washer is used.

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-15

DDrryyeerr wwiillll ssttaayy aawwaakkee ffoorr 33 mmiinnuutteess aafftteerr tthhee

IInnssttaallllaattiioonn CCyyccllee.. IIff yyoouu wwiisshh ttoo iimmmmeeddiiaatteellyy rruunn

tthhee ddrryyeerr tthhrroouugghh aa ddrryyiinngg ccyyccllee,, pprreessss tthhee ccaann--

cceell bbuuttttoonn ttoo ppuutt tthhee uunniitt ttoo sslleeeepp aanndd tthheenn

rreewwaakkee iitt iimmmmeeddiiaatteellyy,, ttoo ccoonnttiinnuuee tthhee nnoorrmmaall

ooppeerraattiinngg mmooddee..

NOTE

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-16

RReevveerrssiinngg DDoooorr

PPrreeppaarriinngg ttoo RReevveerrssee DDoooorr SSwwiinngg

1. Be sure you have adequate swing area before

reversing door.

2. You will need a screw driver with a #2 square

bit.

3. Protect flat work surface, such as top of

washer or floor near washer, with a soft cloth

or towel.

4. Be sure washer is unplugged from power

source.

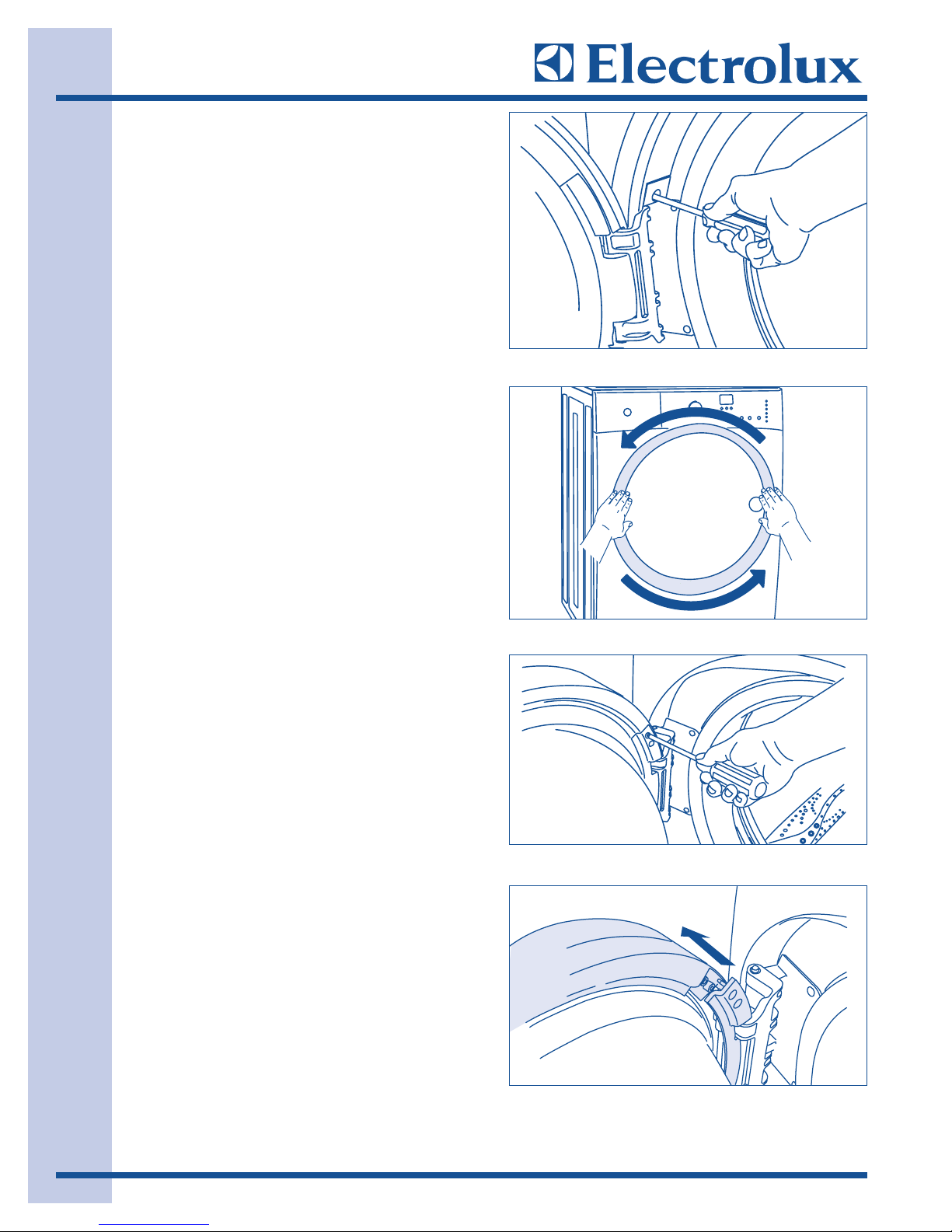

RReemmoovviinngg TTrriimm RRiinngg

1. Open the door to a 90 degree angle.

2. Remove and save the trim plug and long,

course-thread, panhead screw.

(See Figure 2-17)

3. Close the door.

4. Rotate the door trim approximately ¾”

counter-clockwise and pull it away from the

front of the door. (See Figure 2-18)

RReemmoovviinngg DDoooorr ffrroomm HHiinnggee

1. Reopen door to 90 degree angle.

2. Remove 4 long, course-thread, counter-sunk

hinge screws from door. (See Figure 2-19)

3. While supporting the weight of the door with

both hands, separate the door from the hinge.

(See Figure 2-20)

4. Gently place the door face down on a flat,

covered work surface.

FFiigguurree 22--1177..

FFiigguurree 22--1188..

FFiigguurree 22--1199..

