Electrolux EILFU17GS, EILFU21GS Technical & Service Manual

FREEZER SERVICE MANUAL #5995516548 2008 ALL RIGHTS RESERVED

UUpprriigghhtt FFrreeeezzeerr

EEIILLFFUU1177GGSS && EEIILLFFUU2211GGSS

TTeecchhnniiccaall SSeerrvviiccee MMaannuuaall

1-1

SSeeccttiioonn 11

BBaassiicc IInnffoorrmmaattiioonn

BBaassiicc IInnffoorrmmaattiioonn

BBaassiicc IInnffoorrmmaattiioonn

1-2

SSeeccttiioonn 11 -- BBaassiicc IInnffoorrmmaattiioonn

................................

11--11

Table of Contents.................................................... 1-2

Safe Servicing Practices ........................................ 1-3

Features .................................................................. 1-4

Serial Number Breakdown...................................... 1-4

EILFU17GS0 .......................................................... 1-5

EILFU21GS0 .......................................................... 1-6

SSeeccttiioonn 22 -- IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

................................................ 22--11

Important Safety Instructions ................................ 2-2

Safety Precautions.................................................. 2-2

Location .................................................................. 2-4

Electrical Information .............................................. 2-5

Leveling .................................................................. 2-6

Door Removal ........................................................ 2-6

Water Supply .......................................................... 2-7

Unit Dimensions...................................................... 2-8

SSeeccttiioonn 33 -- EElleeccttrroonniicc CCoonnttrrooll ................................................................ 33--11

Electronic Temperature Control.............................. 3-2

Setting Freezer Control .......................................... 3-2

Alarm Function Table .............................................. 3-2

Normal Operation .................................................. 3-3

Temperature Display ............................................ 3-3

Temperature Scale................................................ 3-3

Fast Freeze .......................................................... 3-3

Control Lock ........................................................ 3-3

Mute Sounds ........................................................ 3-3

Alarms .................................................................... 3-4

Temperature Alarm .............................................. 3-4

Power Fail Alarm .................................................. 3-4

Door Ajar .............................................................. 3-4

Communication Error .......................................... 3-4

Thermistor Error.................................................... 3-4

Stuck Key Error .................................................... 3-4

Fail Safe Mode...................................................... 3-4

Defrost Mode .......................................................... 3-5

Defrost Timing ........................................................ 3-5

Manual Defrost ...................................................... 3-5

Showroom Mode .................................................... 3-5

Test Mode .............................................................. 3-5

Service Diagnostic Mode........................................ 3-6

Initiate Service Mode............................................ 3-6

Model Identification .............................................. 3-6

Software Version .................................................. 3-6

Door Switch Status .............................................. 3-6

Thermistor Status ................................................ 3-6

Reset Factory Defaults ........................................ 3-6

Exit Diagnostics Mode.......................................... 3-6

SSeeccttiioonn 44-- RReeffrriiggeerraattiioonn SSyysstteemm

........................................................ 44--11

Definitions .............................................................. 4-2

Safety Warnings...................................................... 4-2

Charging Sealed Systems ...................................... 4-2

Soldering ................................................................ 4-3

Basic Components ................................................ 4-3

Perimeter Hot Tube ................................................ 4-3

Refrigerant Cycle .................................................... 4-3

Low/High Side Leak or Undercharge .................... 4-4

Testing for Refrigerant Leaks.................................. 4-4

Compressor Replacement...................................... 4-4

To Flush the System .............................................. 4-5

To Use Dry Nitrogen to Flush the System .............. 4-5

To Use Refrigerant to Flush the System ................ 4-5

Installing a New Compressor ................................ 4-6

Condenser Replacement ........................................ 4-7

Filter-Drier Replacement ........................................ 4-8

Evaporator and Suction Line Replacement............ 4-8

Equipment Needed for Evacuation & Recharging.. 4-9

Installing Evacuation and Recharging Equipment.. 4-9

Evacuating System ................................................ 4-10

Charging the System .............................................. 4-10

Preparing the Charging Cylinder ............................ 4-10

Final Leak Test ........................................................ 4-11

Verify Refrigerant Type in the System .................... 4-12

Dedicated Equipment ............................................ 4-12

R-134a Refrigeration Systems................................ 4-12

Miscibility of R-134a and Ester Oil ........................ 4-12

Water in the Refrigeration System.......................... 4-13

Vacuum Pump Maintenance .................................. 4-14

Refrigerant Leaks.................................................... 4-14

Leak Detection........................................................ 4-15

R-134a Properties .................................................. 4-15

HFC-134a, CFC-12 Pressure Temp. Chart ............ 4-16

Inhalation Toxicity .................................................. 4-17

Cardiac Sensitization .............................................. 4-17

Spills or Leaks ........................................................ 4-17

Skin and Eye Contact ............................................ 4-17

Combustibility of HFC-134a .................................. 4-18

Leak Testing............................................................ 4-18

Bulk Delivery and Storage ...................................... 4-18

Filling and Charging Operations ............................ 4-18

Refrigerant Recovery Systems .............................. 4-18

Thermal Decomposition.......................................... 4-18

SSeeccttiioonn 55-- CCoommppoonneenntt TTeeaarrddoowwnn

.................................................... 55--11

Warnings and Cautions .......................................... 5-2

Exterior Components.............................................. 5-3

Door Handle ........................................................ 5-3

Kickplate .............................................................. 5-3

Door Hinge and Door Assembly .......................... 5-3

Lower Hinge Assembly ........................................ 5-4

Door Gasket and Inner Panel .............................. 5-4

Door Lock ............................................................ 5-5

Control Panel........................................................ 5-5

Tilt-Out Wire Shelf ................................................ 5-5

Door Shelf Guard.................................................. 5-6

Door Switch .......................................................... 5-6

Interior Components .............................................. 5-6

Upper Shelf Assembly.......................................... 5-6

Wire Basket .......................................................... 5-7

Wire Basket Slide ................................................ 5-7

Light Shield .......................................................... 5-7

Light Fixture.......................................................... 5-7

1-3

SSaaffee SSeerrvviicciinngg PPrraaccttiicceess

AAvvooiidd ppeerrssoonnaall iinnjjuurryy aanndd//oorr pprrooppeerrttyy ddaammaaggee bbyy

oobbsseerrvviinngg iimmppoorrttaanntt SSaaffee SSeerrvviicciinngg PPrraaccttiicceess..

FFoollllo

owwiinngg aarree ssoommee lliimmiitteedd eexxaammpplleess ooff ssaaffee

pprraaccttiicceess::

1. DO NOT attempt a product repair if you have

any doubts as to your ability to complete the

repair in a safe and satisfactory manner.

2. Always Use The Correct Replacement Parts as

indicated in the parts documentation.

Substitutions may defeat compliance with

Safety Standards Set For Home Appliances.

Do not exceed maximum recommended

wattage on light bulb replacements. Doing so

could blow fuses and/or damage transformers.

3. Before servicing or moving an appliance:

• Remove power cord from the electrical outlet,

trip circuit breaker to the OFF position, or

remove fuse.

• Turn off water supply.

4. Never interfere with the proper operation of any

safety device.

5. Use ONLY REPLACEMENT PARTS

CATALOGED FOR THIS APPLIANCE.

Substitutions may defeat compliance with

Safety Standards Set For Home Appliances.

6. GROUNDING: The standard color coding for

safety ground wires is GREEN, or GREEN with

YELLOW STRIPES. Ground leads are not to be

used as current carrying conductors. It is

EXTREMELY important that the service

technician reestablish all safety grounds prior

to completion of service. Failure to do so will

create a hazard.

7. Prior to returning the product to service, ensure

that:

• All electrical connections are correct and

secure.

• All electrical leads are properly dressed and

secured away from sharp edges, hightemperature components, and moving parts.

• All non-insulated electrical terminals,

connectors, heaters, etc. are adequately

spaced away from all metal parts and panels.

• All safety grounds (both internal and external)

are correctly and securely connected.

• All panels are properly and securely

reassembled

Baffle Plate .......................................................... 5-8

Icemaker .............................................................. 5-8

Evaporator Cover ................................................ 5-8

Evaporator Fan Assembly .................................... 5-9

Defrost Thermostat .............................................. 5-9

Thermistor ............................................................ 5-9

Defrost Heater ...................................................... 5-10

Evaporator .......................................................... 5-10

Compressor Area.................................................... 5-11

Power Cord ............................................................ 5-11

Water Valve ............................................................ 5-11

Filter-Drier .............................................................. 5-12

Compressor ............................................................ 5-13

Drain Pan ................................................................ 5-14

Condenser Fan Motor ............................................ 5-14

Condenser .............................................................. 5-15

Control Module ...................................................... 5-15

SSeeccttiioonn 66-- IIcceemmaakkeerr

............................................................................................ 66--11

Rear Mounted Icemaker ........................................ 6-2

Icemaker Components .......................................... 6-3

Front Cover ............................................................ 6-3

Ice Mold .................................................................. 6-3

Mold Heater ............................................................ 6-3

Ice Stripper ............................................................ 6-3

Water Valve Assembly ............................................ 6-3

Thermostat.............................................................. 6-3

Sensing Arm and Linkage ...................................... 6-3

Timing Switches .................................................... 6-4

Thermal Cut-Out (TCO) .......................................... 6-4

Timing Cam and Coupler........................................ 6-4

Timing Gear ............................................................ 6-4

Motor ...................................................................... 6-4

On/Off Switch ........................................................ 6-4

Wiring...................................................................... 6-4

Installing Water Supply Line to Icemaker .............. 6-5

Water Valve Switch- Water Fill Volume .................. 6-5

Test Cycling Icemaker ............................................ 6-5

Operating Cycle Illustrations-Manual Cycle .......... 6-6

Operating Cycle Illustrations-Electrical .................. 6-6

Operating Cycle Illustrations-Mechanical .............. 6-13

Ice Maker Electrical Diagram.................................. 6-16

SSeeccttiioonn 77-- PPaarrttss LLiisstt aanndd EExxppllooddeedd VViieewwss

........................ 77--11

Door Components EILFU17GS .............................. 7-2

Cabinet Components EILFU17GS.......................... 7-4

System Components EILFU17GS .......................... 7-6

Door Components EILFU21GS .............................. 7-8

Cabinet Components EILFU21GS.......................... 7-10

System Components EILFU21GS .......................... 7-12

Ice Maker Components ........................................ 7-14

SSeeccttiioonn 88-- TTrroouubblleesshhoooottiinngg

........................................................................ 88--11

Troubleshooting Chart ............................................ 8-2

SSeeccttiioonn 99-- WWiirriinngg DDiiaaggrraammss........................................................................ 99--11

Wiring Diagram ...................................................... 9-2

BBaassiicc IInnffoorrmmaattiioonn

2211 CCuu.. FFtt.. UUpprriigghhtt FFrreeeezzeerr

EEIILLFFUU2211GG SS

Ye s

20.6 Cu. Ft.

23.2 Sq. Ft.

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

2

2

3

2

1

3

Ye s

Ye s

Ye s

Right Bottom Rear

Left Bottom Rear

115V/60Hz/15A

.69

15

251 Lbs

269 Lbs

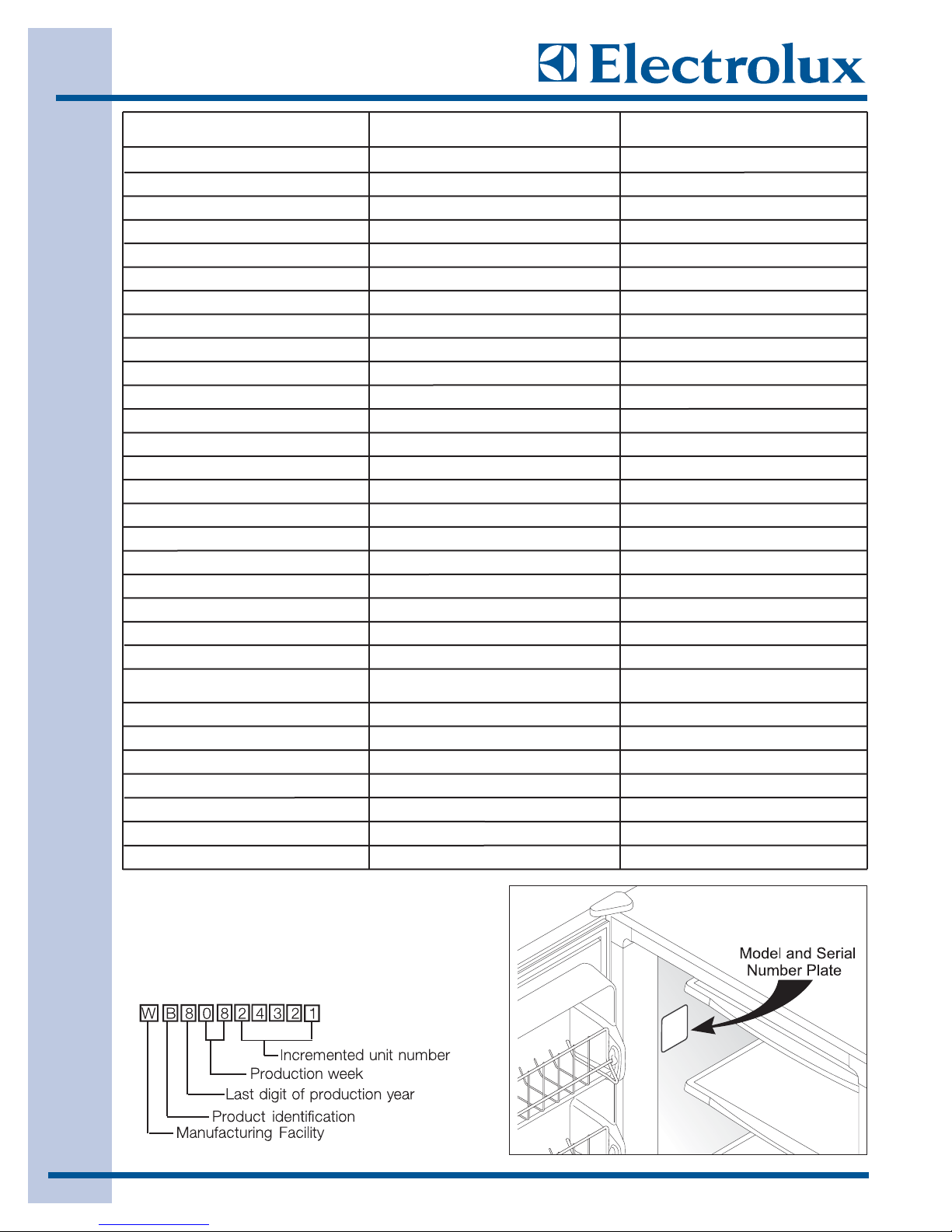

FFeeaattuurreess

Energy Star

Total Volume

Shelf Area

IQ Touch Electronic Control

Digital Exterior Control Center

Frost-Free Performance

Adjustable Temperature Control

Display Temperature Mode

Fast Freeze

High Temperature Alarm System

System Error Alarm

Interior Lighting

Power On Light

Adjustable Glass Shelves

Fixed Glass Shelves

Full Access Baskets

Adjustable Door Bins

Contour Door Shelves

Tilt Out Wire Door Shelves

Automatic Icemaker

Lock With Pop Out Key

Automatic Door Closer

Specifications

Power Supply Connection

Water Inlet Location

Voltage Rating

Connected Load @ 115V

Minimum Circuit Required Amps

Product Weight

Shipping Weight (Approx.)

