Electro Industries EB-S-18, EB-S-23, EB-S-13, EB-S-27 Installation Manual

ELECTRO-BOILER

TS Series

INSTALLATION & OPERATING INSTRUCTIONS

Model EB-S-13

EB-S-18

EB-S-23

EB-S-27

APPLICATION: This Electro-Boiler series is factory equipped with outlet temperature sensing and a smart controller which automatically stages the various elements to operate at the field preset outlet temperature.

Primary application is any hydronic water heating system where reduced flow or radiation can cause overheat conditions (example, zones). However, if it is a mixture of large and small zones, the sudden capacity and flow changes may cause some internal timing/overtemp conditions. With the mixture of zones the zone controller ZTS-* option is highly recommended (see page 2).

This series is equipped for load management interrupt and can apply to standard baseboard radiation, dual heat combinations, under floor radiant, wood boiler supplement, etc.

ACCESSORIES: Attached BL001 lists various accessory or option items which are not part of basic Electro-Boiler. Also page 3 has additional information on slab stat. Page 2 gives information on a zone control update module which stages elements based upon zone capacity.

Note: This product meets the requirements of the ASME Boiler and Pressure Vessel Code.

Drawings: BX501

BX502

BH501

BS501

BL001

01/25/2005 |

BI501 |

TABLE OF CONTENTS

Description |

Page |

Introduction |

1 |

System or Water Flow |

2 |

Multiple Zones & Radiant Temperatures |

2 |

Zone Controller |

2 |

Room Thermostat Placement |

3 |

Multiple Boilers |

3 |

Two-Temperature Operation or Feature |

4 |

Boiler/Plumbing Kit Placement |

4 |

Installation Requirements |

4 |

Mechanical Installation |

|

Under-Floor Radiant |

5 |

Dual Heat |

6 |

Electrical Hookup |

7 |

Water Fill Procedure |

8 |

Controller Setup |

9 |

Operational Tips |

9 |

Replacement Parts List |

11 |

Troubleshooting/Repair Helps |

12 |

Sequence |

12 |

Drawings: |

|

Basic Mechanical |

BX501 |

Piping, Install Kits |

BX502 |

Hookup |

BH501 |

Internal Wiring Schematic |

BS501 |

Boiler Accessories |

BL001 |

01/25/2005 |

BI501 |

INTRODUCTION

With this temperature sensing controller capability, the electric heating element stages are automatically turned on and off to establish a fixed outlet water temperature. This outlet temperature is sensed at the outlet pipe, the controller regulates four stages, and attempts to control the water temperature at a value determined by the setup arrangements. Field setting the outlet temperature at the design or realistic temperature required by the radiation is more efficient.

Even though this temperature sensing series adjusts outlet temperature independent of water flow and prevents high limiting; it is still very important that the hydronic system be correctly designed for the building, the total heat loss requirement, and proper hydronics design and installation practices. This boiler is the energy source for the water flow and radiation system. If the water flow and radiation systems are not adequate for the Btuh heat loss of the building, installing the Electro-Boiler with this temperature control feature will not necessarily supply the comfort and heating for the building.

Control and operate as a “cold boiler” concept. Do not, under any circumstances, simply jumper R and W and allow the temperature sensing controller to operate this Electro-Boiler as a “hot boiler”. Unless there is at least 2 GPM flow, the staging delays will cause temperature overshoot and could open up the manual reset limits.

Standby boiler wiring arrangement is optional, order standby kit EB-S-SB.

In most dual heat installations (with standby kit EB-S-SB) this Electro-Boiler is plumbed in series with an existing oil, gas, or wood boiler. For gas or oil, the Electro-Boiler is generally at the gas/oil outlet; but for wood, the Electro-Boiler must be on the inlet sides. The standby boiler cannot be operated as “hot boiler”. This will defeat the Electro-Boiler. Rewire as required, standby boiler is turned on from the brown wires.

In the case of existing bleeder, and circulation system design.

fossil fuel boiler conversions, it is assumed the expansion tank, valving, air pump are in place, in good operating condition, and adequate for the overall

In the case of new installation (radiant floor or baseboard), use standard hydronics water heating practices with the necessary expansion tank, air bleeder, valving, water pump, etc., sized for the total capacity of the system. The Electro-Boiler is turned on with an “R and W” closure from the zone system wiring.

