Use Care Guide

Gu_a de Uso y Cuidado

Guide d'utilJsation et d'entretien

Thank you for choosing EJectrolux, the new premium brand in home appliances.

This Use & Care Guide is part of our commitment to customer satisfaction and

product quality throughout the service life of your new ice maker.

We view your purchase as the beginning of a relationship. To ensure our ability to

continue serving you, please use this page to record key product information.

Once you have your unit installed, we suggest you keep this manual in a safe

place for future reference. Should any problems occur, refer to the

Troubleshooting section of this manual. This information will help you quickly

identify a problem and get it remedied. In the event you require assistance, please

contact the dealer where you purchased your unit.

MAKEA RECORDFOR@UCKREFERENCE

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

Whenever you call to request information or service, you will need to know your

model number and serial number. You can find this information on the serial plate

located on the inside wall of your unit and on the product registration card.

@2004 EJectrolux Home Products, Inc.

Post Office Box 212378, Augusta, Georgia 30917, USA

All rights reserved. Printed in the USA

information

IPBODU BEG S ATION6£

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

The package containing this manual also includes your product registration

information. Warranty coverage begins at the time your Ebctrolux ice maker was

purchased.

Phase record the purchase date of your Electrolux unit and your dealer's name,

address and tebphone number.

Purchase Date

Eiectrolux Model Number

Electrolux Serial Number

Dealer Name

Dealer Address

Dealer Telephone

Keep this manual and the sales receipt together in a safe place for further

refe re nce.

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

For tolPfree telephone support in the U.S. and Canada:

1-877- 4ELECTROLUX (1-877-435-3287)

For online support and lnternet product information:

www.eleetroluxusa.eorn

TABLEOIF'CONN

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

Finding Information ...........................................2

PleaseReadAndSaveThisGuide...................2

MakeARecordForQuickReference................2

WarrantyRegistrationCard...............................3

Questions?........................................................3

TableOfContents..............................................4

Safety ...................................................................5

ImportantSafetyInstructions..............................5

Installation ..........................................................7

InstallationDimensions.......................................7

Draininstallation................................................8

Drain PumpConnection...................................10

Site Preparation.................................................11

Water Supply Connection ...............................13

Leveling .............................................................15

Door Reversal....................................................16

DoorAdjustment ...............................................18

Built-in Installation ..........................................20

Start-up ..............................................................21

NormalOperation..............................................22

iceCubeThickness.........................................22

iceDispsenserOperationandCare ................23

Maintenance......................................................25

SpecialConsiderations....................................25

MaintainingandCleaning................................25

ExteriorCleaning............................................25

StainlessSteelModels.....................................25

InteriorCleaning..............................................26

CondenserCleaning.......................................27

SelfCleaning...................................................28

InletScreenCleaning......................................29

Storage, Vacation and Moving ........................30

Troubleshooting ...............................................31

ifServiceIsRequired......................................32

Warranty Information .......................................33

IIM £NT S£F Y IINS U _ONS

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

Safety Precautions

Do not attempt to install or operate your unit until you have read the safety

precautions in this manual. Safety items throughout this manual are labeled with a

Danger, Warning or Caution based on the risk type.

Definitions

A This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

GeneramPrecautions

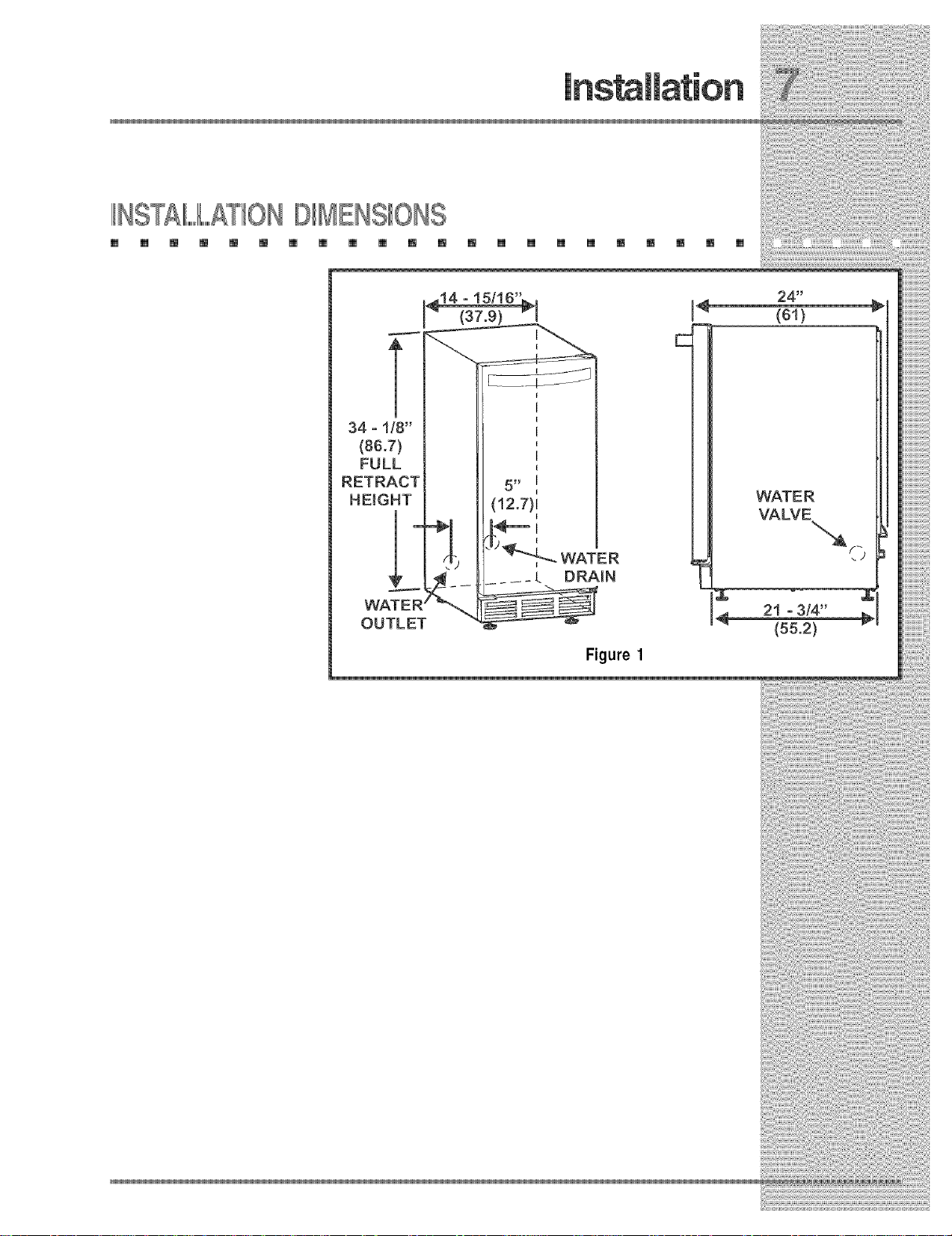

IINSTAII,,,,,,,,,,_,,,,,,,,,,AT_OND_MENS_ONS

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

34 =!/8"

(86.7)

FULL

RETRACT

HEIGHT

(81)

WATER

VALVE

WATER

OUTLET

WATER

DRAIN

Figure 1

"_o

21 =3/4"

(55.2) v

THE£1N

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

Model E151M60E can be installed using a gravity drain or can use a factory installed

or equivalent drain pump.

Follow these guidelines when installing drain lines to prevent water from flowing

back into the ice maker storage bin and/or potentially flowing onto the floor causing

water damage:

GravityDrain

• Drain lines must have a 5/8 inch inside diameter.

• Drain lines must have a 1 inch drop per 48 inches of run (1/4 inch per foot) and

must not create traps.

• The floor drain must be large enough to accommodate drainage from all

drains.

• Insulate the bin drain line to prevent condensation.