FFiigguurree 22--2200..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-17

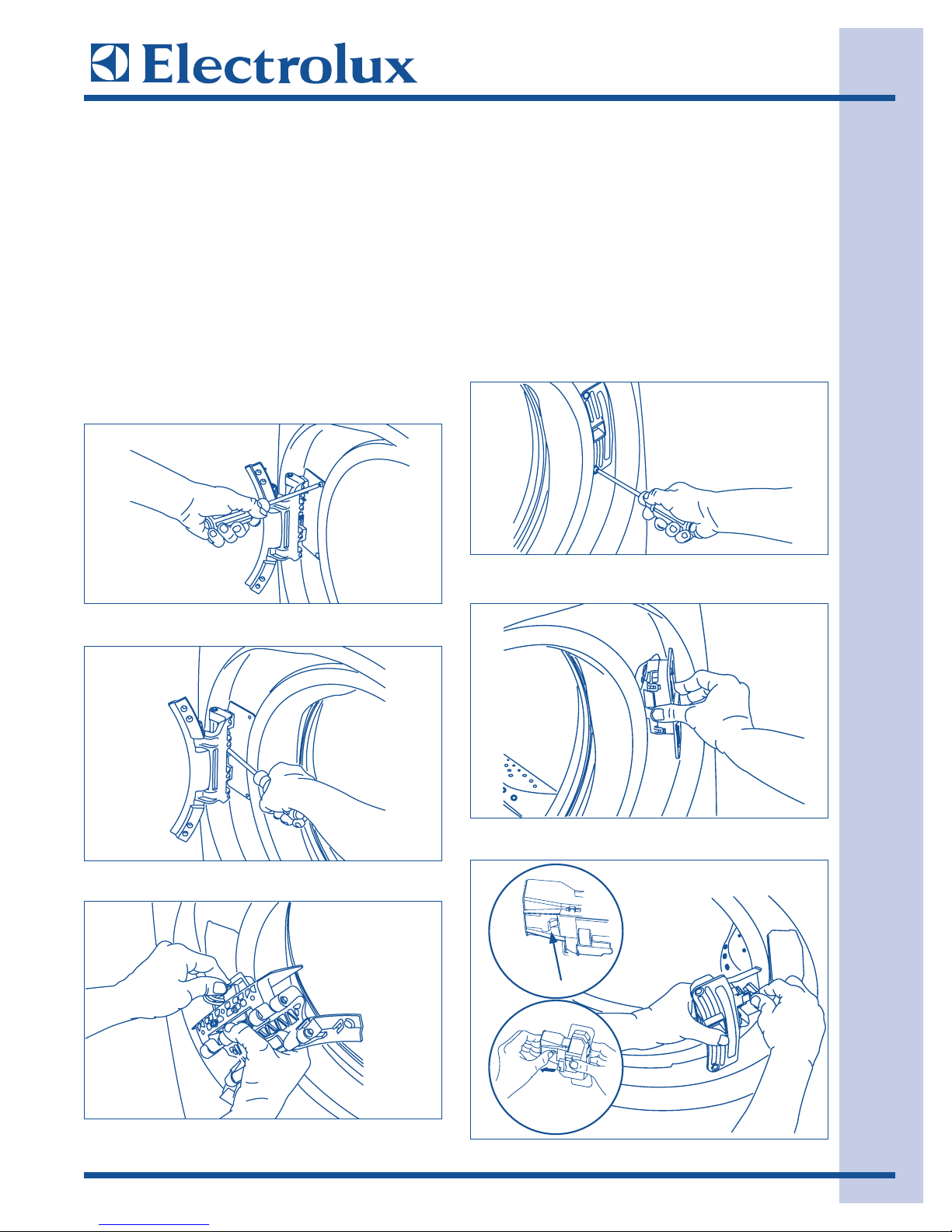

RReemmoovviinngg HHiinnggee ffrroomm FFrroonntt PPaanneell

1. With the hinge in open position, remove 2

short, course-thread, panhead screws on

hinge plate. (See Figure 2-21)

2. Remove 3 short, fine-thread, counter-sunk

screws in hinge side. (See Figure 2-22)

3. Slide the hinge toward the center of the front

panel, and then pivot the hinge inward while

slowly pulling it away from the front panel to

expose the attached harness.

4. Lift up on the tab and the release harness

from the retainer, allowing the harness to lay

outside the front panel. (See Figure 2-23)

RReemmoovviinngg DDoooorr LLoocckk ffrroomm FFrroonntt PPaanneell

1. Remove 2 short, course-thread, panhead

screws from the door lock.

(See Figure 2-24)

2. Slide the lock toward the outer edge of the

front panel. Pivot the lock slightly outward

while slowly pulling it through opening to

expose the attached harness.

(See Figure 2-25)

3. Release the harness from the terminal with

the small lever on back of the lock. Separate

the harness from the lock, allowing the

harness to lay outside the front panel.

(See Figure 2-26)

FFiigguurree 22--2211..

FFiigguurree 22--2222..

FFiigguurree 22--2233..

FFiigguurree 22--2244..

FFiigguurree 22--2255..

