Page 1

E30GF74GPS E36GF75GPS E36GF76GPS

318201761

Page 2

2

Finding Information

READ AND SAVE THESE INSTRUCTIONS

NONO

TETE

NO

TE

NONO

TETE

Installer: Leave instructions with owner. Owner: Read your range Use & Care guide. It

contains important safety information for operating this appliance. It also has many

suggestions for getting the best results from your appliance.

Read all instructions before installing the range.

For your safety, please read and observe all safety instructions. This

guide will help you anticipate all installations connections.

QUESTIONS

For toll-free telephone support in the U.S. and Canada:

1-877- 4ELECTROLUX (1-877-435-3287)

For online support and Internet product information:

www.electroluxusa.com

©2007 Electrolux Home Products, Inc.

Post Office Box 212378, Augusta, Georgia 30917, US

All rights reserved. Printed in the USA

Page 3

Finding Information

TABLE OF CONTENTS

Please Read And Save This Guide .................... 2

Questions .......................................................... 2

Table Of Contents ............................................. 3

Safety ..................................................................... 4

Important Safety Instructions ............................... 4

Definitions ........................................................... 4

Safety Precautions ........................................... 5

Preparing for Installation ................................... 7

3

Verifying Package Contents ................................ 7

Gas/Electric Requirement Table............................... 7

Electrical Power Supply Requirements .................. 8

Gas/Electric Connection Rough-In ..................... 9

Cabinet/Countertop Preparation .......................... 10

General Dimensions ........................................ 11

Wood/Composite Overlay Installation...................... 13

Installing Anti-Tip Bracket ...................................... 14

Installing the 36” Range Optional Backguard......... 15

Removing Oven Door.......................................... 16

Re-Installing Oven Door.................................. 16

Grounding..................................................... 17

Connect Range To Gas Supply.........................17

Installing Range...............................................18

Verifying the Operation ...................................... 19

To Insure Proper and Safe Operation..................... 20

Converting from Natural Gas T o LP Gas................. 21

Page 4

4

Safety

IMPORTANT SAFETY INSTRUCTIONS

Page 5

SAFETY PRECAUTIONS

Safety

5

Page 6

6

Safety

WARNINGWARNING

WARNING

WARNINGWARNING

Never use this appliance as a space heater to heat or warm a room. Doing so may result in carbon

monoxide poisoning and overheating of the oven.

Page 7

Preparing for Installation

VERIFY PACKAGE CONTENTS

• Literature Pack • Griddle (some models)

