ELECTROLUX HOME PRODUCTS NORTH AMERICA

SERVICE MANUAL

3.0 Cu. Ft. HORIZONT AL

AXIS WASHER

5995413084

GOOD & BETTER MODELS

W hite-Westinghouse

December 2004

1

1111111

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe Servicing

Practices be observed. The following are some limited examples of safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

• Remove the power cord from the electrical outlet, trip the circuit breaker to the

OFF position, or remove the fuse.

• Turn off the gas supply.

• Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN, or

GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so will

create a hazard.

6. Prior to returning the product to service, ensure that:

• All electrical connections are correct and secure

• All electrical leads are properly dressed and secured away from sharp edges,

high-temperature components, and moving parts

• All non-insulated electrical terminals, connectors, heaters, etc. are adequately

spaced away from all metal parts and panels

• All safety grounds (both internal and external) are correctly and securely

connected

• All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechanical

training and a level of knowledge of these subjects generally considered acceptable in the

appliance repair trade. Electrolux Home Products cannot be responsible, nor assume any

liability, for injury or damage of any kind arising from the use of this manual.

© 2001 White Consolidated Industries

2

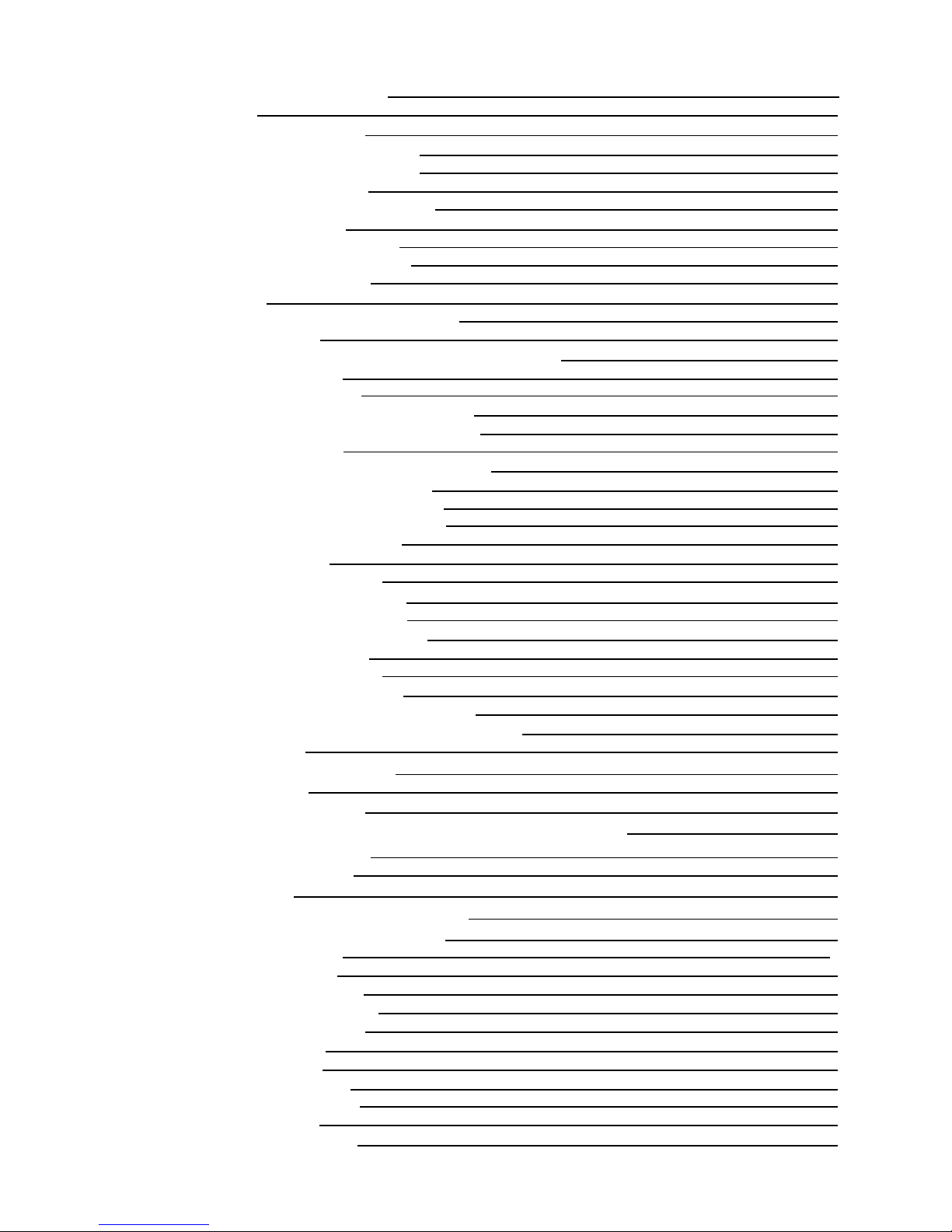

SAFE SERVICING PRACTICES 2

Model lines 7

QUICK REFERENCE SHEET 8

Serial nameplate location 8

Serial number breakdown 8

T ech sheet location 8

Component resistance chart 9

Water fill height 9

Electrical requirements 9

Incoming water pressure 9

Drain requirements 9

Motor 9

Tub pulley to motor pulley ratio 9

Tub capacity 9

Auto temp control temperature specifications 9

Diagnostic test 10

Operation speeds 1 1

Sample schematic (Good Models) 1 2

Sample schematic (Better Models) 1 3

Operation chart 14

SECTION A - INST ALLA TION INSTRUCTIONS 15

What to do if you smell gas 1 5

Pre-installation requirements 1 5

T ools required for inst allation 1 5

Electrical requirements 1 5

Circuit 15

Power supply 1 5

Outlet receptacle 15

Grounding requirements 1 5

Water supply requirements 1 6

Drain requirements 1 6

Rough-in dimensions 17

Location of your washer 1 9

Do not install your washer 1 9

Minimum installation clearances 19

Unpacking 19

Drain hose installation 2 0

Installation 21

Replacement parts 22

SECTION B - Washer & Dryer Pedestal Installation Instructions 2 3

Washer Installation 2 3

Dryer installation 2 5

Warranty 27

SECTION C - OPERA TING INSTRUCTIONS 28

Before operating your washer 28

Operating steps 28

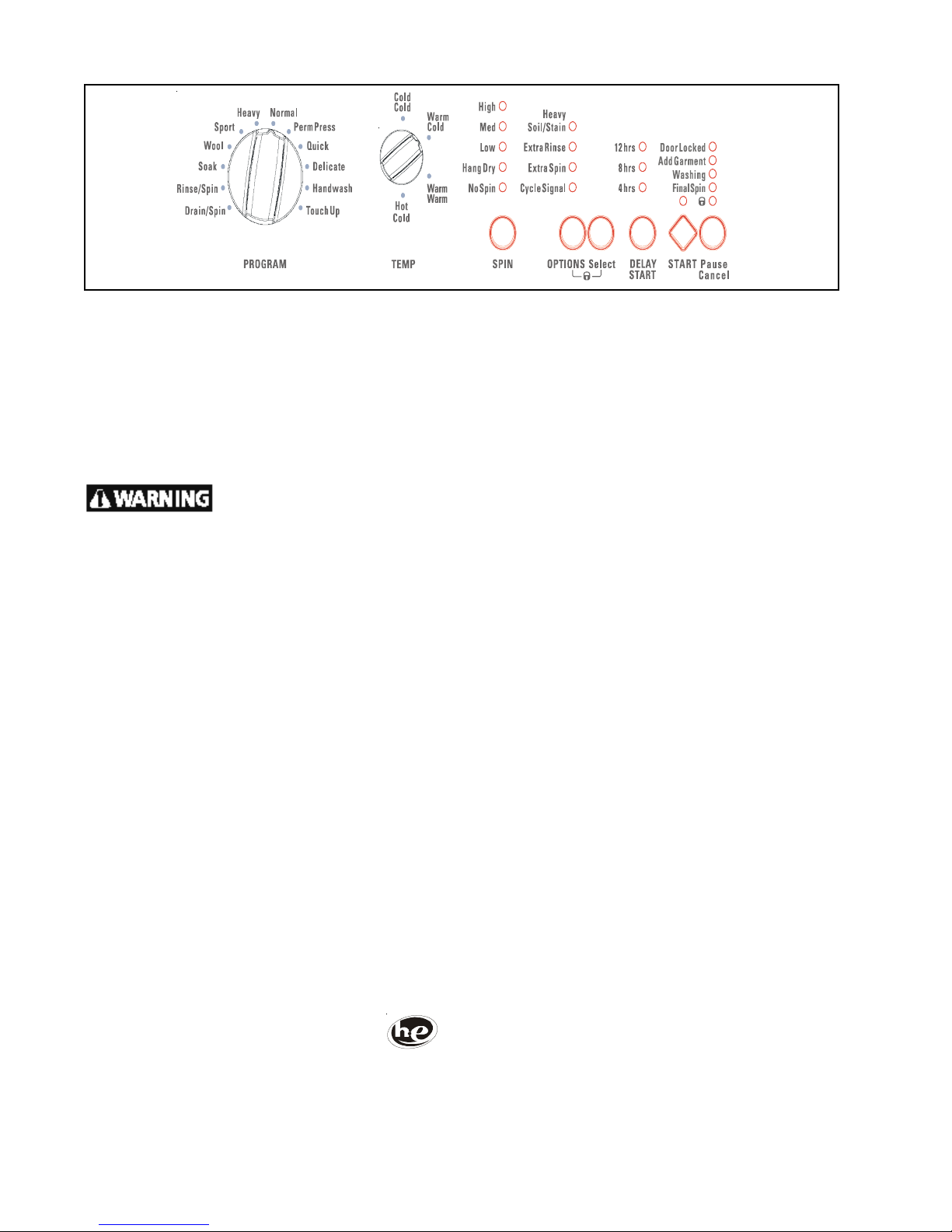

Cycle selection 29

Heavy duty 29

Normal wash 2 9

Perm press 2 9

Quick 29

Sport 29

Delicates 29

Handwash 29

Soak 29

Drain/spin 29

3

Rinse/spin 29

Cycle settings 30

Wash/rinse water temperature 30

Final spin speed 3 0

Water level 30

Cycle options 30

Heavy soil/stain 30

Extra rinse 3 0

Extra spin 30

Cycle signal 3 0

Washer features 3 0

Delay start 3 0

Control lock 3 0

Status lights 30

Washer settings chart 31

Error code chart 3 2

SECTION D - USE & CARE GUIDE 3 3

Product record 33

Y our safety and the safety of others is very important 3 3

Pedestal 33

Important safety instructions 3 3

Read all instructions before using this washer 3 3

Prevent fire 33

Protect Children 3 3

Prevent Injury 34

Washing procedures 35

Sort laundry into loads that can be washed together 35

Prepare items for washing 36

Pretreat stains and heavy soil 3 6

Add laundry load to washer 36

Add detergent, bleach and fabric softener to automatic dispenser 3 7

