Electrex X3M User Manual

X3M

Energy Data Manager

User Manual

Version8 November 2005

The document can be modified without prior information.

1

Index

INTRODUCTION .............................................................................................................................. 6

1.1 COPYRIGHT ........................................................................................................................ 6

1.2 WARRANTY ......................................................................................................................... 6

1.3 RETURN AND REPAIR FORMALITIES................................................................................. 6

1.3.1 RE-SHIPPING OF REPAIRED PRODUCT..................................................................... 6

1.3.2 Return Material Authorization (RMA form).................................................................... 7

2 Safety......................................................................................................................................... 8

2.1 Operator safety .................................................................................................................... 8

3 Mounting .................................................................................................................................... 9

3.1 Dimensions (mm).................................................................................................................9

3.2 Fixing and blocking .............................................................................................................. 9

4 Wiring Diagrams ...................................................................................................................... 10

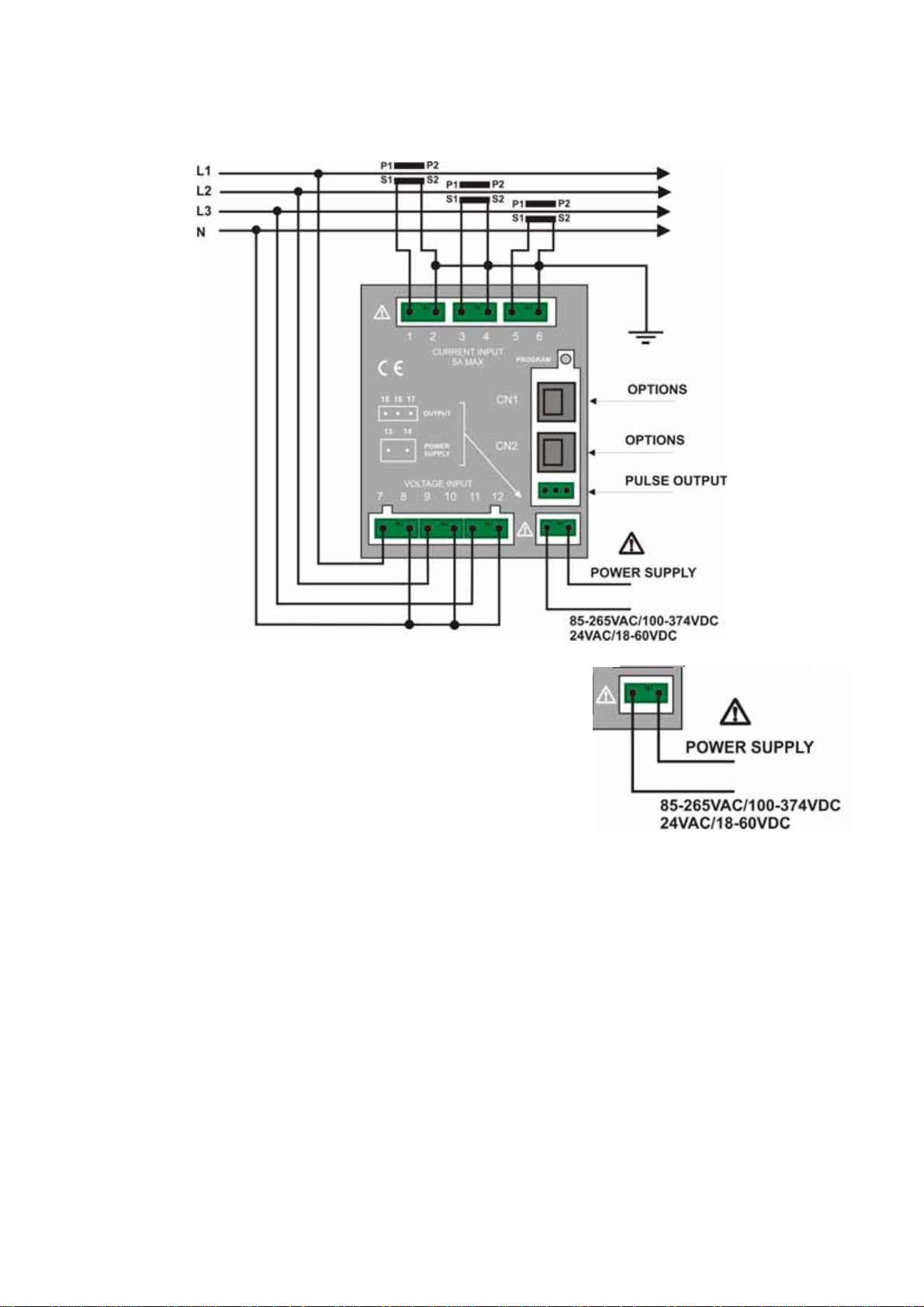

4.1 Power Supply..................................................................................................................... 10

4.2 Measurement Connections................................................................................................ 10

4.2.1 Voltage connection...................................................................................................... 10

4.2.2 Current connection...................................................................................................... 10

4.2.3 4W Star Connection (4 wires) ..................................................................................... 11

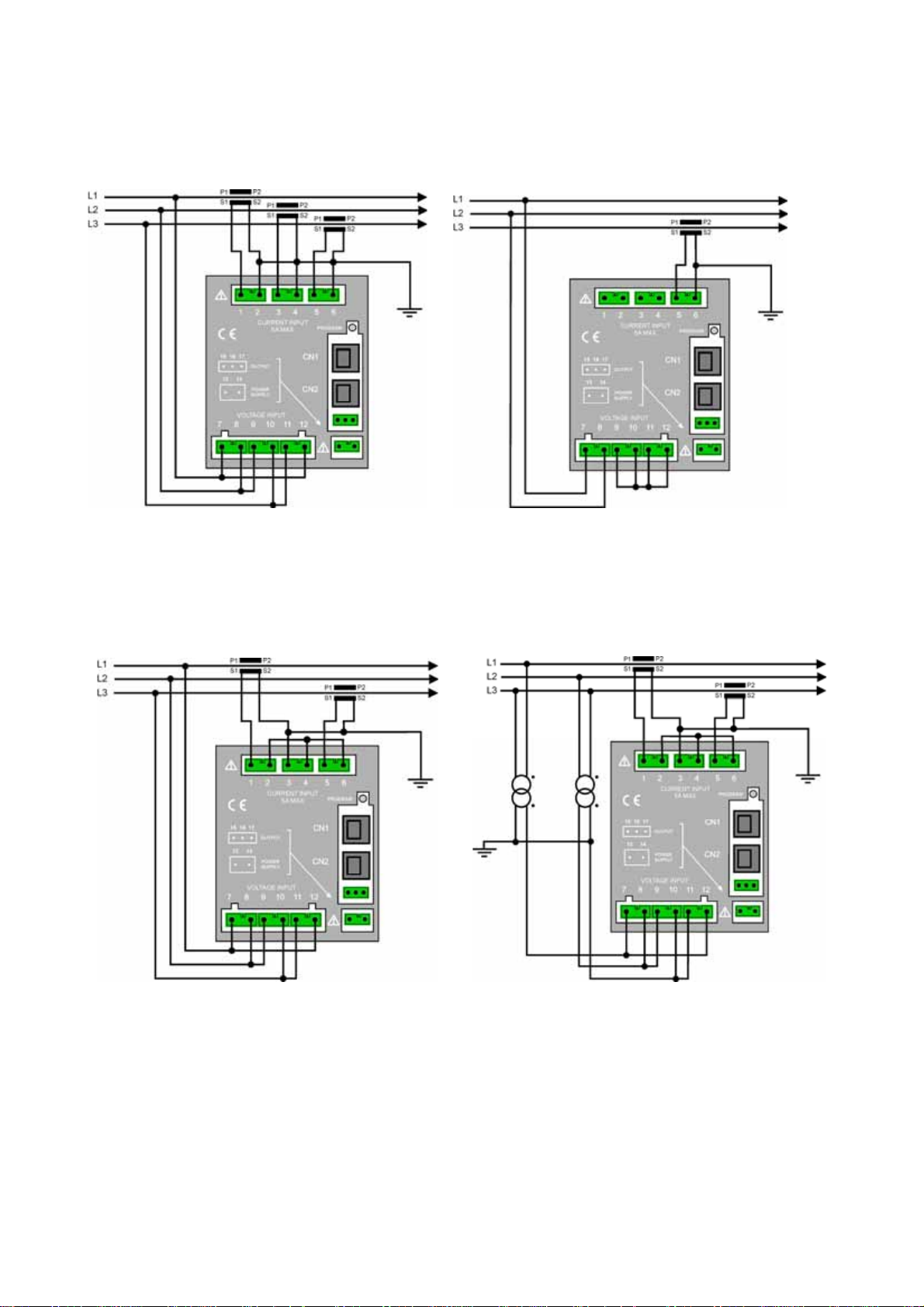

4.2.4 3W Delta Connection (3 wires).................................................................................... 12

4.2.4.1 L1 L3 Phase Connection with 2 CTs.................................................................. 12

4.2.4.2 L1 L2 Phase Connection with 2 CTs.................................................................. 13

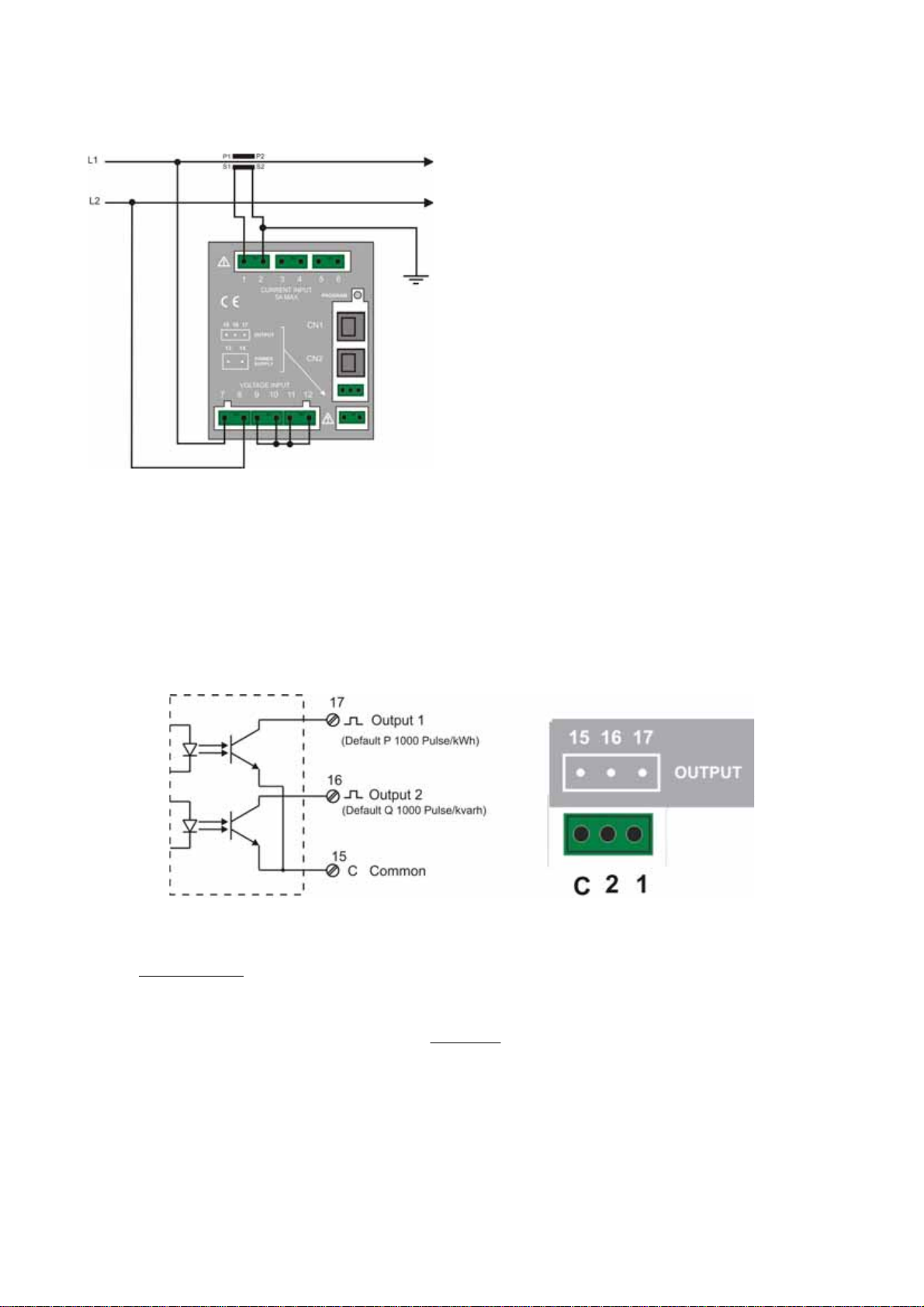

4.2.5 2 Wire Connection (single phase) ............................................................................... 13

4.2.6 2 Wire Connection (double phase).............................................................................. 14

4.3 Output Connection............................................................................................................. 14