raceMakersWith Factory mnstaHedDrain Pump

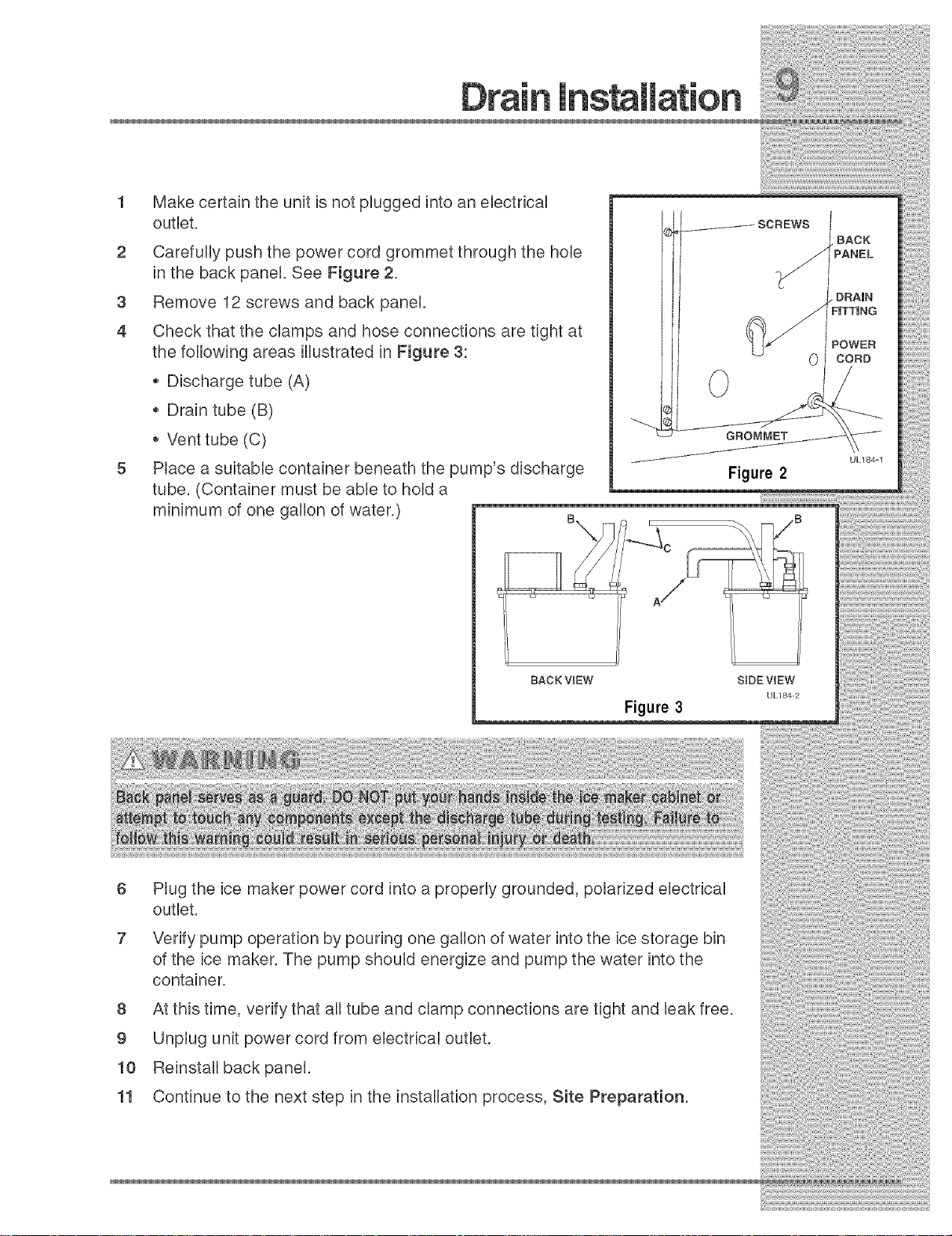

1 Make certain the unit is not plugged into an electrical

outlet.

2 Carefully push the power cord grommet through the hole

in the back panel. See Figure 2.

3 Remove 12 screws and back panel.

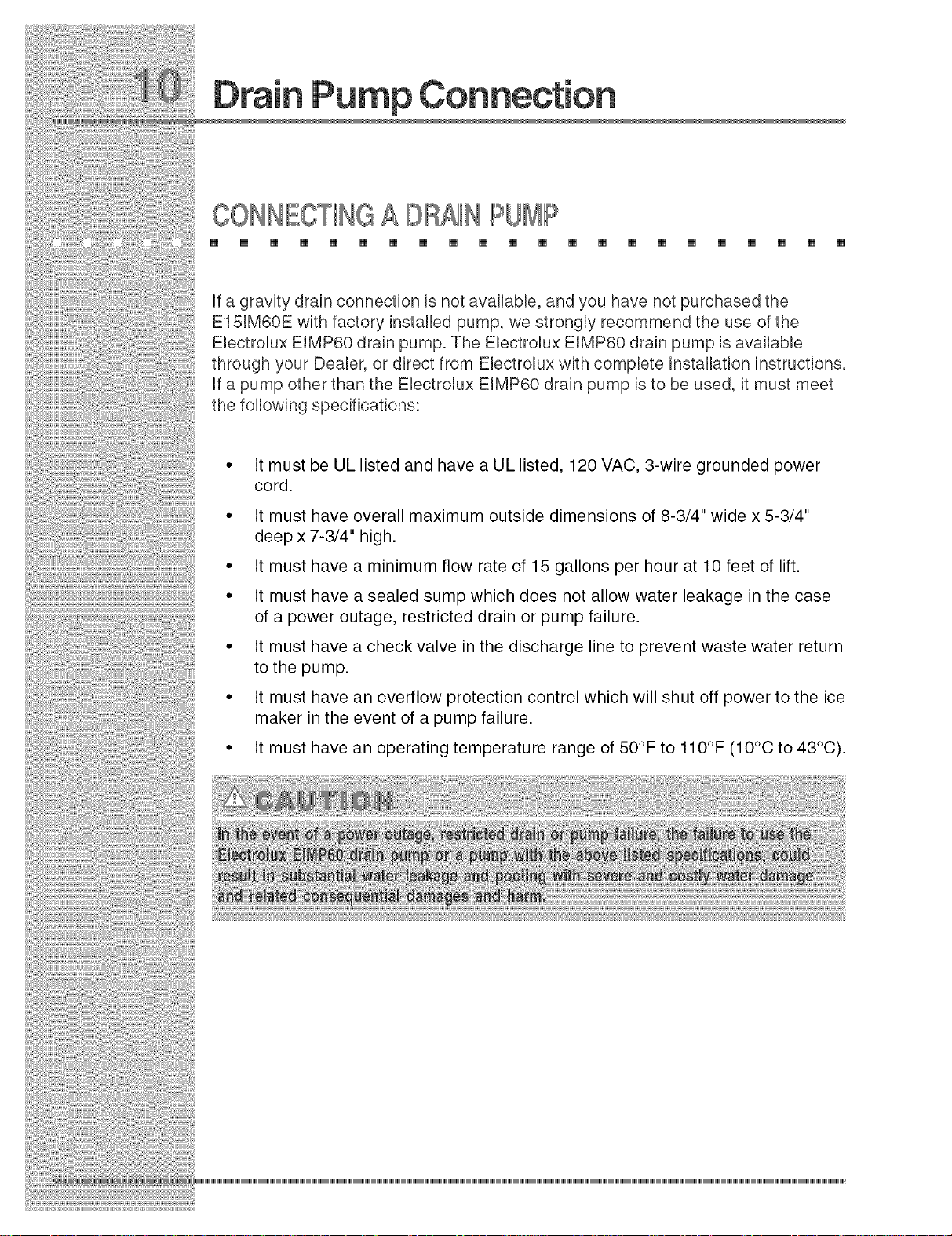

4 Check that the clamps and hose connections are tight at

the following areas illustrated in Figure 3:

Discharge tube (A)

,, Drain tube (B)

,, Vent tube (C)

5 Place a suitable container beneath the pump's discharge

tube. (Container must be able to hold a

minimum of one gallon of water.)

BACK

PANEL

DRAIN

FiTTiNG

POWER

CORD

GROMMET

UL184=1

Figure 2

BACK VIEW

Figure 3

Plug the ice maker power cord into a properly grounded, polarized electrical

outlet.

Verify pump operation by pouring one gallon of water into the ice storage bin

of the ice maker. The pump should energize and pump the water into the

container.

8 At this time, verify that all tube and clamp connections are tight and leak free.

9 Unplug unit power cord from electrical outlet.

10 Reinstall back panel.

11 Continue to the next step in the installation process, Site Preparation.

SDE ViEW

UL184_2

CONNE £ DR£11NPUMP

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

If a gravity drain connection is not availabb, and you have not purchased the

E15JM60E with factory installed pump, we strongly recommend the use of the

Eiectrolux EJMP60 drain pump. The Eiectrolux EIMP60 drain pump is available

through your Dealer, or direct from Ebctrolux with compbte installation instructions.

If a pump other than the Ebctrolux EIMP60 drain pump is to be used, it must meet

the following specifications:

• It must be UL listed and have a UL listed, 120 VAC, 3-wire grounded power

cord.

• It must have overall maximum outside dimensions of 8-3/4" wide x 5-3/4"

deep x 7-3/4" high.

• It must have a minimum flow rate of 15 gallons per hour at 10 feet of lift.

• It must have a sealed sump which does not allow water leakage in the case

of a power outage, restricted drain or pump failure.

• It must have a check valve in the discharge line to prevent waste water return

to the pump.

• It must have an overflow protection control which will shut off power to the ice

maker in the event of a pump failure.

° It must have an operating temperature range of 50°F to 110°F (10°C to 43°C).

IP PAB NGT SITE

[] [] [] [] m m [] [] [] [] m [] m [] [] [] [] m m m m []

1 Position the unit on a flat, level surface, capable of supporting the entire

weight of the unit. Remember that the unit will be significantly heavier once it

is fully loaded.

2 The surrounding air temperature must be at least 50°F (10°C) but must not

exceed 110°F (43°C).

3 The unit must not be located near heat-generating equipment or in direct

sunlight.

4

The unit must be located to allow clearance for water, drain and electrical

connections in the rear of the ice maker.

5

Connect the unit to a grounded and polarized 115 VAC, 60 Hz, 15 A circuit

(normal household current).

6

Avoid connecting the unit to a Ground Fault Interruptor (GFI). GFIs are prone to

nuisance tripping which will cause the unit to shut down. GFIs are generally not

used on circuits which power equipment that must run unattended for long

periods of time.

The unit must be installed according to your local codes and ordinances.

Figure4

6 Install and connect the water supply line. See

Connecting the Water Supply for installation

requirements.

7 Position the unit to allow free air flow through the

front grille (see Figure 6).

8 Wipe out inside of unit with a damp cloth.

0"

CLEARANCE

NEEDED

UL124A

WALL

2 * 3/4"

CLEARANCE

NEEDED

Figure 5

EXHAUST Figure 6 _NTAKE

Whenconnectingthewatersupply,followtheseguidelines:

ReviewthebcaUplumbingcodesbeforeyouinstaUltheunit.

Thewaterpressureshouldbebetween20 and120psi.

MakecertainaSHUT-OFFVALVEis

instaUledinthe 1/4inchwatersupplyHne.

Connectsufficienttubingtotheunittoallow

theunitto bemovedforcleaningand

servicing.However,makecertainthatthe

tubingisnotpinchedordamagedduring

installation.

Ebctroluxrecommendsthe useof copper

tubingforinstallation.