1177 CCuu.. FFtt.. UUpprriigghhtt FFrreeeezzeerr

EEIILLFFUU1177GG SS

Ye s

16.8 Cu. Ft.

20 Sq. Ft.

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

2

2

2

2

1

2

Ye s

Ye s

Ye s

Right Bottom Rear

Left Bottom Rear

115V/60Hz/15A

.62

15

225 Lbs

240 Lbs

BBaassiicc IInnffoorrmmaattiioonn

1-4

SSeerriiaall NNuummbbeerr BBrreeaakkddoowwnn

The serial plate is located on the left side wall of

the freezer interior.

BBaassiicc IInnffoorrmmaattiioonn

1-5

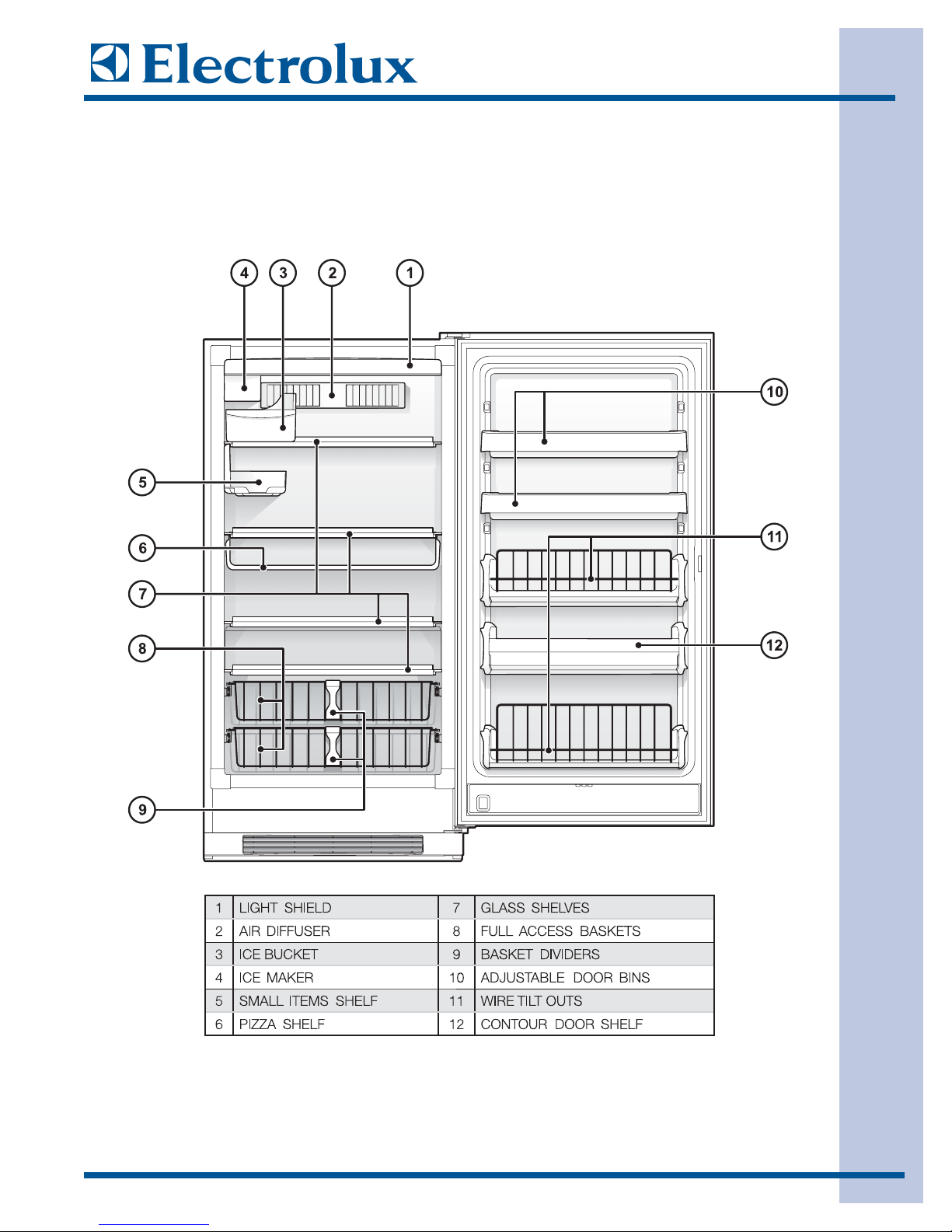

UUnnddeerrssttaannddiinngg FFeeaattuurreess AAnndd TTeerrmmss

Electrolux freezers are designed for optimal convenience and storage flexibility. Use the illustration below

to familiarize yourself with product features and terminology.

NNOOTTEE::

Features may vary according to model.

1177 CCUU.. FFTT.. MMOODDEELL SSHHOOWWNN

BBaassiicc IInnffoorrmmaattiioonn

1-6

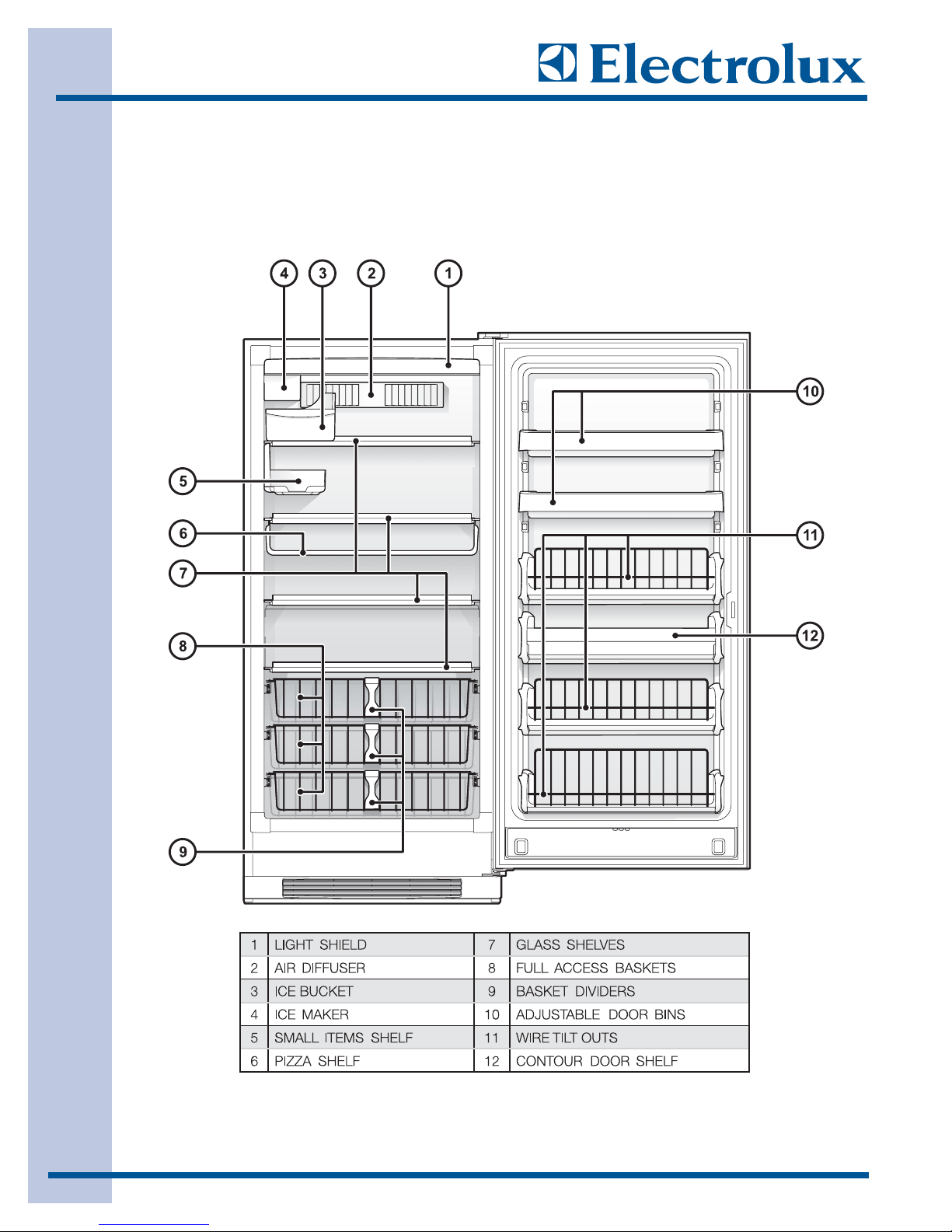

UUnnddeerrssttaannddiinngg FFeeaattuurreess AAnndd TTeerrmmss

Electrolux freezers are designed for optimal convenience and storage flexibility. Use the illustration below

to familiarize yourself with product features and terminology.

NNOOTTEE::

Features may vary according to model.

2211 CCUU.. FFTT.. MMOODDEELL SSHHOOWWNN

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-1

SSeeccttiioonn 22

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-2

IIMMPPOORRTTAANNTT SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS

SSaaffeettyy PPrreeccaauuttiioonnss

Do not attempt to install or operate this appliance until you read the safety precautions in this guide.

Safety items throughout this guide are labeled with a Warning or Caution based on the risk type.

WWAARRNNIINNGG

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CCaauuttiioonn

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

WARNING

EELLEECCTTRROOLLUUXX CCAANNNNOOTT BBEE HHEELLDD RREESSPPOONNSSIIBBLLEE FFOORR DDAAMMAAGGEE TTOO PPRROOPPEERRTTYY OORR IINNJJUURRYY TTOO

PPEERRSSOONNSS CCAAUUSSEEDD BBYY FFAAIILLUURRE

E TTOO CCOOMMPPLLYY WWIITTHH TTHHEE IINNSSTTAALLLLAATTIIOONN,, MMAAIINNTTEENNAANNCCEE AANNDD

SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS CCOONNTTAAIINNEEDD IINN TTHHIISS SSEERRVVIICCEE MMAANNUUAALL..

WARNING

TTOO RREEDDUUCCEE TTHHEE RRIISSKK OOFF FFIIRREE,, EELLEECCTTRRIICCAALL SSHHOOCCKK,, OORR IINNJJUURRYY WWHHEENN UUSSIINNGG YYOOUURR FFRREEEEZZEERR,,

FFOOLLLLOOWW BBAASSIICC SSAAFFEETTYY PPRREECCAAUUTTIIOONNSS IINNCCLLUUDDIINNGG TTHHEE FFOOLLLLOOWWIINNGG::

-- RREEAADD AALLLL IINNSSTTRRUUCCTTIIOONNSS BBEEFFOORREE OOPPEERRAATTIINNGG TTHHEE FFRREEEEZZEERR..

-- BBEEFFOORRE

E PPEERRFFOORRMMIINNGG AANNYY TTYYPPEE OOFF SSEERRVVIICCEE OORR IINNSSTTAALLLLAATTIIOONN,, MMAAKKEE SSUURREE TTHHAATT

EELLEECCTTRRIICC PPOOWWEERR TTOO TTHHEE FFRREEEEZZEERR IISS DDIISSCCOONNNNEECCTTEEDD..

-- TTOO AAVVOOIIDD TTHHEE PPOOSSSSIIBBIILLIITTYY OOFF EEXXPPLLOOSSIIOONN OORR FFIIRREE,, DDOO NNOOTT SSTTOORREE OORR UUSSEE CCOOMMBBUUSSTTIIBBLLEE,,

FFLLAAMMMMAAB

BLLEE,, OORR EEXXPPLLOOSSIIVVEE LLIIQQUUIIDDSS OORR VVAAPPOORRSS ((SSUUCCHH AASS GGAASSOOLLIINNEE)) IINNSSIIDDEE OORR IINN TTHHEE

VVIICCIINNIITTYY OOFF TTHHIISS OORR AANNYY OOTTHHEERR AAPPPPLLIIAANNCCEE..