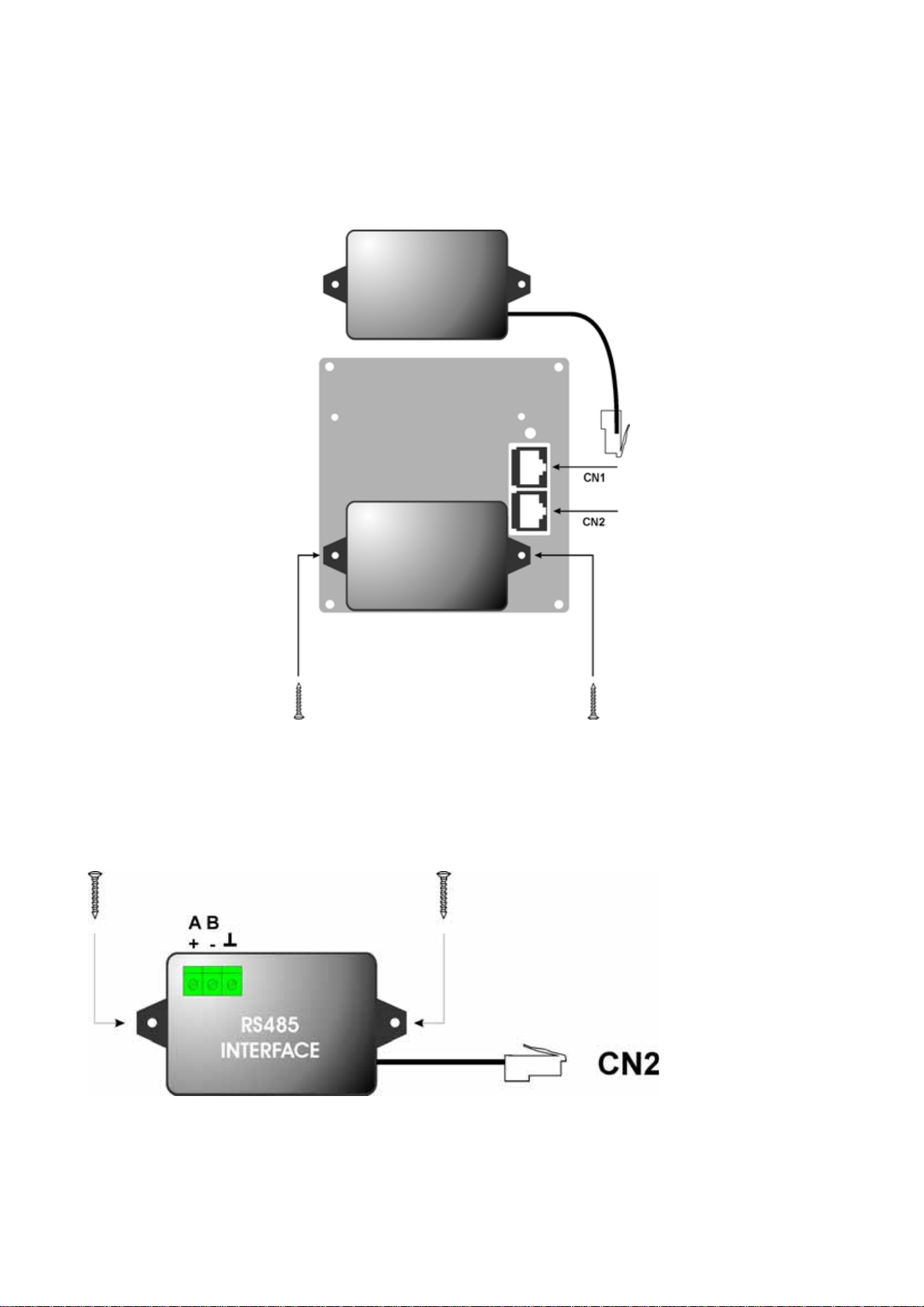

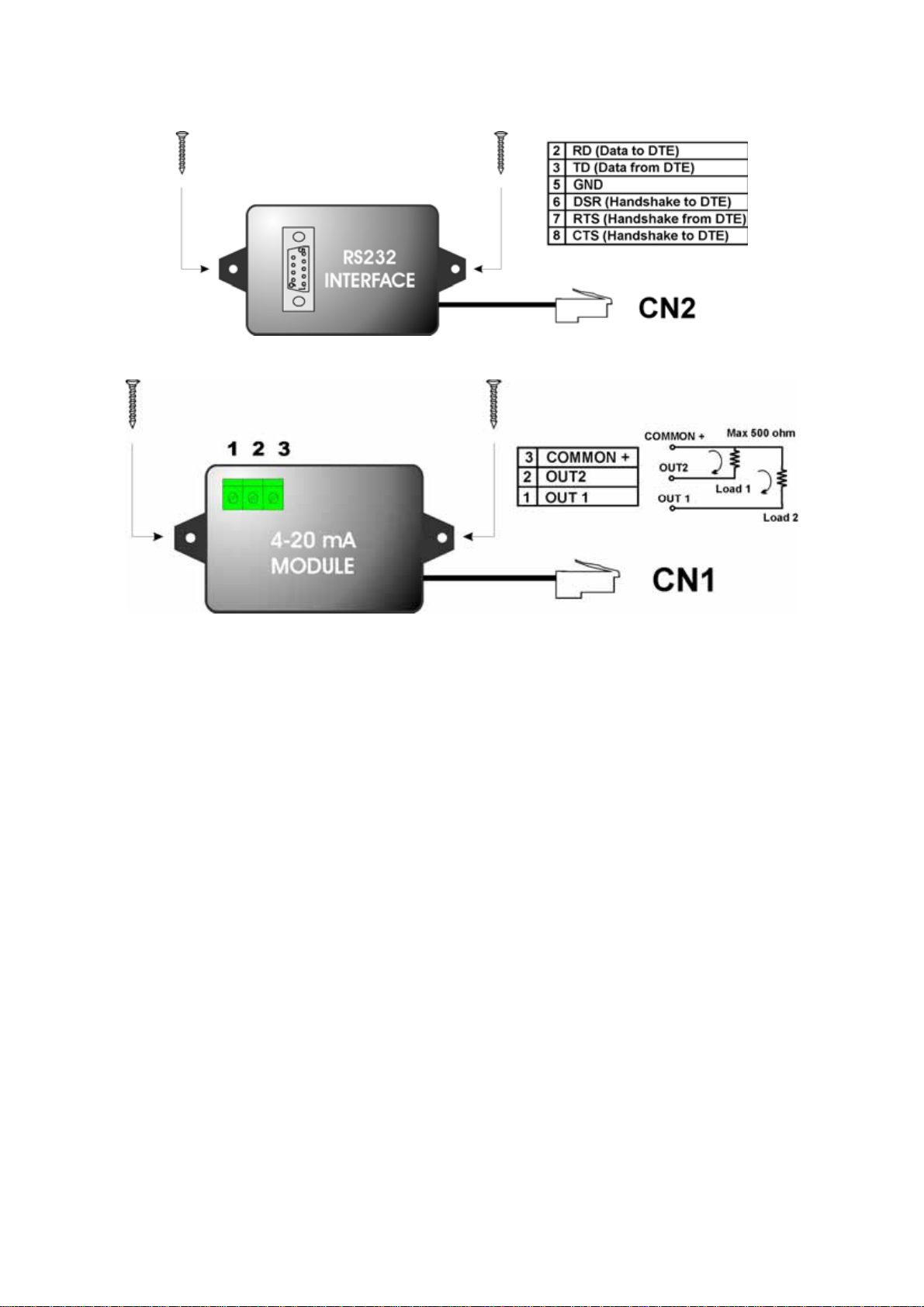

4.4 Connecting Optional Components..................................................................................... 15

4.4.1 RS485 Option.............................................................................................................. 15

4.4.2 RS232 Option.............................................................................................................. 16

4.4.3 Double 4-20 mA analogic Output Option..................................................................... 16

5 Instrument Use ........................................................................................................................ 17

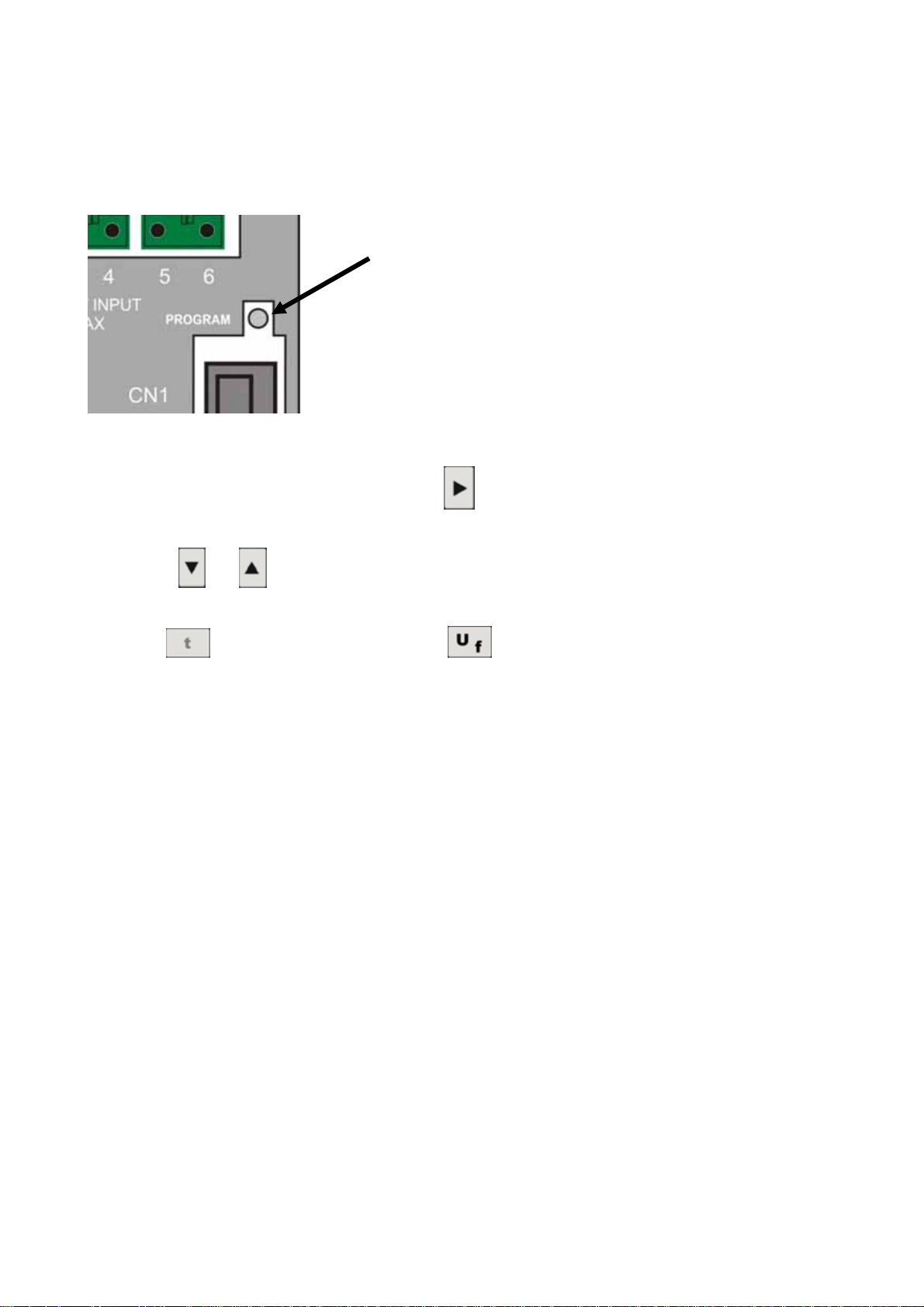

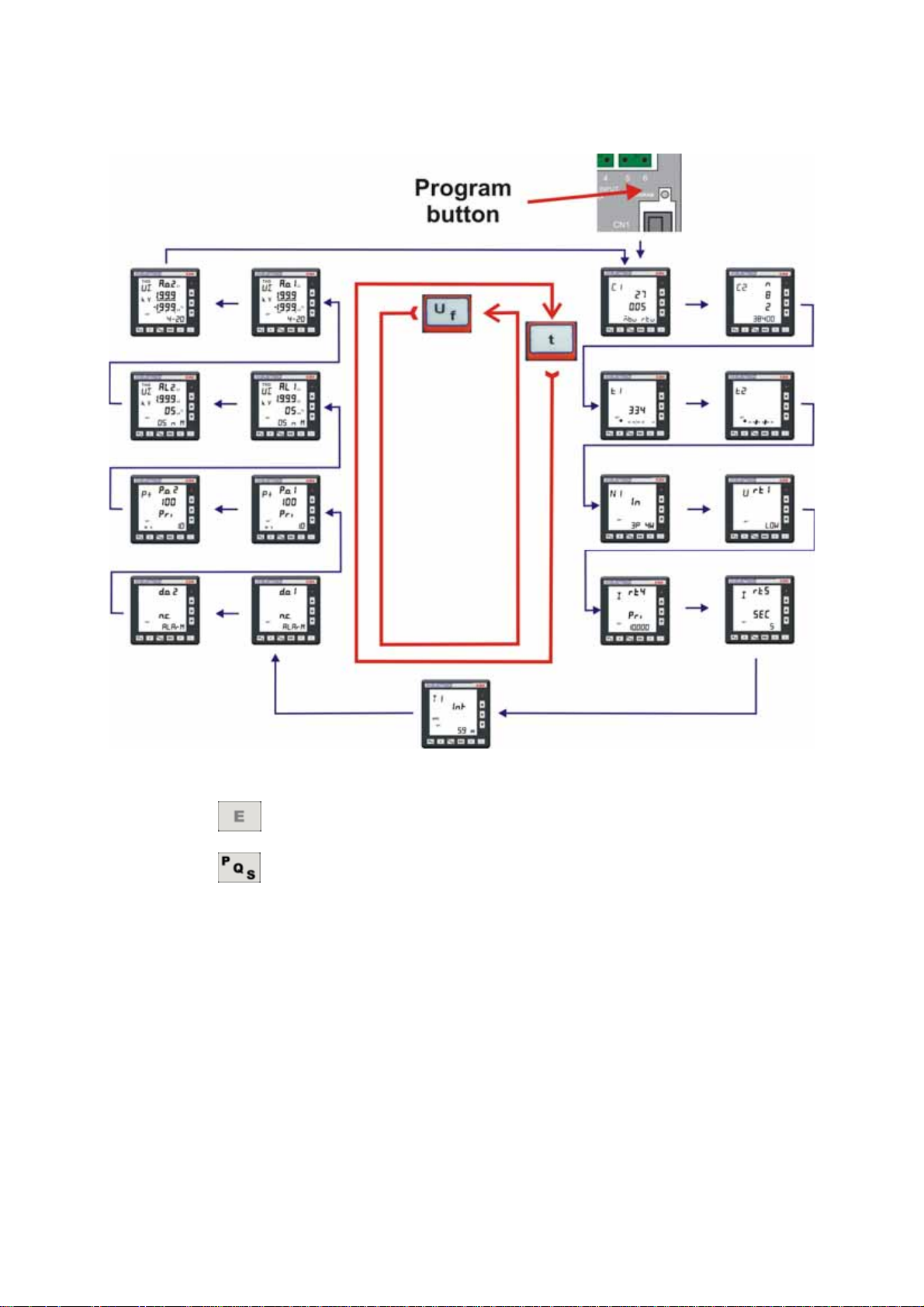

5.1.1 Set up sequence ......................................................................................................... 18

