Page 1

Installation Instructions

Electrolux Front-Load Washer

Instructions d’installation

Laveuse à chargement frontal Electrolux

Instrucciones de Instalación

Lavadora de carga frontal Electrolux

137064300 B (1004)

Page 2

2

Important Safety Instructions

WARNING

For your safety the information in this manual must be followed to minimize the risk of fi re or explosion

or to prevent property damage, personal injury or loss of life. Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of this or any other appliance.

Recognize safety symbols, words and

labels

Safety items throughout this manual are labeled

with a WARNING or CAUTION based on the risk

type as described:

This symbol alerts you to situations that may cause serious body

harm, death or property damage.

This symbol alerts you to situations that may cause bodily injury

or property damage.

WARNING

RISK OF FIRE - Read all of the following instructions before installing and using this appliance:

Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons •

covered with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place

all materials in a garbage container or make materials inaccessible to children.

For your safety the information in this manual must be followed to minimize the risk of fi re or explo-•

sion or to prevent property damage, personal injury or loss of life. Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of this or any other appliance.

Install the washer according to the manufacturer’s instructions and local codes.•

The electrical service to the washer must conform with local codes and ordinances and the latest edi-•

tion of the National Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1

part 1.

To avoid back or other injury, have more than one person move or lift the washer.•

Do not stack a dryer on top of washer already installed on pedestal. Do not stack washer on top of •

dryer. Do not stack washer on top of another washer.

The instructions in this manual and all other literature included with this dryer are not meant to cover •

every possible condition and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and maintaining any appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.•

Do not touch any electrical switch; do not use any phone in your building.•

Clear the room, building or area of all occupants.•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.•

If you cannot reach your gas supplier, call the fi re department.•

Save these instructions for future reference.

Table of contents

Important Safety Instructions ......................................... 2

Installation Requirements ............................................3-5

Installed Dimensions ...................................................... 6

©2010 Electrolux Major Appliances

Installation Instructions .............................................7-11

Reversing Door ........................................................ 12-17

Options ......................................................................... 18

All rights reserved.

Page 3

Installation Requirements

3

Please read and save this guide

Thank you for choosing Electrolux, the new

premium brand in home appliances. These

Installation Instructions are part of our commitment

to customer satisfaction and product quality

throughout the life of your new appliance.

Installation Checklist

Shipping Hardware

Foam shipping support (under wash tub)

removed and stored

Shipping bolts and spacers removed from

rear of appliance and stored

Hole plugs (shipped in bag in drum)

installed in holes in backsheet

Leveling

Washer is level, side-to-side and front-toback

Cabinet is setting solid on all corners

Water Supply

HOT supply is connected to HOT inlet and

COLD supply is connected to COLD inlet

HOT and COLD water supply turned on

No leaks present at water supply

connections or appliance inlet connections recheck in 24 hours

Questions?

For toll-free telephone support in the U.S. and

Canada: 1-877-4ELECTROLUX (1-877-435-3287).

For online support and product information visit

http://www.electroluxappliances.com.

Drain

Stand pipe or wall drain height minimum 24”

Drain hose snapped in “U” channel

(shipped in drum)

Drain hose secured in place with cable tie

(shipped in drum)

Door Reversal

Follow detailed instructions in this guide

Test hinge and latch for function

Electrical Power

House power turned on

Washer plugged in

Final Checks

Installation Instructions and Use and Care

Guide read thoroughly

Door locks and water enters drum when

cycle starts

Registration card sent in

Pre-installation requirements

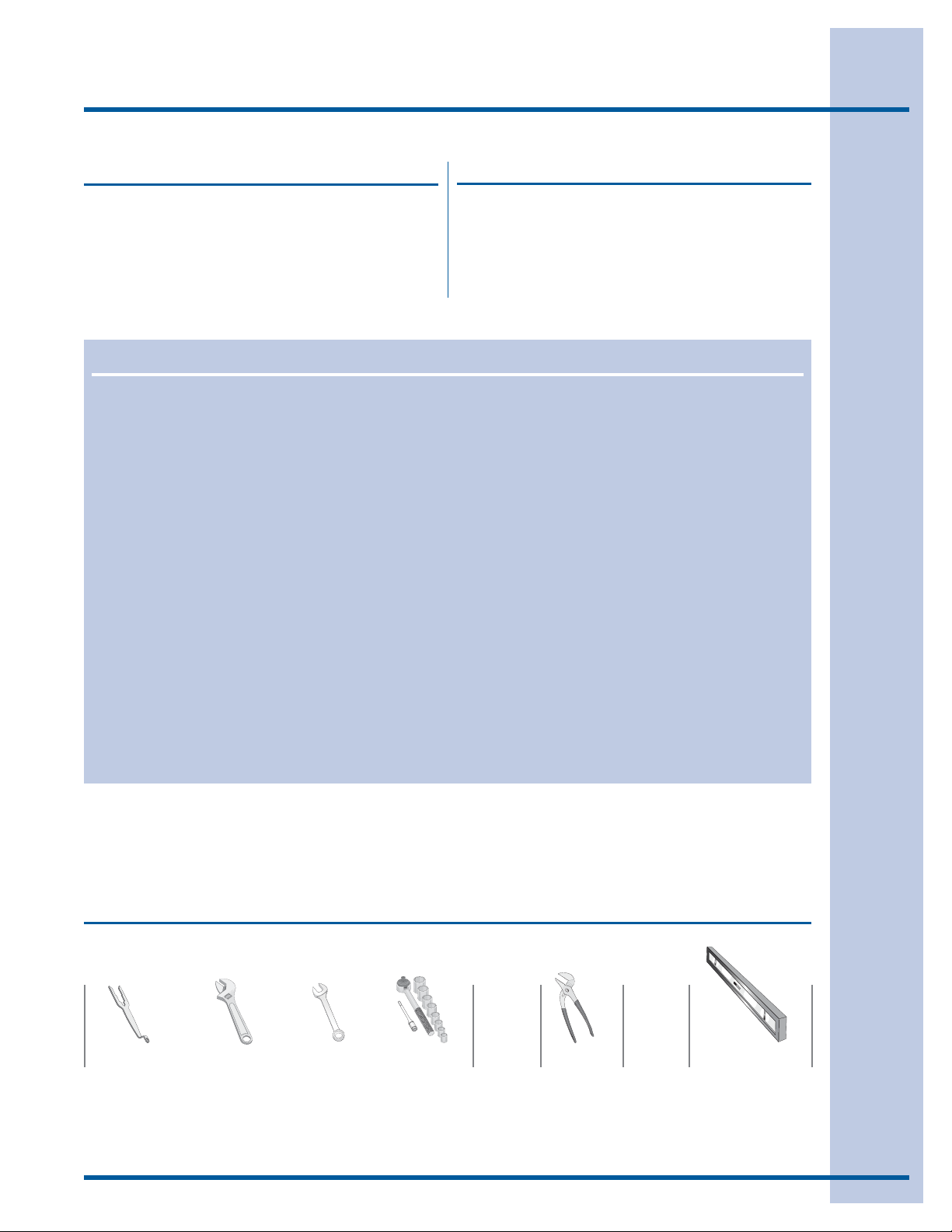

Tools and materials needed for installation:

OR OR OR AND AND

Universal wrench

supplied with

washer

Adjustable

wrench

3/8” or 10 mm

box wrench

Ratchet and

socket set

Adjustable

pliers

Carpenter’s level

Page 4

4

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

Installation Requirements

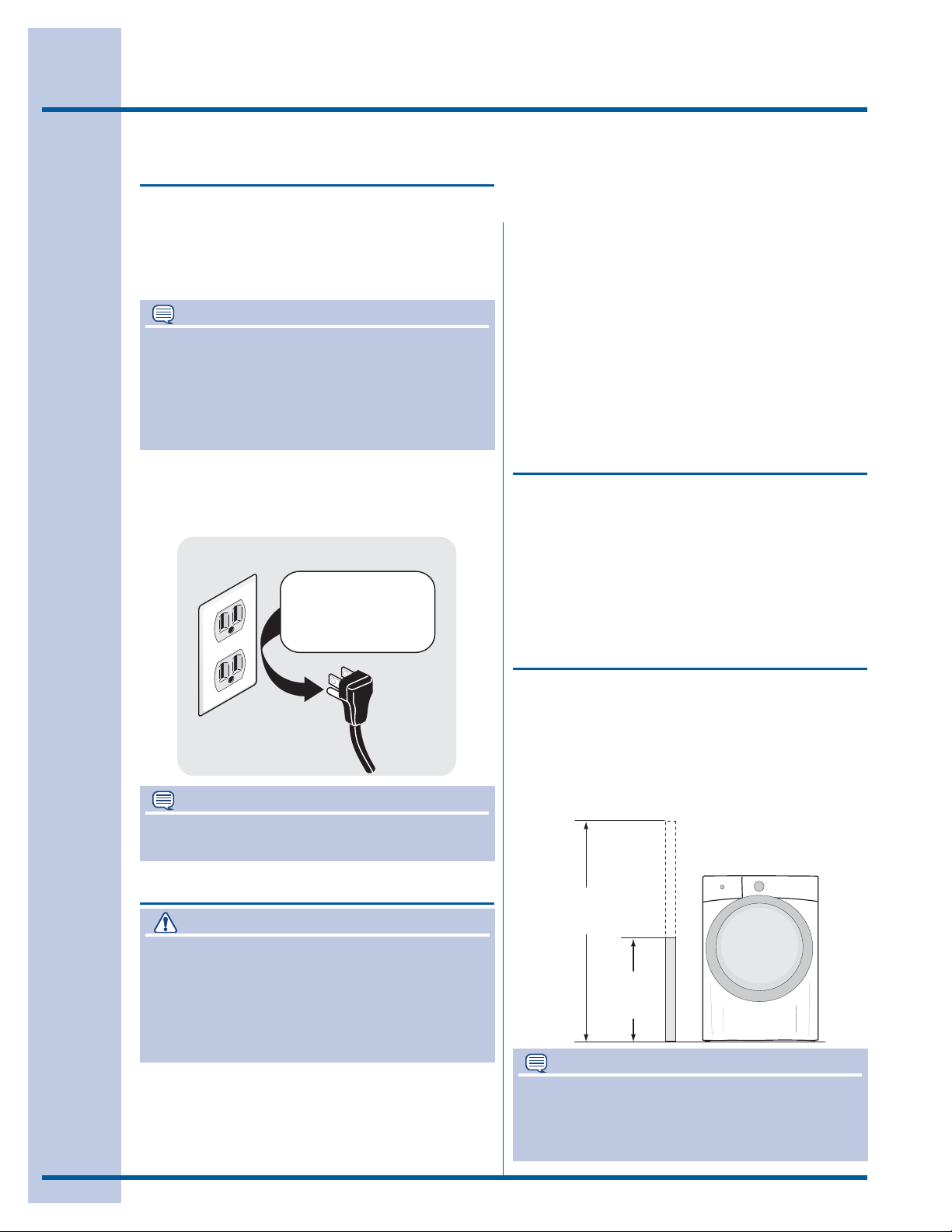

Electrical system requirements

CIRCUIT - Individual, properly polarized and

grounded 15 amp. branch circuit fused with 15

amp. time delay fuse or circuit breaker.

POWER SUPPLY - 2 wire, with ground, 120 volt

single phase, 60 Hz, Alternating Current.

NOTE

Because of potentially inconsistent voltage

capabilities, the use of this washer with power

created by gas powered generators, solar

powered generators, wind powered generators

or any other generator other than the local utility

company is not recommended.

OUTLET RECEPTACLE - Properly grounded

3-prong receptacle to be located so the power

supply cord is accessible when the washer is in

an installed position.

Grounding type

wawall receptacl

Do not,

under

anany cir

cumstances,

cut,

remo

or b

ypass th

grgrounding pr

ong.

supply cord having an equipment-grounding

conductor and a grounding plug, the plug

MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and

grounded in accordance with all local codes and

ordinances or in the absence of local codes,

with the National Electrical Codes, ANSI/NFPA

70 (latest edition). If in doubt, call a licensed

electrician. DO NOT cut off or alter the grounding

prong on the power supply cord. In situations

where a two-slot receptacle is present, it is

the owner’s responsibility to have a licensed

electrician replace it with a properly grounded

three prong grounding type receptacle.

Water supply requirements

Hot and cold water faucets MUST be installed

within 42 inches (107 cm) of your washer’s water

inlet. The faucets MUST be 3/4 inch (1.9 cm) with

threading for laundry hose connection. Water pressure MUST be between 30 and 120 psi. Pressure

difference between hot and cold cannot be more

than 10 psi. Your water department can advise you

of your water pressure.

Drain system requirements

PoPower cord with

3-prong

ounded plug

NOTE

GFI (Ground Fault Interrupter) receptacle is not

required.

Grounding requirements

WARNING

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in

doubt as to whether the appliance is properly

grounded.

The washer MUST be grounded. In the event 1.

of malfunction or breakdown, grounding will

reduce the risk of electrical shock by a path of

least resistance for electrical current.

Since your washer is equipped with a power 2.

Drain capable of eliminating 17 gals (64.3 L) per 1.

minute.

A standpipe diameter of 1-1/4 in. (3.18 cm) 2.

minimum.

The standpipe height above the fl oor should be:3.

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm)

96”

(244cm)

max.

24”

(61cm)

min.

NOTE

Drain hose attached to the washer can reach a 79

in. (201 cm) high standpipe. For higher standpipe,

use hose P/N 137098000, available from an

authorized parts distributor.

Page 5

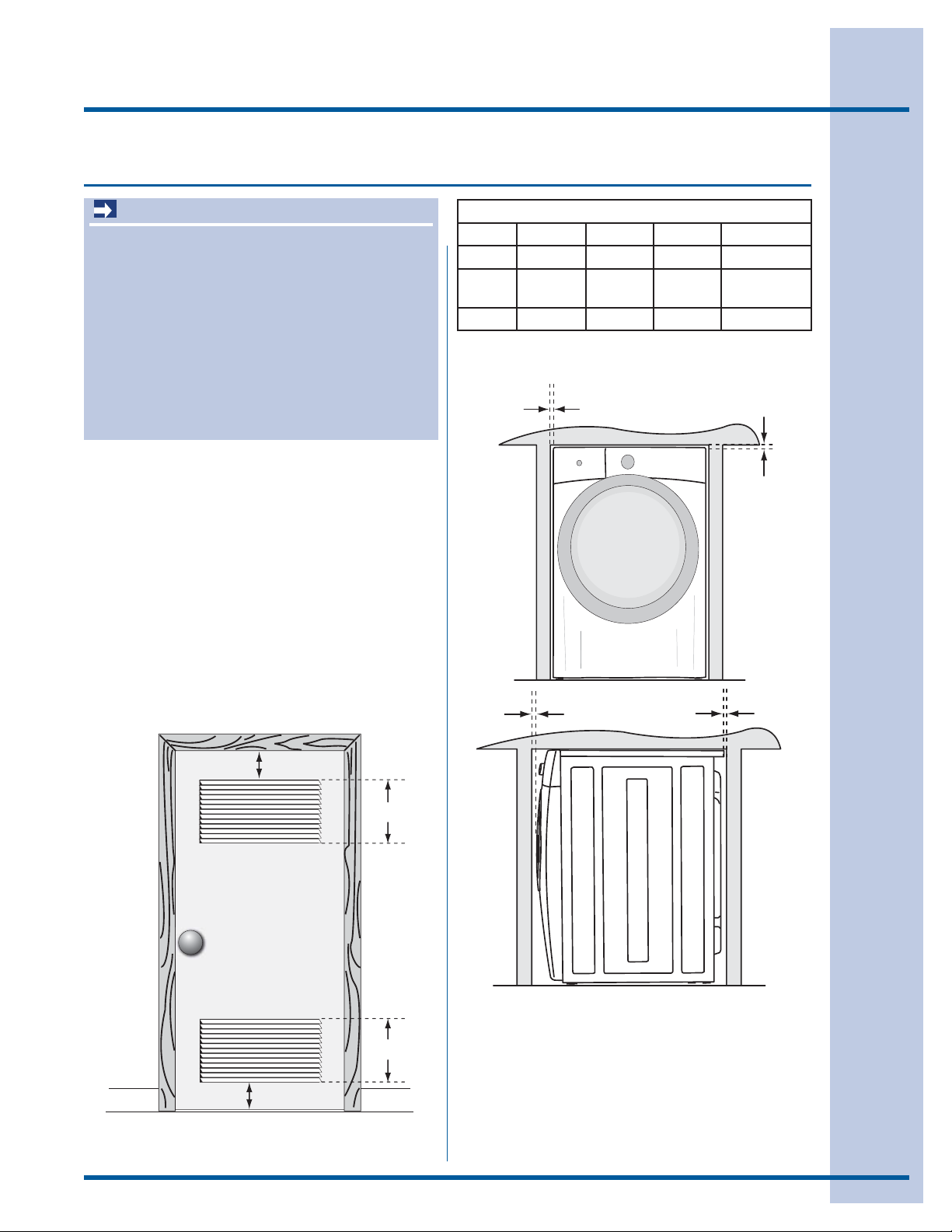

Clearance requirements

Installation Requirements

5

IMPORTANT

DO NOT INSTALL YOUR WASHER:

1. In an area exposed to dripping water or outside weather conditions. The ambient temperature should never be below 60° F (15.6° C) to

maximize detergent effectiveness.