• Anti-Tip Bracket • Simmer Plate

• Burner Grate Pack • Broiler Pan/Insert

• Burner Rings • Stainless Steel Cleaner

• LP Conversion Kit • Wok Ring

• Burner Caps • Oven Racks

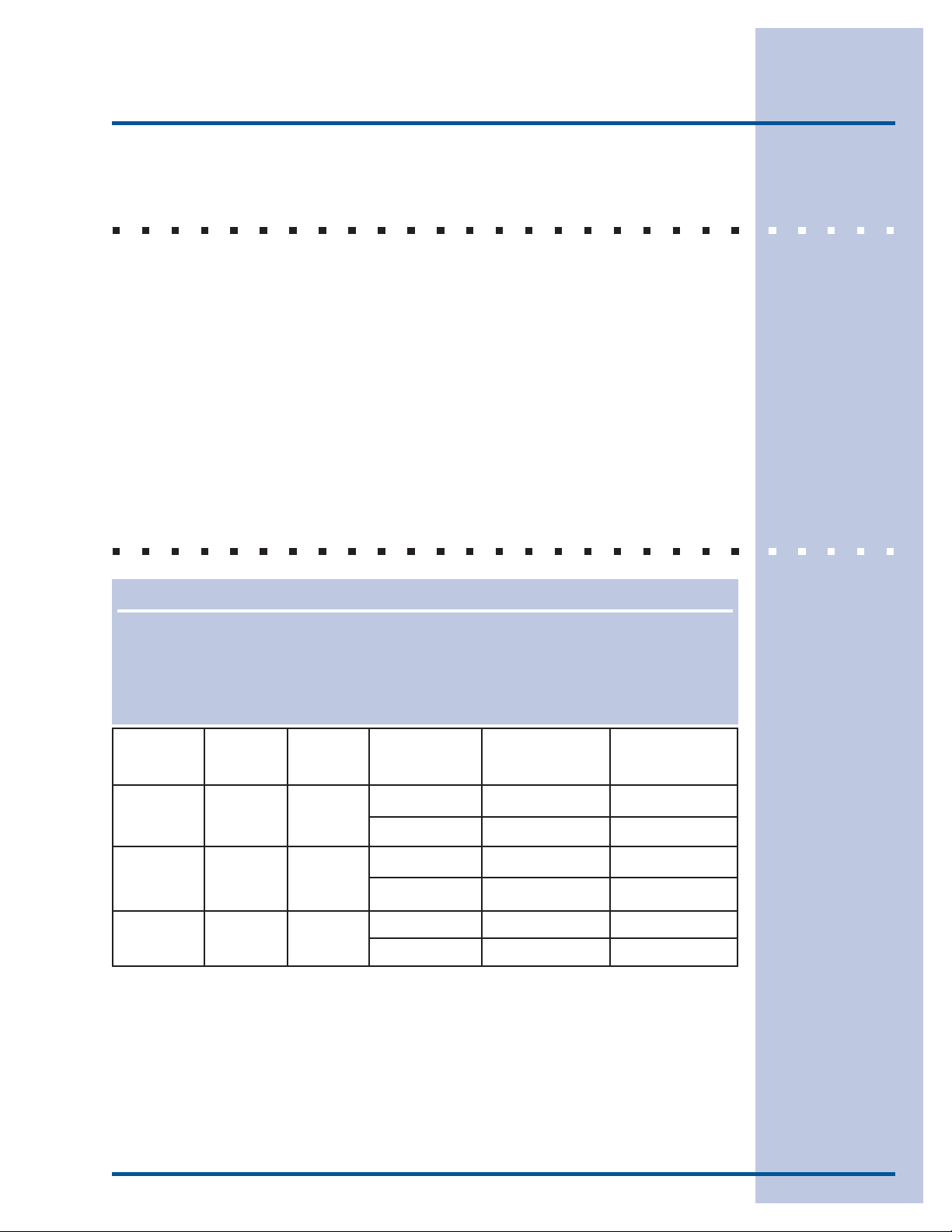

GAS AND ELECTRIC REQUIREMENT TABLE

7

NONO

TETE

NO

TE

NONO

TETE

This range is shipped from the factory pre-set for use with natural gas. For LP conversion see the

accompanying LP Conversion Kit. The electrical information in the table is also located on the

serial number label on the range.

Model No.

Electrical

Circuit

Total

Connected

Gas Type

Manifold Pressure Minimum Gas

Supply

Water Column Inches Water Column Inches

E30GF74GPS

E36GF75GPS

E36GF76GPS

120 V,

60Hz,

120 V,

60Hz,

120 V,

60Hz,

5A

8A

5A

Natural

Liquid Propane

Natural

Liquid Propane

Natural

Liquid Propane

5"

10"

5"

10"

5"

10"

6"

11"

6"

11"

6"

11"

