Electro Industries EMB-S-1, EMB-S-2, EMB-S-4, EMB-S-5, EMB-S-7 Installation Manual

...

Electric

™

Mini-Boiler

Installation & Operating

Instructions

EMB-S-1 120-volt, 1-stage – 1.125 kW 3,841 Btu/h

EMB-S-2 120-volt, 1-stage – 2.5 kW 8,535 Btu/h

EMB-S-4 120-volt, 2-stage – 5 kW 17,020 Btu/h

EMB-S-5 240-volt, 1-stage 30A CB 4.5 kW 15,360 Btu/h

EMB-S-7 240-volt, 2-stage 45A CB 7 kW 23,800 Btu/h

EMB-S-9 240-volt, 2-stage 60A CB 9 kW 30,725 Btu/h

Water Flow – Minimum 0.3 GPM per kW water flow is required through boiler.

Design Temperature Rise – Typical radiant floor system should be designed at 12° to 15°.

Application – Low temperature, low pressure, radiant underfloor heating systems. This model includes factory

installed temperature sensing staging.

Comment – If this application is for traditional hydronics heating requiring temperatures greater than 160 and

capacities larger than shown above, contact factory for other Electro-Boiler product series.

In this approximate sizing the EB-M*-** model series is fully modulating and designed for

temperatures up to 180° F. The EB-M* and EB-W* also have outdoor reset options and other features.

Accessories – Attached BL001 lists various accessory or option items which are not part of basic Electro-Boiler.

Note: This product meets the requirements of the ASME Boiler and Pressure

Vessel Code.

Drawings: BX305

BH310

UAW411

BL001

XX017

05/08/2017 BI307

TABLE OF CONTENTS

Description

System Components 1

System or Water Flow 1

Temperature Sensing Staging Control 1

Room Thermostat Placement 1

Zone Systems or Requirements 2

Built-In Temperature Control 2

Water Flow Calculation 2

Installation Requirements 3

Electric Supply 3

Clearances 3

Page

Mechanical Installation 4

Electrical Hookup 5

Water Fill Procedure 6

Operational Tips 8

Troubleshooting Helps 9

Drawings: BX305

BH310

UAW411

BL001

XX017

05/08/2017 BI307

GENERAL

As stated, this product series applies to under floor hydronics heating. The basic components for an electric

energy heating system typically include:

1. Electric Mini-Boiler itself – covered by this manual.

2. Thermostat hookup control – covered by this manual.

3. Plumbing kit or piping material at the boiler itself – can be ordered as a kit, reference catalog number EMB-PK.

a. These items are shown on plumbing installation drawing BX305.

4. Circulating pump – typically sized for head pressure and system flow requirement, typical catalog number EMB-P2.

5. The under floor circulating tubes and manifolds – provided and manufactured by others, not covered in this manual.

APPROVED TUBING/PIPING

When plumbing this boiler and its peripheral parts to the loop system, all plumbing parts and/or tubing must be

sealed to prevent entrance of oxygen.

Use only tubing or polyethylene tubing with oxygen Diffusion Barrier (ie. PEX).

SYSTEM OR WATER FLOW

In order to prevent rapid stage cycling and long term deterioration of components and elements, it is important

the water flow be greater than the specified 0.3 GPM per kW.