2. In an area (garage or garage-type building)

where gasoline or other fl ammables (including

automobiles) are kept or stored.

3. On carpet. Floor MUST be solid with a maximum slope of 1 inch (2.54 cm). To minimize

vibration or movement, reinforcement of the

fl oor may be necessary.

INSTALLATION IN A RECESS OR CLOSET

If washer and dryer are installed in the same

closet, door ventilation is required: A minimum of

120 square inches (774.2 cm²) of opening, equally

divided at the top and bottom of the door, is

required. Louvered openings should be located 3

inches (7.6 cm) from bottom and top of door. Air

openings are required to be unobstructed when a

door is installed. A louvered door with equivalent

air openings for the full length of the door is

acceptable.

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

Under Counter

Closet 0” (0 cm) 0” (0 cm)* 0” (0 cm) 1” (2.54 cm)

0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

0”

(0cm)

0”

(0cm)

3”

(7.6cm)

3”

(7.6cm)

closet door

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

1”

(2.54cm)

0”

(0cm)

Page 6

6

Installation Requirements

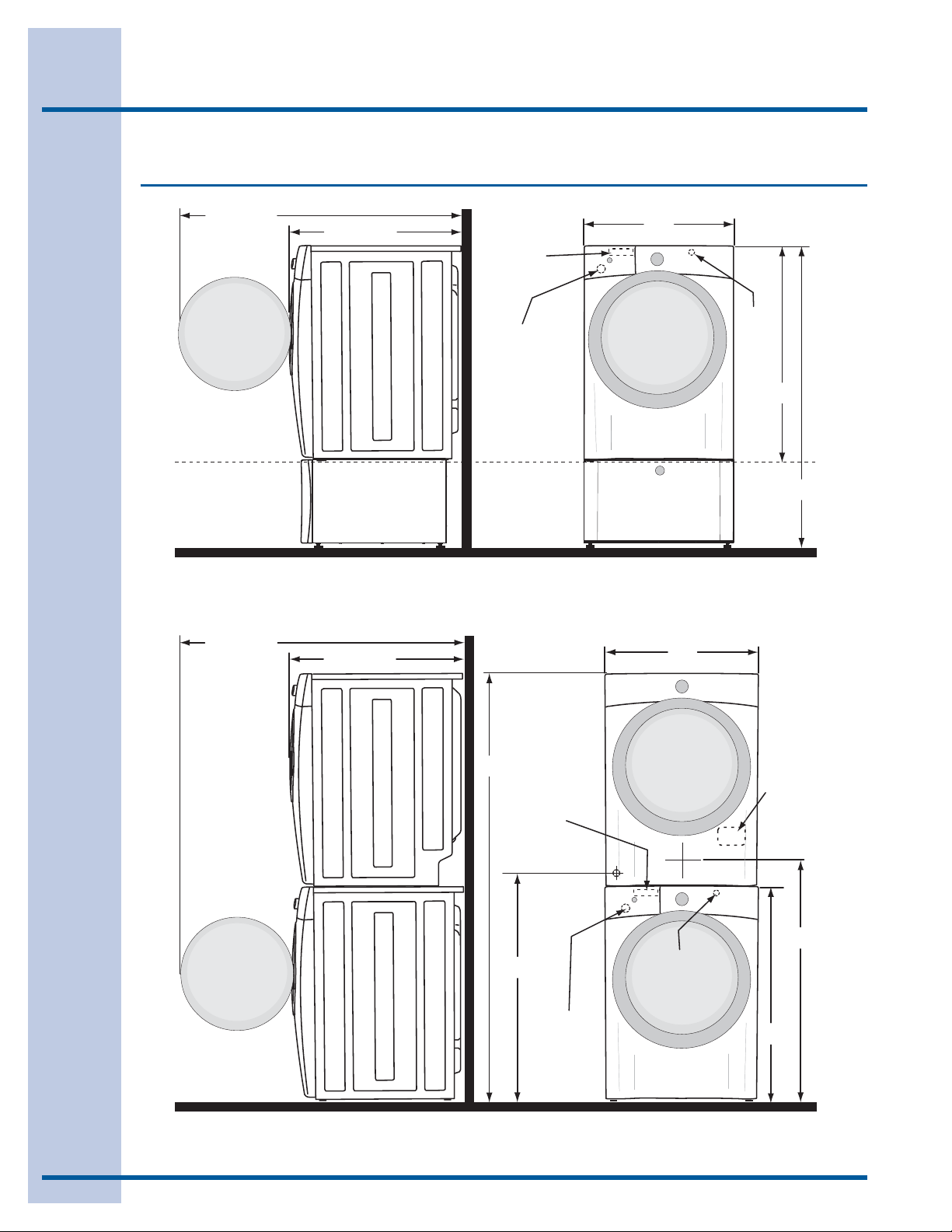

Installed washer dimensions

50.6” (128.53cm)*

to clear open door

freestand washer

on floor

floor line

washer mounted on

optional pedestal

31.50” (80.01cm)*

to front of closed door

water supply

connection

on rear of unit ¹

drain hose

on rear of unit ²

27.00”

(68.58cm)

power

cord

on rear

of unit ³

(96.52cm)

38.00”

53.00”

(134.62cm)

floor line

* To obtain these minimal depth dimensions, dryer must either be vented straight back or with a quick-turn 90° elbow.

Connection of water inlet hose on Steam Models adds 3/4 in. (2 cm) to installation depth.

¹ Hot and cold inlet hose length approximately 48.5 inches (123cm)

² Drain hose length approximately 59 inches (150cm).

³ Power supply cord length approximately 60 inches (152.5cm).

50.6” (128.5cm)*

to clear open door

31.50” (80cm)*

to front of closed door

75.75”

(192.5cm)

gas supply

pipe on rear

of gas unit

39.00”

(99cm)

water supply

connection

on rear of

washer ¹

27.00”

(68.5cm)

power cord

on rear of

washer ³

electrical

supply on

rear of

dryer

centerline

height for

rear vent

41.00”

(105cm)

drain hose

on rear of

washer ²

* To obtain these minimal depth dimensions, dryer must either be vented straight back or with a quick-turn 90° elbow.

Connection of water inlet hose on Steam Models adds 3/4 in. (2 cm) to installation depth.

¹ Hot and cold inlet hose length approximately 48.5 inches (123cm)

² Drain hose length approximately 59 inches (150cm).

³ Power supply cord length approximately 60 inches (152.5cm).

38.00”

(96.5cm)

Page 7

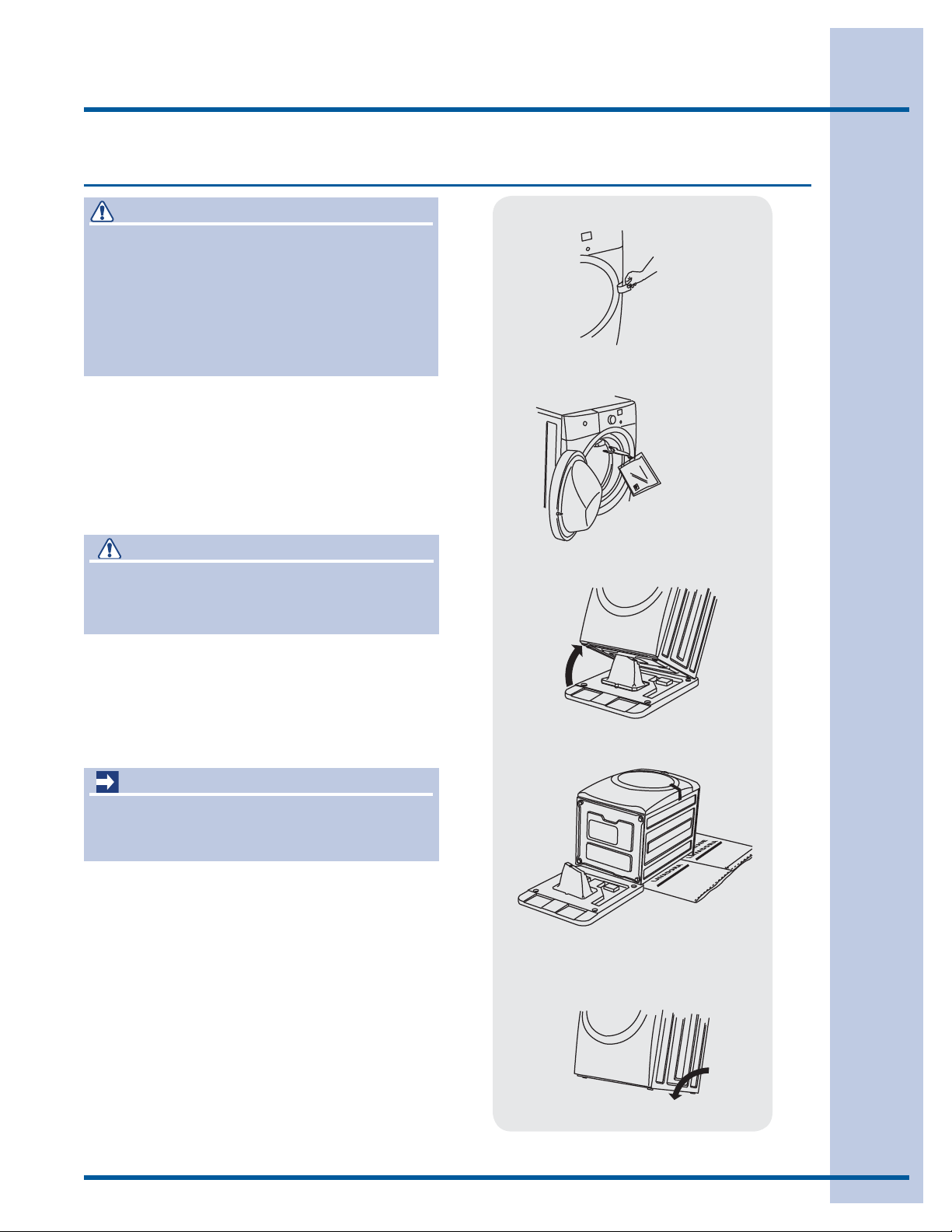

Removing foam packaging

WARNING

SUFFOCATION HAZARD

Destroy the carton and plastic bags after the

washer is unpacked. Children might use them

for play. Cartons covered with rugs, bedspreads,

or plastic sheets can become airtight chambers

causing suffocation. Place all materials in a

garbage container or make materials inaccessible

to children.

Temporarily remove door tape.1.

Open washer door and remove everything from 2.

the drum.

Close door and reapply door tape.3.

Using a rug, blanket or piece of cardboard to 4.

protect the fl oor, carefully lay the washer on it’s

back.

Unpacking Washer

7

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more than one

person move or lift the washer.

Remove styrofoam base and shipping plug and 5.

set them aside.

Carefully return the washer to an upright posi-6.

tion.

Carefully move the washer to within 4 feet (1 m) 7.

of its fi nal location.

IMPORTANT

Save styrofoam base and shipping plug for use

to help prevent washer damage during any future

moves.

Page 8

8

Unpacking Washer

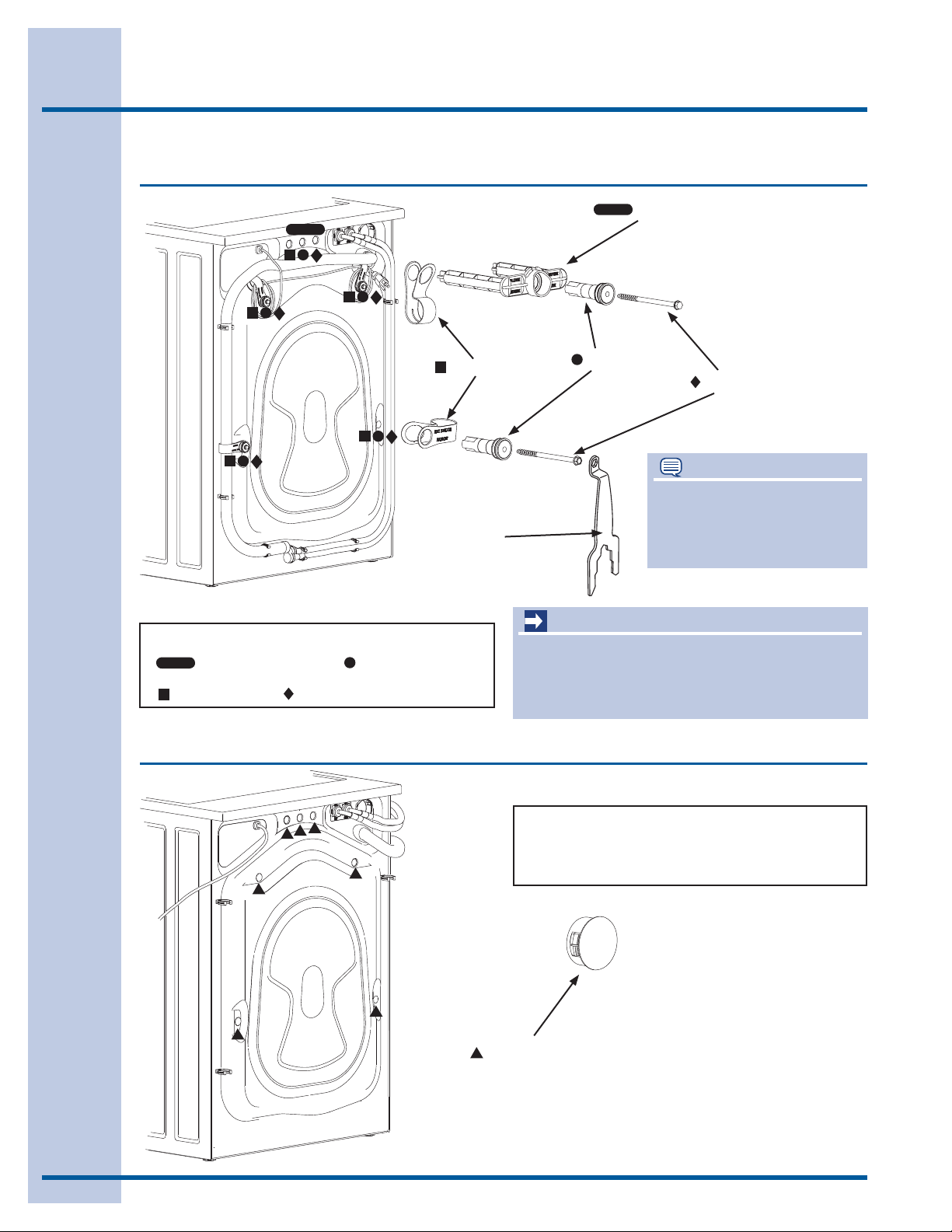

Removing shipping hardware

1 SHIPPING FORK

Remove all of the following:

1 SHIPPING FORK

5 P CLAMPS

5 BOLTS

5 SPACERS

Installing hole plugs

5 P CLAMPS

UNIVERSAL

WRENCH

(SUPPLIED)

5 SPACERS

5 BOLTS

NOTE

Rubber expansion material

on spacers may need time to

relax before they can be easily

pulled through shipping hole.