Page 8

8

Preparing for Installation

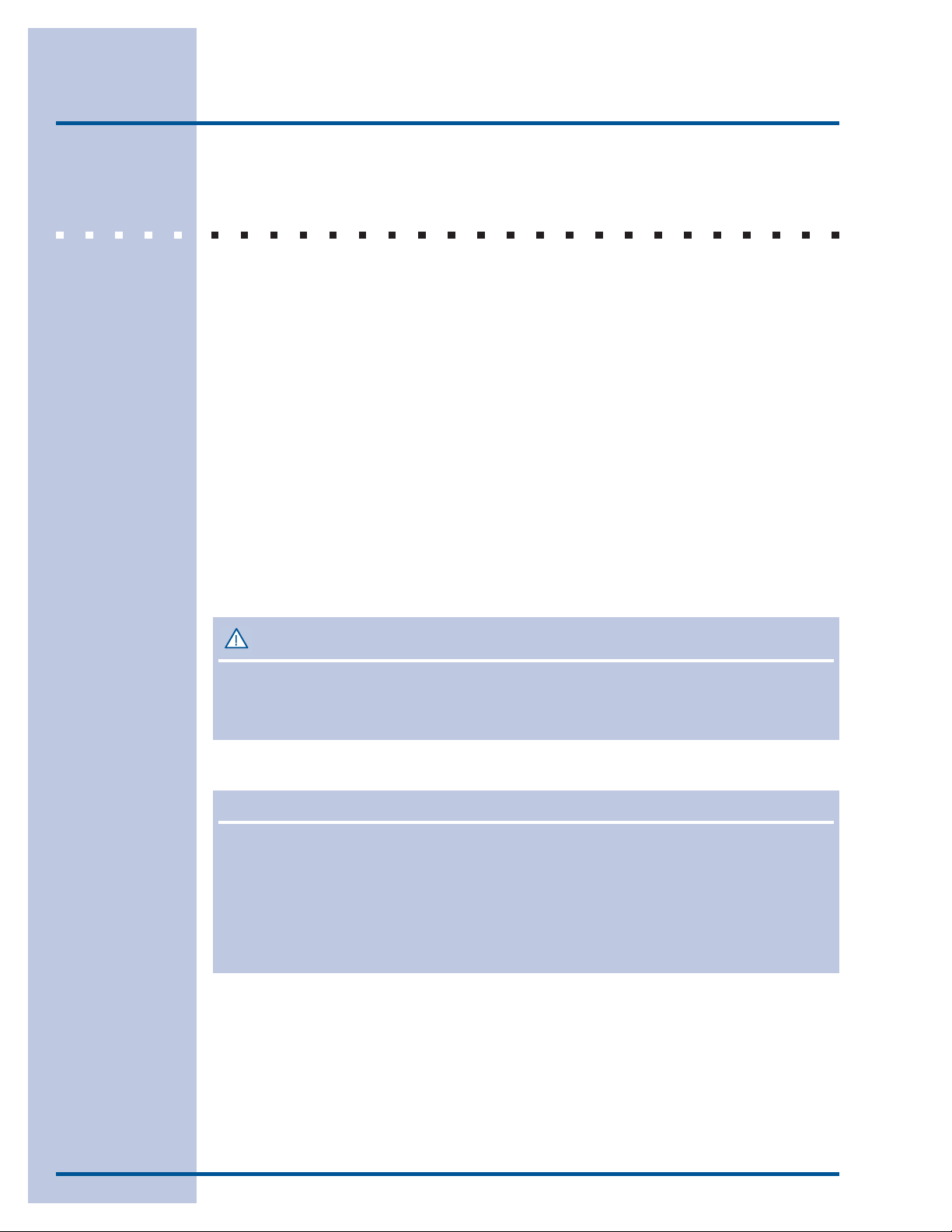

ELECTRICAL POWER SUPPLY REQUIREMENTS

It is the owner’s responsibility to ensure that the electrical connection

of this appliance is performed by a qualified electrician. The electrical

installation, including minimum supply wire size and grounding, must be

in accordance with the National Electric Code ANSI/NFPA 70-1993*

(or latest revision) and local codes and ordinances. In Canada,

electrical grounding must be in accordance with the current CSA C22.1

Canadian Electrical Code Part 1 and/or local codes.

*A copy of the standard must be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

The correct voltage, frequency, and amperage must be supplied to the

appliance from a separate, grounded, circuit that is protected by a

properly sized circuit breaker or time delay fuse.

WARNINGWARNING

WARNING

WARNINGWARNING

If the gas or electric service provided does not meet the product specifications, do not

proceed with the installation. Call the selling dealer, the gas supplier, or a licensed

electrician.

NONO

TESTES

NO

TES

NONO

TESTES

The power supply must be properly grounded. Improper grounding will result in

continuous sparking of the electrodes, even after flame ignition.

If there is any doubt as to whether the power supply is properly polarized or grounded,

have it checked by a qualified electrician.

Use 120V, 60Hz, and properly grounded branch circuit protected by a 15-amp or 20-amp

circuit breaker or time delay fuse.

