Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire or explosion may

result causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer,

service agency orthe gas supplier.

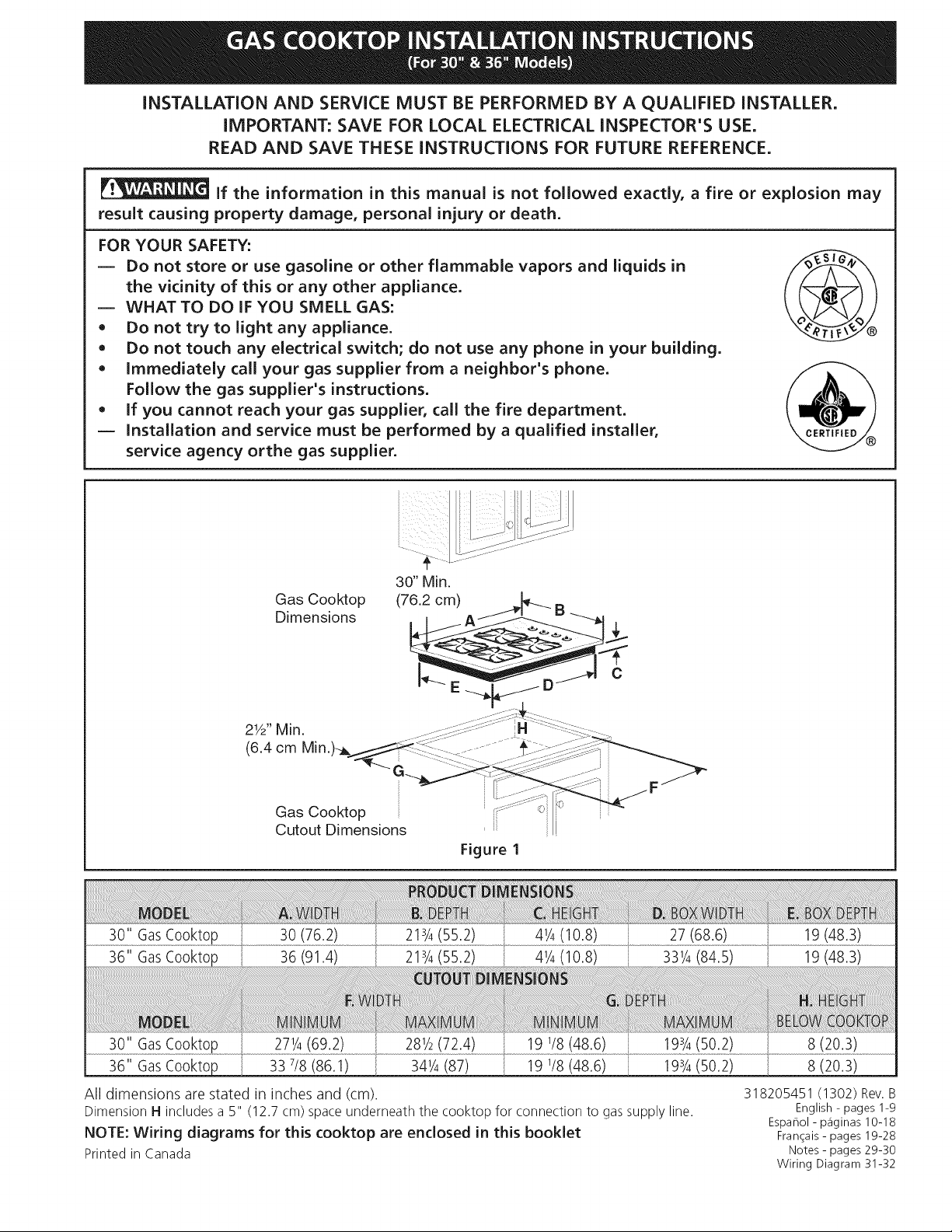

Gas Cooktop

Dimensions

Gas Cooktop

Cutout Dimensions

Figure I

281/2(72.4) 193/4(50.2)

36" GasCooktoL_ 33 7/8(86.1) 341/4(87) 19 1/8(48.6) 193/4(50.2)

All dimensions arestated in inches and (cm).

DimensionH includesa 5" (12.7cm) spaceunderneaththe cooktop for connectionto gassupplyline.

NOTE: Wiring diagrams for this cooktop are enclosed in this booklet

Printedin Canada

8 (20.3)

318205451 (1302) Rev.B

English - pages 1-9

Espahol - p_iginas 10-18

Fran_ais - pages 19-28

Notes - pages 29-30

Wiring Diagram 31-32

Page 2

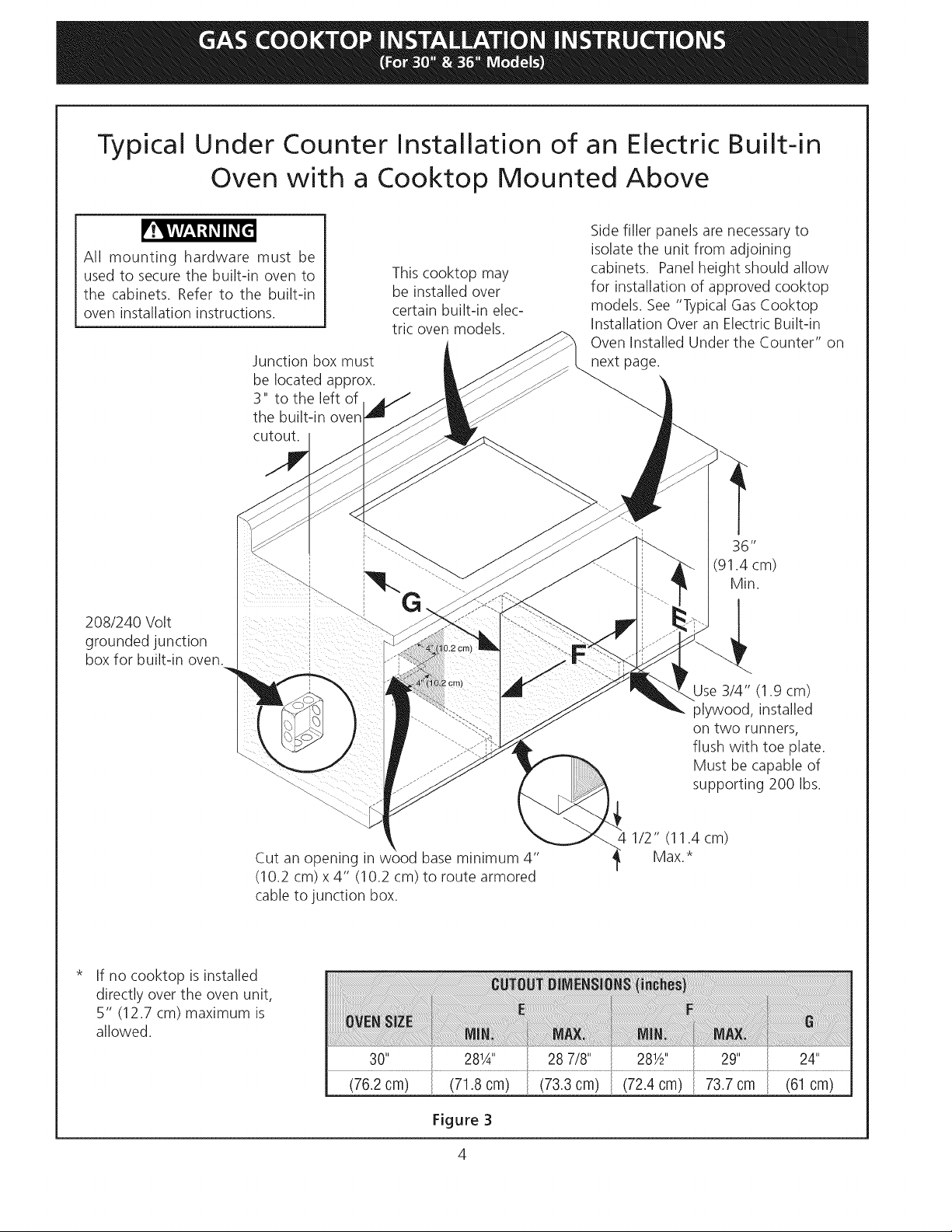

important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing the cooktop.

2. Remove all packing material before connecting the

electrical supply to the cooktop.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

5. Note: For operation at 2000 ft. elevations above see

level, appliance rating shall be reduced by 4 percent

for each additional 1000 ft.

important Note to the Consumer

Keep these instructions with your Use and Care Guide for

future reference.

IMPORTANT SAFETY

INSTRUCTION

Installation of this cooktop must conform with local

codes or, in the absence of local codes, with the National

Fuel Gas Code ANSI Z223.1/NFPA 54 in the United

States, or in Canada, with the Canadian Fuel Gas Code,

CAN/CGA B149 and CAN/CGA B149.2.

• When installed in a manufactured (mobile) home

installation must conform with the Manufactured

Home Construction and Safety Standard, title 24 CFR,

part 3280 [Formerly the Federal Standard for Mobile

Home Construction and Safety, title 24, HUD (part

280)] or, when such standard is not applicable, the

Standard for Manufactured Home Installation, ANSI/

NCSBCSA225.1 or with local codes where applicable.

This cooktop has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide., read it carefully.

Air curtain or other overhead hoods, which operate

by blowing a downward air flow on to a range, shall

not be used in conjunction with gas ranges other

than when the hood and range have been designed,

tested and listen by an independent test laboratory

for use in combination with each other.

Be sure your cooktop is installed and grounded

properly by a qualified installer or service

technician.

This cooktop must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA

No. 70--latest edition in the United States, or in

Canada, with the Canadian Electrical Code, CSA

C22.1 Part 1.

The burners can be lit manually during an

electrical power outage. To light a burner, hold a

lit match to the burner head, then slowly turn the

Surface Control knob to LITE. Use caution when

lighting burners manually.

Do not store items of interest to children in

cabinets above the cooktop. Children could be

seriously burned climbing on the cooktop to reach

items.

To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessiveflame is hazardous.

Never use your cooktop for warming or heating

the room. Prolonged use of the cooktop without

adequate ventilation can be hazardous.

Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

The electrical power to the cooktop

must be shut off while gas line connections are

being made. Failure to do so could result in serious

injury or death.

Page 3

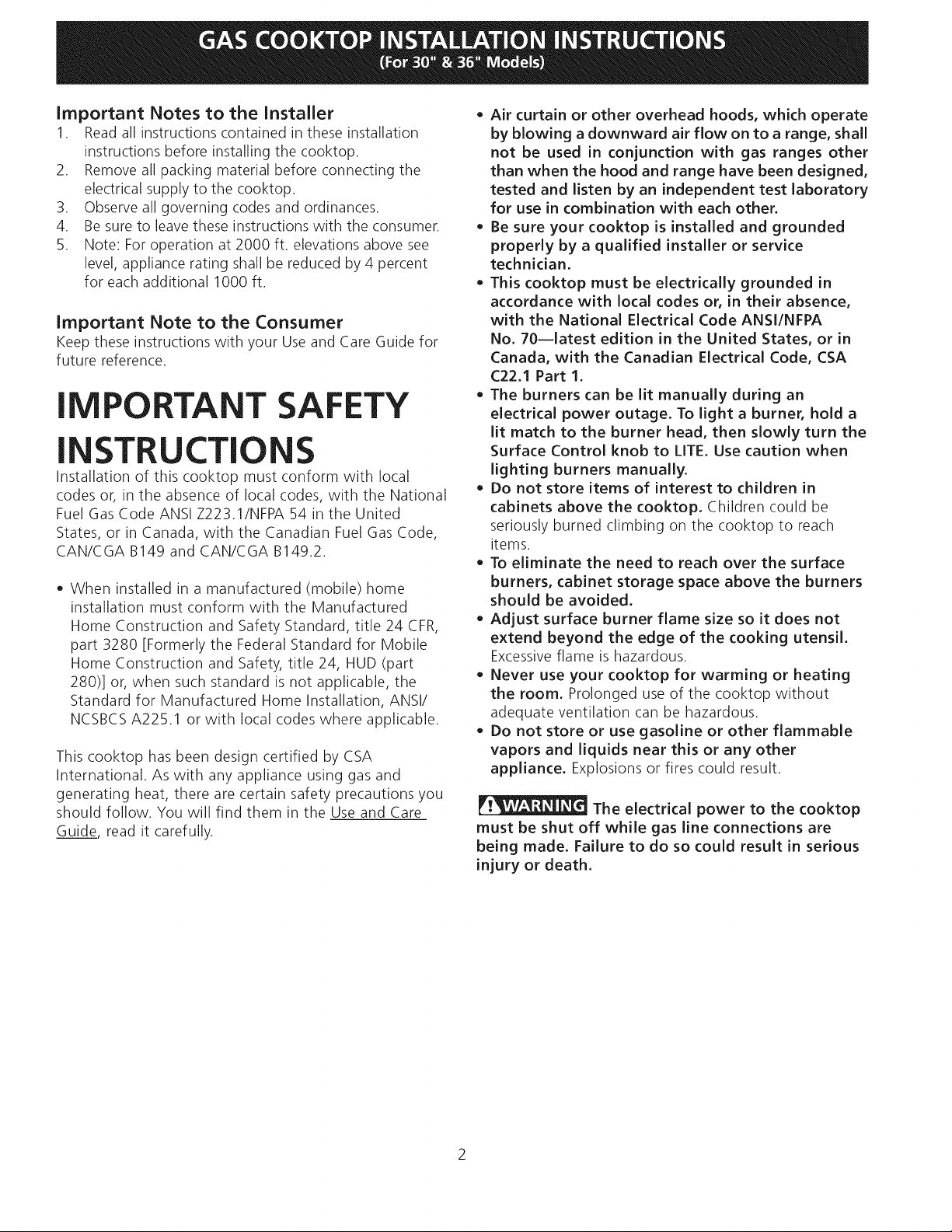

13"(33cm)

Max.Depth

ForCabinet

InstalledAbove

Cooktop.