Start the washer 38

Remove items when the cycle is completed 38

General precautions 38

Stain removal 39

Safe stain removal procedures 4 0

Stain removal 40

Common washing problems 4 1

Care and cleaning 42

Outside 42

Cleaning the dispenser drawer area 42

Winterizing instructions 43

Avoid service checklist 44

Warranty 47

SECTION E - OPERA TION 48

Control 48

Dispenser Drawer Reed Switch 4 8

Door Switch Assembly 48

Pressure Switch 49

Electronic water level sensor 5 0

Water Inlet Valve 50

Auto T emp System (Better Models) 5 2

Automatic Dispenser 52

Drain Pump 56

Speed Control 57

Motor 57

4

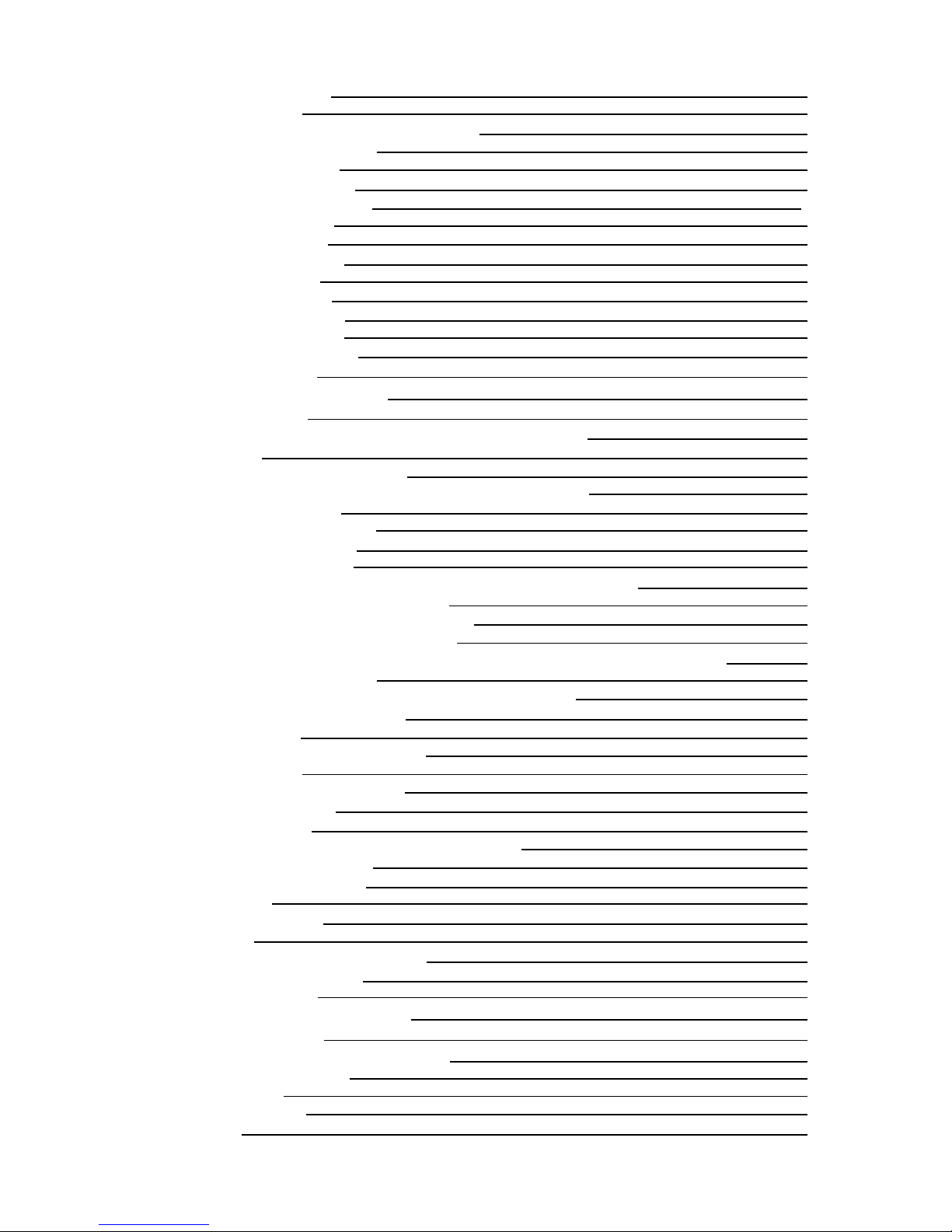

SECTION F - CONSTRUCTION 58

Cabinet 58

Front Panel and Door Assembly 5 8

Bellows (Door Boot) 58

Outer T ub Assembly 58

Spin Basket Assembly 58

SECTION G - TROUBLESHOOTING 59

Failure code chart 60

T est 61

Jacks and plugs 63

SECTION H - TEARDOWN 6 4

Removing the detergent drawer 64

Detergent drawer disassembly 6 4

Removing door strike 6 5

Removing the door handle 65

Removing loading door 65

Disassembling the door 68

Removing loading hinges 6 8

Releasing the bollows from the front panel 67

Removing the door safety switch 6 7

Removing the front service panel 68

Removing the drain pump assembly 6 8

Disassembling the drain pump 6 9

Removing the top panel 69

Removing the pressure switch 7 0

Removing the electronic water level sensor 70

Releasing the console 70

Removing the reed switch 7 1

Removing the water temperature selector knob (Good Models) 7 1

Removing the console 7 2

Removing the electronic control 7 2

Removing the selector knob (Good Models) 7 2

Removing the water temperature selector shaft (Good Models) 7 2

Removing the selector dial (Better Models) 7 3

Removing the selector knob (Better Models) 7 3

Removing the programing buttons and springs 7 3

Removing the front panel 73

Removing the console mounting brace 7 4

Removing the bellow or boot 74

Reinstalling or replacing the boot 75

Removing the weight ring 77

The water inlet and overflow/vent tube grommet 77

Removing the water inlet grommet 77

Removing the overflow/vent tube grommet 78

Removing the overflow/vent tube 78

Removing the water inlet valve assembly 79

Removing the water inlet screens 80

Removing the top rear brace 80

Removing the suspension springs 80

Removing the top center brace 81

Removing the detergent cavity assembly 8 1

Removing the detergent dispenser outlet hose 8 3

Removing the siphon break hose 8 3

Removing the drain sump 8 3

Removing the hose between the drain pump and the drain hose coupler 83

Removing the external drain hose 84

5

Removing the drain hose coupler 84

Removing the rear access panel 85

Drive belt 85

To remove or replace the drive belt 85

Removing the large pulley 85

Removing the drive motor 8 6

Removing the speed control board assembly 8 6

Removing the right hand air shock absorber 8 8

Removing the left hand air shock absorber 8 8

To remove the air bell 89

Removing the tub assembly 8 9

Removing the spin basket and rear tub half 9 1

Removing the spin basket vanes 9 2

6

Model Lines

This manual will cover the Good and Better model lines of the 3.0 Cu. Ft. HORIZONT AL AXIS W ASHER.

Differences:

Good Models

1. Control panel does not have a display .

2. Water fill height control is a pressure switch.

Better Models

1. Control panel has a display .

2. Water fill height control is a electronic pressure

sensor.

3. Does not have a water temperature sensor.

3. Has a water temperature sensor.

7

QUICK REFERENCE SHEET

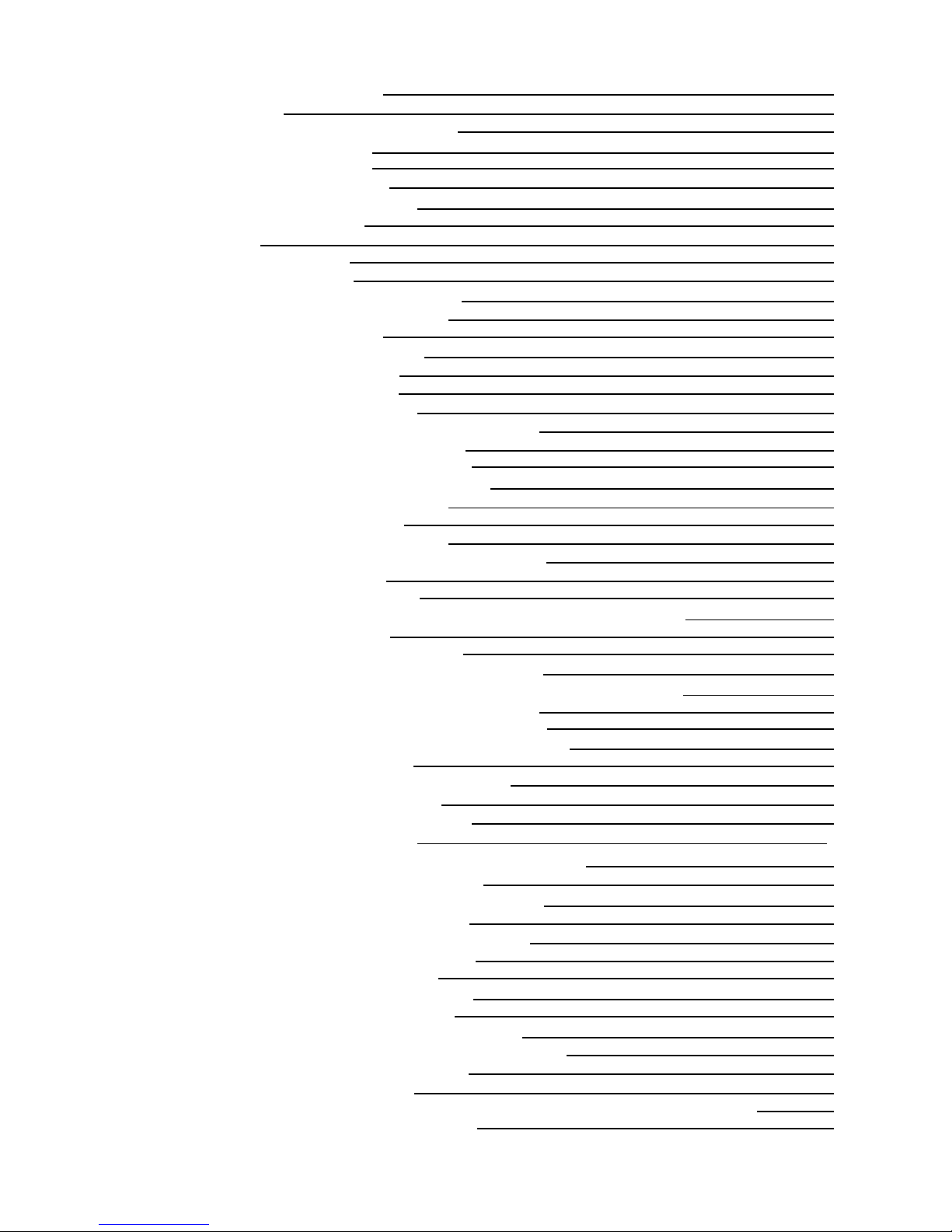

1. Serial nameplate location:

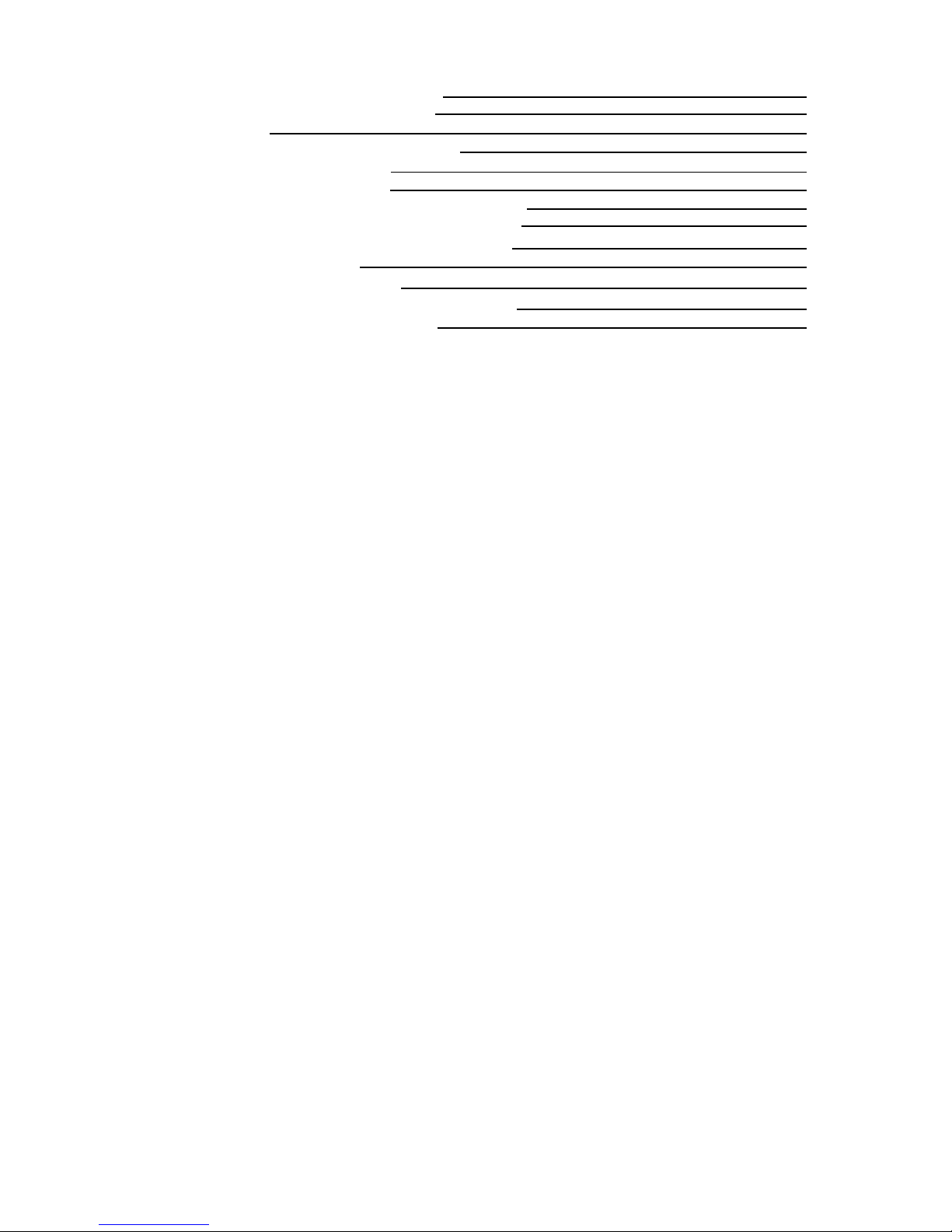

2. Serial number breakdown.

On the front panel at the lower left of the

washer door opening.