IMPORTANT

Save all shipping bolts and spacers for future

use. If the washer is to be transported at a later

date, the shipping hardware must be reinstalled

to help prevent shipping damage.

Locate 7 hole plugs in the small bag supplied

with washer instruction guides. Insert them in

the holes in washer back panel.

7 HOLE PLUGS

(IN BAG)

Page 9

Installation Instructions

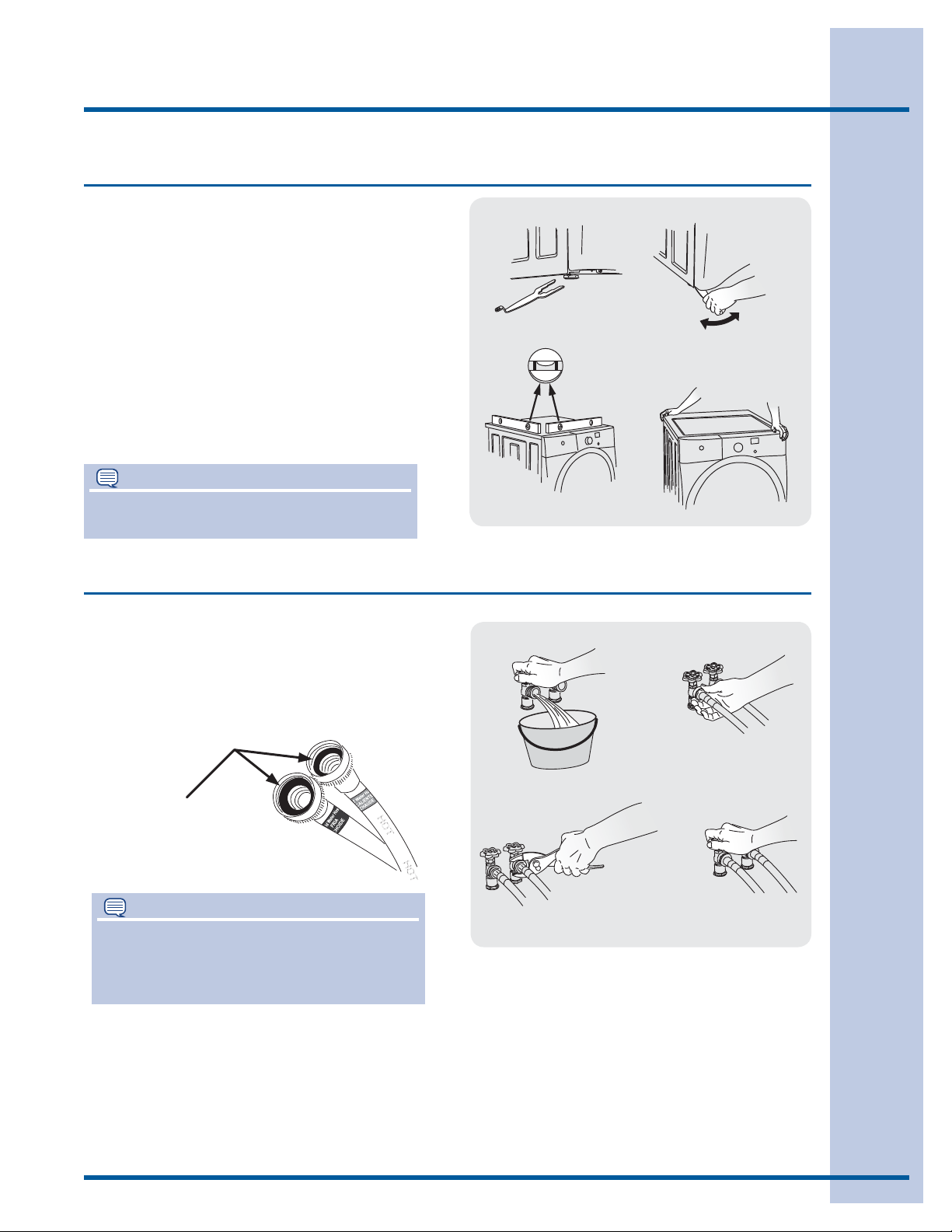

Leveling your washer

Excessive noise and vibration can be prevented by

properly leveling the washer.

For free standing installation and with the 1.

washer within 4 feet (1 m) of its fi nal location,

place a level on top of the washer.

Use the universal wrench to adjust the level-2.

ing legs so the washer is level front-to-rear and

side-to-side, and stable corner-to-corner.

Press down on alternate corners and sides and 3.

feel for the slightest movement. Adjust the

appropriate leg(s) so the washer sits solidly on

the fl oor on ALL four legs. Keep the leveling leg

extension at a minimum for best performance

of the washer.

NOTE

For pedestal installations, see additional

installation instructions included with the pedestal.

9

a

c

b

raise

lower

d

Connecting inlet water

Run some water from the hot and cold faucets 1.

to fl ush the water lines and remove particles

that might clog the water valve screens and to

determine which faucet is hot and which is cold

supply.

Look in the end of each water supply inlet hose 2.

and verify that the rubber washers are in place.

RUBBER WASHERS

MUST BE PRESENT

NOTE

HOT and COLD water inlet hoses are color

coded for identifi cation. The HOT inlet hose is

marked with a RED band and the COLD inlet

hose is marked with a BLUE band.

Connect the HOT inlet hose to the HOT water 3.

supply and the COLD inlet hose to the COLD

water supply. Tighten by hand until snug.

Tighten each supply connection another 2/3 4.

turn with pliers. Do not bend, kink or pinch

water inlet hoses.

Turn on the water and check for leaks.5.

a

b

c

d

Page 10

10

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

Installation Instructions

Connecting drain and electrical

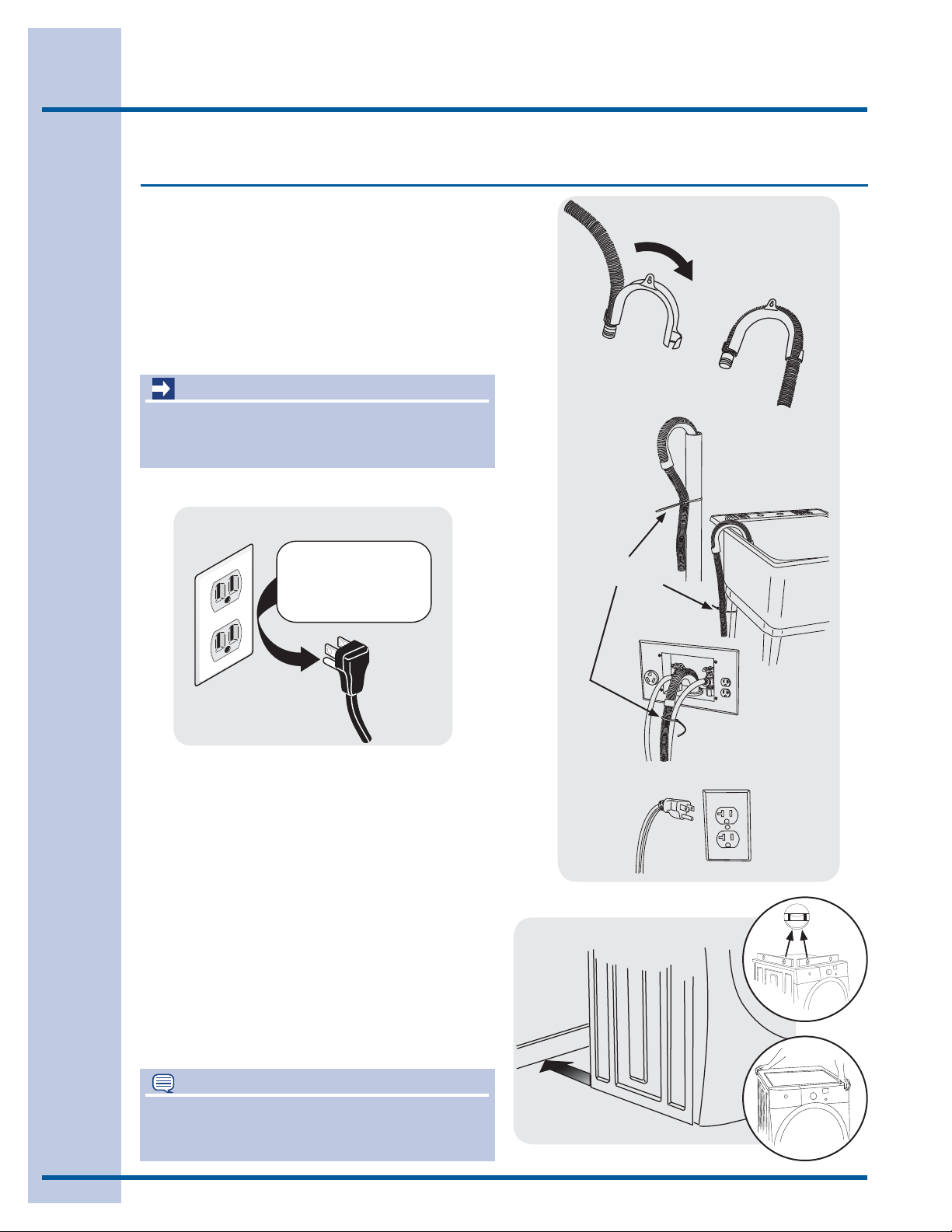

Snap one end of the drain hose hanger 1.

(shipped in washer drum) onto the drain hose.

Continue wrapping it around the hanger and

snap it in place.

Place the hook end of the drain hose in the drain 2.

opening. Secure the drain hose with the cable tie

(provided in the enclosure package) to the standpipe, inlet hose, laundry tub, etc. so the hose

does not pull out from the force of the water.

IMPORTANT

Check to ensure the power is off at a circuit

breaker/fuse box before plugging the power cord

into an outlet.

Plug the power cord into a grounded outlet.3.

Grounding type

wawall receptacl

Do not,

under

anany cir

cumstances,

cut,

remo

or b

ypass th

grgrounding pr

ong.

CABLE TIE

PoPower cord with

3-prong

Turn on the power at a circuit breaker/fuse box.4.

Carefully slide the washer to its fi nal position. 5.

Recheck for level and rock corners for stability.

Remove and discard door tape.

Read the 6. Use & Care Guide provided with the

washer. It contains valuable and helpful information that will save you time and money.

See the next page about performing a brief, 7.

helpful “Installation Cycle” on your new washer.

If you have any questions during initial opera-8.

tion, please review the “Service Prevention

Checklist” in your Use & Care Guide before

calling for service.

Place these instructions in a location near the 9.

washer for future reference.

NOTE

A wiring diagram and technical data sheet are

located under the washer top panel, on top of the

detergent dispenser housing.

ounded plug

Page 11

Installation Instructions

Performing Installation Cycle

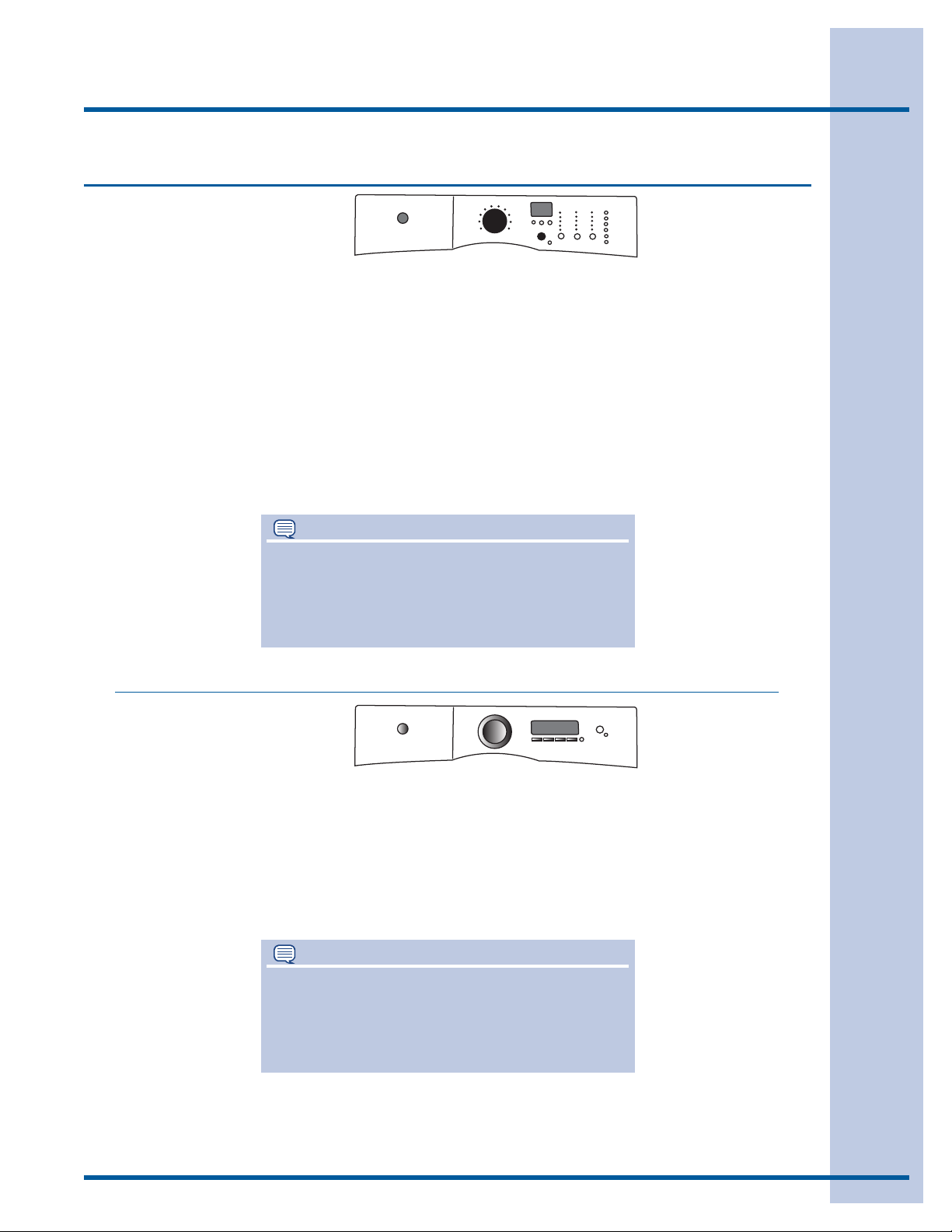

If your washer has this console:

Empty washer’s drum and close door.1.