5.1.2 Configuration Procedure ............................................................................................. 19

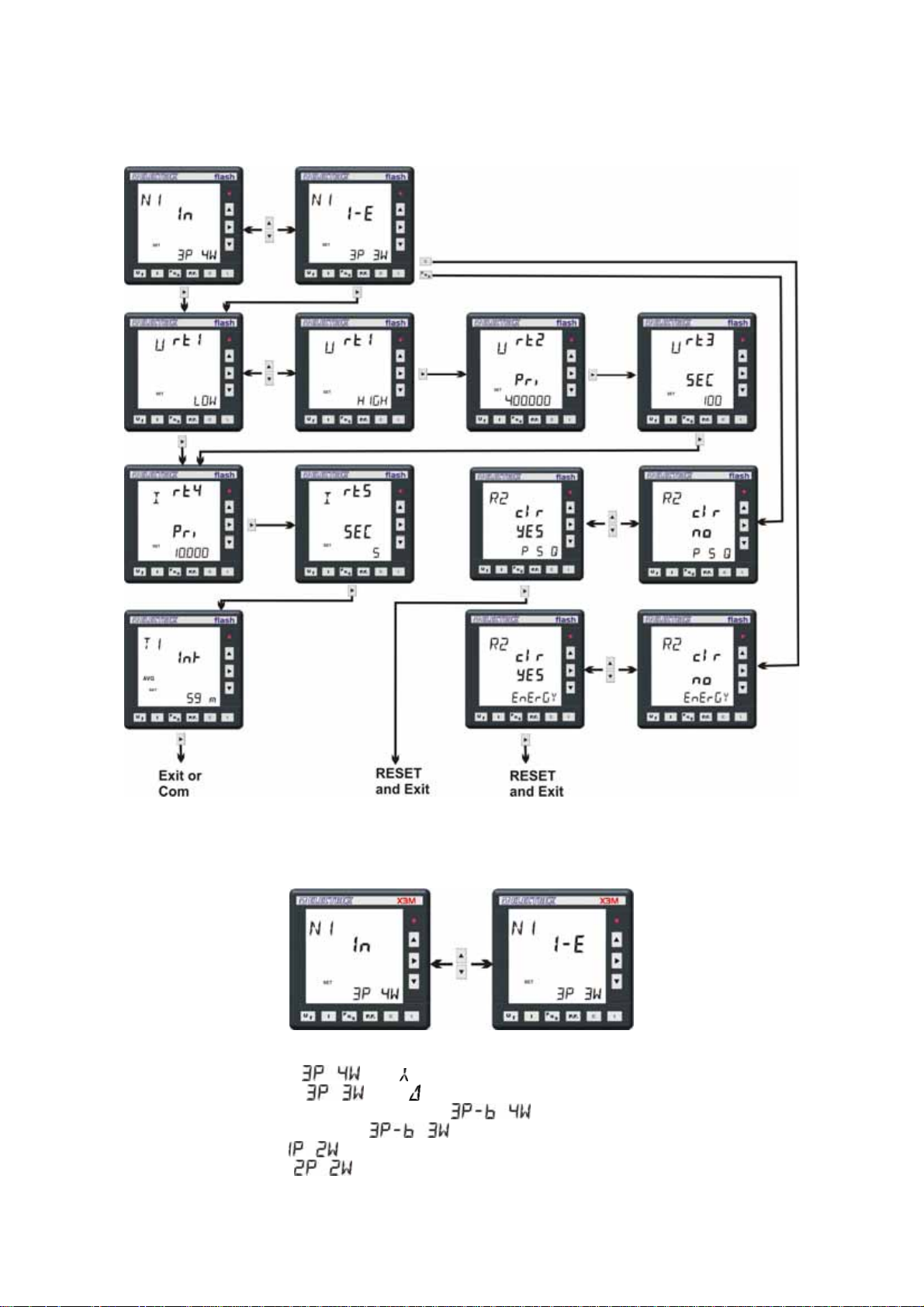

5.1.2.1 Electrical system configuration........................................................................... 19

5.1.2.2 Communication Parameters Configuration ........................................................ 21

5.1.2.3 Output Configuration .......................................................................................... 21

5.1.2.4 Pulse characteristics configuration..................................................................... 22

5.1.2.4.1 Pulse output set up with Modbus registers..................................................................... 22

5.1.2.5 Alarm Configuration ........................................................................................... 23

5.1.2.5.1 Alarm set up with Modbus registers. .............................................................................. 24

5.1.2.6 Analog 4-20 mA Outputs Configuration. ............................................................ 25

5.1.2.6.1 Analog output set up with Modbus registers................................................................... 26

5.1.2.6.2 4-20 mA output configuration of the average AVG values ............................................. 26

5.1.2.7 Clock calendar configuration (for X3M-D only) .................................................. 27

5.1.2.7.1 Clock set up with Modbus registers. ............................................................................... 28

5.1.2.7.2 Time zones ..................................................................................................................... 29

5.1.3 Reset Procedure ......................................................................................................... 33

5.2 Readings............................................................................................................................ 34

5.2.1 Readings selection keys.............................................................................................. 34

5.2.1.1 Voltage and Frequency Readings...................................................................... 34

5.2.1.1.1 3P 4 W Configuration...................................................................................................... 34

5.2.1.1.2 3P 3 W Configuration...................................................................................................... 35

5.2.1.1.3 3P-b 4W Configuration ................................................................................................... 35

5.2.1.1.4 3P-b 3W Configuration ................................................................................................... 35

5.2.1.1.5 1P 2W Configuration....................................................................................................... 35

5.2.1.1.6 2P 2W Configuration....................................................................................................... 35

5.2.1.2 Current readings ................................................................................................ 36

2

5.2.1.2.1

5.2.1.2.2 3P 3W Configuration....................................................................................................... 36

5.2.1.2.3 3P-b 4W Configuration ................................................................................................... 36

5.2.1.2.4 3P-b 3W Configuration ................................................................................................... 36

5.2.1.2.5 1P 2W and 2P 2W Configuration.................................................................................... 36

3P 4W Configuration....................................................................................................... 36

5.2.1.3 Powers ............................................................................................................... 37

5.2.1.3.1 3P 4W Configuration....................................................................................................... 37

5.2.1.3.2 3P 4W only Import Configuration.................................................................................... 37

5.2.1.3.3 3P 3W / 3P-b 3W / 2P 2W Configuration........................................................................ 38

5.2.1.3.4 3P-b 4W Configuration ................................................................................................... 38

5.2.1.3.5 1P 2W Configuration....................................................................................................... 38

5.2.1.4 P.F. Visualization ............................................................................................... 39

5.2.1.4.1 3P 4W Configuration....................................................................................................... 39

5.2.1.4.2 3Pb 4W Configuration..................................................................................................... 39

5.2.1.4.3 3P 3W e 3Pb 3W Configuration...................................................................................... 39

5.2.1.4.4 1P 2W e 2P 2W Configuration........................................................................................ 39

5.2.1.5 Energy................................................................................................................ 40

5.2.1.6 Only Import Energy Display ............................................................................... 40

5.2.1.7 Tariff Energies and Tariff Maximum Demand..................................................... 41

5.2.1.8 Calendar Clock and Life Time........................................................................... 41

6 Instrument Description............................................................................................................. 42

6.1 Introduction ........................................................................................................................ 42

6.2 Simplicity and versatility..................................................................................................... 43

6.3 Total harmonic distortion Measurement (THD).................................................................. 43

6.4 Energy Measurement......................................................................................................... 43

6.5 Storage .............................................................................................................................. 43

6.6 Calibration Led................................................................................................................... 44

6.7 Digital Outputs ................................................................................................................... 44

6.8 Pulse Output ...................................................................................................................... 44

6.9 Alarms................................................................................................................................ 44

6.10 Communication............................................................................................................... 44

6.11 Clock / Calendar ............................................................................................................. 45

6.11.1 Clock Format............................................................................................................ 45

6.12 Memory........................................................................................................................... 45

6.12.1 Dimensions .............................................................................................................. 45

6.12.2 Memory Read/Write. ................................................................................................ 45

6.12.3 File Structure............................................................................................................ 45

6.12.4 Record Structure...................................................................................................... 46

6.13 Average and peak Energy .............................................................................................. 46

6.14 Tariff Time Bands ........................................................................................................... 46

7 System Architecture................................................................................................................. 47

7.1 General Features............................................................................................................... 47

7.1.1 X3M.............................................................................................................................47

7.1.2 Options........................................................................................................................ 48

7.1.2.1 RS485 Port......................................................................................................... 48

7.1.2.2 RS232 Port......................................................................................................... 48

7.1.2.3 2 x 4-20 mA Analog Output................................................................................ 48

8 Parameters and formulas ........................................................................................................ 49

8.1 3P 4W Three phase with 4 wire neutral............................................................................ 49

8.1.1 Available Reading: ...................................................................................................... 49

8.1.2 Measurement Formulas: ............................................................................................. 51

8.2 3P 3W Three phase without neutral................................................................................... 53

8.2.1 Available Reading: ...................................................................................................... 53

8.2.2 Measurement Formulas: ............................................................................................. 55

8.3 3P-b 4W Balanced Three phase with neutral ................................................................... 57

8.3.1 Available Reading: ...................................................................................................... 57

8.3.2 Measurements Formulas:............................................................................................ 59

3

8.4 3P-b 3W Balanced three Phase without neutral 3 wires.................................................. 60

8.4.1 Available Reading: ...................................................................................................... 60

8.4.2 Measurement Formulas: ............................................................................................. 62

8.5 1P (2W) Single phase....................................................................................................... 63

8.5.1 Available Reading: ...................................................................................................... 63

8.5.2 Measurement Formulas: ............................................................................................. 65

8.6 2P (2W) Double phase...................................................................................................... 66

8.6.1 Available Reading: ...................................................................................................... 66

8.6.2 Measurements Formulas:............................................................................................ 68

8.6.3 Sampling: .................................................................................................................... 69

8.6.4 Grid frequency Measurement:..................................................................................... 69

8.7 Average values and energy Calculation. ........................................................................... 69

8.7.1 Energy counting .......................................................................................................... 69

8.7.2 Average Powers / maximum demand (m/Max) ........................................................... 69

9 MODBUS Protocol.................................................................................................................. 70

9.1 Foreword:........................................................................................................................... 70

9.2 “Device dependent” Functions........................................................................................... 71

9.2.1 (0x11) Slave ID Report................................................................................................ 71

9.2.2 (0x07) Exception Status Read..................................................................................... 72

9.3 “User defined” Functions.................................................................................................... 72

9.3.1 (0x42) Slave Address Change .................................................................................... 72

9.4 Register Mapping............................................................................................................... 73

9.4.1 Holding registers ......................................................................................................... 73

9.4.2 Parameter selection tables.......................................................................................... 80

9.4.3 X3M Input registers ..................................................................................................... 84

9.4.4 Input Registers (backward compatibility area) ............................................................ 88

9.4.5 Coils (back compatibility)............................................................................................. 91

9.4.6 X3M coils..................................................................................................................... 91

10 File organization and management in the X3M flash memory. ............................................ 92

10.1 File system .....................................................................................................................92

10.1.1 Types of file.............................................................................................................. 94

10.1.2 File structure ............................................................................................................ 95

10.1.3 Structured Files........................................................................................................ 95

10.1.4 Descriptors............................................................................................................... 96

10.1.5 Homogenous files .................................................................................................. 103

10.1.6 Non Homogeneous files......................................................................................... 106

10.2 Type 0 files ................................................................................................................... 107

10.2.1 File status............................................................................................................... 108

10.2.2 Service status......................................................................................................... 108

10.3 Type 1 files ................................................................................................................... 109

10.3.1 Service configuration.............................................................................................. 110

10.4 Type 4 files ................................................................................................................... 112

10.4.1 Service Configuration............................................................................................. 114

10.4.2 Example of configuration file: “Events.xmbf”.......................................................... 116

10.4.3 Type 5 files............................................................................................................. 118

10.4.4 Service configuration.............................................................................................. 119

10.4.5 Example of configuration file: “Peaks.xmbf”........................................................... 120

10.5 Type 7 files ................................................................................................................... 121

10.5.1 Service configuration.............................................................................................. 121

10.5.2 Reset...................................................................................................................... 122

10.5.3 Example of configuration file: “EnergyCounters.xmbf”........................................... 123

10.6 Type 8 files ................................................................................................................... 124

10.6.1 Service configuration.............................................................................................. 124

10.6.2 Reset...................................................................................................................... 125

10.6.3 Example of configuration file: “MaximumDemands.xmbf”...................................... 126

10.6.4 Clock / Calendar..................................................................................................... 127

4

10.6.4.1 Timezones........................................................................................................ 127

10.6.4.2 Files.................................................................................................................. 128

10.6.4.3 Clock related Modbus registers........................................................................ 128

10.6.5 Upgrading the firmware.......................................................................................... 129

11 The XMBF.EXE utility (Electrex ModBus File) ................................................................... 130

11.1 Commands for PC handling of the files of the X3M memory........................................ 130

11.1.1 Short commands.................................................................................................... 131

11.2 Operation type .............................................................................................................. 131

11.2.1 --read Download............................................................................................... 131

11.2.2 --write Upload .................................................................................................. 131

11.2.3 --del Delete....................................................................................................... 132

11.2.4 --create Create................................................................................................. 132

11.2.5 --reboot Instrument restart from zero.............................................................. 132

11.3 Communication port ..................................................................................................... 132

11.3.1 IP Address.............................................................................................................. 132

11.3.2 Com Port................................................................................................................ 132

11.4 Protocol format ............................................................................................................. 132

11.5 Address ........................................................................................................................ 132

11.6 File number................................................................................................................... 132

11.7 File Name ..................................................................................................................... 133

11.8 Destination.................................................................................................................... 133

11.8.1 --dpath=DestinationPath..................................................................................... 133

11.8.2 --dfile=DestinationFileName............................................................................. 133

11.9 Output format................................................................................................................ 134

11.9.1 TXT Output............................................................................................................. 134

11.9.2 Print to screen........................................................................................................ 134

11.9.3 HEX output............................................................................................................. 134

11.9.4 HTML Output.......................................................................................................... 136

11.9.5 XLS output type...................................................................................................... 138

11.10 Application examples ................................................................................................ 140

11.10.1 Changing the readings stored by Service (1) Load Profiles............................. 140

11.10.2 Changing the thresholds of Service (4) Events................................................ 143

11.10.3 Changing the parameters stored by Service (5) Peaks ................................... 146

12 Technical Characteristics ................................................................................................... 148

13 Firmware Revisions............................................................................................................ 150

14 Order codes ....................................................................................................................... 150

15 DECLARATION OF CONFORMITY .................................................................................. 150

5

INTRODUCTION

We thank you for choosing an Electrex instrument

We invite you to carefully read this instructions manual for the best use of the X3M instruments.