WATER

CONNECTmON

Figure 7

ULI03 CO

Figure8

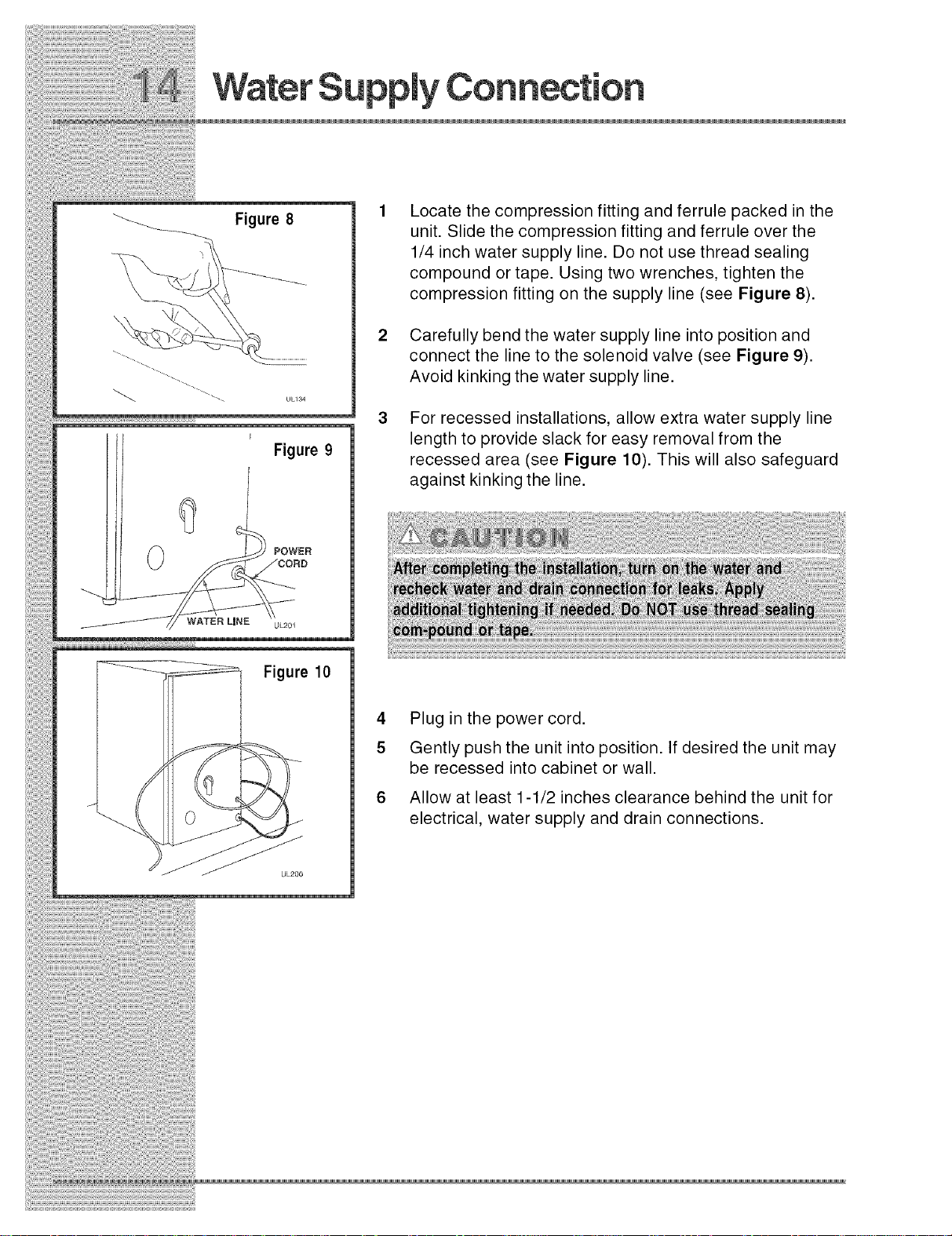

Locate the compression fitting and ferrule packed in the

unit. Slide the compression fitting and ferrule over the

1/4 inch water supply line. Do not use thread sealing

compound or tape. Using two wrenches, tighten the

compression fitting on the supply line (see Figure 8).

\

Carefully bend the water supply line into position and

connect the line to the solenoid valve (see Figure 9).

Avoid kinking the water supply line.

% . UL134

For recessed installations, allow extra water supply line

F

Figure 9

length to provide slack for easy removal from the

recessed area (see Figure 10). This will also safeguard

against kinking the line.

POWER

WATER LiNE UL201

Figure 10

UL200

4 Plug in the power cord.

5 Gently push the unit into position. If desired the unit may

be recessed into cabinet or wall.

6 Allow at least 1-1/2 inches clearance behind the unit for

electrical, water supply and drain connections.

IILEV T UNiT

[] [] m m m m [] [] [] [] [] [] m [] [] [] [] m [] m m []

Use a ReveUto check the ReveUnessof the ice maker

from front to back and from side to side (see Figure

11).

tf the ice maker is not bveU, adjust the feet on the

corners of the unit as necessary (see Figure 12).

Check the bvelness after each adjustment and

repeat the previous steps until the unit is bveL

Figure 11

Figure 12

Figure 13

REVERSINGTHEBOOR(SOMEMO ILLS}

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

AH EbctroUux units may be bft or right hand opening. The door

opening is easily reversed by moving the hinge hard-ware to the

opposite side (see Figure 13).

To reverse the door:

1 Remove top hinge screw pin (7/64" AUUenwrench) from

cabinet (see Figure 14). Remove door by tilting forward

and Rifting off bottom hinge pin.

\

2 Remove pUastb screw plugs (3 top and 3 bottom) from

new hinge location (see Figure 15), and remove hinge pin

hole plug in top of door (see Figure 16). Do not discard.

J

Figure 14

SCREW

PLUGS

Figure 15

Figure 16

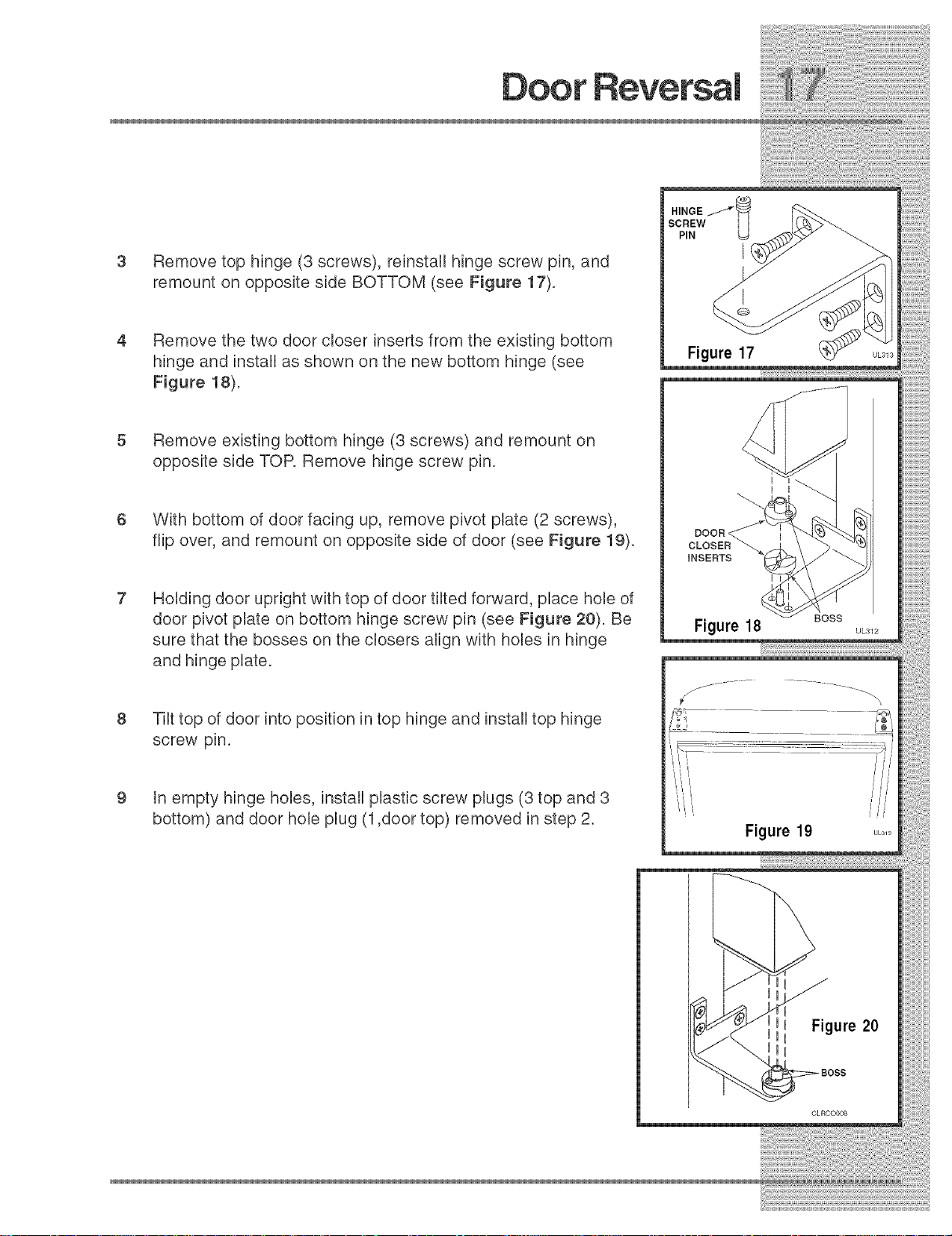

Remove top hinge (3 screws), reinstall hinge screw pin, and

remount on opposite side BOTTOM (see Figure 17).