18"Min.

(45.7cm)

11/2"(3.8cm)MinimumDistance

BetweenRearEdgeofCutout

andNearestCombustibleSurface

AboveCountertop.

30" (76.2 cm)

Min. Clearance

Between

the Top of

the Cooking

Platform and

--T!

Clearance

Unprotected

Wood or Metal

Cabinet

B

24" (6! cm)

2

To eliminate the risk of

burns or fire from reaching over heated

surfaces, cabinet storage space located

above the cooktop should be avoided.

If cabinet storage is provided, risk can

be reduced by installing a range hood

that projects horizontally a minimum of

5" (12.7 cm) beyond the bottom of the

cabinets.

Drawers Cannot Be Used with This

Cooktop Since Burner Box Extends

3%2" (8.02 cm) Below Surface of

Countertop.

36" Cooktop

Figure 2 - CABINET DESIGN

36" (91.4 cm)

C

7"(17.8 cm)

7"(17.8 cm)

7" (17.8 cm)

7" (17.8 cm)

3

Page 4

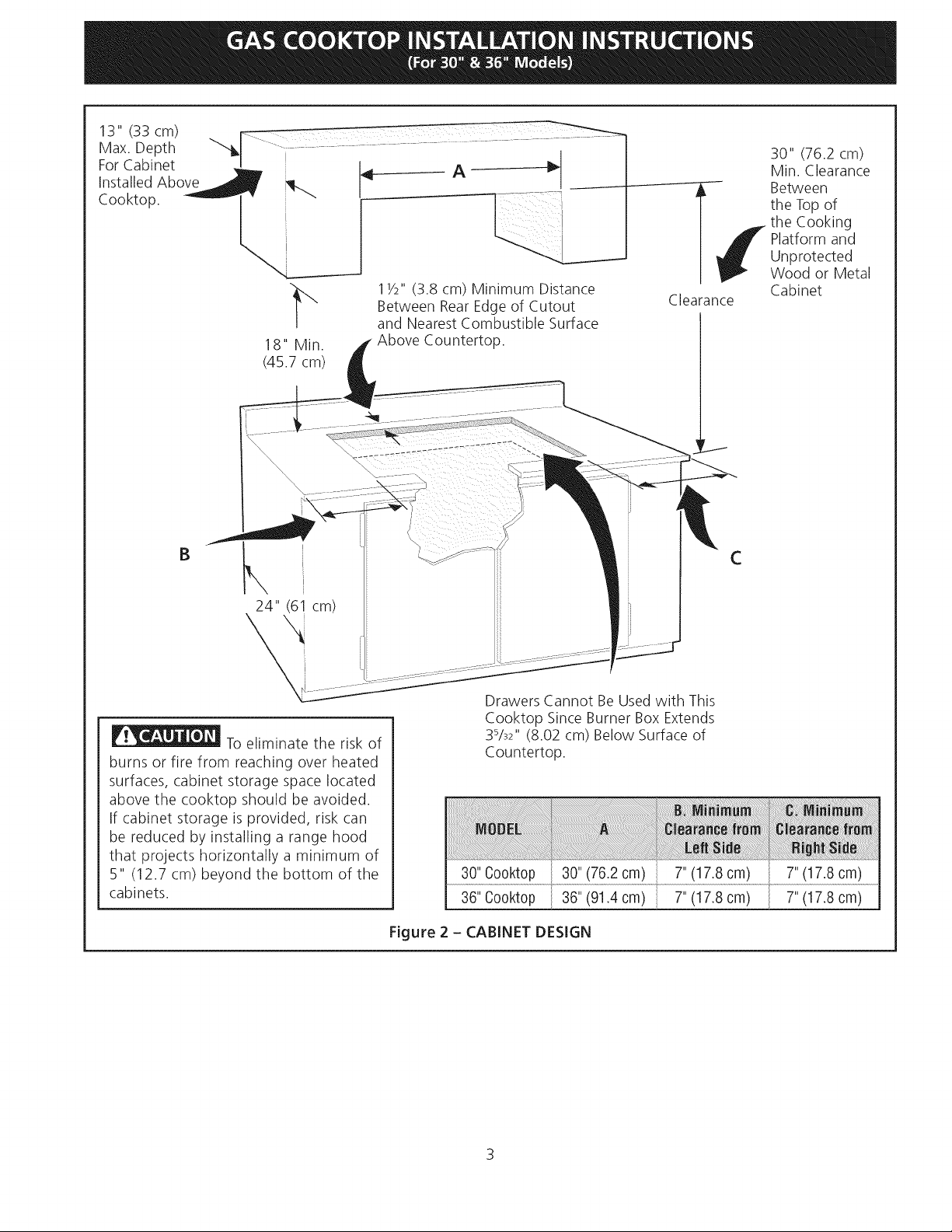

Typical Under

Counter Installation of an Electric Built-in

Oven

All mounting hardware must be

used to secure the built-in oven to

the cabinets. Refer to the built-in

oven installation instructions.

208/240 Volt

grounded junction

box for built-in oven.

with a Cooktop Mounted Above

Junction box must

be located approx.

3" to the left of

the built-in oven

cutout.

This cooktop may

be installed over

certain built-in elec-

tric oven models.

Side filler panels are necessaryto

isolate the unit from adjoining

cabinets. Panel height should allow

for installation of approved cooktop

models. See "Typical Gas Cooktop

Installation Over an Electric Built-in

Oven Installed Under the Counter" on

next page.

36"

(91.4 cm)

Min.

Cut an opening in wood base minimum 4"

(10.2 cm) x 4" (10.2 cm) to route armored

cable to junction box.

If no cooktop is installed

directly over the oven unit,

5" (12.7 cm) maximum is

allowed.

(76.2 cm) (71.8 cm)

Figure 3

Use 3/4" (1.9 cm)

plywood, installed

on two runners,

flush with toe plate.

Must be capable of

supporting 200 Ibs.

4 1/2" (11.4 cm)

Max.*

(73.3 cm) (72.4 cm) 73.7 cm (61 cm)

Page 5

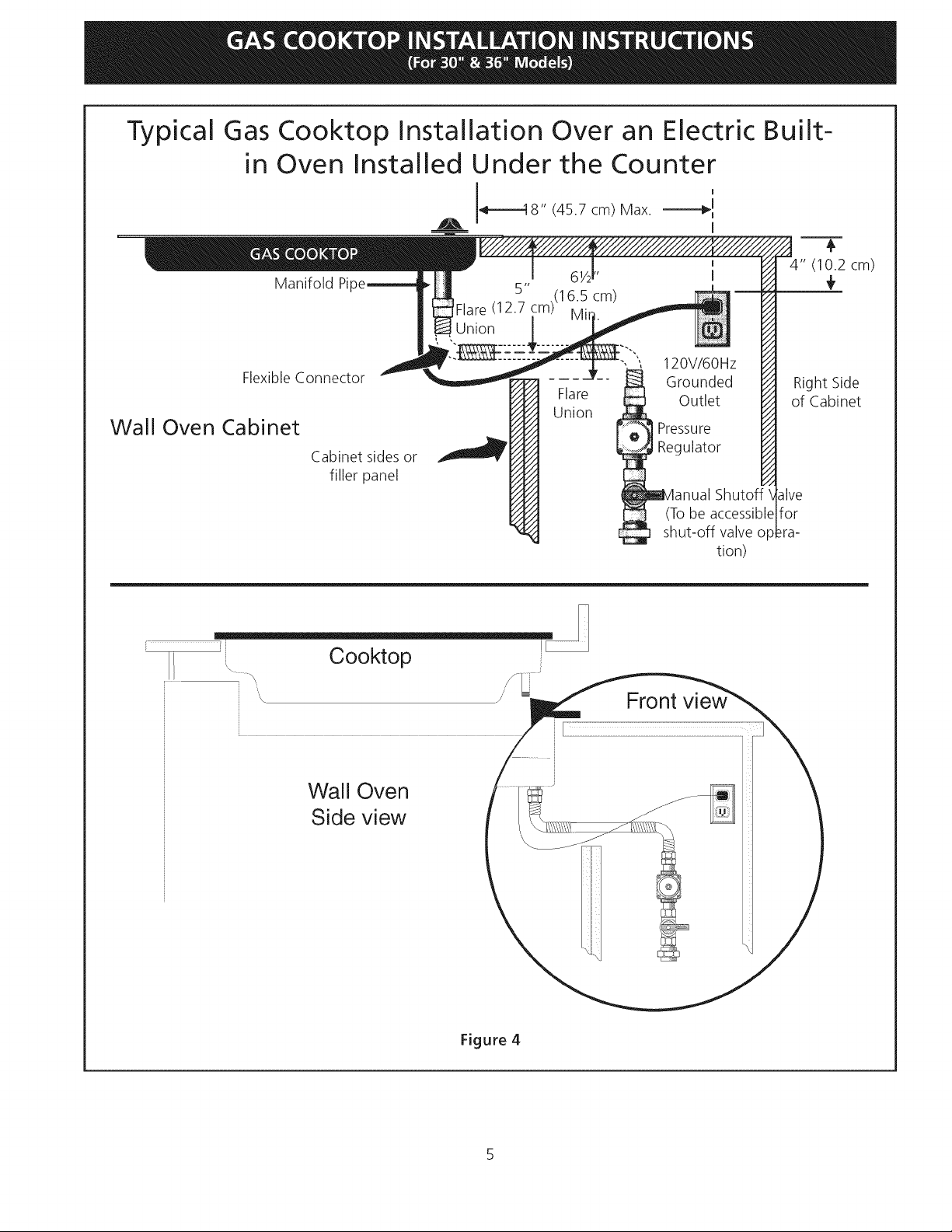

Typical Gas Cooktop Installation Over an Electric Built-

in Oven Installed Under the Counter

I I8" (45.7 cm) Max. ----'_I

I

4" (10.2 cm)

Manifold Pil

Flare (12.7 cm)(1

Union

/i

6.5

cm)

÷

Flexible Connector

Wall Oven Cabinet

Cabinet sides or

filler panel

Wall Oven

Side view

Flare

Union

120V/6OHz

Grounded

Outlet

Pressure

Regulator

(Tobe

shut-off valve op

Front

Right Side

of Cabinet

Shutoff

for

_ra-

tion)

Figure 4

Page 6

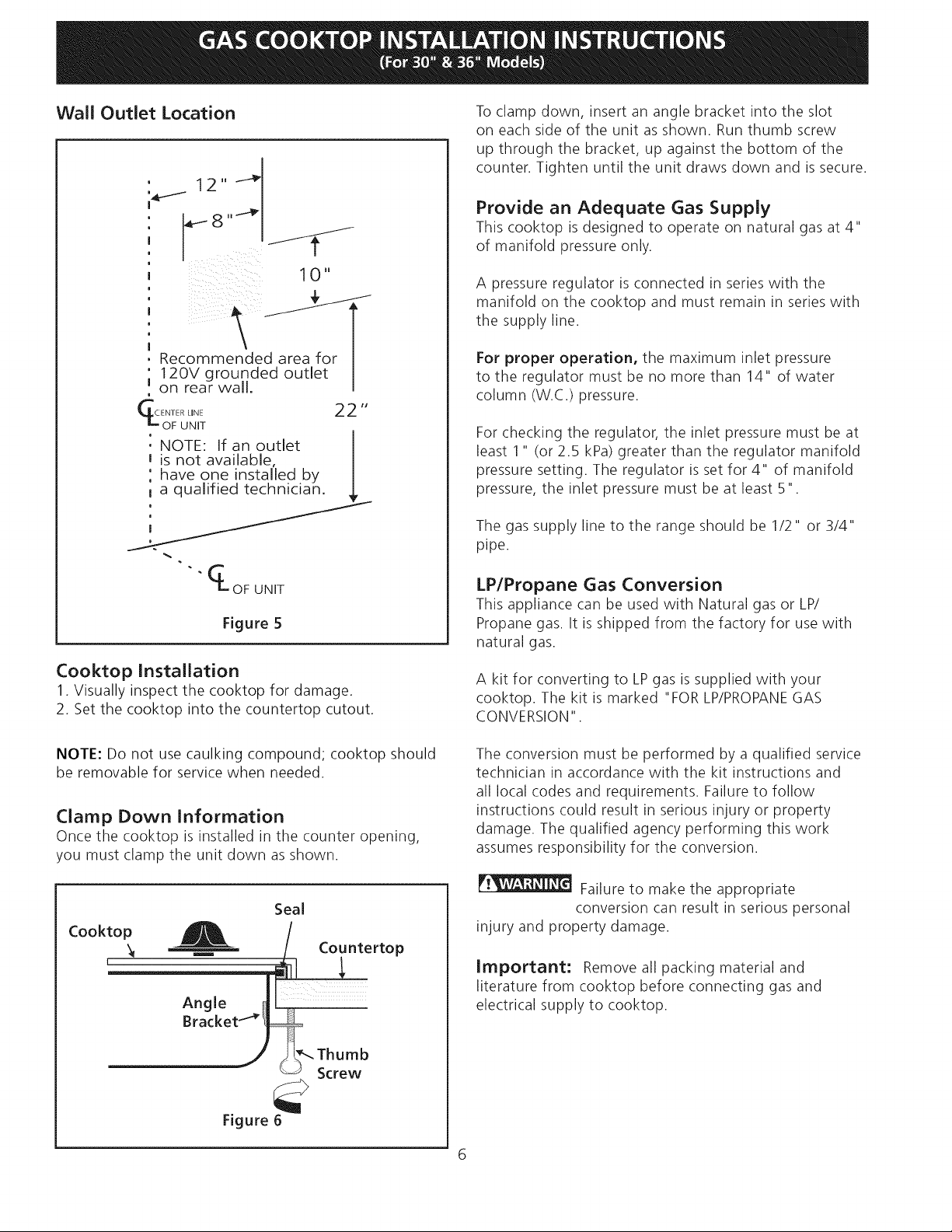

Wall Outlet Location

, 12,, --_

I 1 0 "

o

I

, Recommended area for

' 12OV grounded outlet

u on rear wall.

m

CL_olFUL_ET 22 "

: NOTE: If an outlet

J is not available, I

: have one installed by I

t a qualified technician.

