ELECTRO-BOILER

Commercial Series

INSTALLATION & OPERATING INSTRUCTIONS

Model EB-CX Series

APPLICATION: This Electro-Boiler is factory equipped with WarmFlo smart controller.

WarmFlo automatically regulates outlet water temperature at the temperature

level set on the front panel. This is a dial switch having eight positions. Setting

of this dial is dependent upon the setup configuration of the controller included

with the Electro-Boiler being installed. Two possible control strategies exist:

Non-outdoor reset – this control strategy does not utilize an outdoor

temperature sensor. Setting the dial is a fixed value, 90° F to 176° F.

Outdoor reset – this control strategy utilizes an outdoor sensor, thus the

boiler output target temperature will shift based on the outdoor

temperature. See outdoor reset curve detailed in this manual for more

information.

Primary application is any hydronic water heating system where reduced flow or

radiation can cause overheat conditions (example, zones). However, if it is a

mixture of large and small zones, the sudden capacity and flow changes may

cause some internal timing/over temp conditions. With the mixture of zones the

Electro Industries’ zone controller option is highly recommended.

This series is equipped for load management interrupt and can apply to standard

baseboard radiation, dual heat combinations, under floor radiant, wood boiler

supplement, etc.

ACCESSORIES: Attached BL001 lists various accessory or option items which are not part of

basic Electro-Boiler.

Note: This product meets the requirements of the ASME Boiler and Pressure Vessel Code.

05/19/2016 BI517

TABLE OF CONTENTS

Description Page

Table 1, Specific Model Number, Specific Information 1

Introduction 2

System or Water Flow 3

Multiple Zones & Radiant Temperatures 3

Zone Controller 3

Room Thermostat Placement 4

Multiple Boilers 4

Two-Temperature Operation or Feature 4

Installation Requirements 6

Mechanical Installation

Under-Floor Radiant 8

Dual Heat 9

Electrical Hookup 10

Water Fill Procedure 11

Controller Setup 12

Operational Tips 14

Replacement Parts List 16

Troubleshooting/Repair Helps 17

WarmFlo Operational Information 18

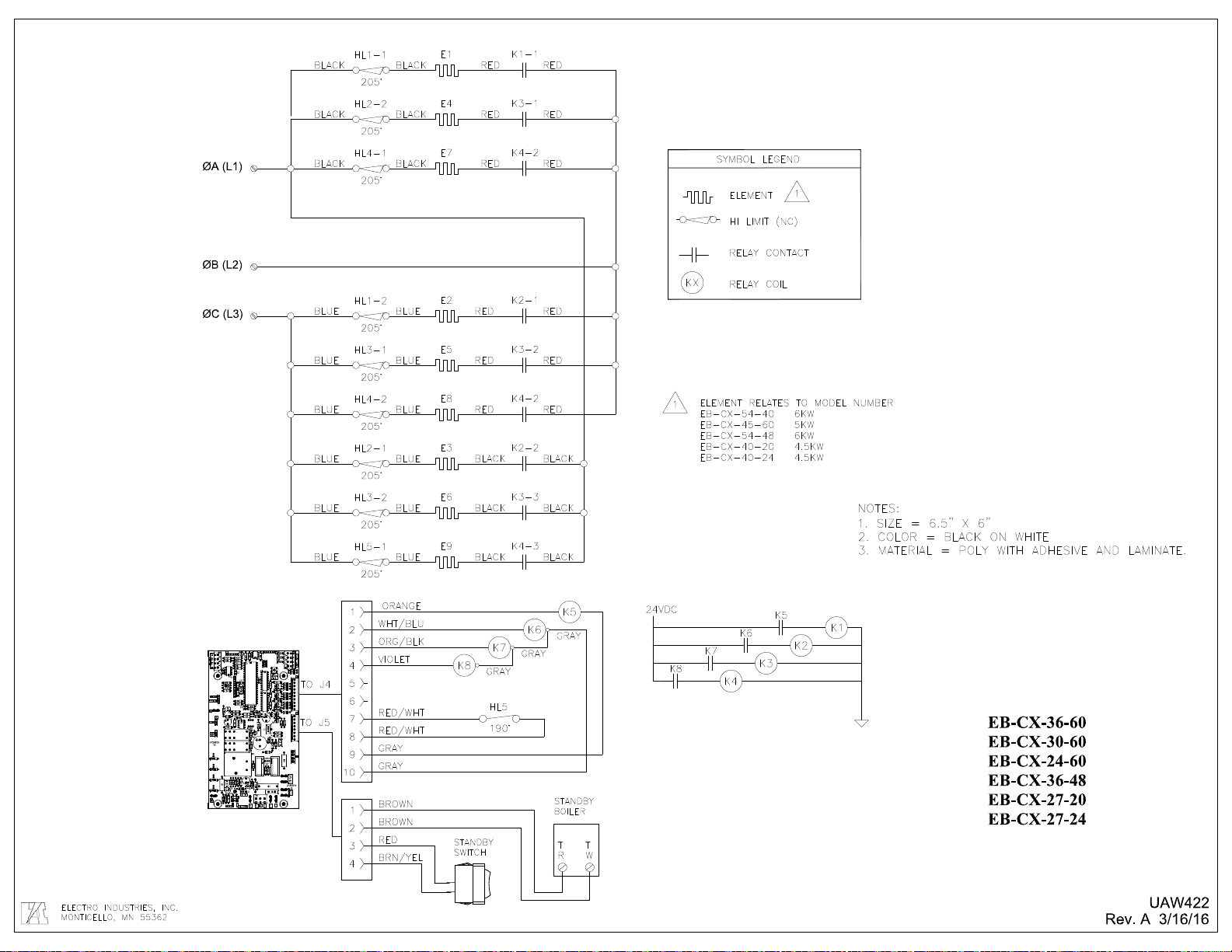

Drawings:

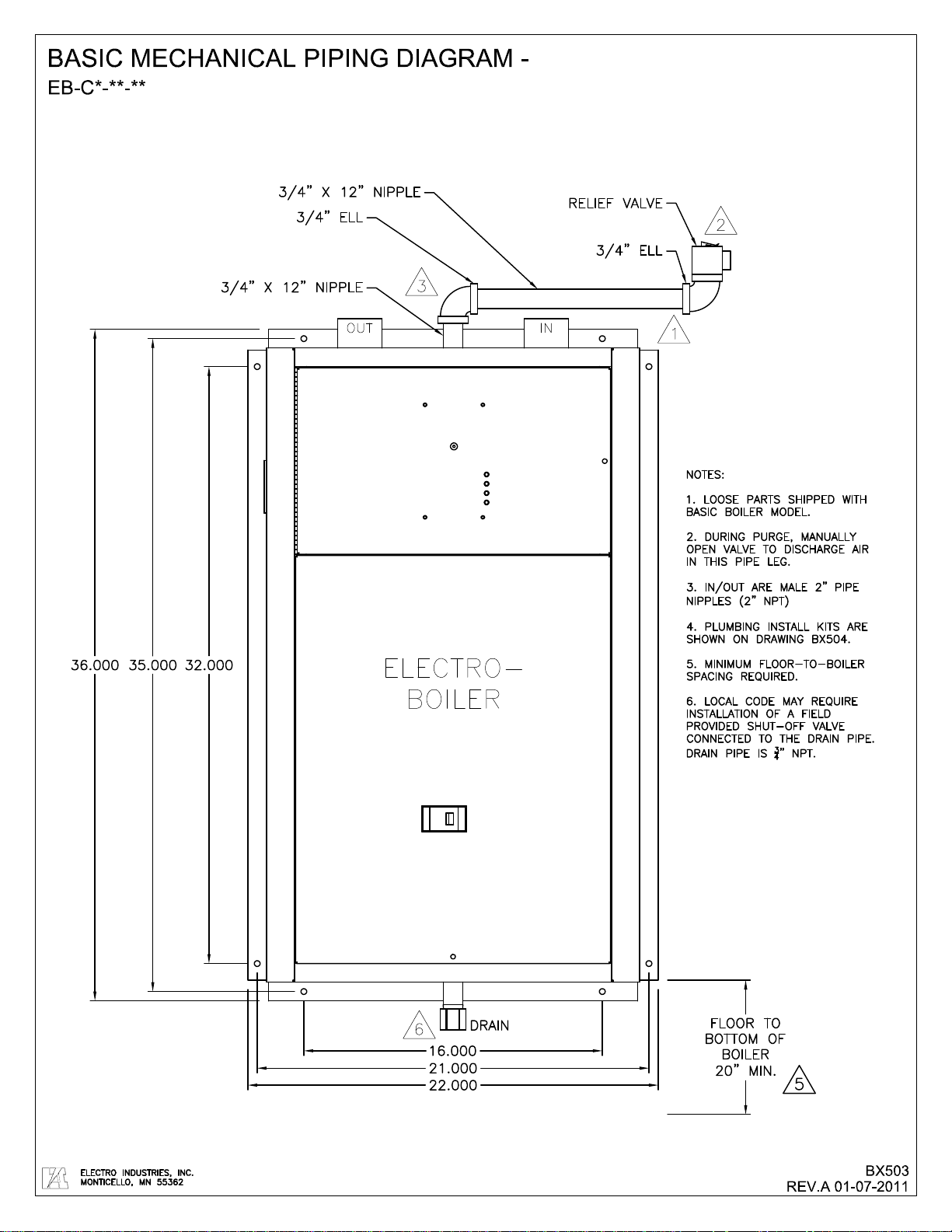

Basic Mechanical and Piping BX503, BX504

Hookup BH514, BH515

Internal Wiring Schematic UAW419, UAW420,

UAW421, UAW422

Low Voltage Wiring Diagram UAW849

Boiler Accessories BL001

Warranty – Single Phase Models XX017

Warranty – 3-Phase Models XX024

05/19/2016 BI517

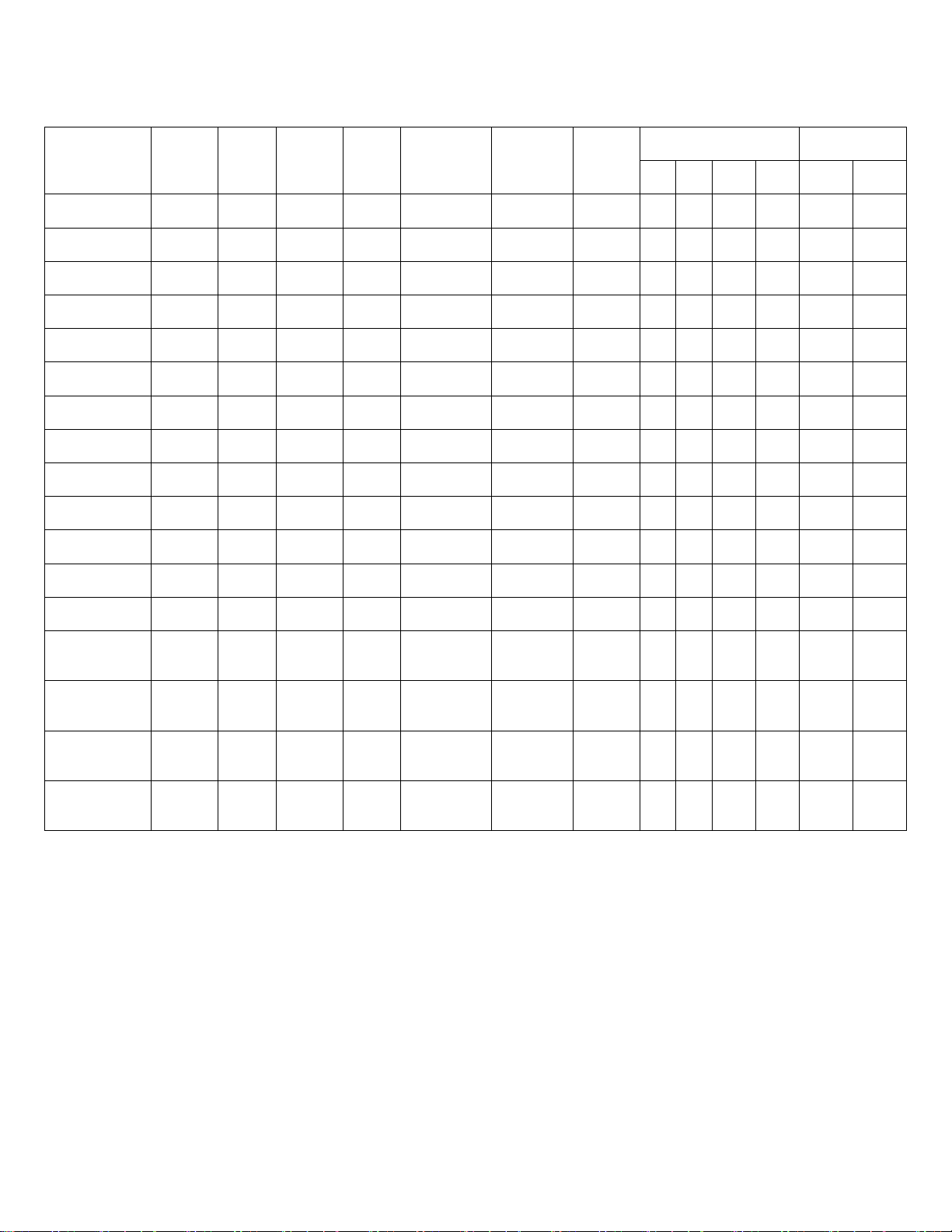

Model

EB-CX-18-60

EB-CX-24-60

EB-CX-30-60

EB-CX-36-60

EB-CX-45-60

EB-CX-54-60

EB-CX-18-48

EB-CX-36-48

EB-CX-54-48

EB-CX-27-20

EB-CX-40-20

EB- CX-27-24

EB-CX-40-24

EB-CX-31

EB-CX-36

EB-CX-40

EB-CX-44

Table 1 – Specific Model Number, Specification Information

Stages – kW Flow Rate

Voltage

Rating

600V

3-phase

600V

3-phase

600V

3-phase

600V

3-phase

600V

3-phase

600V

3-phase

480V

3-phase

480V

3-phase

480V

3-phase

208V

3-phase

208V

3-phase

240V

3-phase

240V

3-phase

240V

Single

phase

240V

Single

phase

240V

Single

phase

240V

Single

phase

kW

Rating

18 61,500 18 30 3 3 6 6 6 4 8

24 82,000 23 30 3 6 4 4 8 8 4 11

30 102,500 29 45 3 6 5 5 10 10 4 14

36 123,000 35 45 3 6 6 6 12 12 4 16

45 153,500 44 60 3 9 5 10 15 15 4 20

54 184,500 52 70 3 9 6 12 18 18 4 24

18 61,500 22 30 3 3 6 6 6 - 4 8

36 123,000 44 60 3 6 6 6 12 12 4 16

54 184,500 65 80 3 9 6 12 18 18 4 24

27 92,000 75 100 3 6 4.5 4.5 9 9 4 12

40.5 138,000 113 150 3 9 4.5 9 13.5 13.5 4 18

27 92,000 65 80 3 6 4.5 4.5 9 9 4 12

40.5 138,000 98 125 3 9 4.5 9 13.5 13.5 4 18

31.5 107,500 131 80 + 100 2 + 2 7 9 9 9 4.5 4 14

36 123,000 150 100 + 100 2 + 2 8 9 9 9 9 4 16

40 136,500 167 125 + 125 2 + 2 8 10 10 10 10 4 18

44 150,000 183 125 + 125 2 + 2 8 11 11 11 11 4 20

Btu/h Amps

Disconnect

CB

Source

Terminals

Element

Qty

1 2 3 4

@15° ΔT

Min

GPM

Max

GPM

05/19/2016

1 BI5172

INTRODUCTION

With this WarmFlo configuration, the electric heating elements are automatically controlled to establish a

fixed outlet water temperature. This outlet temperature is sensed by the WarmFlo controller and is

controlled to achieve and maintain the boiler’s set point temperature.

Even though this WarmFlo configured unit adjusts outlet temperature independent of water flow and

prevents high limiting even with marginal water flow, it is still very important that the hydronic system be

correctly designed for the building, the total heat loss requirement, and proper hydronics design and

installation practices. This boiler is the energy source for the water flow and radiation system. If the

water flow and radiation systems are not adequate for the Btu/h heat loss of the building, installing the

Electro-Boiler with WarmFlo will not necessarily supply the comfort and heating for the building.

“Cold boiler” notation – do not, under any circumstances, simply jumper R and W and allow the

temperature sensing controller to operate this Electro-Boiler as a “hot boiler”. Unless there is at least 4

GPM flow, the staging delays will cause temperature overshoot and could open up the manual reset

limits.

In most dual heat installations this Electro-Boiler is plumbed in parallel with an existing oil, gas, or wood

boiler. If piped in series, the Electro-Boiler is generally at the gas/oil outlet; but for wood boiler systems,

the Electro-Boiler must be on the inlet sides. The standby boiler cannot be operated as “hot boiler”. This

will defeat the Electro-Boiler. Rewire as required using the included standby boiler interface (brown

wires).

In the case of existing fossil fuel boiler conversions, it is assumed the expansion tank, valving, air

bleeder, and circulation pump are in place, in good operating condition, and adequate for the overall

system design.

In the case of new installation (floor radiant or baseboard), use standard hydronics water heating practices

for the necessary expansion tank, air bleeder, valving, water pump, etc., sized for the total capacity of the

system. The Electro-Boiler is turned on with an “R and W” closure from the zone system wiring.

The Table 1 model number identification shows the design rating and voltage source required for the

specific model. If you do not use the voltage source required for the specific model, performance derating may need to be taken into consideration. Also damage can result if the specific model is not

serviced with the voltage source shown in Table 1.

This EB-CX-** model series is low pressure (30 psig maximum) hydronic hot water with an operating

range between 90° F and 176° F, supply temperature.

APPROVED TUBING/PIPING

When plumbing this boiler and its peripheral parts to the loop system, all plumbing parts and/or tubing

must be sealed to prevent entrance of oxygen.

Use only tubing or polyethylene tubing with oxygen Diffusion Barrier.

05/19/2016

2 BI5172

SYSTEM OR WATER FLOW

In order to prevent hi-limiting and assure full 20+ years parts life, the piping system/basic

plumbing/circulator pump must be arranged to provide flow greater than minimum GPM shown in Table

1. If zoned system, this applies when the smallest zone is operating.

MULTIPLE ZONES AND RADIANT TEMPERATURES

Same water temperature all zones – in this case the system can be setup as one pump with the water

circulated through the boiler and directly to a manifold containing the various zone valves. Although this

model series has a built-in outlet sensing and controller mechanism for staging the elements, also consider

the next section, Zone Controller. If not using zone controller, the end switches of all of the zone valves

are paralleled and directly control R and W to turn on the boiler.

Various water temperature requirements – if this is the case, a primary loop with mixing valve for the

various zone temperature requirements is necessary. Injection pump techniques can also be used.

However, usually injection pump techniques come with a controller which is designed to protect a gas

boiler from cool water return. This is simply not needed and a duplication with the temperature sensing

controller within this Electro-boiler and the injection pump controller will be of no benefit within the

operating system. The zone valve/zone pump control strategy must be wired to provide the boiler “R and

W” contact closure and the primary pump is connected to the boiler pump contacts. This assures the

primary pump is active and running whenever the boiler is turned on via contact closure on “R and W”.