HINGE _"_

SCREW I I

PiN _=_

i

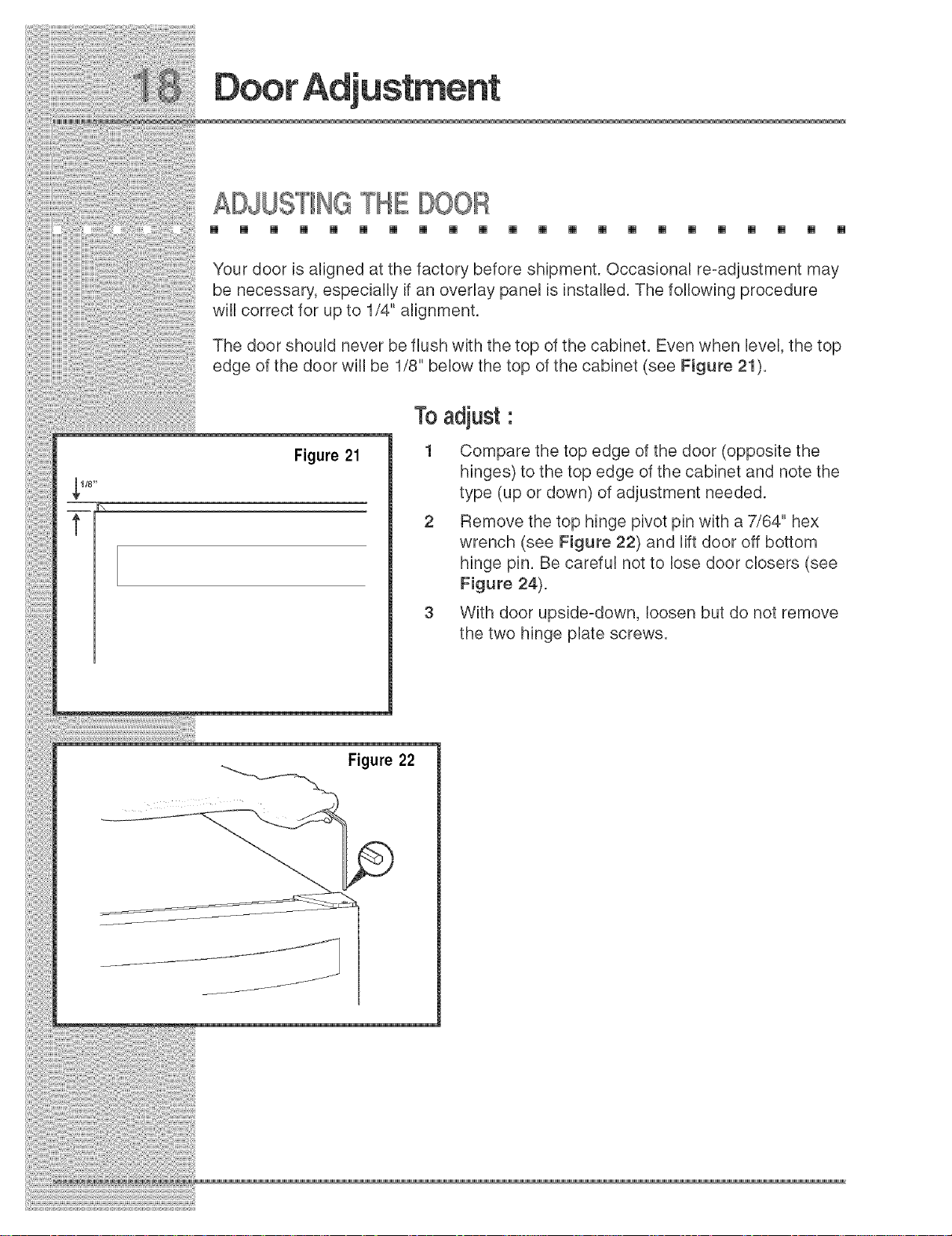

Remove the two door cioser inserts from the existing bottom

hinge and instali as shown on the new bottom hinge (see

Figure 18).

Remove existing bottom hinge (3 screws) and remount on

opposite side TOP. Remove hinge screw pin.

With bottom of door facing up, remove pivot plate (2 screws),

flip over, and remount on opposite side of door (see Figure 19).

Holding door upright with top of door tiited forward, piace hole of

door pivot plate on bottom hinge screw pin (see Figure 20). Be

sure that the bosses on the closers align with holes in hinge

and hinge plate.

Tilt top of door into position in top hinge and instali top hinge

screw pin.

Figure 17

i

tn empty hinge holes, instali plastic screw plugs (3 top and 3

bottom) and door hole plug (1,door top) removed in step 2.

Figure 19

CLROO008

£DJUST NGTHEOB

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

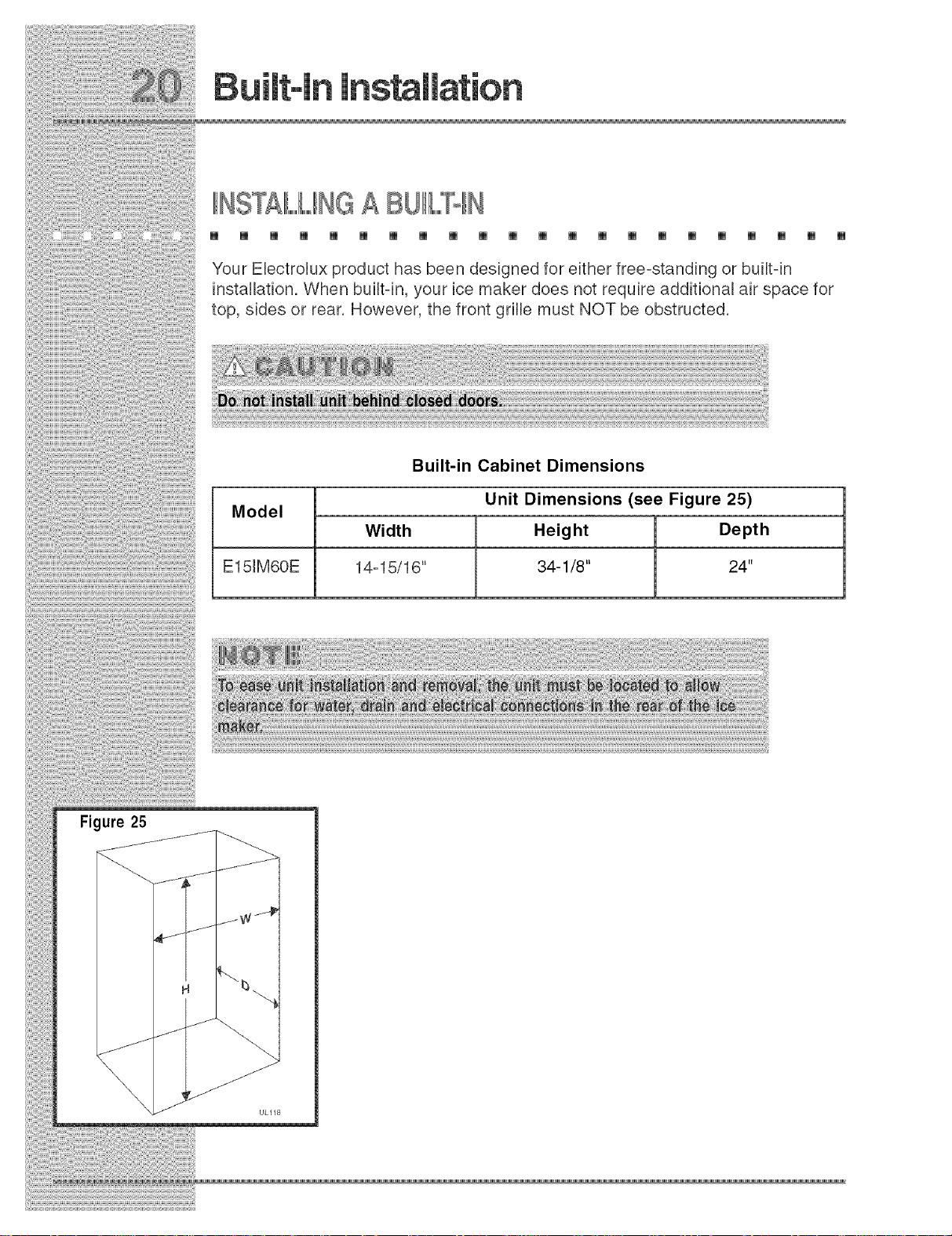

Your door is aligned at the factory before shipment. OccasionaU re=adjustment may

be necessary, especially if an overlay paneU is installed. The following procedure

will correct for up to 1/4" alignment.

The door shouUd never be flush with the top of the cabinet. Even when bveU, the top

edge of the door wiIRbe 1/8" below the top of the cabinet (see Figure 21).

Toadjust :

,_1/8"

t

Figure 21

Figure 22

1 Compare the top edge of the door (opposite the

hinges) to the top edge of the cabinet and note the

type (up or down) of adjustment needed.

2 Remove the top hinge pivot pin with a 7/64" hex

wrench (see Figure 22) and lift door off bottom

hinge pin. Be careful not to lose door closers (see

Figure 24).

3 With door upside-down, loosen but do not remove

the two hinge plate screws.

f

4 tf door edge opposite the Nnges needs to

move up, move plate toward outside of

door. tf door edge needs to move down,

move plate toward inside of door (see

Figure 23). Repeat until top edge of door is

parallel with top of cabinet and tighten

screws securely.

5 After adjustment is complete, remove the

door closers from the bottom hinge, clean

thoroughly and apply petroleum jelly to the

mating surfaces of the closers (see

Figure 24). Be sure that bosses on closers

align with holes in Mnge and hinge plate.

Mount door and install top hinge pivot pin.

MOUNTING _ IS NOTCH

HOLES _

RAISE _ LOWER

OUTSIDE OUTSIDE

DOOR EDGE DOOR EDGE

CLRCOOOla

DOOR

BOSS

Figure 24 UL3_2

£

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

Your Electrolux product has been designed for either free-standing or built4n

installation. When built=in, your ice maker does not require additional air space for

top, sides or rear. However, the front grille must NOT be obstructed.