After you plug in the washer the fi rst time: wake up the washer by pressing any button, rotate cycle 2.

knob to hand wash cycle, press the start button and then the cancel button.

Wake up the washer again by pressing any button, then immediately and simultaneously press and 3.

hold both the eco friendly and my favorite buttons for 5 seconds, or until the LCD display changes.

The LCD window will display 4. INSTAL CYCLE and show estimated time of cycle completion. Press the

start button. The Installation Cycle will automatically test for if water has been turned on. At cycle

completion, the LCD window may display INSTAL PASS!, meaning your new washer is properly installed

and ready for use. If it prompts an action such as NO WATER, CHECK HOSES or

CALL SERVICE 877 435 3287, review the installation steps and make the necessary corrections be-

fore you attempt to use the washer.

Your washer will exit the Installation Cycle and return to normal operation the next time you wake it up.5.

11

NOTE

Washer will stay awake for 3 minutes after the

Installation Cycle. If you wish to immediately run the

washer through a washing cycle, press the cancel

button to put the unit to sleep and then rewake it

immediately to continue the normal operating mode.

Please read the 6. Use & Care Guide and enjoy your new premium washer!

If your washer has this console:

After you plug in the washer the fi rst time: wake up the washer by pressing any button and then follow 1.

the prompts on the LCD User Interface, including language selection.

The Installation Cycle will automatically test for, and if water has been turned on. At cycle completion, 2.

the LCD window may display INSTAL PASS!, meaning your new washer is properly installed and ready

for use. If it prompts an action such as NO WATER, CHECK HOSES or

CALL SERVICE 877 435 3287, review the installation steps and make the necessary corrections be-

fore you attempt to use the washer.

Your washer will exit the Installation Cycle and return to normal operation the next time you wake it up.3.

NOTE

Washer will stay awake for 3 minutes after the

Installation Cycle. If you wish to immediately run the

washer through a washing cycle, press the cancel

button to put the unit to sleep and then rewake it

immediately to continue the normal operating mode.

Please read the 4. Use & Care Guide and enjoy your new premium washer!

Page 12

12

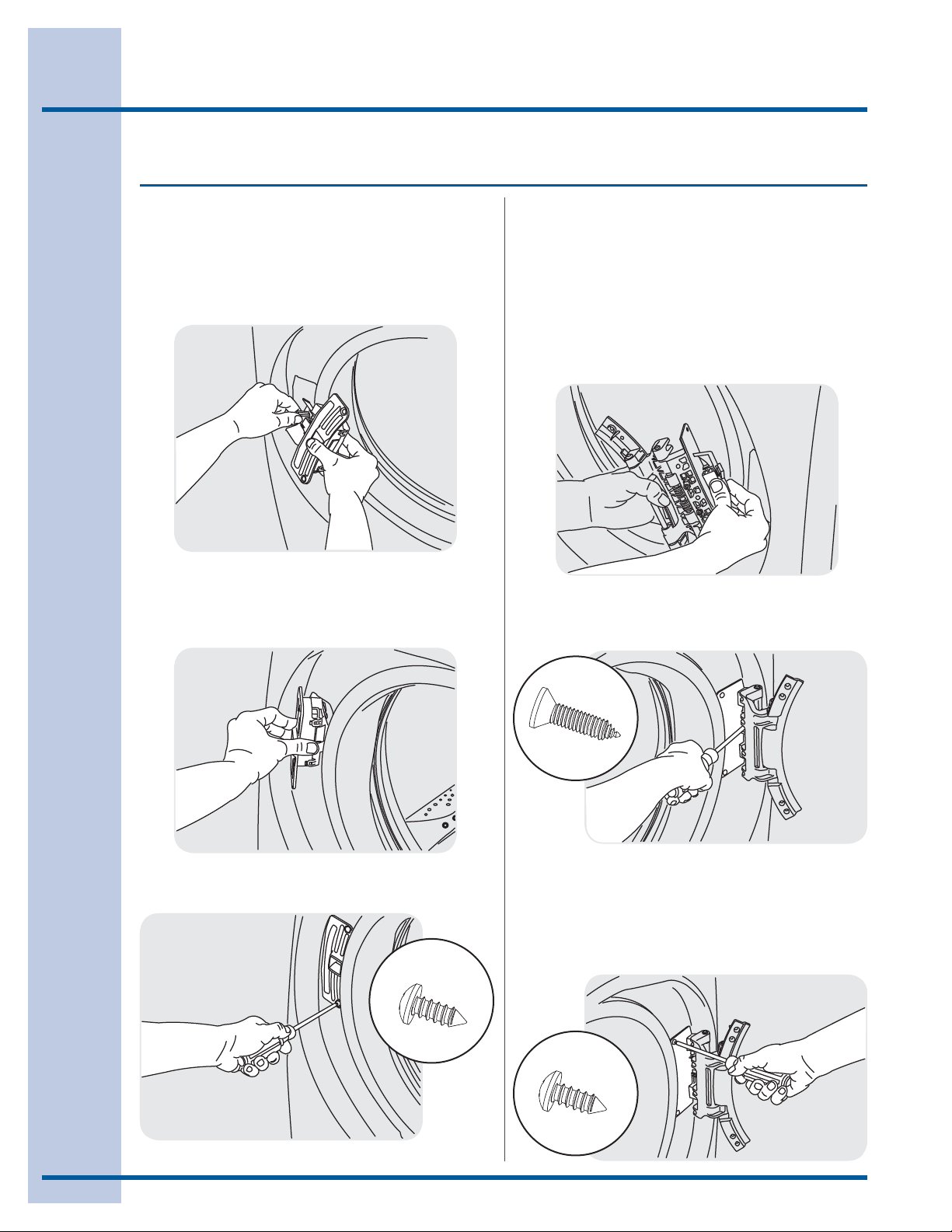

Reversing Door

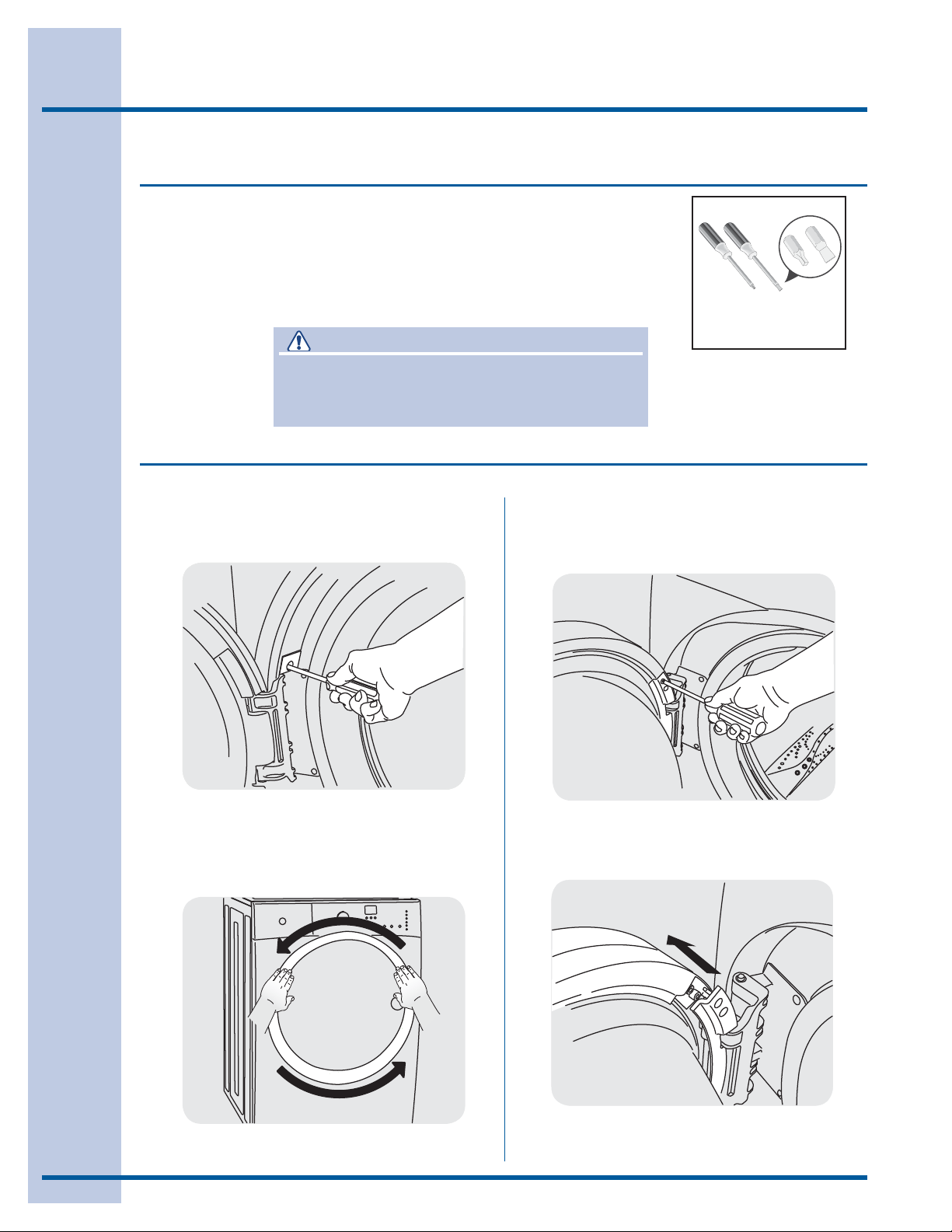

Preparing to reverse door swing

1 Be sure you have adequate swing area before reversing door.

2 You will need a screw driver with a #2 square bit.

3 Protect fl at work surface, such as top of washer or fl oor near

washer, with a soft cloth or towel.

4 Be sure washer is unplugged from power source!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before servicing

could result in personal injury or even death.

Removing door and hardware

A) Removing Trim Ring

1 Open the door to a 90 degree angle.

2 Remove and save the trim plug and long,

course-thread, panhead screw.

B) Removing Door from Hinge

1 Reopen door to 90 degree angle.

2 Remove 4 long, course-thread, counter-sunk

hinge screws from door.

Tools needed:

Screwdrivers with

#2 square &

straight bit

3 Close the door.

4 Rotate the door trim approximately ¾”

counter-clockwise and pull it away from the

front of the door.

3 While supporting the weight of the door

with both hands, separate the door from the

hinge.

4 Gently place the door face down on a fl at,

covered work surface.