X C 4 4 8 1 5 6 9 3

Incremented unit number

Production week

Last digit of production year

Product identification

Manufacturing facility

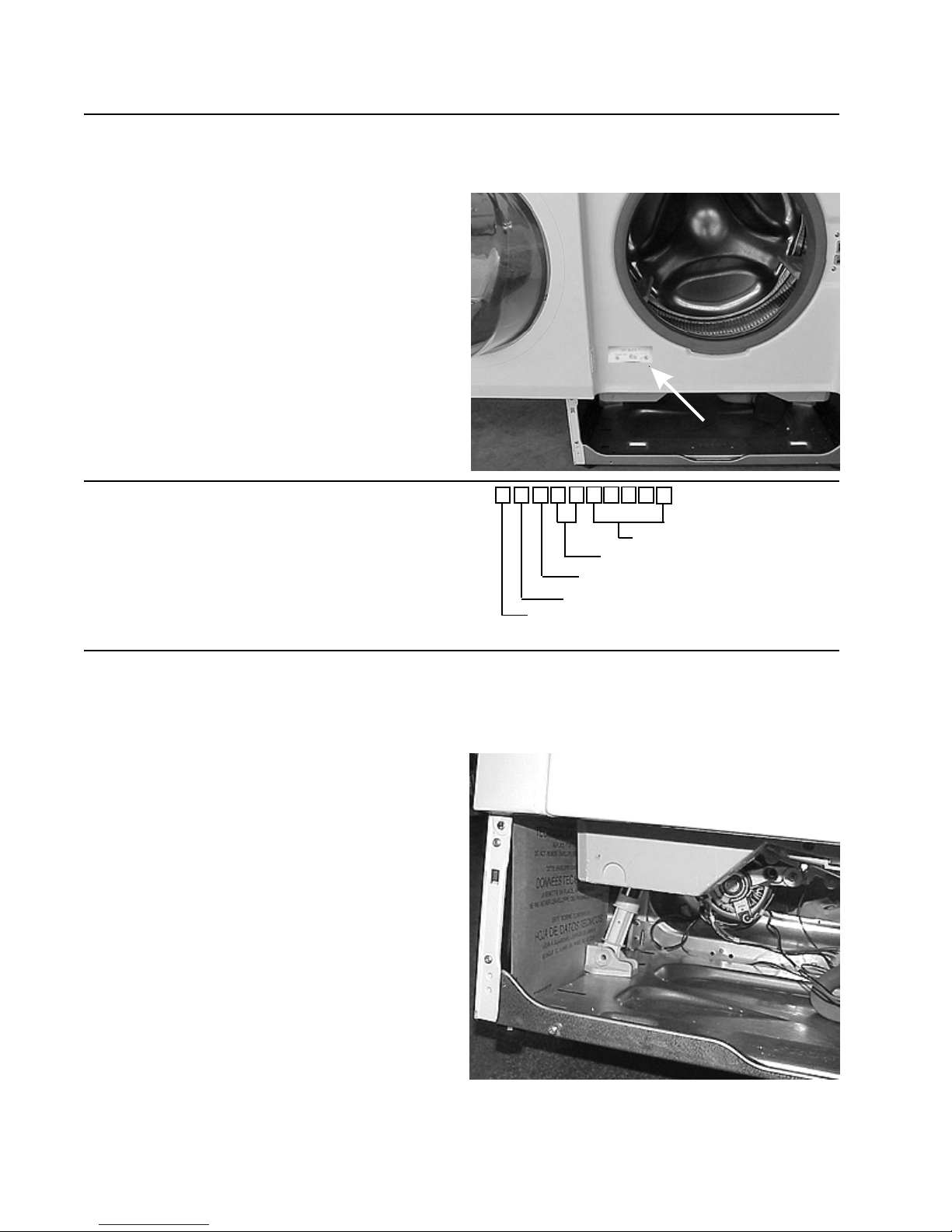

3. Tech sheet location

On the lefthand bodyside behind the front

access panel.

8

QUICK REFERENCE SHEET

Component resistance chart.

Good Models

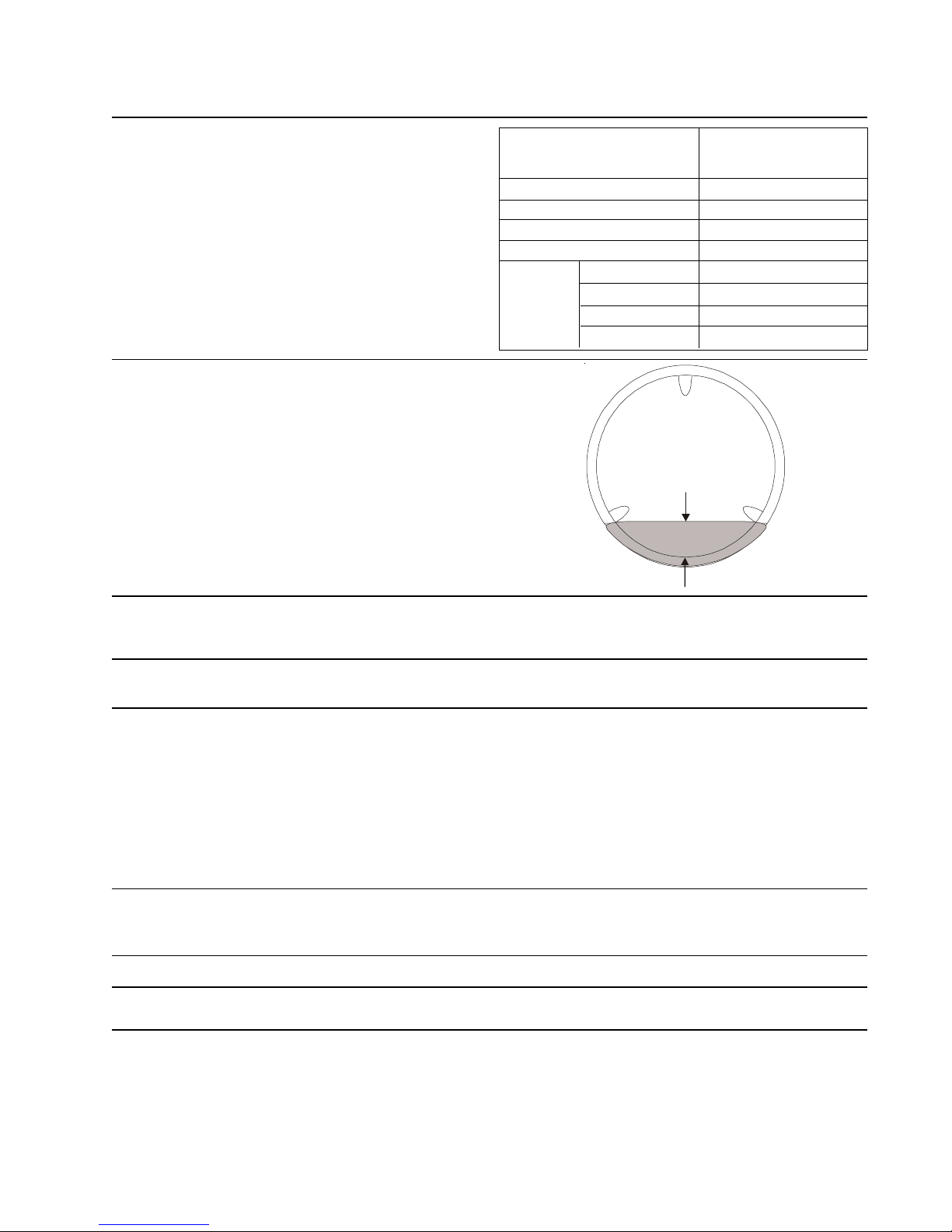

Water fill height 3 ± .5 “

No load, start position of permanent press cycle.

Better Models

Water fill height dependent upon selected cycle.

Resistance Ω

Electrical component @ 77° F (25°C)

Dispenser valve solenoids 800 ± 7%

Door lock solenoid 1325 ± 10%

Pump motor 12 ± 7%

NTC Thermistor 50K ± 2%

M1 TO M2 5.3 ± 7%

Motor

M2 TO M3 5.3 ± 7%

M1 TO M3 5.3 ± 7%

M4 TO M5 118 ± 7%

Electrical requirements.

Incoming water pressure.

Drain requirements.

Motor.

Tub Pulley to Motor Pulley Ratio. 16 TO 1

Tub Capacity. 3.0 cu. ft.

Automatic T emperature Control S pecifications. (Better Models).

Regulated hot wash temperature 130° ± 7° F

Regulated warm wash and rinse temperature 90° ± 7° F

Regulated cold wash and rinse temperature 65° ± 7° F

Circuit - Individual, properly polarized and grounded 15

amp. branch circuit fused with 15 amp. time delay fuse

or circuit breaker.

30 and 120 pounds per square inch (maximum

unbalance pressure, hot vs. cold, 10 psi.)

Drain capable of eliminating 17 gals (64.3 L) per minute.

A standpipe diameter of 1-1/4 in. (3.18 cm) minimum.

The standpipe height above the floor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm)

No load agitate wattage - Max 150

No load spin wattage - Max 550

9

Diagnostic T est:

The diagnostic test is performed by using the Program

Knob. T o ST ART THE TEST :

• On non-digital display models, turn the

Program Knob to

start position, Drain/Spin.

• On digital display models, turn the Program

Knob to start position, Drain/Spin.

• Press Pause/Cancel to turn off LEDs.

• Within 5 seconds, press and hold the Optionand

Pause/Cancel buttons until LEDs start

sequentially chasing, then release buttons.

1. All the LEDs will sequentially light. Pressing a

button below a light cluster will light all the LEDs in

that cluster at one time to confirm functionality .

2. Turn the program knob (1) click clockwise from the

start position. The hot water solenoid will activate

and hot water should enter through the detergent

compartment.

3. Turn the program knob (2) clicks from the start

position. The bleach water solenoid will activate and

cold water should enter through the bleach

compartment.

4. Turn the program knob (3) clicks from the start

position. The bleach and the wash water solenoids

will activate and cold water should enter through the

softener compartment.

5. Turn the program knob (4) clicks from the start

position. The door lock solenoid will activate.

6. Turn the program knob (5) clicks from the start

position. The door lock solenoid will deactivate and

the loading door can be opened.

10. Turn the program knob (9) clicks from the start

position. The control will signal the last error code.

See Section F, Troubleshooting, for det ails for

properly identifying the error code on non-digital

display models.

Exiting Diagnostic Mode

There are two options for exiting the Diagnostic T est mode

and returning the washer to normal operation:

a) Unplug the power cord, wait 5-8 seconds, then

reconnect the power cord OR

b) Turn the program knob clockwise 2 or 3 clicks after

the Start Position. Press Options and Pause/Cancel

buttons together for a few seconds until wash cycle

LEDs appear.

If a situation arises where you cannot exit the

Diagnostic mode as described above and the bank

of 5 LED’s on the right end remain ON regardless of

Program Knob position, a combination of pushed

buttons caused the control to enter a special factory

test mode. Disconnect power to reset the control to

return washer to normal operation is this occurs.

T o clear latest stored error code:

Place the control into Diagnostic test Mode.

• Turn the program knob clockwise 9 clicks from the

Start Position. The control will signal the last error

code.

• Press and hold the Options and Pause/Cancel

buttons for 3 seconds. The code will be cleared.

• Exit Diagnostic Mode to return the washer to normal

operation.

7. Turn the program knob (6) clicks from the start

position. The washer will fill and tumble.

8. Turn the program knob (7) clicks from the start

position. The washer will fill and spin (leakage test).

9. Turn the program knob (8) clicks from the start

position. The drain pump and door lock solenoid will

activate and the washer will operate in high spin.