Built-in Cabinet Dimensions

Model

Width Height Depth

E151M60E 14=15/16" 34-1/8" 24"

Unit Dimensions (see Figure 25)

IINmAL,,,,,A

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

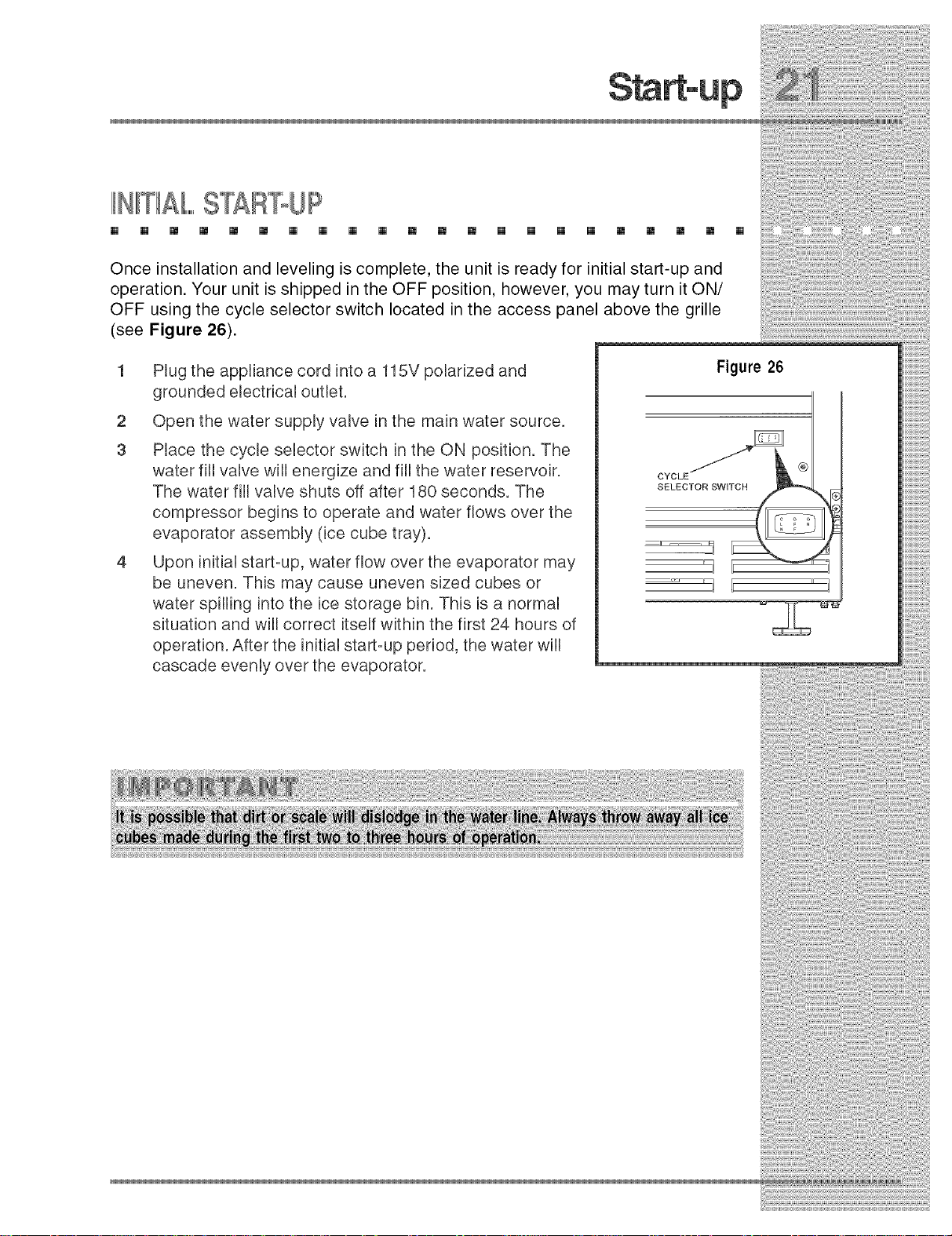

Once installation and leveling is complete, the unit is ready for initial start-up and

operation. Your unit is shipped in the OFF position, however, you may turn it ON/

OFF using the cycle selector switch located in the access panel above the grille

(see Figure 26).

1 PRugthe appliance cord into a 115V polarized and

grounded electrical outlet.

2 Open the water supply valve in the main water source.

3 PRace the cycle selector switch in the ON position. The

water fiIRvalve wifl energize and fill the water reservoir.

The water fill valve shuts off after 180 seconds. The

compressor begins to operate and water flows over the

evaporator assembly (ice cube tray).

4 Upon initial start=up, water flow over the evaporator may

be uneven. This may cause uneven sized cubes or

water spilfing into the ice storage bin. This is a normal

situation and will correct itself within the first 24 hours of

operation. After the initial start=up period, the water will

cascade evenly over the evaporator.

Figure 26

CYCLE

SELECTOR SWITCH

NORMAILOPER£T ON

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

The ice maker is designed to make clear ice from most water sources on a

consistent basis. Water is constantly circulated over the evaporator assembly. As

the water freezes, gravity causes any sediment to drop into the water trough and

not become imbedded in the ice. This gives a clearer ice cube with a low mineral

content. When the ice reaches the desired thickness, it falls off the evaporator and

into the storage bin. The cycle is then repeated. When the level of ice reaches the

top of the storage bin the unit shuts off. As the ice level in the bin drops the unit will

automatically restart to keep the bin full. Your unit's ice production rate may vary

depending on many considerations. Ambient air temperatures, water

temperatures, condenser cleanliness and ice-maker cleanliness are all

contributing factors to how quickly the unit produces ice. Certain sounds are

normal during the unit's operation. You may hear the compressor or fan motor, the

water valve, the water circulation pump or ice dropping into the ice storage bin.

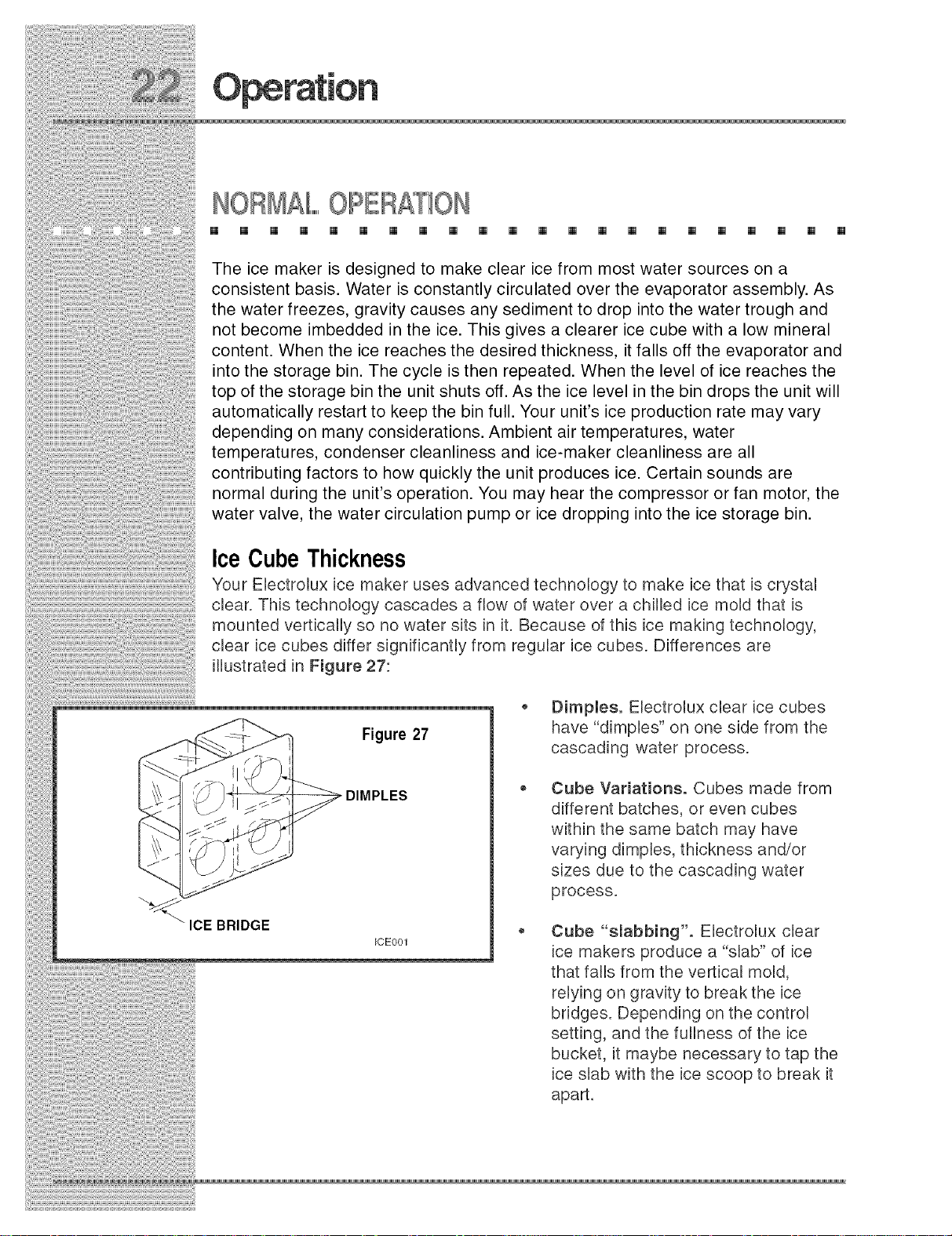

Ice Cube Thickness

Your Ebctrolux ice maker uses advanced technology to make ice that is crystal

clear. This technology cascades a flow of water over a chilled ice mold that is

mounted vertically so no water sits in it. Because of this ice making technology,

clear ice cubes differ significantly from regular ice cubes. Differences are

illustrated in Figure 27:

Figure 27

ICE001

Dimpieso Electrolux clear ice cubes

have "dimples" on one side from the

cascading water process.

Cube Variations. Cubes made from

different batches, or even cubes

within the same batch may have

varying dimples, thickness and/or

sizes due to the cascading water

process.

Cube "slabbing'. Ebctrolux clear

ice makers produce a "slab" of ice

that falls from the vertical mold,

relying on gravity to break the ice

bridges. Depending on the control

setting, and the fullness of the ice

bucket, it maybe necessary to tap the

ice slab with the ice scoop to break it

apart.

liCEDISPENSEROPERATION& CARE

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

The be cube thbkness control is factory set for best overall performance. The

factory setting is designed to

maintain an be bridge of

approximately 1/16" to 1/8" under

normal conditions resulting in a

dimple of approximately 1/4" to 1/2"

in depth (see Figure 28). A fuller

cube with less of a dimple results in

a thicker ice bridge. As the ice bridge

becomes thicker, the tendency for

the cubes to stay together as a slab

increases. A bridge thicker than 1/8"

may cause cubes to over-fill the ice

bucket.

GOOD

Figure 28

1/16" TO 1/8"

ICE BRIDGE

DIMPLE _\ LITTLE OR //

TOO DEEP \\ NO DIMPLE /

BRIDGE BRIDGE

TOO THIN TOO THICK

BAD

To adjust:

1 Disconnect power to the unit.

2 Remove the screws securing the

front access panel (see Figure 29).