208 Volt application – the elements within the standard product are rated a 240 volts. If operating at 208, there will be approximately 25% reduced capacity. The internal transformer may or may not adequately operate the control system from a 208 source. Voltage measurements between “R” and “C” must be 22VAC or greater when the system is in the complete operational mode. True 3-phase, 208-volt, models are available in the WarmFlo series. Contact factory, models EB-WO-13-2 and EB-WO-27-2.

In the case of under floor radiant heating, the basic components for the electric energy, heating system typically includes:

1.Electric boiler itself, drawing BX501 – covered by this manual.

2.Plumbing kit or piping material at the boiler itself – can be ordered as a kit.

•EB-BK-TS – shown on plumbing installation drawing BX502, pages 1 and 2.

•EB-PK-TS – shown on plumbing installation drawing BX502, page 3.

3.Circulating pump – typically sized for head pressure and system flow requirement, typical catalog number EB-P2. Large pump maybe required for 23 or 27 kW.

4.The under floor circulating tubes and manifolds – provided and manufactured by others, not covered in this manual.

APPROVED TUBING/PIPING

When plumbing this boiler and its peripheral parts to the loop system, all plumbing parts and/or tubing must be sealed to prevent entrance of oxygen.

Use only tubing or polyethylene tubing with oxygen Diffusion Barrier.

01/25/2005 |

1 |

BI501 |

SYSTEM OR WATER FLOW

In order to prevent hi-limiting and assure full 20+ years parts life, the piping system/basic plumbing/circulator pump must be arranged to provide flow greater than minimum GPM shown in Table 1. If zoned system, this applies when the smallest zone is operating.

TABLE 1 - ELECTRO-BOILER SPECIFICATION 240 volts, 60 Hz, single phase

Model |

Btuh |

Rating |

Amp |

Stages |

GPM |

EB-S-13 46,000 |

13.5 kW |

56A |

3 |

2-6 |

|

EB-S-18 |

61,400 |

18 kW |

75A |

4 |

2-8 |

EB-S-23 |

76,800 |

22.5 kW |

94A |

4 |

2-12 |

EB-S-27 |

92,150 |

27 kW |

113A |

4 |

2-18 |

MULTIPLE ZONES AND RADIANT TEMPERATURES

EB-S-27 can be wired for 208, 3- phase – call factory for drawing EH013. Also note at 208 there is a significant reduction in capacity. Suggest using 3-phase, 208, WarmFlo models EB-WO-13-2 or EB-WO-27-2.

Same water temperature all zones – in this case the system can be setup as one pump with the water circulated through the boiler and directly to a manifold containing the various zone valves. Although this model series has a built-in outlet sensing and controller mechanism for staging the elements, also consider the next section, Zone Controller. If not using zone controller, the end switches of all of the zone valves are paralleled and directly control R and W to turn on the boiler.

Various water temperature requirements – if this is the case, a primary loop with mixing valve for the various zone temperature requirements is necessary. Injection pump techniques can also be used. However, usually injection pump techniques come with a controller which is designed to protect a gas boiler from cool water return. This is simply not needed and a duplication with the temp. sensing controller within this Electro-boiler and the injection pump controller will be of no benefit within the operating system. The zone valve/zone pump control strategy must be wired to provide the boiler “R and W” contact closure and the primary pump is connected to the boiler pump contacts. This assures the primary pump is active and running whenever the boiler is turned on via contact closure on “R and W”. At least one zone must be open before turning on the primary pump/Electro-Boiler. Do not design a system where the Electro-Boiler is supposed to operate as a “hot boiler” based upon its outlet sensor without the primary pump circulating water, minimum 2 GPM is required.

New, improved feature – the EB-ZTS-1 zone controller priority zone now has the ability to communicate with this TS Series boiler and it will automatically switch to a low mass high water temperature (150 or 180) during zone 1, priority switch on, operation. With this feature the TS boiler can automatically take care of two temperature requirements thus eliminating the need for the technique described in the paragraph above.

ZONE CONTROLLER

This EB-S series boiler controls the electric elements based upon water temperature independent of flow; therefore, in theory, a staging zone controller is not required; however, there are three suggestions or reasons why a zone controller can simplify the installation and enhance overall performance.

1.Zone wiring and troubleshooting convenience – the addition of the zone board (fits within basic boiler cabinet) allows for easy terminal block and point to point wiring for each zone thermostat and each zone valve. Also there are LED’s associated with the thermostat action and the zone valve action. This greatly simplifies wiring and future troubleshooting with a neat terminal block wiring arrangement and the onboard LED’s – order EB-ZTS-1.