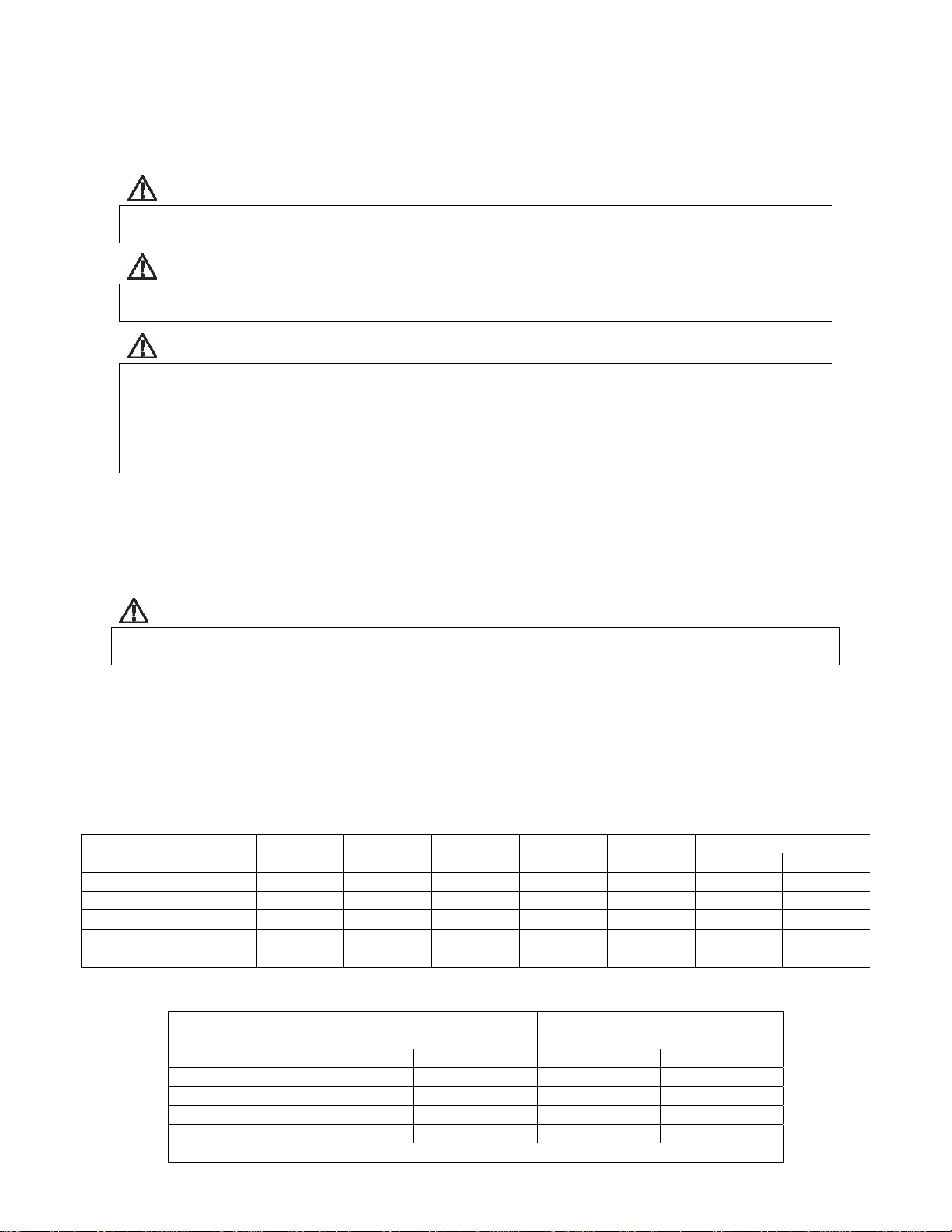

WATER FLOW REQUIREMENTS

Model

EMB-S-1 .75 2.83 .01 .003 .37 1.39 .003 .001

EMB-S-2 1.7 6.43 .01 .006 .85 3.21 .02 .006

EMB-S-4 3.41 12.88 .08 .024 1.70 6.42 .04 .012

EMB-*-5 3.07 11.60 .06 .018 1.53 5.78 .02 .006

EMB-*-7 4.78 18.06 .12 .036 2.39 9.03 .06 .01

EMB-*-9 6.14 23.20 .23 .07 3.07 11.60 .10 .03

* = S or H

Note: Head Loss based on 110° F return temperature.

Flow – 10° F/6° C Head Loss Flow – 20° F/11° C Head Loss

gpm lpm ft m gpm lpm ft m

(MINIMUM 0.3 GPM PER KW WATER FLOW THROUGH BOILER)

Water Temperature Rise

TEMPERATURE SENSING STAGING CONTROL

This model series is factory equipped with a digital supply water sensor and a staging controller. The controller

regulates the elements to maintain a preset maximum or preset operating temperature. The control board has a

front panel screwdriver adjustment (see Operational Tips section) for setting the operating temperature point.