FFiigguurree 22--2266..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-18

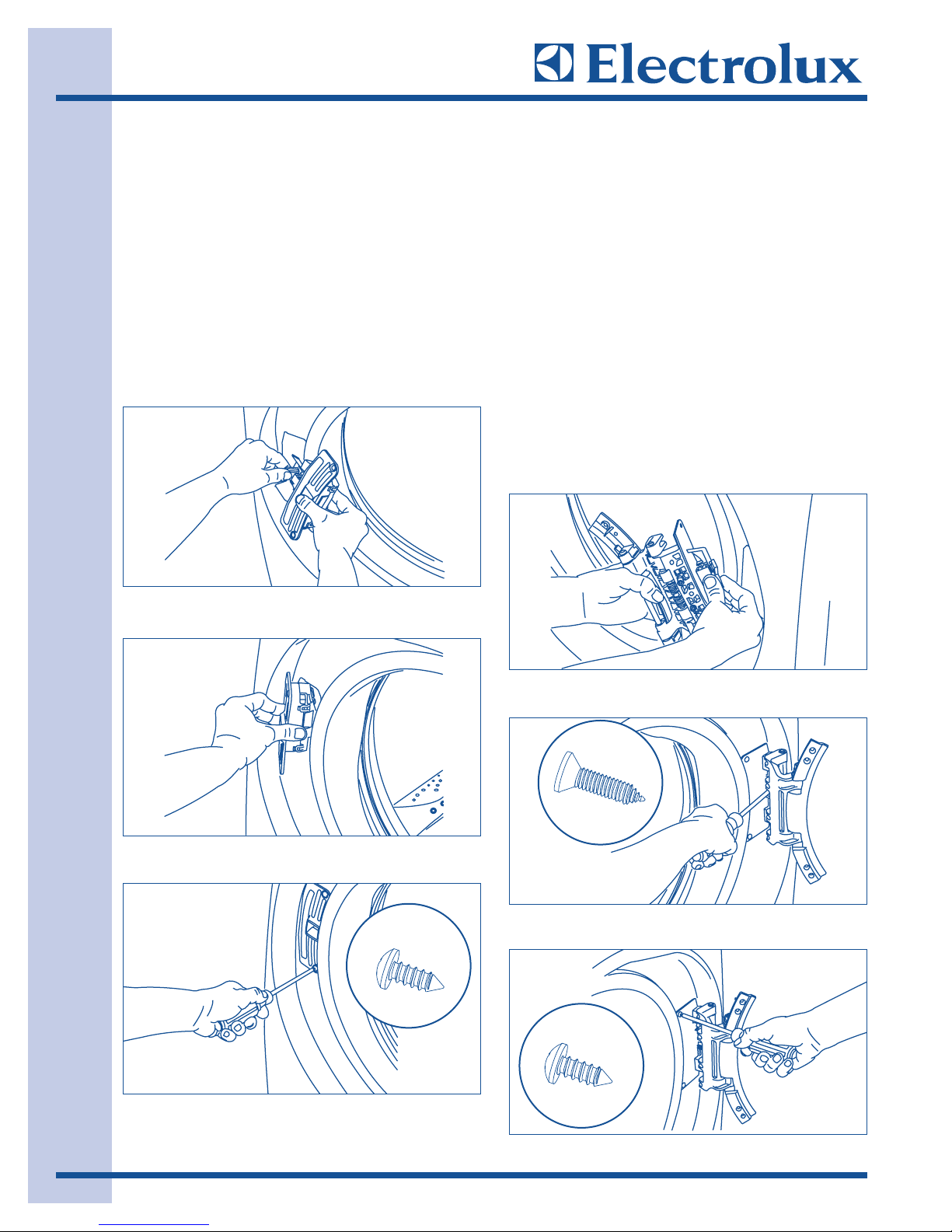

RReeaattttaacchhiinngg DDoooorr LLoocckk ttoo FFoonntt PPaanneell

1. Rotate the door lock and move it to the

opposite opening.

2. Connect the harness to the door lock by

inserting it in the terminal and firmly pushing

it in place. (See Figure 2-27)

3. Insert the harness connection through the

front panel first, and then pivot the lock until

it is flush. Slide the lock toward the center of

the front panel until the screw holes line up.

(See Figure 2-28)

4. Secure the lock with 2 short, course-thread,

panhead screws. (See Figure 2-29)

RReeaattttaacchhiinngg HHiinnggee ttoo FFrroonntt PPaanneell

1. Rotate the hinge and move it to the opposite

opening.

2. Connect the harness to the hinge retainer

by inserting it in the retention terminal and

gently pushing until you hear the fastening

tab click.

(See Figure 2-30)

3. Gently pull on the harness to be sure it is

secure.

4. Use the side locating pins to align the hinge

and install 1 short, fine-thread, counter-sunk

screw in the center hole of hinge side.

(See Figure 2-31)

5. Install the other 2 short, fine-thread, counter

sunk screws in upper and lower holes of hinge

side.

6. Install 2 short, course-thread, panhead

screws through hinge plate. (See Figure 2-32)

FFiigguurree 22--2277..

FFiigguurree 22--3300..

FFiigguurree 22--3311..

FFiigguurree 22--3322..

FFiigguurree 22--2299..

FFiigguurree 22--2288..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-19

RReemmoovviinngg SSttrriikkeerr PPllaattee

1. Remove 2 long, course-thread, counter-sunk

screws and striker plate. (See Figure 2-33)

2. Set the striker plate to the side for later.

RReemmoovviinngg LLaattcchh IInnddiiccaattoorr

1. Grasp the indicator on the latch side

between finger and thumb and rock it

upward, pivoting away from the center of the

glass.

(See Figure 2-34)

2. Gently push the indicator toward the center

of the lens to release the tab.

3. Rock the tab upward.

(See Figure 2-35)

4. Pull the indicator out and set it aside.

(See Figure 2-36)

FFiigguurree 22--3333..

FFiigguurree 22--3344..

FFiigguurree 22--3355..