-- TTHHIISS AAPPPPLLIIAANNCCEE IISS EEQQUUIIPPPPEEDD WWIITTHH AA TTHHRREEEE--PPRROONNGG GGRROOUUNNDDIINNGG PPLLUUGG FFOORR PPRROOTTEECCTTIIOONN

AAGGAAIINNSST

T PPOOSSSSIIBBLLEE EELLEECCTTRRIICC SSHHOOCCKK HHAAZZAARRDDSS.. PPLLUUGG IITT OONNLLYY IINNTTOO AA DDEEDDIICCAATTEEDD,,

GGRROOUUNNDDEEDD EELLEECCTTRRIICCAALL OOUUTTLLEETT.. WWHHEENN

OONNLLYY AA SSTTAANNDDAARRDD TTWWOO--PPRROONNGG EELLEECCTTRRIICCAALL

OOUUTTLLEETT IISS AAVVAAIILLAABBLLEE,, TTHHEE CCUUSSTTOOMMEERR MMUUSSTT HHAAVVEE IITT RREEPPLLAACCEEDD WWIITTHH AA DDEEDDIICCAATTEEDD,,

PPRROOPPEERRLLYY GGRROOUUNNDDEEDD TTHHRREEEE--PPRROONNGG EELLEECCTTRRIICCAALL OOUUTTLLEETT BBEEFFOORREE UUSSIINNGG TTHHIISS

AAPPPPLLIIAANNCCEE.. DDOO NNOOTT UUNNDDEERR AANNYY CCIIRRCCUUMMSSTTAANNCCEESS,, CCUUTT OORR RREEMMOOVVEE TTHHEE TTHHIIRRDD ((GGRROOUUNNDD))

PPRROONNGG FFRROOMM TTHHEE PPOOWWEERR CCOORRDD.. DDOO NNOOTT UUSSEE AANN A

ADDAAPPTTEERR PPLLUUGG.. DDOO NNOOTT UUSSEE AANN

EEXXTTEENNSSIIOONN CCOORRDD.. DDOO NNOOTT UUSSEE AA PPOOWWEERR CCOORRDD TTHHAATT IISS FFRRAAYYEEDD OORR DDAAMMAAGGEEDD.. TTHHEE UUSSEE

OOFF AA GGRROOUUNNDD FFAAUULLTT IINNTTEERRRRUUPPTTEERR ((GGFFII)) IISS NNOOTT RREECCOOMMMMEENNDDEEDD..

-- DDOO NNOOTT IINNSSTTAALLLL OORR UUSSEE AA DDAAMMAAGGEEDD AAPPPPL

LIIAANNCCEE.. IIFF YYOOUU RREECCEEIIVVEE AA DDAAMMAAGGEEDD

AAPPPPLLIIAANNCCEE,, IIMMMMEEDDIIAATTEELLYY CCOONNTTAACCTT YYOOUURR DDEEAALLEERR OORR BBUUIILLDDEERR..

-- DDOO NNOOTT UUSSE

E TTHHEE FFRREEEEZZEERR UUNNTTIILL IITT HHAASS BBEEEENN PPRROOPPEERRLLYY IINNSSTTAALLLLEEDD BBYY AA QQUUAALLIIFFIIEEDD

IINNSSTTAALLLLEERR AACCCCOORRDDIINNGG TTOO TTHHEESSEE IINNSSTTAALLLLAATTIIOONN IINNSSTTRRUUCCTTIIOONNSS.. TTHHEE IINNSSTTAALLLLEERR MMUUSSTT

SSHHOOWW TTHHEE CCUUSSTTOOMMEERR TTHHEE LLOOCCAATTIIOONN OOFF TTHHEE PPOOWWEERR PPLLUUGG SSOO TTHHAATT TTHHEEYY KKNNOOWW WWHHEERREE

AANNDD HHOOWW TTOO DDIISSCCOONNNNEECCTT PPOOWWEERR TTOO TTHHEE FFRREEEEZZEERR..

-- DDOO NNOOTT IINNSSTTAALLLL,, RREEPPAAIIRR,, OORR RREEPPLLAACCEE AANNYY PPAARRTT OOFF TTHHEE FFRREEEEZZEERR UUNNLLEESSSS

SSPPEECCIIFFIICCAALLLLYY RREECCOOMMMMEENNDDEEDD IINN TTHHEE LLIITTEERRAATTUURREE AACCCCOOMMPPAANNYYIINNGG IITT.. AA QQUUAALLIIFFIIE

EDD

SSEERRVVIICCEE TTEECCHHNNIICCIIAANN SSHHOOUULLDD PPEERRFFOORRMM AALLLL OOTTHHEERR SSEERRVVIICCEE..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-3

WARNING

DDEESSTTRROOYY CCAARRTTOONN,, PPLLAASSTTIICC BBAAGGSS,, AANNDD AANNYY EEXXTTEERRIIOORR WWRRAAPPPPIINNGG MMAATTEERRIIAALL IIMMMMEEDDIIAATTEELLYY

AAFFTTEERR TTHHEE FFRREEEEZZEERR IISS UUN

NPPAACCKKEEDD.. CCHHIILLDDRREENN SSHHOOUULLDD NNEEVVEERR UUSSEE TTHHEESSEE IITTEEMMSS FFOORR PPLLAAYY..

CCAARRTTOONNSS CCOOVVEERREEDD WWIITTHH RRUUGGSS,, BBEEDDSSPPRREEAADDSS,, PPLLAASSTTIICC SSHHEEEETTSS OORR SSTTRREETTCCHH WWRRAAPP MMAAYY

BBEECCOOMMEE AAIIRR TTIIGGHHTT CCHHAAMMBBEERRSS AANNDD CCAANN QQUUIICCKKLLYY CCAAUUSSEE SSUUFFFFOOCCAATTIIOONN..

AA CCHHIILLDD

MMIIGGHHTT SSUUFFFFOOCCAATTEE IIFF HHEE CCRRAAWWLLSS IINNTTOO TTHHEE FFRREEEEZZEERR TTOO HHIIDDEE OORR PPLLAAYY.. RREEMMOOVVEE

TTHHEE DDOOOORR//LLIIDD OOFF TTHHEE FFRREEEEZZEERR WWHHEENN NNOOTT IINN UUSSEE,, EEVVEENN IIFF YYOOUU PPLLAANN TTOO DDIISSCCAARRDD TTHHEE

FFRREEEEZZEERR.. MMAANNYY CCOOMMMMUUNNIITTIIEESS HHAAVVEE LLAAWWSS RREEQQUUIIRRIINNGG YYOOUU TTOO TTAAKKEE TTHHIISS SSAAFFEETTYY

PPRREECCAAUUTTIIOONN..

RREEMMOOVVEE OORR DDIISSCCAARRDD AANNYY SSPPAACCEERRSS UUSSEEDD TTOO SSEECCUURREE TTHHEE SSHHEELLVVEESS DDUURRIINNGG SSHHI

IPPPPIINNGG..

SSMMAALLLL OOBBJJEECCTTSS AARREE AA CCHHOOKKEE HHAAZZAARRDD TTOO CCHHIILLDDRREENN..

CCHHIILLDD EENNTTRRAAPPMMEENNTT AANNDD SSUUFFFFOOCCAATTIIOONN AARREE NNOOTT PPRROOBBLLE

EMMSS OOFF TTHHEE PPAASSTT.. JJUUNNKKEEDD OORR

AABBAANNDDOONNEEDD RREEFFRRIIGGEERRAATTOORRSS OORR FFRREEEEZZEERRSS AARREE SSTTIILLLL DDAANNGGEERROOUUSS–– EEVVEENN IIFF TTHHEEYY WWIILLLL SSIITT

FFOORR ““JJUUSSTT AA FFEEWW DDAAYYSS””.. IIFF YYOOUU AARREE GGEETTTTIINNGG RRIIDD OOFF YYOOUURR OOLLDD RREEFFRRIIGGEERRAATTOORR OORR

FFRREEEEZZEERR,, PPLLEEAASSEE FFO

OLLLLOOWW TTHHEE IINNSSTTRRUUCCTTIIOONNSS BBEELLOOWW TTOO HHEELLPP PPRREEVVEENNTT AACCCCIIDDEENNTTSS::

••RREEMMOOVVEE TTHHEE DDOOOORR//LLIIDD..

••LLEEAAVVEE SSHHEELLVVEESS IINN PPLLAACCE

E SSOO CCHHIILLDDRREENN MMAAYY NNOOTT EEAASSIILLYY CCLLIIMMBB IINNSSIIDDEE..

••HHAAVVEE TTHHEE RREEFFRRIIGGEERRAANNTT RREEMMOOVVEEDD BBYY AA QQUUAALLIIFFIIEEDD TTEECCHHNNIICCIIAANN..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-4

LLooccaattiioonn

1. Choose a place that is near a grounded

electrical outlet. Do Not use an extension cord or

an adapter plug.

2. If possible, place the freezer out of direct

sunlight and away from the range, dishwasher or

other heat sources.

3. The freezer must be installed on a floor that is

level and strong enough to support a fully loaded

freezer.

4. Consider water supply availability for models

equipped with an automatic ice maker.

5. The freezer should be located where surrounding

temperature will not exceed 110ºF (43ºC) or drop

below 40°F (5°C)

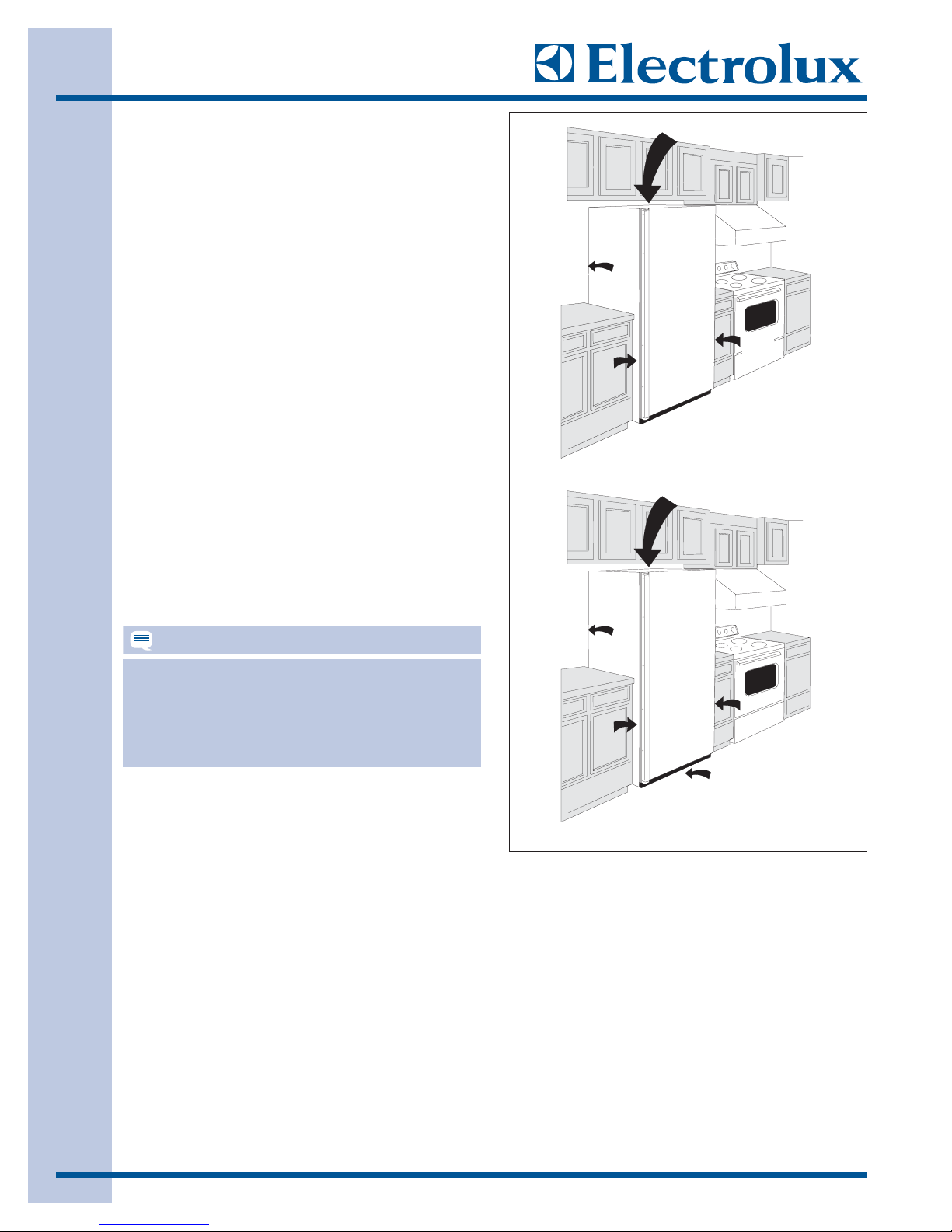

6. For ease of installation, proper air circulation

and electrical connections, refer to the illustration

for recommended clearances.

7. For dynamic condenser models, DO NOT block

the toe grille on the lower front of your freezer.

Sufficient air circulation is essential for the proper

operation of your freezer.

r

TThhee eexxtteerriioorr wwaallllss ooff tthhee ffrreeeezzeerr mmaayy bbeeccoommee

qquuiittee wwaarrmm aass tthhee ccoommpprreessssoorr wwoorrkkss ttoo ttrraannssffeerr

hheeaatt ffrroomm tthhee iinnssiiddee.. TTeemmppeerraattuurreess aass mmuucchh aass

3300°°FF wwaarrmmeerr tthhaann rroooomm tteemmppeerraattuurreess ccaann bbee

eexxppeecctteedd..

1”Air Space

1”

3/8”

3/8”

Installation for 17 cu. ft.

with dynamic condense

3”Air Space

NOTE

3”

3”

3”

1”

Installation for 21 cu. ft.

without dynamic condenser

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-5

EElleeccttrriiccaall IInnffoorrmmaattiioonn

These guidelines must be followed to ensure that

safety mechanisms in the design of this freezer will

operate properly.

Refer to the serial plate for correct electrical rating.

The power cord of the freezer is equipped with at

three-prong grounding plug for protection against

shock hazards. It must be plugged directly in to its

own properly grounded three-prong receptacle,

protected with a 15 amp time delay fuse or circuit

breaker. The receptacle must be installed in

accordance with the local codes and ordinances.