SAFETY WARNING: If power is removed during this

test, the door can be opened. T o prevent injury , DO

NOT put your hands inside when the tub is rotating

10

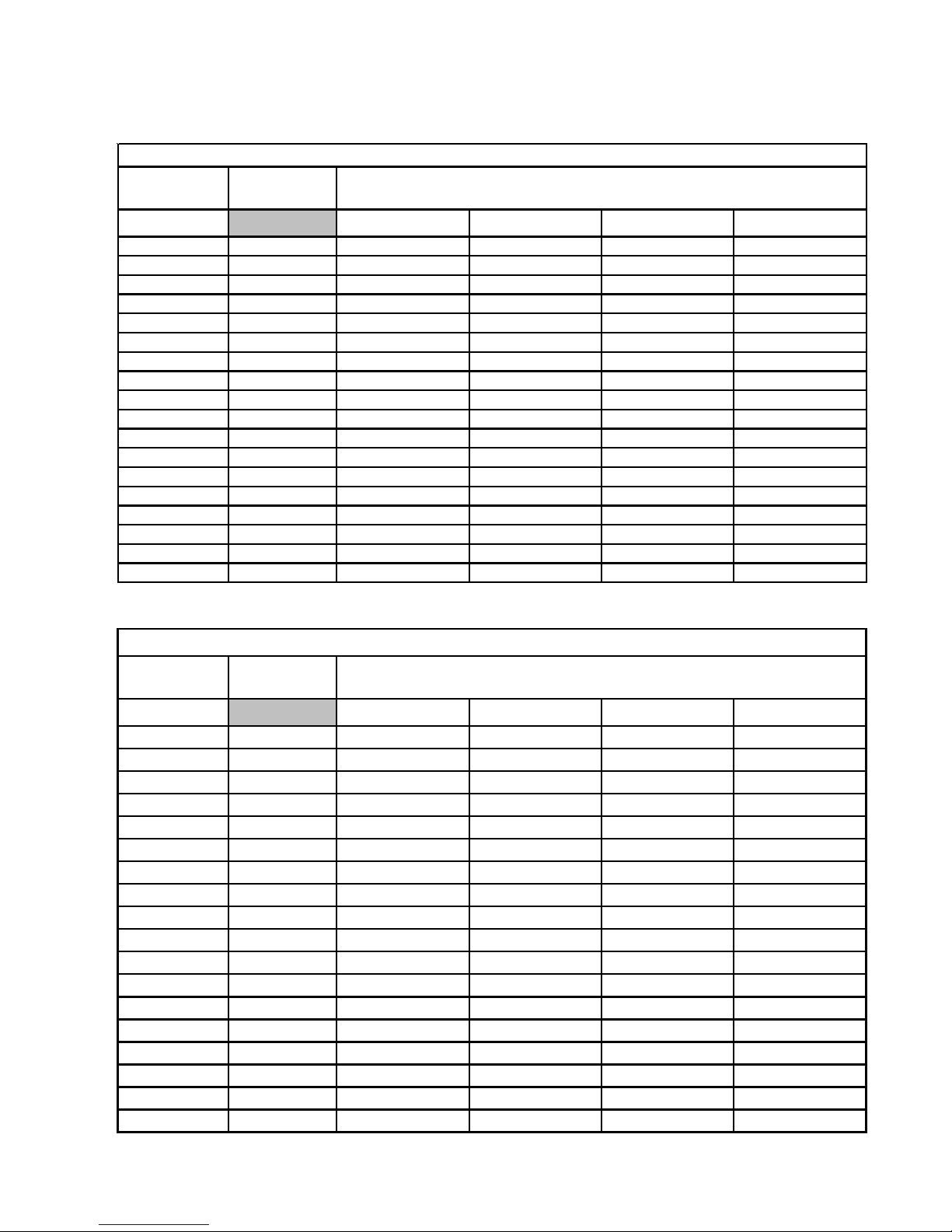

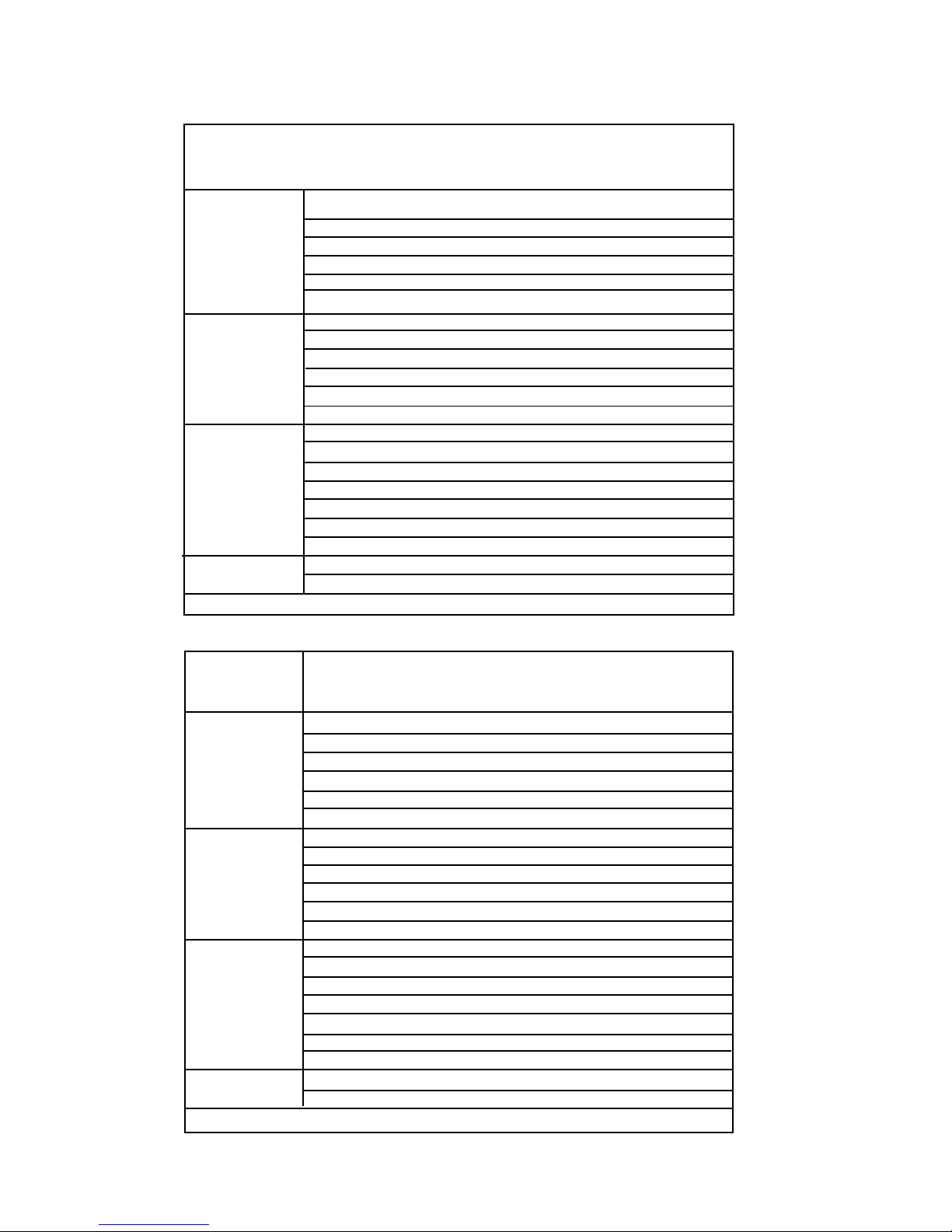

OPERATION SPEEDS

GOOD MODELS

Agitation

Speed

CYCLE High Medium Low Hang Dry

Heavy 47 1000 900 850 NA

Normal 47 1000 900 850 NA

EcoNormal47NANANANA

Perm Press 47 900 850 800 450

Quick 47 1000 900 850 NA

EcoQuick 47 NA NA NA NA

Delicate 32 450 400 350 350

Handwash 32 450 400 350 350

Touch Up 47 1000 900 850 450

Drain Spin NA 1000 900 850 450

Rinse Spin NA 1000 900 850 450

Soak 47 450 400 350 NA

Wool 32 NA NA NA NA

Silk 32 NA NA NA NA

Bulky 47 900 850 800 NA

Sport 47 900 850 800 450

Towels 47 NA NA NA NA

Jeans 47 NA NA NA NA

Spin

Speeds

BETTER MODELS

Agitation

Speed

CYCLE High Medium Low Hang Dry

Heavy 47 1100 1000 950 NA

Normal 47 NA NA NA NA

EcoNormal 47 1100 1000 950 NA

Perm Press 47 900 850 800 450

Quick 47NANANANA

EcoQuick 47 1100 1000 950 NA

Delicate 32 450 400 350 350

Handwash 32 450 400 350 350

Touch Up 47 1100 1000 950 450

Drain Spin NA 1100 1000 950 450

Rinse Spin NA 1100 1000 950 450

Soak 47 450 400 350 NA

Wool 32 450 400 350 NA

Silk 32 NA NA NA NA

Bulky 47 900 850 800 NA

Sport 47 900 850 800 450

Towels 47 1100 1000 950 NA

Jeans 47 1100 1000 950 NA

Spin

Speeds

11

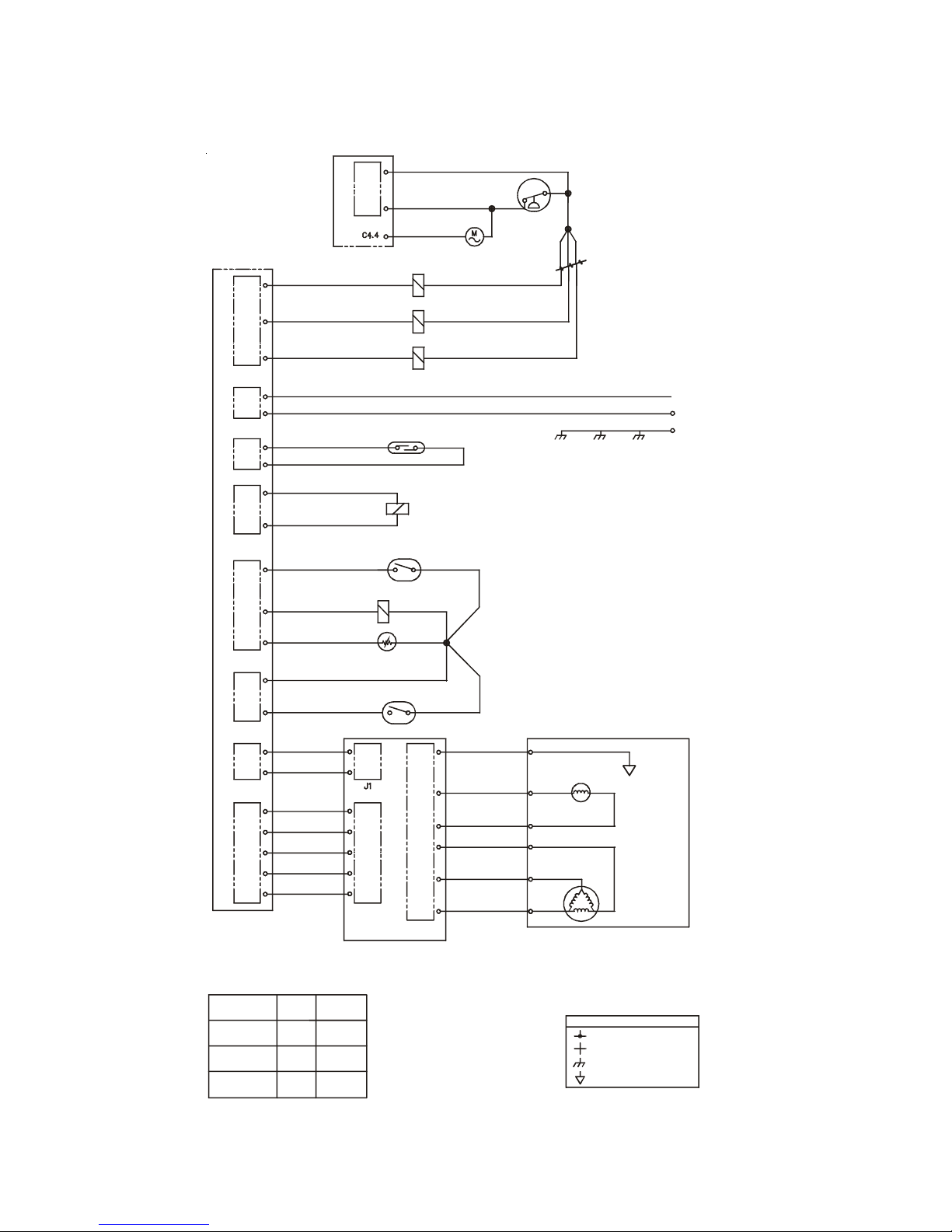

SAMPLE SCHEMATIC FOR GOOD MODELS

J14

J8

J3

J2

2

BLACK/RED

1

PUMP

BLACK/RED

BLACK/RED

BLACK/RED

RED/BLK

GRN

GRAY

WHT

BRN

RED

ORG

2

1

2

PRESSURE

SWITCH

CABINET TUB

C5.5

C5.4

C5.3

C5.2

C5.1

GREEN

TAC HO

GENERATOR

1

2

T

X

Y

MOTOR

Z

SPEED

CONTROL

MOTOR

FRAME

L1

N

GROUND

C3.2

J5

TAN/BLK

C3.1

J4

PURP

C4.3

J4

J7

J1

J6

C4.2

C4.1

C2.1

C2.2

C2.1

C2.2

C3.1

C3.3

C5.1

C5.3

C5.5

C2.2

C2.1

C2.1

C2.2

C5.5

C5.4

C5.3

C5.2

C5.1

TAN

RED

BLK

WHT

BLK

BLK

BRN

YEL

ORG

GRAY

PINK

RED/BLK

BLK

BLU

BLK

RED

WHT

BLK

BLU

YEL

AUXILIARY SWITCH

C2.2

MOTOR CONTROL BOARD

PINK/BLK

COLD 1

COLD 2

HOT

DISPENSE R DRA WER

REED SWITCH

1

+T NTC

(SELECT MODELS)