Figure 29

Figure 30

I

DIAL IS

FACTORY

SET AT"O"

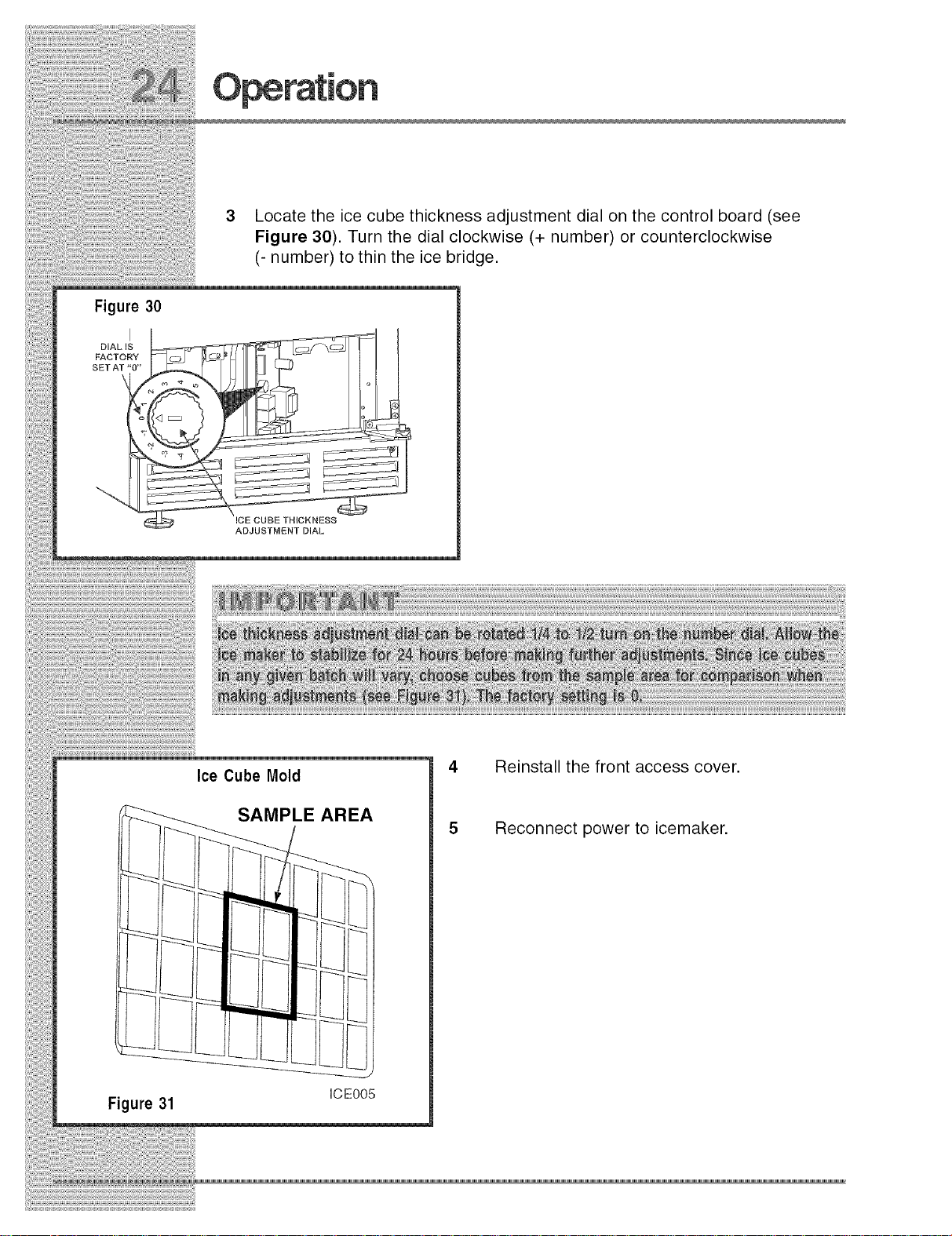

3 Locate the ice cube thickness adjustment dial on the control board (see

Figure 30). Turn the dial clockwise (+ number) or counterclockwise

(- number) to thin the ice bridge.

ICE CUBE THICKNESS

ADJUSTMENT DIAL

_!i !!_i_i!i!_i_i!ii!_i_!_!_i_i!!i!_i!;_i_i!_!i!i!i_!_!i_!_!!i_!_!i_!_i!_!_!i_!_!i!_i_!_!i_i_i!i_i!_!_i_ii_i!_ii_!_i_i!_i_!_i_i!iiiii!iiii!iiiii!iiii!iiiii!iiii!iiiii!iiii!iiiii!iiii!iiiii!iiii!iiiii!iiii!iiiiiii!iiil;ii!iiii!iii!iiiiiiiiiii!iiiili!ii!iii!i!ii!i

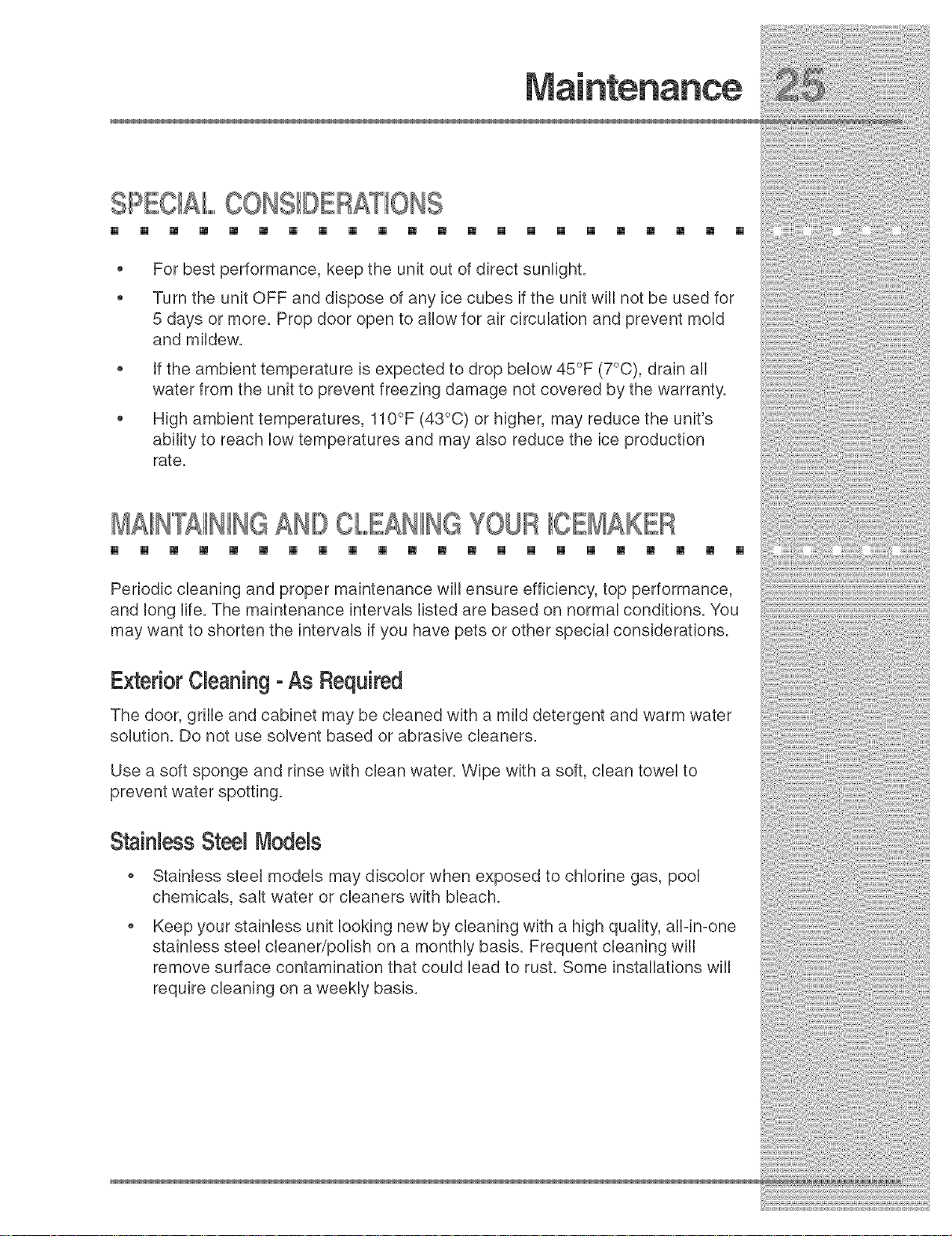

Figure 31

Ice Cube Mold

SAMPLE AREA

Reinstall the front access cover.

Reconnect power to icemaker.

ICEO05

SPECiAl,,,,,,,,,,CONSDERATIONS

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

For best performance, keep the unit out of direct sunlight.

Turn the unit OFF and dispose of any be cubes if the unit will not be used for

5 days or more. Prop door open to allow for air circulation and prevent mold

and mildew.

tf the ambbnt temperature is expected to drop below 45°F (7°C), drain all

water from the unit to prevent freezing damage not covered by the warranty.

High ambient temperatures, 110°F (43°C) or higher, may reduce the unit's

ability to reach low temperatures and may also reduce the ice production

rate.

MAINTAININGANDCLEANIINGYOUR CEMAKEB

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

Periodic cleaning and proper maintenance will ensure efficiency, top performance,

and long life. The maintenance intervals listed are based on normal conditions. You

may want to shorten the intervals if you have pets or other special considerations.

ExteriorCleaningoAs Required

The door, grille and cabinet may be cleaned with a mild detergent and warm water

solution. Do not use solvent based or abrasive cleaners.

Use a soft sponge and rinse with clean water. Wipe with a soft, clean towel to

prevent water spotting.

StainlessSteel Models

• Stainbss steel models may dbcolor when exposed to chlorine gas, pool

chembab, salt water or cleaners with bleach.

• Keep your stainless unit looking new by cleaning with a high quality, alPin-one

stainless steel cleaner/polish on a monthly bash. Frequent cleaning will

remove surface contamination that could lead to rust. Some installations will

require cleaning on a weekly basis.

®

DO NOT CLEAN WITH STEEL WOOL PADS.

o

DO NOT USE CLEANERS THATARE NOT SPECIFICALLY INTENDED FOR

STAINLESS STEEL (this includes glass, tile and counter cleansers).

tf any surface discolors or rusting appears, clean it quickly with Bon-Ami or

Barkeepers Friend Cleanser and a non-abrasive cloth. Always clean in the

direction of the grain. Always finish this process with a high quality, aINn-one

stainless steel cleaner/polish to prevent further problems.