Page 9

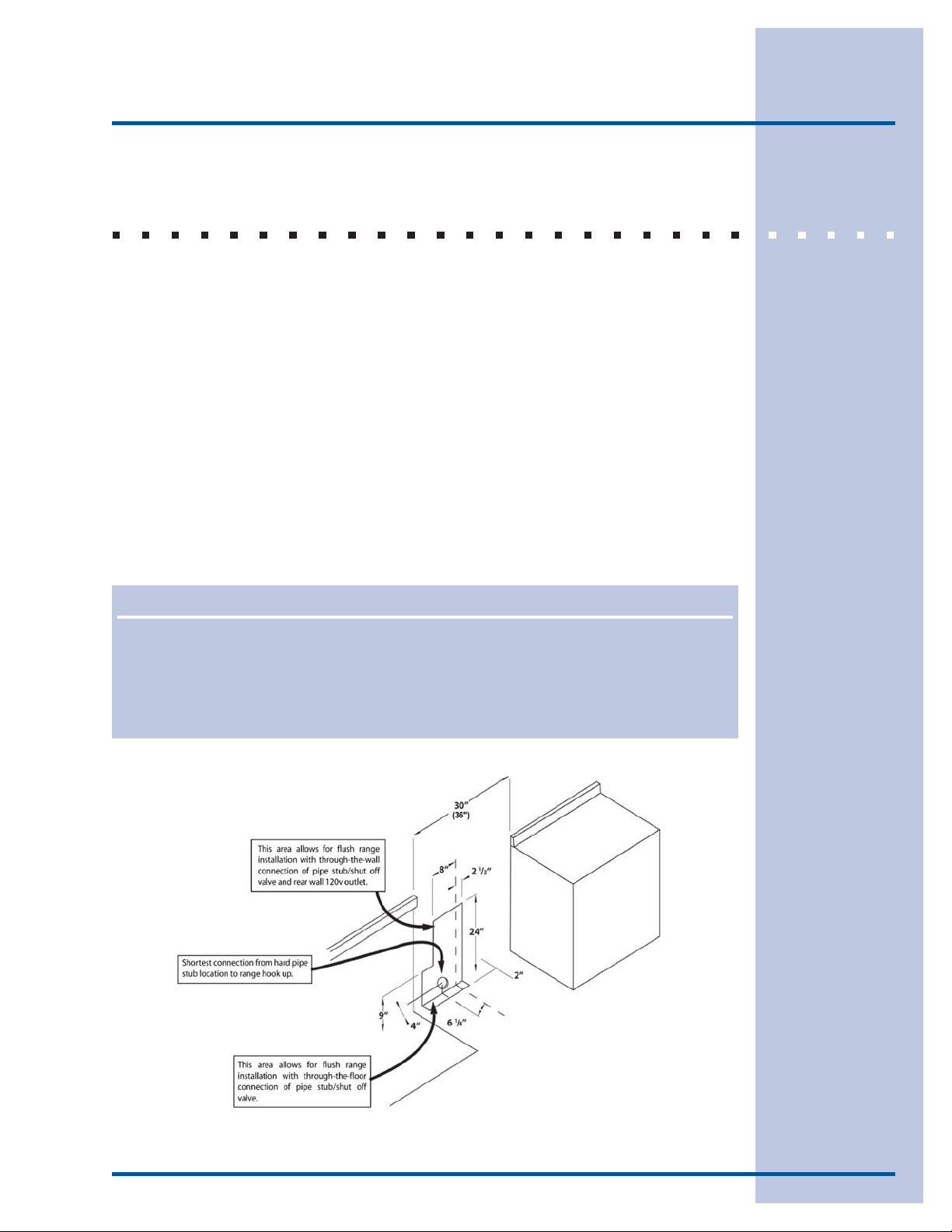

Preparing for Installation

GAS AND ELECTRICAL ROUGH-IN

Locations

A manual shut valve must be installed in the gas piping, external to the

appliance, for the purpose of turning on or shutting off gas to the

appliance. Place the location of the range and the gas supply to allow

access to the valve when the unit is installed. Access to the remote

circuit breaker panel/fuse box, with the range in place, must also be

allowed for in the installation. Any openings in the wall behind the

appliance and in the floor under the appliance must be sealed. Both the

gas supply piping and shut-off valve, and the electrical junction box/

receptacle must be located so they do not interfere with the range when

it is installed. In addition, the junction box must be located so the range

can be removed for service when the conduit supplied with the unit is

attached to the junction box. Do not lengthen the conduit or wiring

provided with the range.

9

NONO

TESTES

NO

TES

NONO

TESTES

The areas shown in the illustrations, denote the location of the gas stub and the

electrical junction box/receptacle. These are suggested locations. For replacement

purposes, the location of the existing utilities may be utilized provided that they do not

interfere with the sides or rear of the range. If installing the gas valve behind the range,

verify that local building codes will permit this.

Figure 1

Center Line

Page 10

10

Preparing for Installation

CABINET AND COUNTERTOP PREPARATION

Check your local building codes for the proper method of installation. In the

absence of local codes, this appliance should be installed in accordance with the

National Fuel Gas Code ANSI Z223.1/NFP A 54. In Canada, installation must

conform to current Natural Gas Installation Code, CAN1-1.1-M and the local codes

where applicable. This range has been design-certified according to ANSI Z21.1b,

latest edition. Be certain that the appliance being installed is correct for the gas

service being provided. Refer to the rating label located on the kick panel and/or the

table on page 7 for gas supply requirements.

All dimensions shown are based on standard American cabinets, 36 inches

(914mm) high at the finished countertop by 24 inches (610mm) deep, with a 25

inch (635mm) overall countertop depth. When installing the range into nonstandard

cabinets, minimum clearances shown in the diagrams on page 11 must be

maintained.

Carefully check the location where the range is to be installed. For best

performance, the range should be placed away from drafts that may be caused by

doors, windows and HV AC outlet s.

NONO

TESTES

NO

TES

NONO

TESTES

• If cabinet storage space is to be provided directly above the range, the risk of

personal injury may be reduced by installing a ventilating hood that projects

horizontally a minimum of 5 inches beyond the face of the cabinets.

• The range may be installed flush to the rear wall. We recommend installing a

noncombustible material on the rear wall above the range and up to the vent

hood. It is not necessary to install noncombustible materials behind the range

below the countertop height.

• The minimum distance from the sides of the range above the countertop to

combustible side walls must be at least 10 inches..

• All models are delivered with a 3.5” backguard from the factory. A 9” backguard

is available on the E36GF75GPS AND E36GF76GPS as options.

• Utilities may be located: In the lower left corner of the adjacent right cabinet.

(Refer to Figure 2)

IMPORIMPOR

IMPOR

IMPORIMPOR

• Contact your local building department to verify compliance with local code

interpretation.

TT

ANTANT

T

ANT

TT

ANTANT

Page 11

Preparing for installation

GENERAL DIMENSIONS

Plan the installation so that the electrical connection, gas shut-off valve, and pressure

regulator are accessible from the front of the cabinet.