To clamp down, insert an angle bracket into the slot

on each side of the unit as shown. Run thumb screw

up through the bracket, up against the bottom of the

counter. Tighten until the unit draws down and is secure.

Provide an Adequate Gas Supply

This cooktop is designed to operate on natural gas at 4"

of manifold pressure only.

A pressure regulator is connected in series with the

manifold on the cooktop and must remain in series with

the supply line.

For proper operation, the maximum inlet pressure

to the regulator must be no more than 14" of water

column (W.C.) pressure.

For checking the regulator, the inlet pressure must be at

least 1" (or 2.5 kPa) greater than the regulator manifold

pressure setting. The regulator is set for 4" of manifold

pressure, the inlet pressure must be at least 5".

The gas supply line to the range should be 1/2" or 3/4"

pipe.

It OF UNIT

Figure 5

Cooktop Installation

1. Visually inspect the cooktop for damage.

2. Set the cooktop into the countertop cutout.

NOTE: Do not use caulking compound; cooktop should

be removable for service when needed.

Clamp Down Information

Once the cooktop is installed in the counter opening,

you must clamp the unit down as shown.

Seal

Cooktop

x_ _ Countertop

Angle

Bracketl_t(

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

A kit for converting to LPgas is supplied with your

cooktop. The kit is marked "FOR LP/PROPANEGAS

CONVERSION".

The conversion must be performed by a qualified service

technician in accordance with the kit instructions and

all local codes and requirements. Failure to follow

instructions could result in serious injury or property

damage. The qualified agency performing this work

assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal

injury and property damage.

Important: Remove all packing material and

literature from cooktop before connecting gas and

electrical supply to cooktop.

Figure 6

Thumb

Screw

Page 7

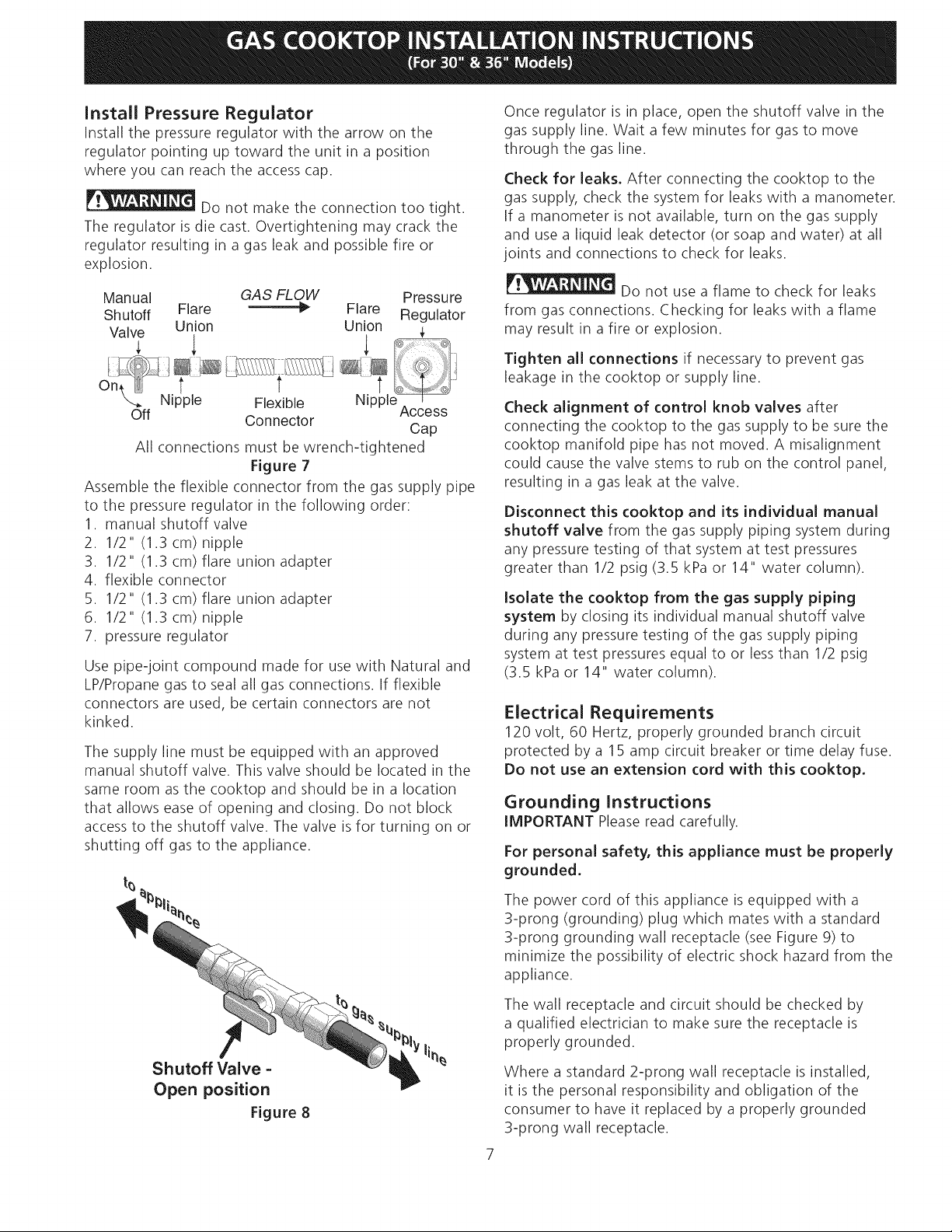

install Pressure Regulator

Install the pressure regulator with the arrow on the

regulator pointing up toward the unit in a position

where you can reach the access cap.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Manual GAS FLOW Pressure

Shutoff Flare _1_ Flare Regulator

Valve Union Union

On, ltr/ t t ....

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

1. manual shutoff valve

2. 1/2" (1.3 cm) nipple

3. 1/2" (1.3 cm) flare union adapter

4. flexible connector

5. 1/2" (1.3 cm) flare union adapter

6. 1/2" (1.3 cm) nipple

7. pressure regulator

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the cooktop and should be in a location

that allows ease of opening and closing. Do not block

access to the shutoff valve. The valve isfor turning on or

shutting off gas to the appliance.

Nipple Flexible Nipple

Off Connector

All connections must be wrench-tightened

Figure 7

Access

Cap

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

Check for leaks. After connecting the cooktop to the

gas supply, check the system for leaks with a manometer.

if a manometer is not available, turn on the gas supply

and use a liquid leak detector (or soap and water) at all

joints and connections to check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of control knob valves after

connecting the cooktop to the gas supply to be sure the

cooktop manifold pipe has not moved. A misalignment

could cause the valve stems to rub on the control panel,

resulting in a gas leak at the valve.

Disconnect this cooktop and its individual manual

shutoff valve from the gas supply piping system during

any pressure testing of that system at test pressures

greater than 1/2 psig (3.5 kPa or 14" water column).

Isolate the cooktop from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.5 kPa or 14" water column).

Electrical Requirements

120 volt, 60 Hertz, properly grounded branch circuit

protected by a 15 amp circuit breaker or time delay fuse.

Do not use an extension cord with this cooktop,

Grounding Instructions

IMPORTANT Pleaseread carefully.

For personal safety, this appliance must be properly

grounded,

Shutoff Valve -

Open position

Figure 8

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle (see Figure 9) to

minimize the possibility of electric shock hazard from the

appliance.

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard 2-prong wall receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3-prong wall receptacle.

7

Page 8

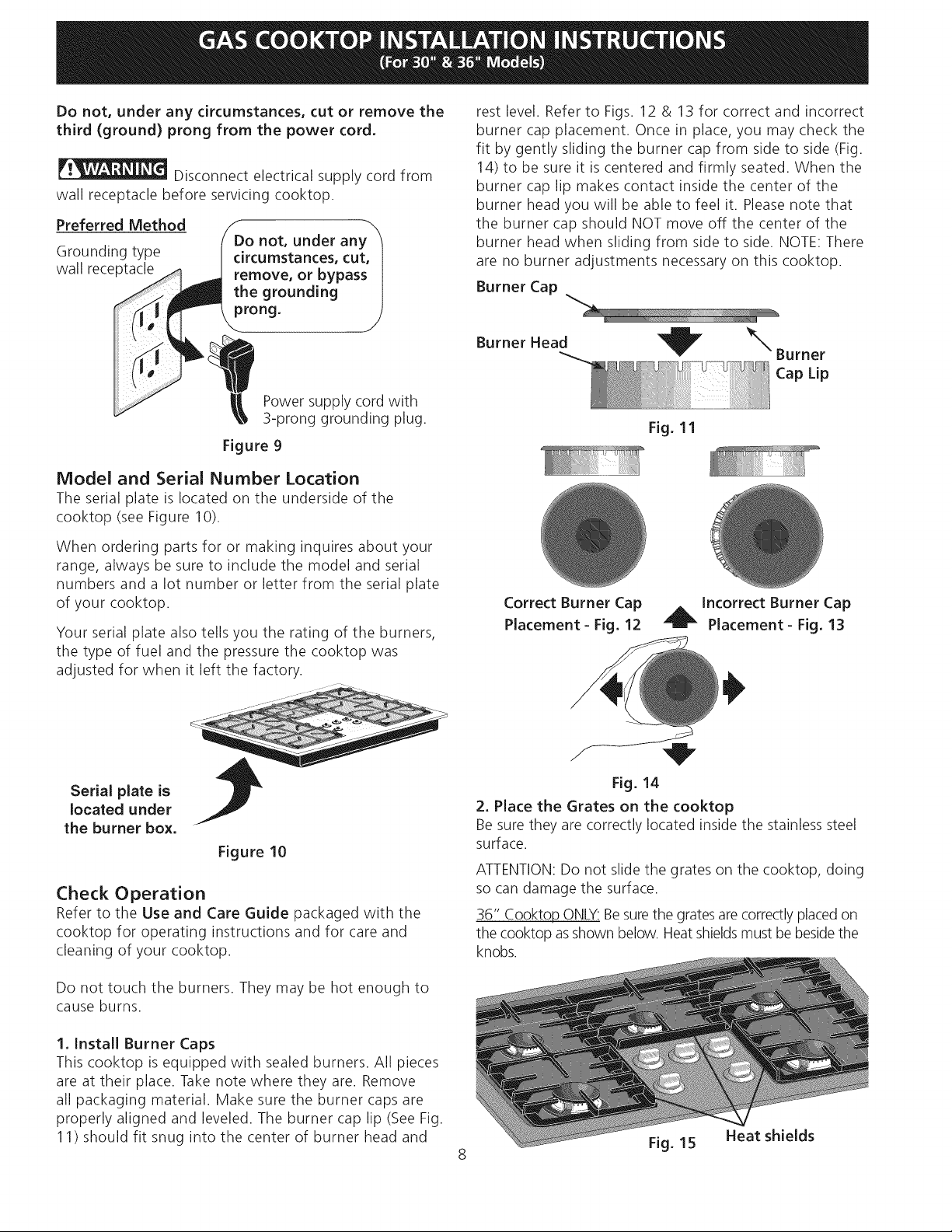

Donot,underanycircumstances,cutor removethe

third (ground)prongfromthepowercord.

Disconnectelectricalsupplycordfrom

wallreceptaclebeforeservicingcooktop.

Preferred Method

Grounding type

wall receptacle

Model and Serial Number Location

The serial plate is located on the underside of the

cooktop (see Figure 10).

When ordering parts for or making inquires about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

of your cooktop.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the cooktop was

adjusted for when it left the factory.

not, under any

circumstances, cut,

remove, or bypass

the grounding

prong.

Power supply cord with

3-prong grounding plug.

Figure 9

rest level. Refer to Figs. 12 & 13 for correct and incorrect

burner cap placement. Once in place, you may check the

fit by gently sliding the burner cap from side to side (Fig.

14) to be sure it is centered and firmly seated. When the

burner cap lip makes contact inside the center of the

burner head you will be able to feel it. Please note that

the burner cap should NOT move off the center of the

burner head when sliding from side to side. NOTE: There

are no burner adjustments necessary on this cooktop.

Burner Cap

Burner Head "_ _ Burner

Cap Lip

Fig. 11

Correct Burner Cap _ Incorrect Burner Cap

Placement- Fig. 12 _ Placement- Fig. 13

Serial plate is

located under

the burner box.

Figure 10

Check Operation

Refer to the Use and Care Guide packaged with the

cooktop for operating instructions and for care and

cleaning of your cooktop.

Do not touch the burners. They may be hot enough to

cause burns.

1. Install Burner Caps

This cooktop is equipped with sealed burners. All pieces

are at their place. Take note where they are. Remove

all packaging material. Make sure the burner caps are

properly aligned and leveled. The burner cap lip (See Fig.

11) should fit snug into the center of burner head and

Fig. 14

2. Place the Grates on the cooktop

Be sure they are correctly located inside the stainless steel

surface.

ATTENTION:Do not slide the grates on the cooktop, doing

so can damage the surface.

36" Cooktop ONLY:Besurethe grates arecorrectlyplaced on

the cooktop asshown below. Heat shieldsmust be besidethe

knobs.

Fig. 15

Heat shields

Page 9

,

Turn on Electrical Power and Open Main Shutoff

Gas Valve

,

Check the Igniters

Operation of electric igniters should be checked

after cooktop and supply line connectors have been

carefully checked for leaks and the cooktop has been

connected to electric power.