1.1 COPYRIGHT

Electrex S.r.l. All rights are reserved.

It is forbidden to duplicate, adapt, transcript this document without Electrex written authorization, except

when regulated accordingly by the Copyright Laws.

Copyright© 2003-2004

1.2 WARRANTY

This product is covered by a warranty against material and manufacturing defects for a period of 36 months

period from the manufacturing date

The warranty does not cover the defects that are due to:

• Negligent and improper use

• Failures caused by atmospheric hazards

• Acts of vandalism

• Wear out of materials

Electrex reserves the right, at its discretion, to repair or substitute the faulty products

The warranty is not applicable to the products that will result defective in consequence of a negligent and

improper use or an operating procedure not contemplated in this manual.

1.3 RETURN AND REPAIR FORMALITIES

Electrex accepts the return of instruments for repair only when authorized in advance. For instrument

purchased directly, the repair authorization must be requested to Electrex directly by using the enclosed

RMA form. We recommend otherwise to contact your local distributor for assistance on the return/repair

formalities. In both the cases, the following information must be supplied:

• Company full data

• Contact name for further communication

• Product description

• Serial number

• Description of the returned accessories

• Invoice / Shipping document number and date

• Detailed description of the fault and of the operating condition when the fault occurred

The Electrex repair lab will send the authorization number to the customer directly or to the distributor as per

applicable case.

The RMA authorization number shall be clearly marked on the packaging and on the return transport

document.

WARNING: Failure to indicate the RMA number on the external packaging will entitle our warehouse to

refuse the delivery upon arrival and to return the parcel at sender’s charge.

The material must be shipped:

- within 15 working days from the receipt of the return authorization number

- free destination i.e. all transport expenses at sender’s charge.

- to the following address: Electrex S.r.l.

Atn. Repair laboratory

- the units covered by warranty must be returned in their original packaging.

1.3.1 RE-SHIPPING OF REPAIRED PRODUCT

The terms for re-shipment of repaired products are ex-works, i.e. the transport costs are at customer charge.

Products returned as detective but found to be perfectly working by our laboratories, will be charged a fixed

fee (40.00 Euro + VAT where applicable) to account for checking and testing time irrespective of the

warranty terms.

Via Claudia 96 - 41056 Savignano s/P (MO) - Italy

6

1.3.2 Return Material Authorization (RMA form)

Request for the authorization number for the return of goods

Date:

Company:

Contact name:

TEL: FAX:

Product description:

Serial number:

Description of the returned accessories (if any):

Original purchase Invoice (or Shipping document) number and date.

NB: The proof of purchase must be provided by the customer. Failure to complete this area will automatically void all warranty.

Detailed description of the malfunction and of the operating conditions when the fault occurred

Tick off for a quotation

Should a product be found by our laboratories to be perfectly working, a fixed amount of 40 E uro (+VAT if applicable) will be charged

to account for checking and testing time irrespective of the warranty tems.

Space reserved to ELECTREX

R.M.A. No.

The RMA number shall be clearly indicated on the external packaging and on the shipping document:. Failure to observe this

requirement will entitle the ELECTREX warehouse to refuse the delivery.

7

2 Safety

This instrument was manufactured and tested in compliance with IEC 61010 class 2 standards for operating

voltages up to 250 VAC rms phase to neutral.

In order to maintain this condition and to ensure safe operation, the user must comply with the indications

and markings contained in the following instructions:

• When the instrument is received, before starting its installation, check that it is intact and no damage

occurred during transport.

• Before mounting, ensure that the instrument operating voltages and the mains voltage are

compatible then proceed with the installation.

• The instrument power supply needs no earth connection.

• The instrument is not equipped with a power supply fuse; a suitable external protection fuse must be

foreseen by the contractor.

• Maintenance and/or repair must be carried out only by qualified, authorized personnel

• If there is ever the suspicion that safe operation is no longer possible, the instrument must be taken

out of service and precautions taken against its accidental use.

• Operation is no longer safe when:

1) There is clearly visible damage.

2) The instrument no longer functions.

3) After lengthy storage in unfavorable conditions.

4) After serious damage occurred during transport

The instruments must be installed in respect of all the local regulations.

2.1 Operator safety

Warning: Failure to observe the following instructions may lead to a serious danger of death.

- During normal operation dangerous voltages can occur on instrument terminals and on

voltage and current transformers. Energized voltage and current transformers may generate

lethal voltages. Follow carefully the standard safety precautions while carrying out any

installation or service operation.

- The terminals of the instrument must not be accessible by the user after the installation. The

user should only be allowed to access the instrument front panel where the display is

located.

- Do not use the digital outputs for protection functions nor for power limitation functions. The

instrument is suitable only for secondary protection functions.

- The instrument must be protected by a breaking device capable of interrupting both the

power supply and the measurement terminals. It must be easily reachable by the operator

and well identified as instrument cut-off device.

- The instrument and its connections must be carefully protected against short-circuit.

Precautions: Failure to respect the following instructions may irreversibly damage to the instrument.

- The instrument is equipped with PTC current limiting device but a suitable external protection

fuse should be foreseen by the contractor.

- The outputs and the options operate at low voltage level; they cannot be powered by any

unspecified external voltage.

- The application of currents not compatible with the current inputs levels will damage to the

instrument.

8

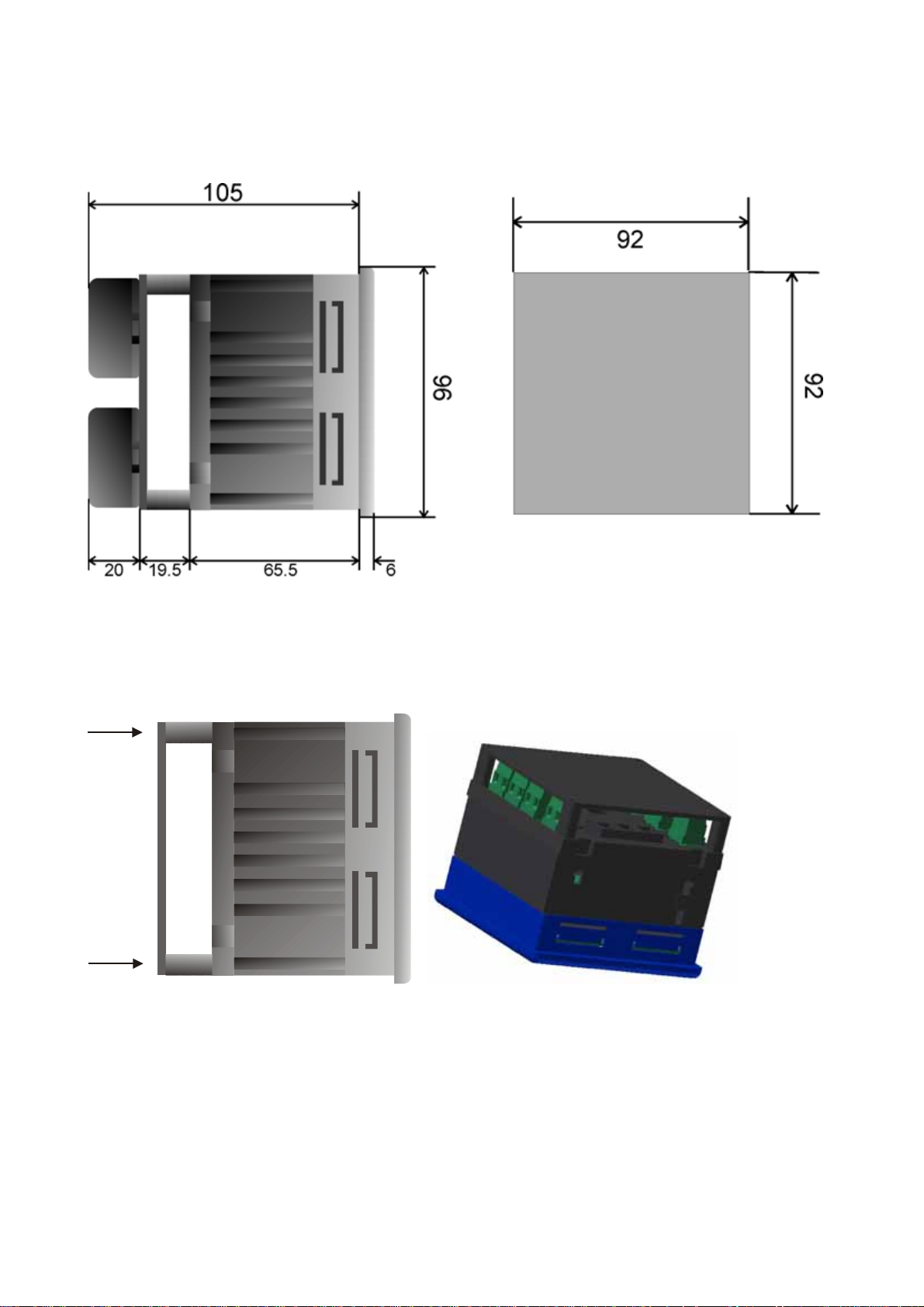

3 Mounting

3.1 Dimensions (mm)

3.2 Fixing and blocking

The connection terminals of the instrument are held in place by a plastic panel, which must be mounted

using 4 screws (supplied). This set up will prevent the disconnection of the current measurement terminals.

9

4 Wiring Diagrams

4.1 Power Supply

The instrument is fitted with a separated power supply with extended

functioning range. The terminals for the power supply are numbered

(13 and 14). Use cables with max cross-section of 4 mm

2

.

4.2 Measurement Connections

4.2.1 Voltage connection

Use cables with max cross-section of 4 mm2 and connect them to the terminals marked VOLTAGE INPUT

on the instrument according to the applicable diagrams that follow.

4.2.2 Current connection

It is necessary to use external CTs with a primary rating adequate to the load to be metered and with a 5A

secondary rating. The number of CTs to be used (1, 2 or 3) depends upon the type of network.

Connect the CT output(s) to the terminals marked CURRENT INPUT of the instrument according to the

applicable diagrams that follow.

Use cables with cross-section adequate to the VA rating of the CT and to the distance to be covered. The

max cross-section for the terminals is 4 mm

N.B. The CT secondary must always be in short circuit when not connected to the instrument in order to

avoid damages and risks for the operator.

Warning: THE PHASE RELATIONSHIP AMONG VOLTAGE AND CURRENT SIGNALS MUST BE

CAREFULLY RESPECTED. ALL DISREGARD OF THIS RULE OR OF THE WIRING DIAGRAM

LEADS TO SEVERE MEASUREMENT ERRORS.

2

.

10

4.2.3 4W Star Connection (4 wires)

Low voltage 3 CTs Average or high voltage 3 TCs 3 CTs

Configuration 3P 4W Configuration 3P 4W

Low Voltage 1 CT (balanced and symmetric)

Configuration 3P-b 4W

11

4.2.4 3W Delta Connection (3 wires)

Connection with 3 CTs Connection with 1CT

Low Voltage 3 CTs Low Voltage 1 CT

3P 3W Configuration 3P-b 3W Configuration

(Balanced and symmetric)

4.2.4.1 L1 L3 Phase Connection with 2 CTs

Low Voltage Average or High Voltage

3P 3W Configuration 3P 3W Configuration

12

4.2.4.2 L1 L2 Phase Connection with 2 CTs

Low Voltage 2 CTs Average or High Voltage 2 CTs 2 TCs

3P 3W Configuration 3P 3W Configuration

4.2.5 2 Wire Connection (single phase)

Low Voltage Neutral phase 1 Ct

1P 2W Configuration

13

4.2.6 2 Wire Connection (double phase)

×

Low Voltage phase 1 CT

2P 2W Configuration

4.3 Output Connection

The instrument is equipped with two opto-isolated transistor outputs rated 27 Vdc, 27 mA (DIN 43864

standards).

The outputs working mode is set by default to operate as pulse output proportional to the Active energy

(output 1) and to the Reactive energy (output 2). They support an output rate of 1.000 pulses per kWh (or

kvarh) referred to the instrument input range without any CT and PT multiplier.

In order to calculate the energy value of each pulse the following formula must be considered.