Figure 2

Ventilation

Hood

13"

(330 mm)

Max

Top of

Finished

Counter

10" (254 mm) Min.

to combustible sides walls

above the range (both sides)

18" (457 mm)

Min

Vertical non-

combustible

30" (762 mm) Min

surface

11

25"

(635 mm)

Model

E30GF74 Series

E36GF75 Series

E36GF76 Series

Recommended utility location

E30GF74GPS, E36GF75GPS,

E36GF76GPS

Cutout Dimensions

“A”

30” (762 mm)

Minimum Recommended

36” (914 mm)

Minimum Recommended

36” (914 mm)

Minimum Recommended

“B”

30 1/16” (764 mm)

36 1/16” (916 mm)

36 1/16” (916 mm)

Page 12

12

Preparing for Installation

GENERAL DIMENSIONS

Page 13

Preparing for Installation

WOOD/COMPOSITE OVERLAY INSTALLATION

13

The bottom of an overhead hood should be 30” minimum to 36” above the

countertop. This would typically result in the bottom of the hood being 66” to 72”

above the floor. These dimensions provide safe an ef ficient operation of the hood.

Page 14

14

Inst allation

INSTALLING THE ANTI-TIP BRACKET

**

**Note: Increase or decrease this dimension as

necessary for range top to be flush with countertop.

FIG. 3

Page 15

Inst allation

INSTALLING THE 36” RANGE OPTIONAL

BACKGUARD

Y our Electrolux IconMR range was shipped with a backguard in place. These instructions

cover the installation of one of the optional backguards.

Installing the Range Optional Backguard:

WARNINGWARNING

WARNING

WARNINGWARNING

Be sure the range is not connected to gas or power before proceeding.

1. Remove existing backguard by removing 4 screws on rear of backguard (2 screws

per side).

2. Remove the backguard from its box.

3. T o avoid scratches, place small scrap s of thin cardboard on the rear of the side

panels where the backguard will make contact. With the assistance of at least

one other person, carefully lift the backguard and place down on to the range top.

Special attention should be given to the lower flange in front of the backguard,

which must be fit between the stainless steel side panels.

15

4. Fasten the screws through the rear flange in the same location in which they were

removed from factory supplied backguard.

5. Connect the gas line to the regulator. Reposition and att ach the access panel or

the back cover if the entire back cover was removed.

6. Y ou are now ready to continue with the range installation.

Figure 3

Backguard

Backguard Installation

(36" range shown)

Page 16

16

Inst allation

REMOVING THE OVEN DOOR

Open the door to its fully opened position. Rotate the catch over the retaining arm on each

hinge. Lift the oven door to about a 30 degree angle from the horizontal position. Pull the

door away from the oven while continuing to lift.

WARNINGWARNING

WARNING

WARNINGWARNING

Do not attempt to disengage the hinge catches with the door removed from the oven. The hinge

springs could release causing personal injury.

Do not lift or carry the oven door by the handle door.

Figure 4

To remove

oven door,

rotate catch as

shown.

RE-INSTALLING THE OVEN DOOR

Grasp the oven door on opposite sides and lift it until the door hinges are aligned with the

openings in the oven frame. Holding the door at about a 30 degree angle from the horizontal,

slide the hinges into the openings until the bottom hinge arms drop fully into the two hinge

receptacles. Lower the door to the fully opened position, and then rotate the two hinge

catches toward the oven.

Open and close the door completely to ensure that it is properly installed.

Peel off the protective layer of plastic that covers the door panel.

Page 17

Inst allation

GROUNDING

1 The range is equipped with a three-prong power cord (grounding plug which mates

with a standard three-prong grounding wall receptacle to minimize the possibility of

electrical shock hazard from the range).

2 Where a standard two-prong wall receptacle is encountered, it is the responsibility

and obligation of the customer to have it replaced with a properly grounded threeprong wall receptacle. Do not cut or remove the grounding prong from the power

cord.

17

CONNECT RANGE TO GAS SUPPLY

1 Turn off gas.

2 Install a male 1/2” flare union adapter to 1/2” NPT internal thread of regulator inlet.

3 Connect flexible gas line connector to end union and regulator inlet.

4 Install the male flare union adapter on the manual shut-off valve, taking care to support the

shut-off valve . Do not allow the valve to move or turn.

5 Position the range into the cabinet to allow connection of flexible connector at the shut-off

valve.

6 When all connections have been made, make sure all range controls are in the “OFF”

position and turn on main gas supply valve.

7 Use a leak detector at all joints and connections to check for leaks in the system. Do not

use a flame to check for gas leaks.

The appliance must be isolated from the building’s gas supply piping system by closing

it’s individual manual shut-off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig (3.5kPa).

NONO

TETE

NO

TE

NONO

TETE

The gas pressure regulator is preset at the factory for natural gas to use with the appliance. To

convert the range to LP gas, see instructions supplied in the LP conversion package.

Page 18

18

Inst allation

CONNECT RANGE TO GAS SUPPLY

WARNINGWARNING

WARNING

WARNINGWARNING

• Do not apply excessive pressure when tightening gas connections and fittings.

• Do not use teflon tape or plumber’s putty on gas flex line connections.