2.Prevents over control or false staging up and down when the temperature sensors are attempting to regulate – since Electro Industries’ zone controller also has staging “smarts”, the addition of the zone controller will provide smoother boiler temperature control. The zone board has a dial switch for each

01/25/2005 |

2 |

BI501 |

zone and the installer selects one of four zone capacity sizes. When dialing in the size closest to the zone Btu/h capacity, the zone controller “smarts” only allows the appropriate boiler stage which can handle that capacity. Also this is additive if more than one zone calls at any one time – order EB-ZTS-1.

3.Two temperature system with unbalanced zones – if the application includes zone one requiring high temperature (fin tube, air handler, etc.) and the remaining zones are radiant floor low temperature, this zone controller (EB-ZTS-1) will automatically raise the output of the high temperature zone. This is a priority arrangement, zone 1 holds off the other zones while the high temperature output is heating. If at the end of the high temperature zone there is a call on any of the low temperature zones (up to three plus slave 4), there will be a pump only function until the outlet temperature drops below the front panel dial setting.

Field zone controller installation – the above mentioned zone controller board is installed within the basic cabinet. However, the zone controller board must communicate with the main TS boiler board. All production units after approximately January 10, 2004 have a compatible control board. If the zone controller installation is in a boiler manufactured prior to that date, call factory to review the requirements for a main controller board upgrade.

ZONE CIRCULATORS

The EE-5051 switching relay can be used to interface line voltage pumps with the boiler R and W control terminals, see drawing BH008. This switching relay can be combined with the above zone controller board.

ROOM THERMOSTAT PLACEMENT

Fin tube radiation, fan coil, etc. – heat only wall t-stat, connected to operate zone valves (see previous section) or for single zone the t-stat is connected directly to Electro-Boiler R and W.

Floor radiant – comfort and proper space heating response is a direct relationship to the thermostat type and the placement of the thermostat sensing bulb. Typically an under floor heating system can be broken down into three categories.

A.Energy storage, water tubing is under the concrete or within the sand base

– the controlling thermostat must have a remote bulb, and this remote bulb must sense the concrete slab temperature (slab stat). Coordinated with the concrete pour, install a ¾” PVC, minimum bend radius of 7 inches, and locate at approximately center (vertical) of the concrete slab. The thermostat sensing bulb can later be pushed down this PVC conduit. If the slab is already poured without conduit for slab stat, use electronic remote sensing thermostat such as Electro Industries’ ES-24-SRO or ES-24-C-RS. These devices only require a ¼” hole drilled in the floor at some convenient location (preferably off a center wall, not within 2 feet of outside wall).

B.Floor covering, medium to high insulation – use slab stat as described in paragraph A above.

C.Quick response, hydronic tubing just under the concrete surface, no flooring material over the concrete – in this case, heated water can directly radiate into the room, a standard wall mount room thermostat is adequate. Mount room thermostat on an inside wall similar to most heating systems.

MULTIPLE BOILERS

This boiler series now includes a method for automatically staging any number of parallel-plumbed boilers. Order plug-in relay EB-C- STG5.

The thermostat is connected only to the first boiler, when all stages are on for more than 5 minutes, this new plug-in relay module turns on the next boiler (R and W), and a second EB-C-STG5 could be used to turn on the third, etc.