To operate the surface burner:

A. Push in and turn a surface burner knob to the

LITEposition. You will hear a small ticking noise;

this is the sound of the electric ignitor which

lights the burner.

B. After the burner lights, turn to the desired flame

size. The controls do not have to be set at a

particular mark. Usethe marks as a guide and

adjust the flame as needed.

5.

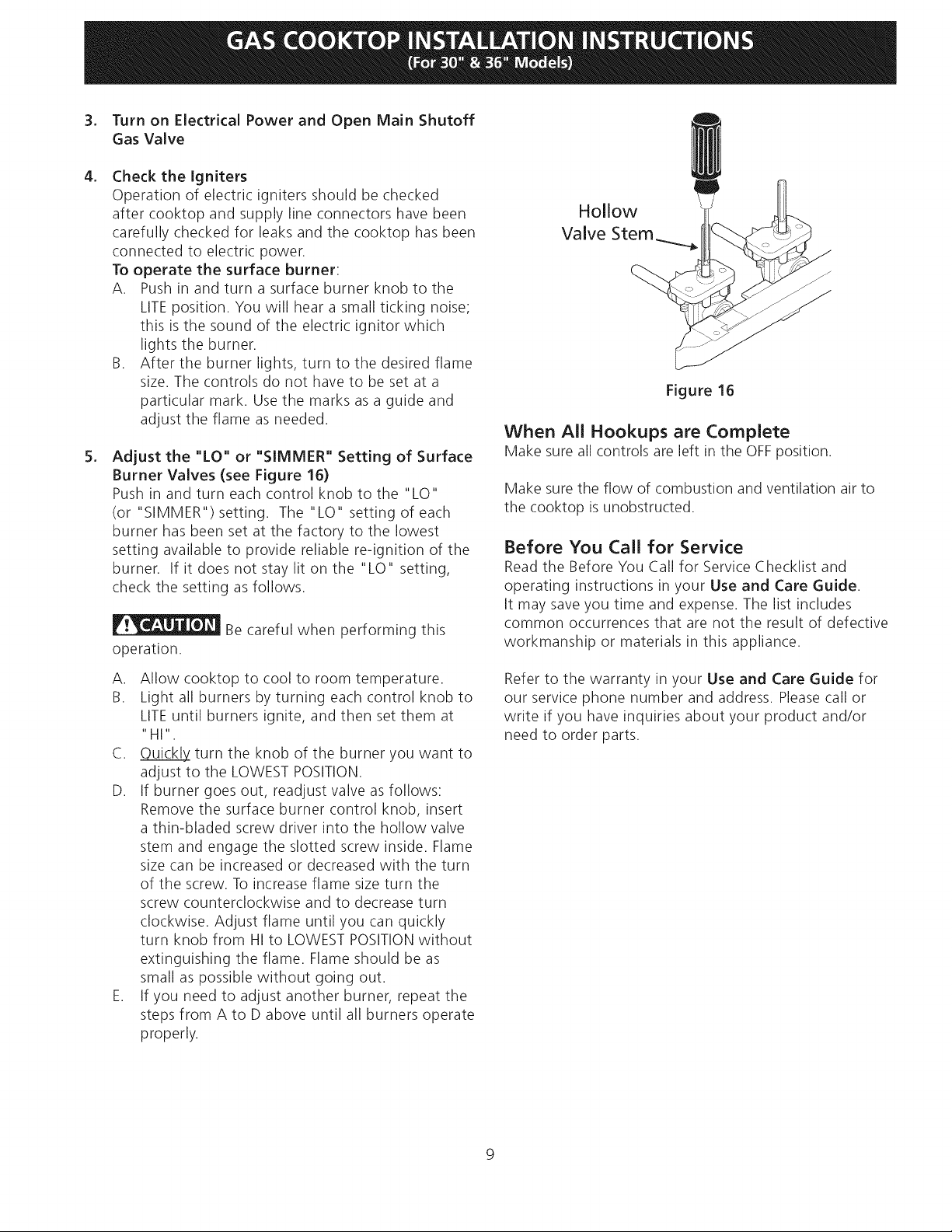

Adjust the "LO" or "SIMMER" Setting of Surface

Burner Valves (see Figure 16)

Push in and turn each control knob to the "LO"

(or "SIMMER") setting. The "LO" setting of each

burner has been set at the factory to the lowest

setting available to provide reliable re-ignition of the

burner. If it does not stay lit on the "LO" setting,

check the setting as follows.

Be careful when performing this

operation.

Hollow

Valve Stem_

Figure 16

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Make sure the flow of combustion and ventilation air to

the cooktop is unobstructed.

Before You Call for Service

Read the Before You Call for Service Checklist and

operating instructions in your Use and Care Guide.

It may save you time and expense. The list includes

common occurrences that are not the result of defective

workmanship or materials in this appliance.

A. Allow cooktop to cool to room temperature.

B. Light all burners by turning each control knob to

LITEuntil burners ignite, and then set them at

"HI".

C. _ turn the knob of the burner you want to

adjust to the LOWEST POSITION.

D. If burner goes out, readjust valve as follows:

Remove the surface burner control knob, insert

a thin-bladed screw driver into the hollow valve

stem and engage the slotted screw inside. Flame

size can be increased or decreased with the turn

of the screw. To increase flame size turn the

screw counterclockwise and to decrease turn

clockwise. Adjust flame until you can quickly

turn knob from HI to LOWESTPOSITIONwithout

extinguishing the flame. Flame should be as

small as possible without going out.

E. If you need to adjust another burner, repeat the

steps from A to D above until all burners operate

properly.

Refer to the warranty in your Use and Care Guide for

our service phone number and address. Please call or

write if you have inquiries about your product and/or

need to order parts.

9

Page 10

LA INSTALACION Y EL SERVICIO DEBEN SER REAUZADOS POR UN INSTALADOR CALIFICADO.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL iNSPECTOR ELI__CTRICOLOCAL.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA FUTURAS REFERENCIAS

Si todas las instrucciones de _ste manual no son observadas a la letra, se puede

ocurrir incendios o explosiones que pueden causar daEos materiales, lesiones o la muerte.

PARA SU SEGURIDAD:

-- No almacene o utilice gasolina u otros vapores y liquidos inflamables cerca

de _ste o cualquier otro artefacto.

-- QUE HACER SI HAY FUGAS DE GAS :

• No intente de encender ningun artefacto

®

No toque ningun interruptor el_ctrico; no utilice ningun aparato telef6nico en su edificio.

Llame inmediatamente el abastecedor de gas desde el tel_fono de un vecino.

Siga las instrucciones del abastecedor de gas.

En caso que no puede contactar el abastecedor de gas Ilame al departamento de

bomberos.

--La instalacion y el servicio t_lefonico deben ser realizados por un instalador

calificado, por un servicio tecnico certificado o por el abastecedor de gas.

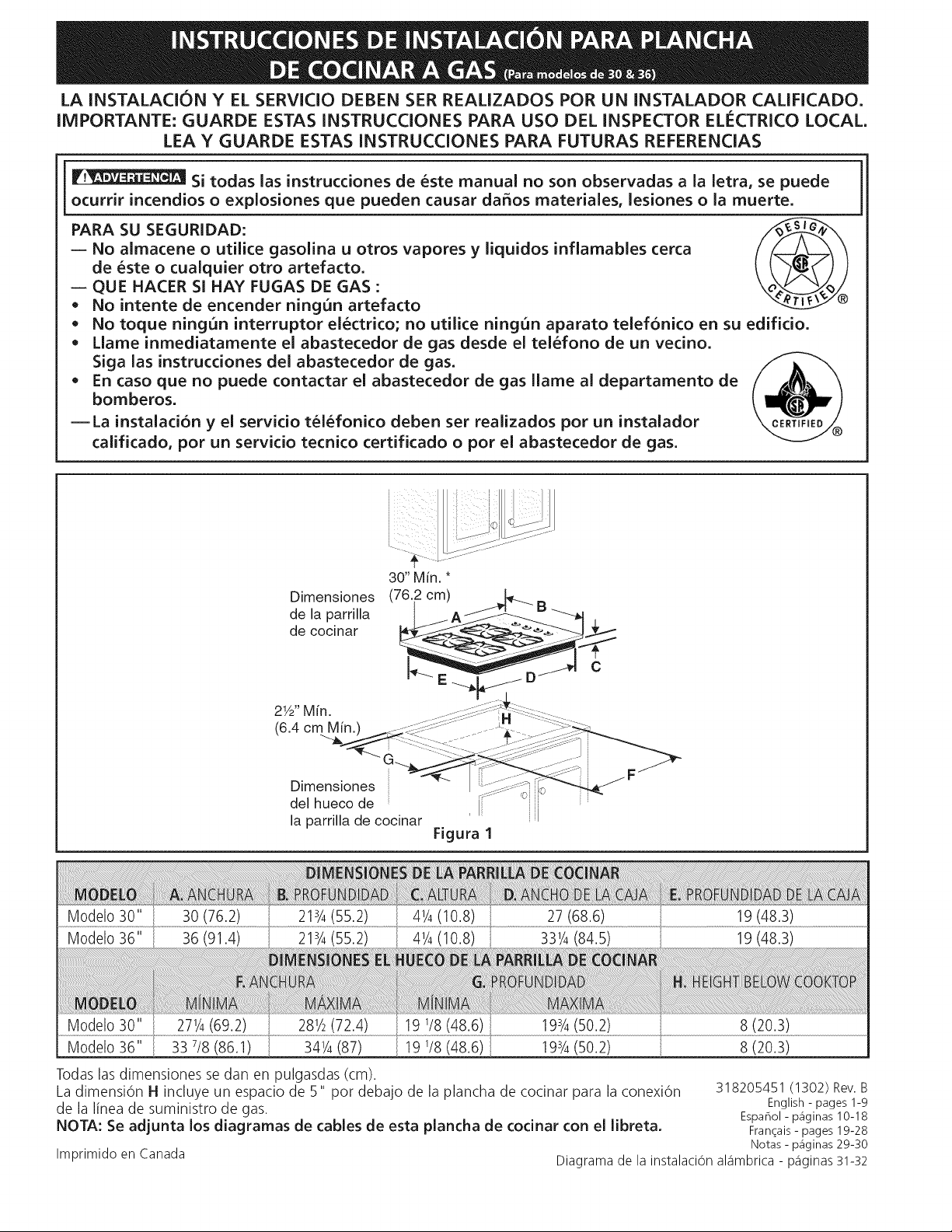

Modelo 36"

Modelo 36"

Dimensiones

de la parrilla

de cocinar

2W' Min.

(6.4 cm Min.

Dimensiones

del hueco de

la parrilla de cocinar

Figura I

30 (76.2)

36 (91.4)

213/4(55.2)

213/4(55.2) 41/4(10.8) 331/4(84.5) 19 (48.3)

281/2(72.4) 19 1/8(48.6) 195/4(50.2)

33 7/8(86.1) 341/4(87) 19 1/8(48.6) 193/4(50.2)

8 (20.3)

8 (20,3)

Todas las dimensiones se dan en pulgasdas (cm).

La dimensi6n H incluye un espacio de 5" pot debajo de la plancha de cocinar para la conex16n 318205451 (1302) Rev.B

de la linea de suministro de gas. English- pages 1-9

Espahol - p_iginas 10-18

NOTA: Se adjunta los diagramas de cables de esta plancha de codnar con el libreta. Fran_ais-pages19-28

Imprimido en Canada Diagramade lainstalaci6nal_imbrica- p_iginas31-32

Notas - p_iginas 29-30

Page 11

Notas importantes para el instalador:

1. Leatodas las instrucciones de instalaciOn antes de

realizar la instalaci6n de la plancha de cocinar.

2. Retire todos los articulos de embalaje antes de realizar

lasconexiones el_ctricas a la plancha de cocinar.

3. Observe todos los c6digos o reglamentos estatales

4. Aseg0rese que el consumidor tenga estas instrucciones.

5. Nota: Para el correcto funcionamiento en lugares

superiores a los 2000 ft, el r_gimen del mecanismo debe

reducirse un 4% pot cada 1000 ft sobre el nivel del mar.

Notas importantes para el consumidor

Guarcle todas las instrucciones con su manual del usuario

para futuras referiencias.

INSTRUCCIONES DE

SEGURIDAD IMPORTANTES

La instalaciOn de esta plancha de cocinar debe realizarse

en conformidad con los c6digos locales o, si estos no

existen, con el National Fuel Gas Code ANSI Z223.1/NFPA

54 en los Estados Unidos, o en Canada, con el Canadian

Fuel Gas Code, CAN/CGA B149 y CAN/CGA B149.2.

• La instalaciOn de aparatos diseflados para instalaciOn

en casas prefabricadas (m6viles) debe conformar con el

Maufactured Home Consturction and Safet Standard,

titulo 24CFR, parte 3280 [Anteriormente el Federal

Standard for Mobil Home Construction and Safety,

titulo 24, HUD (parte 280)] o cuando tal est_indar no se

aplica, el Standard fo Manufactured Home Installation,

ANSI/NCSBCS 225.1, o con los c6digos locales.

El diseho de esta plancha de cocinar cuenta con la

aprobaci6n de la CSA internacional. AI igual que todos los

artefactos a gas que generan calor, deben seguirse ciertas

medidas de seguridad. Vienen con el Manual del Usuario.

Lea atentamente el manual.

• No se deben usar cortinas de aire ni ninguna

otra campana de ventilacion superior que sople

aire hacia abajo sobre la estufa a gas a menos

que la campana de ventilaci6n y la estufa hayan

sido dise_adas, probadas y certificadas pot un

laboratorio de pruebas independiente para el uso

combinado de la una con la otra.