At least one zone must be open before turning on the primary pump/Electro-Boiler. Do not design a

system where the Electro-Boiler is supposed to operate as a “hot boiler” based upon its outlet sensor

without the primary pump circulating water, minimum 4 GPM is required.

Electro Industries’ Zone Controllers – the Electro Industries’ zone controller priority zone has the

ability to communicate with this TS Series boiler and it will automatically switch to a low mass high

water temperature (150 or 180) during zone 1, priority switch on, operation. With this feature the TS

boiler can automatically take care of two temperature requirements thus eliminating the need for the

technique described in the paragraph above.

ZONE CONTROLLER

This EB-CX Series boiler controls the electric elements based upon

water temperature independent of flow; therefore, in theory, a staging

zone controller is not required; however, there are three suggestions or

reasons why a zone controller can simplify the installation and enhance

overall performance.

1. Zone wiring and troubleshooting convenience – the addition of the zone board allows for easy terminal

block and point to point wiring for each zone thermostat and each zone valve. Also there are LED’s

associated with the thermostat action and the zone valve action. This greatly simplifies wiring and future

troubleshooting with a neat terminal block wiring arrangement and the onboard LED’s.

2. Prevents over control or false staging up and down when the temperature sensors are attempting to

regulate – since Electro Industries’ zone controller also has staging “smarts”, the addition of the zone

controller will provide smoother boiler temperature control. The zone board has a dial switch for each

zone and the installer selects one of four zone capacity sizes. When dialing in the size closest to the zone

Btu/h capacity, the zone controller “smarts” only allows the appropriate boiler stage which can handle that

capacity. Also this is additive if more than one zone calls at any one time

3. Two temperature system with unbalanced zones – if the application includes zone one requiring high

temperature (fin tube, air handler, etc.) and the remaining zones are radiant floor low temperature, this zone

controller will automatically raise the output of the high temperature zone. This is a priority arrangement,

zone 1 holds off the other zones while the high temperature output is heating. If at the end of the high

temperature zone there is a call on any of the low temperature zones (up to three plus slav e 4), there will be

a pump only function until the outlet temperature drops below the front panel dial setting.

05/19/2016

3 BI5172

ROOM THERMOSTAT PLACEMENT

Fin tube radiation, fan coil, etc. – heat only wall t-stat, connected to operate zone valves (see previous

section) or for single zone the t-stat is connected directly to Electro-Boiler R and W.

Floor radiant – comfort and proper space heating response is a direct relationship to the thermostat type

and the placement of the thermostat sensing bulb. Typically an under floor heating system can be broken

down into three categories.

A. Energy storage, water tubing is under the concrete or within the

sand base – the controlling thermostat must have a remote bulb, and

this remote bulb must sense the concrete slab temperature (slab stat).

Coordinated with the concrete pour, install a ¾” PVC, minimum bend

radius of 7 inches, and locate at approximately center (vertical) of the

concrete slab. The thermostat sensing bulb can later be pushed down

this PVC conduit. If the slab is already poured without conduit for slab

stat, use electronic remote sensing thermostat.

B. Floor covering, medium to high insulation – use slab stat as described in paragraph A above.

C. Quick response, hydronic tubing just under the concrete surface, no flooring material over

the concrete – in this case, heated water can directly radiate into the room, a standard wall mount

room thermostat is adequate. Mount room thermostat on an inside wall similar to most heating

systems.

MULTIPLE BOILERS

This boiler series now includes a method for automatically staging any

number of parallel-plumbed boilers. Order plug-in relay EB-C-STG5.

The thermostat is connected only to the first boiler, when all stages are

on for more than 5 minutes, this new plug-in relay module turns on the

next boiler (R and W), and a second EB-C-STG5 could be used to turn

on the third, etc. (reference BH507).

TWO-TEMPERATURE OPERATION OR FEATURE

When using Electro’s zone controller in priority mode, the boiler

system can automatically raise the outlet temperature with zone 1

calling. This is setup for default of 150° or pulling a jumper peg the

high temperature value is 176°. See appropriate zone controller

installation manual for details.

05/19/2016

4 BI5172

Outdoor Reset Option

The EB-CX-** boiler comes equipped with an outdoor sensor (shipped loose). This sensor can be

connected to the board to allow for outdoor reset function.

What is Outdoor Reset?

Outdoor reset is where the Electro Boiler DT (desired water temperature) shifts up and down based on the

outdoor temperature. The water temperature coming out of the boiler will be higher when it’s cold outside

and lower when it’s warmer outside. The idea is to have the boiler work with the building heat loss to

maintain a more even BTU delivery to the space. This helps with overall system efficiency as well.

Outdoor Reset Activation

If it is determined that outdoor reset is required for this application, it needs to be activated.

Follow this sequence to activate outdoor reset:

Step 1: Power down the Electro-Boiler

Step 2: Connect the outdoor sensor

Red wire to “RED”

Black wire to “OT”

White wire to “COM”

Step 3: Power up the Electro-Boiler

See: CONTROLLER SETUP for more information on outdoor reset.

05/19/2016

5 BI5172

INFORMATION/WATER FLOW CALCULATIONS

Water flow, GPM, can easily be calculated if the temperature rise across the electric boiler can be

measured.

The formula below can only be used when the temperature rise is stable and the boiler is not hi-limiting.

In other words, verify constant current draw and stable outlet temperatures for at least 15 minutes.

GPM – Single Phase

GPM =

Volts x Amps x 3.4

500 x Temp. rise

GPM – 3-Phase

GPM =

Volts x Amps x 1.732 x 3.4

500 x Temp. rise

INSTALLATION REQUIREMENTS

1. All installation work must be performed by trained, qualified contractors or technicians. Electro

Industries, Inc., sponsors installation and service schools to assist the installer. Visit our web site at

electromn.com for upcoming service schools.

WARNING

ALL ELECTRICAL WIRING MUST BE IN ACCORDANCE WITH NATIONAL ELECTRIC CODE

AND LOCAL ELECTRIC CODES, ORDINANCES, AND REGULATIONS.

WARNING

OBSERVE ELECTRIC POLARITY AND WIRING COLORS. FAILURE TO OBSERVE COULD

CAUSE ELECTRIC SHOCK AND/OR DAMAGE TO THE EQUIPMENT.

CAUTION

This unit can only be used for its intended design as described in this manual. Any internal

wiring changes, modifications to the circuit board, modifications or bypass of any controls, or

installation practices not according to the details of this manual will void the product warranty,

the CSA/us certification label, and manufacturer product liability. Electro Industries, Inc.,

cannot be held responsible for field modifications, incorrect installations, and conditions which

may bypass or compromise the built-in safety features and controls.

2. This installation manual and Electro-Boiler products relate only to the addition of the Electro-Boiler

to the hydronics system. The owner/ installer assumes all responsibility and/or liability associated

with any needed installation of the gas/oil boiler, pump, plumbing, system design, hydronics systems

or backup gas/oil boiler, etc. Any instructions or comments made within this manual (or factory

phone assistance) relating to the gas/oil furnace are provided as comments of assistance and “helps”

only.

CAUTION

Hazards or unsafe practices could result in property damage, product damage, severe personal

injury and/or death.

05/19/2016

6 BI5172

3. Remember, safety is the installer’s responsibility and the installer must know this product well

enough to instruct the end user on its safe use.

Safety is a matter of common sense - - a matter of thinking before acting. Professional installers have

training and experienced practices for handling electrical, sheet metal, and material handling

processes. Use them.