DOOR LOCK

4.1 4.2

DOOR LOCK

2.1 4.4

3.1

3.3

WAX MOTOR

DOOR SWITCH

2.2 4.3

C2.1

C5.1

C5

C5.3

C5.4

C5.5

J3

C7.1

C7.3

C7.4

.2

C7.5

C7.6

C7.7

J5

DISPENSE R VALVE

EVENT

DETERGENT

BLEACH

SOFTNER

X = CLOSED O = OPEN

COLD 1

O

X

X

COLD 2

X

O

X

12

WIRING CODES

CONNECTION

NO CONNECTION

CABINET GROUND

LOCAL GROUND

/

/

/

/

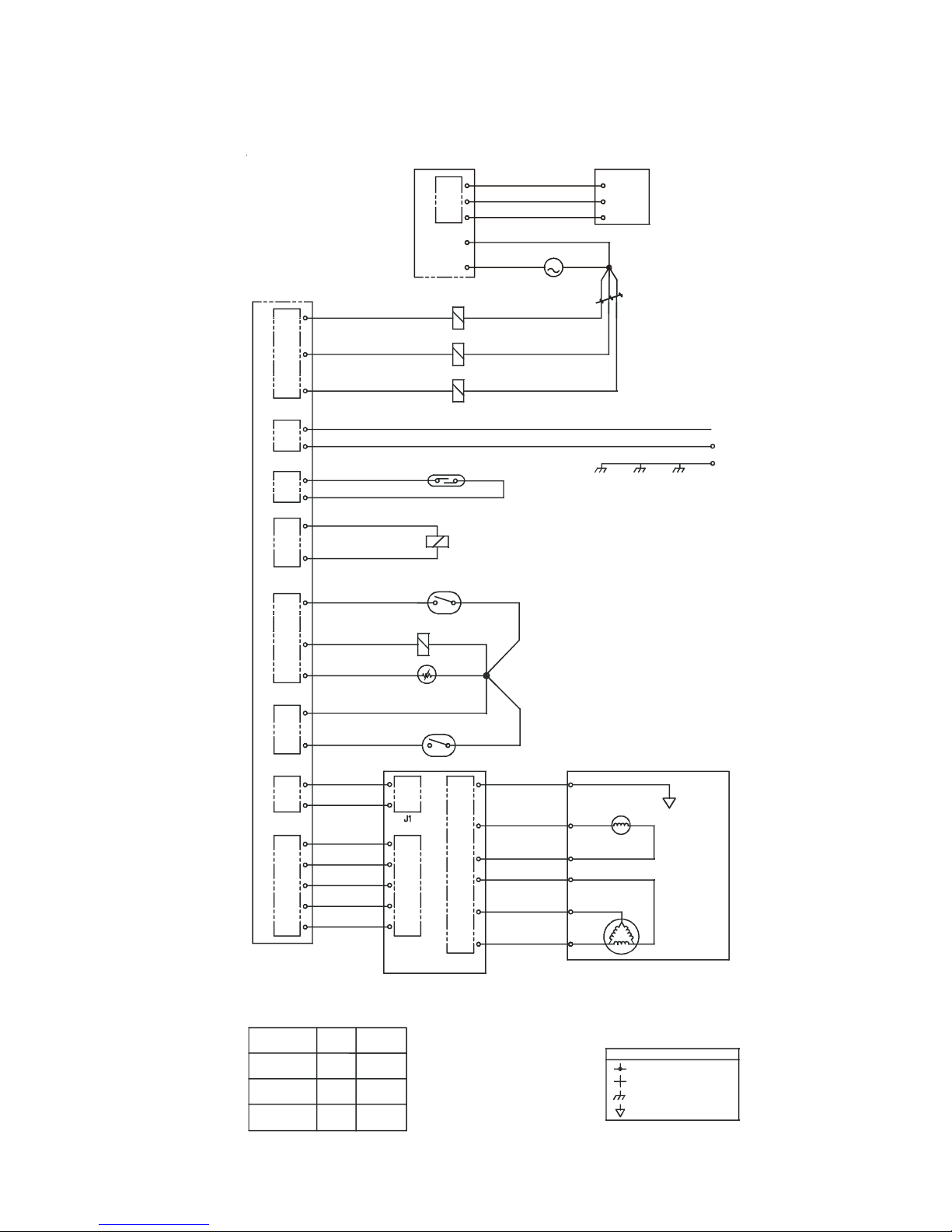

SAMPLE SCHEMATIC FOR BETTER MODELS

LEVEL SENSOR

BLACK/RED

PINK/BLK

BLACK

BLU

WHT

RED

1

PUMP

RED

C5.5

C5.3

C5.1

M

2

C4.3

PURP

J9

J5

J4

BLEACH

C4.2

C4.3

C4.4

C3.1

C4.4

J14

J8

J3

J2

J4

J7

J1

J6

C4.2

C4.1

C2.1

C2.2

C2.1

C2.2

C3.1

C3.3

C5.1

C5.3

C5.5

C2.2

C2.1

C2.1

C2.2

C5.5

C5.4

C5.3

C5.2

C5.1

TAN

RED

BLK

WHT

BLK

BLK

BRN

YEL

ORG

GRAY

PINK

RED/BLK

BLK

BLU

BLK

RED

WHT

BLK

BLU

YEL

WASH

HOT

DISPENSE R DRA WER

REED SWITCH

1

DOOR LOCK

AUXILIARY SWITCH

4.1 4.2

DOOR LOCK

2.1 4.4

3.1

WAX MOTOR

DOOR SWITCH

2.2 4.3

C2.1

C2.2

C5.1

C5.2

C5.3

C5.4

C5.5

J3

MOTOR CONTROL BOARD

2

+T NTC

(SELECT MODELS)

3.3

C7.1

C7.3

C7.4

C7.5

C7.6

C7.7

J5

RED

BLACK

BLACK

BLK

GRN

GRAY

WHT

BRN

RED

ORG

RED

RED

GREEN

CABINET TUB

TAC HO

GENERATOR

1

C5.5

C5.4

C5.3

C5.2

C5.1

Y

MOTOR

2

T

X

Z

SPEED

CONTROL

MOTOR

FRAME

L1

N

GROUND

DISPENSE R V A L V E

EVENT

DETERGENT

BLEACH

SOFTNER

X = CLOSED O = OPEN

COLD 1

O

X

X

COLD 2

X

O

X

13

WIRING CODES

CONNECTION

NO CONNECTION

CABINET GROUND

LOCAL GROUND

OPERA TION CHART

Wash Cycle Wash Phase *Estimated

Step Time

(sec)

Heavy Fill and Tumble 6 0

Fill Then Tumble 3 0 0

(Heavy opt.) Fill Then Tumble 1 2 0

(Normal) Fill Then Tumble 66 0

Tumble 120

Drain/spin 180

Rinse/Spin Fill and Tumble 9 0

Fill Then Tumble 18 0

Drain/spin 180

Fill and Tumble 90

Fill Then Tumble 18 0

Drain/spin 180

Extra Rinse Fill and Tumble 90

Fill Then Tumble 24 0

Drain/spin 180

Fill and Tumble 90

Fill Then Tumble 120

Drain 3 0

Spin 570

Extra spin Spin 1 80

Tumble 150

*Estimated Cycle Time (min) Stop 53

Pump Dispenser

OFF Wash (Det)

OFF Wash (Det)

OFF Wash (Det)

OFF Wash (Det)

OFF OFF

ON OFF

OFF BLEACH

OFF BLEACH

ON OFF

OFF BLEACH

OFF BLEACH

ON OFF

OFF BLEACH

OFF BLEACH

ON OFF

OFF FABRIC

OFF FABRIC

ON OFF

ON OFF

ON OFF

OFF OFF

OFF OFF

Wash Cycle Wash Phase *Estimated Pump Dispenser

Step Time

(sec)

Normal Fill and Tumble 60

Fill Then Tumble 30 0

(Normal) Fill Then Tumble 18 0

(Light) Fill Then Tumble 30 0

Tumble 120

Drain/spin 60

Rinse/Spin Fill and Tumble 9 0

Fill Then Tumble 18 0

Drain/spin 180

Fill and Tumble 90

Fill Then Tumble 18 0

Drain/spin 180

Extra Rinse Fill Then Tumble 90

Fill Then Tumble 18 0

Drain/spin 180

Fill and Tumble 90

Fill Then Tumble 180

Drain 3 0

Spin 570

Extra spin Spin 1 80

Tumble 150

*Estimated Cycle Time (min) Stop 49

OFF Wash (Det)

OFF Wash (Det)

OFF Wash (Det)

OFF Wash (Det)

OFF OFF

ON OFF

OFF BLEACH

OFF OFF

ON OFF

OFF BLEACH

OFF OFF

ON OFF

OFF BLEACH

OFF BLEACH

ON OFF

OFF FABRIC

OFF FABRIC

ON OFF

ON OFF

ON OFF

OFF OFF

OFF OFF

14

SECTION A - Installation Instructions

4. Carpenter’s level.

ELECTRICAL REQUIREMENTS

Full Size Tumble Action Washers

Before beginning installation, carefully read these

instructions. This will simplify the

installation and ensure the washer is installed

correctly and safely. Leave these instructions

near the washer after installation for future reference.

NOTE: The electrical service to the washer must

conform with local codes and ordinances

and the latest edition of the National Electrical

Code, ANSI/NFP A 70.

For your safety the information in

this manual must be followed to minimize the risk

of fire or explosion or to prevent property damage,

personal injury or loss of life.

-Do not store or use gasoline or other flammable

vapors and liquid in the vicinity of this or any other

appliance.

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPL Y - 2 wire, with ground, 120 volt, single

phase, 60 Hz, Alternating Current. NOTE: The use of

this washer with power created by gas powered

generators, solar powered generators, wind powered

generators or any other generator other than the local

utility company is not recommended.

OUTLET RECEPT ACLE - Properly grounded 3-prong

receptacle to be located so the power supply cord is

accessible when the washer is in an installed position.

WHA T TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch; do not use any

phone in your building.

· Clear the room, building or area of all occupants.

· Immediately call your gas supplier from a

neighbor’s phone. Follow the gas suppliers

instructions.

· If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer , service agency or the gas supplier.

PRE-INSTALLATION REQUIREMENTS

T ools Required for Installation:

1. Phillips screwdriver

2. 10 mm socket with ratchet.

3. Channel-lock adjustable pliers.

NOTE: GFI (Ground Fault Interrupter) receptacle is not

required.

GROUNDING REQUIREMENTS

Improper connection of the

equipment grounding conductor can result in a risk of

electrical shock. Check with a licensed electrician if you

are in doubt as to whether the appliance is properly

grounded.

1. The washer MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance

for electrical current.

2. Since your washer is equipped with a power supply

cord having an equipment-grounding conductor and a

grounding plug, the plug MUST be plugged into an

appropriate, copper wired receptacle that is properly

15

installed and grounded in accordance with all local

codes and ordinances or in the absence of local codes,

with the National Electrical Codes, ANSI/NFP A 70

(latest edition). If in doubt, call a licensed electrician.

DO NOT cut off or alter the grounding prong on the

power supply cord. In situations where a two-slot

receptacle is present, it is the owner’s responsibility

to have a licensed electrician replace it with a

properly grounded three prong grounding type

receptacle.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within

42 inches (107 cm) of your washer’s water inlet. The

faucets MUST be 3/4 inch (1.9 cm) garden hose type

so inlet hoses can be connected. Water pressure MUST

be between 30 and 120 pounds per square inch

(maximum unbalance pressure, hot vs. cold, 10 psi.)

Your water department can advise you of your water

pressure. The hot water temperature should be about

140 degrees F (60 degrees C).