Asegurese que la plancha de cocinar sea instalada

y puesta a tierra correctamente pot un instalador

o t_cnico calificado.

La plancha de cocinar debe conectarse

el_ctricamente a tierra de acuerdo con los codigos

locales o, de no existir, con el codigo el_ctrico

ANSI/NFPA No. 70 =ultima edicion en los Estados

Unidos, or in Canada, con el Canadian Electrical

Code, CSA C22.1 Parte 1.

Los quemadores pueden encenderse

manualmente durante una interrupcion del

suministro el_ctrico. Para encender un quemador,

mantenga un fosforo encendido en el extremo del

quemador, luego gire suavemente la perilla hasta

LITE (encendido). Tenga cuidado al encender los

quemadores en forma manual.

No deje articulos que interesan los ni_os en los

armarios que est_n sobre la la plancha de cocinar.

Les podria causar quemaduras graves si intentan

subirse para alcanzarlos.

Para eliminar el riesgo de extender pot encima

de los quemadores superiores, deberia evitar

el espacio de almacenamiento del armario,

Iocalizado pot encima de estos quemadores

Gradue el tama_o de la llama de modo que

no sobrepase el borde del utensilio de cocina.

Demasiada llama es peligrosa.

• No utilice jamas la cocina como calefactor. Eluso

prolongado de la cocina sin la ventilaci6n adecuada

puede set peligroso.

Mantenga el area cerca de este artefacto

o de cualquier otto artefacto despejada de

sustancias combustibles, gasolina y otros Iiquidos

inflamables. Se puecle ocurrir incendios o explosiones.

i!_ El suministro electrico a la plancha

de cocinar debe de set cerrado durante las

conexiones a la linea.m De Io contrario se puede

resultar lesiones graves o la muerte.

Ubicacion de ia toma de corriente de ia

pared

' 12"

,

I-

I 10"

I

_,rea recomendada la toma de

, corriente a tierra de 120V en Wa

I pared posterior,

J

APARATO

_LDEL 2 2"

NOTA: Si no existe una toma /

de corriente, contacte a un

eJectricista calificado para

realizar Ja instalaci6n.

- Figura 5

" _JLDEL APARATO

/

1_

11

Page 12

M_ix.profundidad

de gabinetes

instalados pot

encima de la

plancha de

empotar es 13"

(33 cm).

18" Min.

(45.7 cm)

24" (61 cm_

11/2"(3.8 cm) Minimo Distancia

entre el horde posterior del

hueco y lamas cerca superficie

combustible pot encima del

mostrador.

_T_430" (76.2

cm) Minimo

de espacio

entre la parte

I i la plataforma

Esoacio de la plancha

superior de

de cocinar y

el fondo de

una madera

non protegida

o armario

metalico.

C

\

Para eliminar el

riesgo de alargar sobre los unidades en

calentamiento de la superficie, deberia

evitarse el espacio de almacenamiento del

armario, ubicado sobre las unidades de la

superficie. Si se cuenta con este espacio,

se puede disminuir el peligro instalando

una cubierta de cocina que se extienda

horizontalmente en 5" (12.7 cm) minimo

pot sobre la parte inferior delantera en

los armarios.

Figura 2- DESENO DEL ARMARIO

No es posible utilizar cajones con

esta parrilla de cocinar porqu@ la

caja de empalme se extiende de

3%2" (8.02 cm) pot encima de la

superficie del mostrador.

30" (76.2 cm) 7"(17.8 cm)

36" (91.4 cm) 7"(17.8 cm)

7"(17.8 cm)

7"(17.8 cm)

12

Page 13

Tipica instalaci6n de un horno el ctrico empotrado con una

plancha de cocinar por encima

Entrepa_os Ilenador de lados son

necesarios para aislar el aparato de

los armarios adyacentes. La altura de

Todas las fijaciones de

montaje deben de estar

utilizadas para sujetar

el homo empotrado a

los armarios. Refiere

a las instrucciones de

instalaci6n del homo

empotrado.

Esta plancha de cocinar puede instalarse

por encima de algunos modelos de homo

electrico empotrado.

Aproximadamente 3"

(7.6

panel debe de permitir la instalaci6n

de modelos de planchas de cocinar

aprobantes. Ver "lnstalaciOn t[pica de

plancha de cocinar a gas por encima de

un homo electrico empotrado instalado

debajo del mostrador" en la pagina 4.

36"

(91.4 cm)

"- Minimo

Caja de empalme a tierra de

208/240 voltaje para homo

empotrado

* (Si no hay plancha de cocinar

instalada directamente sobre

el aparato, un maximo de 5"

(12.7 cm) esta permitido)

** Un minimo de 32" (81.3 cm)

desde la parte superior del

armario hasta la parte superior

de las ruedas debe de set

mantenido.

Corte una abertura en la basa de madera

m[nimo 4" (10.2 cm) x 4" (10.2 cm) para

conducir elcable blindado a la caja de

empalme.

30"

(76.2 cm) (71.8 cm)

Figura 3

(73.3 cm)

Utilice 3/4" (1.9 cm) de madera

contrachapada, instalada sobre 2 ruedas,

perpendicular a una cima de contomo de

)laca. Debe de poder sostener 150 Ibs.

41/2" Max.*

1.4 cm)

(72.4 cm)73.7 cm

(61 cm)

13

Page 14

Instalacion tipica de la plancha de cocinar a gas por encima de un horno

electrico empotrado instalado debajo del mostrador

I I

._ 18" (45.7 cm) M&x."-""_I

÷

4" (I0.2cm)

Tubomulti

61/2"

5" (13.5 cm)

(12.7 cm) Min.

UniOn

Conector

Cabinet sides or

filler panel

Armario del homo de pared

ESTUFA DE GAS

UniOn

Vista anterior

UniOn

120Vl6OHzToma

de cordente a

tierra

Regulador de

presiOn

V&Ivula de derre manual

(Debe de ser accesible para el

fundona-miento de la v&Ivula

de derre)

Lado derecho

del armado

Vista de lado del

homo de pared

Figura 4

14

Page 15

Instalaci6n de ia piancha de cocinar

1, Examine visualmente la plancha de cocinar para saber

si hay daho,

2, Fije el la plancha de cocinar en el recorte del

mostrador,

Inforrnacion para sujetar el aparato

Una vez que el aparato est,1instalado en la apertura del

mostrador, se tiene que sujetar como se indica.

Planchade Junta de estanqueidad

cocinar A /

_ / Mostrador

i H

.,_ _" TomiellOsde

Figura _

Para ajustar el aparato, inserte la consola de escuadra, con

el lado desviado, en lasranuras en cada lado del aparato.

El tornillo de orejas debe entonces de pasar a trav_s del

soporte y hasta la parte de abajo del mostrador. Apri_telo

hasta que el aparato se quede ajustado.

Provea un adecuado surninistro de gas

Esta plancha de cocinar est,1disehada para utilizar gas

natural de 4" de presiOn m01tiple solamente.

Se conecta un regulador de presiOn en serie al m01tiple de

la plancha de cocinar y debe permanecer en serie con la

linea de suministro de gas.

Para que manejo correcto, la presiOnde entrada m_ixima

hacia el regulador no debe exceder 14" de presiOn de la

columna de agua.

Para controlar el regulador, la presi6n de entrada debe

ser de al menos 1" (o 2.5 Kpa) mayor que el ajuste de la

presi6n del mOltiple del regulador. El regulador se ajusta a

4" de la presi6n del mOltiple, la presi6n de entrada debe

de ser de al menos 5".

La linea de suministro de gas por el homo deberia tener un

tubo de 1/2" o de 3/4".

Conversion de gas propano/licuado

Esta plancha de cocinar ha sido disehada para utilizar gas

natural o gas propano. Ha sido fijada en la f_ibrica para

utilizarse con gas natural.

Si desea hacer la conversion para utilizar el gas propano,

use las piezas con orificios fijados provistos en el

paquete del manual de instrucciones para la instalaciOn

en el paquete escrito "PARA LA CONVERSIONEN GAS

PROPANO". Siga lasinstrucciones que est_incon los

orificios.

Para hacer la conversion del gas natural al gas propano,

es necesario utilizar el servicio de un t_cnico calificado,

in acuerdo con las instrucciones del fabricante y todos

los cOdigos y reglamentos reguladores. Si todas las

instrucciones no son observadas, se puede ocurrir severos

lesiones o dahos materiales. La agencia calificada que hace

el trabajo asuma la responsabilidad para la conversion.

Si la conversion apropiada no esta

observada, se puede ocurrir severos lesiones o dahos

materiales.

Importante: Retire todos los articulos de embalaje y

folletos de la cocina antes de realizar las conexiones de gas

y el_ctricas a la cocina.

Instalaci6n del regulador de presion

Instale el regulador de presiOn con la flecha del regulador

apuntando hacia la unidad en una posici6n que permita

alcanzar la tapa de entrada.

No ajuste demasiado la conexi6n. El

regular est,1fundida a presi6n. AI ajustar demasiado se

puede romper el regulador causando una fuga de gas y un

posible incendio o explosi6n.

Valvula de FLUJO DEL GAS Regulator

cierre UniOn Uni6n

manual

Abierto _ t iI

(on) _ Boquilla Conector II

Apagado flexible Tapade

(Off) entrada

Todas las conexiones deben ajustarse con

Monte el conector flexible del tubo del suministro de gas al

regulador de presiOn en funcionamiento:

1. wilvula de cierre manual

2. boquilla de 1/2" (1.3 cm)

3. adaptor de 1/2" (1.3 cm)

4. conector flexible

5. adaptator de 1/2" (1.3 cm)

6. boquilla de 1/2" (1.3 cm)

7. regulador de presiOn.

Utilice un compuesto de tubo articulado para uso de gas

natural y propano para sellar todas las conexiones de

gas. Si se utilizan conectores flexibles, aseg0rese que los

conectores no est_intorcidos.

El tubo de suministro de gas deberia incluir una wilvula de

cierre certificada. Estawilvula deberia estar ubicada en la

misma habitaciOn de la plancha de cocinar y deberia estar

en un lugar que permita una abertura y cierre f_iciles. No

bloquee las entradas de la wilvula de cierre. La wilvula sirve

para abrir o cerrar el paso del gas al artefacto.

15

_ de presi6n

una Ilave de tuerca

Figura 7

Page 16

V_lvula de cierre =

Abierta

Figura 8

Abra la wilvula de cierre en el tubo de suministro de gas.

Espere unos minutos para que el gas pase a trav_s del tubo

de gas.

Verifique si hay fugas. Luego de conectar la cocina al

gas, verifique elsistema con un manOmetro. Si no cuenta

con _ste instrumento, d_ la vuelta al suministro de gas de

la cocina y utilice un detector de fugas liquidas (o agua

yjabOn) en todas las articulaciones y conexiones para

verificar si existen fugas.

No use ning0n tipo de llama para

verificar si hay fugas de gas. Verifique si hay fugas con una

llama puede ocasionar incendio o explosi6n.

Ajuste todas las conexiones en caso que sea necesario,

para evitar fugas de gas en la cocina o en el tubo de

suministro de gas.

Verifique la alineaci6n de las v_lvulas luego de

conectar la plancha de cocinar al suministro de gas para

asegurar que no se ha movido lawilvula del m01tiple de la

plancha de cocinar.

Desconecte la cocina y su v_lvula de cierre individual

del sistema detuberia del suministro de gas durante cualquier

ensayo de presi6n del sistemaen ensayos de presi6n

superiores a 1/2 psig (3.5 kPao 14" columna de agua).

Aparte la cocina del sistema de tuberia del suministro

de gas cerrando su wilvula de cierre individual manual,

durante cualquier ensayo de presi6n del sistema de

suministro de gas en ensayos iguales o inferiores a 1/2 psig

(3.5 kPao 14" columna de agua).

disminuir la posibilidad de peligro de choques el@ctricos

desde el artefacto.

Un electricista calificado debe verificar el enchufe de pared

y el circuito para asegurar que el enchufe est_qconectado a

tierra correctamente.

En caso de encontrarse con un enchufe de pared de dos

patas, es la personal responsabilidad y la obligaci6n del

consumidor reemplazarlo por el enchufe de pared a tierra

de tres patas correspondiente.

No debe, bajo ninguna circunstancia cortar o retirar

la tercera pata (tierra) del cable de encendido.

Desconecte el cable del suministro

el#ctrico del enchufe de pared antes de reparar la plancha

de cocinar.

M F:TODO PREFERIDO

Enchure de

pared a tierra

Figura 9

bajo

encendido,

Cablo de encendido

con enchufe de tres

patas a tierra

Modeio y ubicacion del nurnero de serie

La placa de n0mero de serie est_qubicada en el lado de

abajo de la caja de quemadores (vea la figura 10).

Aseg0rese de incluir el modelo, n0mero de serie y el

n0mero o letra del Iote que se encuentran en la placa, en

todo pedido de partes o solicitud de informaci6n acerca de

su plancha de cocinar.

La placa de n0mero de serie tambi@n indica las

especificaciones de los quemadores, el tipo de combustible

y la presi6n para la cual fue ajustada la plancha de cocinar

en la f_ibrica.

Requerimientos electricos

Un circuito derivado conectado correctamente a tierra de 120

voltios, 60 Hertz protegido por un interruptor autom_qticode

15 amp o un fusible de retardo. No utilice un cable flexible

de extensi6n en esta plancha de cocinar.

Instrucciones para la puesta a tierra

IMPORTANTE Pot favor, lea atentamente.

Como medida de seguridad personal, est_ artefacto

debe conectarse a tierra correctamente.

El cable de encendido de este artefacto incluye un enchufe

de tres patas (a tierra) que calza con un enchufe de pared

de tres patas de conexi6n a tierra (ver Figura 9) para

La placa de serie

est_ ubicada

bajo la hornilla.