Consult a qualified electrician. Receptacles with

Ground Fault Circuit Interrupters (GFCI) are NOT

RECOMMENDED. DO NOT USE AN EXTENSION

CORD OR AN ADAPTER PLUG.

If the voltage varies by 10 percent or more, freezer

performance may be affected. Operating the freezer

with insufficient power can damage the motor. Such

damage is not covered under the warranty. If you

suspect your voltage is high or low, consult your

power company for testing.

To prevent the freezer from being turned off

accidentally, do not plug the unit in to an outlet

controlled by a wall switch or pull cord.

Do not pinch, knot, or bend the power cord in any

manner.

WARNING

NNEEVVEERR UUNNPPLLUUGG TTHHEE FFRREEEEZZEERR BBYY PPUULLLLIINNGG

OONN TTHHEE PPOOWWEERR CCOORRDD.. AALLWWAAYYSS GGRRIIPP TTHHEE

PPLLUUGG FFIIRRMMLLYY AANNDD PPUULLLL SSTTRRAAIIGGH

HTT OOUUTT

FFRROOMM TTHHEE RREECCEEPPTTAACCLLEE..

TTUURRNNIINNGG TTHHEE CCOONNTTRROOLL TTOO ““OOFFFF”” TTUURRNNSS

OOFFFF TTHHEE CCOOMMPPRREESSSSOORR BBUUTT DDOOEESS NNOOTT

DDIISSCCO

ONNNNEECCTT PPOOWWEERR TTOO OOTTHHEERR EELLEECCTTRRIICCAALL

CCOOMMPPOONNEENNTTSS..

IInnssttaallllaattiioonn IInnffoorrmmaattiioonn

2-6

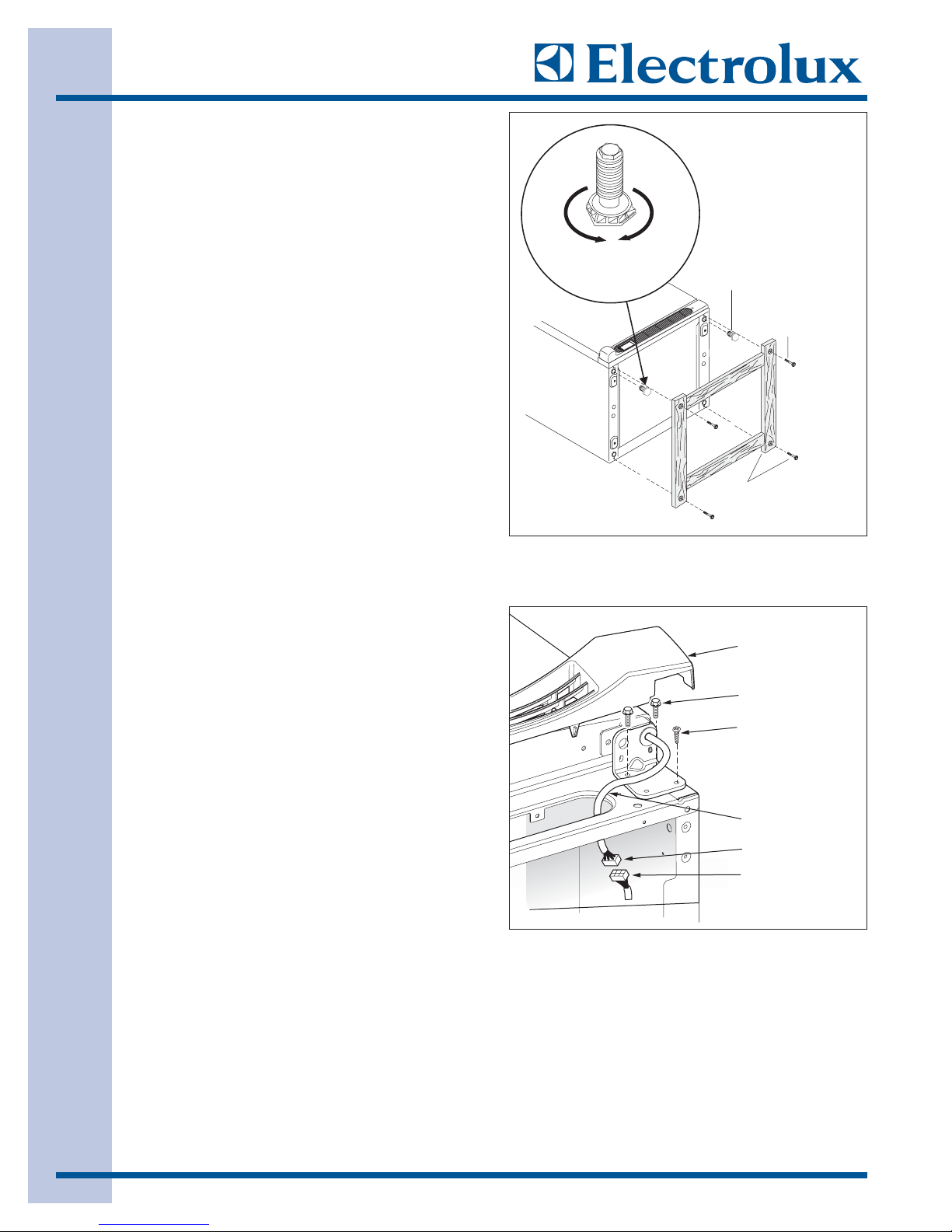

LLeevveelliinngg

The freezer must have all bottom corners resting

firmly on a solid floor. The floor must be strong

enough to support a fully loaded freezer. It is VERY

IMPORTANT for your freezer to be level in order to

function properly. If the freezer is not leveled during

installation,the door/lid may be misaligned and not

close or seal properly, causing cooling, frost or

moisture problems.

TToo LLeevveell UUnniitt

After discarding crating screws and wood base, use

a carpenter’s level to level the freezer from front to

back. Adjust the plastic leveling feet in front, ½

bubble higher, so that the door closes easily when

left half way open.

DDoooorr RReemmoovvaall

For some installations it may be necessary to remove

the door to fit through the entrance of the installation

site.

To remove the door, follow the steps below.

1. Make sure electrical plug is disconnected from

the wall outlet.

2. Gently lay freezer on its back on a soft clean

surface.

3. Lift plastic cover off upper hinge assembly.

4. Using a 3/8” open end wrench or socket, extract

screws securing the top hinge to the unit frame.

5. Remove the toe grille by grabbing the toe grille

at the top with both hands, then pull away from

the unit until toe grille disengages from the unit.

6. Reach under bottom of cabinet and disconnect

wire leads of door connector from the cabinet

connector.

7. Using a 3/8” open end wrench or socket,

extract screws securing the bottom hinge to the

unit frame. Use a phillips head screwdriver to

extract the remaining screw from the bottom

hinge assembly.

8. Lift the door assembly off of the unit frame.

Tu r n

Right To

Lower

Tu r n

Left To

Raise

Plastic

Leveling F eet

Crating

Screw

Discard The (4) Crating

Screws And Wood Base

Grille/ Kickplate

Hinge Bolt

Hinge Screw

Wire

Door Connector

Cabinet Connector

2-7

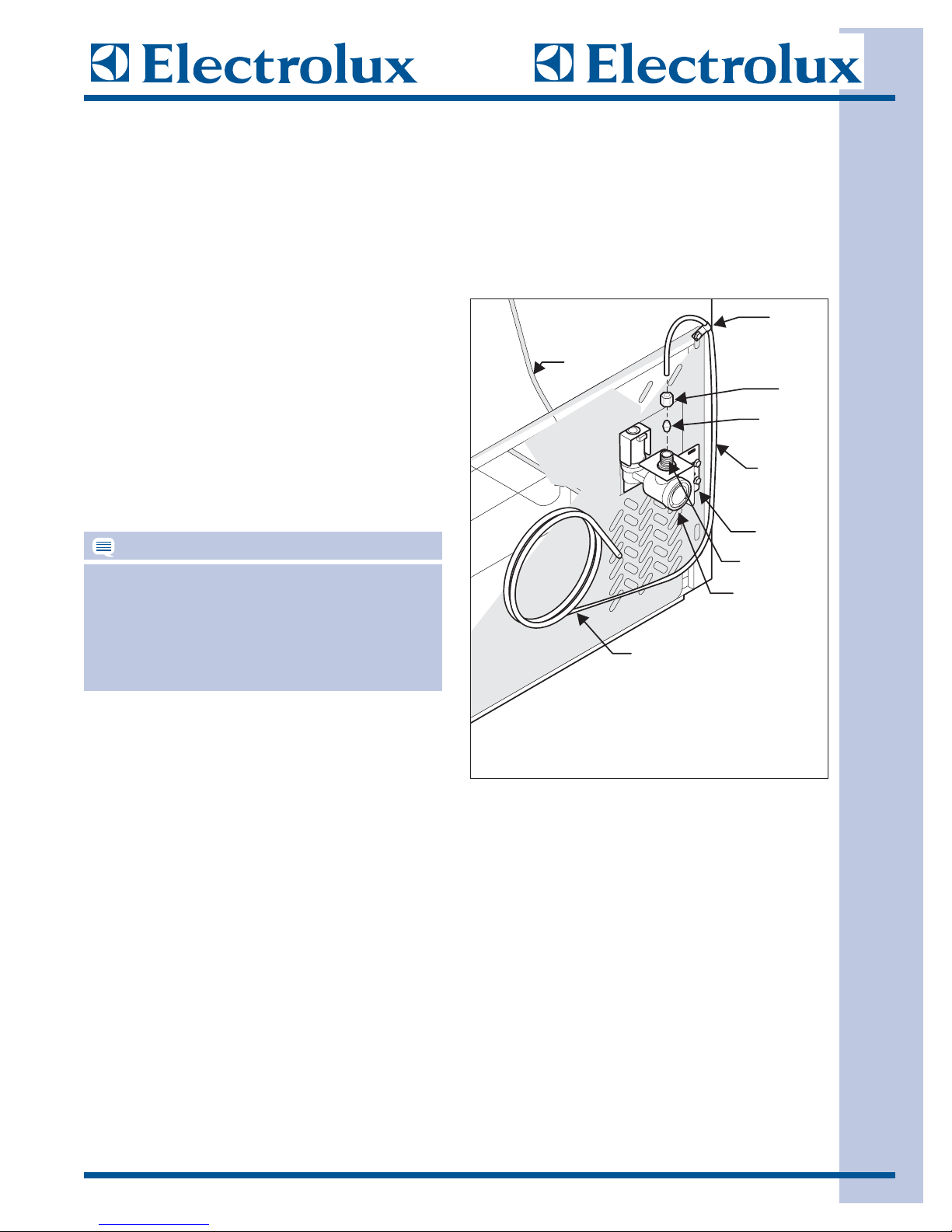

WWaatteerr SSuuppppllyy

The automatic ice maker requires a permanent water

supply to function correctly. During installation,

establish this water supply by connecting a copper

tube from the household water system to a valve at

the rear of the freezer.

WWhhaatt yyoouu wwiillll nneeeedd::

• Access to a cold water line with pressure of 20120 psi. (System supplied with cold water only.)

• Copper tubing with ¼inch (6.4mm) Outside

Diameter (OD). Length for this tubing is the

distance from the rear of the freezer to your

house hold water supply line plus seven feet

(2.1 meters).

• A shut-off valve for the connection between the

household water line and the freezer supply line.

Do not use a self-piercing shut-off valve.

• A compression nut and ferrule (sleeve) for the

water supply connection at the rear of freezer.

TToo ccoonnnneecctt tthhee wwaatteerr ssuuppppllyy ttoo tthhee rreeaarr ooff tthhee

ffrreeeezzeerr::

1. Ensure that the freezer is not plugged in.

2. Flush the supply line until water is clear by

placing the end of the copper tube in a sink or

bucket and opening the shut-off valve. Then turn

off water supply at valve.

3. Unscrew the plastic cap from the water valve

inlet at the rear of the freezer. Discard the cap.

4. Slide the brass compression nut, then the ferrule

(sleeve) onto copper tube.

5. Push the copper tube into water valve inlet as far

as it will go (¼ inch).

6. Slide the ferrule (sleeve) into valve and finger

tighten the compression nut onto valve. Tighten

another half turn with a wrench. Do not

over-tighten.

7. Secure the copper tube to your freezer’s rear

panel with a steel clamp and screw (See

Illustration).

8. Coil the excess copper tubing (about 2½ turns)

Behind your freezer as shown. Arrange

coiled tubing to avoid vibration or wear against

other surfaces.

9. Open water supply shut-off valve and tighten

any connections that leak.

10. Reconnect power to freezer.

11. Turn icemaker on and lower ice level arm to start

icemaker operation.

NOTE

KKiitt ## 55330033991177995500 iiss aavvaaiillaabbllee ffrroomm yyoouurr ddeeaalleerr

tthhaatt pprroovviiddeess aallll mmaatteerriiaallss ffoorr aa wwaatteerr ssuuppppllyy

iinnssttaallllaattiioonn,, iinncclluuddiinngg 2255 ffeeeett ooff ccooppppeerr ttuubbiinngg,, aa

ssaaddddllee ttyyppee sshhuuttooffff vvaallvvee,, ((22)) 11//44”” bbrraassss

ccoommpprreessssiioon

n nnuuttss,, ((22)) ffeerrrruulleess//sslleeeevveess aanndd ffuullll

iinnssttrruuccttiioonnss..