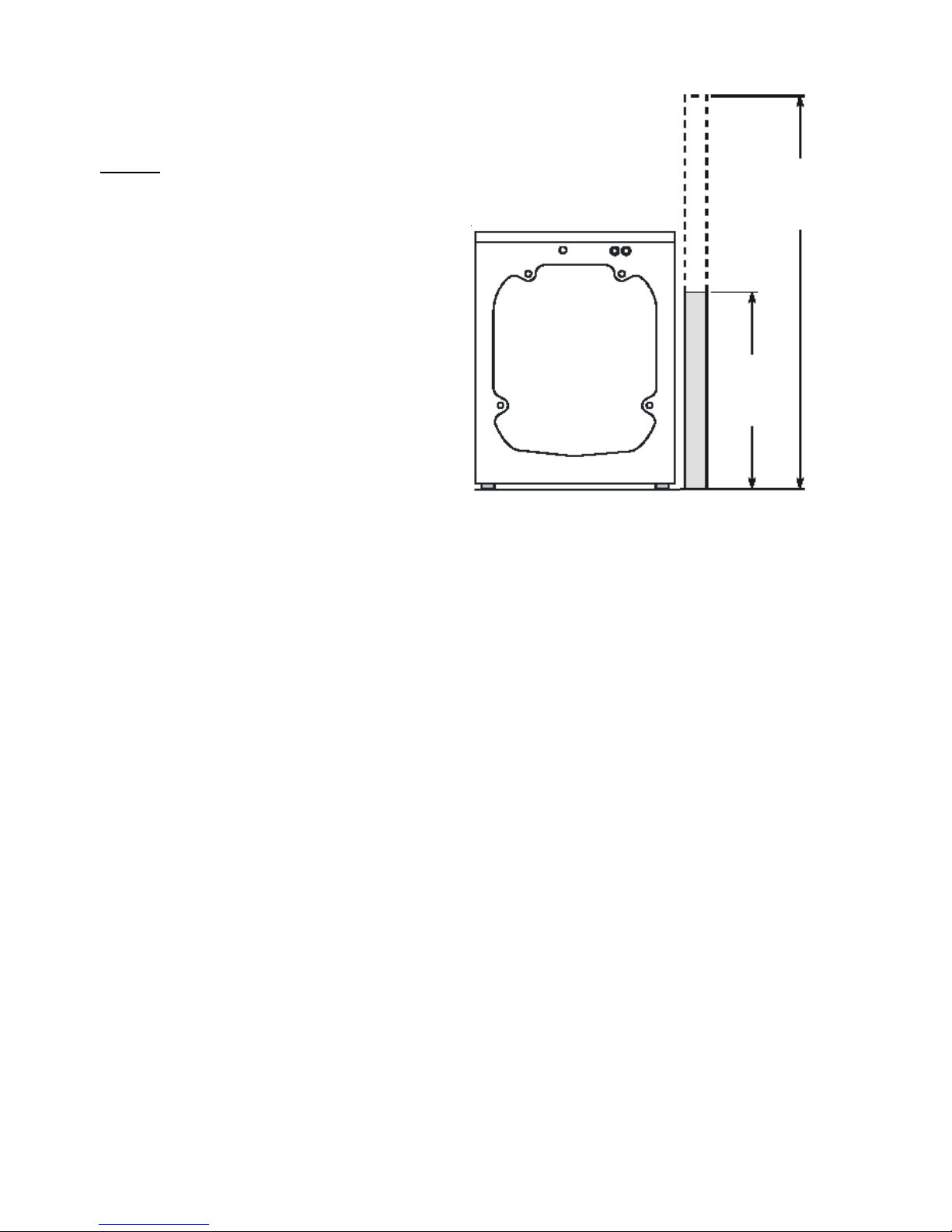

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gals (64.3 L) per

minute.

2. A standpipe diameter of 1-1/4 in. (3.18 cm)

minimum.

96 in.

(244 cm)

Max

24 in

(61 cm)

Min

BACK

NOTE:

Drain hose attached to the washer can reach a 90 in.

(229 cm) high standpipe. For a higher standpipe, use

hose P/N 134369410 available from an authorized parts

distributor.

3. The standpipe height above the floor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm)

16

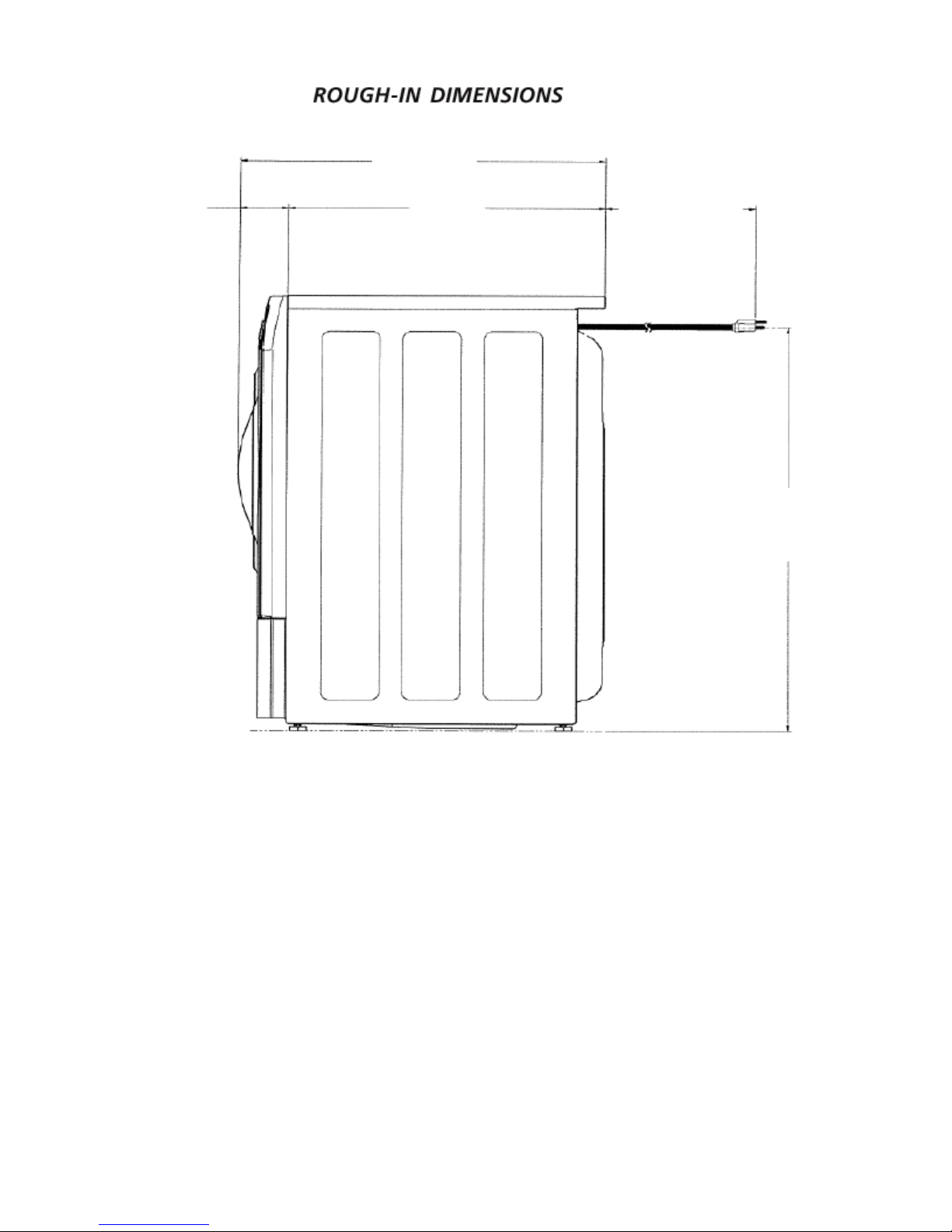

27.75”

(70.5)

3.75”

(9.5)

24”

(61)

60”

(152.4)

POWER CORD

33.40”

(84.8)

SIDE

17

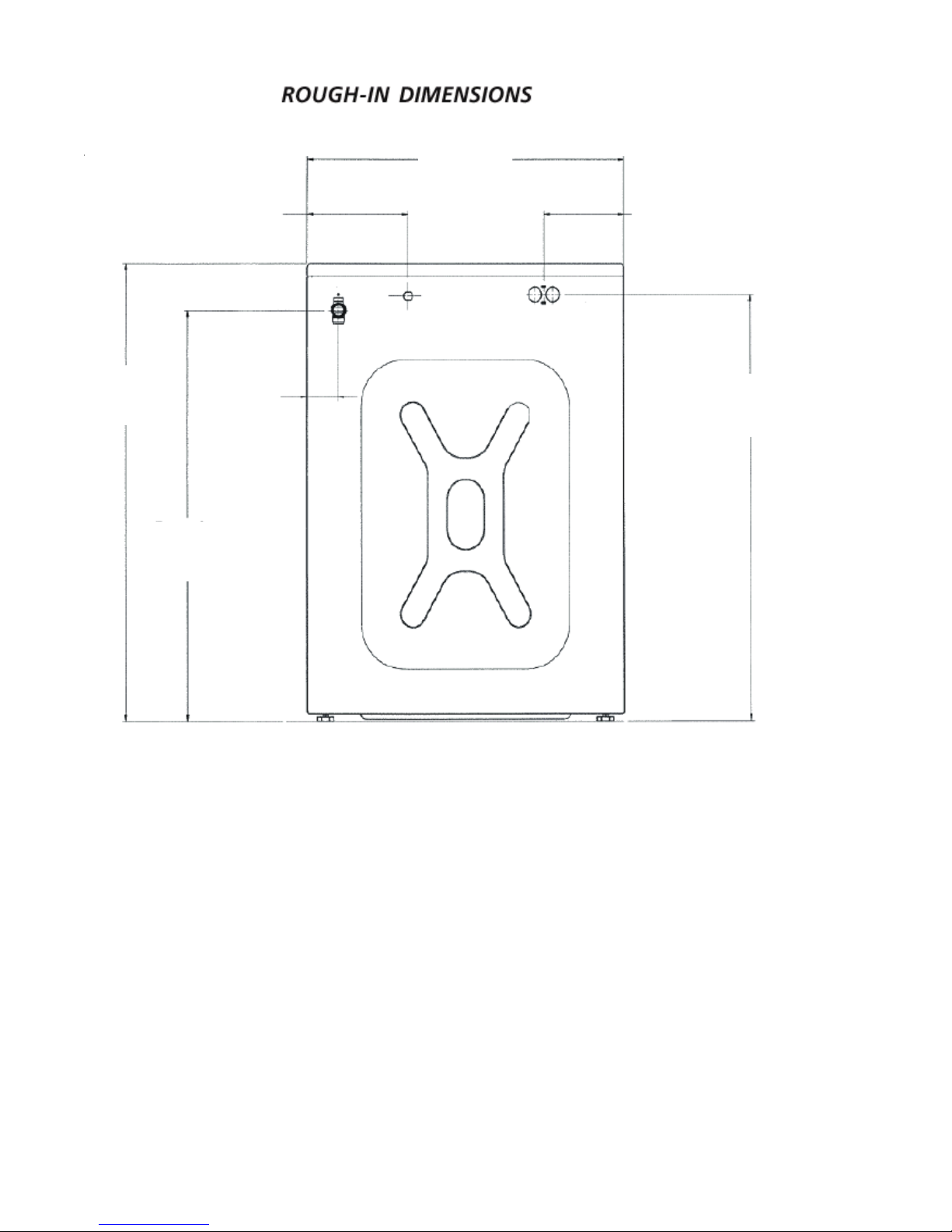

27”

(68.6)

36”

(91.3)

DRAIN

32.25”

(81.9)

8.5”

(21.6)

2.75”

(7)

6.75”

(17.1)

WA TER INLETS

33.5”

(85.1)

BACK

18

LOCA TION OF YOUR WASHER

DO NOT INST ALL YOUR W ASHER:

1. In an area exposed to dripping water or outside

weather conditions. The ambient temperature should

never be below 60 ° F (15.6 ° C) for proper washer

(detergent breakdown) operation.

2. In an area where it will come in contact with curtains

or drapes.

3. In an area (garage or garage-type building) where

gasoline of other flammables are kept or stored

(including automobiles).

4. On carpet. Floor MUST be solid with a maximum

slope of 1/2 in. per foot (1.27 cm per 30.5 cm). To

ensure vibration or movement does not occur,

reinforcement of the floor may be necessary .

IMPORT ANT

MINIMUM INSTALLA TION CLEARANCES

When installed in alcove or closet:

Sides, Rear = 0 in. (0 cm)

Top = 0 in. (0 cm)

When installed in closet: Front = 1 in. (2.54 cm)

Closet door ventilation required: 2 louvered openings

each 60 in 2 (387 cm 2 ), 3 in. (7.6 cm) from top and

bottom of door.