During initial turn on (slab stat call for heat) there is an initial pump on in attempt to stabilize the loop

temperature followed by stage 1. After approximately 4 minutes if the water supply sensor value is still below

the set point, stage 2 is turned on. At this point, the water temperature is sampled every 4 minutes to determine

correct element sequence. Assuming proper flow, the element power will regulate to maintain this preset

temperature.

ROOM THERMOSTAT PLACEMENT

Comfort and proper space heating response is a direct relationship to the room thermostat type and the

placement of the thermostat sensing bulb. Typically an under floor heating system can be broken down into two

categories.

Energy storage, water tubing is under the concrete or within the sand base - The controlling

thermostat must have a remote bulb, and this remote bulb must sense the concrete slab temperature (slab

stat). Coordinated with the concrete pour, install a ¾” PVC, minimum bend radius of 7 inches, and

locate at approximately center (vertical) of the concrete slab. The thermostat sensing bulb can later be

pushed down this PVC conduit. If the slab is already poured without conduit for slab stat, use electronic

05/08/2017 1 BI307

remote sensing thermostat such as Electro Industries’ ES-24-BR. This type of device only requires a

5/16” hole drilled in the concrete at some center wall location.

Quick response, hydronics tubing just under the concrete surface, no flooring material over the

concrete – slab stat is still suggested and preferred, but a standard wall mount room thermostat can be

adequate. Mount room thermostat on an inside wall similar to most heating systems.

Comment: If the slab was poured without the conduit, Electro Industries can provide a remote

sensing slab stat with a remote sensor requiring only a 5/16” hole. If it is at an inside wall, the

5/16” hole need only be 1’ or 2” away from the plate. If it is an outside wall you should go in

about 24”. Simply insert the sensor about 2” and fill with basic silicone to keep the sensor

protected within the hole.

ZONE SYSTEMS OR REQUIREMENTS

If there are zones with capacities and flow less than this boiler’s total capacity, consideration should be given

towards installing a zone controller with the ability to cut off one element for small zones. Low cost multi-zone

interlock, EB-5415A, can provide this function. It also has its own 40VA transformer for powering zone valves.

For two pump zones, EB-Z2P can provide all the pump relay and easy wiring features. Connecting common

and W OUT becomes the interface to turn on this boiler. Unlike the larger Electro-Boiler zone control interface,

no remote bus wires are required, but this EB-Z2P requires 24-volt from the Mini-Boiler internal transformer.

This boiler’s internal pump contact (orange wires) is not used.

TEMPERATURE CONTROL

The hi-limits within this unit are for safety purposes only. The system installation must have a proper

responding slab sensing thermostat or zone controlling device to properly turn the boiler on and off. If the water

flow is greater than the nominal GPM specified, this boiler should not reach hi-limit and the hydronics loop

should continue to flow in the normal heating pattern until the operating slab stat is satisfied. If hi-limiting is

experienced prior to satisfying the operating slab stat, there is probably a water flow issue.

In addition to the built-in supply sensing point and electronic operating temperature control point, there is a 190°

automatic reset hi-limit and a 205° F top vessel manual reset hi-limit.

INFORMATION/WATER FLOW CALCULATIONS

Water flow, GPM, can easily be calculated if the temperature rise across the electric boiler can be measured.

The formula below can only be used when the temperature rise is stable and the boiler is not hi-limiting. In

other words, verify constant current draw and stable outlet temperatures for at least 15 minutes.

GPM=

INFORMATION/WATER FLOW CALCULATIONS – METRIC

L/min =

Volts x Amps x 3.4

500 x Temp. rise 500 x 10 degree rise 5000

Volts x Amps x 3.587

251.04 x Temp. rise ° C 251.04 x 6° C rise 1506.24

Example:

Example:

240 volts x 36 amps x 3.4

240 volts x 36 amps x 3.587

=

=

29376

30991.68

= 5.8 gpm

= 20.57 L/min

05/08/2017 2 BI307

INSTALLATION REQUIREMENTS

1. All installation work must be performed by trained, qualified contractors or technicians. Electro Industries,

Inc., sponsors installation and service schools to assist the installer. Visit our web site at electromn.com

for upcoming service schools.