Steel

p

Plastic Water Tubing

to Ice Maker

Fill Tu be

Copper water line

from household water supply

Clam

Brass

Compression

Wa

Water Valve

Nut

Ferrule

(Sleeve)

Coppe r

water

lin

ter

alve

V

Bracke t

Valve Inlet

e

(Include enough tubing in loop

to allow moving freezer out

for cleaning)

2-8

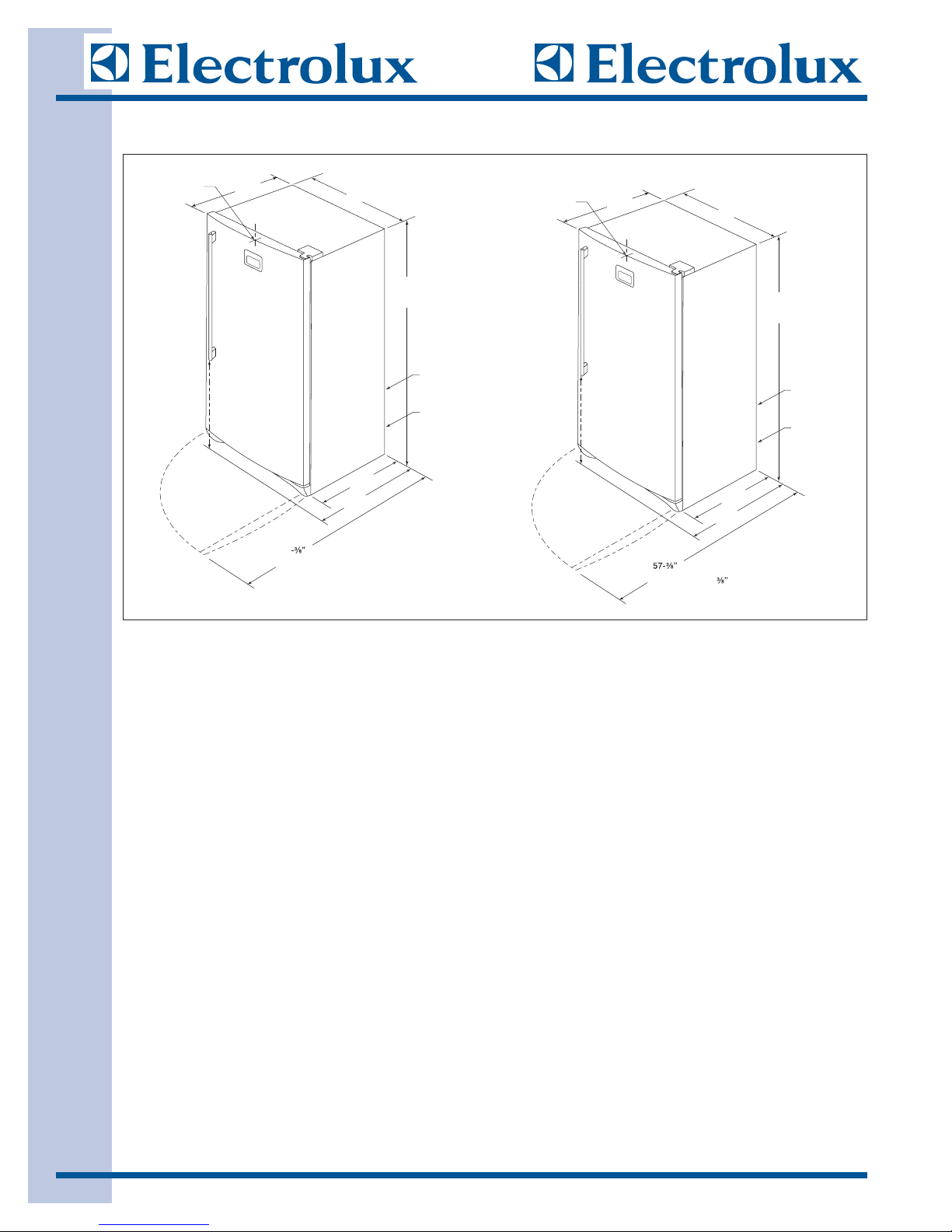

UUnniitt DDiimmeennssiioonnss

EEIILLFFUU2211GG SS

Unit Dimensions

EEIILLFFUU1177GG SS

Unit Dimensions

Overall depth at center

of arc 29-½”

28 ½”

C

L

32”

5

”

70- min.

8

∕

5

”

71- max.

∕8

Water line

inlet location

(left bottom rear)

Power cord

location

(right bottom rear)

Overall depth at center

of arc 27-½”

26½”

C

L

32”

65-½” min.

66-½” max.

Water line

inlet location

(left bottom rear)

Power cord

location

(right bottom rear)

31-¼”

59

(with doors 90˚ open)

26 -¼”

Note:

To allow for proper airow,

3”minumum

airspace required on each

side, with 1” at back and top

with 1” at bottom.

surrounding

(with doors 90˚ open)

24-¼”

29-¼”

Note:

To allow for proper airow,

airspace required on each

side, with 1” at back and top.

minumum

surrounding

EElleeccttrroonniicc CCoonnttrrooll

3-1

SSeeccttiioonn 33

EElleeccttrroonniicc CCoonnttrrooll

EElleeccttrroonniicc CCoonnttrrooll

3-2

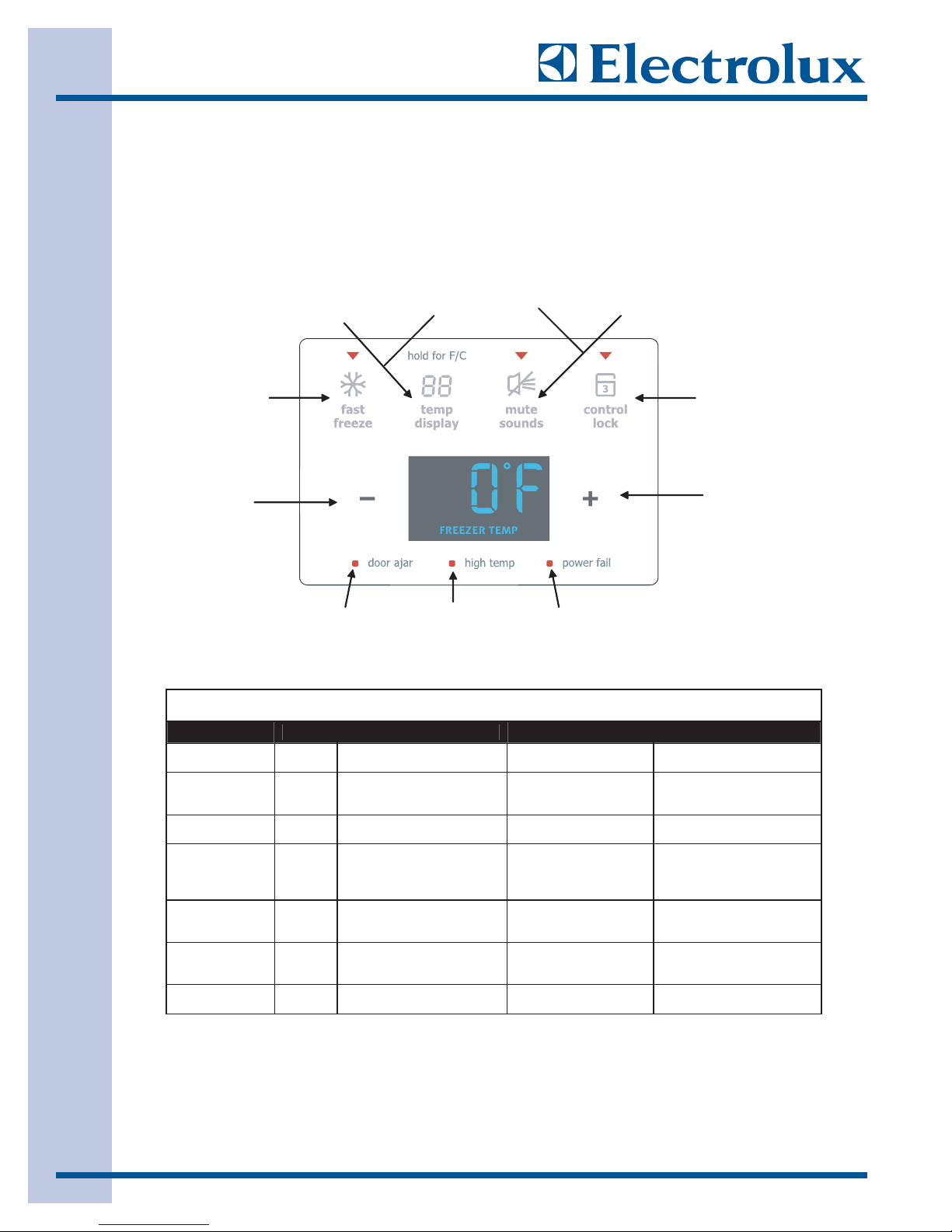

EElleeccttrroonniicc TTeemmppeerraattuurree CCoonnttrrooll

The electronic temperature control is located on the freezer door. Temperature is factory preset to provide

satisfactory food storage temperatures. Refer to the SETTING FREEZER CONTROL Quick Reference Guide

below for more details.

NNOOTTEE::

The unit can reach as low as -35 degrees during the Fast Freeze Mode but ideally the mode is for

initial startup and the addition of product during restock.

NNOOTTEE::

Standard Ice Maker Production; 3.5-4 lbs/24hrs.

NNOOTTEE::

A more in depth description of the alarms is given on page 3-4.

SETTING FREEZER CONTROL

Press to start or

cancel the fast

freeze feature.

Press to

decrease the

temperature

setting

Press and

hold for 3

seconds to

toggle F or C

in the display.

Indicates the

door has been

open 5 minutes

or more.

Turns the

temperature

display ON or

OFF.

Indicates the

temperature was

above +23°F ( -9°C)

for at least one

hour.

Press to

mute

audible

alarms.

Indicates the

power was

interrupted.

ALARM FUNCTION TABLE

Press to turn the

sounds ON or OFF.

When the LED is ON,

the sounds are muted.

Press and hold

for 3 seconds to

start or cancel

control lock.

Press to

increase the

temperature

setting

Display Priority Visual Alarm Alarm Status Action(s) Required

“HI” 3 “HI Temp” LED ON and

Alternating “E1”

and temperature

Alternating “CE”

and temperature

Alternating “E2”

and temperature

Actual

Temperature

Set Temperature 5

mute sounds LED ashes

2

mute sounds LED ashes; 1

second set temperature, 1

second “E1”

1

mute sounds LED ashes; 1

second set temperature, 1

second “CE”

4

mute sounds

second set temperature, 1

second “E2”

6

power fail LED on and mute

sounds

door ajar

sounds

LED ashes

LED on and

LED ashes

LED ashes; 1

mute

Freezer temperature

over the safe limit

Fail Safe Mode Check thermistor status

Communication Error Check connection between

Stuck Key Error Check membrane keys.

Cabinet greater than 10

degrees over the SET

TEMP. at power up.

Door open for more than

5 minutes

Press the mute sounds key

to stop the audible alarm

Press the mute sounds key

to stop the audible alarm

UI and ECU. Press the mute

sounds key to stop the

audible alarm

Press the mute sounds key

to stop the audible alarm

Press the mute sounds key

to stop the audible alarm

Press the mute sounds key

to stop the audible alarm

EElleeccttrroonniicc CCoonnttrrooll

3-3

NNoorrmmaall OOppeerraattiioonn

The user can select any temperature setting from -10°F to 10°F (-24°C to -12°C). Press the plus (

++))

key to

increment or the minus (

--

) key to decrement the temperature setting by one degree each key press. If a key

is not pressed within 3 seconds, the confirmation tone sounds and the set temperature blinks once before

changing to the new temperature setting. The display turns off 10 seconds later.

If the temperature display is OFF, the first press of ++or --key displays the current temperature setting. Then

pressing the ++or --will change the current setting. If the temperature display is ON, the first press of the ++or

--

will change the current setting by one degree.

The OFF setting is the position past the 10°F setting. A confirmation tone is sounded when switching to OFF

position. In the OFF position, all functions (compressor, defrost, and alarms) will be disabled except the light

control. When a temperature alarm condition is present and the set temperature is changed to the OFF

setting, the visual and audible alarms end.

TTeemmppeerraattuurree DDiissppllaayy

Press the

tteemmpp ddiissppllaayy

key to toggle temperature display ON or OFF. The default setting is OFF.

The acceptance tone sounds when the option is changed. The "FREEZER TEMP" LED on the display is

always ON.

TTeemmppeerraattuurree SSccaallee

Press and hold the

tteemmpp ddiissp

pllaayy

key for 3 seconds to switch between degrees F and degrees C. The

confirmation tone sounds after the 3 seconds. Initial default setting is Fahrenheit. Temperature displayed is

rounded to the nearest whole number.

If the temperature display is OFF, the display turns on and displays the set temperature and the change in

temperature scale. The display returns to OFF state after 3 seconds. If the temperature display is ON, the

temperature scale change is visible.

FFaasstt FFrreeeezzee

Engagement of the fast freeze function turns the compressor on for 72 hours. The fast freeze LED is enabled

when fast freeze is engaged and the acceptance tone sounds. The

ffaasstt ffrreeeezzee

key toggles the state ON or

OFF. The set temperature is displayed if temp display state is ON. The user is allowed to change the set

temperature while in fast freeze mode. The new set temperature will be used when the fast freeze cycle is

complete. Defrost will function normally during fast freeze. Fast freeze will not engage if the temperature

setting is "OFF". If fast freeze is activated during defrost, the LED will turn on but the compressor will not

come on until after the defrost cycle is completed. The freezer returns to the previous temperature setting

after the 72 hours. Manual defrost is not available while in fast freeze mode.

CCoonnttrrooll LLoocckk

Press and hold the

ccoonnttrrooll lloocckk

key for three seconds to activate or deactivate the freezer control lockout

feature which prevents user key entries. After the three seconds, the confirmation tone sounds and the

control lock LED will be displayed indicating that the control is locked. If a key is pressed while locked, the

control lock LED will flash twice and the invalid tone will sound. If an alarm occurs while in the locked mode,

the mute sounds key will be enabled to mute the alarm. When the lockout is deactivated, the control lock

LED will turn off.

MMuuttee SSoouunnddss

The

mmuuttee ssoouunnddss

key will enable or disable the audible sounds, i.e. key acceptance and confirmation tones.