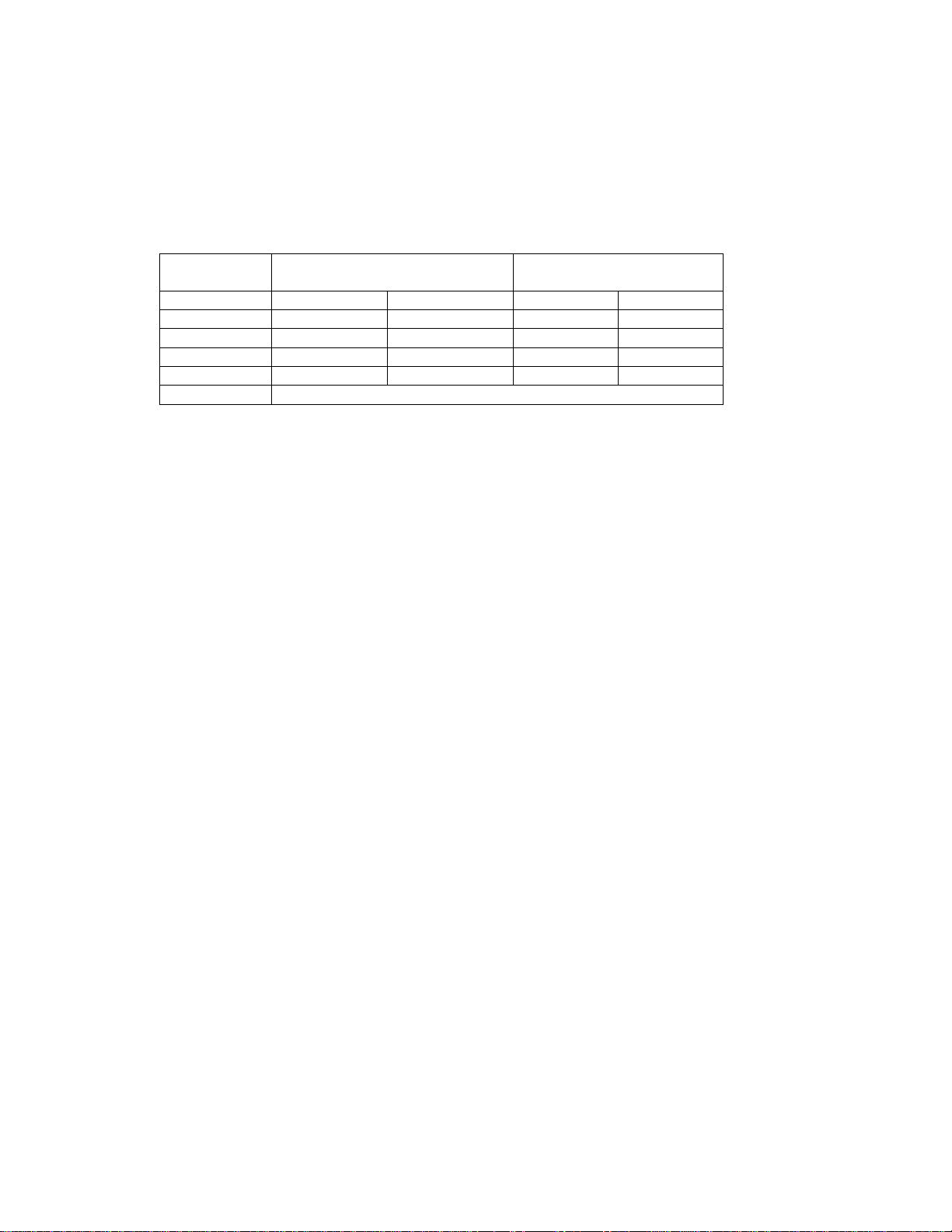

CLEARANCES

MINIMUM CLEARANCE FROM

COMBUSTIBLE SURFACES

BACK 0 INCH 0 MM 0 INCH 0 MM

LEFT 1 INCH 25 MM 16 INCHES 406 MM

RIGHT 1 INCH 25 MM 6 INCHES 152 MM

FRONT 1 INCH 25 MM 24 INCHES 610 MM

TOP 1 INCH 25 MM 24 INCHES 610 MM

BOTTOM REQUIRED CLEARANCE – 16 INCHES/406 MM

SUGGESTED MINIMUM

SERVICE CLEARANCE

05/19/2016

7 BI5172

MECHANICAL INSTALLATION – UNDER-FLOOR RADIATION

CAUTION

Electro Industries Inc. requires the use of dielectric isolation between the boiler vessel supply

and return piping when the boiler is plumbed using copper or any other dissimilar metal.

Damage to the vessel caused by galvanic corrosion voids Electro Industries’ warranty.

Reference drawing BX503

1. With the typical radiant floor system, a dual heat backup boiler is uncommon. If a backup boiler is

required, please reference “Mechanical Installation – Dual Heat” section.

2. Unpack the Electro-Boiler, the safety relief and pipe fittings are packed within a small carton. The

safety relief is plumbed to the ¾” pipe as shown on BX503 (or may be part of other components

shown on BX503).

3. The Electro-Boiler must be positioned with the vessel vertical. The water IN/OUT ports must be at the

top. The unit will not function properly with the vessel in a horizontal position.

NOTE: Mount at least 20 inches above the floor to allow element removal and service at the bottom.

4. The plumbing components and plumbing layout shown on drawing BX503 have been very carefully

chosen and should be plumbed as shown. When following this diagram, the water fill procedure

becomes very simple and almost guarantees the removal of all air or prevents air locking problems.

Experienced hydronic heating installers may be able to eliminate some components but the inclusion

of these components guarantees installation and initial operating success.

5. The vessel is factory constructed with an “air trap” chamber at the top of the vessel, connected to the

¾” pipe and arrangement shown on BX503.

6. The key mechanical components required include:

Expansion Tank – as a closed loop hydronic heating system, a minimal expansion tank is

required. This can be an air diaphragm tank as provided in the plumbing kit or a basic

“empty” tank where air is compressed at the tank top.

Inlet Temperature Gauge – recommended to observe the operation of the system.

Air Vent – install with the pressure relief valve as shown on drawing BX503.

Inline Air separator – this can be installed ahead of the pump with the expansion tank

moved to this point. However, the vessel designed air trap and the piping arrangement

leading to the air bleeder works very well.

Pressure Safety Valve – this is required and is furnished as a loose component with the

boiler unit itself. Failure to install the provided, 30 PSI, pressure relief valve as shown void

warranty and the product listing. During purging there is a requirement to bleed out the

initial air within this ¾” pipe leg by manually holding open the relief valve. Add the

necessary pipe extension to the relief valve to prevent water damage on this unit or

surrounding area.

Gate Valve/Drain Valve – these are for servicing and easy fill purposes.

Circulating Pump – depending upon system lift and system loop resistance, the proper

circulating pump is required to guarantee the minimum GPM flow as specified in Table I, page 1.

Comment: Circulator pump can be in the outlet or inlet. Newer, higher quality pumps seem to

work better in the “supply” line, plus pumping away from the expansion tank is preferred.

7. To ensure safe boiler operation adequate system pressure must be maintained. Some expansion tanks

may have an integral regulator and “port” for water source hookup.

8. Depending upon water conditions, determine whether water additives are necessary.

9. Purge and fill water system. Do not allow the electric element to come on until the system is purged

and you have verified proper water circulation. If the pump is needed, jumper the two orange wires

in order to operate the pump directly from its own 120 volt source.

10. Purge each loop individually, one at a time.

11. Check for leaks.

05/19/2016

8 BI5172

MECHANICAL INSTALLATION – DUAL HEAT

CAUTION

Electro Industries Inc. requires the use of dielectric isolation between the boiler vessel supply

and return piping when the boiler is plumbed using copper or any other dissimilar metal.

Damage to the vessel caused by galvanic corrosion voids Electro Industries’ warranty.

Reference drawing BX504

1. Unpack the Electro-Boiler. The safety relief and pipe fittings are packed within a small carton.

2. In most dual heat installations this Electro-Boiler is plumbed in parallel with an existing oil, gas, or

wood boiler. If piped in series, the Electro-Boiler is generally at the gas/oil outlet; but for wood

boiler systems, the Electro-Boiler must be on the inlet sides. The standby boiler cannot be operated

as “hot boiler”. This will defeat the Electro-Boiler. Rewire as required using the included standby

boiler interface (brown wires).

3. Standard hydronic hot water heating practices apply. This procedure assumes adequate piping size to

meet the flow requirements of the specific boiler model, expansion tank, pump, zones, etc. are

properly designed and installed.

4. The Electro-Boiler must be positioned with the vessel vertical. The water IN/OUT ports must be at

the top. The unit will not function properly with the vessel in a horizontal position.

NOTE: Mount at least 20 inches above the floor to allow element removal and service at the

bottom.

5. Typically this unit is wall hung next to the existing boiler.

6. Use the ¾” pipe fittings to install the safety relief valve and air vent. Add the necessary piping to the

safety relief valve so that water damages do not occur in the surrounding area.

7. Connect the “hot” water line from the fossil fuel boiler to the Electro-Boiler "inlet". Connect the

Electro-Boiler "outlet" to the main feed line. When facing the Electro-Boiler vessel, the "outlet" is on

the LEFT.

NOTE: Wood applications, plumb so electric feeds the wood boilers.

8. If piping contains any "U" bend, an air vent may be required at the top.

9. When possible, isolating ball valves are recommended for easy servicing.

10. To ensure safe boiler operation and prevent element damage, the system should contain a pressure

regulator and an automatic water fill valve. Expansion tank may have an integral regulator and “port”

for water source hookup.

11. Depending upon water conditions, determine whether water additives are necessary.

12. Purge and fill water system. Do not allow the electric element to come on until the system is purged

and you have verified proper water circulation. If the pump is needed, short out the two orange wires

in order to operate the pump directly from its own 120 volt source.

13. Check for leaks.

05/19/2016

9 BI5172

ELECTRICAL HOOKUP

1. Heating Power Source – using model number on nameplate, locate line item on Table 1, page 1.

This supplies the necessary wiring information. National Electric Code and local codes will

determine the type and size of wire between this unit’s CB disconnect screws and the distribution

panel connection. The “Amps” column represents continuous running current, does not represent the

wiring or disconnect amps.

Only copper wire is allowed inside Electro Industries’ enclosure.

The model associated with the design voltage rating has the proper 24-volt transformer. If

installing in any other voltage rating, 24-volt transformer may need to be replaced or resized.

208/480/600 3-phase use drawing BH515

240 single phase use drawing BH514

If single feed to the dual multi-breaker models, single feed bus 5701 or 5702 may apply.

2. Grounding – copper conductor is required, size per NEC code relating to the current of each feed.

3. Circulating Pump – the terminal block (orange wires) below the circuit breakers represents a switch

closure (10-amp maximum) to operate an external circulating pump motor. Voltage for the pump

must come from a separate source.

The pump is controlled as a direct function of the R and W input.

If this is connected with a standby boiler, generally the assumption is series plumbing with

the single pump. In this case, the R and W function will operate the pump whether in electric

or standby mode.

If a standby boiler installation has parallel plumbing with two pumps, field wiring and

controls will be necessary to properly operate (and typically check valve isolate) the standby

boiler self-contained pump from the system pump controlled by these two terminal screws.

Note: If using zone pumps, this function and connection is not used.

4. Operating Thermostat – two types can be used. Connection is at the control board bottom.

Standard Mechanical – connect to “R” and “W”, bottom right. Set thermostat internal heat

anticipator to 0.2.

Floor Sensing Stat – connect to “R” and “W”, bottom right. Place slab sensor in the slab.