KK

×

PTCT

K

=

P

Example: CT = 100/5; PT = 20.000/100

Other pulse rate settings may be however programmed as described in the instrument set up section.

The operating mode of the digital outputs may also be changed to work as alarm output or as remote output

device controlled by the Modbus protocol as described in the instrument set up section.

/

kWhPulse

Where: K

= energy of each pulse; KCT = CT ratio ; K

p

Pulse/kWh = Pulse rate

20020

=

P

1000

=

pulsekWhK

/4

= PT ratio ;

PT

or kWh = Pulse count / 4

14

4.4 Connecting Optional Components

The optional components of X3M are assembled on the back panel of the instrument, where the RJ45

connectors are located

The optional component feature settings are only displayed when one of them is connected to the instrument

CN1 = 4-20 mA module or Hardware key

CN2 = RS485 or RS232 interface

4.4.1 RS485 Option

15

4.4.2 RS232 Option

4.4.3 Double 4-20 mA analogic Output Option

Self powered output, do not use external power supply.

16

5 Instrument Use

The programming procedure allows to vary the instrument functioning parameters.

You can enter the procedure with the button Program located at the back of the instrument.

In this environment, you can enter the measurement parameters and the network configuration.

The various fields can be selected by pressing the

button which also allows navigating to all the Setup

pages

Pressing the

and buttons you can modify the selected input fields (flashing)

The content of a field can be either numeric or a parameter controlling the device behavior.

The button

advances to the next page, while selects the previous page

By pressing the button PROGRAM (while in any configuration page) the menu is exited and the configuration

saved.

17

5.1.1 Set up sequence

Within the first page of the instrument set up menu, the following functions are available too.

- a pressure of the

- a pressure of the

Here below the page format and the programming flow.

key opens the energy counters reset page.

key opens the reset page of the average and maximum demand.

NOTE: all the modifications to the instrument programming parameters are effective

only when you exit the programming page pressing the PROGRAM button located

on the instrument rear panel.

18

5.1.2 Configuration Procedure

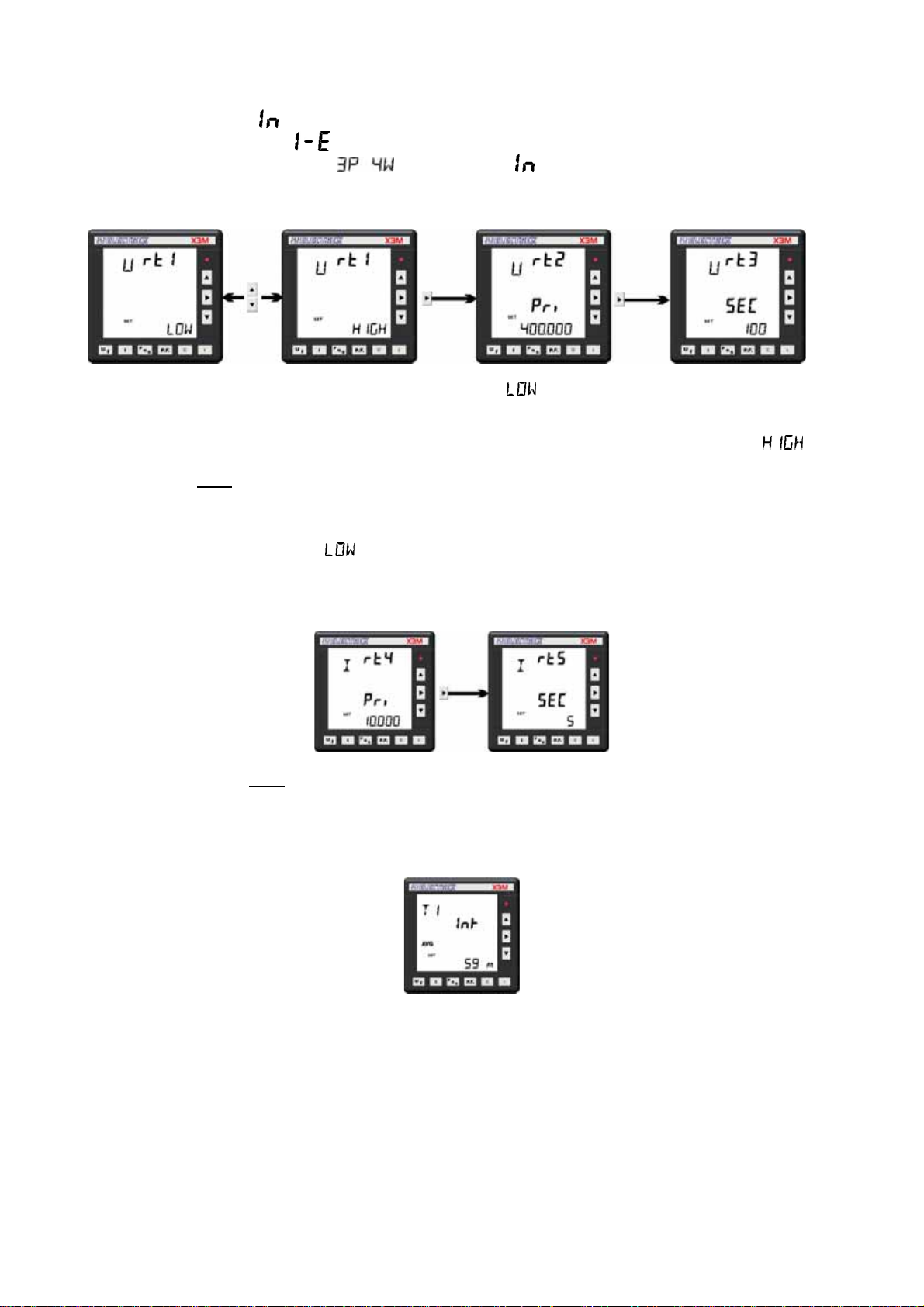

5.1.2.1 Electrical system configuration

The first programming page shows the configuration of the type of electrical system.

The first selection sets the type of electrical system and the type of wiring used:

• 3 phase 4 wire system

• 3 phase 3 wire system

• balanced 3 phase 4 wire system (1 CT only)

• balanced 3 phase 3 wire system

• single phase system

• double phase system

, Star ,

, delta ,

,

,

.

The second selection sets whether the operating mode is:

19

• Import only user

• Import-Export system

The instrument is set by default to

CTs connection errors

The following page enables to set the type of voltage measurement.

.

and Import only mode. and automatically corrects possible

If the voltage measurement is direct in low voltage, select

setting page.

If the voltage measurement is made on the HT side and/or via a voltage transformer, select

proceed to the next page for setting the Volatge transformer (PT) primary and secondary values

Enter the PT rated

measurement are unsuitable to this purpose.

The primary and the secondary values must be integers, the ratio can also be fractional.

The instrument is set by default to

After the voltage setting, the current set up page is prompted for programming the CT values; it requires the

entry of the CT primary rating and the CT secondary rating.

Ensure to enter the CT rated

When using 2 or 3 current transformers ensure that all the current transformers have the same ratings.

The instrument is set by default to [

The next page allows to set the integration time for calculating the Average and the Maximum Demand.

primary and secondary values indicated on the PT label; the values taken by

primary and secondary values as indicated on the CT label.

00005/5].

; the menu passes directly to the currents

and

The value is expressed in minutes in a 1 to 60 min. range.

The instrument supports two average values: one calculated by using the sliding window method and the

other one calculated on a fixed time basis. The time setting that is programmed by keyboard is the average

demand integration time with the sliding window method. The Maximum Demand too is calculated on the

sliding window basis.

The integration time on a fixed time basis is used for storing the energy data however this setting is available

only as a MODBUS register via serial port setting.

20

5.1.2.2 Communication Parameters Configuration

This menu appear only upon connection to the instrument of an RS-485 or an RS-232 optional module.

The setting of the RS485 communication characteristics requires to scroll the programming pages with two

keys;

The

key advances to the next page, the key returns to the previous page

The first page is the following:

This page enables the setting of respectively:

- communication speed

- number of data bits

- parity

- stop bits

All these data are correlated depending upon the stop bit value.

Additional parameters regarding the MODBUS communication protocol may be

set in the next page:

- Mode: it may be configured to RTU or to ASC (ASCII) mode.

- Slave Address

- Transmission delay; it stands for the time delay the instrument will wait prior

to reply to a data query. It is expressed in milliseconds, the default value is

100 msec and a 0 setting is also possible.

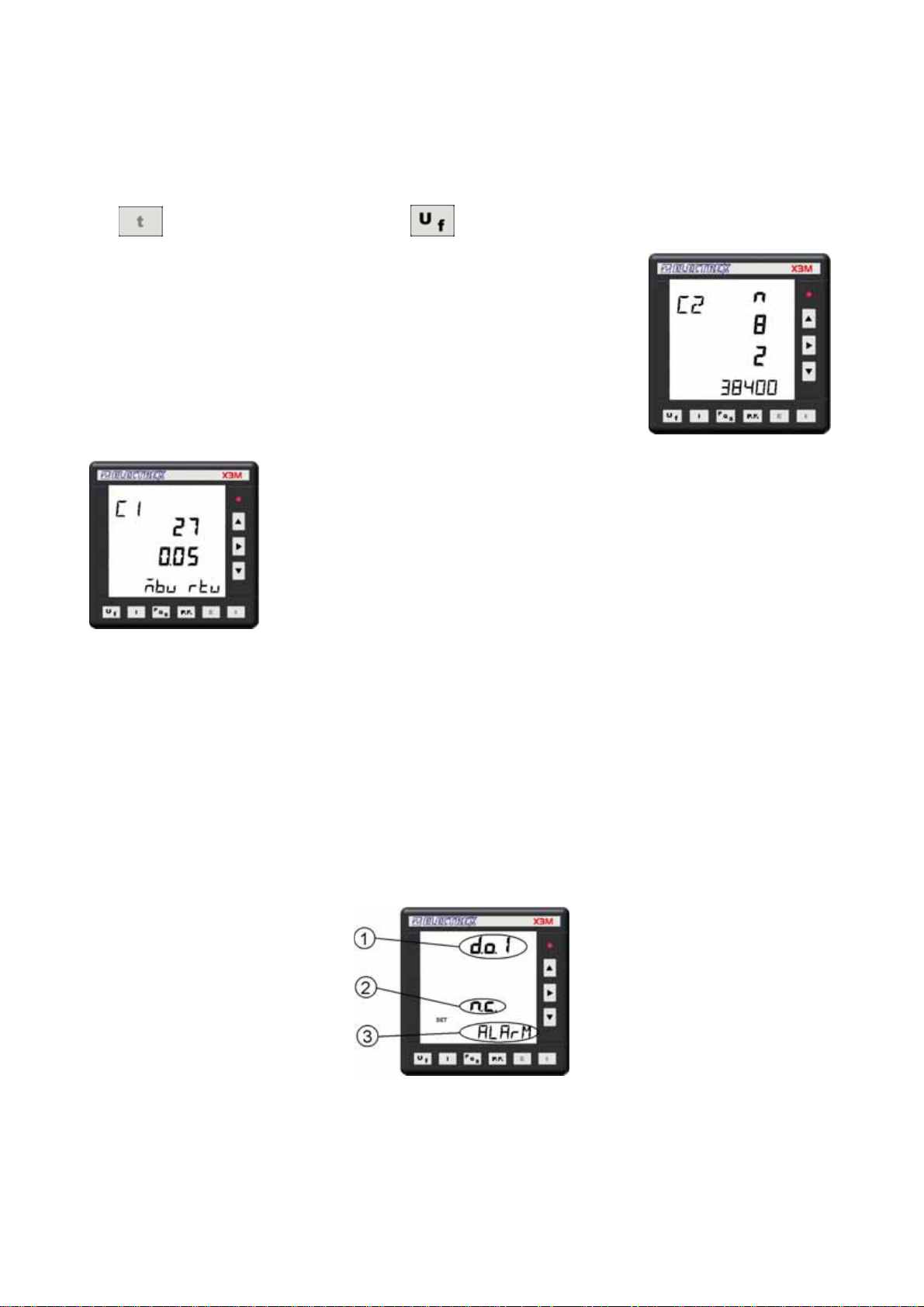

5.1.2.3 Output Configuration

The instrument is equipped with 2 digital outputs that are set by default to operate as pulse outputs

proportional to P

instrument range without any CT and PT multiplier.

The operating mode of digital outputs may be changed to operate as alarm output or as remote output

device controlled by the Modbus protocol.

When operating on the Modbus protocol, in order to ensure a protection to the outputs in case of

communication failure, it is possible to configure a watchdog timer (programmable from 0 to 60 minutes; 0 =

disabled).

The following entry fields are prompted (example for output 1):

(output 1) and Q∑ (output 2) at a rate of 1.000 pulses per kWh (or kvarh) referred to the

∑

(1) Digital out number being programmed.

(2) Contact: it configures the rest state of the output transistor.

n.c. normally closed or n.o. normally open:

(3) Mode of operation:

PULSE (default setting) for operation as pulse output

21

ALARM for operation as alarm contact output

REM Remote for operation as remote output device controlled via Modbus

5.1.2.4 Pulse characteristics configuration

If the PULSE selection is operated, the following page is shown allowing the configuration of the pulse

characteristics:

Where:

(1) Pulse output number being programmed.

(2) Pulse duration in mSec; programmable from 50 up to 900 in steps of 10

(3) Identifies the quantity proportional to the pulse output, selecting among:

Imported Active Power (import)

Inductive reactive Power with imported Active Power

Capacitive reactive Power with imported Active Power

Apparent Power with imported Active Power

Exported Active Power (export)

Inductive reactive Power with exported Active Power

Capacitive reactive Power with exported Active Power

Apparent Power with exported Active Power

(4)

the pulses take into account the CT and PT ratio and are referred to their primary readings

the pulses are referred to the CT (and PT) secondary reading without any multiplier .