The default state is mute sounds OFF and the corresponding LED is OFF. When you press

m

muuttee ssoouunnddss

to

enable mute feature, the acceptance key tone does not sound. When you press

mmuuttee ssoouunnddss

to disable mute

option, the acceptance key tone does sound. When you turn ON the mute sounds, the mute sounds LED

turns ON and all tones except alarms are eliminated. When the tones have been muted, the audible alarms

will still operate normally. The mute sounds key is also used for muting audible alarms.

EElleeccttrroonniicc CCoonnttrrooll

3-4

AAllaarrmmss

TTeemmppeerraattuurree AAllaarrmm

If the temperature of the cabinet remains above alarm activation temperature of 23.0°F +/- 3 F° (-5°C +/- 2°C)

for more than 1 hour, the high temp LED will turn ON, mute sounds LED will flash, the display will show "HI",

and the buzzer sounds the alarm tones. "HI" will continue to be displayed until the

mmuuttee ssoouunnddss

key is

pressed even if cabinet temperature decreases. The highest temperature will display for 10-seconds. Next,

the freezer will display the set temperature if cabinet temperature is not above the upper control limit. If the

cabinet temperature is above the upper control limit, the actual cabinet temperature will be displayed until the

set temperature is reached. The display will not turn off until the temperature is below the alarm temperature.

PPoowweerr FFaaiill AAllaarrmm

The red power fail LED will illuminate when the microprocessor initiates and the cabinet temperature is greater

than 10°F over the set temperature. The current temperature will be displayed and blinking. To acknowledge

the alarm, press the

mmuuttee ssoouunnddss

key. The audible alarm and power fail LED will then turn OFF. If the temp

display is OFF, the display will turn OFF 10 seconds after the alarm is cleared.

DDoooorr AAjjaarr AAllaarrmm

When the door is left open for 5 or more minutes, the alarm sounds. The door ajar LED turns ON. The

display will not change. Close the door or press the

mmuuttee ssoouunnddss

key to turn the audible alarm off. The door

ajar LED remains on until the door is closed.

CCoommmmuunniiccaattiioonn EErrrroorr

If a communication error occurs, the freezer will operate in "Fail Safe Mode". The display will alternate

between "CE" and set temperature in 1 second intervals. The mute sounds LED flashes. Check connection

between UI & ECU. Press the

mmuuttee ssoouunnddss

key to stop the audible alarm. No features will activate during a

communication error because the error will prevent proper operation.

TThheerrmmiissttoorr EErrrroorr

If a thermistor error occurs, the freezer will operate in "Fail Safe Mode". The display will alternate between

"E1" and set temperature in 1 second intervals. The mute sounds LED flashes. Check the thermistor status.

Press the

mmuuttee ssoouunnddss

key to stop the audible alarm.

SSttuucckk KKeeyy EErrrroorr

If a key is stuck, the freezer will maintain the current set temperature. The display will alternate between "E2"

and set temperature in 1 second intervals. The mute sounds LED flashes. Check membrane keys. Try

pressing mute sounds key to stop the audible alarm. The audible indication times out in 30 seconds.

FFaaiill SSaaffee M

Mooddee

When the unit goes into Fail Safe mode for a communications or thermistor error, the compressor will run

continuously.

EElleeccttrroonniicc CCoonnttrrooll

3-5

DDeeffrroosstt MMooddee

All models have an automatic defrost mode. Defrost will not engage if the control is in "OFF" position. When

defrost is manually initiated or terminated, an audible confirmation beep will occur.

DDeeffrroosstt TTiimmiinngg

After each 12 hours of accumulated compressor run time, a 30 minute defrost cycle is automatically engaged.

Before initiating the defrost cycle, the compressor is turned off. The freezer will exit defrost mode after 30

minutes and start cooling to maintain the previous control setting.

MMaannuuaall DDeeffrroosstt

Changing defrost states has precedence over normal run mode. Defrost can be toggled ON or OFF. Each

time defrost mode is changed, it will reset the compressor run time. Defrost state can be changed by

pressing and holding both

ffaasstt ffrreeeezzee

and

mmuuttee ssoouunnddss

keys simultaneously for 3 or more seconds.

The confirmation tone will sound to confirm that the state has changed and "dEF" will display for 3 seconds.

If the display is OFF, display returns to OFF state after 3 seconds. The user is allowed to change the set

temperature while in manual defrost. The new set temperature will be used when the defrost cycle is

complete. Diagnostic mode is not available while in manual defrost.

SShhoowwrroooomm M

Mooddee

Showroom mode allows a sales person to demonstrate the freezer features without turning the compressor on

or going through defrost cycles. Set the control to OFF position. Press and hold the + and - keys for 3

seconds to initiate show room mode. The display will show "SS" displaying for 3 seconds and the

confirmation tone will sound. All keys should operate normally during showroom mode. The cabinet light will

operate during showroom mode but the compressor and defrost heater will remain OFF. Set the control to

OFF and press and hold the + and - key for 3 seconds to end the showroom mode. No alarms will occur

during showroom mode. The showroom mode is automatically exited after a power failure.

TTeesstt MMooddee

To initiate "Test Mode" the J4 pins should be shorted before power up. All LED segments will illuminate for the

duration of 2 seconds. Each key that is pressed on the control will cause an LED to illuminate and stay

illuminated while in this mode. A numeric segment will be illuminated in each display with each key press. To

test communication, TX would need to be connected to RX. Remove power to exit the test mode.

Press the

ffaasstt ffrreeeezzee

key to illuminate the fast freeze LED.

Press the

tteemmpp ddiissppllaayy

key to illuminate the high temp LED.

Press the

mmuuttee ssoouunnddss

key to illuminate the mute sounds LED.

Press the

ccoonnttrrooll lloocckk

key to illuminate the control lock LED.

Press the (minus) "--" key to illuminate the door ajar LED.

Press the (plus) "++" key to illuminate the power fail LED.

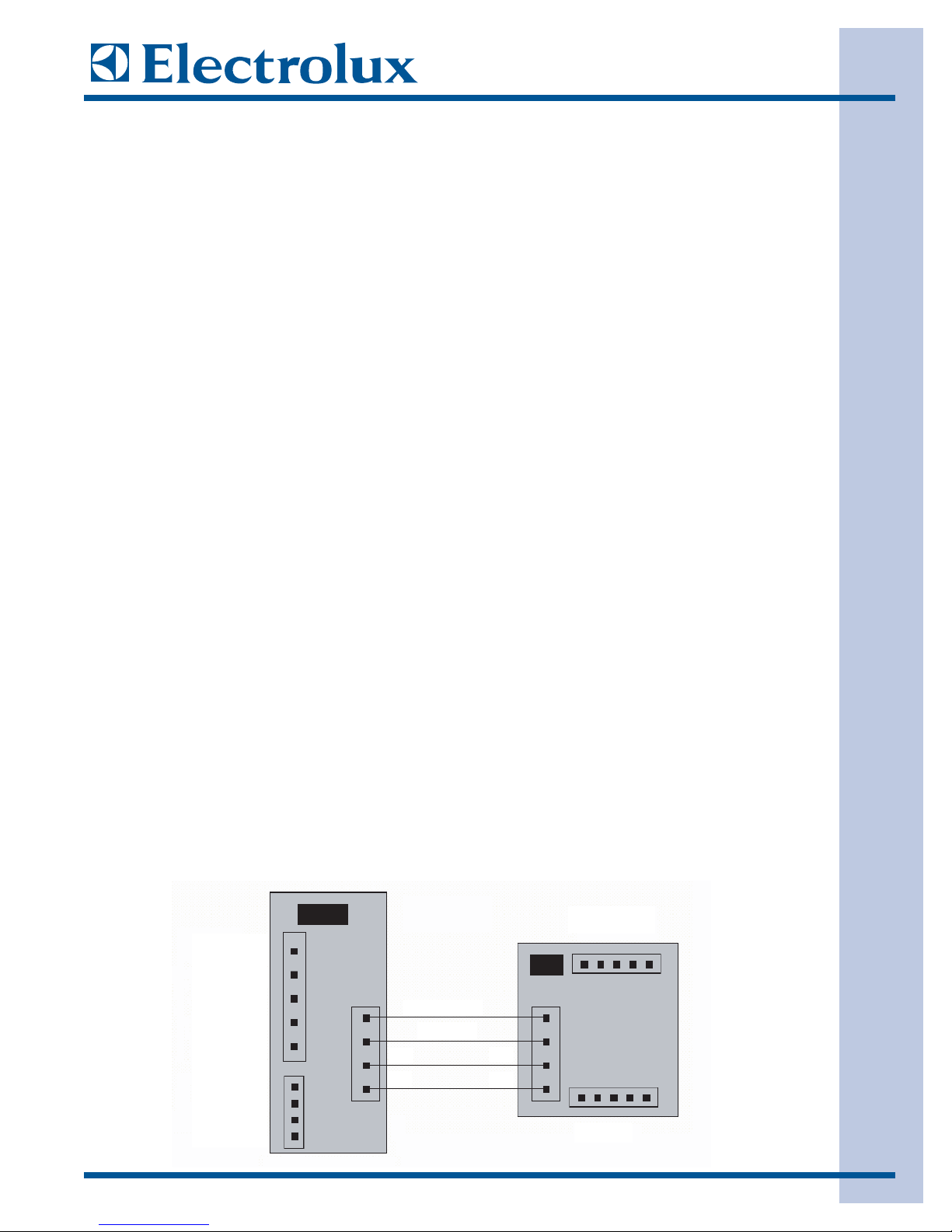

ECU

Neutral Input

Light Out

Programming

Header

UI

Heater Out

Comp. Out

Line Input L1

Thermistor

Door Switch

TX

RX

5V Power

Ground

RX

TX

Keypad

EElleeccttrroonniicc CCoonnttrrooll

3-6

SSeerrvviiccee DDiiaaggnnoossttiicc MMooddee

IInniittiiaattee SSeerrvviiccee MMooddee

The service technician should set the temperature to 0 F, then press and hold both the ++and --keys

simultaneously for 3 seconds.

When the diagnostics mode is entered, the number "88" is displayed and the confirmation tone is sounded.

The status information will be displayed for 3 seconds and then return to the diagnostics indicator.

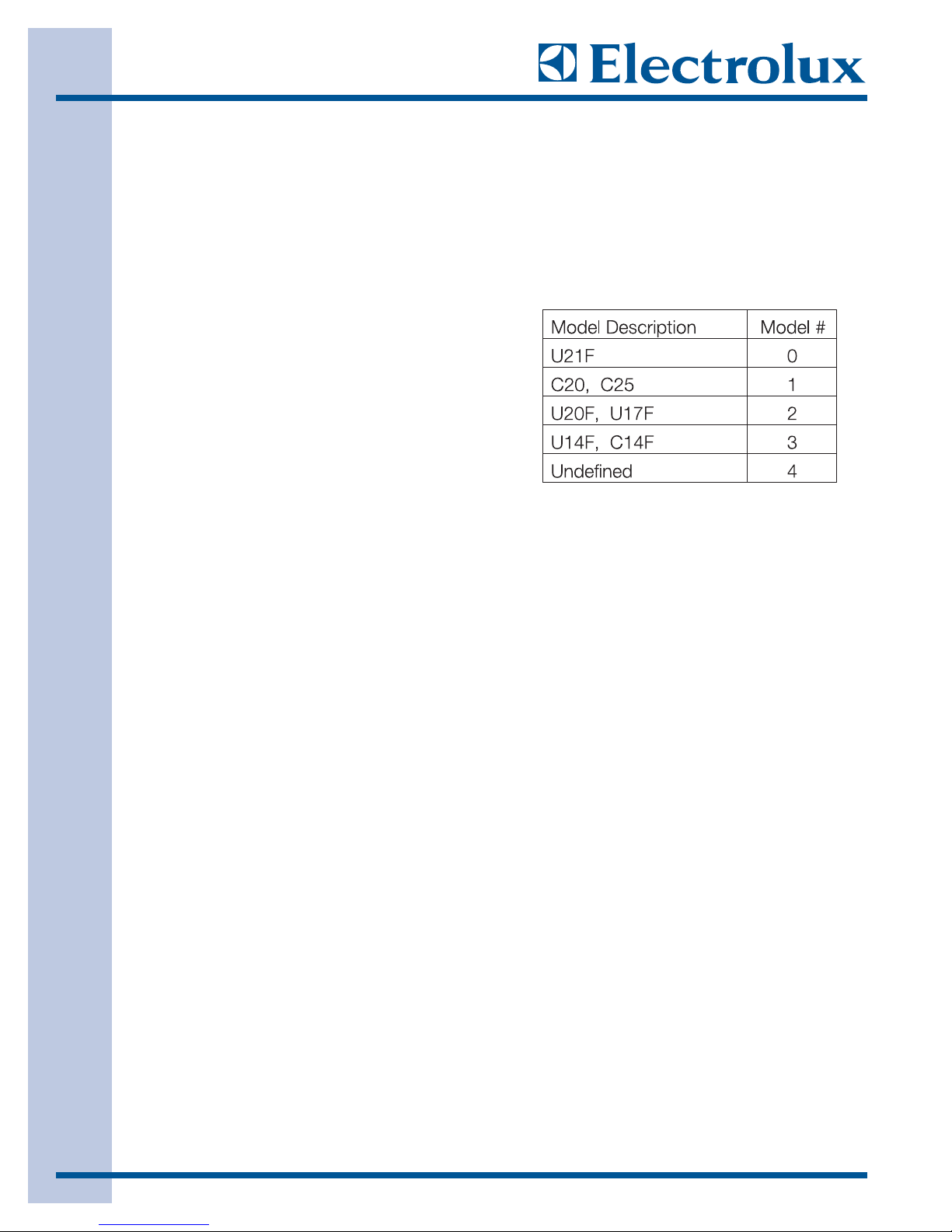

MMooddeell IIddeennttiiffiiccaattiioonn

Press the plus (++) key to display the model number.