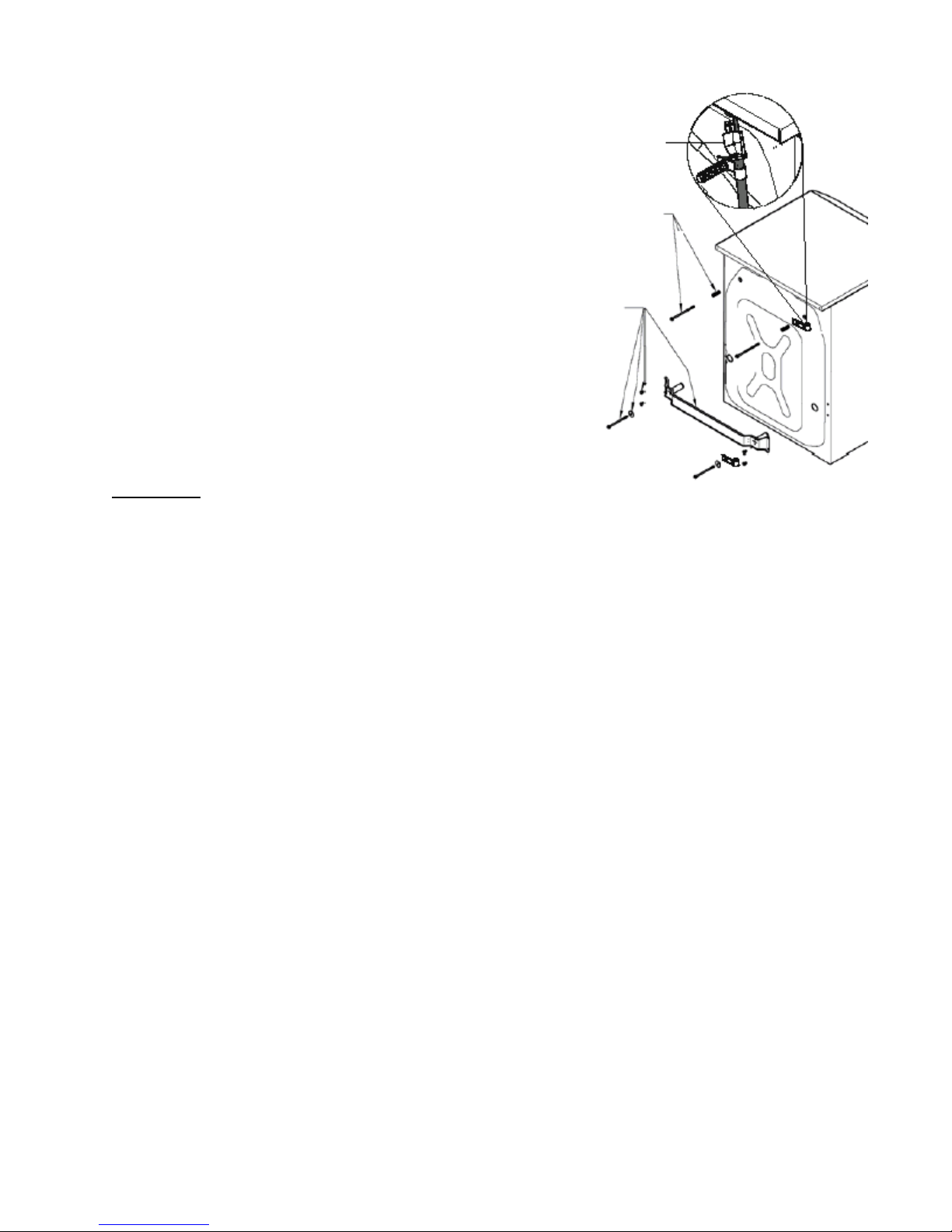

POWER CORD

REMOVE TWO

UPPER BOL TS,

‘P’ CLAMPS,

AND SPRINGS

REMOVE LOWER

BOL TS AND

WASHERS (2),

SCREWS (4),

AND BRACE

6. Remove the following from the back panel of the

washer:

4 packaging bolts,

2 packaging springs,

2 washers,

2 metal “P” clamps,

4 screws,

1 packaging brace.

7. Remove the 4 transport plugs from the literature

pack and install them in the corresponding holes

in the back panel of the washer.

UNPACKING

1. Cut the shipping carton along the dotted line along

the base of the unit.

2. While in the carton carefully lay the washer on its

back side.

3. Remove the styrofoam base.

4. Carefully return the washer to an upright position

and remove the carton.

5. Carefully move the washer to within 4 feet (122cm) of

the final location.

19

8. Remove the 4 small hole plugs from the literature

pack and install them in the side panel holes

vacated by the packaging brace.

9. Using the shipping posts, prop up the front of the

washer approximatley 2 inches to gain access to

the service panel screws.

10. Remove the 2 screws and remove the service panel.

REMOVE LEFT

AND RIGHT

FOAM BLOCKS

TWO SCREWS

UNDER P ANEL

1 1. Remove the two (2) styrofoam blocks located

under the drum (a yellow ribbon surrounds the items

to be removed). Lift up on the drum, tilt the base of

the foam blocks inwards toward the rear of the

washer until free, then pull them out.

12. Remove and discard the yellow ribbon from the front

of the washer.

13. Replace the service panel and screws.

STOP RIB

PUSH HOSE

INTO COUPLER

TO STOP

3. Using pliers, squeeze the ears of the spring clamp

and position the clamp so the clamp ears align with

and contact the tabs on the drain hose. This assures

proper location of the clamp to prevent leaks.

DRAIN HOSE T AB

SPRING

CLAMP

PROVIDED

ON HOSE

NOTE: If the washer is to be transported at a later

date, the shipping support hardware must

be reinstalled to prevent shipping damage.

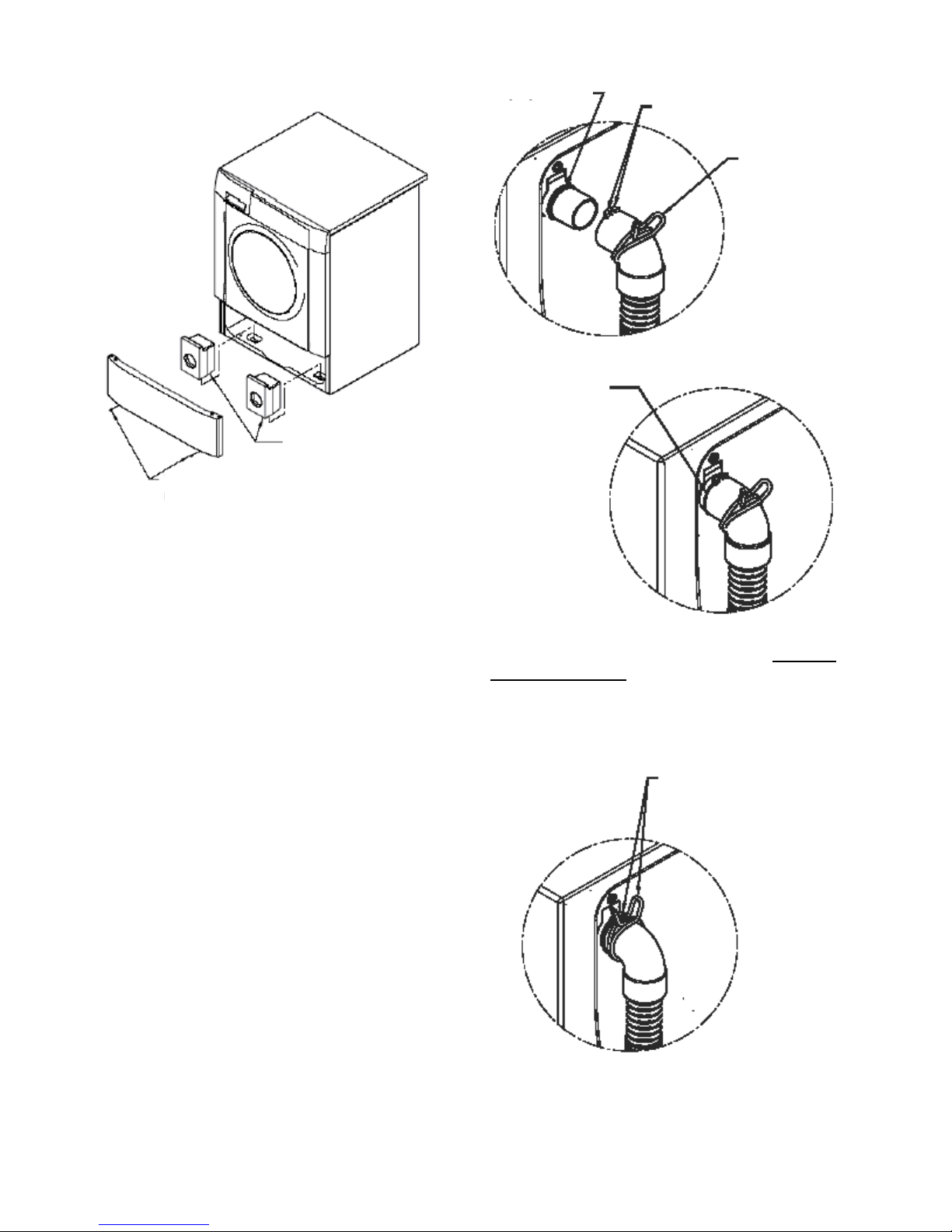

Drain Hose Installation

The drain hose is field installed to allow hose orientation

to the left or right, up or down depending on location of

the house drain. The hose is shipped in the washer tub

with the spring clamp on the coupler elbow and drain

hose hanger installed on the end of the hose.

1. Remove the drain hose from the tub of the washer.

2. Push the hose onto the drain coupler at the upper

left of the washer back panel until the hose contacts

the STOP RIB.

ALIGN SPRING

CLAMP EARS WITH

T ABS ON HOSE

20

T ABS

INSTALLATION

ORIENT HOSE

TO RIGHT,

LEFT , UP

OR DOWN

AS NEEDED

BEFORE

PLACING

CLAMP IN

POSITION

ALW A YS ALIGN CLAMP

EARS WITH T ABS

ON HOSE

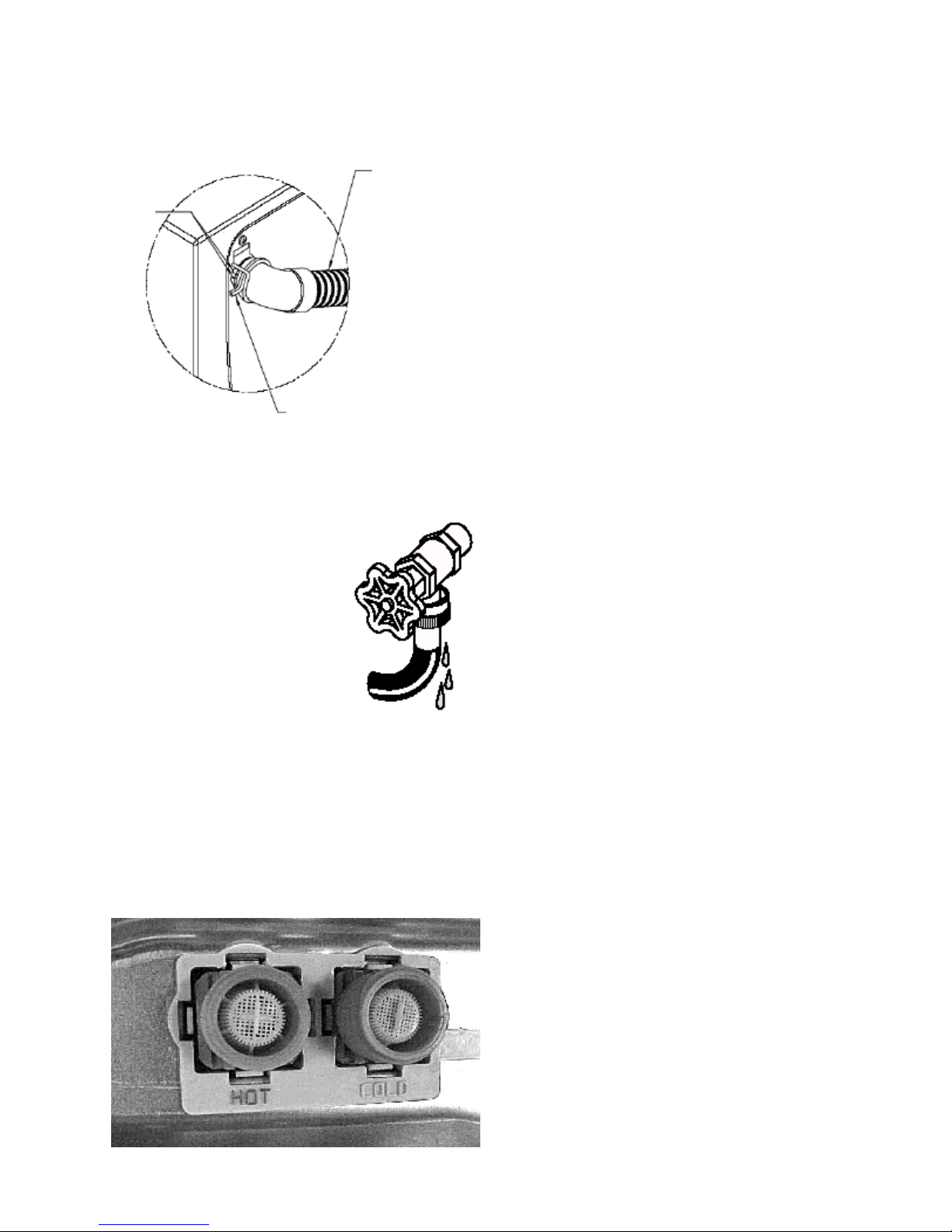

4. Connect the inlet hose ends to the HOT and COLD

water faucets tightly by hand, then tighten another

2/3 turn with pliers. Turn the water on and check

for leaks.

NOTE: Use only new hoses.

5. Carefully move the washer to its final location.

NOTE: Do not use the dispenser drawer or door

to lift washer .

6. With the washer in its final position, place a level

on top of the washer. No rocking of the washer

should exist. Adjust the front leveling legs up or

down to ensure the washer is resting solid. Rear

leg adjustment is accessible through the front

service panel.

NOTE: Keep the leg extension at a minimum to

prevent excessive vibration. The farther out

the legs are extended the more the washer

will vibrate.

1. Run some water from the

hot and cold faucets to flush

the water lines and remove

particles that might clog up

the water valve screens.