01/25/2005 |

3 |

BI501 |

TWO-TEMPERATURE OPERATION OR FEATURE

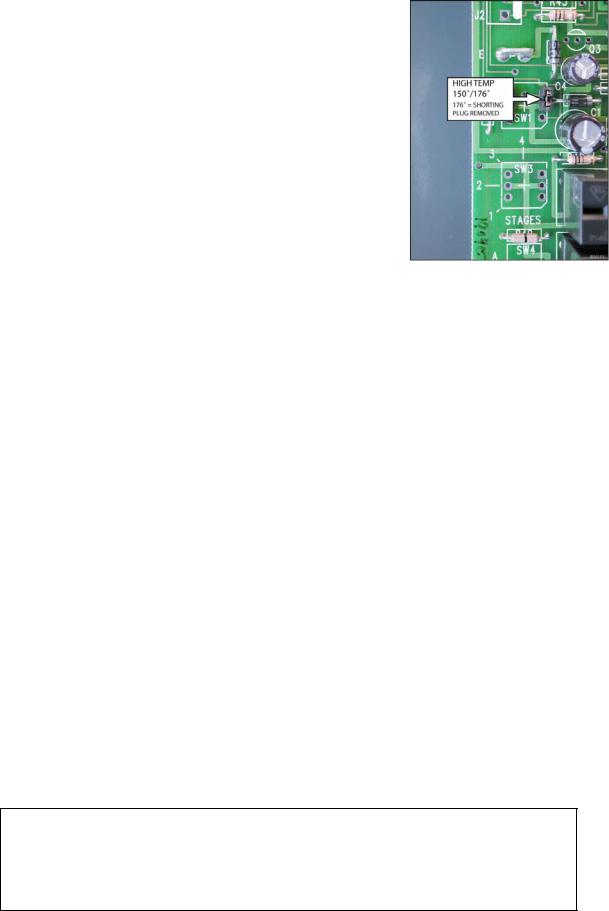

When using Electro’s zone controller in priority mode, the boiler system can automatically raise the outlet temperature with zone 1 calling. This is setup for default of 150° or pulling a jumper peg the high temperature value is 176°. See appropriate zone controller installation manual for details.

BOILER/PLUMBING KIT PLACEMENT

This model series is wall hung and the vessel must be vertical, drawing BX501.

The plumbing kit items are located adjacent to the boiler housing itself as shown on drawing BX501 or BX502.

For future servicing, the unit itself must be installed 20” or more above the floor, the elements are screwed in from the bottom.

INFORMATION/WATER FLOW CALCULATIONS

Water flow, GPM, can easily be calculated if the temperature rise across the electric boiler can be measured.

The formula below can only be used when the temperature rise is stable and the boiler is not hi-limiting. In other words, verify constant current draw and stable outlet temperatures for at least 15 minutes.

GPM = Volts x Amps x 3.4 500 x Temp. rise

INSTALLATION REQUIREMENTS

1.All installation work must be performed by trained, qualified, contractors, or technicians. Electro Industries, Inc. sponsors installation and service schools to assist the installer. Visit our web site at electromn.com for upcoming service schools.

2.All electrical wiring must be in accordance with the national Electric Code and local electric codes, ordinances, and regulations.

3.Observe electric polarity and wiring colors. Failure to observe could cause electric shock and/or damage to the equipment.

4.This unit can only be used for its intended design as described in this manual. Any internal wiring changes, modifications to the circuit board, modifications or bypass of any controls, or installation practices not according to the details of this manual will void the product warranty, the CSA certification label, and manufacturer product liability. Manufacturer cannot be held responsible for field modifications, incorrect installations, and conditions which may bypass or compromise the built-in safety features and controls.

CAUTION

CAUTION

This unit can only be used for its intended design as described in this manual. Any internal wiring changes, modifications to the circuit board, modifications or bypass of any controls, or installation practices not according to the details of this manual will void the product warranty, the CSA/us certification label, and manufacturer product liability. Electro Industries, Inc., cannot be held responsible for field modifications, incorrect installations, and conditions which may bypass or compromise the built-in safety features and controls.

01/25/2005 |

4 |

BI501 |

MECHANICAL INSTALLATION – UNDER-FLOOR RADIATION

CAUTION

CAUTION

Electro Industries Inc. requires the use of dielectric isolation between the boiler vessel supply and return piping when the boiler is plumbed using copper or any other dissimilar metal. Damage to the vessel caused by galvanic corrosion voids Electro Industries’ warranty.

Reference drawing BX501

1.With the typical radiant floor system, a dual heat backup boiler is uncommon. If a backup boiler is required, please reference “Mechanical Installation – Dual Heat” section.

2.Unpack the Electro-Boiler, the safety relief and pipe fittings are packed within a small carton. The safety relief is plumbed to the ¾” pipe as shown on BX501 (or may be part of other components shown on BX502, page 2).

3.The Electro-Boiler must be positioned with the vessel vertical. The water IN/OUT ports must be at the top. The unit will not function properly with the vessel in a horizontal position.

NOTE: Mount at least 20 inches above the floor to allow element removal and service at the bottom.

4.The plumbing components and plumbing layout shown on drawing BX502 have been very carefully chosen and should be plumbed as shown. When following this diagram, the water fill procedure becomes very simple and almost guarantees the removal of all air or prevents air locking problems. Experienced hydronic heating installers may be able to eliminate some components but the inclusion of these components guarantees installation and initial operating success.

5.The vessel is factory constructed with a “air trap” chamber at the top of the vessel, connected to the ¾” pipe and arrangement shown on BX502, page 2.