• Turn all control valves to the “OFF” position. Turn on gas supply and check all lines and

connections with leak detector, such as soap and water solution. Do not use flame to

check for leaks. After verifying that there are no gas leaks, turn off the gas supply to the

range by turning the gas shut-off valve to the “OFF” position.

• For LP installations, the LP gas tank must have its own high pressure regulator. This is in

addition to the pressure regulator provided with the range.

• The maximum gas supply pressure to the regulator must never exceed 1/2 pound per square

INSTALLING THE RANGE

WARNINGWARNING

WARNING

WARNINGWARNING

The 30” and 36” ranges require an Anti-Tip device. Before installing the range, you must locate and

secure the Anti-Tip bracket to the floor.

Measure from the floor to the countertop and adjust the leveling legs as required to position

the top frame at the desired height, based on the cabinet and countertop installation.

Carefully slide the range into position in the cutout.

Make sure the anti-tip bracket is installed as directed on page 14.

1. Slide range forward.

2. Make sure the anti-tip bracket is securely attached to

the wall behind the range.

3. Safely slide the range slightly and move back against wall, making sure the

pin slides under bracket.

Installing the burner components

Remove the burner bases, burner heads, burner caps, and porcelain grates from their

shipping packages. Place each burner onto its corresponding burner base, being certain

that the burners align with the ignitor correctly . Set each burner cap on top of its

corresponding burner head. Place each grate onto the top frame.

WARNINGWARNING

WARNING

WARNINGWARNING

Never attempt to operate the cooktop section of the range with any of the burner caps or grates

removed.

Page 19

Operation

VERIFYING THE OPERATION

Before beginning the test procedure, ensure that all cooktop control valves are in

the “OFF” position, and all burner rings, burner caps, and grates are properly

positioned on the top frame. Turn on the gas supply at the shut-of f valve.

Turn on the power supply to the range. Select a temperature of 350°F by rotating

the oven selector knob to “350”. Rotate knob to the “Off” position to stop the

heating process.

Test each top burner separately by pressing and turning one control knob at a time

counterclockwise to the “HIGH” position. All ignitors will sp ark continuously, but

only the burner with gas flowing to it will ignite. (It will take approximately 4 seconds

for ignition to occur, at which time the ignitors will stop sp arking. If ignition does not

occur within 4 seconds, turn off the knob, wait for at least 2 minutes to allow any

gas to dissipate, then repeat this ignition test.) The control knob can then be

rotated counterclockwise from “HIGH” to “LOW” to adjust the flame height

progressively.

19

Repeat the ignition test for all burners. When installed properly, the flame will be

steady and quiet. It will also have a sharp, blue inner cone that will vary in length

proportional to the burner size.

WARNINGWARNING

WARNING

WARNINGWARNING

• The range and shut-off valve must be disconnected from the gas supply piping during any

pressure testing exceeding 1/2 psi (3.5kPa).

• The range must be isolated from the gas supply piping by closing the shut-off valve during

any pressure testing at or below 1/2 psi (3.5kPa).

NONO

TESTES

NO

TES

NONO

TESTES

If either the oven or cooktop does not operate properly follow these troubleshooting steps:

• Verify the power and the gas are supplied to the range.

• Check the electrical connections and gas supply to ensure the installation has been

completed correctly.

• If the appliance still does not work, contact an authorized service company. Do not attempt

to repair the appliance yourself. Electrolux is not responsible for service required to correct

faulty installation.

Page 20

20

Operation

TO ENSURE PROPER AND SAFE OPERATION

NONO

TETE

NO

TE

NONO

TETE

REFER TO THE USE AND CARE MANUAL FOR DETAILED INSTRUCTIONS.

• Read all instructions before using this appliance. Install or locate the appliance only in

accordance with the provided Installation Instructions.

• Do not attempt to adjust, repair , service, or replace any part of your appliance unless it

is specifically recommended in this guide.

• Do not leave children alone or unattended in the area where the range is in use. Never

allow children to sit or stand on any part of the oven. Do not let children play with the

range.

• All other servicing should be referred to a qualified service agency .

• Have the technician show you the location of the gas shut off valve and how to shut it off

in an emergency situation.

• Always disconnect power to appliance before any type of servicing.

• Do not use abrasive or caustic cleaners or detergents on this appliance. They may

cause permanent damage to the surface.

• When cooking, set the burner controls so that the flame heats only the bottom of the

utensil and does not overlap at the sides of the utensil.

• Utensils (pots & pans) that conduct heat slowly, i.e. glass pots, should be used in

conjunction with burner flames at a low or medium setting.

• Turn off all controls and wait for appliance parts to cool before touching or cleaning

them.

• Do not touch the burner grates or surrounding areas until they are cool.

• Do not use water on grease fires.

• Clean appliance with caution.

• Always turn pot handles to the side or back of the range. Do not turn handles towards

the area where they are easily burned. Handles should not extend over adjacent

burners.

• Use range only for cooking tasks expected of a home appliance as outlined in this

manual.

• When using the cooktop, do not touch the grates, burner caps, burner bases, or any

other parts in proximity to the flame. These components may be hot enough to cause

burns.