Page 13

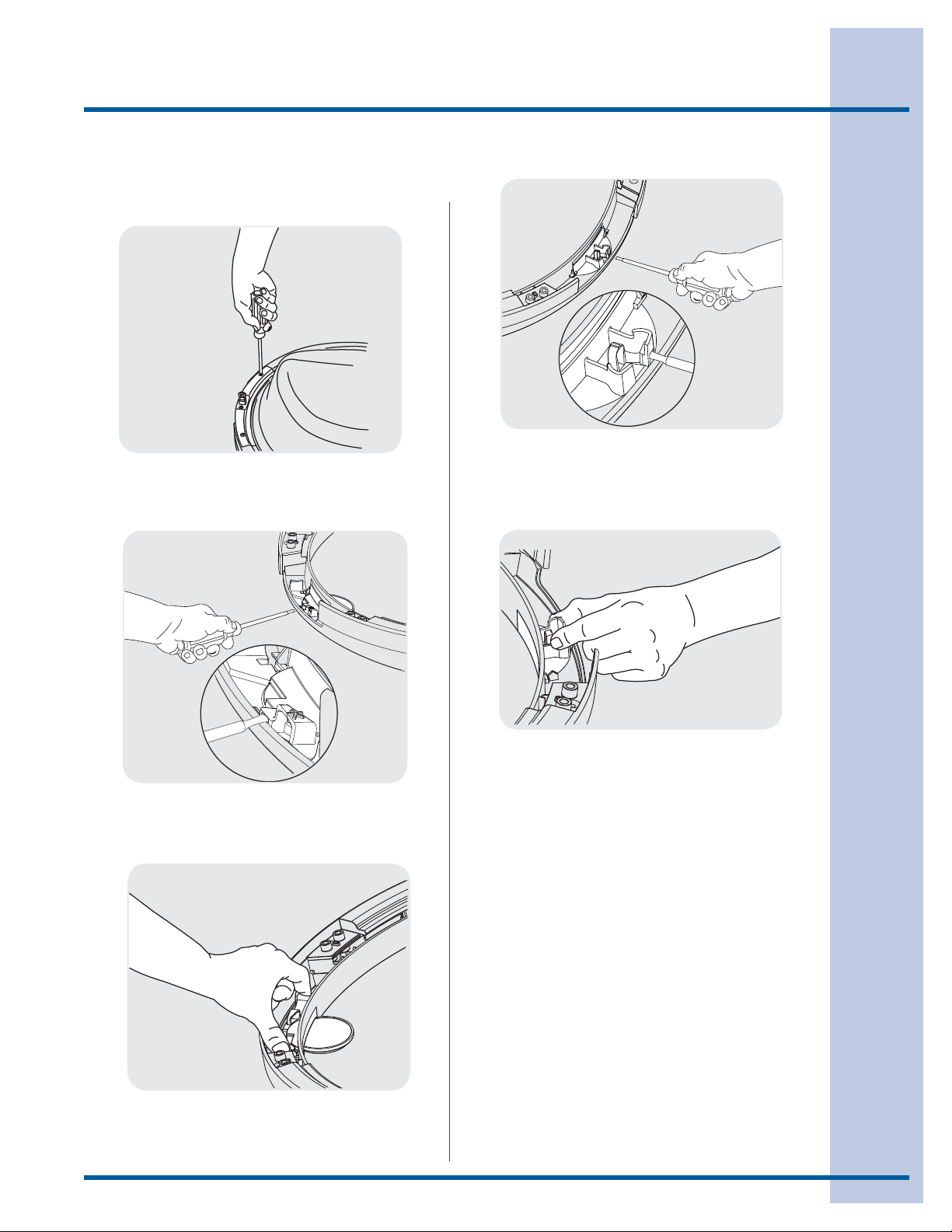

Reversing Door

13

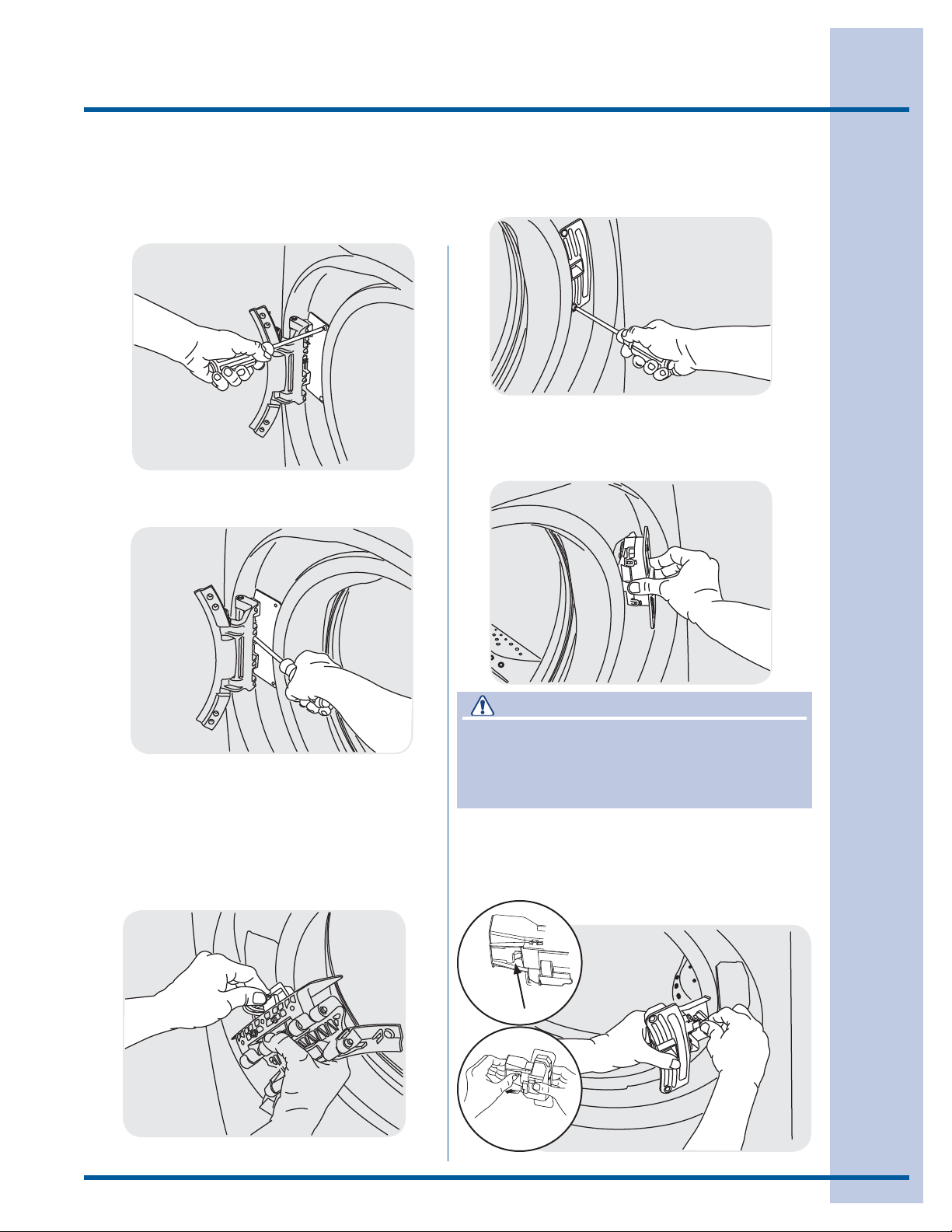

C) Removing Hinge from Front Panel

1 With the hinge in open position, remove 2

short, course-thread, panhead screws on

hinge plate.

2 Remove 3 short, fi ne-thread, counter-sunk

screws in hinge side.

D) Removing Door Lock from Front Panel

1 Remove 2 short, course-thread, panhead

screws from the door lock.

2 Slide the lock toward the outer edge of the

front panel. Pivot the lock slightly outward

while slowly pulling it through opening to

expose the attached harness.

3 Slide the hinge toward the center of the front

panel, and then pivot the hinge inward while

slowly pulling it away from the front panel to

expose the attached harness.

4 Lift up on the tab and the release harness

from the retainer, allowing the harness to lay

outside the front panel.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before

servicing could result in personal injury or even

death.

3 Release the harness from the terminal with

the small lever on back of the lock. Separate

the harness from the lock, allowing the

harness to lay outside the front panel.

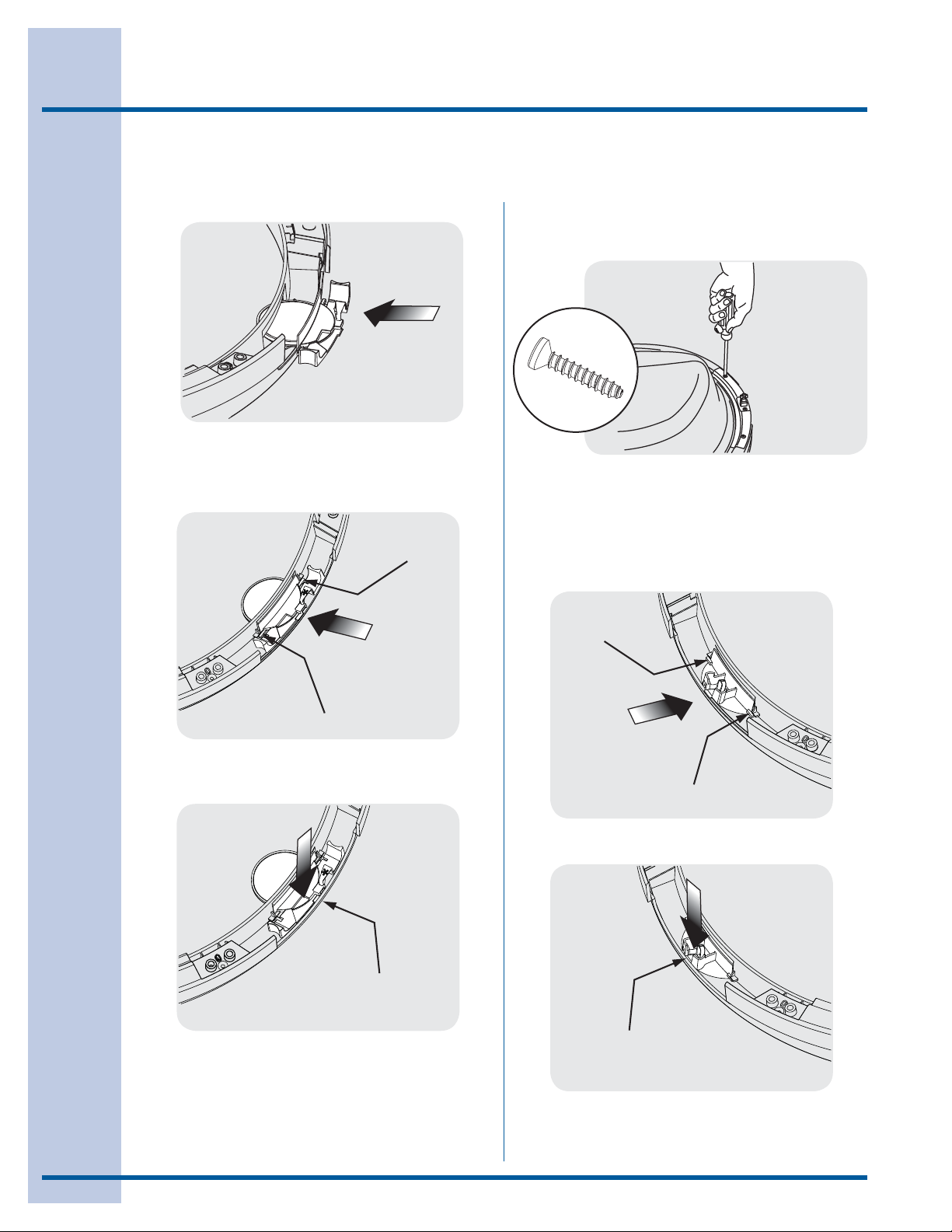

Page 14

14

Reversing Door

Reversing door and hardware

E) Reattaching Door Lock to Front Panel

1 Rotate the door lock and move it to the

opposite opening.

2 Connect the harness to the door lock by

inserting it in the terminal and fi rmly pushing

it in place.

3 Insert the harness connection through the

front panel fi rst, and then pivot the lock until

it is fl ush. Slide the lock toward the center of

the front panel until the screw holes line up.

F) Reattaching Hinge to Front Panel

1 Rotate the hinge and move it to the opposite

opening.

2 Connect the harness to the hinge retainer

by inserting it in the retention terminal and

gently pushing until you hear the fastening

tab click.

3 Gently pull on the harness to be sure it is

secure.

4 Use the side locating pins to align the hinge

and install 1 short, fi ne-thread, counter-sunk

screw in the center hole of hinge side.

4 Secure the lock with 2 short, course-thread,

panhead screws.

5 Install the other 2 short, fi ne-thread, counter-

sunk screws in the upper and lower holes of

hinge side.

6 Install 2 short, course-thread, panhead

screws through hinge plate.

Page 15

Reversing Door

15

G) Removing Striker Plate

1 Remove 2 long, course-thread, counter-sunk

screws and striker plate.

2 Set the striker plate to the side for later.

H) Removing Latch Indicator

I) Removing Hole Plug

1 Insert fl at blade screwdriver into open slot of

hole plug.

2 Gently pry upward to release tab.

1 Insert fl at blade screwdriver into open slot of

latch indicator.

2 Gently pry upward to release tab.

3 Pull the indicator out and set it aside.

3 Pull the hole plug out and set it aside.

Page 16

16

insert tab

insert tab

press down

and snap

press down

and snap

insert indicator

through

slot

Reversing Door

J) Reinserting Latch Indicator

1 Rotate the latch indicator and move it to the

opposite hole in the door.

insert indicator

through

2 Firmly insert the two small tabs on either

side of the latch indicator into the two slots

on either side of the hole in the door.

slot

insert tab

K) Reattaching Striker Plate

1 Rotate the striker plate and move it to the

opposite side of door above the indicator.

2 Reattach with 2 long, course-thread,

counter-sunk screws.

L) Reinserting Hole Plug

1 Rotate the hole plug and move it to the

opposite hole in the door.

2 Firmly insert the two small tabs on either

side of the hole plug into the two slots on

either side of the hole in the door.

insert tab

3 Firmly press downward on the indicator until

the tab snaps in place.

press down

and snap

insert tab

insert tab

3 Firmly press downward on the hole plug until

the tab snaps in place.

press down

and snap

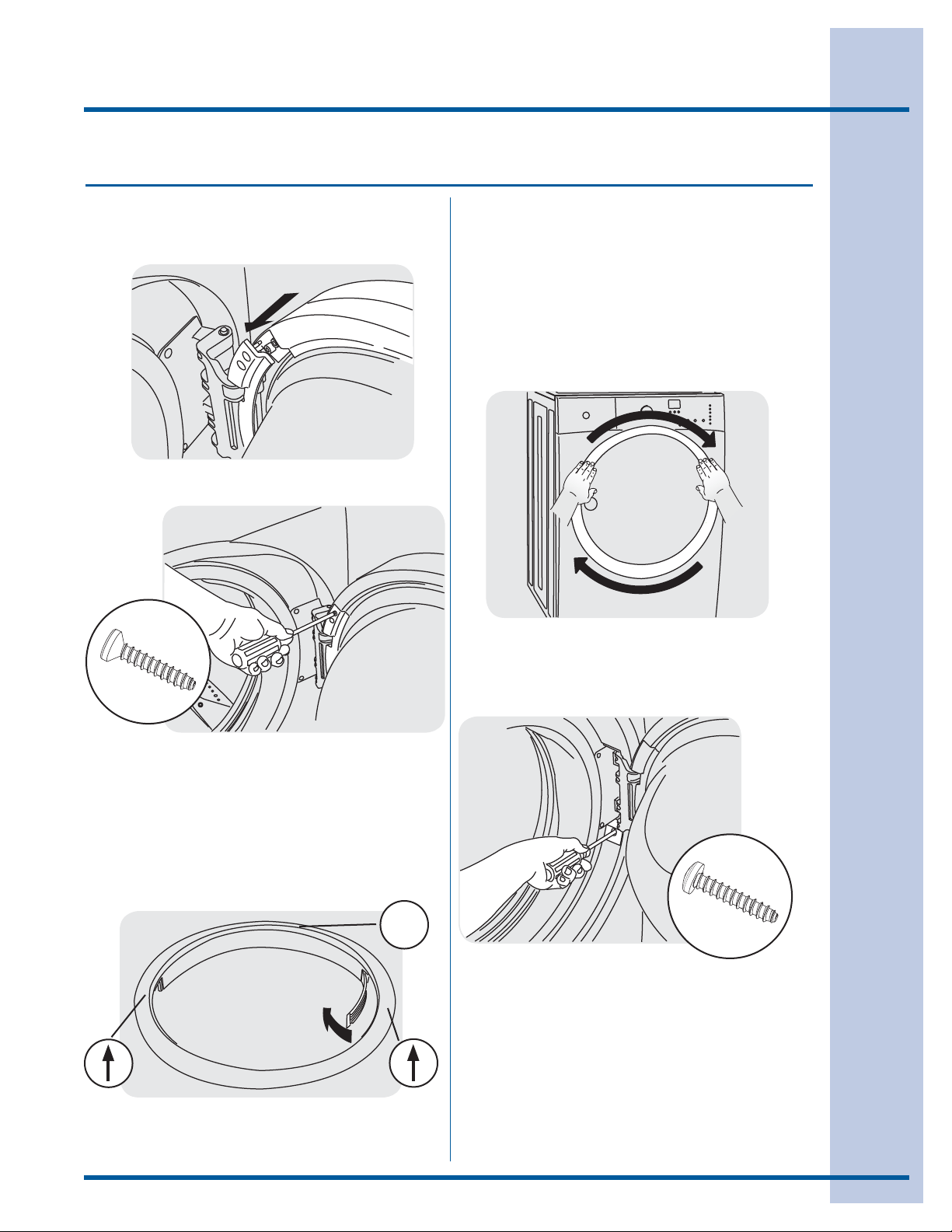

Page 17

Reattaching door and hardware

Reversing Door

17

M) Reattaching Door Assembly

1 Open the hinge to a 90 degree angle.

2 Install the door onto the hinge locating pins.

3 Secure the door with 4 long, course-thread,

counter-sunk screws.

O) Reinstalling Trim Ring

1 Close the door.

2 Orient the trim so 12 position is

approximately ¾” to the left of top center.

The opening in the trim ring should be on the

hinge side.

3 Insert the trim ring in the slots and rotate it

clockwise approximately ¾”.

P) Reinstalling Trim Plug

1 Open the door to a 90 degree angle.

2 Install the trim plug with 1 long, course-

thread, panhead screw.

4 Close the door and test the operation of the

latch.

N) Reversing Trim Ring

1 Trim ring orientation is marked on the back.

2 Remove the trim ring cover plate. To remove

the cover plate from the right, pivot point is

up. To remove the cover plate from the left,

pivot point is down.

UP

3 Rotate the trim ring cover plate and move

it to the opposite opening in the trim and

reinsert.

Q) Plug in washer and continue operation.

Page 18

18

26.44”

(67.16cm)

15.00”

(38.10cm)

27.00”

(68.58cm)

Options

Accessories

MATCHING STORAGE PEDESTAL*

Island White Pedestal - P/N EPWD15IW

Mediterranean Blue Pedestal - P/N EPWD15MB

Silver Sands Pedestal - P/N EPWD15SS

Turquoise Sky Pedestal - P/N EPWD15TS

Red Hot Red Pedestal - P/N EPWD15RR

Kelly Green Pedestal - P/N EPWD15KG

A storage pedestal accessory, specifi cally designed for

this washer may be used to elevate the dryer for ease

of use. This pedestal will add about 15” (38.1cm) to the

height of your unit for a total height of 53” (134.62 cm).

*Other colors may be available. Contact the source where you

purchased your washer.

DRYER STACKING KIT

P/N 134700400

Depending on the model you purchased, a kit for stacking

a matching dryer on top of this washer may have been

included in the initial purchase of your dryer. If your

model did not include a stacking kit or you desire another

stacking kit, you may order one.