2. Remove the inlet hoses and

rubber washers from the

plastic bag located in the

drum of the washer and

install the rubber washers in

each end of the inlet hoses.

3. Carefully connect the inlet hose (90° elbow end)

marked “HOT” to the outside “H” outlet of the water

valve. Tighten by hand, then tighten another 2/3 turn

with pliers. Carefully connect the other inlet hose

(90° elbow end) to the inside “C” outlet of the water

valve. Tighten by hand, then tighten another 2/3 turn

with pliers. Do not crossthread or over-tighten

these connections.

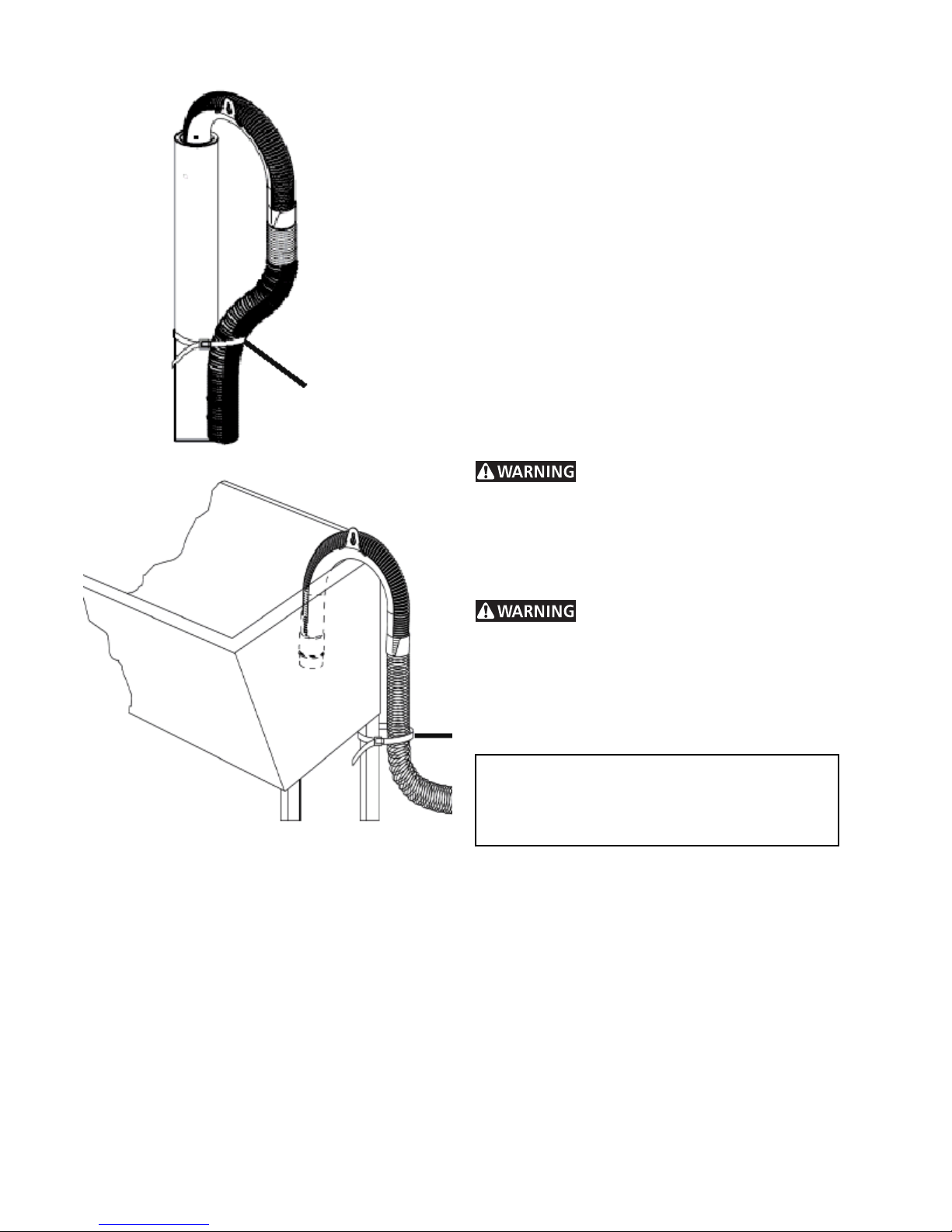

7. Place the hook end of the drain hose in the drain

opening. Secure the drain hose with the cable tie

(provided in the enclosure package) to the

standpipe, inlet hose, laundry tub, etc. so the hose

does not pull out from the force of the water.

Cable Tie

21

12. If your washer does not operate, please review the

“Avoid Service Checklist” in your Owner’s Guide

before calling for service.

13. Place these instructions in a location near the

washer for future reference.

NOTE: A wiring diagram and technical data sheet are

located in an envelope attached to the left hand

side panel on the inside of the washer .

REPLACEMENT PARTS

Cable Tie

Cable

Tie

If replacements parts are needed for your washer , call

Sears Parts and Service Toll Free Number 1-800-4MY -HOME (1-800-469-4663).

TM

Destroy the carton and plastic bags

after the washer is unpacked. Children might use them

for play. Cartons covered with rugs, bedspreads, or

plastic sheets can become airtight chambers causing

suffocation. Place all materials in a garbage container

or make materials inaccessible to children.

The instructions in this manual and all

other literature included with this washer are not meant

to cover every possible condition and situation that may

occur. Good safe practice and caution MUST be applied

when installing, operating and maintaining any

appliance.

Maximum benefits and enjoyment are achieved when

all the Safety and Operating instructions are

understood and practiced as a routine with your

laundering tasks.

8. Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at a

circuit breaker/fuse box before plugging

the power cord into an outlet.

9. Turn on the power at a circuit breaker/fuse box.

10. Read the Operating Instructions and Owner’s Guide

provided with the washer. They cont ain valuable and

helpful information that will save you time and money .

1 1. Run the washer through a complete cycle. Check

for water leaks and proper operation.

22

SECTION B - Washer & Dryer

Pedestal Installation Instructions

IMPORTANT: Read and save these

instructions.

This kit is intended to be installed

by persons having electrical and

mechanical training and a level of

knowledge considered acceptable

in the appliance repair trade.

Y our safety and the safety of others are very

important. Many important safety messages

are provided in these instructions and on

your appliance. Always read and obey all

safety messages.

WARN I NG

EXCESSIVE WEIGHT HAZARD

Two or more people may be required to move and

install the washer & dryer onto pedestals.

Failure to comply may cause back or other injury .

WASHER INSTALLATION

Washer Installation Kit

1. Remove the washer installation hardware from

the plastic bag.

2. Attach the rear brackets to the pedestal with four

#8 screws (2 per bracket).

T ools needed:

level

7/16” open end wrench or ratchet &

socket

9/16” open end wrench

adjustable wrench

#2 Phillips screwdriver

flat blade screwdriver

23

3. Remove the front service panel from the washer.

Using two or more people, carefully lift the

washer onto the pedestal and set flush against

the rear brackets as shown.

NOTE: If washer was previously installed,

disconnect power cord, remove inlet hoses

from water faucets and tape the drain hose to

the top of the washer to eliminate excess

water on the floor. Also, make sure the

leveling legs are adjusted fully into the

washing machine.

6. Insert the bolt/spacer assembly up through the

pedestal with the front spacer positioned in the

square hole of the pedestal and the bolt coming

through the slotted hole in the washing machine

base.

7. Install a rubber washer, flat washer and hex nut

onto the carriage bolt. Tighten the hex nut.

4. Align the sides of the washer with the sides of

the pedestal and attach the washer to the rear

brackets using four #10 screws (2 per bracket).

5. Open the drawer of the pedestal; assemble a

carriage bolt through a front spacer and rubber washer.

24

8. Repeat installation of bolt/spacer assembly for the

other side.

9. After closing the pedestal drawer , carefully move the

washer/pedestal assembly into

position. NOTE: Because of the increased weight

caused by the addition of the pedestal, two or

more people may be required.

DRYER INSTALLATION

Dryer Installation Kit

1. Remove the dryer installation hardware from the

plastic bag.

2. Attach the rear brackets to the pedestal with four

#8 screws (2 per bracket).

NOTE: The washer/pedestal assembly MUST be

on a solid floor and level for proper operation.

After leveling the washer/pedestal assembly,

adjust the lock nut on each leveling leg against

the pedestal base and tighten with a wrench.

Keep the leg extension at a minimum to prevent

excessive vibration.

10. Refer to the installation instructions that came

with the washer to properly complete electrical,

water, and drain connections. If questions arise,

please refer to the Owner’s Guide that came with the

washer for contact information.

25

3. Attach the front brackets to the pedestal with

four #8 screws (2 per bracket).

NOTE: If dryer was previously installed,

disconnect power cord and vent hose.

Also, make sure the leveling legs are

adjusted fully into the dryer.

5. Set the dryer down onto the pedestal making sure

the service panel bracket on the dryer is behind the

front brackets of the pedestal.

4. Using two or more people, carefully lift the dryer onto

the pedestal, tilting the dryer back slightly to engage

the slots in the rear of the dryer with the tabs of the

rear brackets on the pedestal.

26

6. With the pedestal drawer open for better access,

install the two #10 screws through the front

brackets in the pedestal into the service panel

bracket of the dryer.

7. After closing the pedestal drawer , carefully move the

dryer/pedestal assembly into position.

NOTE: Because of the increased weight

caused by the addition of the pedestal,

two or more people may be required.

8. Refer to the installation instructions that came with

WARRANTY

Full One Y ear W arranty on Mechanical Part s

NOTE: The dryer/pedestal assembly

on a solid floor and level for proper

operation. After leveling the

dryer/pedestal assembly, adjust the lock

nut on each leveling leg against the

pedestal base and tighten with a wrench.

Keep the leg extension at a minimum to

prevent excessive vibration.

the dryer to properly complete electrical and venting

connections. If questions arise, please refer to the

Owner’s Guide that came with the dryer for contact

information.

MUST be

Sample warranty - always check

warranty with product

For one year from date of purchase, when this pedestal is installed with the listed washer or dryer (see

owners manual for specific model) and operated according to the information in the Use and Care Guide,

Operating Instructions and Installation Instructions, the supplier will replace any of its mechanical parts if

they are defective in workmanship or material. Keep your bill of sale. The date of the bill establishes the

warranty period should parts be required. This written warranty gives you specific rights. Y ou may also have

other rights which vary from state to state.

Warranty Restriction

If the pedestal is used for any other purpose than private family use or used with any product that requires

modification for installation, the warranty is null and void.

Warranty Part s

Warranty parts are available by contacting the supplier where the pedestal was purchased or refer to the

Use and Care Guide that came with the washer or dryer that is installed on the pedestal for contact

information.

27

SECTION C - OPERATING

INSTRUCTIONS

• Any water remaining in the dispenser at the end of

the cycle is a result of siphoning action and part of

normal operation.

Before Operating Y our Washer

Read your washer Owner’s Guide. It has important safety

and warranty information. It also has many suggestions

for best washing results.

To reduce the risk of fire, electric

shock or injury to persons, read the IMPORTANT

SAFETY INSTRUCTIONS in your washer Owner’s Guide

before operating this appliance.

Operating Steps

Read and follow “Washing Procedures” in your Owner’s

Guide. It provides detailed information for preparing the

wash load and choosing control settings to ensure best

washing results.

1. Sort laundry into loads that can be washed together.

2. Prepare items for washing.

3. Pretreat stains and heavy soil.

4. Add laundry load to the wash drum.

5. Add laundry product s to the dispenser.

6. Select the appropriate cycle and temperature for the

load.

• Turn the PROGRAM knob to select the cycle.

• Turn the TEMP knob to select the wash and rinse

temperatures.

• If the water temperature combination is not

appropriate for that cycle, the status lights will blink

and the signal will beep 3 times.

7. The suitable final spin speed and options for that cycle

will automatically be displayed.

• T o change the final spin speed, press SPIN until the

indicator for the desired selection is lighted.

• T o select or delete an option, press OPTIONS, then

SELECT . The indicator light will stop blinking when

the option has been selected. It will not light if the

option is not available for that cycle.

• Adjustments to the cycle will be remembered each

time that cycle is selected in the future.

• See “Washer Settings Chart” chart for factory

settings.

• Detergent, bleach and fabric softener will be dispensed

at the proper time in the cycle.

• Slide saftey latch to the right to open the dispenser

drawer.

• Add the recommended amount of a high efficiency

detergent to the detergent compartment.

• If desired, add liquid chlorine bleach and liquid fabric

softener to the appropriate compartments.

• Slowly close dispenser drawer. The washer will not

operate with the drawer open.

Note: To provide the best care for your laundry

items, not every temperature, speed and

option is available with every cycle.

8. Select DELA Y START to delay the beginning of the

cycle for 4, 8 or 12 hours.

9. Start the washer .

• Close the door and press START. The washer will not

operate with the door open.

• As a safety measure, the door will automatically lock

during the entire wash cycle and the DOOR LOCK

indicator will be lighted.

28

Loading...

Loading...