• Use dry potholders. Moist or damp potholders on hot surfaces may result in burns from

steam. Do not let potholders touch hot surface areas. Do not use a towel or other bulky

cloth.

• Do not heat unopened food containers. Build up of pressure may cause the container to

explode and result in injury .

• During and after use, so not touch interior surfaces of the oven until cool.

NONO

TETE

NO

TE

NONO

TETE

Prior to operating the cooktop or oven sections of the range, please read the accompanying Use

and Care Manual carefully. Important safety, service and warranty information is contained within

this manual.

Page 21

Conversion T o LP Gas

INSTRUCTIONS FOR CONVERTING RANGE

OPERATION TO OPERATE ON LP GAS

INSTALLATION AND SERVICES MUST BE PERFORMED BY

A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR THE LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNINGWARNING

WARNING

WARNINGWARNING

This conversion kit must be installed by a qualified service technician in accordance

with the manufacturer’s instructions and all applicable codes and requirements of the

authority having jurisdiction. Failure to follow instructions may result in fire, explosion

or production of carbon monoxide causing property damage, personal injury or loss of

life. The qualified service agency is responsible for the proper installation of this kit.

The installation is not proper and complete until the operation of the converted

appliance is checked as specified in the manufacturer’s instructions supplied with this

kit.

21

CACA

UTIONUTION

CA

UTION

CACA

UTIONUTION

Before proceeding with the conversion, shut off the gas supply before disconnecting

electrical power to the range. Be sure power supplies are off before installing the

conversion kit. Failure to do so could cause serious bodily injury.

TOOLS REQUIRED FOR L.P. CONVERSION:

3/8” AND 5/8” OPEN END WRENCH

1/8” WIDE FLAT BLADE SCREWDRIVER

PHILLIPS SCREWDRIVER

9/32 NUT DRIVER

5/32 NUT DRIVER

7mm NUT DRIVER

Page 22

22

Conversion T o LP Gas

INSTRUCTIONS FOR CONVERTING RANGE FROM

NATURAL GAS TO LP GAS

Determine the combination of top burners that are featured on your range.

Identify the parts you need from this kit to complete the L.P. conversion. When

burners are converted from natural to L.P. the BTU ratings are as follows:

Top burner 15,000 BTU L.P. Gas

Oven Burner 22,000 BTU L.P. Gas

Oven Broiler 16,500 BTU L.P. Gas

Griddle 18,500 BTU L.P. Gas

Quantity Part Description Notes

1 LP Conversion kit label

1 Instruction for convert i ng range t o LP Gas

1 LP Conversion Label

6 Orifice - Top Burner, #58

6 Orifice - Simm er B urner, .46mm

1 Orifice - Oven Burner, #55

1 Orifice - Oven Broiler, #56

1 Orifice - Griddle, #55

6 Main burner bypass jet, blue ring

6 Simmer burner bypass jet

*Note: For operation at elevations above 2000 ft., appliance rating shall be reduced

at a rate of 4 percent for each 1000 ft. above sea level

IMPORIMPOR

IMPOR

IMPORIMPOR

After replacing the natural gas to LP orifices, be sure to keep the original factory

installed natural gas orifices for future range conversion back to natural gas. The

factory orifices are marked with the following: Top Burners 165; Oven Burner 226; Oven

Broiler 185; Griddle 206; Main Burner Bypass Jet; Simmer Bypass Jet

TT

ANTANT

T

ANT

TT

ANTANT

Page 23

Conversion T o LP Gas

HOW TO CONVERT THE RANGE FOR USE WITH

LP/PROPANE GAS

1. CONVERT THE PRESSURE REGULATOR

To access the gas regulator, pull the range away from the cabinet wall. The gas

regulator is located at the bottom right corner of the range.

WARNINGWARNING

WARNING

WARNINGWARNING

a. Electrical shock hazard can occur and result in injury or death. Disconnect electrical

power to the range before servicing. Do not remove regulator or allow it to turn during servicing.

b. Unscrew the cap from the regulator. Do not remove the spring from the regulator (see Figure 1)..

c. Unscrew the plastic insert from the cap (see Figure 2 and 3). Turn the insert around so that the

longer stem is facing toward the cap (see Figure 4). Screw the insert into the cap.

d. Replace the cap on the regulator.

23

Figure 1

Figure 2

Figure 3

Position for NG

Figure 4

Position for LP

Page 24

24

Conversion T o LP Gas

CONVERT TOP BURNER FOR USE WITH

LP/PROPANE GAS

CACA

UTIONUTION

CA

UTION

CACA

UTIONUTION

Save the natural gas orifices removed from the appliance for possible future

conversions to natural gas. Take extra care when handling steel parts.

a. Remove top grates, burner caps and inner burner rings.

b. Lift off outer burner heads and burner bases.

c. Remove the factory installed natural gas orifices from the center of the orifice

holders using a 7mm nut driver. Remember to keep the original natural

gas orifices for future conversions back to natural gas. Refer to page 22 under

“IMPORT ANT” to identify their markings.

d. Using a 9/32” nut driver, replace the main orifice in each orifice holder with orifice

size (#58). Tighten each orifice until snug. Use caution not to over tighten.

e. Using a 5/32” nut driver, replace the Simmer orifice in each orifice holder with the

orifice size (0.46).

f. Replace the outer burner heads back to the main burner bases. Replace the inner

burner rings, burner caps and grates.

a.

c.

b.

e.