(5) Pulse weight: programmable from 0,1 Wh up to 1 MWh through all the intermediate steps.

Example: 1.0 Wh = 1000 pulses/kWh.

(6) Identifies SETUP.

5.1.2.4.1 Pulse output set up with Modbus registers.

To set up the pulse output the Modbus Holding Registers from 120 to 127 have to be used.

Refer to chapter 9 for the details.

22

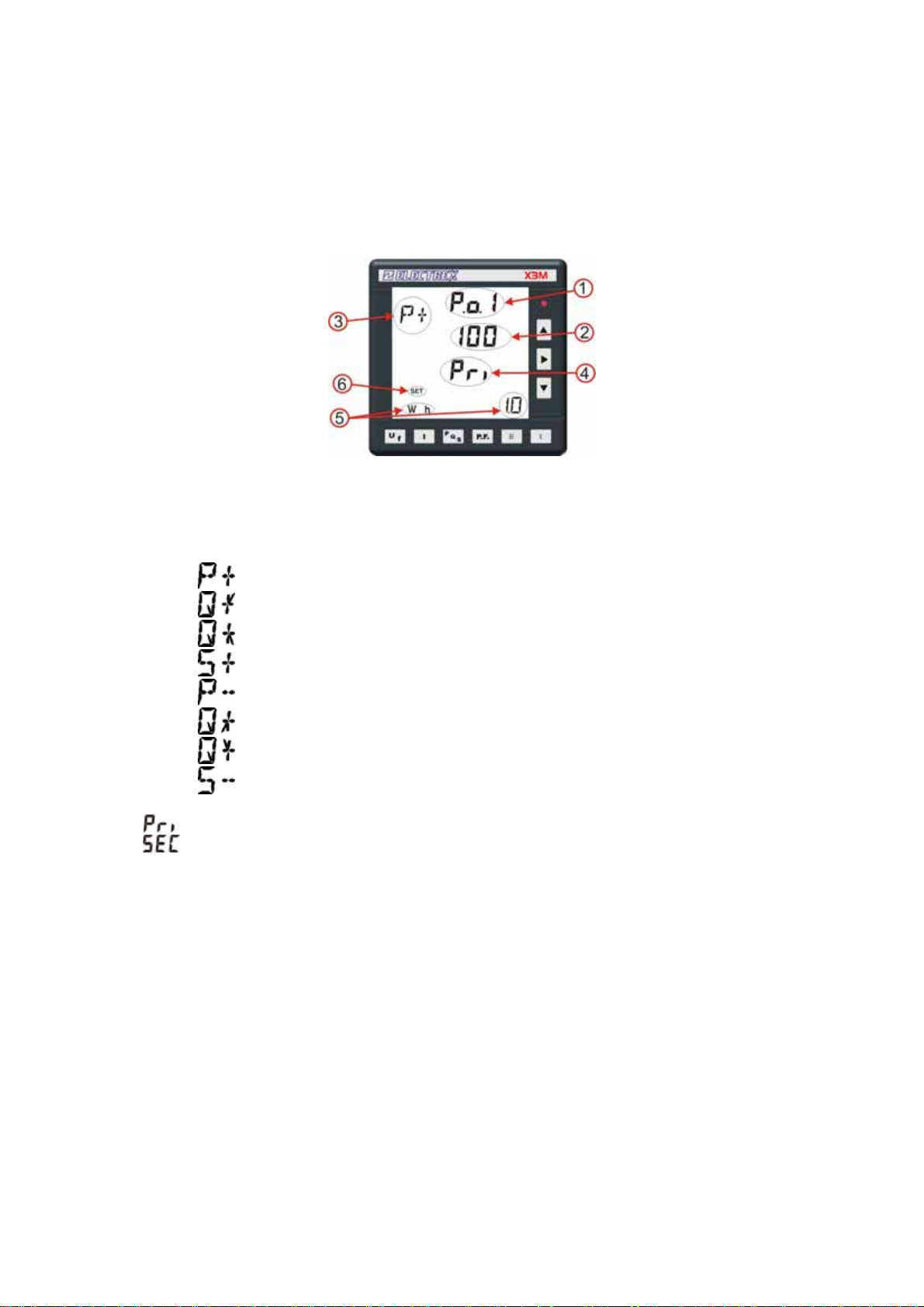

5.1.2.5 Alarm Configuration

The Instrument is equipped with two alarms that are triggered by a programmable threshold on anyone of

the measured parameters.

The types of alarm available are: maximum, minimum and 1-of-3.

A minimum alarm is triggered when the selected parameter is lower than the alarm threshold.

A maximum alarm is triggered when the selected parameter exceeds the alarm threshold.

A 1-of-3 alarm is triggered when anyone of the phase readings, whichever the phase involved, trespasses

the alarm threshold – this alarm can be either maximum or minimum. On a 1-of-3 current alarm, the

threshold is expressed as percentage (rather than a value) that stands for the unbalance between the

phases. The alarm therefore triggers when the percent difference between two of the three phases exceeds

the threshold; it is calculated as 100 x (I

All alarms allow also the setting of an hysteresys and a delay time.

The hysteresys (in percent) sets the difference between the triggering threshold and the end threshold (this

prevents repeated alarm triggering when the reading oscillates around the trigger value). Example: a 5%

hysteresys on a threshold of 100, triggers the alarm when the reading exceeds 100 but it will switch off the

alarm when the reading becomes lower than 95.

The delay time sets a time delay for triggering on the alarm after its actual occurrence (or triggering off after

its actual end).

The alarm setup procedure is activated from the output configuration screen or at the end of page

max

– I

min

)/I

max

.

configuration using the

button or the button.

The fields meaning of Alarm 1 is as follows:

(A) Alarm No. identification (AL1 = alarm 1 that may be associated to output 1)

(1)Parameter type applying to Alarm 1. The possible choices are:

-- Disabled

U Voltage

f Frequency

I Current

P Active Power

Q Reactive Power

S Apparent Power

λ (PF) Power Factor

THD

U

THD

Total Harmonic Distortion (current)

I

Total Harmonic Distortion (voltage)

(2) Quantity definition: The possible definitions are:

Average star value (voltage, current and THD only).

Average system voltage (voltage and voltage THD only)

Neutral value (current only)

Three phase power (only on active, reactive, apparent power)

23

L1 Phase 1 quantity.

L2 Phase 2 quantity.

L3 Phase 3 quantity.

L1-L2 Phase L1 phase L2 value (Phase to phase Voltages and THD only)

L2-L3 Phase L2 phase L3 value (Phase to phase Voltages and THD only)

L3-L1 Phase L3 phase L1 value (Phase to phase Voltages and THD only)

1di 3

Alarm on all three phases. The symbols L1-L2, L2-L3 and L3-L1 are flashing

(voltage and THD only).

1di 3

AVG Alarm on average powers.

(3)Threshold voltage: programmable in the range –1999 +1999

(4)Decimal point position. The quantity can be scaled by powers of ten by using the m, K, M symbols

and the decimal point. Range is between 10-3 and 109.

(5)Hysteresis value, from 0% to 99%

(6)Latency time, from 0 to 99 seconds

(7)Output trigger type. n=normal (the relay is active for the duration of the alarm), p=pulsed (the alarm

triggering generates a pulse).

(8) Alarm type: M=max; m=min

The procedure for alarm 2 is identical.

Alarm on all the three phases. The symbols L1, L2 and L3 are flashing

(voltage,current and THD only).

5.1.2.5.1 Alarm set up with Modbus registers.

To set up the alarm t the Modbus Holding Registers from 95 to 106 have to be used.

Refer to chapter 9 for the details.

24

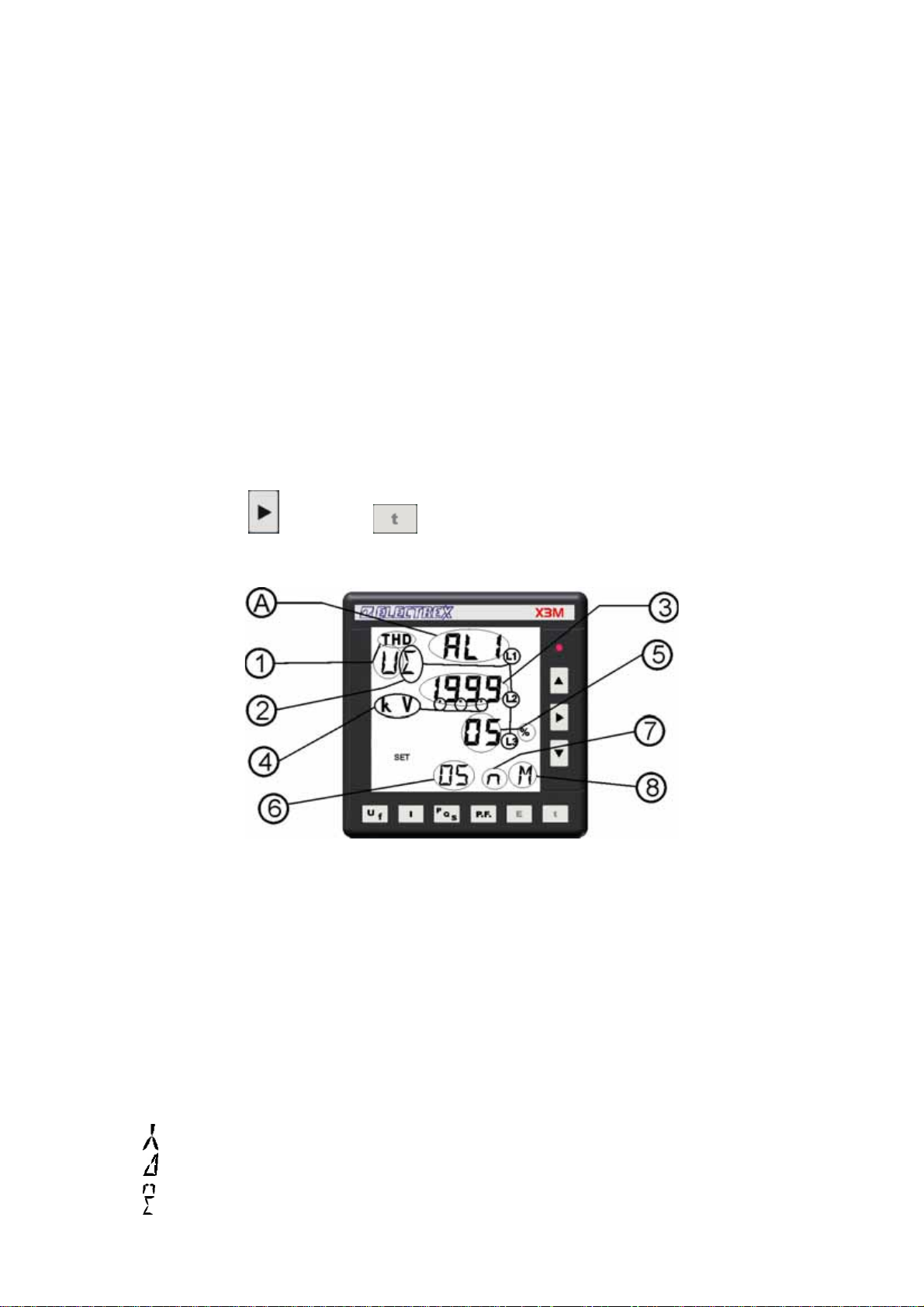

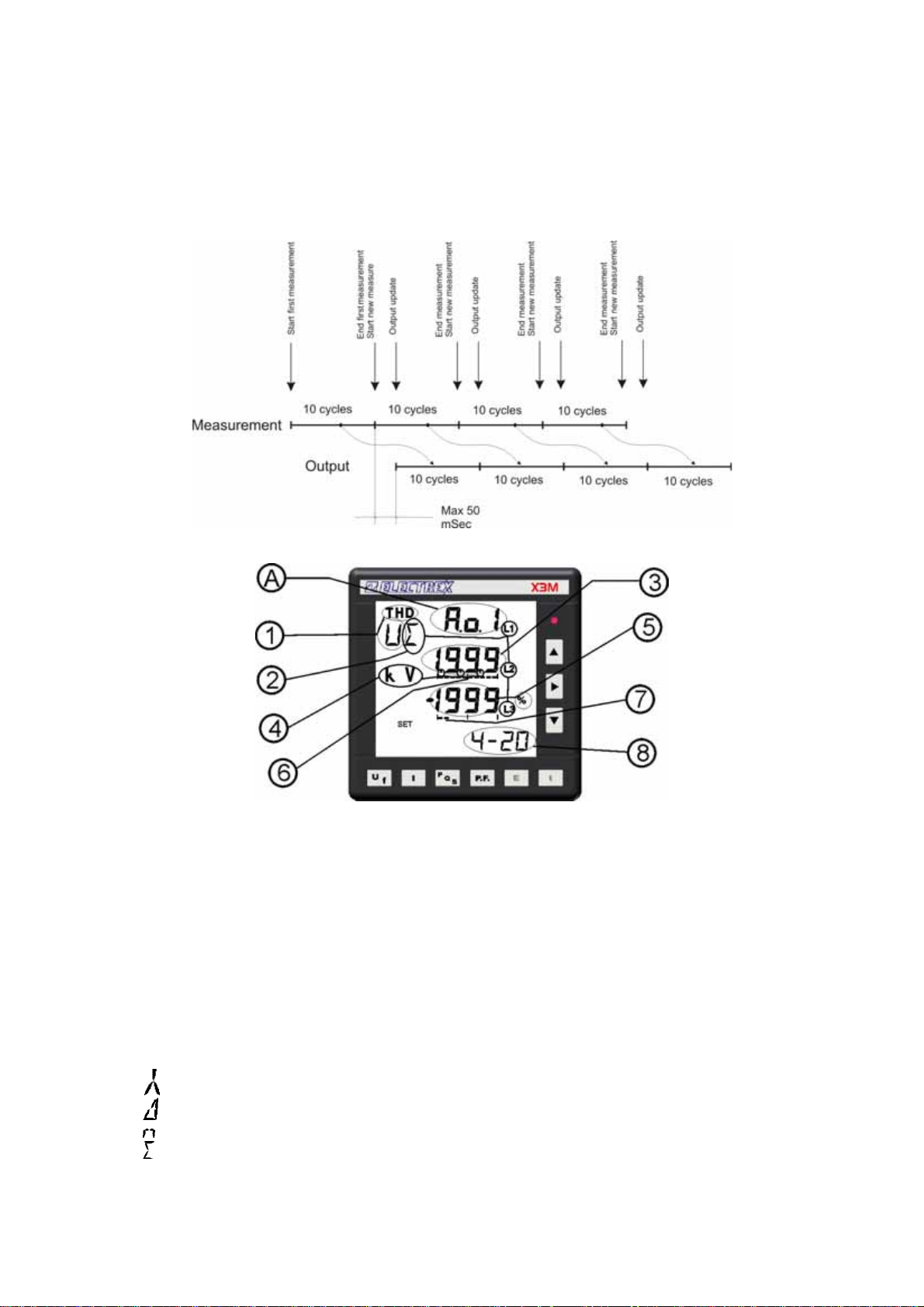

5.1.2.6 Analog 4-20 mA Outputs Configuration.

The instrument supports two 4-20 mA or 0-20 mA analog outputs with 500 ohms maximum load. Each output

is to one of the parameters handled by the instrument.