Once you have displayed the model ID, press and hold

the plus (++) and

ffaasstt ffrreeeezzee

keys for 3 or more seconds

to select the option to change the model ID. The model

ID will increment or decrement by pressing the ++or

--

key. The model ID can be saved immediately by

pressing

mmuuttee ssoouunnddss

key.

SSooffttwwaarree VVeerrssiioonn

Press the

ffaasstt ffrreeeezzee

key to display the production software version for the model. (The limitation is 00 - 99

production software versions per model.) The minus and 2 digit version number "-xx" is displayed.

DDoooorr SSwwiittcchh SSttaattuuss

Press the "--" key to display the door switch status.

If the door switch is open, the letter "

ddOO

" is displayed.

If the door switch is closed, the letter "

ddCC

" is displayed.

TThheerrmmiissttoorr SSttaattuuss

Press the mute sounds key to display the thermistor status.

If the thermistor is operating properly, the characters "

-- --

" are displayed.

If the thermistor is open, the letter "

ttOO

" is displayed.

If the thermistor is shorted, the letter "

ttSS

" is displayed.

The thermistor status is not updated in showroom mode. The characters "

-- --

" are always displayed

RReesseett FFaaccttoorryy DDeeffaauullttss

Press the

ffaasstt ffrreeeezzee

key while the software version is displayed to reset all EEPROM values to the factory

defaults. The model ID will not be affected. The user interface will exit diagnostics mode and automatically

restart in normal power up operation.

EExxiitt DDiiaaggnnoossttiicc MMooddee

To exit service mode, the service technician should press and hold both the ++and --keys simultaneously for 3

or more seconds. The buzzer beeps at the end of 3 seconds.

4-1

RReeffrriiggeerraattiioonn SSyysstteemm

SSeeccttiioonn 44

RReeffrriiggeerraattiioonn SSyysstteemm

4-2

RReeffrriiggeerraattiioonn SSyysstteemm

NOTE

IInnssttrruuccttiioonnss ggiivveenn hheerree aarree ffuurrnniisshheedd aass aa

gguuiiddee.. PPeerrssoonnss aatttteemmppttiinngg ttoo uussee tthheessee

iinnssttrruuccttiioonnss ttoo mmaakkee rreeppaaiirrss ttoo tthhee sseeaalleedd

rreeffrriiggeerraattiioonn ssyysstteemm sshhoouulldd hhaavvee aa wwoorrkkiinngg

kknnoowwlleeddggee ooff rreeffrriiggeerraattiioonn aanndd

pprreevviioouuss ttrraaiinniinngg

oonn sseeaalleedd ssyysstteemm rreeppaaiirr,, aanndd aann EEPPAA cceerrttiiffiiccaa--

ttiioonn ffoorr sseerrvviicciinngg rreeffrriiggeerraattiioonn ssyysstteemmss..

NOTE

EElleeccttrroolluuxx ddooeess nnoott ppeerrmmiitt tthhee uussee ooff rreeccoovveerreedd

rreeffrriiggeerraanntt iinn tthhee sseerrvviicciinngg ooff oouurr pprroodduuccttss ffoorr

iin

n--wwaarrrraannttyy aanndd oouutt--ooff--wwaarrrraannttyy rreeppaaiirrss oorr ffoorr

pprroodduuccttss ccoovveerreedd bbyy sseerrvviiccee ccoonnttrraaccttss..

TThheerreeffoorree,, oonnllyy

nneeww rreeffrriiggeerraanntt oorr rreeffrriiggeerraanntt tthhaatt

hhaass bbeeeenn rreeccllaaiimmeedd bbaacckk ttoo nneeww ssppeecciiffiiccaattiioonnss

bbyy aa rreeffrriiggeerraanntt mmaannuuffaaccttuurreerr iiss ttoo bbee uusseedd..

IMPORTANT

EEffffeeccttiivvee JJuullyy 11,, 11999922,, tthhee UUnniitteedd SSttaatteess cclleeaann

aaiirr aacctt ggoovveerrnnss tthhee ddiissppoossaall ooff rreeffrriiggeerraannttss ssuucchh

aas

s RR--113344aa.. TThheerreeffoorree,, wwhheenn ddiisscchhaarrggiinngg oorr

ppuurrggiinngg tthhee sseeaalleedd ssyysstteemm uussee aann EEPPAA aapppprroovveedd

rreeffrriiggeerraanntt r

reeccoovveerryy ssyysstteemm aass oouuttlliinneedd iinn tthhee

ffiinnaall rruullee oonn tthhee pprrootteeccttiioonn ooff ssttrraattoosspphheerriicc

oozzoonnee aanndd rreeffrriiggeerraanntt rreeccyycclliinngg,, wwhhiicchh wwaass

ppuubblliisshheedd iinn tthhee FFeeddeerraall RReeggiisstteerr MMaayy 1144,, 11999933..

DDeeffiinniittiioonnss

RReeccoovveerryy::

To remove refrigerant in any condition from a

system and store it in an external container without

necessarily testing or processing it in any way.

RReeccyycclliinngg::

To clean refrigerant for reuse by oil separation and

single or multiple passes through devices, such as

replaceable core filter-driers, which reduce

moisture, acidity and particulate matter. This term

usually applies to procedures implemented at the

field job site or at a local service shop.

RReeccllaaiimm::

To reprocess refrigerant to new product

specifications by means which may include

distillation, will require chemical analysis of the

refrigerant to determine that appropriate product

specifications are met. This term usually implies

the use of processes or procedures available only

at a reprocessing or manufacturing facility.

SSaaffeettyy WWaarrnniinnggss

CCoommpprreessssoorr TTeessttiinngg

Whenever testing a compressor, extreme caution

should be used to prevent damaging the terminals.

A compressor with a damaged terminal or a

grounded winding can expel a terminal from its

insulated housing when the compressor is

energized. If this happens, a mixture of refrigerant

and oil will be released that could be ignited by an

external heat source (open flame, heater, etc.).

Also, if there is air in the system when this

happens, a spark at the compressor shell could

ignite the refrigerant and oil mixture.

CChhaarrggiinngg SSeeaalleedd SSyysstteemmss

Overcharging a refrigeration system with refrigerant

can be dangerous. If the overcharge is sufficient

to immerse the major parts of the motor and

compressor in liquid refrigerant, a situation has

been created which, when followed by a sequence

of circumstances can lead to the compressor shell

seam separating.

A hydraulic block occurs, preventing the

compressor from starting. This condition is known

as locked rotor. Electric current continues to flow

through the compressor motor windings which

become, in effect, electric resistance heaters.

The heat produced begins to vaporize the excess

refrigerant liquid causing a rapid increase in

system pressure. If the compressor protective

devices fail, the pressure within the system may

rise to extremes far in excess of the design limits.

Under these conditions, the weld seam around the

compressor shell can separate with explosive

force, spewing oil and refrigerant vapor which

could ignite.

To eliminate this exceedingly rare but potential

hazard, never add refrigerant to a sealed system.

If refrigerant is required, evacuate the existing

charge and recharge with the correct measured

amount of the refrigerant specified for the system.

1. All joints to be soldered must have proper fit.

Clearance between tubes to be soldered

should be from .001” to .006”. It is not

practical to actually measure this; however,

you do not want a dry fit or loose fit. Tubing

joints should overlap about the distance of

their diameter except for restrictor tubes,

which should be inserted 1.25”.

2. Clean all joint areas with fine steel wool or

preferably an abrasive cloth, such as grit cloth

No. 23 or Scotch-Brite.

3. Apply a thin film of liquid flux recommended

for silver soldering to surfaces to be joined and

to surfaces immediately adjacent to joint.

4. Align tubing so no stress is on joint. Do not

move tubing while solder is solidifying or leaks

will result.

5. Use a torch of adequate capacity so joint can

be quickly heated with a minimum of heat

travel to other points. Use a good grade of

silver solder.

6. Solder connections. If tubing is properly

cleaned and fluxed, solder will flow readily.

Use only enough solder to make a good bond.

7. Allow joint to cool, then wash exterior with

water to remove flux.

BBaassiicc CCoommppoonneennttss

The basic components of a refrigerator are a

compressor, condenser, evaporator, heat

exchanger (capillary tube and suction line), drier

and perimeter hot tube.

PPeerriimmeetteerr HHoott TTuubbee

To reduce the possibility of condensation forming

on the exterior of the cabinet in high humidity

areas, a perimeter hot tube (refrigerant tube) has

been installed in the unit. The perimeter tube

extends up the left side,across the top of the

freezer and down the right side into the filter drier.

When the compressor operates, warm refrigerant

flows through the primary condenser, then into the

primary hot tube, warming the cabinet front

exterior.

The perimeter hot tube is not replaceable. In the

unlikely event of a leak in the hot tube, a kit is

available to bypass the hot tube in the sealed

system. An electrical heater wire must be installed

within the tubing. Refer to the appropriate parts list

of the model being serviced for the correct kit part

number.

RReeffrriiggeerraanntt CCyyccllee

The refrigerant cycle is a continuous cycle that

occurs whenever the compressor is in operation.

Liquid refrigerant is evaporated in the evaporator

by the heat that enters the cabinet through the

insulated walls and by the heat from product load

and door openings. The refrigerant vapor is then

drawn from the evaporator, through the suction line

to the compressor. Compression raises the

pressure and temperature of the vapor in the

compressor and the vapor is then forced through

the discharge valve into the discharge line and into

the condenser. Air passing over the condenser

surface removes heat from the high pressure vapor

which then condenses to a liquid. The liquid

refrigerant then flows from the condenser to the

evaporator through the small diameter liquid line

(capillary tube). Before it enters the evaporator, the

liquid refrigerant is sub-cooled in the heat

exchanger by the low temperature suction vapor in

the suction line. When refrigerant is added, the

frost pattern will improve, the suction and

discharge pressures will rise, the condenser will

become hot and the wattage will increase.

4-3

RReeffrriiggeerraattiioonn SSyysstteemm

WWEEAARR AAPPPPRROOVVEEDD SSAAFFEETTYY GGLLAASSSSEESS WWHHEENN

WWOORRKKIINNGG WWIITTHH OORR OONN AANNYY PPRREESSSSUURRIIZZEEDD

SSYYSSTTEEMM OORR EEQQUUIIPPMMEENNTT.. HHAAVVEE AANN

A

APPPPRROOVVEEDD DDRRYY TTYYPPEE FFIIRREE EEXXTTIINNGGUUIISSHHEERR

HHAANNDDYY WWHHEENN UUSSIINNGG AANNYY TTYYPPEE OOFF GGAASS

OOPPEERRAATTEEDD TTOORRCCHH..

DDuurriinngg aapppplliiccaattiioonn ooff hheeaatt,, uussee wweett ccllootthhss ttoo

pprreevveenntt hheeaatt ffrroomm ccoonndduuccttiinngg ttoo aarreeaass ootthheerr

tthhaann tthhee ssoollddeerreedd jjooiinntt.. UUssee aa sshheeeett ooff mmeettaall oorr

ttoorrcchh gguuaarrdd ppaadd aass aa hheeaatt ddeefflleeccttoorr ttoo kkeeeepp

ffllaammee aawwaayy ffrroomm i

innffllaammmmaabbllee mmaatteerriiaallss aanndd

ppaaiinntteedd ssuurrffaacceess..

WARNING

CAUTION

4-4

RReeffrriiggeerraattiioonn SSyysstteemm

LLooww//HHiigghh SSiiddee LLeeaakk oorr UUnnddeerrcchhaarrggee

A loss of refrigerant can result in any of the

following:

1. Excessive or continuous compressor

operation.

2. Above normal freezer compartment

temperature.

3. A partially frosted evaporator (depending on

amount of refrigerant loss).

4. Below normal freezer compartment

temperature.

5. Low suction pressure (vacuum).

6. Low wattage.

The condenser will be “warm to cool”, depending

on the amount of refrigerant lost.

In the case of a low side refrigerant leak resulting

in complete loss of refrigerant, the compressor will

run but will not refrigerate. Suction pressure will

drop below atmospheric pressure and air and

moisture will be drawn into the system saturating

the filter drier.

If there is reason to believe the system has

operated for a considerable length of time with no

refrigerant and the leak occurred in the low side of

the system, excessive amounts of moisture may

have entered the system. In such cases the two

stage service Dryer Filter part number 5303918288

and vacuum procedure listed under Refrigerant

Leaks need to be followed to prevent repetitive

service.

If a slight undercharge of refrigerant is indicated

and no leak can be found after a thorough leak

test, the charge can be corrected without changing

the compressor.

If a high side leak is located and some refrigerant

remains in the system it is not necessary to

change the compressor.

TTeessttiinngg ffoorr RReeffrriiggeerraanntt LLeeaakkss

If the system is diagnosed as short of refrigerant

and the system has not been recently opened,

there is probably a leak in the system. Adding

refrigerant without first locating and repairing the

leak or replacing the component will not

permanently correct the difficulty. The leak must be

found. Sufficient refrigerant may have escaped to

make it impossible to leak test effectively. In such

cases, add a ¼” line piercing valve to the

compressor process tube. Add sufficient

refrigerant vapor to increase the pressure to 40 to

50 lb. per sq. in. Check the low side for leaks.

Run the compressor 2 or 3 minutes and check the

high side for leaks. Recover refrigerant using an

EPA approved recovery system.

CCoommpprreessssoorr RReeppllaacceemmeenntt

To check for contamination, obtain oil sample from

old compressor.

1. If the oil has burned odor, but no color change

or residue — follow instructions on page 4-6

“Installing A New Compressor”.

2. If oil has a burned odor and a sugar or gritty

feel as well as showing signs of contamination

(dark color), follow instructions in next section,

To Flush The System. Remove as much of

contamination as possible from system before

installing new compressor and filter-drier.