WARNING

ALL ELECTRICAL WIRING MUST BE IN ACCORDANCE WITH NATIONAL ELECTRIC CODE AND

LOCAL ELECTRIC CODES, ORDINANCES, AND REGULATIONS.

WARNING

OBSERVE ELECTRIC POLARITY AND WIRING COLORS. FAILURE TO OBSERVE COULD CAUSE

ELECTRIC SHOCK AND/OR DAMAGE TO THE EQUIPMENT.

CAUTION

This unit can only be used for its intended design as described in this manual. Any internal wiring changes,

modifications to the circuit board, modifications or bypass of any controls, or installation practices not

according to the details of this manual will void the product warranty, the CSA/us certification label, and

manufacturer product liability. Electro Industries, Inc., cannot be held responsible for field modifications,

incorrect installations, and conditions which may bypass or compromise the built-in safety features and

controls.

2. This installation manual and Electro-Boiler products relate only to the addition of the Electro-Boiler to the

hydronics system. The owner/ installer assumes all responsibility and/or liability associated with any

needed installation of the gas/oil boiler, pump, plumbing, system design, hydronics systems or backup

gas/oil boiler, etc. Any instructions or comments made within this manual (or factory phone assistance)

relating to the gas/oil furnace are provided as comments of assistance and “helps” only.

CAUTION

Hazards or unsafe practices could result in property damage, product damage, severe personal injury and/or

death.

3. Remember, safety is the installer’s responsibility and the installer must know this product well enough to

instruct the end user on its safe use.

Safety is a matter of common sense - - a matter of thinking before acting. Professional installers have

training and experienced practices for handling electrical, sheet metal, and material handling processes. Use

them.

Model Volts Watts Amps CB Phase Btu/h

EMB-S-2 120 2,500 20.8 – 1-60 8,532 1 –

EMB-S-4 120 5,000 41.6 – 1-60 17,065 1 1

EMB-S-5 240 4,500 18.7 30 1-60 15,358 1 –

EMB-S-7 240 7,000 29.1 45 1-60 23,890 1 1

EMB-S-9 240 9,000 37.5 60 1-60 30,717 1 1

MINIMUM CLEARANCE FROM

COMBUSTIBLE SURFACES

BACK 0 INCH 0 MM 0 INCH 0 MM

LEFT 1 INCH 25 MM 6 INCHES 152 MM

RIGHT 1 INCH 25 MM 6 INCHES 152 MM

FRONT 1 INCH 25 MM 24 INCHES 610 MM

TOP 1 INCH 25 MM 24 INCHES 610 MM

BOTTOM REQUIRED CLEARANCE – 18 INCHES/457 MM

ELECTRIC SUPPLY

Element

Stg 1 Stg 2

CLEARANCES

SUGGESTED MINIMUM

SERVICE CLEARANCE

05/08/2017 3 BI307

MECHANICAL INSTALLATION

CAUTION

Electro Industries Inc. requires the use of dielectric isolation between the boiler vessel supply

and return piping when the boiler is plumbed using copper or any other dissimilar metal.

Reference drawing BX305

The plumbing components and piping layout shown on drawing BX305 has been very carefully picked and

should be plumbed as shown. When following this diagram, the water fill procedure becomes very simple and

almost guarantees the removal of all air or prevents air locking problems. Experienced hydronic heating

installers may be able to eliminate components such as regulated fill valve, check valve, temperature gauge, etc.,

but the inclusion of these components guarantees installation and initial operating success.

The key mechanical components required include:

Damage to the vessel caused by galvanic corrosion voids Electro Industries’ warranty.

Boiler/Plumbing Kit Placement – This model series is wall hung and the vessel must be vertical.

The plumbing kit items are located adjacent to the boiler housing itself as shown on

drawing BX305.

For future servicing, the unit itself must be installed a minimum of 18” above the floor. The

elements are screwed in from the bottom.

Allow adequate space for cover removal and maintenance.

Expansion Tank - As a closed loop hydronic heating system, a minimal expansion tank is required.

This can be an air diaphragm tank as provided in the plumbing kit or a basic “empty” tank where air

is compressed at the tank top.