If needed, can connect thermostat “C” to boiler “C

NOTE: Power robbing/power stealing thermostat – if you have a power robbing or power stealing

thermostat, you must use the resistor included with the thermostat. Place this jumper between boiler

“W” and boiler “C”. If resistor is not used, intermittent boiler operation can be expected.

Comment: If zone valve or zone pumps see appropriate sections.

5. Load Management Interrupt Control – this Electro-Boiler series has been pre-wired and designed

for an external utility load management receiver connection. The control board lower left BLU and

BLU/WHT wires represent the two contact points, extend these wires to the utility load control

device.

As shipped, this unit is only equipped for off-peak = N.C. logic. If reversed logic is required, contact

the factory for modification.

Optional – if load management is not used, simply keep the two blue wires shorted.

Optional – if the power company disconnects 240V for load control, contact factory for

BH029 for special wiring requirements.

6. Outdoor Sensor (OT) – applies with the outdoor reset control strategy only. If possible shade from

direct sun rays.

05/19/2016

10 BI5172

7. Zone Valves or Zone Pumps – see page 3 for zone controller options.

WARNING

THE END SWITCHES FROM THE ZONE VALVES MUST BE AN ISOLATED CONTACT WITH NO

VOLTAGE PRESENT ON THESE WIRES OR SCREW TERMINALS. THIS IS VERY IMPORTANT

TO MAKE SURE THERE ISN’T ANY INTERFERENCE OR FEEDBACK BETWEEN THE

TRANSFORMER OPERATING THE ZONE VALVE SYSTEM AND THE TRANSFORMER WITHIN

THIS ELECTRO-BOILER PRODUCT. ONCE THIS HAS BEEN DETERMINED, ALL END

SWITCHES ARE SIMPLY PARALLELED WITH THE TWO WIRES GOING TO “R” AND “W”.

8. If this is a dual heat application with standby boiler, the 2 brown wires from this Electro-Boiler

connect to the standby boiler R and W or T and T. These 2 brown wires represent a contact closure to

activate the standby boiler during load control or when the front panel switch is in the “standby”

position.

WATER ADDITIVES

1. Unless the source water is unusually poor and/or rust elements, additives are not required. It is

recommended the water source comes through a water softener or use distilled water.

2. Impurities within a closed loop hydronics boiler are considerably less damaging than the typical

domestic water heater. In a closed loop electric boiler, the water impurities “boil out” and the

system essentially makes its own pure water. As a closed system, this “pure water” becomes the

operating mode. In the case of domestic water tank, there is always new water entering with new

impurities.

3. However, if additives are required, use the recommendations and source from your local

professional plumber, specializing in hydronics heating systems.

WATER FILL PROCEDURE

The following procedure applies to non-glycol or antifreeze.

CAUTION

If the building supply pressure is connected directly to supply water ball valve without pressure

reducing regulator, user needs to make sure the pressure within the boiler loop does not exceed 30

PSI. Careful control of the supply water ball valve opening can take care of this. Also at steps 6

and 10, use caution to make sure the building water supply pressure does not “spike” the system.

1. Connect the temporary water supply source (probably hose connection) to the "water supply

connection" input.

NOTE: If water supply connection is permanent, some local building codes may require

special anti-siphon check valve, RPZ check valve, or equivalent between the boiler fill

regulator and the domestic water source or the city water connection.

2. Connect a drain hose to hose bib, "drain valve".

3. Open "drain valve" and close "inlet gate valve" (between drain valve and boiler inlet).

4. Verify “top gate valve” is open.

5. Do not apply 240 heating power during water fill sequence.

6. Open “water supply valve” and open household water supply source.

7. Allow system to circulate, discharging through drain valve, for at least 15 minutes.

8. Put your ear against the metal pipe and listen for air bubbles. If the water flow is consistent and

quiet, the system is probably purged and water filled.

9. Close the "drain valve". Open the "inlet gate valve".

10. The cold system pressure at the gauge should be approximately 10 to 14 PSI.

05/19/2016

11 BI5172

11. Close “water supply valve” and disconnect water supply.

12. Optional – energize circulating pump during this fill operation. The water pressure from the

household system and as plumbed should typically flow through the circulating pump without the

pump running.

COMMENT: Purge one loop at a time.

Red dial switch, front panel:

CONTROLLER SETUP

Non-outdoor reset –simply set the “knob” to the desired outlet temperature shown here and on the

front panel decal.

This control strategy is accomplished via disconnecting the outdoor sensor and performing a power

reset to the boiler (low voltage power cycle).

Outdoor reset – the temperature decal will relate to the OT 0° set point and the “knob” numbers

coincide with the curves below. High and low mass also relate to the ramp-up water temperature

starting point, as shown. Select the high or low mass with the rate of temperature rise based on

outdoor temp (OT).

Comment: The WF-ANZ* test set allows field change of the base temperature start point.

This control strategy is accomplished via connecting the outdoor sensor and performing a power

cycle on the boiler (low voltage power cycle).

The front panel temperature selection number coincides to the curves below. This temperature value

shown on the front decal is actually the supply water at 0° outside.

05/19/2016

12 BI5172

Staging/Modulating Jumper

The control board on the EB-CX series boiler line is a universal controller with the capability of

interfacing with many different models of TS Electro boilers.

With regard to the EB-CX boiler line, the “staging” setting is the only available

option for this jumper setting.

Circulator pump mode – as factory set, the circulator pump is controlled directly from the “W” input

terminal. In this setup the circulator pump continues during load control interrupt (or optional remote

standby switch). There is a provision within the controller board (inside) to allow the circulator pump to

not operate during load control interrupt.

On the inside control board, just above the two bottom

terminal blocks, is a small pin jumper arrangement. The

black “device” sets up the pump mode. Just below this

pin jumper arrangement are W and L lettering. When

the two pin shorting device is in the W position, the

pump is a direct function of R to W input. When the two

pin jumper is in the L position, the pump is interrupted

during a load control.

WARNING

THIS SHORTING DEVICE MUST BE IN ONE OF THE TWO POSITIONS FOR THE CIRCULATOR

PUMP TO PROPERLY OPERATE.

05/19/2016

13 BI5172

OPERATIONAL TIPS

Energy Selector Switch

If this system does not have a standby operating (gas or oil) boiler, this

switch must always be in the “normal” position.

To activate standby boiler, simply position front panel switch to “standby”.

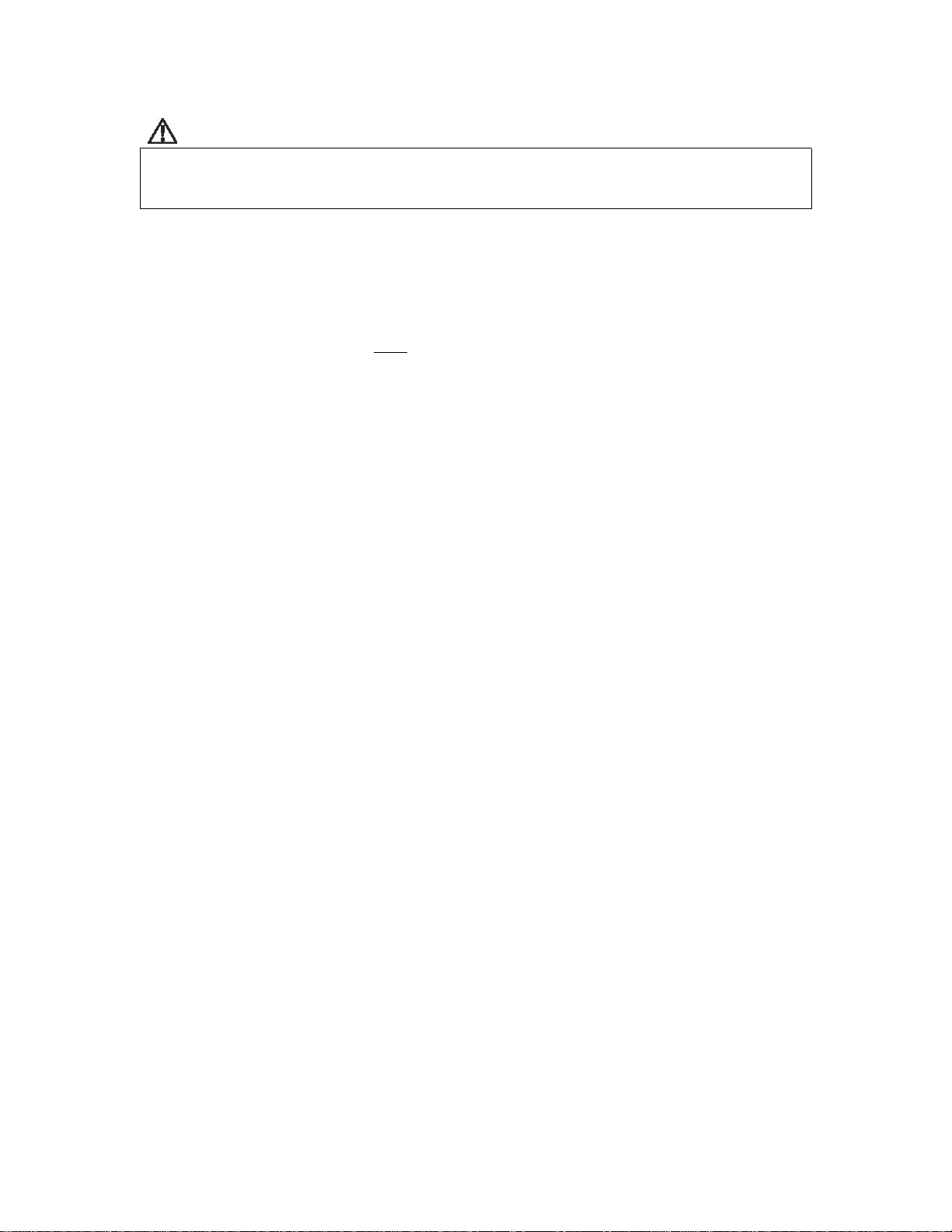

Monitor Lights, Front Panel

190°F AUTO RESET LIMIT, red – this will only

illuminate when the vessel hi-limit opens due to

excessive high water temperature. This hi-limit is

self-resetting.