,, USE OF ABRASIVE PADS SUCH AS SCOTCHBRFE WiLL CAUSE THE

GRAINING tN THE STAINLESS TO BECOME BLURRED.

Rust that is allowed to linger can penetrate into the surface of the stainless

steel and become impossible to remove.

mnteriorCleaningoAs Required

1 Disconnect power to the ice maker.

2 Open the door and remove any ice from the storage bin.

3 Wipe down the interior and storage bin with a solution of non-abrasive mild

soap or detergent and warm water. Rinse with clean water.

4 Sanitize the bin with a solution of 1 tablespoon of bleach in 1 gallon of warm

water. Rinse thoroughly with clean water.

5 Check that all drain connections are in place.

6 Reconnect power to the unit.

CondenserCleaning-- Every3 Months

To maintain operational efficiency, clean the condenser every three months

(depending on environmental conditions, more or less frequent cleaning may be

necessary).

To remove and replace the grille for access to

the condenser fins follow this procedure (see

Figure 32):

1 Remove the screws at each end of the

grille.

2 Remove the grille.

Figure 32

CONDENSER

Clean the condenser coil using a brush with a "combing" action, or a vacuum

cleaner. Do not touch the condenser coil.

4

Position the grille to align the screw holes with the cabinet.

5

Insert the grille screws and tighten. Do not over tighten.

Sdf Cleaning-- Every6 Months

To maintain operational efficiency, clean the unit every six months (depending on

water conditions more or lees frequent cleaning may be necessary), if the ice

maker requires more frequent cleaning, consult a qualified plumber to test the

water quality and recommend appropriate treatment.

Ice machine cleaner is used to remove lime scale and other mineral deposits.

Refer to the following steps for mineral deposit removal.

1 Set the cycle selector switch to OFF and allow the ice

to melt off of the evaporator.

J / F

2 Remove all ice from the storage bin.

3 Remove inside front cover (see Figure 33).

FRONT

COVER

Figure 33

Removetheoverflowtubebyliftingit upwhileusinga

slightbackandforthmotionto loosenitfromthe drain

hole(seeFigure34).Thewaterinthereservoirwillflow

downthe drain.

Replacetheoverflowtubeafterallofthewaterhas

drainedfromthe reservoir.

6

MovethecycleselectorswitchtotheCLNposition.

7

Whenwaterbeginstoflowoverthe evaporator

(approximately3 minutes),addonepackageof Electrolux

ice MacNneCleanertothewaterreservoir.

8

Reinstallinsidefrontcover.

9

Whentheself-cleaningprocessstops(approximately45

minutes)it maybedesirableto cleanthestoragebinat

tMstime (seeInterior Cleaning).

10

MovethecycleselectorswitchtotheiCE/ONpositiontoresumeice

production.

InletScreenCleaning-- EveryYear

The solenoid valve inlet screen must be cleaned at least once each year as

follows:

Figure 34

UL209a

1 Shut off the water at the water supply valve.

Figure 35

2 Pull the unit out to access the back panel (see

Figure 35).

3 Disconnect electrical power to the unit.

4 Disconnect the entire hose connector from the water

solenoid valve (see Figure 35).

5 Use a tooth brush to clean sediment from the inlet

screen. DO NOT remove the screen.

Re=connect the water supply fine to the water solenoid

valve. Tighten connector securely. Open the water

supply valve and check for leakage at the water

connection. Make sure the water supply line is not

kinked.

7 Reconnect power to the unit before reqnstalling..

Make sure the drain system is working properly and the drain hose is not

pinched or kinked. Pour one gallon of cool, fresh water into the ice bin. The

water should drain freely.. If your ice maker is equipped with a drain pump, the

pump should drain the ice bin.

WATER

CONNECTmON

UL103 CO

DBABNBNGIB:'":'ORNON@SE

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

If the unit is to be stored, moved or not used for extended periods, it will be

necessary to drain the system of water.

1 Disconnect power from the unit.

2 Remove ice from the storage bin.

3 Shut off water supply at the main water source.

4 Disconnect the inlet and outlet lines to the water valve and allow them to

drain.

[] []

5

Reconnect inlet and outlet lines to the water valve.

6

Replace back panel.

7

Drain water from the water trough and drain line by removing the overflow

tube (see Figure 34).

8

Clean the ice maker and storage bin before next use.

9

Prop door open to allow for air circulation and prevent mold and mildew.

BEFOREYOUCALL FORSERVICE

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

tf the unit appears to be malfunctioning, read through Normal Operation first. If the

problem persbts, check the Troubleshooting Guide. Locate the problem in the

guide and refer to the cause and its remedy before calling for servbe. The problem

could be sometNng very simpb whbh can be solved without a servbe call.

Troubleshooting - What to check when problems

Occur

Problem PossibleCause Remedy

Unitdoesnotoperate.

Unitrunsbutnoiceisproduced. • Nowaterbeingsuppliedtothe • Checktoseethatwaterisconnectedandturned

Unitrunsbutproducesverylittleice. • Dirtycondensercoils.

Iceis slowto releaseordoesnot

releasefromtheevaporator.

• No electricalpowertotheunit.

• Cycleselectorswitchset

improperly.

• Low airtemperaturearoundunit.

unit. ontothe unit.

• Highairtemperaturearoundunit.

• Scaleandmineralbuildupinunit.

• Inadequateairflowatthefrontof

theunit.

• Ice-makingsystemisdirty. • Rununitthroughautomaticcleancycle.See

• Unitis netlevel. • SeeLevelingthe Unit.

• Low airtemperaturearoundthe unit. • Surroundingairtemperaturemustbeatleast50°F

• Makesurepowercordispluggedin. Checkfor

blownfuseortrippedcircuitbreaker.

• MakesurecycleselectorswitchissettoICE/ON.

• Surroundingairtemperaturemustbeatleast

45°F(7°C).

• Cleanthe condenser.SeeMaintenance.

• Surroundingair temperatureof ever90°F(32°C).

Lowiceproductionathightemperaturesis

normal.

• Cleanunit.SeeMaintenance.

• Removeitemsblockingairflow.

Maintenance.

(t0°C).

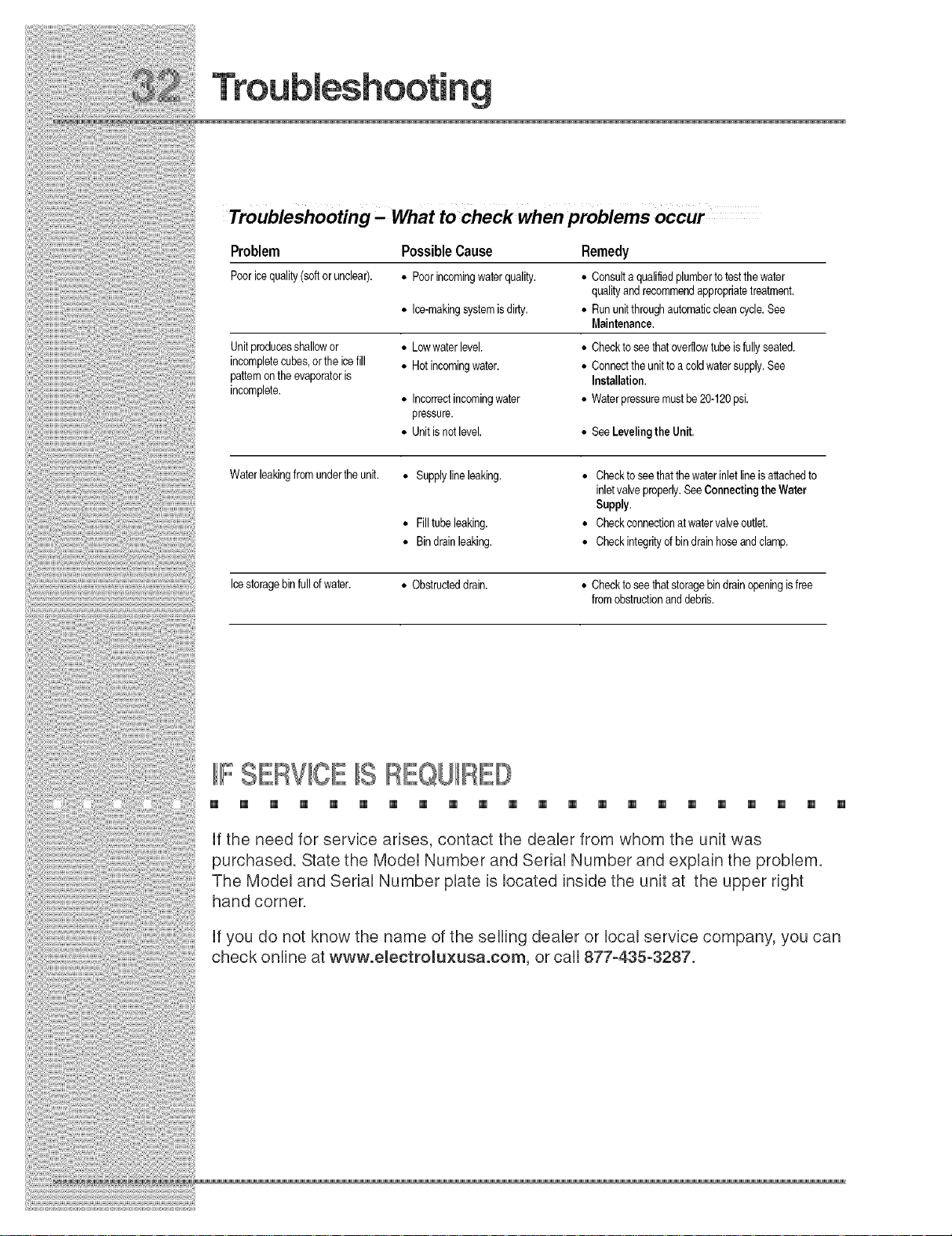

Troubleshooting - What to check when problems occur

Problem

Pooricequality(softorunclear).

Unitproducesshallowor

incompletecubes,orthe icefill

pattemontheevaporatoris

incomplete.