Temperature/Pressure Gauge - Recommended to observe the operation of the system. Actually a

temperature gauge at the inlet and outlet is desirable.

Pressure Safety Valve - This is required at the hot outlet and is furnished as a loose component

with the boiler unit itself. Failure to install the provided, 30 PSI, pressure relief valve as shown

void warranty and the CSA product listing.

Add the necessary pipe extension from the relief valve to the floor to prevent water damage on this unit

or surrounding area.

Gate Valve/Drain Valve - These are for servicing and easy fill purposes.

Circulating Pump - Depending upon system lift and system loop resistance (feet of head), the

proper circulating pump is required to guarantee the minimum GPM flow as specified on the cover

sheet.

Comment: Circulator pump can be in the outlet or inlet. However, the circulator pump should “pump

away from” the expansion tank.

Air Vent – Whenever there is a plumbing point higher than any of the components shown or an

adjacent line (any vertical “U” trap), an air vent valve should be provided.

Building Water Supply Connection – Reference drawing BX305, note 4, some local building

codes require sophisticated check valve or anti-siphon check valve when the hydronics heating

system is permanently connected to the domestic water system. The intent of this connection is

temporary and for fill purposes only. The installer has the responsibility of complying with local

building codes.

05/08/2017 4 BI307

ELECTRICAL HOOKUP

Reference drawing BH310

WARNING

DISCONNECT ALL ELECTRICAL POWER BEFORE ELECTRICALLY CONNECTING OR

SERVICING THE UNIT. FAILURE TO DISCONNECT THE ELECTRICAL POWER BEFORE

WORKING ON THIS PRODUCT CAN CREATE A HAZARD LEADING TO PERSONAL INJURY

OR DEATH.

1. Panel breaker sizes – based upon the installed unit capacity, cover page shows model

number/amps/kW, service from appropriate size panel breaker based on NEC code.

2. Now the larger size EMB-S model series includes a factory provided circuit breaker. This qualifies for

a local disconnect at the product or appliance.

3. 240-Volt Power Source – route and install the proper current carrying conductors, suggested by local

codes, from service panel fuse or circuit breaker. Nameplate shows current & KW rating. Use only

copper wire within this unit enclosure or at the circuit breaker connection.

The source is either from the standard service panel or may be part of an off-peak separately metered

panel/CT metered enclosure. Consult with local utility if questions on off-peak installations.

WARNING

USE ONLY COPPER WIRE FOR CONNECTION TO THE CIRCUIT BREAKER TERMINALS

AND INSIDE THIS PRODUCT’S CABINET.

WARNING

TO AVOID THE RISK OF ELECTRIC SHOCK OR DEATH, WIRING TO THE UNIT MUST BE

PROPERLY GROUNDED. FAILURE TO PROPERLY GROUND THE UNIT CAN RESULT IN A

HAZARD LEADING TO PERSONAL INJURY OR DEATH.

NOTE: This model series is designed and equipped for 240-volt residential single phase. If this unit is

used on 208 volt, energy capacity is reduced and there is a possibility of intermittent relay operation. The

installed transformer has a primary tap for 208.

4. Circulating Pump – the orange pigtail wires, at the control board cube relay, represent a switch closure

(see drawing – 10-amp maximum) to operate the circulating pump motor. Voltage for the pump must

come from a separate source. Wiring entrance must be left KO, do not combine with thermostat cable

or other control wiring.

5. Operating Thermostat – zone valve dry contact end switch is an operating contact, direct wired

thermostats include:

Standard Mechanical – connect to control board “R” and “W”. Important! -Set thermostat

internal heat anticipator to 0.2.

Electro-Stat (ES-24-BR) – 3-wire connection required. This is an electronic remote sensing

device, remote sensor can be up to 25 feet, cut and splice as required. Use only stranded wire,

shielded cable not required. The primary advantages include the capability for longer sensor and

the sensor itself is less than 5/16”. This means it can be installed after the slab is complete by

simply drilling a ¼” hole, 1/8” slot, etc. slightly out from an inside wall.

- R to R, W to W, C to C, green to ground

- Use drawing EH308 (with ES product) for hookup, note change in load control connection.

05/08/2017 5 BI307

Loading...

Loading...