The output is updated every 10 cycles of the network frequency (i.e. every 200mSec with 50 Hz mains) with

a maximum delay of 50 mSec from the actual measurement.

(A)Output identification, A.o.1 = Analog output 1.

(1) Parameter applying. The possible choices are:

-- Disabled

U Voltage

f Frequency

I Current

P Active Power

Q Reactive Power

S Apparent Power

λ (PF) Power Factor

THD

THD

U

I

Total Harmonic Distortion (Voltage)

Total Harmonic Distortion (Current)

(2) Parameter definition: The possible choices are:

Average star value (applicable to voltage, current and THD only).

Average system value (applicable to voltage and THD only).

Neutral value (applicable to current only)

Three phase value (applicable to active, reactive and apparent power only)

L1 Phase 1 Value.

L2 Phase 2 Value.

L3 Phase 3 Value.

25

L1-L2 Phase-phase (L1-L2) value (applicable to system voltages and THD only)

L2-L3 Phase-phase (L2-L3) value (applicable to system voltages and THD only)

L3-L1 Phase-phase (L3-L1) value applicable to system voltages and THD only)

AVG Average value (applicable to average powers - demand - only).

(3) Threshold voltage: programmable in the range –1999 +1999

(4) The quantity can be scaled by powers of ten by using the m, K, M symbols and the decimal point.

Range is between 10-3 and 109.

(5) Beginning of range value (4 or 0 mA), programmable from –1999 to 1999.

(6) It can be associated to the above value and it identifies it as end of scale value (end of range

symbol). It cannot be modified.

(7) Associated to the value above identifies it as beginning of range value (empty on 0 mA, two marks

on 4 mA). It cannot be changed

(8) Output type: 4-20 mA or 0-20 mA.

Output 2 requires the same procedure

5.1.2.6.1 Analog output set up with Modbus registers.

To set up the analog output the Modbus Holding Registers from 80 to 91 have to be used.

Refer to chapter 9 for the details.

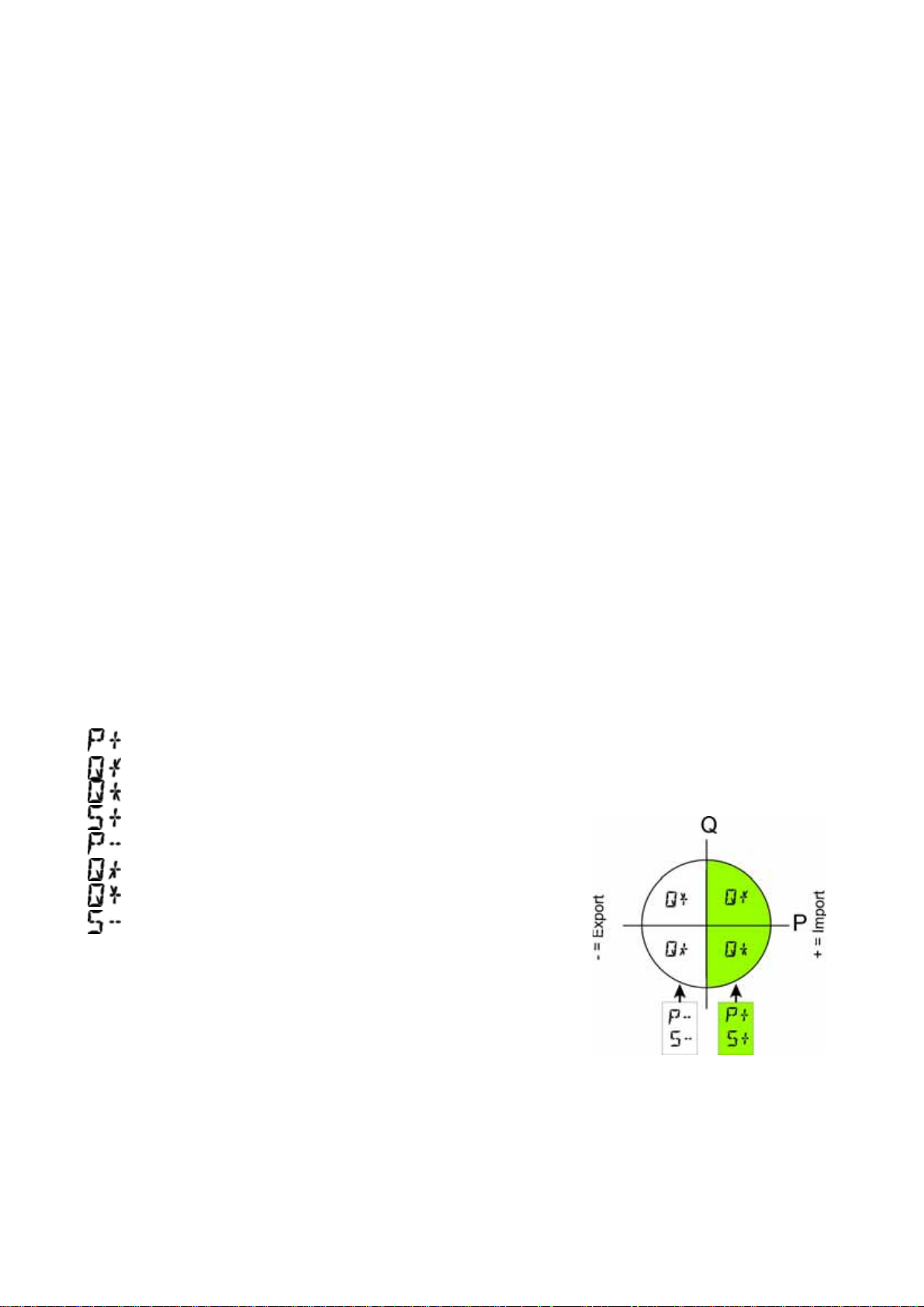

5.1.2.6.2 4-20 mA output configuration of the average AVG values

In Import-Export mode, the instrument can provide the measuring on the 4 dials, but the selection can be

made on a dial at a time.

In selection mode, the measures are visualized as follows:

Imported Active Power (import)

Inductive reactive Power with imported Active Power.

Capacitive reactive Power with imported Active Power

Apparent Power with imported Active Power

Exported Active Power (export)

Inductive reactive Power with exported Active Power

Capacitive reactive Power with exported Active Power

Apparent Power with exported Active Power

The quadrant selection is operated according to the following

trigonometric convention:

26

5.1.2.7 Clock calendar configuration (for X3M-D only)

The X3M-D is equipped with a clock/calendar with internal battery having a 15 years life time.

The clock/calendar supports the time zone handling functions and the automatic change from Standard Time

to Daylight Saving Time and vice versa.

The instrument is set by default to the Europe/Rome time and time zone.

The clock/calendar setting is covered by the last two SETUP pages.

Clock format

The following Time formats are foreseen:

Coordinated Universal Time (UTC): commonly known as GMT (Greenwich Mean Time): it is the

universal time, applicable to any place on earth.

Standard Time: it is the local time of a specific time zone, based on the sun cycles (known as Solar

Time

Daylight Saving Time it is the local time of a specific time zone when an offset on standard time is

applied (DST offset). The introduction of this offset allows to increase the availability of hours with

natural light in the summer evenings.

Wall time: it is how we refer to the clock time in each time zone. The Wall time actually coincides with

the Daylight Saving Time or the Standard Time depending whether an offset Solar time is

occurring or not.

The difference between Standard Time and UTC time is called GMT offset.

Summarizing:

GMT offset = UTC – Standard Time

Wall Time = Standard Time + DST offset = UTC + GMT offset + DST offset

The instrument RTC supports the following time information:

• UTC Date/time

• Time zone identification

Starting from the UTC time, the instrument automatically calculates the local time (Wall Time) of any place

on earth

The pertinent time zone is entered to the instrument by a numeric index (time zone index) either on the set

up procedure or on a MODBUS register.

NOTE:

The clock is updated by using the local time or “wall time” that the instrument converts in UTC, consequently,

if the time zone is wrong, the clock will be wrong too.

The instrument clock operates in UTC, therefore a correct time zone attribution is essential. Check

whether the time zone entry is correct before modifying the clock. Otherwise a wrong time setting

could be involuntarily programmed

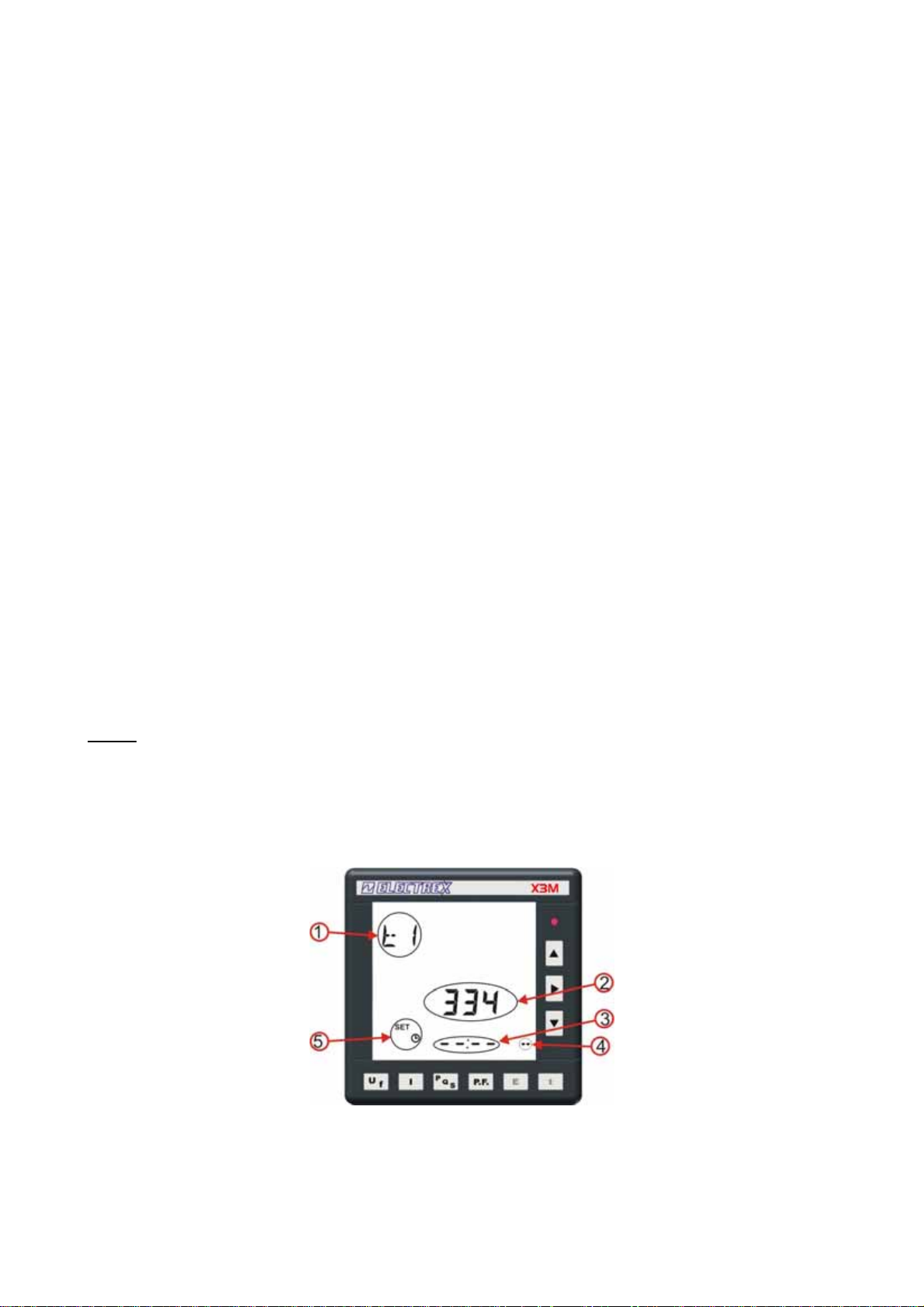

(1) It identifies the time programming page N° 1.

(2) Time zone 334 = Europe/Rome is valid all over central Europe. See the enclosed layout to identify

the right time zone

27

(3) Time Configuration in hours and minutes. Starting the selection the configuration is

Pushing the button

first the hours then the minutes. The hour change will occur only exiting the programming mode.

The hour change will influence the data storage thus it is important to operate modifications only if

strictly necessary, otherwise leave to the instrument management software the clock update.. If

you maintain the configuration

edited and clock changes be avoided, it is necessary to set the display to

located after the last valid hour or minute (i.e. beyond 11 pm or under 12 am).