DRAIN HOSE EXTENSION KIT

P/N 137098000

In order to reach standpipe heights or distances beyond

the reach of the drain hose supplied, order the DRAIN

HOSE EXTENSION KIT.

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installation in a mobile home requires the use of a

MOBILE HOME INSTALLATION KIT.

CAUTION

Failure to use accessories manufactured

by (or approved by) the manufacturer could

result in personal injury, property damage or

damage to the washer.

27.00”

(68.58cm)

15.00”

(38.10cm)

26.44”

(67.16cm)

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

Your washer was supplied with a UNIVERSAL

APPLIANCE WRENCH. If you desire another wrench,

you may order one.

TOUCH UP PAINT PENS

Island White Touch Up Pen - P/N 5304468812

Mediterranean Blue Touch Up Pen - P/N 5304468813

Silver Sands Touch Up Pen - P/N 5304468814

Turquoise Sky Touch Up Pen - P/N 5304468815

Red Hot Red Touch Up Pen - P/N 5304471226

Kelly Green Touch Up Pen - P/N 5304471231

*Other colors may be available. Contact the source where you

purchased your washer.

Replacement parts: 1-877-4ELECTROLUX (1-877-435-3287)

If replacements parts are needed for your washer,

contact the source where you purchased your

washer, call 1-877-4ELECTROLUX (1-877-435-3287),

or visit our website, www.electroluxappliances.com,

for the Electrolux Authorized Parts Distributor nearest

you.

WARNING

ELECTRICAL HAZARD

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

Page 19

Installation Instructions

Electrolux Front-Load Washer

Instructions d’installation

Laveuse à chargement frontal Electrolux

Instrucciones de Instalación

Lavadora de carga frontal Electrolux

Page 20

2

Mesures de sécurité importantes

AVERTISSEMENT

Pour votre sécurité, l'information contenue dans ces instructions doit être suivie afi n de réduire les

risques d'incendie ou d'explosion ou pour prévenir les dommages matériels, les blessures ou la mort.

Vous ne devez ni entreposer, ni utiliser d'essence ou d'autres vapeurs ou liquides infl ammables à

proximité de cet appareil ou de tout autre appareil électroménager.

Sachez reconnaître les symboles, les avertissements et les étiquettes de sécurité.

Les mesures de sécurité présentées dans ce guide

sont identifi ées par le mot AVERTISSEMENT ou ATTENTION selon le type de risque présenté.

propos des situations pouvant causer des dommages

matériels, des blessures graves ou même la mort.

pos des situations pouvant causer des dommages

matériels ou des blessures.

Ce symbole vous avertit à

Ce symbole vous avertit à pro-

AVERTISSEMENT

RISQUE D’INCENDIE - Lisez toutes les instructions de sécurité suivantes avant d’installer et d’utiliser

votre appareil :

Détruisez le carton d'emballage et les sacs en plastique après avoir déballé l'appareil. Les enfants pour-•

raient les utiliser pour jouer. Le carton recouvert de tapis, les couvertures et les feuilles de plastique peuvent

être étanches à l'air et provoquer la suffocation. Déposez tous les matériaux d'emballage dans un conteneur

à déchets ou faites en sorte que les enfants ne puissent y avoir accès.

Pour votre sécurité, l’information contenue dans ces instructions doit être suivie afi n de réduire les •

risques d’incendie ou d’explosion ou pour prévenir les dommages matériels, les blessures ou la mort.

Vous ne devez ni entreposer, ni utiliser d’essence ou d’autres vapeurs ou liquides infl ammables à

proximité de cet appareil ou de tout autre appareil électroménager.

Installez l'appareil conformément aux instructions du fabricant et aux codes locaux.•

L’installation électrique de la laveuse doit être conforme aux codes et aux règlements locaux ainsi qu’à la •

toute dernière édition du National Electrical Code (ANSI/NFPA 70), ou au Canada, au Code canadien de

l’électricité (C22.1, article 1).

Pour éviter les blessures au dos ou d’autres types de blessure, demandez l’aide d’autres personnes •

pour déplacer ou soulever la laveuse.

Ne superposez pas une sécheuse sur une laveuse déjà installée sur un socle. Ne superposez pas une •

laveuse sur une sécheuse. Ne superposez pas une laveuse sur une autre laveuse.

Les instructions comprises dans ce guide et toute autre documentation fournie avec cet appareil ne sont •

pas conçues pour couvrir toutes les éventualités ou situations qui pourraient survenir. Vous DEVEZ faire

preuve de bon sens et de prudence durant l'installation, l'utilisation et l'entretien de tout appareil ménager.

QUE FAIRE SI VOUS DÉTECTEZ UNE ODEUR DE GAZ :

Ne mettez pas d'appareil en marche.•

Ne touchez à aucun commutateur électrique; n'utilisez aucun téléphone de votre domicile.•

Évacuez la pièce, le bâtiment ou la zone touchée.•

En utilisant le téléphone d'un voisin, appelez immédiatement le fournisseur de gaz. Suivez ses instructions.•

Si vous ne pouvez joindre votre fournisseur de gaz, appelez les pompiers.•

Conservez ces instructions pour vous y reporter ultérieurement.

Table des matières

Mesures de sécurité importantes ................................... 2

Exigences d’installation ............................................... 3-5

Dimensions de l’installation ............................................ 6

© Electrolux Major Appliances, 2010

Instructions d’installation ..........................................7-11

Inversion de la porte ................................................ 12-17

Options ......................................................................... 18

Tous droits réservés.

Page 21

Exigences d’installation

3

Veuillez lire et conserver ce

guide

Merci d'avoir choisi Electrolux, la nouvelle

marque de qualité en matière d'électroménager.

Ces instructions d'installation font partie de notre

engagement à vous satisfaire et à vous fournir un

produit de qualité pendant toute la durée de vie de

votre nouvel appareil.

Liste de vérifi cation d’installation

Matériel d’expédition

Le support d’expédition en mousse (sous la

cuve de lavage) a été enlevé et remisé

Les boulons d’expédition situés à l’arrière

de l’appareil ont été enlevés et remisés

Les bouchons (inclus dans le sac situé

dans la cuve) ont été insérés dans les trous

situés dans la paroi arrière de la laveuse

Mise à niveau

La laveuse est au niveau latéralement et de

l’avant vers l’arrière

Les quatre coins de la caisse reposent

fermement sur le plancher

Alimentation en eau

Le tuyau d’entrée d’eau CHAUDE est

raccordé au robinet d’eau CHAUDE et le

tuyau d’entrée d’eau FROIDE est raccordé

au robinet d’eau FROIDE

Les robinets d’eau CHAUDE et d’eau

FROIDE sont ouverts

Les raccords d’alimentation en eau ou les

raccords d’arrivée d’eau de l’appareil ne

présentent aucune fuite -

refaites une vérifi cation 24 heures plus tard

Des questions?

Pour rejoindre le service sans frais aux États-Unis

et au Canada :

1 877 4ELECTROLUX (1 877 435-3287).

Pour obtenir de l'aide et de l'information sur

les produits en ligne, visitez le site http://www.

electroluxappliances.com

Tuyau de vidange

La colonne montante ou le drain de mur est

à une hauteur d’au moins 61 cm (24 po)

Le tuyau de vidange est fi xé dans le canal

en « U » (inclus dans la cuve)

Le tuyau de vidange est fi xé avec l’attache

(incluse dans la cuve)

Inversion de la porte

Suivez les instructions détaillées contenues

dans ce guide

Vérifi ez que la charnière et le loquet

fonctionnent correctement

Alimentation en électricité

Le système électrique de la maison est

sous tension

La laveuse est branchée

Vérifi cations fi nales

Vous avez lu entièrement les instructions

d’installation et le Guide d’utilisation et

d’entretien

La porte se verrouille et le tambour tourne

lorsqu’un cycle démarre

La carte d’enregistrement est envoyée

Exigences avant l'installation

Outils et matériel nécessaires à l'installation :

OU OU OU ET ET

Clé universelle

fournie avec

la laveuse

Clé à

molette

Clé polygonale

de 3/8 po

ou de 10 mm

Cliquet et

ensemble

de douilles

Pince

réglable

Niveau de charpentier

Page 22

4

Prise murale

avec mise

à la terre

Ne coupez pas, n'enlevez pas et

ne mettez pas hors circuit la broche

de mise à la terre de cette che.

Cordon électrique muni

avec mise à la terre

d’une che à trois broches

Exigences d'installation

Exigences des systèmes élect.

CIRCUIT - Circuit indépendant de 15 ampères,

polarisé et mis à la terre, avec fusible temporisé

ou disjoncteur de 15 A.

ALIMENTATION ÉLECTRIQUE - Câble monophasé

à deux fi ls mis à la terre, 120 volts, 60 Hz;

courant alternatif.

REMARQUE

Étant donné les variations de tension possibles,

l'utilisation de cette laveuse avec une source

d'alimentation produite par une génératrice à

essence, solaire ou éolienne ou par toute autre

source d'alimentation différente de celle fournie

par les services publics n'est pas recommandée.

PRISE - Prise à trois alvéoles et mise à la terre

située à un endroit où il est possible de

raccorder le cordon d'alimentation de la laveuse

une fois que cette dernière est installée.

Prise murale

avec mise

à la terre

Ne coupez pas, n'enlevez pas et

ne mettez pas hors circuit la broche

de mise à la terre de cette che.

Cordon électrique muni

d’une che à trois broches

avec mise à la terre

règlements locaux ou, si aucun code local ne régit

ce type d'installation, à la plus récente édition du

National Electrical Code (ANSI/NFPA 70). En cas

de doute, faites appel à un électricien qualifi é. NE

COUPEZ PAS et NE MODIFIEZ PAS la broche de

mise à la terre du cordon d'alimentation. Si votre

prise murale n'est pourvue que de deux fentes,

il incombe au propriétaire de faire appel à un

électricien qualifi é pour la remplacer par une prise à

trois alvéoles et mise à la terre de façon adéquate.

Exigences relatives à

l'alimentation en eau

Les robinets d'eau chaude et d'eau froide DOIVENT être

installés à une distance de 107 cm (42 po) ou moins

de l'arrivée d'eau de votre laveuse. Les robinets DOIVENT être de 1,9 cm (3/4 po) et fi letés en fonction d'un

raccordement de tuyau de laveuse. La pression de l'eau

DOIT se situer entre 206,8 et 827,4 kPa (30 et 120 lb/

po²). La différence de pression entre l'eau chaude et

l'eau froide ne doit pas dépasser 68,9 kPa (10 lb/po²).

Le service des eaux de votre localité peut vous informer

sur la pression de votre alimentation en eau.

Exigences relatives au

système d'évacuation

REMARQUE

Une prise GFI (disjoncteur de fuite de terre) n'est

pas nécessaire.

Exigences relatives à la mise

à la terre

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

Un raccordement inadéquat du conducteur de terre

de l'équipement peut accroître les risques de choc

électrique. En cas de doute quant à la mise à la

terre de l'appareil, consultez un électricien qualifi é.

Cet appareil DOIT être mis à la terre. En cas de 1.

mauvais fonctionnement ou de panne, la mise

à la terre diminue les risques de choc électrique

en fournissant au courant électrique une trajectoire de moindre résistance.

Étant donné que votre laveuse est équipée d'un 2.

cordon d'alimentation pourvu d'un conducteur de

mise à la terre et d'une fi che de mise à la terre, la

fi che DOIT être raccordée à une prise appropriée

(avec conducteurs en cuivre) correctement installée

et mise à la terre conformément aux codes et

Le drain doit pouvoir évacuer 64,3 L (17 gal) 1.

d'eau à la minute.

Tuyau d'évacuation d'au moins 3,18 cm (1-2.

1/4 po) de diamètre.

Le tuyau d'évacuation doit être situé entre une 3.

hauteur minimale de 61 cm (24 po) et une

hauteur maximale de 96 po (244 cm)

96”

(244cm)

max.

24”

(61cm)

min.

REMARQUE

Le tuyau de vidange raccordé à la laveuse peut convenir

à un tuyau d'évacuation de 201 cm (79 po) de hauteur.

Pour des tuyaux d'évacuation plus hauts, utilisez le tuyau

portant le numéro de pièce 137098000 que vous pouvez

obtenir auprès d'un distributeur de pièces autorisé.

Page 23

Exigences de dégagement

Exigences d'installation

5

IMPORTANT

N'INSTALLEZ PAS VOTRE LAVEUSE :

1. À un endroit exposé aux écoulements d'eau

ou aux aléas des conditions météorologiques

extérieures. La température ambiante ne devrait jamais tomber sous 15,6 °C (60 °F) afi n

d'optimiser l'effi cacité du détergent.

2. À un endroit (garage ou bâtiment similaire) où

de l'essence ou d'autres substances infl ammables sont entreposées (incluant des automobiles).

3. Sur un tapis. Le plancher DOIT être solide

et présenter une pente inférieure à 2,54 cm

(1 po). Afi n d'éviter les vibrations et le déplacement de l'appareil, il peut être nécessaire

de renforcer le plancher.

INSTALLATION DANS UN ENDROIT EN

RETRAIT OU UNE ARMOIRE

Si la laveuse et la sécheuse sont installées dans

le même placard, une ventilation est requise dans

la porte : Une ouverture d'au moins 774,2 cm2

(120 po2), divisée également au-dessus et audessous de la porte, est requise. Les ouvertures à

persiennes doivent être situées à 7,6 cm (3 po) du

haut et du bas de la porte. Les ouvertures d'aération

ne doivent pas être obstruées lorsqu'une porte est

installée. Une porte à persiennes dont les ouvertures

sur l'ensemble de la porte sont équivalentes aux

recommandations peut être utilisée.

DÉGAGEMENTS MINIMAUX - Centimètres (pouces)

CÔTÉS ARRIÈRE DESSUS AVANT

Alcôve 0 cm (0 po) 0 cm (0 po)* 0 cm (0 po) s. o.

Sous

le comptoir

Placard 0 cm (0 po) 0 cm (0 po)* 0 cm (0 po)

1”

(2.54cm)

0 cm (0 po) 0 cm (0 po)* 0 cm (0 po) s. o.

0”

(0cm)

0”

(0cm)

0”

(0cm)

2,54 cm

(1 po)

3”

(7.6cm)

3”

(7.6cm)

Porte de placard

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

Page 24

6

g

Exigences d'installation

Dimensions, laveuse installée

50.6” (128.53cm)*

Avec la porte

grande ouverte

Laveuse autonome

sur le plancher

Plancher

Laveuse montée sur

le socle optionnel

31.50” (80.01cm)*

À partir de l'avant de la porte

lorsqu'elle est fermée

Raccord de

l'alimentation en eau

à l’arrière de la laveuse ¹

Tuyau de vidange

à l'arrière de la laveuse ²

27.00”

(68.58cm)

Cordon

d’alimentation

à l'arrière

de la laveuse ³

38.00”

(96.52cm)

53.00”

(134.62cm)

Plancher

* Pour obtenir ces dimensions de profondeur minimales, la sécheuse doit être ventilée tout droit par l'arrière ou au moyen d'un coude de 90° dont

la courbe est immédiate. Le raccordement du tuyau d'arrivée d'eau sur les modèles à la vapeur ajoute 2 cm (3/4 po) à la profondeur d'installation.

¹ La conexión de la manguera de admisión en los modelos a vapor añade 3/4" (2 cm) a la profundidad de instalación.

² Longueur de tuyau de vidange, environ 150 cm (59 po).