6.The key mechanical components required include:

•Expansion Tank – as a closed loop hydronic heating system, a minimal expansion tank is required. This can be an air diaphragm tank as provided in the plumbing kit or a basic “empty” tank where air is compressed at the tank top.

•Inlet Temperature Gauge – recommended to observe the operation of the system.

•Air Vent Relief – install with the pressure relief valve as shown on drawing BX502, page 2 or part of the air eliminator shown on BX502, page 3.

•Inline Air separator – this can be installed ahead of the pump with the expansion tank moved to this point. However, the vessel designed air trap and the piping arrangement leading to the air bleeder shown on BX502 page 2 works very well.

•Pressure Safety Valve – this is required and is furnished as a loose component with the boiler unit itself. Failure to install the provided, 30 PSI, pressure relief valve as shown void warranty and the CSA product listing. During purging there is a requirement to bleed out the initial air within this ¾” pipe leg by manually holding open the relief valve. Add the necessary pipe extension to the relief valve to prevent water damage on this unit or surrounding area.

•Gate Valve/Drain Valve – these are for servicing and easy fill purposes.

•Circulating Pump – depending upon system lift and system loop resistance, the proper circulating pump is required to guarantee the minimum GPM flow as specified in Table I, page2.

Comment: Circulator pump can be in the outlet or inlet. Newer, higher quality pumps seem to work better in the “supply” line, plus pumping away from the expansion tank is preferred.

7.To ensure safe boiler operation adequate system pressure must be maintained. Some expansion tanks may have an integral regulator and “port” for water source hookup.

8.Depending upon water conditions, determine whether water additives are necessary.

9.Purge and fill water system. Do not allow the electric element to come on until the system is purged and you have verified proper water circulation. If the pump is needed, jumper the two orange wires in order to operate the pump directly from its own 120 volt source.

10.Purge each loop individually, one at a time.

11.Check for leaks.

01/25/2005 |

5 |

BI501 |

MECHANICAL INSTALLATION – DUAL HEAT

CAUTION

CAUTION

Electro Industries Inc. requires the use of dielectric isolation between the boiler vessel supply and return piping when the boiler is plumbed using copper or any other dissimilar metal. Damage to the vessel caused by galvanic corrosion voids Electro Industries’ warranty.

Reference drawings BX501 and BX502 pages 1-3

1.Unpack the Electro-Boiler. The safety relief and pipe fittings are packed within a small carton.

2.In most dual heat installations this Electro-Boiler is plumbed in series with an existing oil, gas, or wood boiler. For gas or oil, the Electro-Boiler is at the gas/oil outlet; but for wood, the Electro-Boiler must be on the inlet sides. The standby boiler cannot be operated as “hot boiler”. This will defeat the Electro-Boiler. Rewire as required, standby boiler is turned on from the brown wires.

COMMENT: For this series boiler the control is part of an optional plug-in package, EB-S-SB.

3.Standard hydronic hot water heating practices apply. This procedure assumes adequate piping size to meet the flow requirements of the specific boiler model, expansion tank, pump, zones, etc. are properly designed and installed.

4.The Electro-Boiler must be positioned with the vessel vertical. The water IN/OUT ports must be at the top. The unit will not function properly with the vessel in a horizontal position.

NOTE: Mount at least 20 inches above the floor to allow element removal and service at the bottom.

5.Typically this unit is wall hung next to the existing boiler.

6.Use the ¾” pipe fittings to install the safety relief valve and air vent. Add the necessary piping to the safety relief valve so that water damages do not occur in the surrounding area.

7.Connect the “hot” water line from the fossil fuel boiler to the Electro-Boiler "inlet". Connect the Electro-Boiler "outlet" to the main feed line. When facing the Electro-Boiler vessel, the "outlet" is on the LEFT.

NOTE: Wood applications, plumb so electric feeds the wood boilers.

10.If piping contains any "U" bend, an air vent may be required at the top.

11.When possible, isolating ball valves are recommended for easy servicing.

12.To ensure safe boiler operation and prevent element damage, the system should contain a pressure regulator and an automatic water fill valve. Expansion tank may have an integral regulator and “port” for water source hookup.

13.Depending upon water conditions, determine whether water additives are necessary.

14.Purge and fill water system. Do not allow the electric element to come on until the system is purged and you have verified proper water circulation. If the pump is needed, short out the two orange wires in order to operate the pump directly from its own 120 volt source.

15.Check for leaks.

01/25/2005 |

6 |

BI501 |

Loading...

Loading...