Page 25

Conversion T o LP Gas

CONVERT OVEN BURNER ORIFICE TO LP/PROPANE

GAS

a. Remove the toe kick panel.

b. Remove the two (2) screws on the bottom of the toe kick panel. Hold the bottom

edge of toe kick panel at the middle section and slightly lift towards the front. Hold

the toe kick panel on both ends and slowly pull away towards the front.

c. Remove the (2) screws holding the orifice bracket and locate the orifice. Remove

orifice using a adjustable wrench. Replace with oven burner orifice size (#55). Do

not over tighten. Replace the orifice bracket, aligning the new orifices into the air

shutter of the oven burner.

a. b.

25

c.

Page 26

26

Conversion T o LP Gas

CONVERT BROIL BURNER ORIFICE FOR LP/

PROPANE GAS (16.500 BTU)

a. Remove back cover (See Fig. a)

b. Using an adjustable wrench, remove the orifice from the orifice holder . Replace with

oven broiler orifice size (#55).

a.

b.

Page 27

Conversion T o LP Gas

CONVERT GRIDDLE ORIFICE FOR LP/PROPANE GAS

(18,500 BTU)

(FOR 36” RANGES EQUIPPED WITH 4 TOP BURNERS AND A GRIDDLE)

a. Remove back cover (See “Fig. a” on previous page)

b. Carefully remove the griddle plate using caution as the plate is very heavy .

As the plate’s lif ted, make sure to remove the thermostat located beneath the

plate.

c. Using an adjustable wrench, remove the orifice from the orifice holder . Replace

with griddle orifice size (#56).

b.

27

c.

Page 28

28

Conversion T o LP Gas

CONVERT GAS VALVES FOR LP/PROPANE GAS

a. Remove control knobs, bezel and control panel.

b. Using a flat screwdriver, replace main burner byp ass jets with byp ass jet s for LP

and simmer byp

for NG) in the plastic bag labeled main jets and simmer bypass

(blue for NG) jets in the bag for the simmer jets.

a.

ass jets with bypass jets for LP. Save the main bypass jets (blue

b.

Page 29

Conversion T o LP Gas

RECONNECT GAS AND ELECTRICAL SUPPLY TO

RANGE

Leak testing of the appliance shall be conducted according to the installation

instructions provided with the range.

Checking for Manifold Gas Pressure

If it is necessary to check the manifold gas pressure, remove the burner cap, inner

ring, outer burner head and burner base of the right front top burner and connect a

manometer (water gauge) or other pressure test device to the burner orifice. Use a

rubber hose, and hold the end of the tube tight over the orifice. Turn the gas valve

on. For a more accurate pressure check, have at least two (2) other top burners

burning. Be sure that the gas supply (inlet) pressure is at least one inch above the

specified range manifold pressure. The gas supply pressure should never be over

14” water column. When properly adjusted, the manifold water column pressure is

10” for LP/Propane gas or 5” for Natural Gas.

29

CACA

UTIONUTION

CA

UTION

CACA

UTIONUTION

Do not use a flame to check for gas leaks

a. Disconnect the range and its individual shut-off valve from the gas supply piping

system during any pressure of that system at test pressures greater than 14” of

water column pressure.

b. The appliance must be isolated from the gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the supply system

at test pressure equal to or less than 14” water column pressure.

Page 30

30

Conversion T o LP Gas

AIR SHUTTER OVEN BURNER

The air shutter for the oven burner may need adjustment, especially if the unit has

been converted for use with LP/Propane gas. The approximate flame length of the

oven burner is one inch (distinct inner blue flame).

To Determine if the oven burner flame is proper:

a. With the toe kick removed, set the oven to bake at 350°F and observe the flame.

If the flame is yellow in color

blue lifting away from the burner , reduce the air shutter opening size.

b. Turn of f oven and allow it to cool before adjusting the air shutter . To adjust, loosen

the lock screw, reposition the air shutter and tighten the lock screw. Retest the

burner by repeating the steps above.

When the burner flame is a distinct blue color burning steadily , the air shutter is

adjusted correctly .

, increase the air shutter opening size. If the flame is

INSTALLATION OF NEW LP/PROPANE

RATING/SERIAL PLATE

Record the model and serial number on the LP/Propane Rating Serial plate

provided in this kit. The information can be obtained from the existing Rating / serial

plate. Place the new plate as close as possible to the existing Rating / Serial plate

on range.

Loading...

Loading...