³ Longueur du cordon d'alimentation, environ 152,5 cm (60 po).

50.6” (128.53cm)*

Avec la porte

grande ouverte

31.50” (80.01cm)*

À partir de l'avant de la porte

lorsqu'elle est fermée

75.75”

(192.5cm)

Raccord de

l'alimentation

en eau à l’arrière

de la laveuse ¹

Alimentation en gaz

à l’arrière

de l'appareil à gaz

39.00”

(99cm)

27.00”

(68.5cm)

Cordon d’alimentation

à l'arrière de la laveuse ³

Alimentation

électrique

à l’arrière de

la sécheuse

Hauteur

de la ligne

centrale

de l'évent

arrière

41.00”

(105cm)

Tuyau de vidange

à l'arrière

de la laveuse ²

* Pour obtenir ces dimensions de profondeur minimales, la sécheuse doit être ventilée tout droit par l'arrière ou au moyen d'un coude de 90° dont

la courbe est immédiate. Le raccordement du tuyau d'arrivée d'eau sur les modèles à la vapeur ajoute 2 cm (3/4 po) à la profondeur d'installation.

¹ La conexión de la manguera de admisión en los modelos a vapor añade 3/4" (2 cm) a la profundidad de instalación.

² Longueur de tuyau de vidange, environ 150 cm (59 po).

³ Lon

ueur du cordon d'alimentation, environ 152,5 cm (60 po).

38.00”

(96.5cm)

Page 25

Déballage de la laveuse

Retrait de l'emballage en mousse

AVERTISSEMENT

RISQUE D'ÉTOUFFEMENT

Détruisez le carton d'emballage et les sacs en

plastique après avoir déballé l'appareil. Les

enfants pourraient les utiliser pour jouer. Le

carton recouvert de tapis, les couvertures et les

feuilles de plastique peuvent être étanches à

l'air et provoquer la suffocation. Déposez tous

les matériaux d'emballage dans un conteneur

à déchets ou faites en sorte que les enfants ne

puissent y avoir accès.

Retirez temporairement le ruban de la porte.1.

Ouvrez la porte de la laveuse et retirez tout ce 2.

qui se trouve dans le tambour.

Fermez la porte et posez le ruban de porte à 3.

nouveau.

Pour protéger le plancher, utilisez un tapis, une 4.

couverture ou une pièce de carton et couchez

la laveuse sur le côté arrière.

7

ATTENTION

DANGER DE POIDS EXCESSIF

Pour éviter les blessures au dos ou d'autres

types de blessure, demandez l'aide d'autres

personnes pour déplacer ou soulever la laveuse.

Retirez la base en styromousse et le bouchon 5.

d'expédition; mettez-les de côté.

Remettez soigneusement la laveuse en position 6.

verticale.

Déplacez soigneusement la laveuse à moins de 7.

1,2 m (4 pi) de son emplacement défi nitif.

IMPORTANT

Conservez la base en styromousse et le bouchon

d'expédition afi n d'éviter d'endommager

l'appareil dans le cas d'un déplacement éventuel.

Page 26

8

Déballage de la laveuse

Retrait de la quincaillerie d'expédition

1 FOURCHE D'EXPÉDITION

Retirez les composants suivants :

1 FOURCHE D'EXPÉDITION

5 CALES D'ESPACEMENT

5 SERRES EN P

5 BOULONS

Pose des bouchons

5 CALES D'ESPACEMENT

5 SERRES EN P

CLÉ

UNIVERSELLE

(FOURNIE)

5 BOULONS

REMARQUE

Il se peut que le matériel de

caoutchouc utilisé pour les

espaceurs nécessite quelque

temps pour se relâcher afi n

de pouvoir être retiré des

trous d'expédition.

IMPORTANT

Conservez les boulons et cales d'espacement

d'expédition pour un usage ultérieur. Si la

laveuse doit être transportée plus tard, ces

pièces d'expédition doivent être installées pour

éviter de l'endommager.

Trouvez les 7 bouchons du petit sac fourni avec

les guides de votre laveuse. Insérez-les dans les

trous du panneau arrière de la laveuse.

7 BOUCHONS

(DANS UN SAC)

Page 27

Instructions d’installation

Mise à niveau de votre appareil

Les bruits excessifs et les vibrations peuvent être évités

en mettant correctement la laveuse à niveau.

Pour une installation autonome où la laveuse est à 1.

moins de 1,2 m (4 pi) de son emplacement défi nitif,

placez un niveau sur le dessus de l'appareil.

Utilisez la clé universelle pour ajuster les pieds de 2.

mise à niveau de façon à ce que la laveuse soit de

niveau d'avant en arrière et latéralement, et qu'elle

soit stable aux quatre coins.

Appuyez sur chaque coin et chaque côté pour 3.

déterminer les endroits qui nécessitent un réglage.

Ajustez les pieds de mise à niveau appropriés de

manière à ce que la laveuse repose solidement sur

ses QUATRE pieds. Gardez les pieds de mise à

niveau le plus près possible de la laveuse afi n d'op-

timiser le rendement de la laveuse.

REMARQUE

Pour une installation sur socle, reportez-vous

aux instructions d'installation complémentaires

incluses avec le socle.

9

a

c

b

soulever

abaisser

d

Branchement de l'entrée d'eau

Faites couler de l'eau chaude et froide des robinets 1.

pour purger les tuyaux d'eau, pour éliminer toute

particule qui pourrait obstruer les grillages des robinets, et pour déterminer quels robinets fournissent

l'eau chaude et l'eau froide.

Regardez dans l'extrémité de chaque tuyau d'en-2.

trée d'eau pour confi rmer la présence de rondelles

en caoutchouc.

LES RONDELLES

EN CAOUTCHOUC

DOIVENT ÊTRE

PRÉSENTES

REMARQUE

Les tuyaux d'entrée d'eau CHAUDE et FROIDE

sont dotés d'un code de couleur. Le tuyau

d'entrée d'eau CHAUDE est marqué d'une bande

ROUGE et le tuyau d'entrée d'eau FROIDE est

marqué d'une bande BLEUE.

Branchez le tuyau d'entrée d'eau CHAUDE au 3.

robinet d'eau CHAUDE, et le tuyau d'eau d'entrée

d'eau FROIDE au robinet d'eau FROIDE. Serrez

fermement à la main.

Avec des pinces, serrez chaque raccord de 2/3 de 4.

tour. Ne pliez pas, n’entortillez pas et ne coincez

pas les tuyaux d’alimentation en eau.

Ouvrez les robinets et vérifi ez la présence de fuites.5.

a

b

c

d

Page 28

10

Prise murale avec

mise à la terre

à la terre de cette che.

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

Cordon électrique muni

avec mise à la terre

d’une che à trois broches

Instructions d’installation

Branchement électrique et branchement du tuyau de vidange

Fixez l'une des extrémités du crochet du tuyau de vidange 1.

(inclus dans la cuve) au tuyau de vidange. Continuez de

l'enrouler autour du crochet et pincez-le en position.

Placez le côté du tuyau de vidange en forme de crochet 2.

dans l'ouverture du tuyau d'évacuation. Fixez le tuyau de

vidange au moyen d'une attache (incluse dans la trousse

d'installation fournie) au tuyau d'évacuation, au tuyau d'entrée, à la cuve à lessive, etc. de façon à ce que le tuyau ne

puisse être arraché sous la force de l'eau.

IMPORTANT

Assurez-vous que l'alimentation électrique est coupée au

disjoncteur ou au boîtier de fusibles avant de brancher le

cordon d'alimentation dans une prise électrique.

Branchez le cordon d'alimentation à la prise électrique 3.

mise à la terre.

Prise murale avec

mise à la terre

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

à la terre de cette che.

ATTACHE

Cordon électrique muni

d’une che à trois broches

avec mise à la terre

Ouvrez l'alimentation électrique au disjoncteur ou au boî-4.

tier de fusibles.

Faites glisser soigneusement la laveuse à son emplace-5.

ment défi nitif. Vérifi ez à nouveau la stabilité de l'appareil.

Retirez et jetez le ruban de la porte.

Reportez-vous au 6. Guide d'utilisation et d'entretien fourni

avec la laveuse. Il contient des renseignements très utiles

qui vous permettent d'économiser temps et argent.

Reportez-vous à la page suivante pour savoir com-7.

ment effectuer un « programme d'installation » rapide

et pratique pour votre nouvelle laveuse.

Pour toute question relative à l'utilisation initiale, 8.

veuillez revoir la section intitulée « Liste de vérifi cation

avant service » de votre Guide d'utilisation et d'entre-

tien avant d'effectuer une demande de service.

Laissez ces instructions à proximité de la laveuse 9.

pour vous y reporter ultérieurement.

REMARQUE

Un schéma électrique et une fi che technique sont situés

sous le panneau supérieur de la laveuse, au-dessus du

logement de distributeur de détergent.

Page 29

Instructions d'installation

Programme d'installation

Si votre laveuse est munie de cette console :

Videz la cuve de la laveuse, puis fermez la porte.1.

Après avoir branché la laveuse pour la première fois : réactivez la laveuse en appuyant sur n'importe 2.

quel bouton, tournez le bouton des programmes à HAND WASH (Lavage manuel), appuyez sur

START (Mise en marche), puis sur CANCEL (Annuler).

Réactivez la laveuse à nouveau en appuyant sur n'importe quel bouton, puis appuyez immédiatement 3.

et simultanément sur les boutons ECO FRIENDLY (Écologique) et MY FAVORITE (Mes préférences)

pendant 5 secondes ou jusqu'à ce que l'affi chage ACL se modifi e.

L'affi cheur ACL indiquera le message 4. INSTAL CYCLE (Programme d'installation) suivi du temps approximatif

de la durée du programme. Appuyez sur le bouton START (Mise en marche). Le programme d'installation

procédera automatiquement à la vérifi cation de l'alimentation en eau. À la fi n du programme, l'écran ACL

affi chera peut-être le message INSTAL PASS! (Installation réussie), ce qui signifi e que votre nouvelle laveuse

est bien installée et prête à être utilisée. Si l'écran affi che un message comme NO WATER (Pas d'eau), CHECK

HOSES (Vérifi er les tuyaux) ou CALL SERVICE 877 435 3287 (Placer un appel de service au 1 877 435-

3287), vérifi ez chaque étape d'installation et apportez les correctifs nécessaires avant d'utiliser votre appareil.

La laveuse quittera le programme INSTALL CYCLE (Programme d'installation) et reviendra à son mode 5.

de fonctionnement normal la prochaine fois que vous la réactiverez.

11

REMARQUE

La laveuse demeurera activée pendant trois minutes après la fi n du programme

d'installation. Si vous souhaitez utiliser l'appareil pour un cycle de lavage, appuyez

sur le bouton CANCEL (Annuler) pour mettre l'appareil en mode de veille, puis

réactivez-le immédiatement pour continuer au mode de fonctionnement normal.

Veuillez lire le 6. Guide d'utilisation et d'entretien et profi tez de votre nouvelle laveuse de qualité!

Si votre laveuse est munie de cette console :

Après avoir branché la laveuse pour la première fois : réactivez la laveuse en appuyant sur n'importe quel 1.

bouton et suivez les instructions qui s'affi chent sur l'interface utilisateur ACL, y compris le choix de la langue.

Le programme d'installation procédera automatiquement à la vérifi cation de l'alimentation en eau. À la 2.

fi n du programme, l'écran ACL affi chera peut-être le message INSTAL PASS! (Installation réussie), ce qui

signifi e que votre nouvelle laveuse est bien installée et prête à être utilisée. Si l'écran affi che un message

comme NO WATER (Pas d'eau), CHECK HOSES (Vérifi er les tuyaux) ou CALL SERVICE 877 435 3287

(Placer un appel de service au 1 877 435-3287), vérifi ez chaque étape d'installation et apportez les correctifs nécessaires avant d'utiliser votre appareil.

La laveuse quittera le programme INSTALL CYCLE (Programme d'installation) et reviendra à son mode 3.

de fonctionnement normal la prochaine fois que vous la réactiverez.

REMARQUE

La laveuse demeurera activée pendant trois minutes après la fi n du programme

d'installation. Si vous souhaitez utiliser l'appareil pour un cycle de lavage, appuyez

sur le bouton CANCEL (Annuler) pour mettre l'appareil en mode de veille, puis

réactivez-le immédiatement pour continuer au mode de fonctionnement normal.

Veuillez lire le 4. Guide d'utilisation et d'entretien et profi tez de votre nouvelle laveuse de qualité!

Page 30

12

Inversion de la porte

Préparation à l'inversion de la porte

1 Assurez-vous qu'il y a suffi samment d'espace avant d'inverser la porte.

2 Vous aurez besoin d'un tournevis à pointe carrée n° 2.

3 Protégez la surface de travail, comme le dessus de la laveuse ou le

plancher près de la laveuse, avec un chiffon doux ou une serviette.

4 Assurez-vous que la laveuse n'est pas branchée à une source

d'alimentation!

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

Le fait de ne pas débrancher l'appareil de sa source d'alimentation en

électricité avant son entretien peut causer des blessures, voire la mort.

Retrait de la porte et de la quincaillerie

A) Retrait de l'anneau de garniture

1 Ouvrez la porte à un angle de 90 degrés.

2 Retirez et conservez le bouchon de garniture

et la longue vis à tête cylindrique large et

fi lets grossiers.

B) Retrait de la porte de la charnière

1 Ouvrez à nouveau la porte à un angle de

90 degrés.

2 Retirez les quatre vis longues à tête fraisée

de charnière de la porte.

Outils

nécessaires :

Tournevis avec

embouts carré

no 2 et droit

3 Fermez la porte.

4 Faites tourner la garniture de porte environ

20 mm (¾ po) dans le sens antihoraire et

retirez-la de la porte.

3 En soutenant le poids de la porte avec vos

deux mains, séparez la porte de la charnière.

4 Placez soigneusement la porte face contre

terre sur la surface de travail protégée.

Page 31

C)

Retrait de la charnière du panneau avant

1 Avec la charnière en position ouverte, retirez

les deux vis courtes à tête cylindrique large

de la plaque de charnière.

2 Retirez les trois vis courtes à tête fraisée de

la charnière latérale.

Inversion de la porte

D)

Retrait du loquet de porte du panneau avant

1 Retirez les deux vis courtes à tête

cylindrique large du loquet de porte.

2 Faites glisser le loquet vers le rebord externe

du panneau avant. Faites pivoter le loquet

légèrement vers l'extérieur en le tirant

doucement dans l'ouverture pour apercevoir

le faisceau qui y est branché.

13

3 Faites glisser la charnière vers le centre

du panneau avant, puis faites-la pivoter

lentement vers l'intérieur en l'éloignant du

panneau avant de manière à apercevoir le

faisceau qui y est branché.

4 Soulevez la languette et dégagez le faisceau

du dispositif de retenue. Laissez reposer le

faisceau à l'extérieur du panneau avant.

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

Le fait de ne pas débrancher l'appareil de sa

source d'alimentation en électricité avant son

entretien peut causer des blessures, voire la mort.

3 Dégagez le faisceau du connecteur muni

du petit levier derrière le loquet. Séparez

le faisceau du loquet et laissez pendre le

faisceau à l'extérieur du panneau avant.

Page 32

14

Inversion de la porte

Inversion de la porte et de la quincaillerie

E) Remontage du loquet de porte au

panneau avant

1 Faites pivoter le loquet de porte et déplacez-

le du côté opposé de l'ouverture.