16

Figura 10

Page 17

Verifique ia operacion

Refiera al Manual del Usuario que viene con la plancha

de cocinar para las instrucciones de funcionamiento y el

mantenimiento y la limpieza de su plancha de cocinar.

No toque a los quemadores. Pueden estar suficientemente

calientes par causar quemaduras.

1. Instalacion de las tapas de quemadores

Esta plancha de cocinar est,1equipada con quemadores

sellados. Todas las piezas est_inen su lugar. Tome nota

en donde est_in.Quite todo el material de protecci6n.

Elreborde de la tapa del quemador (veala Fig. 11)

debe calzar firmemente en el centro de la cabeza del

quemador y quedar nivelado. Consulte la figuras 12 y

13 para conocer lasmaneras correctas e incorrectas de

colocar la tapa del quemador. Una vez que est# en su

lugar, puede verificar si cabe deslizando suavemente

la tapa del quemador de lado a lado (Fig 14) para

asegurarse de que est# centrada y firmemente asentada.

Cuando el reborde de la tapa del quemador haga

contacto en el centro de la cabeza del quemador, podr_i

escuchar un chasquido. Tengaen cuenta que la tapa del

quemador NO se debe mover del centro de la cabeza del

quemador cuando intente moverla de lado a lado. NOTA:

No es necesario realizar ajustes en los quemadores de

esta plancha de cocinar.

Tapa del

quemador

Cabeza del

quemador

Fig. 11

_'x_' Reborde de

la tapa del

quemador

2. Coloque las parrillas en la tabla de codna

Aseg0rese que las parrillas est_in bien Iocalizadas dentro de

la superficie de acero inoxidable.

ATENCION- no deslice las parrillas dentro de la tabla de

cocina esto puede provocar da_os.

Tablade cocina 36" SOLAMENTE: aseg0rese que las parri-

Ilas est_n colocadas correctamente dentro de la tabla de

cocina como se muestra en la fig. 15, el escudo protector

de calor debe de encontrarse del lado de las perillas.

Escudo protector

de calor

Fig.15

=

Abre el suministro electrico y la wilvula de cierre

principal del gas.

=

Verifique los dispositivos de encendido

La manipulaciOn de los dispositivos de encendido

el_ctrico deberia verificarse tras haber revisado

detenidamente la plancha de cocinar y los conectores

del tubo del suministro de fugas y tras haber conectado

la plancha de cocinar al suministro el_ctrico.

Para operar en la superficie del quemador:

A. Presione y gire la perilla de control hasta LITE.Se

escuchar_ia un pequeho ruido. Estees el ruido

producido pot el dispositivo de encendido el_ctrico

cuando enciende el quemador.

B. Una vez que el quemador est,1encendido, gire

hasta obtener el tamaho de la llama deseada. No

es necesario ajustar los controles en una marca

determinada. Use las marcas como guia y ajuste la

llama seg0n se desea.

Colocaci6n correcta de Colocaci6n incorrecta

la tapa del quemador= de la tapa del

Fig. 12 quemador= Fig. 13

Fig. 14

17

Page 18

5. Verifiqueelajuste"LO" O "SIMMER" de las v_lvulas

de superficie de quemador (vet Figura 16)

Presioney gire el bot0n de control al ajuste "LO" (o

"SIMMER"). Elajuste "LO" de cada quemador ha

sido creado en la f_ibrica para fijarse al menor ajuste

disponible para entregar un re encendido confiable

del quemador. Si no queda encendido en el ajuste

"LO", verifique el ajuste "LO" como se muestra a

continuaciOn.

A. Deje que la cocina seenfrie a temperatura

ambiente.

B. Enciende todos los quemadores girando cada bot6n

de control hasta LITEpara encender los quemadores

y fijarlos en "HI".

C. Gire r@idamente el quemador hasta LOWEST

POSITION.

D. Si el quemador se apaga, reajuste la wilvula como

se muestra a continuaciOn:

Retire el bot6n de control del quemador, inserte un

destornillador de cuchillo delgado en el w%tago del

agujero de la wilvula y encaje el tornillo ranurado. El

tamaho de la llama se puede aumentar o disminuir

girando eltornillo. Grad0e la llama hasta que se

pueda girar r@idamente hacia abajo desde HI

hasta LOWESTPOSITIONsin apagar la llama. La

llama deberia set Io m_qsbaja posible y estable sin

apagarse.

E. Si se desea ajustar otto quemador, repita los pasos

de A a D descritos hasta que los quemadores

funcionen correctamente.

Cuando se ban realizado todos los sisternas

de conexion

Aseg0rese que todos los controlos est_qnen la posici0n de

OFF(apagado).

Aseg0rese que el flujo de combusti6n y ventilaci6n de aire

de la cocina no est_qnobstruidos

Antes de ilarnar ai servicio

Lea la secciOn Lista de Control de Averias en su Manual

del Usuario. Esto le podr_i ahorrar tiempo y gastos. Esta

lista incluye ocurrencias comunes que no son el resultado

de defectos de materiales o fabricaci6n de este artefacto.

Lea la garantia y la informaci6n sobre el servicio en su

Manual del Usuario para obtener el n0mero de tel@fono

y la direcci6n del servicio. Pot favor Ilame o escriba si

tiene preguntas acerca de su estufa o necesita repuestos.

El hueco del

w%tago de la

wilvula

Figura 16

18

Page 19

UN INSTALLATEURQUALIFII_ DOlT EFFECTUERL'INSTALLATIONET LESERVICE

iMPORTANT: CONSERVEZCESiNSTRUCTiONSPOUR LESINSPECTEURSLOCAUX.

LISEZCESiNSTRUCTiONSETCONSERVEZ-LESPOUR Ri_FI_RENCESULTI_RIEURES.

r.,:\/:l.li[--]--]:lul:l_il Sl les instructions de ce manuel ne sont pas sulvles aw , v - v _ ...... la lettre, il pourrait en r_sulter un

[incendie ou une exp os on suscept b e de causer des dommages mater e s, des blessures ou m_me la mort.

POUR VOTRE SI_CURITI_:

-- N'entreposez et n'utilisez pas d'essence ou d'autres produits inflammables a proximite de

cet appareil ou de tout autre appareil.

-- QUE FAIRE SI VOUS Dt_CELEZUNE ODEUR DE GAZ:

• Ne tentez d'allumer aucun appareil.

• N'actionnez aucun interrupteur _lectrique; n'utilisez aucun appareil telephonique de I'edifice.

• Communiquez imm_diatement avec votre fournisseur de gaz en vous servant du telephone

d'un voisin. Suivez les instructions que le fournisseur vous donnera.

• S'il vous est impossible de rejoindre votre distributeur de gaz, communiquez avec le service

d'incendie.

-- L'installation et I'entretien doivent _tre effectues par un installateur qualifi& un service

d'entretien ou de reparation accredite ou le distributeur de gaz.

Dimensions de la

plaque de cuisson

2Y2"Min.

(6.4 cm Min.

Dimensions de d_coupage

pour la plaque de cuisson

Figure 1

19 1/8(48.6)

Moddes 36" 33 7/8(86.1) 341/4(87)

193/4(50,2) 8 (20,3)

Toutes les dimensions sont en pouces (cm). 318205451 (1302) Rev.B

La dimension H est le d_gagement requis sous la plaque de cuisson pour le raccordement au gaz. Espahol-p_iginas10-18

English - pages 1-9

NOTE: Le schema de c_blage de la plaque de cuisson est indus a la fin de ce feuillet, Fran_ais-pages19-28

Imprim_ aux Etats-Unis Notes - pages 29-30

Schemas de c_blage - pages 31-32

Page 20

Notes importantes a I'lnstallateur

1. Liseztoutes les instructions contenues dans ce feuillet

avant d'installer I'appareil.

2. Enlevez tout le materiel d'emballage avant de connecter

I'alimentation de gaz _ la plaque de cuisson.

3. Respecteztous les codes et r_glements applicables.

4. N'oubliez pas de laisser ces instructions au

consommateur.

5. Note: Pour I'utilisation _ plus de 2000 pieds d'_l_vation

au dessusdu niveau de la met, la puissance de

I'appareil devrait _tre r_duite de 4% pour chaque 1000

pieds additionnels.

Note importante au consomrnateur

Conservez ces instructions avec le guide de I'utilisateur

pour r_f_rence ult_rieure.

INSTRUCTIONS DE SI'CURITI"

IMPORTANTES

Cet appareil dolt _tre install_ conform_ment aux

r_glements Iocaux, ou en I'absence de r_glements,

au code National de Gaz ANSI Z223.1/NFPA 54 aux

Etats-Unis, ou aux normes CAN/ACG-B149 et CAN/

ACG-B149.2 au Canada.

• L'installation d'appareils conc us pour les maisons

(mobiles) dolt se conformer aux normes de la

Manufactured Home Construction and Safety Standard,

titre 24CFR, pattie 3280 (ant_rieurement Federal

Standard for Mobile Home Construction and Safety,

titre 24, HUD (pattie 280)) ou en I'absence de normes,

aux normes de la Manufactured Home Installation 1982

(Manufactured Home Sites, Communities and Setups),

ANSI/NCSBCS A225.1 ou aux codes Iocaux.

La conception de cette plaque de cuisson a _t_

approuv_e par American Gas Association (A.G.A.).

II faut prendre certaines precautions d'usage Iors de

I'utilisation de tout appareil fonctionnant au gaz naturel

ou produisant de la chaleur. Vous trouverez celles-ci dans

votre Guide d'utilisateur lisez-les avec attention.

• Les rideaux d'air ou [es hottes de cuisinieres qui

projettent un courant d'air descendant vers [a table

de cuisson, ne doivent pas _tre uti[ises avec des

appareils a gaz, sauf si [a hotte et ['apparei[ ont

ete con_us, testes et repertories par un [aboratoire

d'essai independant pour pouvoir fonctionner

conjointement.

• Assurez-vous que votre apparel[ est correctement

instal[e et mis _ la terre par un insta[lateur ou un

technicien d'entretien qua[ifie.

• Le circuit e[ectrique de cette plaque de cuisson doit

Ctre mis a [a terre conformement aux r_glements

Iocaux, ou en I'absence de r_glements, au code national

de I'_lectricit_ ANSI/NFPA no. 70- derni_re _dition aux

Etats-Unis ou _ la norme canadienne d'_lectricit_, ACNOR

C22.1, partie 1, au canada.

• Lors d'une panne de courant electrique, les br0leurs

de surface peuvent Ctre aHumes manue[iement;

placez une al[umette al[umee pres de [a tCte

du br0[eur et tournez [entement [e bouton de

commande de surface a la position L[TE. Redoublez

de prudence si vous aHumez un br0[eur de surface

manueHement.

• N'entreposez pas d'objets susceptib[es d'interesser

[es enfants dans [es armoires situees au-dessus de

la cuisiniere. IIs risquent de se br01er s_rieusement s'ils

tentent de grimper sur I'appareil.

• Evitez de placer des armoires de rangement

au-dessus des breleurs afin d'eliminer les gestes

inutiles au-dessus de ceux-ci.

• Reg[ez la flamme du br01eur pour qu'el[e ne depasse

pas [e bord de Fustensi[e uti[ise pour [a cuisson. Une

flamme excessiveest dangereuse.

• N'utilisez jamais votre appareil pour rechauffer ou

chauffer la piece. L'utilisation prolong_e de la plaque

de cuisson sans une ventilation adequate peut s'av_rer

dangereuse.

• Ne gardez pas de produits combustibles, d'essence

et d'autres produits inflammables a proximite de

cet apparei[ ou de tout autre apparei[. II pourrait en

r_sulter des explosions ou un incendie.

| ,T T 3

E''-'\i=l"tl/['$1=lul=l_ill [[ faut couper I'aiimentation

e[ectrique durant [e branchement, A defaut de ce

faire i[ peut en resu[ter des blessures graves ou la

mort.

20

Page 21

L'armoire

sup_rieurene

doltpasexc_der

uneprofondeur

de13"(33cm)

I

18" Min.

(45.7 cm Min.)

11/2"(3.8 cm) minimum

__command6entre le rebord

arri6re de d6coupage et le

mur en mat6riel combustible

le plus proche du dessusdu

comptoir

D_gagement

minimum de 30"

(76.2 cm) entre le

haut de la surface

de cuisson et la base

de I'armoire en bois

ou en m6tal non

D6gagement

B

24" {61 cm_

2

r!v,_\,A_:_i_,,,l_,,imPour _liminer les

risques de br01ures ou de feu en

allongeant le bras au-dessus des

surfaces de cuisson chaudes, _vitez

d'installer des armoires au-dessus de la

plaque de cuisson. Si vous devez en

installer, il est possible de r_duire le

risque en placant une hotte pour

cuisini_re qui exc_de horizontalement

d'un minimum de 5" (12.7 cm)la base

de I'armoire.

Des tiroirs ne peuvent pas _tre utilis_s

avec ce type d'appareil puisque le bottler

d_passe de 3 5/32" (8.02 cm) en dessous

du comptoir

7"(17.8 cm)

M0d_les 36"

36" (91.4 ore) 7"(17.8 ore)

C

7"(17.8 cm)

Figure 2 - OUVERTURE DU D{:COUPAGE DE DESSUS DU COMPTOIR

21

Page 22

Lesattachesanti-versements

doivent_treutilis@espour

retenirlefourencastr@aux

armoires.

Approx. 3"

Bottederaccorde-

mentde208/240

Volts,mise_la

terre.

Cettetabledecuissonpeut-

_treinstalbeaudessusde

certainsmod@lesdefours

encastr@s@lectriques.