(4) Identifies the standard time.

summer time.

(5) Identifies the clock set up page.

and it is possible to visualize the actual time and date and modify them,

the clock will not be modified. Should modifications be

which is

while identifies the daylight saving or

In the second page of clock set up it is possible to program the calendar.

(6) It identifies the time programming page N° 2.

(7) Area of calendar setting and starting from left: year, month, day

it is possible to avoid the modification saving, switching to the initial position

which does not save modifications.

. Even for the date

5.1.2.7.1 Clock set up with Modbus registers.

To set up the calendar clock the Modbus Holding Registers from 140 to 165 have to be used.

Refer to chapter 9 for the details.

28

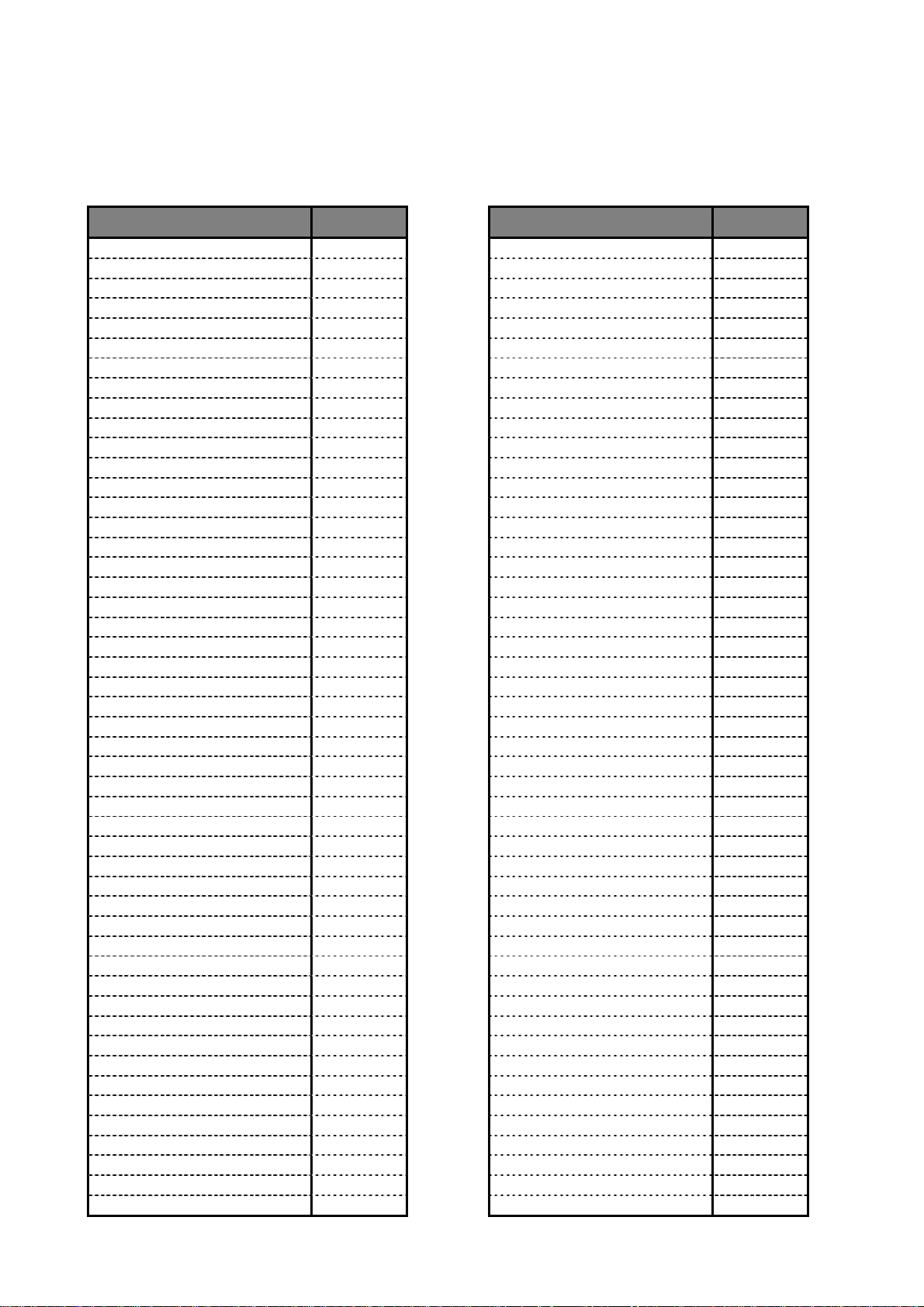

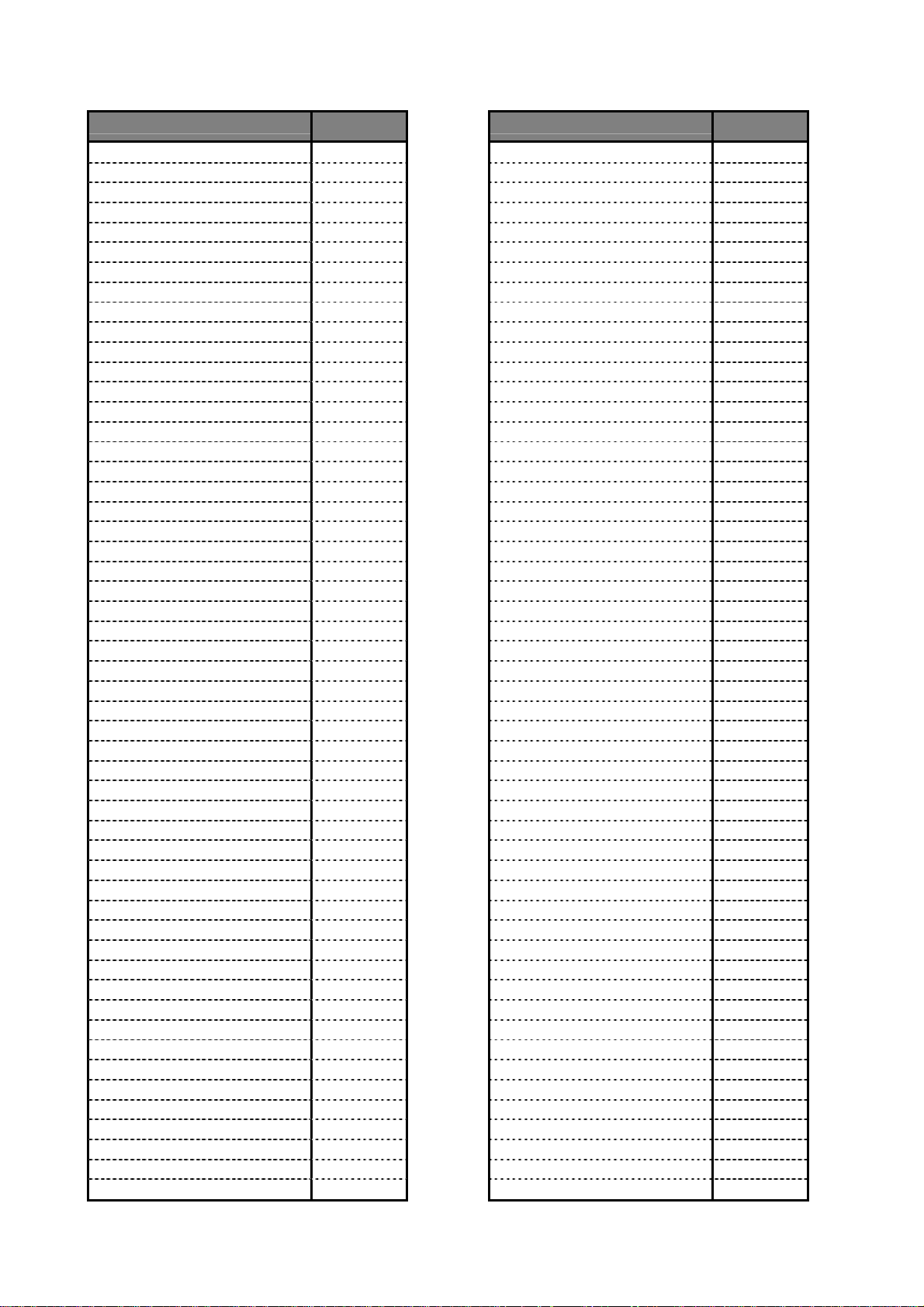

5.1.2.7.2 Time zones

The pertinent time zone is entered to the instrument by a numeric index (time zone index).

The time zone index and the standard time zone names are shown in the charts below:

Standard Timezone Name (FW > 1.06)

Africa/Abidjan

Africa/Accra

Africa/Addis_Ababa

Africa/Algiers

Africa/Asmera

Africa/Bamako

Africa/Bangui

Africa/Banjul

Africa/Bissau

Africa/Blantyre

Africa/Brazzaville

Africa/Bujumbura

Africa/Cairo

Africa/Casablanca

Africa/Ceuta

Africa/Conakry

Africa/Dakar

Africa/Dar_es_Salaam

Africa/Djibouti

Africa/Douala

Africa/El_Aaiun

Africa/Freetown

Africa/Gaborone

Africa/Harare

Africa/Johannesburg

Africa/Kampala

Africa/Khartoum

Africa/Kigali

Africa/Kinshasa

Africa/Lagos

Africa/Libreville

Africa/Lome

Africa/Luanda

Africa/Lubumbashi

Africa/Lusaka

Africa/Malabo

Africa/Maputo

Africa/Maseru

Africa/Mbabane

Africa/Mogadishu

Africa/Monrovia

Africa/Nairobi

Africa/Ndjamena

Africa/Niamey

Africa/Nouakchott

Africa/Ouagadougou

Africa/Porto-Novo

Africa/Sao_Tome

Africa/Timbuktu

X3M-D

Timezone Index

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Standard Timezone Name (FW > 1.06)

Africa/Tripoli

Africa/Tunis

Africa/Windhoek

America/Adak

America/Anchorage

America/Anguilla

America/Antigua

America/Araguaina

America/Argentina/Buenos_Aires

America/Argentina/Catamarca

America/Argentina/ComodRivadavia

America/Argentina/Cordoba

America/Argentina/Jujuy

America/Argentina/La_Rioja

America/Argentina/Mendoza

America/Argentina/Rio_Gallegos

America/Argentina/San_Juan

America/Argentina/Tucuman

America/Argentina/Ushuaia

America/Aruba

America/Asuncion

America/Bahia

America/Barbados

America/Belem

America/Belize

America/Boa_Vista

America/Bogota

America/Boise

America/Cambridge_Bay

America/Campo_Grande

America/Cancun

America/Caracas

America/Cayenne

America/Cayman

America/Chicago

America/Chihuahua

America/Costa_Rica

America/Cuiaba

America/Curacao

America/Danmarkshavn

America/Dawson

America/Dawson_Creek

America/Denver

America/Detroit

America/Dominica

America/Edmonton

America/Eirunepe

America/El_Salvador

America/Fortaleza

X3M-D

Timezone Index

49

50

51

52

53

54

55

56

66

71

400

76

109

401

121

402

403

404

405

57

58

59

60

61

62

63

64

65

67

68

69

70

72

73

74

75

77

78

79

80

81

82

83

84

85

86

87

88

89

29

Standard Timezone Name (FW > 1.06)

America/Glace_Bay

America/Godthab

America/Goose_Bay

America/Grand_Turk

America/Grenada

America/Guadeloupe

America/Guatemala

America/Guayaquil

America/Guyana

America/Halifax

America/Havana

America/Hermosillo

America/Indiana/Knox

America/Indiana/Marengo

America/Indiana/Vevay

America/Indianapolis

America/Inuvik

America/Iqaluit

America/Jamaica

America/Juneau

America/Kentucky/Monticello

America/La_Paz

America/Lima

America/Los_Angeles

America/Louisville

America/Maceio

America/Managua

America/Manaus

America/Martinique

America/Mazatlan

America/Menominee

America/Merida

America/Mexico_City

America/Miquelon

America/Monterrey

America/Montevideo

America/Montreal

America/Montserrat

America/Nassau

America/New_York

America/Nipigon

America/Nome

America/Noronha

America/North_Dakota/Center

America/Panama

America/Pangnirtung

America/Paramaribo

America/Phoenix

America/Port_of_Spain

America/Port-au-Prince

America/Porto_Velho

America/Puerto_Rico

America/Rainy_River

X3M-D

Timezone Index

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

110

111

112

113

114

115

116

117

118

119

120

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

141

140

142

143

144

Standard Timezone Name (FW > 1.06)

America/Rankin_Inlet

America/Recife

America/Regina

America/Rio_Branco

America/Santiago

America/Santo_Domingo

America/Sao_Paulo

America/Scoresbysund

America/St_Johns

America/St_Kitts

America/St_Lucia

America/St_Thomas

America/St_Vincent

America/Swift_Current

America/Tegucigalpa

America/Thule

America/Thunder_Bay

America/Tijuana

America/Toronto

America/Tortola

America/Vancouver

America/Whitehorse

America/Winnipeg

America/Yakutat

America/Yellowknife

Antarctica/Casey

Antarctica/Davis

Antarctica/DumontDUrville

Antarctica/Mawson

Antarctica/McMurdo

Antarctica/Palmer

Antarctica/Rothera

Antarctica/Syowa

Antarctica/Vostok

Asia/Aden

Asia/Almaty

Asia/Amman

Asia/Anadyr

Asia/Aqtau

Asia/Aqtobe

Asia/Ashgabat

Asia/Baghdad

Asia/Bahrain

Asia/Baku

Asia/Bangkok

Asia/Beirut

Asia/Bishkek

Asia/Brunei

Asia/Calcutta

Asia/Choibalsan

Asia/Chongqing

Asia/Colombo

Asia/Damascus

X3M-D

Timezone Index

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

30

Loading...

Loading...