2 Branchez le faisceau au loquet de porte en

l'insérant dans le connecteur et en appuyant

fermement.

3 Insérez premièrement le connecteur de

faisceau dans le panneau avant, puis faites

pivoter le loquet jusqu'à ce qu'il soit bien

ajusté. Faites glisser le loquet vers le centre

du panneau avant, de manière à aligner les

trous de vis.

F) Remontage de la charnière au panneau

avant

1 Faites pivoter la charnière et déplacez-la du

côté opposé de l'ouverture.

2

Raccordez le faisceau au dispositif de retenue

de la charnière en l'insérant dans la borne de

retenue, et en poussant doucement jusqu'au

déclic de la languette de fi xation.

3 Tirez soigneusement sur le faisceau pour

vérifi er s'il est bien fi xé.

4 Utilisez les tiges de positionnement pour

aligner la charnière et posez une vis courte

à tête fraisée dans le trou central de la

charnière latérale.

4 Fixez le loquet avec les deux vis courtes à

tête cylindrique large.

5 Utilisez deux autres vis courtes à tête fraisée

dans les trous supérieur et inférieur de la

charnière latérale.

6 Posez deux vis courtes à tête cylindrique

large dans la plaque de charnière.

Page 33

Inversion de la porte

15

G) Retrait de la plaque-percuteur

1 Retirez les deux vis longues à tête fraisée et

la plaque-percuteur.

2 Réservez la plaque-percuteur pour une

utilisation ultérieure.

H) Retrait du voyant de loquet

I) Retrait du bouchon

1 IInsérez un tournevis à pointe plate dans la

fente ouverte du bouchon.

2 Soulevez légèrement la languette pour la

dégager.

1 Insérez un tournevis à pointe plate dans la

fente ouverte du voyant de loquet.

2 Soulevez légèrement la languette pour la

dégager.

3 Dégagez le voyant et mettez-le de côté.

3 Dégagez le bouchon et mettez-le de côté.

Page 34

16

insérez le

languette

insérez le

languette

Appuyez et

enclenchez

insérez l'indicateur

du loquet

dans la fente

insérez le

languette

insérez le

languette

Appuyez et

enclenchez

Inversion de la porte

J) Réinstallation du voyant de loquet

1 Faites pivoter le voyant de loquet et

déplacez-le dans le trou opposé de la porte.

insérez l'indicateur

du loquet

dans la fente

2 Insérez solidement les deux petites

languettes d’un côté ou de l’autre du voyant

de loquet dans les deux fentes d’un côté ou

de l’autre du trou de la porte.

insérez le

languette

K) Remontage de la plaque-percuteur

1 Faites pivoter la plaque-percuteur et

déplacez-la du côté opposé de la porte, audessus du voyant.

2

Réinstallez les deux vis longues à tête fraisée.

L) Réinstallation du bouchon

1 Faites pivoter le bouchon et déplacez-le

dans le trou opposé de la porte.

2 Insérez solidement les deux petites

languettes d’un côté ou de l’autre du

bouchon dans les deux fentes d’un côté ou

de l’autre du trou de la porte.

insérez le

languette

3 Appuyez fermement sur le voyant jusqu’à ce

que la languette s’enclenche en position.

Appuyez et

enclenchez

insérez le

languette

insérez le

languette

3 Appuyez fermement sur le bouchon jusqu’à

ce que la languette s’enclenche en position.

Appuyez et

enclenchez

Page 35

Inversion de la porte

Remontage de la porte et de la quincaillerie

17

M) Remontage de la porte

1 Ouvrez la charnière à un angle de 90 degrés.

2 Installez la porte sur les tiges de

positionnement de la charnière.

3 Fixez la porte avec les quatre vis longues à

tête fraisée.

3 Faites tourner le couvercle de l'anneau

de garniture. Déplacez-le vers l'ouverture

opposée de la garniture et réinsérez-le.

O) Réinstallation de l'anneau de garniture

1 Fermez la porte.

2 Dirigez la garniture de manière à ce que la

position 12 soit à environ 20 mm (¾ po) à la

gauche du point haut central. L'ouverture de

l'anneau de garniture devrait être du côté de

la charnière.

3 Insérez l'anneau de garniture dans les fentes

et tournez-le dans le sens horaire environ

20 mm (¾ po).

4 Fermez la porte et vérifi ez le fonctionnement

du loquet.

N) Inversion de l'anneau de garniture

1 Le sens de l'anneau de garniture est inscrit à

l'arrière.

2 Retirez le couvercle de l'anneau de garniture.

Pour retirer le couvercle de la droite, le point

de pivot est vers le haut. Pour retirer le

couvercle de la gauche, le point de pivot est

vers le bas.

UP

P) Réinstallation du bouchon de l'anneau

de garniture

1 Ouvrez la porte à un angle de 90 degrés.

2 Installez le bouchon de garniture avec la

longue vis à tête cylindrique large et fi lets

grossiers.

Q) Branchez l’appareil et poursuivez l'utilisation.

Page 36

18

26.44”

(67.16cm)

15.00”

(38.10cm)

27.00”

(68.58cm)

Options

Accessoires

SOCLE DE RANGEMENT ASSORTI*

Socle Blanc des îles - Pièce nº EPWD15IW

Socle Bleu méditerranéen - Pièce nº EPWD15MB

Socle Sables argentés - Pièce nº EPWD15SS

Socle Ciel turquoise - Pièce nº EPWD15TS

Socle Rouge - Pièce nº EPWD15RR

Socle Vert Kelly - Pièce nº EPWD15KG

Un socle de rangement, conçu expressément pour cette laveuse,

peut être utilisé afi n de soulever votre appareil, facilitant ainsi son

utilisation. Le socle ajoute environ 38,1 cm (15 po) à votre laveuse,

pour une hauteur totale de 134,62 cm (53 po).

*Il se peut que d’autres couleurs soient disponibles. Communiquez avec le

marchand qui vous a vendu votre laveuse.

NÉCESSAIRE DE SUPERPOSITION DE SÉCHEUSE

PIÈCE N° 134700400

Selon le modèle que vous avez acheté, il se peut qu’un

nécessaire pour superposer cette sécheuse sur une laveuse

assortie ait été inclus dans l’achat initial de votre sécheuse.

Si votre modèle ne comprenait pas de nécessaire de

superposition ou que vous en désirez un autre, il vous est

possible d’en commander un.

NÉCESSAIRE DE RALLONGE DE TUYAU DE VIDANGE

PIÈCE N° 137098000

Pour atteindre un tuyau d'évacuation qui est trop haut ou

trop loin pour la longueur de tuyau fournie, commandez le

NÉCESSAIRE DE RALLONGE DE TUYAU DE VIDANGE.

TROUSSE D'INSTALLATION DE MAISON MOBILE

PIÈCE N° 137067200

Toute installation dans une maison mobile nécessite l'utilisation

d'une TROUSSE D'INSTALLATION DE MAISON MOBILE.

ATTENTION

Tout défaut d'utiliser les

accessoires fabriqués ou certifi és

par le fabricant pourrait entraîner

des blessures, des dommages

aux biens ou à la laveuse.

27.00”

(68.58cm)

15.00”

(38.10cm)

26.44”

(67.16cm)

CLÉ D'APPAREIL UNIVERSELLE

PIÈCE N° 137019200

Votre laveuse est fournie avec une CLÉ D'APPAREIL

UNIVERSELLE. Si vous souhaitez obtenir une autre clé, vous

pouvez la commander.

CRAYONS DE PEINTURE DE RETOUCHE*

Crayon de retouche Blanc des îles - Pièce nº 5304468812

Crayon de retouche Bleu méditerranéen - Pièce nº 5304468813

Crayon de retouche Sables argentés - Pièce nº 5304468814

Crayon de retouche Ciel turquoise - Pièce nº 5304468815

Crayon de retouche Rouge - Pièce nº 5304471226

Crayon de retouche Vert Kelly - Pièce nº 5304471231

*Il se peut que d’autres couleurs soient disponibles. Communiquez avec le

marchand qui vous a vendu votre laveuse.

Pièces de rechange : 1 877 4ELECTROLUX (1 877 435-3287)

Si vous devez commander des pièces de rechange

pour votre laveuse, communiquez avec le marchand

qui vous a vendu votre appareil, composez le

1 877 4ELECTROLUX (1 877 435-3287), ou visitez

notre site Web à l'adresse www.electroluxappliances.

com, pour connaître le distributeur de pièces autorisé

Electrolux le plus près de chez vous.

AVERTISSEMENT

RISQUE ÉLECTRIQUE

Étiquetez tous les fi ls avant de les débrancher

pendant l'entretien des commandes. Des erreurs de

câblage pourraient nuire au bon fonctionnement de

l'appareil, et même être dangereuses. Vérifi ez le bon

fonctionnement de l'appareil après tout entretien.

Page 37

Installation Instructions

Electrolux Front-Load Washer

Instructions d’installation

Laveuse à chargement frontal Electrolux

Instrucciones de Instalación

Lavadora de carga frontal Electrolux

Page 38

2

Instrucciones importantes de seguridad

ADVERTENCIA

Para su seguridad, debe seguir la información de esta guía para minimizar el riesgo de incendio o

explosión o para evitar daños a la propiedad, lesiones personales o incluso la muerte. No almacene ni

utilice gasolina ni otros líquidos o vapores infl amables cerca de este o de cualquier otro electrodoméstico.

Identifi cación de los símbolos, palabras

y avisos de seguridad

Las indicaciones de seguridad incluidas en este

manual aparecen precedidas de un aviso titulado

“ADVERTENCIA” o “PRECAUCIÓN”, de acuerdo

con el nivel de riesgo.

sobre situaciones que pueden causar lesiones personales graves, la muerte o daños materiales.

sobre situaciones que pueden causar lesiones personales

o daños materiales.

Este símbolo le advierte

Este símbolo le advierte

ADVERTENCIA

PELIGRO DE INCENDIO - Lea las siguientes instrucciones antes de instalar y utilizar este electrodoméstico:

Después de desembalar la lavadora, destruya los cartones y las bolsas de plástico. Los niños podrían •

utilizarlos para jugar. Los cartones cubiertos con alfombras, cubrecamas, o láminas de plástico pueden convertirse en cámaras de aire herméticamente cerradas y provocar asfi xia. Coloque todos los

materiales en un basurero o manténgalos fuera del alcance de los niños.

Para su seguridad, debe seguir la información de esta guía para minimizar el riesgo de incendio o ex-•

plosión o para evitar daños a la propiedad, lesiones personales o incluso la muerte. No almacene ni utilice gasolina ni otros líquidos o vapores infl amables cerca de este o de cualquier otro electrodoméstico.

Instale la lavadora de ropa de acuerdo con las instrucciones del fabricante y los códigos locales.•

La reparación eléctrica de la lavadora debe cumplimentar los códigos y las ordenanzas locales y la •

última edición del Código Eléctrico Nacional (National Electrical Code), el ANSI/NFPA 70, o bien en

Canadá, el CSA C22.1 del Código Eléctrico de Canadá (Canadian Electrical Code) Parte 1.

Para evitar lesiones en la espalda u otro tipo de lesiones, procure levantar o mover la lavadora con la •

ayuda de más de una persona.

No apile la secadora sobre la lavadora si ya está instalada sobre un pedestal. No apile la lavadora •

sobre la secadora. No apile la lavadora sobre otra lavadora.

Las instrucciones de esta guía y todo el material que se incluye con esta secadora no tienen como •

propósito cubrir todas las condiciones y situaciones que puedan presentarse. Cuando instale, opere o

repare cualquier artefacto DEBE tener cuidado y hacer uso de buenas prácticas de seguridad.

QUÉ HACER SI SIENTE OLOR A GAS:

No intente encender ningún electrodoméstico.•

No toque ningún interruptor eléctrico; no utilice ningún teléfono en la vivienda.•

Despeje la habitación, el edifi cio o el área de todos los ocupantes.•

Llame inmediatamente a su proveedor de gas desde el teléfono de un vecino. Siga las instrucciones •

del proveedor de gas.

Si no puede ponerse en contacto con el proveedor de gas, llame a los bomberos.•

Conserve estas instrucciones para referencia futura.

Índice

Instrucciones importantes de seguridad ........................ 2

Requisitos de instalación ............................................3-5

Dimensiones de la lavadora instalada ............................ 6

©2010 Electrolux Major Appliances

Instrucciones de instalación ......................................7-11

Inversión de la puerta ..............................................12-17

Opciones ...................................................................... 18

Todos los derechos reservados.

Page 39

Requisitos de instalación

3

Lea y conserve esta guía

Gracias por elegir Electrolux, la nueva marca de

alta calidad de electrodomésticos para el hogar.

Estas instrucciones de instalación forman parte de

nuestro compromiso de satisfacer al cliente y de

ofrecer un producto de calidad a lo largo de la vida

útil de su nuevo electrodoméstico.

Lista de verifi cación de instalación

Ferretería de envío y transporte

Se retiró y guardó el soporte de espuma de

empaque (debajo de la tina de lavado)

Se retiraron y guardaron los pernos y

espaciadores de la parte trasera del

electrodoméstico

Se instalaron los tapones (empacados en

una bolsa en el interior del tambor) en los

agujeros de la lámina trasera

Nivelación

La lavadora está nivelada de lado a lado y

de adelante hacia atrás

El lavadora descansa fi rmemente sobre sus

cuatro esquinas

Suministro de agua

Se conectó el suministro de agua CALIENTE

a la admisión de agua CALIENTE y el

suministro de agua FRÍA a la admisión de

agua FRÍA

Se abrió el suministro de agua CALIENTE y

FRÍA

No hay escapes en las conexiones del

suministro de agua o en las conexiones de

admisión del electrodoméstico vuelva a verifi car a las 24 horas

¿Preguntas?

Para obtener asistencia telefónica gratuita en los

Estados Unidos y Canadá:

1-877-4ELECTROLUX (1-877-435-3287).

Para obtener asistencia e información en línea

sobre el producto, visite:

http://www.electroluxappliances.com.

Drenaje

Tubo vertical o drenaje de pared a una altura

mínima de 24” (61 cm)

Manguera de drenaje enganchada en el canal

en “U” (empacado en el tambor)

Manguera de drenaje fi jada en su lugar con

un amarre para cables (empacado en el

tambor)

Inversión de la puerta

Siga las instrucciones detalladas en esta guía

Pruebe la bisagra y el gancho para

asegurarse de que funcionen

Suministro eléctrico

El suministro eléctrico del hogar está activado

La secadora está enchufada

Inspección fi nal

Lea bien las instrucciones de instalación y la

guía de uso y cuidado

La puerta se cierra y el tambor gira cuando

se inicia el ciclo

Tarjeta de registro enviada

Requisitos de preinstalación

Herramientas y materiales necesarios para la instalación:

OOO Y Y

Llave universal

proporcionada con

la lavadora

Llave

ajustable

Llave de cubo

de 3/8" o 10 mm

Juego de

manguito

y trinquete

Pinzas

ajustables

Nivel de carpintero

Page 40

4

Tom

acorriente

con puesta

a tierra

Cordón eléctrico

de 3 clavijas con

puesta a tierra

No corte, retire ni deshabilite

la clavija de conexión a tierra

bajo ninguna circunstancia.

Requisitos de instalación

Requisitos del sistema eléctrico

CIRCUITO - Circuito individual de bifurcación

de 15 amp., correctamente polarizado y con

conexión a tierra con fusible de retardo de 15

amp. o con interruptor automático.

SUMINISTRO ELÉCTRICO: corriente alterna de