(7.6 cm)

Des panneaux lat6raux de s6paration doivent

6tre instalbs pour isoler I'appareil des armoires

accobes. Lahauteur des panneaux dolt

permettre I'installation des mod61esde tables

de cuisson approuv6es. Reportez-vous aux

informations typiques d'une table de cuisson

a gaz install6e au-dessus d'un four encastr6

61ectrique install6 sous le comptoir.

32" Min.**

(81.3 cm Min.**)

36" Min.

(91.4 cm Min.)

Utiliser un contreplaqu_ de 3/4"(1.9 cm) mont_

sur deux solives, dont I'ar_te est _ _galit_ avec

le coup-de-pied. II dolt supporter une charge

de 150 livres (68 kg).

* Un maximum de 5" (12.7 cm)

est permis si aucune table de

cuisson n'est install@eau dessus

de I'appareil.

** Une distance minimale de 32"

(81.3 cm) est requise entre le

dessous du comptoir et le haut

de la plaque de bordure.

Figure 3 - INSTALLATION TYPIQUE D'UN FOUR ENCASTRF:ELECTRIQUE SOUS LE COMPTOIR

D@couperune ouverture dans le plancher en bois

de 9" x 9" (22.9 cm X 22.9 cm) minimum, distant

de 2" (5.1 cm) du mur gauche, pour y conduire le

c_ble arm@vers la botte de raccordement.

4 1/2"Max.*

(11.4 cm Max.*)

(76.2 cm) (71.8 cm) (73.3 cm)

ET D'UNE TABLE DE CUISSON AU-DESSUS

(72.4 cm) 73.7 cm (61 cm)

22

Page 23

18"Max.

(45.7cm) _t.

Tubeenm_talflexible

conduitd'alimentationengaz

MurdeI'armoiregauche

oumurdes_paration

Armoire

TABLE DE CUISSON A GAZ

-\,

\ .........................................................................................................................................................................................................../

5" Max.

Manchon

_.5cm)

6 1/2"Min.

_vas_

Vue de face

I

Prisede

120V/6OHz

mise _ la terre

R_gulateur

de pression

Robinet d'arr_t manuel

(l'acc_s au robinet d'arr_t

dolt _tre facile)

4" (10.2 cm)

Mur de

droite de

I'armoire

Vue de c6te du

four encastre

Figure 4 - INSTALLATION TYPIQUE D'UNE TABLE DE CUISSON A GAZ

AU-DESSUS D'UN FOUR ENCASTR!t ltLECTRIQUE INSTALLIe SOUS LE COMPTOIR

23

Page 24

Emplacement de la prise de courant

rnurale

12" (30.5 cm) _"

j 10" (25.4 cm)

I'1L'emplaceme

' recommand_ pour

j la prise de courant

' de 120V avec 22"

contact de mise _ la (55.9 cm)

NOTE: Si aucune

prise de courant

n'est disponible,

demandez _ un

_lectricien qualifi_

d'en installer une.

Figure 5

, terre se trouve sur le

' mur arri_re.

I

CL de I'appareil J_

m

"CL de I'appareil

/

Pour la fixation, ins_rez le support de fixation en placant

le c6t_ en retrait de celui-ci dans la fente setrouvant

sur chaque c6t_ de I'_l_ment. Ins_rez la vis _ oreilles

travers le support de fixation jusqu'_ ce qu'elle entre en

contact avecle dessous du comptoir. Serrezjusqu'_ ce que

I'appareil s'enfonce dans son emplacement.

Fournissez une alimentation en gaz

adequate

Cette plaque de cuisson a _t_ concue pour fonctionner

au gaz naturel avec une pression d'admission de 4"

(10.2 cm).

Un r_gulateur de pression est branch_ en s_rie avec la

rampe _ gaz de la plaque de cuisson, et dolt rester en

s_rie sur le tuyau d'alimentation.

Pour un fonctionnement normal, la pression int_rieure

maximale au r_gulateur ne dolt pas _tre sup_rieure _ la

pression d'une colonne d'eau (C.E.) de 14" (35.6 cm).

Pour v_rifier le r_gulateur, la pression d'admission dolt

_tre sup_rieure d'au moins 1" (2.5 cm) (ou de 0.25

kPa) _ celle du r_gulateur ajust_ _ la rampe _ gaz. Le

r_gulateur _tant ajust_ _ 4" (10.2 cm) de pression, la

pression d'admission dolt _tre d'au moins 5" (12.7 cm).

La conduite d'alimentation en gaz branch_e _ la plaque de

cuisson dolt avoir un diam_tre de 1/2" (1.2 cm) _ 3A" (1.9

cm).

Installation de I'appareil

1. Inspectez visuellement la plaque de cuisson.

2. Placezla plaque de cuisson dans I'ouverture du

comptoir.

NOTE: Ne calfeutrez pas la plaque de cuisson. Elledolt

pouvoir _tre enlev_e du comptoir pour r_paration si

n_cessaire.

Instructions de fixation

Une fois I'appareil install_ dans I'ouverture du comptoir,

fixez-le tel qu'indiqu_.

Plaque de

cuisson /

_ _ / Comptoir

fixation J H

Figure 6

Joint d'_tancheite

Conversion au gaz de petrole

liquefie ou gaz propane

Cet appareil fonctionne au gaz naturel ou au gaz

propane. II est r_gl_ en usine pour fonctionner au gaz

naturel.

Si vous d_sirez convertir votre plaque de cuisson au

gaz propane, servez-vous des orifices _ d_bit fixe qui

sont fournis et emball_s dans un sac marqu_ "POUR

CONVERSIONAU GAZ PROPANE"; ce sac se trouve

dans I'enveloppe de documents contenant le feuillet

Instructions d'installation. Suivre les instructions

d'installation se trouvant dans I'enveloppe qui contient

les orifices.

Un installateur qualifi_ dolt effectuer I'installation et

le service, conform_ment aux instructions du fabricant

et _ tousles codes et r_glements applicables. Si ces

instructions ne sont pas suivies _ la lettre, il pourrait

en r_sulter de s_rieuses blessures corporelles ou des

dommages materiels. L'entreprise d'installation qui

effectue ce travail assume la responsabilit_ de la

conversion.

lr!v:\'_;ii_'_l_il Si on n'effectue pas la conversion

appropri@e, il pourrait en r@sulterdes blessures

corporelles et des dommages mat@riels.

24

Page 25

Important:EnleveztoutI'emballageetla

documentationdelaplaquedecuissonavantde

brancherlegazetlecourant_lectriquesurcelle-ci.

Installez le regulateur de pression

Installez le r_gulateur de pression avec la fbche qui se

trouve sur le r_gulateur dans la direction de la plaque de

cuisson et dans une position facile d'acc_s.

r!_'.'\Vl:lliil-$1:l_VAl:llilRISQUE D'INCENDIE. Ne serrez

pas trop les raccords. Le r_gulateur est fabriqu_ en

alliage moub. Un serrage excessif pourrait le fissurer et

provoquer une fuite de gaz susceptible de causer un

incendie ou une explosion.

Le tuyau d'alimentation dolt _tre _quip_ d'un robinet

d'arr_t approuv_. Ce robinet devrait _tre situ_ dans la

m_me piece que la plaque de cuisson et _ un endroit

permettant de I'ouvrir et de le former sans difficultY. Ne

bloquez pas I'acc_s au robinet d'arr_t. IIsort _ allumer ou

a former I'alimentation en gaz de I'appareil.

A la cuisini_re

Au tuyau

d'alimentation de

gaz naturel

Robinet R_gulateur

d'arr_t _ de pression

manuel Joint Joint

OuvertX_Ferm@ Tuyau souple

Tous los raccords doivent _tre serf,s _ la cb.

Raccordez le tuyau souple d'alimentation au r_gulateur

de pression en respectant I'ordre suivant:

1- robinet d'arr_t;

2- mamelon de 1/2";

3- adaptateur de 1/2";

4- tuyau souple de raccordement;

5- adaptateur de 1/2"

6- mamelon de 1/2"

7- r_gulateur de pression.

Utilisez du mastic _ joints de tuyaux pour assurer

I'_tanch_it_ des raccords de gaz naturel et de gaz de

p_trole liqu_fi_. V_rifiez que los tuyaux souples de

raccordement, s'il yen a, ne sont pas tordus.

Circulation du gaz

de

raccordement

Figure 7

Robinet d'arr_t

Figure 8

Ouvrez le robinet d'arr_t du tuyau d'alimentation de gaz

naturel. Attendez quelques minutes pour permettre au

gaz de se d_placer dans le tuyau d'alimentation.

V6rifiez qu'il n'y ait pas de fuites. La v_rification

pour los fuites dolt _tre faite solon los instructions du

manufacturier. Apr_s avoir raccord_ I'alimentation en

gaz a la plaque de cuisson, a I'aide d'un manom_tre

v_rifiez sile syst_me ne fuit pas. Si vous ne disposez pas

d'un manom_tre, ouvrez I'alimentation en gaz et utilisez

un liquide d_tecteur de fuites sur tous los joints et los

raccords.

l'"_\'i_;ii_"]'l_ul_il RISQUE D'INCENDIE. N'utilisez

pas de flamme nue pour v_rifier s'il y a des fuites aux

raccords de gaz naturel. La d_tection des fuites a I'aide

d'une flamme pourrait provoquer un incendie ou une

explosion.

Si n_cessaire, resserrez tousles raccords afin de

pr#venir los fuites de gaz dans la plaque de cuisson ou le

tuyau d'alimentation.

Apr_s avoir roll# la plaque de cuisson a I'alimentation en

gaz, v6rifiez I'alignement des robinets, afin de vous

assurer que le conduit de la rampe a gaz n'a pas _t_

d_plac_.

Lors de toute v_rification de pression du circuit _ une

pression sup_rieure _ 1/2Ib/po2 (3.5 kPa ou 14" C.E.),

d6branchez la plaque de cuisson et son robinet

d'arr6t individuel de I'alimentation en gaz.

Lors de toute v_rification de pression du circuit

d'alimentation en gaz a une pression inf_rieure ou _gale

a 1/2Ib/po2 (3.5 kPa ou 14" C.E.), isolez la plaque de

cuisson du r_seau d'alimentation en gaz en fermant son

robinet d'arr_t manuel.

25

Page 26

Branchez [e courant electrique a la

plaque de cuisson au gaz

Alimentation en electridte

Circuit de d_rivation de 120 volt, 60 Hertz, avec mise

la terre appropri_e, prot_g_ par un disjoncteur de

15 amperes ou un fusible temporis_. N'utilisez pas

de rallonge _lectrique pour brancher la plaque de

cuisson.

IMPORTANT Veuillez life attentivement.

Pour votre propre securitY, cet appareil doit Ctre

correctement mis a la terre.

Afin de r_duire au minimum les risques de chocs

_lectriques, le cordon d'alimentation de cet appareil est

muni d'une fiche de contact tripolaire (mise a la terre)

enfichable dans une prise de courant murale tripolaire

standard avec mise a la terre (Figure 9).

II est conseill_ de faire v_rifier la prise de courant murale

et le circuit par un _lectricien qualifi_, afin de s'assurer

que la prise de courant est correctement mise a la terre.

M_thode pr_f_r_e

Dans le cas ou il n'y a qu'une prise de courant murale

bipolaire standard, il incombe au client de la remplacer

par une prise de courant murale tripolaire correctement

mise _ la terre.

II est strictement interdit de couper ou d'enlever

la troisi_me tige (mise a la terre) du cordon

d'alimentation.

d'alimentation _lectrique de la prise de courant murale

avant de r_parer ou de nettoyer la plaque de cuisson.

PAS, sous aucu_

circonstance,couper,[

enleverou outrepasser[

latige deraisea la )

terre. /

Assurez-vous que

l'appareil est bien mis

la terre avant de l'utiliser

Figure 9

D_branchez le cordon

Emplacement des numeros de modele

et de serie

La plaque signai_tique est situ_e sous la plaque de

cuisson (voir la figure 10).

Pour toute commande de pi_ces ou demande de

renseignements, au sujet de la plaque de cuisson,

assurez-vous de toujours inclure les num_ros de module

et de s_rie, ainsi que le num_ro ou la lettre du lot de la

plaque signal_tique de votre plaque de cuisson.

Emplacement de la J- Figure 10

plaque signaletique

Verification du fonctionnement

R_f_rez-vous au Guide de I'utilisateur fourni avec votre

appareil pour le mode de fonctionnement et I'entretien

de votre plaque de cuisson.

Ne touchez pas aux br01eurs, lls peuvent _tre assez

chauds pour causer des br01ures graves.

1.Installation des couvercles de br0leurs

Cette plaque de cuisson est munie de br01eurs scell_s.

Toutes les pi_ces sont situ_es aux bons endroits. Enlevez

toutes les composantes d'emballage. Assurez-vous

que les couvercles de br01eurs sont bien en places et de

niveau. Leguide du couvercle de br01eur (Fig. 11) dolt

s'asseoir parfaitement au centre de la t_te du br01eur

et setenir _ niveau. R_f_rez-vous aux figures 12 et 13

pour le placement ad_quat des couvercles de br01eurs.

Une fois en place, vous pouvez v_rifier que le couvercle

est bien _ sa place en le glissant d_licatement d'un c6t_

I'autre (Fig. 14) pour s'assurer qu'il est bien centr_

et assit fermement. Lorsque le guide du couvercle fera

contact _ I'int_rieur de la t_te du br01eur, vous pourrez

le sentir. Notez que le couvercle du br01eur ne dolt pas

bouger du centre de la t_te du br01eur Iorsque vous

le glissez d'un c6t_ _ I'autre. NOTE: Aucun r_glage

de br01eurs n'est n_cessaire sur ce type de plaque de

cuisson.

26

Page 27

Couvercle de

br_leur

T_te de Rebord du

br_leur couvercle

de br6leur

Fig. 11

2. Placez les grilles sur la table de cuisson.

Assurez-vous que les grilles de br01eur sont plac_es

correctement _ I'int_rieur de la surface en acier inoxydable.