NOTE

TThhee lliinnee ppiieerrcciinngg vvaallvvee ((ccllaammpp--oonn ttyyppee)) sshhoouulldd

bbee uusseedd ffoorr tteesstt ppuurrppoosseess oonnllyy.. IItt mmuusstt bbee

rreemmoovveedd ffrroomm ssyysstteemm aafftteerr iitt hhaass sseerrvveedd iittss

ppuurrppoossee..

NOTE

IItt iiss rreeccoommmmeennddeedd tthhaatt ssyysstteemm bbee fflluusshheedd wwiitthh

ddrryy NNiittrrooggeenn.. HHoowweevveerr,, iiff rreeffrriiggeerraanntt iiss uusseedd ttoo

fflluus

shh tthhee ssyysstteemm yyoouu mmuusstt llooookk aatt tthhee sseerriiaall

ppllaattee ttoo sseeee wwhhaatt ttyyppee ooff rreeffrriiggeerraanntt iiss uusseedd iinn

tthhee ssyysstteem

m.. TThhiiss iiss tthhee oonnllyy rreeffrriiggeerraanntt tthhaatt ccaann

bbee uusseedd ttoo fflluusshh tthhee ssyysstteemm aanndd iitt mmuusstt bbee

rreeccoovveerreedd..

CAUTION

NNEEVVEERR iinnssttaallll aa nneeww ccoommpprreessssoorr wwiitthhoouutt ffiirrsstt

cchheecckkiinngg ffoorr ppoossssiibbllee ssyysstteemm ccoonnttaammiinnaattiioonn..

4-5

RReeffrriiggeerraattiioonn SSyysstteemm

TToo FFlluusshh TThhee SSyysstteemm

TToo UUssee DDrryy NNiittrrooggeenn TToo FFlluusshh TThhee SSyysstteemm::

1. Remove compressor and filter-drier. Connect

process coupling to outlet tube of condenser.

2. Fasten cloth over other end of coil to prevent

old oil from spraying over room.

3. Connect hand shut-off valve on flushing hose

to process coupling.

4. Slowly open hand shut-off valve and allow

nitrogen to flow through condenser until

discharge is clear.

5. Disconnect cap tube from evaporator. Flush

evaporator in same manner as condenser.

6. Flush cap tube. This is only possible if you

have proper service valve adapter.

7. Reassemble system.

CAUTION

DDOO NNOOTT eexxcceeeedd 330000 PPSSIIGG..

CAUTION

UUssee eexxttrreemmee ccaarree wwhheenn uussiinngg DDrryy NNiittrrooggeenn ttoo

fflluusshh ssyysstteemmss.. PPrreessssuurree iinn nniittrrooggeenn ccyylliinnddeerr

ccoouulldd bbee a

ass hhiigghh aass 22000000 ppssii.. NNiittrrooggeenn ccyylliinnddeerr

mmuusstt bbee eeqquuiippppeedd wwiitthh aapppprroovveedd pprreessssuurree

rreegguullaattoorr aanndd pprreessssuur

ree rreelliieeff vvaallvvee.. EEnnssuurree tthhaatt

yyoouurr hhoosseess hhaavvee aaddeeqquuaattee rraattiinnggss ffoorr pprreessssuurree

iinnvvoollvveedd aanndd tthhaatt aallll ooff yyoouurr eeqquuiippmmeenntt iiss iinn

ggoooodd ccoonnddiittiioonn.. TThhee eenndd ooff tthhee fflluusshhiinngg hhoossee oonn

tthhiiss ttaannkk rreegguullaattoorr mmuusstt bbee eeq

quuiippppeedd wwiitthh aa

hhaanndd sshhuutt--ooffff vvaallvvee ((RRoobbiinnaaiirr NNoo.. 4400338800)).. CClloossee

hhaanndd sshhuutt--ooffff vvaallvvee aanndd aaddjjuusstt nniittrrooggeenn rreegguullaattoorr

ttoo ccoorrrreecctt pprreessssuurree bbeeffoorree pprroocceeeeddiinngg wwiitthh

fflluusshhiinngg pprroocceedduurree..

TToo UUssee RReeffrriiggeerraanntt TToo F

Flluusshh TThhee SSyysstteemm::

1. Disconnect the suction and discharge lines

from the compressor and remove the

filter-drier. Connect process coupling to outlet

and inlet tube of condenser.

2. Connect hose to outlet process coupling and

charging cylinder. Connect another hose to

inlet coupling and recovery system.

3. Open charging cylinder and allow refrigerant to

flow through condenser until discharge into

bag is clear.

4. Disconnect capillary tube from evaporator.

Flush evaporator in same manner as

condenser.

5. Flush cap tube. This is only possible if you

have proper service valve adapter.

6. Reassemble system.

NOTE

TThhee lliinnee ppiieerrcciinngg vvaallvvee ((ccllaammpp--oonn ttyyppee)) sshhoouulldd

bbee uusseedd ffoorr tteesstt ppuurrppoosseess oonnllyy.. IItt mmuusstt bbee

rreemmoovveedd f

frroomm ssyysstteemm aafftteerr iitt hhaass sseerrvveedd iittss

ppuurrppoossee..

CAUTION

DDOO NNOOTT eexxcceeeedd 115500 PPSSIIGG..

CAUTION

DDOO NNOOTT eexxcceeeedd 330000 PPSSIIGG..

CAUTION

RReeffrriiggeerraanntt uusseedd ffoorr fflluusshhiinngg mmuusstt bbee rreeccoovveerreedd

iinnttoo aa rreeccoovveerryy ssyysstteemm.. MMeetteerr aammoouunntt ooff

rreeffrriiggeerraanntt uusseedd ffoorr fflluusshhiinngg wwiitthh yyoouurr cchhaarrggiinngg

ccyylliinnddeerr.. DDOO NNOOTT OOVVEERRFFIILLLL TTHHEE BBAAGG..

A new compressor which is cold (e.g. after having

been kept in a cold service van) should be left to

warm to the surrounding temperature before the

plugs on the compressor connections are

removed. This will help prevent condensation from

forming in the oil and the compressor. Also, avoid

opening the system when any of the components

or lines are cold.

1. Disconnect electrical supply to refrigerator.

2. Remove compressor access panel.

3. Remove all components needed to pull the

compressor assembly from the unit.

4. Pull compressor assembly straight out.

5. Recover refrigerant by using EPA approved

recovery system.

6. Remove leads from compressor motor

terminals.

7. Remove mounting clips and washers.

8. After refrigerant is completely recovered, cut

suction and discharge lines as close to

compressor as possible. Leave only enough

tubing to pinch off and seal defective

compressor. Plug or tape any open system

tubing to avoid entrance of moisture and air

into system. Remove inoperable

compressor and transfer mounting parts to

new compressor.

9. Install new compressor in exact same manner

as original compressor.

4-6

RReeffrriiggeerraattiioonn SSyysstteemm

NOTE

RReelleeaassee hhoollddiinngg cchhaarrggee ((rreelleeaassee sslloowwllyy ttoo aavvooiidd

ooiill ddiisscchhaarrggee)) oonn nneeww ccoommpprreessssoorr ttoo eennssuurree

tthheerree iiss

nnoo lleeaakk iinn sseeaamm oorr ttuubbiinngg.. RReeiinnssttaallll

rruubbbbeerr pplluugg..

NOTE

TThhee ffoolllloowwiinngg iinnssttrruuccttiioonnss aarree ggeenneerraalliizzeedd ttoo

hheellpp tthhee tteecchhnniicciiaann uunnddeerrssttaanndd tthhee pprroocceedduurreess

ooff sseeaalleedd ssyysstteemm rreeppaaiirrss.. SSeeee SSeeccttiioonn 55

CCoommppoonneenntt TTeeaarrddoowwnn oonn tthhee eexxaacctt sstteeppss ooff

aacccceessssiinngg tthhee ccoommppoonneennttss o

off tthhee rreeffrriiggeerraattiioonn

ssyysstteemm..

NOTE

IIff llooww--ssiiddee pprroocceessss ttuubbee iiss ttoooo sshhoorrtt,, ssiillvveerr

ssoollddeerr ffoouurr iinncchh ppiieeccee ooff ttuubbiinngg oonnttoo pprroocceessss

ttuubbee aat

t tthhiiss ttiimmee..

IInnssttaalllliinngg aa NNeeww CCoommpprreessssoorr

Replacement of compressor and installation of

filter-drier must be done in a continuous sequence

so system is exposed to atmosphere no longer

than necessary.

All replacement compressors are shipped with

rubber plugs in the suction, discharge and process

tubes and contain the correct oil charge and a

holding charge of inert gas. Compressors have a

low-side process tube attached to the compressor

shell. A high-side process tube is attached to the

filter-drier.

Replacement compressors for refrigerator may

have an oil cooler even if the original compressor

did not. If the product is not equipped for an oil

cooler, leave the plastic caps in place and install

the compressor connecting only to the suction and

discharge lines of the new compressor.

Before installing the replacement compressor

remove the discharge plug and check for the pop

sound of the inert gas leaving the compressor.

If the compressor checks OK, reinstall the plug.

Do not remove any of the plugs again until the

compressor is in position and you are ready to

braze the lines.

NOTE

EEnnttiirreellyy nneeww ccoommpprreessssoorrss hhaavvee bbeeeenn ddeevveellooppeedd

oorr uussee wwiitthh RR--113344aa aanndd EEsstteerr ooiill rreeffrriiggeerraattiioonn

ssyysstteemmss.

. BBootthh ccoommpprreessssoorr aanndd eelleeccttrriicc mmoottoorr

hhaavvee bbeeeenn mmooddiiffiieedd.. OOlldd ccoommpprreessssoorrss iinntteennddeedd

ffoorr RR--1122 rreeffrriiggeerra

anntt mmuusstt nnoott bbee uusseedd ffoorr nneeww

ssyysstteemmss cchhaarrggeedd wwiitthh RR--113344aa..

CAUTION

DDOO NNOOTT uussee ccoommpprreessssoorr iiff yyoouu ddoo nnoott hheeaarr tthhiiss

ssoouunndd..

CAUTION

OOnn RR--113344aa ssyysstteemmss,, ccoommpprreessssoorr mmuusstt NNOOTT bbee

lleefftt ooppeenn ttoo aattmmoosspphheerree ffoorr mmoorree tthhaann 1100

mmiinnuutteess ttoo pprreevve

enntt mmooiissttuurree ccoonnttaammiinnaattiioonn ooff ooiill..

WARNING

DDOO NNOOTT OOPPEERRAATTEE RREECCIIPPRROOCCAATTIINNGG

CCOOMMPPRREESSSSOORR WWHHEENN CCHHAARRGGIINNGG LLIIQQUUIIDD

RREEFFRRIIGGEERRAANNTT IINNTTOO SSYYSSTTEEMM TTHHRROOUUGGHH IITTSS

PPRROOCCEESSSS TTUUBBEE..

CCoonnddeennsseerr RReeppllaacceemmeenntt

1. Disconnect electrical supply to refrigerator.

2. Remove compressor access panel.

3. Recover refrigerant by using EPA approved

recovery system.

4. Remove condenser fan mounting screws.

5. Unplug fan motor harness located in back of

fan motor.

6. Remove fan motor and fan blade.

7. After refrigerant is completely recovered,

disconnect inlet and discharge lines from

condenser.

8. Lift front of condenser and pull out of retainers

mounted to the drain pan.

9. Remove old condenser out the back of

cabinet.

10. Install replacement condenser.

11. Remove original filter-drier.

12. Install new filter-drier at condenser outlet.

13. Evacuate and charge the system using

recommended procedure described under

Evacuating and Recharging.

14. Reassemble unit.

4-7

RReeffrriiggeerraattiioonn SSyysstteemm

10. Reform both suction and discharge lines to

align with new compressor. If they are too

short, use additional lengths of tubing. Joints

should overlap 0.5” to provide sufficient area

for good solder joint. Clean and mark area

where tubing should be cut. Cut tubing with

tubing cutter. Work as quickly as possible to

avoid letting moisture and air into system.

11. Solder all connections according to soldering

procedure.

12. Remove original filter-drier.

13. Install new filter-drier at condenser outlet.

14. Evacuate and charge system using recommended procedure described under

Evacuating and Recharging.

15. Reconnect compressor terminal leads in

accordance with refrigerator wiring diagram.

16. Reassemble unit.

CAUTION

DDOO NNOOTT uunnbbrraazzee oolldd ffiilltteerr--ddrriieerr ffrroomm ssyysstteemm..

TThhiiss wwiillll vvaappoorriizzee aanndd ddrriivvee mmooiissttuurree ffrroomm

ddeessiiccccaanntt b

baacckk iinnttoo ssyysstteemm.. TThhee oolldd ffiilltteerr--ddrriieerr

sshhoouulldd bbee ccuutt oouutt ooff ssyysstteemm..

CAUTION

DDOO NNOOTT uunnbbrraazzee oolldd ffiilltteerr--ddrriieerr ffrroomm ssyysstteemm..

TThhiiss wwiillll vvaappoorriizzee aanndd ddrriivvee mmooiissttuurree ffrroomm

ddeessiiccccaanntt b

baacckk iinnttoo ssyysstteemm.. TThhee oolldd ffiilltteerr--ddrriieerr

sshhoouulldd bbee ccuutt oouutt ooff ssyysstteemm..

NOTE

TThhee ffoolllloowwiinngg iinnssttrruuccttiioonnss aarree ggeenneerraalliizzeedd ttoo

hheellpp tthhee tteecchhnniicciiaann uunnddeerrssttaanndd tthhee pprroocceedduurreess

ooff sseeaalleedd ssyysstteemm rreeppaaiirrss.. SSeeee SSeeccttiioonn 55

CCoommppoonneenntt TTeeaarrddoowwnn oonn tthhee eexxaacctt sstteeppss ooff

aacccceessssiinngg tthhee ccoommppoonneennttss o

off tthhee rreeffrriiggeerraattiioonn

ssyysstteemm..

Loading...

Loading...