Waterleakingfromundertheunit. • Supplylineleaking.

Icestoragebinfullofwater. • Obstructeddrain. • Checktoseethatstoragebindrainopeningisfree

PossibleCause

• Poorincomingwaterquality.

• Ice-makingsystemisdirty.

• Lowwater level.

• Hot incomingwater.

• Incorrectincomingwater

pressure.

• Unitisnetlevel.

• Filltube leaking.

• Bindrainleaking.

Remedy

• Consultaqualifiedplumbertotestthewater

qualityandrecommendappropriatetreatment.

• Rununitthreughautomaticcleancycle.See

Maintenance.

• Checktoseethatoverflowtube isfullyseated.

• Connecttheunittoacoldwatersupply.See

Installation.

• Waterpressuremustbe20-120psi.

• SeeLevelingtheUnit.

• Checktoseethatthewaterinletlineis attachedto

inletvalveproperly.SeeConnectingtheWater

Supply.

• Checkconnectionatwatervalveoutlet.

• Checkintegrityofbindrainhoseandclamp.

fromobstructionand debris.

IIFSERVICEIISREQUR

[] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] [] []

If the need for servbe arbes, contact the dealer from whom the unit was

purchased. State the Model Number and Serial Number and explain the problem.

The Model and Serial Number plate is located inside the unit at the upper right

hand corner.

If you do not know the name of the selling dealer or local service company, you can

check online at www.emectromuxusa.com, or call 877-435-3287.

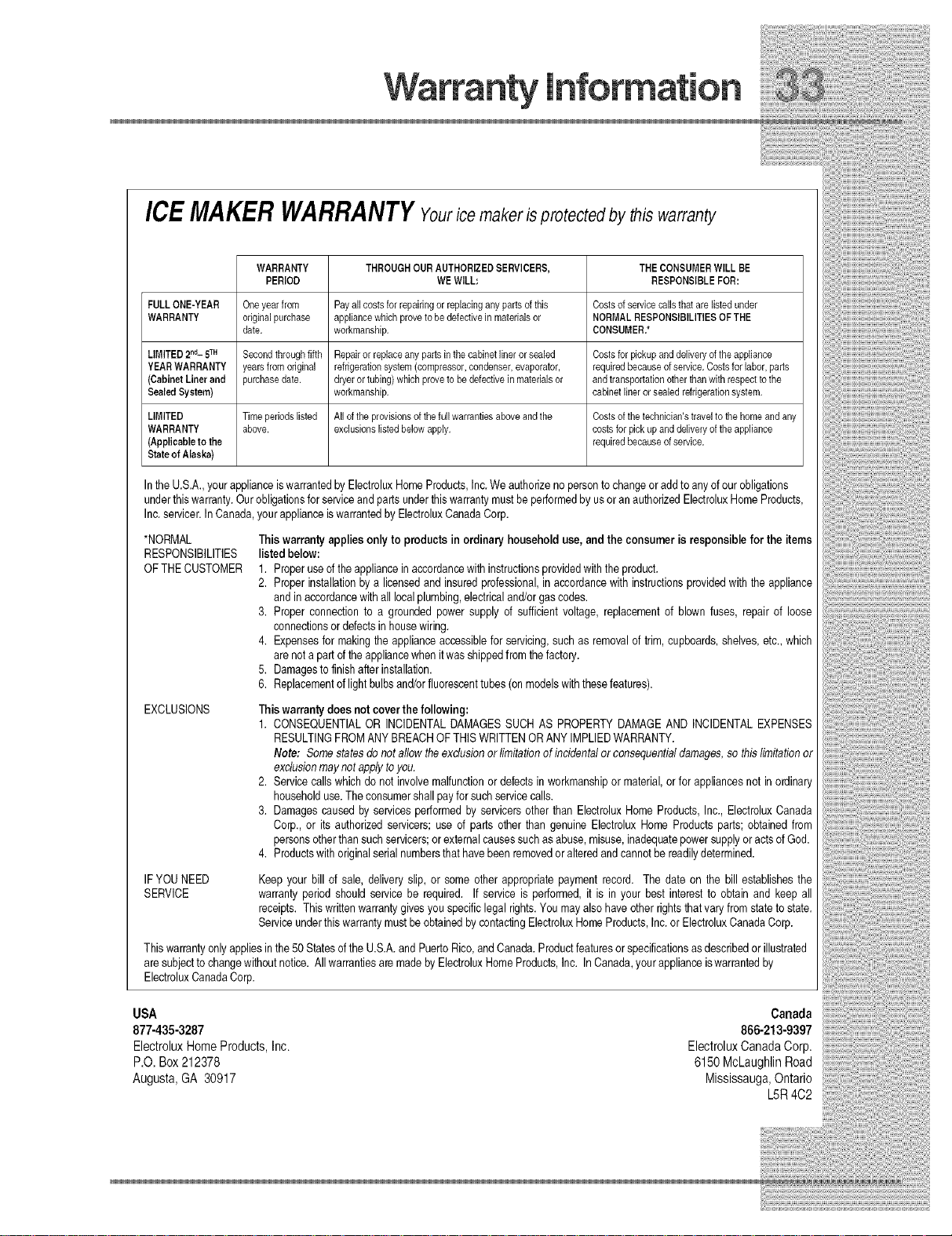

ICEMAKERWARRANTYYourice makerisprotectedby this warranty

WARRANTY THROUGHOURAUTHORIZEDSERVICERS, THECONSUMERWILLBE

PERIOD WEWILL: RESPONSIBLEFOR:

FULLONE-YEAR Oneyearfrom Payallcostsforrepairingorreplacinganypartsofthis Costsofservicecallsthatarelistedunder

WARRANTY originalpurchase appliancewhichprovetobedefectivein materialsor NORMALRESPONSIBILITIESOFTHE

LIMITED2"d-5TM Secondthroughfifth Repairorreplaceanypartsinthecabinetlinerorsealed Costsforpickupanddeliveryoftheappliance

YEARWARRANTY yearsfromoriginal refrigerationsystem(compressor,condenser,evaporator, requiredbecauseofservice.Costsforlabor,parts

(CabinetLinerand purchasedate. dryerortubing)whichproveto bedefectiveinmaterialsor andtransportationotherthanwithrespecttothe

SealedSystem) workmanship, cabinetlinerorsealedrefrigerationsystem.

LIMITED Timeperiodslisted Alloftheprovisionsofthefullwarrantiesaboveandthe Costsofthetechnician'straveltothehomeandany

WARRANTY above, exclusionslistedbelowapply, costsforpickupanddeliveryof theappliance

(Applicableto the requiredbecauseofservice.

Stateof Alaska)

Inthe U.S.A.,yourapplianceiswarrantedbyElectroluxHomeProducts,Inc.We authorizenopersonto changeoradd to anyofourobligations

underthiswarranty.Our obligationsfor serviceandpartsunderthiswarrantymustbe performedbyusoran authorizedElectroluxHomeProducts,

Inc.servicer.InCanada,yourapplianceiswarrantedbyElectroluxCanadaCorp.

*NORMAL

RESPONSIBILITIES

OFTHEOUSTOMER

EXCLUSIONS

IFYOUNEED

SERVICE

Thiswarrantyonlyappliesinthe50Statesof the U.S.A.andPuertoRico,andCanada.Productfeaturesor specificationsasdescribedor illustrated

are subjectto changewithoutnotice. All warrantiesaremadeby ElectroluxHomeProducts,Inc. InCanada,yourapplianceiswarrantedby

ElectroluxCanadaCorp.

date. workmanship. CONSUMER,*

Thiswarranty appliesonlyto productsin ordinaryhousehold use, andthe consumeris responsiblefor the items

listedbelow:

1. Properuseoftheappliancein accordancewith instructionsprovidedwiththeproduct.

2. Properinstallationby a licensedand insuredprofessional,inaccordancewithinstructionsprovidedwiththeappliance

andin accordancewith all localplumbing,electricaland/orgascodes.

3. Proper connectionto a groundedpowersupply d sufficientvoltage, replacementof blown fuses, repairof loose

connectionsor defectsinhousewiring.

4. Expensesfor makingtheapplianceaccessiblefor servicing,such as removalof trim,cupboards,shelves,etc.,which

arenotapartd theappliancewhenit wasshippedfromthefactory.

5. Damagesto finishafterinstallation.

6. Replacementof light bulbsand/orfluorescenttubes (onmodelswiththesefeatures).

Thiswarrantydoesnot coverthefollowing:

1. CONSEQUENTIALOR INCIDENTALDAMAGESSUCH AS PROPERTYDAMAGEAND INCIDENTALEXPENSES

RESULTINGFROMANYBREACHOF THISWRITTENORANY IMPLIEDWARRANTY.

Note: Somestatesdonot allowthe exclusionor limitationof incidentalor consequentialdamages,so this limitationor

exclusionmaynot applytoyou.

2. Servicecallswhichdo not involvemalfunctionor defectsin workmanshipor material,orfor appliancesnot inordinary

householduse.Theconsumershallpayforsuch servicecalls.

3. Damagescausedby services performedby servicersotherthan ElectroluxHomeProducts,Inc.,ElectroluxCanada

Corp.,or its authorizedservicers;use of parts otherthan genuineElectroluxHomeProductsparts; obtainedfrom

personsotherthan suchservicers;orexternalcausessuchasabuse,misuse,inadequatepowersupplyoractsofGod.

4. Productswithoriginalserialnumbersthathavebeenremovedor alteredandcannotbereadilydetermined.

Keepyour bill of sale, deliveryslip, or some otherappropriatepayment record. The date on the bill establishesthe

warrantyperiod should service be required. If service is performed,it is in your best interest to obtainand keep all

receipts.This writtenwarrantygivesyouspecificlegalrights.Youmayalsohaveother rightsthat varyfrom stateto state.

Serviceunderthis warrantymustbeobtainedby contactingElectroluxHomeProducts,Inc.or ElectroluxCanadaCorp.

USA Canada

877-435-3287 866-213-9397

ElectroluxHomeProducts,Inc. ElectroluxCanadaCorp.

P.O.Box212378 6150McLaughlinRoad

Augusta,GA 30917 Mississauga,Ontario

L5R4C2

Loading...

Loading...