BOILER POWER, green – basically this is

illuminated at all times. It represents 24-volt power

source, good fuse, controller logic is operational,

and a good outlet sensor. If the outlet sensor is

inoperative, incorrectly wired, or malfunctioning;

this green monitor LED should be in the blinking or

pulsing mode (see Troubleshooting section).

ELECTRIC MODE, amber – when illuminated the

system is in the electric mode. If it is not

illuminated the utility load control receiver is in the

interrupt or on-peak mode. If there is an optional or

remote standby switch, the status of the standby

switch is also monitored by this amber LED.

THERMOSTAT CALL, red – indicates a remote

switch closure (t-stat or zoning end switch) is

closed between terminals R and W.

Inside Controller Board

STAGES, red – these four LED’s indicate which electric element stages are on and active.

Flow Switch Statement

A flow switch is not included with the boiler. However, one can be added to the LMC circuit. Simply

place the field provided flow switch in series with this circuit.

NOTE: The “L/W” (J3) jumper must be in the “W” position.

05/19/2016

14 BI5172

Manual Reset, Hi-Limit

At the top of the vessel there will be either two or three surface mount hi-limits preset at 205° F. There is

no light indicator associated with these safety hi-limits. Also these 205° F safety limits break the L2

current carrying 240-volt wire going to the elements. Reset involves locating a small shiny lever or metal

tab protruding on the side of the black safety limit base. This small tab is pressed inward approximately

1/8” to “snap in” the contacts.

CAUTION

The wires and screws have 240-volt potential and can be dangerous. Turn off circuit breakers

before investigating or attempting to reset the 205° F safety limits.

WARNING – HIGH VOLTAGE

MUST SHUT OFF HIGH VOLTAGE BEFORE

ATTEMPTING TO RESET.

Internal Fuse

The fuse on the controller board protects the transformer secondary, external items connected to “R”, and

the circuit board itself. Replace with 5-amp fast blow, mini-automotive fuse or equivalent.

Stat Heat Anticipator - If it is a mechanical stat, verify heat anticipator has been set at Ø.2 (non-zone

system).

System Pressure

The side press/temperature gauge should be at approximately 10 to 16 PSI at room temperature water and

should not rise more than approximately 4 PSI at the operating or hot water temperature. If the pressure

change is more than approximately 4 PSI, the expansion tank is too small or there is a problem with the

expansion tank piping, expansion tank itself.

Cold slab, outdoor reset and temperature sensing prevent full boiler on – by adding a temporary

jumper between the lower W screw terminal and the upper left “E” tab, all temperature sensing functions

are bypassed and the control board will step in all the stages.

CAUTION

This jumper shall not be a permanent function, jumper needs to be removed after slab is

approaching normal temperature.

05/19/2016

15 BI5172

Replacement Parts

WFSB Water sensor, 3 ft.

WFS25F Outdoor sensor (OT)

EB5623 Controller, temperature sensing

UFUSE0442 5-amp, fast blow mini-automotive fuse

5127 Control relay, 1 pole

5535 Safety hi-limit, manual, 205°

5537 First hi-limit, auto-reset, 190°

5453 Relief valve, 30 PSIG

5456 Gauge press/temperature

EB5520 Electric element, 240, 4.5 kW

5541 Transformer 208/240V primary, 24V, 40VA

5542 Transformer 480V primary, 24V, 50VA

5543 Transformer, 600V primary, 24V, 50VA

5527 Heating relay, 3 pole DP

5528 Heating relay, 1 pole DP

5126 Heating relay, 2 pole DP

5661 30-amp 480V 3 pole circuit breaker

5662 60-amp 480V 3 pole circuit breaker

5663 80-amp 480V 3 pole circuit breaker

5658 100-amp 3 pole circuit breaker

5659 125-amp 3 pole circuit breaker

5660 150-amp 3 pole circuit breaker

5657 80-amp 3 pole circuit breaker

5653 80-amp 2 pole circuit breaker

5643S 100-amp 2 pole circuit breaker

5655 50-amp 3 pole 3 phase circuit breaker

5664 70-amp 3 pole 3 phase circuit breaker

5665 45-amp 3 pole 3 phase circuit breaker

EB5508-06 Electric element 600, 6 kW

EB5508-04 Electric element 600, 4 kW

EB5508-05 Electric element 600, 5 kW

EB5520 Electric element 240, 4.5 kW

EB5521 Electric element 208, 4.5 kW

EB5522 Electric element 240, 5.5 kW

EB5524 Electric element 240, 2.5 kW

EB5525 Electric element 480, 6 kW

EB5526 Electric element 240, 5 kW

05/19/2016

16 BI5172

TROUBLESHOOTING/REPAIR HELPS

1. This WarmFlo controller contains several interference suppression components, but as an electronic

logic product, unpredictable and unusual transients or interference may sometimes cause strange

results. If the WarmFlo controller is “acting strange”, one immediate step would be power down

reset. Simply turn off boiler power or breaker number 1, when the green LED goes out, count to 1Ø,

and re-energize power supply.

2. Inoperative temperature sensor, if the internal program can detect a bad sensor (shorted, open wire,

etc. – not necessarily bad value) the front panel green LED will be pulsing. By checking the pulsing

pattern, the appropriate sensor can be identified.

- OT sensor – 1 blink every second

- ST sensor – 2 blinks every second

- Both bad – 3 blinks every second

3. The temperature sensor can be further evaluated with diagnostic program from standard PC or Palm

software. This includes the ability to “fool” the sensor or set in an offset for various troubleshooting

purposes. This software disk comes with a special cable needed for PC hookup.

- WF-ANZ* – Handheld/Analyzer

- ET-SOFT-HTG – PC software disk and cable

4. The terminal blocks for control wire hook-up are designed for a wire insertion and screw clamp

down. If there is no wire connected and the screw is loose, the screw may not necessarily make a

good electrical contact to the inside components. Example – if you are jumpering the thermostat

terminals without thermostat wire connection or if you are attempting to measure voltage on the

screw head, you may get erroneous or unpredictable results if the screw is not tightened down.

5. The outdoor sensor (OT) must be sensing the actual outside temperature for this controller to

correctly operate. Do not simply leave the outdoor sensor “hang in the room” and attempt to run this

system (outdoor reset control strategy only).

6. Temperature sensing bypass – the inside control board, left side, contains a “E” tab which can be

used to directly step in the heating stages and in essence bypass the temperature sensing and control

functions. The “E” tab has the highest priority and overrides all temperature sensor functions. In

other words, when jumpering from W to E all four stages are hard on. Note: Verify pump is

operating prior to using the E terminal. Since activating this E terminal causes full electric element

output, this function should only be used to verify all stages or troubleshoot proper 24Ø current at

each element.

7. Use general heating system logic information and basic understanding of the terminal block wiring

functions measure various voltage points to determine proper operation.

8. Acquiring the PC software or Palm with serial port hookup cable is a positive tool for understanding

and troubleshooting the WarmFlo controller. Either test set device can display all temperatures, real

time evaluation of WarmFlo functions and provide temperature offsets for assimilating winter

conditions.

Sensor Temperature Calibration - Both remote sensors are digital electronic and factory calibrated.

Normally these do not require field calibration or verification. However, if sensor temperature error is

determined, there are two field calibration techniques. Proceed with extreme caution.

1. The outdoor sensor (OT) can be calibrated with ice (32F). This is not a checking temperature

situation. If you proceed with this function, the sensor automatically goes to 32F. Notice a small

push button next to the sensor terminal block, with the sensor at 32F, push and hold for

approximately ten seconds. When the green LED next to the fuse “blinks” at you, release and now

the outdoor sensor is set at 32F.

Use PC software to calibrate sensor. See other paragraphs.

2.

05/19/2016

17 BI5172

OPERATIONAL INFORMATION

In order for the installer to completely understand the WF II functions and operational sequence it is

recommended to thoroughly read and understand the information below. This knowledge can help in

determining settings that can be set according to the end customers needs.

Warning, field reprogramming – within WarmFlo II internal logic and non-volatile memory, it can

detect whether it is operating from one of the above factory pre-programmed chips or if it has been

modified (reprogrammed) with PC software or Handheld. Once the user or field technician has

downloaded (save), from that time forward the WarmFlo II physical control board is no longer governed

by the above table, or the chip code written on the plug-in chip, etc. In other words, power up/power

down, reset, or removing and re-plugging the chip does not affect any altered reprogrammed functions. It

is smart enough to know it is no longer the original chip and that specific physical board, from this time

forward, must be under the control of the PC software/Palm.

Delay, transfer from standby to electric – if the unit was operating in SB for more than 1 minute, the

follow-up transfer back to electric engages a 2-minute delay before any of the electric stages are

activated. The pump will react to the call for heat, but the elements will stay off for 2 minutes in order for

the pump to cool down the standby boiler vessel.

Staging disables at specified outdoor temperatures – the factory setup allows all four stages to come

on at outdoor temperatures below 120° F. Using download reprogramming, an outdoor temperature can

be set for each stage allowing the disable of specific stages above the preset temperature.