ATTENTION:Ne glissez pas les grilles sur la surface de la

table de cuisson, ceci pourrait endommager la surface.

ModUle 36" SEULEMENT:Assurez-vousque lesgrillessont aux

bons endroits tel qu'illustr_ plus bas.L'_cranthermique doit

_tre plac_autour desboutons de commande.

Couvercle install_

correctement =Fig. 12

Couvercle

incorrectement install_

=Fig. 13

lecran thermique

Fig. 15

3. V_rifiez les allumeurs

II faut v_rifier le fonctionnement des allumeurs

_lectriques apr_s que la plaque de cuisson et les raccords

du tuyau d'alimentation aient _t_ eux-m_mes v_rifi_s

relativement aux fuites et que la plaque de cuisson ait

_t_ branch_e _ la prise de courant.

Pour faire fonctionner le br01eur de surface :

A. Enfoncez et tournez la commande _ "LITE". Vous

entendrez un petit d_clic; c'est le bruit de I'allumeur

_lectrique qui allume le br01eur.

B. Apr_s I'allumage du br01eur, r_glez la flamme

I'intensit_ voulue. Lescommandes n'ont pas besoin

d'etre r_gl_es vis-a-vis d'un rep_re particulier. Utilisez

les rep_res comme guide et r_glez la flamme au

besoin.

27

Page 28

4.R#glezlaposition LOW ou SIMMER (Figure 16)

Enfoncez et tournez chaque bouton de commande

la position "LOW" (ou "SIMMER"). La position "LOW"

de chaque brOleur a #t# r#gl#e le plus bas possible pour

permettre un r#allumage faible du brOleur. S'il ne reste

pas allure# _ la position "LOW", v#rifiez le r#glage

comme suit:

A. Laissez refroidir la plaque de cuisson _ la temp#rature

de la piece.

B. Allumez tousles brOleurs en tournant chaque bouton

de commande _ "LITE" jusqu'_ ce que les brOleurs

s'allument, puis r#glez-les _ la position "HI".

C. Tournez rapidement le bouton de commande du

brOleur _ r#gler de la position "HI" _ la position

"LOW".

D. Si un brOleur s'_teint, r_glez le robinet comme suit:

Enlevez le bouton de commande du brOleuB ins@rez

un tournevis a lame fine dans I'axe creux du robinet,

et engagez-le dans la visa t@te fendue a I'int_rieur.

On peut augmenter ou diminuer la taille de la fiamme

en tournant la vis. R_glez la fiammejusqu'a ce que

vous puissiez tourner rapidement le bouton de la

position "HI" a la position "LOW" sans que la flamme

ne s'_teigne. La flamme devrait @treaussi faible que

possible et stable sans s'@teindre.

E. Si vous avez besoin de r_gler un autre brOleuB r@_tez

les @tapesA a D ci-ctessusjusqu'a ce que tousles

brOleursfonctionnent correctement.

Lorsque tous ies raccordernents sont

terrnines

V_rifiez que toutes les commandes sont _ la position arr_t.

Assurez-vous que la circulation de I'air pour la combustion

et la ventilation a la plaque de cuisson n'est pas obstru@s.

Avant d'appeler le service d'entretien

Consultez la liste des v_rifications preventives et les

instructions d'op_ration clans votre Guide de I'utilisateur.

Vous sauverez probablement du temps et de I'argent. La

liste contient les incidents ordinaires ne r_sultant pas de

d_fectuosit_s clans le materiel ou la fabrication de cet

appareil.

Pour obtenir notre adresse et notre num@ro de t@l@hone

r@f@rez-vous_ la garantie et aux renseignements sur les

services d'entretien dans votre Guide de I'utilisateur.

Pri@rede nous t@l@honer ou de nous @crirepour toute

demande d'information au sujet de votre appareil et/ou

si vous d@sirezcommander des pi@ces.

Axe creux

du robinet

o

Figure 16

28

Page 29

29

Page 30

30

Page 31

TOP BURNER IGNITER

OPTIONAL

OUENADOR DE ENCENDIDO SUPERIOR

OPCIONAL

BOUG[E D'ALLUMAGE-BRLILEUR

TOP BURNER IGNITER

OPTIONAL

OUEMAOOR DE ENCENOIDO SUPERIOR

OPCIONAL

BOUGIE D'ALLUMAGE-BRULEUR

FACULTATIF

--]

TOP BURNER [GNITER

OUEHADOR DE ENCEND I DO SUPER IOR

BOUGIE D'ALLUMAGE BRULEUR

TOP BURNER IGNITER

OUEMADOR DE ENCENDIDO SUPERIOR

BOUGIE D'ALLUMAGE-BRULEUR

sX

LI

i

E

i

E

l

_T

RIGHT REAR

BK I

IGNSW.

INTENCTRASERO

DERECHO

INTER, ALLUM.

D. AR

LEFT REAR

IGNSW

INTENC.TRASERC

[ZOU[ERDO

[NTER.ALLUM

GAR.

LEFT FRONT

[GN_SW_

INT,ENO. DE

FAENTE IZOUIERDO

INTERALLUM_

G. AV

RIGHT FRONT LEFT FRONT LEFT RFAR

[GNSW ]GNSW IGNSW

[NTENC. DE ]NTENO DE [NTE_C, TRASERO

FRENTE DERECHO FRENTE IZOUIERDO ]ZOUIERDO

INTERALLUM INTERALLUM. iNTER ALLUM

D, AV G.AV, GAR

i i

i i

i i

i i

i i

i i

i i

i i

CAUTION:

LABEL ALL WIRES PRIOR TO OIBBONNECTION WHEN SERVICING CONTROLS.

WIRING ERROR CAN CAUSE IMPROPER AND DANGEROUS OPERATION

VERIFY PROPER OPERATION AFTER SERVICING

AVISO:

ETIOUETE TODOS LOS ALANBRES ANTES DE DESCONECTAR PAR

REALIZAR ET MANTENIMIENTO OF LOB CONTROLES, ERROR DE

ALAMBRAJE PUEDE CAUSAR UN FUNCIONAMIENTO [NCORRECTO

Y PELIGROSOVERIOUE BI EL FUNC[ONAMIENTO ESTA

CORRECTO DESPUES DEL MANTENIMIENTO

AVERTiSSENENT:

ETIOUETER CHAQUE FIL AVAN- LE DEBRANCHEMENT DE CEUX-CIUNE ERREUR DE

BRANCHEMENT PEUT CAUSER UNE OPERATION DANGEREUSE. VERIFIER LE BON

FONCT!ONNEMENT DE L'APPAREIL APRES TOUTE REPARATION

RIGHT REAR

IGNBW.

iNT. ENCTRASERO

DERECHO

iNTERALLUH

D_AR

LU

li....

i i

i }

i }

RIGHT FRONT

IGNSW

INTENC DE

FRENTE DERECHO

INTERALLUH

OAV.

TOP BURNER IGNITER

OUEMADOR DE ENCENDiDO SUPERIOR

BOUGIE D'ALLUHAGE BRULEUR _ ......... _

_&B_LN5

DISCONNECT POWER BEFORE SERVICING UNIT

AVISO

DESCONECTE LA ENERGIA ANTES DE REALIZAR

EL MANTENIHIENTO DEL ELECTRODOMESTICO

AVERTISSEMENT

CCOPER LE COURANT AVANT O'EFFECTUEA LA

REPARATION,

COLOR CODE / CCOIGOS DE COLOR / CODE COULEUR

_H]]_- 7 BLANCO 7 BLANC

BLACK / NEG_aO / NOIR

GROUND _!

PUESTA A TIERRA

MISE A LA TERRE

POWER CORD

PARA TRANSPORTE

DE FUERZA

CABLE

D'ALIMENTATION

2 18 200

/ 20 150

WIRE GAGE

ALAMBRE MEDIDA TEHP._C

FIL CAb

EMPALME

CONNECTEUR

i] CONNECTOR

3304

3321

STYLE UL

TOP BURNER IGNITER

OUEMADOR DE ENCENO]DO SUPERIOR

BOUG!E D'ALLUMAGE-BRULEUR _

TOP BURNER IGNITER

QUEMAOOR DE ENCENDIOO SUPERIOR

BOUGIE D'ALLUMAGE BRULEUR _3_

TOP BURNER IGNITER

QUEMADOR DE ENCENOIO0 SUPERIOR

BOUGIE D'ALLUMAGE-BRULEUR

--C) 0 LO

_t 14) 0 NO

IGNITER MODULE BOARD

CUAORO DE MODULO DE ENCENOIDO

BLOC CONNECTION ALLUMEUR

5180471 1I AEV.B

Page 32

!OP BURNFR !GN [ TFq

QUEHADOR DE ENC ND]DO SUP R]OR

BOUG[E D" ALLUHAGE BRULEUR

OUEHADOR DE ENCENDiDO SUPERIOR

BOUGiE D'ALLUHAGE BBULEUR

TOP BURNER ]GN}TER

i

OUEHAOOR BE ENCENDiDO SUPERIOR

BOUGIE D'ALLUNAGE-BRULEUR

TOP BURNER iGNITER _/_](]\ E

TO URNER ION [ T!:R

OUEVADOR DE ENCEND]OO SUPER OR

BOUG I D" AI.I.UHAOE BRULEUR

iGNSW

iNTENCTRASERO

DERECHO

t IGHT REAR

iNTERALLUH

BAR

GN SW

'NT ENC TRASERO

ZOU '_ERDO

I LEFT BEAR

NTER ALLUH

GAR

R ,I

IGNSW

INTENC DE

FRENTE ]ZQUiE_DO

I EFT FRONT

]NTERALLUM

OAV

CAUTI_;

LABP_ ALL WiRmS PRIOR TO DiSCONNFCTJON WHEN SERVICING CONTROLS•

WIRING ERROR CAN CAUSE IMPROPER AND DANGEROUS OPERATION

VERIFY PROPER OPERATION AFTER SERVICING

AVlSO:

ETIOUEmE ?ODDS LOS ALAMBBES ANTES DE DESCONECTAR PAB

REALiZAR ET MANTENiHIENTO DE LOS CONTROLESERROR DE

ALAMBRAJE °UED _ CAUSAR UN FUNCIONAM]ENTO [NCORRECTO

Y PEIGROSOVFRiQUE SI =} FUNCIONAH]ENTO ESTA

CORRECTO DESPUES DEL MANTENIHIENTO

L1

AVERTISSEMENT;

ETIOUE_ER CHAOuE FiL AVANT LE DEBRANCHEHENT DE CEUX C]UNE ERREUR DE

BRANCHEHENT PEUT CAUSER UNE OPERATION DANGEREUSEVER/FleR LE BON

FDNCTIONNEMENT DE L'APPAREiL APRES TOUTE REPARATION

CENTRE REAR RIGHT FRONT

[ONSW iGNSW

INTENC CENTRO iNTENC DE

TRASERO FRENTE DERECHO

INTERALLUM iNTERALLUN

CAR DAV

_EFT FRONT LEFT REAR RIGHT REAR

]GNSW [ONSW ]ONSW

INTENC DE [ NT¸eNC¸TRABERO INTENCTRASEAO

FRENTE IZOUiERDO IZOUIERDO OERECHO

INTERAL_UM INTPRALLUM /NTERALLUH

OAV OAR DAR

'OP BUNR IGNI I

QUEHADOR DE ENCEND DO UPER]OR

LO

bJ

BOUGIE D' ALLU AGE BRULEUR

(_ LO •

R-4

L

_GNSW

iNTENC DE

FRENTE DERECHO

RIGHT FRONT

iNTERALLUH

DAV

]GNSW

]NT ENC CENTRO

TRASERO

]NTERALLUM

CENTRE REAR

CAR

m

/

JGN ER HODXE BOARD

CUADRO DE MODULO DE ENCEND',DO

BLOC CONNEC1 ON ALLUMEUR

WARNING

DISCONNECT POWER BEFORE SERVICING UNiT

AVISO

DEBCONECTE LA ENEBQIA ANTES DE REALIZAR

EL HANTeN]H ENTO DFL ELECTRODO FST ',CO POWER CORD

O SCON EC1 POWFR _3Er ORE DERV ]C ] NGUN _T PARR TRANSPORTE

AVER SSe PNT DE _UERZA

COUPER LE COURANT AVANT D' FECTUER LA CABE

F1PANAI,0N D" A ]HENTAT,O

W'i? ::GAG UL STYL! COLOR CODE / COD GOB E COLOR

AAMBR_MEDOA/_Er_r'_c/MO_OU J ...................

Tv ....0 ..uu L;_

GROUND

PUES_A A T]ERRA

HBE A LA TERRE

CONNECTOR

EHPALME

CONNECTEUR

TOP BURNFR ]GN TER

QUEHADOR DE ENCEOI DO SUPER] OR

BOUG E ©" ALLUMAGE-B;_ULEUR

NOTE:

SERV ICE : F REPLACEMENT OF TERM INALS BECOMES NECESSAR v, COMPARABLE W IRE TYPE AND

GAGE AND CON ARA LE TE;_MINALS MUST E USED

NO1A :

EN CASO OUE SEA NECESAR]O O REMPi. AZAR LOS BORNES, S N CEBAR O DE {T L:: AR

EL HISMO T':PO DE ALAMBRE v DE MEDIDOR v EL MlSMO T_:O DE BORNES

NOT e :

SERV/CE:S DeS F]LS OU DES COSSES DO]VENT ETR_ RENPLACES, UT L SEZ DES P ECES

DE CA', BRE ET DE TYPES EOUIVALENTS

e

-_..}

IGNITER MODULE BOARD

--I N C

CUADRO DE HODULO DE ENCENDIDO

BLOC CONNECiiON ALLUNEUR

i 318047112 REV. A

Loading...

Loading...