05/19/2016

18 BI5172

ELECTRO-BOILER

DUAL HEAT PIPING DIAGRAM

TO SYSTEM

FROM SYSTEM

T

OU

ELECTRO

BOILE

SAFETY

LVE

VA

#

5453

1

INLET

GAT

VALV

E

E

DRAIN VALVE

(THREADED INTO TEE)

I

N

WATER SUPPLY VALVE

AUTO FILL VALVE

(REGULATOR)

WATER SUPPL

C

ONNECTI

Y

ON

EXPANSI

T

TAN

ON

K

I

NOU

-

R

NOTES:

1. LOOSE PARTS SHIPPED WITH BASI

OILER MODEL.

B

C

2. IF WOOD BOILER, REVERSE ORDER

OIL/GAS BOILER

(WITH PUMP

)

2

(ELECTRIC FEEDS WOOD).

3. MINIMUM 20" SPACING BETWEEN

FLOOR AND BOTTOM OF BOILER.

ELECTRO INDUSTRIES, INC

MONTICELLO, MN

55362

DRAI

N

3

BX

.

Rev.A 02-14-06

504

BOILER ACCESSORIES

BOILER ACCESSORIES

ZONE CONTROLLER

This will simplify your wiring and make zoning applications much easier. In addition, enhanced communicating

features have the ability to stage the electric boiler based upon the connected zone capacity.

Standard Features

• Utility load control

• Terminal block wiring, visual

wiring layout

• Indicator lights showing zone

operation

• 24-volt, 40VA transformer

120/208/240 connection

• Fuse protection

• Priority option

• Dual temperature operation

• Applies to digital or

standard thermostats

• Dial switch, select each zone

capacity

Pumps, Actuators, Valves

EB-ZTA-1 - install within boiler cabinet

EB-ZEA-1 - with enclosure and 40VA transformer

EB-ZEA-2 - add additional 4, enclosure and 40VA

Pumps

EB-ZEA8 - with enclosure and 40VA transformer for

Zone Valves

EB-ZTS-1 - install within boiler cabinet, encl. option

EB-ZTS-2 - add additional 4, enclosure and 40VA

EB-ZES8 - with enclosure, no transformer, for

SLAB STAT

Sensing and controlling the system based upon radiant fl oor surface temperature

or the concrete mass has very positive benefi ts. Radiant fl oor air stat in the same

area as a forced air roomstat presents serious control problems. A remote sensing

slab stat for the radiant fl oor removes this issue.

Remote sensing slab stat is required for storage applications.

8 zone pumps

8 zone valves

ES-24-BR

SWITCHING RELAY - EE-5051 MULTI-BOILER - EB-C-STG5

This DPDT 24-volt switching relay provides a convenient

solution to any AC or DC application.

OTHER OPTIONS

• Ideal for zone pumps

• 24V coil

• 120V, 10A, contact sets

• Easy to wire and nicely packaged

Specifi cations subject to change without notice, all rights reserved.

Electrically connects between 2nd and 3rd, 3rd and 4th, etc.

SOT-1 Switchover to standby, total run time

5701 Single feed bus for 2 CB’s (SQ-D CB)

5702 Single feed bus for 3 CB’s (SQ-D CB)

EB-S-SB Dual boiler option for EB-S Series

WF-ANZ7 WarmFlo Analyzer, now applicable to WO and

WA Series

Monticello, Minnesota

800.922.4138

www.electromn.com

TWO SUPPLY WATER TEMPERATURE REQUIREMENT

• Handled as the priority zone on multi-zone (EB-ZEA-1) or two

pump (EB-Z2P) controllers

• Priority switch on, zone 1 active - TS boiler automatically changes

to 150° (or selection 176°) supply water setting

• All other zones are held off

• With zone 1 satisfi ed or 60-minute timeout, the boiler automatically

returns to the preset temperature and reacts to the other zones

Low T emp High T emp

Radiant, slab Radiant, staple up

Radiant, slab Baseboard

Radiant, slab Fan coil

Radiant, slab Water heater, side arm

Radiant, slab Hanging unit heater (garage, shop, etc.)

INSTALLATION PLUMBING KITS

These installation kits provide the critical plumbing components needed for easy installation of the Electro-Boiler. In addition to the

items shown in the matrix below, each kit includes all necessary ball valves, drain valve, tees, elbows, nipples, bushings, cou plings,

etc. for direct connection to circulator pump and/or manifold.

Electro Industries’ boilers come standard equipped with outlet temperature/pressure gauge, pressure relief safety valve, and when

applicable, the WarmFloTM electronic control sensors. These kits provide the additional components for easy installation:

Model Application Return Gauge Expansion Tank Air Vent

EMB-BK All EMB Series 2.1 gal. (7.9 L), 40,000 Btu/h Basic fl oat type

EMB-PK All EMB Series

EB-PK-M EB-MS, -MA, -MO Series

EB-BK-TS EB-S, -WA, -WO Series 4.5 gal. (17 L), 135,000 Btu/h Basic fl oat type

EB-PK-TS EB-S, -WA, -WO Series

2.1 gal. (7.9 L), 40,000 Btu/h Enhanced air separator, EAS

4.5 gal. (17 L), 135,000 Btu/h Enhanced air separator, EAS

4.5 gal. (17 L), 135,000 Btu/h Enhanced air separator, EAS

CIRCULATING PUMPS

5585 - Mini-Boiler &

10 kW TS Series

•

120V, 1/25 HP, maintenance-free wet

rotor circulator

• Pump curve example - 5 GPM (19 L)

@ 11 ft. of head (32.9 kPa)

03/05/2014 BL001

5586 - TS Series, Standard 5578 - 3/4” Pipe

• 120V, 1/6 HP, maintenance-free oil

lubricated circulator

• Pump curve example - 10 GPM (37.8 L)

@ 20 ft. of head (50.8 kPa)

5582 - 1” Pipe

5579 - 1-1/4” Pipe

• Two fl anges, with isolation valve

Electro Industries, Inc. Residential

Limited Product Warranty

Effective November 1, 2009

Electro Industries, Inc. warrants to the original owner, at the original installation site, for a period of two (2)

years from date of original purchase, that the product and product parts manufactured by Electro

Industries, Inc. are free from manufacturing defects in materials and workmanship, when used under

normal conditions and when such product has not been modified or changed in any manner after leaving

the plant of Electro Industries, Inc. If any product or product parts manufactured by Electro Industries,

Inc. are found to have manufacturing defects in materials or workmanship, such will be repaired or

replaced by Electro Industries, Inc. Electro Industries, Inc., shall have the opportunity to directly, or

through its authorized representative, examine and inspect the alleged defective product or product parts.

Electro Industries, Inc. may request that the materials be returned to Electro Industries, Inc. at owner’s

expense for factory inspection. The determination as to whether product or product parts shall be

repaired, or in the alternative, replaced, shall be made by Electro Industries, Inc. or its authorized

representative.

Electro Industries, Inc. will cover labor costs according to the Repair / Replacement Labor Allowance

Schedule for a period of ninety (90) days from the date of original purchase, to the original owner, at the

original installation site. The Repair / Replacement Labor Allowance is designed to reduce the cost of

repairs. This Repair / Replacement Labor Allowance may not cover the entire labor fee charged by your

dealer / contractor.

TWENTY YEAR (20) LIMITED WARRANTY ON BOILER ELEMENTS AND VESSELS

Electro Industries, Inc. warrants that the boiler elements and vessels of its products are free from defects

in materials and workmanship through the twentieth year following date of original purchase. If any boiler

elements or vessels are found to have a manufacturing defect in materials or workmanship, Electro

Industries, Inc. will replace them.

TWENTY YEAR (20) LIMITED WARRANTY ON SPIN FIN ELEMENTS

Electro Industries, Inc. warrants that the spin fin elements of its products are free from defects in materials

and workmanship through the twentieth year following date of original purchase. If any spin fin elements

are found to have a manufacturing defect in materials or workmanship, Electro Industries, Inc. will replace

them.

FIVE YEAR (5) LIMITED WARRANTY ON OPEN WIRE ELEMENTS

Electro Industries, Inc. warrants that the open wire elements of its products are free from defects in

materials and workmanship through the fifth year following date of original purchase. If any open wire

elements are found to have a manufacturing defect in materials or workmanship, Electro Industries, Inc.

will replace them.

Page 1 of 2 XX017

CONDITIONS AND LIMITATIONS:

1. This warranty is limited to residential, single family dwelling installations only. Any commercial or multi-unit

dwelling installations fall under the Electro Industries Commercial Limited Product Warranty.

2. Electro Industries, Inc. shall not be liable for performance related issues resulting from improper installation,

improper sizing, improper duct or distribution system, or any other installation deficiencies.

3. If at the time of a request for service the original owner cannot provide an original sales receipt or a warranty

card registration then the warranty period for the product will have deemed to begin the date the product is

shipped from the factory and NOT the date of original purchase.

4. The product must have been sold and installed by a licensed electrician, plumbing, or heating contractor.

5. The application and installation of the product must be in compliance with Electro Industries, Inc. specifications,

as stated in the installation and instruction manual, and all state, provincial and federal codes an d statutes. If

not, the warranty will be null and void.

6. The purchaser shall have maintained the product in accordance with the manual that accompanies the unit.

Annually, a qualified and licensed contractor must inspect the product to assure it is in proper working condition.

7. All related heating components must be maintained in good operating condition.

8. All lines must be checked to confirm that all condensation drains properly from the unit.

9. Replacement of a product or product part under this limited warranty does not extend the warranty term or

period.

10. Replacement product parts are warranted to be free from defects in material and workmanship for ninety (90)

days from the date of installation. All exclusions, conditions, and limitations expressed in this warranty apply.

11. Before warranty claims will be honored, Electro Industries, Inc. shall have the opportunity to directly, or through

its authorized representative, examine and inspect the alleged defective product or product parts. Remedies

under this warranty are limited to repairing or replacing alleged defective product or product parts. The decision

whether to repair or, in the alternative, replace products or product parts shall be made by Electro Industries, Inc.

or its authorized representative.

THIS WARRANTY DOES NOT COVER:

1. Costs for labor for diagnosis, removal or reinstallation of an alleged defective product or product part,

transportation to Electro Industries, Inc., and any other materials necessary to perform the exchange, except as

stated in this warranty. Replacement material will be invoiced to the distributor in the usual manner an d will be

subject to adjustment upon verification of defect.

2. Any product or product part that has been damaged as a result of being improperly serviced or operated,

including, but not limited to, the following: operated during construction phase, with insufficient water or air flow;

allowed to freeze; subjected to flood conditions; subjected to improper voltages or power supplies; operated with

air flow or water conditions and/or fuels or additives which cause unusual deposits or corrosion in or on the

product; chemical or galvanic erosion; improper maintenance or subject to any other abuse or negligence.

3. Any product or product part that has been damaged as a result of natural disasters, including, but not limited to,

lightning, fire, earthquake, hurricanes, tornadoes or floods.

4. Any product or product part that has been damaged as a result of shipment or handling by the freight carrier. It

is the receiver’s responsibility to claim and process freight damage with the carrier.

5. Any product or product part that has been defaced, abused or suffered unusual wear and tear as determined by

Electro Industries, Inc. or its authorized representative.

6. Workmanship of any installer of the product or product part. This warranty does not assume any liability of an y

nature for unsatisfactory performance caused by improper installation.

7. Transportation charges for any replacement product, product part or component, service calls, normal

maintenance; replacement of fuses, filters, refrigerant, etc.

THESE WARRANTIES DO NOT EXTEND TO ANYONE EXCEPT THE ORIGINAL PURCHASER AT RETAIL AND ONLY WHEN THE PRODUCT IS

IN THE ORIGINAL INSTALLATION SITE. THE REMEDIES SET FORTH HEREIN ARE EXCLUSIVE.

ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE

HEREBY DISCLAIMED WITH RESPECT TO ALL PURCHASERS OR OWNERS. ELECTRO INDUSTRIES, INC. IS NOT BOUND BY PROMISES

MADE BY OTHERS BEYOND THE TERMS OF THESE WARRANTIES. FAILURE TO RETURN THE WARRANTY CARD SHALL HAVE NO

EFFECT ON THE DISCLAIMER OF THESE IMPLIED WARRANTIES.

ALL EXPRESS WARRANTIES SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS LIMITED WARRANTIES SET FORTH HEREIN AND

EXCLUDE ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES RESULTING FROM THE BREACH THEREOF. SOME STATES

OR PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS OR EXCLUSIONS MAY NOT APPLY. PRODUCTS OR PARTS OF OTHER MANUFACTURERS ATTACHED ARE SPECIFICALLY

EXCLUDED FROM THE WARRANTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY HAVE OTHER RIGHTS WHICH VARY UNDER THE LAWS OF EACH

STATE. IF ANY PROVISION OF THIS WARRANTY IS PROHIBITED OR INVALID UNDER APPLICABLE STATE OR PROVINCIAL LAW, THAT

PROVISION SHALL BE INEFFECTIVE TO THE EXTENT OF THE PROHIBITION OR INVALIDITY WITHOUT INVALIDATING THE REMAINDER OF

THE AFFECTED PROVISION OR THE OTHER PROVISIONS OF THIS WARRANTY.

Page 2 of 2 XX017

Electro Industries, Inc.

3-Phase Boiler Limited Product Warranty

Electro Industries, Inc. warrants to the original owner, at the original installation site, for

a period of one (1) year from date of installation, that the product and product parts

manufactured by Electro Industries are free from manufacturing defects in materials and

workmanship, when used under normal conditions and when such product has not been

modified or changed in any manner after leaving the plant of Electro Industries. If any

product or product parts manufactured by Electro Industries are found to have

manufacturing defects in materials or workmanship, such will be repaired or replaced by

Electro Industries. Electro Industries, shall have the opportunity to directly, or through

its authorized representative, examine and inspect the alleged defective product or

product parts. Electro Industries may request that the materials be returned to Electro

Industries at owner’s expense for factory inspection. The determination as to whether

product or product parts shall be repaired, or in the alternative, replaced, shall be made

by Electro Industries or its authorized representative.

ONE YEAR (1) LIMITED WARRANTY ON BOILER PARTS

Electro Industries, Inc. warrants that the parts of its 3-Phase Boilers are free from

defects in materials and workmanship through the first year following date of installation.

If any product parts are found to have a manufacturing defect in materials or

workmanship, Electro Industries will repair or replace them at their discretion.

Effective September 1, 2008

ONE YEAR (1) LIMITED WARRANTY ON BOILER ELEMENTS

Electro Industries, Inc. warrants that the elements of its 3-Phase Boilers are free from

defects in materials and workmanship through the first year following date of installation.

If any elements are found to have a manufacturing defect in materials or workmanship,

Electro Industries will replace them.

FIVE YEAR (5) LIMITED WARRANTY ON BOILER VESSELS

Electro Industries, Inc. warrants that the boiler vessels of its 3-Phase Boilers are free

from defects in materials and workmanship through the fifth year following date of

installation. If any vessels are found to have a manufacturing defect in materials or

workmanship, Electro Industries will repair or replace them at their discretion.

Page 1 of 2 XX024

THESE WARRANTIES DO NOT COVER:

1. Costs for labor for removal and reinstallation of an all eged defective product or product parts,

transportation to Electro Industries, and any other materials necessary to perform the exchange,

except as stated in this warranty. Replacement material will be invoiced to the distributor in the usual

manner and will be subject to adjustment upon verification of defect.

2. Any product that has been damaged as a result of being improperly serviced or operated, including,

but not limited to, the following: operated with insufficient water or air flow; allowed to freeze;

subjected to flood conditions; subjected to improper voltages or power supplies; operated with air flow

or water conditions and/or fuels or additives which cause unusual deposits or corrosion in or on the

product; chemical or galvanic erosion; improper maintenance or subject to any other abuse o r

negligence.

3. Any product that has been damaged as a result of natural disasters, including, but not limited to,

lightning, fire, earthquake, hurricanes, tornadoes or floods.

4. Any product that has been damaged as a result of shipment or handling by the freight carrier. It is the

receiver’s responsibility to claim and process freight damage with the carrier.

5. Any product that has been defaced, abused or suffered unusual we ar and tear as determined by

Electro Industries or its authorized representative.

6. Workmanship of any installer of the product. This warranty does not assume any liability of any

nature for unsatisfactory performance caused by improper installation.

7. Transportation charges for any replacement part or component, service calls, normal maintenance;

replacement of fuses, filters, refrigerant, etc.

CONDITIONS AND LIMITATIONS:

1. If at the time of a request for service the original owner can not provide an original sales receipt or a

warranty card registration then the warranty period for the product will have deemed to begin thirty

(30) days after the date of manufacture and NOT the date of installation.

2. The product must have been sold and installed by a licensed electrician, plumbing, or heating

contractor.

3. The application and installation of the product must be in complian ce with Electro Industries

specifications, as stated in the installation and instruction manual, and all state and federal codes and

statutes. If not, the warranty will be null and void.

4. The purchaser shall have maintained the product in accordance with the manual that accompanies

the unit. Annually, a qualified and licensed contractor must inspect the product to assure it is in

proper working condition.

5. All related heating components must be maintained in good operating condition.

6. All lines must be checked to confirm that all condensation drains pr operly from the unit.

7. Replacement of a product or product part under this limited warranty does not extend the warranty

term or period.

8. Replacement product parts are warranted to be free from defects in material and workmanship for

ninety (90) days from the date of installation. All exclusions, conditions, and limitations expressed in

this warranty apply.

9. Before warranty claims will be honored, Electro Industries shall h ave the oppo rtunity to directly, or

through its authorized representative, examine and inspect the alleged defective product or product

parts. Remedies under this warranty are limited to repairing or replacing alleged defective product or

product parts. The decision whether to repair or, in the alternative, replace products or product parts

shall be made by Electro Industries or its authorized representative.

THESE WARRANTIES DO NOT EXTEND TO ANYONE EXCEPT THE ORIGINAL PURCHASER AT RETAIL AND ONLY WHEN THE PRODUCT IS IN THE ORIGINAL

INSTALLATION SITE. THE REMEDIES SET FORTH HEREIN ARE EXCLUSIVE.

ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED WITH

RESPECT TO ALL PURCHASERS OR OWNERS. ELECTRO INDUSTRIES, INC. IS NOT BOUND BY PROMISES MADE BY OTHERS BEYOND THE TERMS OF THESE

WARRANTIES. FAILURE TO RETURN THE WARRANTY CARD SHALL HAVE NO EFFECT ON THE DISCLAIMER OF THESE IMPLIED WARRANTIES.

ALL EXPRESS WARRANTIES SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS LIMITED WARRANTIES SET FORTH HEREIN AND EXCLUDE ANY

LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES RESULTING FROM THE BREACH THEREOF. SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY. PRODUCTS OR PARTS OF

OTHER MANUFACTURERS ATTACHED ARE SPECIFICALLY EXCLUDED FROM THE WARRANTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY HAVE OTHER RIGHTS WHICH VARY UNDER THE LAWS OF EACH STATE. IF ANY

PROVISION OF THIS WARRANTY IS PROHIBITED OR INVALID UNDER APPLICABLE STATE LAW, THAT PROVISION SHALL BE INEFFECTIVE TO THE EXTENT OF

THE PROHIBITION OR INVALIDITY WITHOUT INVALIDATING THE REMAINDER OF THE AFFECTED PROVISION OR THE OTHER PROVISIONS OF THIS WARRANTY.

Page 2 of 2 XX024

Loading...

Loading...