Page 1

Elecraft® KX3

KXBC3 NiMH Battery Charger and

Real Time Clock

Installation Instructions

Revision A2, October 19, 2012

opy

C

right © 2012, Elecraft, Inc., All Rights Reserved

Introduction

When the KX3 is equipped with an internal battery using eight AA size NiMH cells, the KXBC3 allows

charging the battery from an external 13.8 VDC supply without removing it from the KX3. The KXBC3 also

provides a Real Time Clock and 24 hour alarm that will automatically power up the KX3.

The internal battery powers the KX3 whenever the external power source is removed, or any time the external

power supply voltage falls below the internal battery voltage. Although any type of AA size cells may be used

for the KX3 internal battery, only NiMH cells rated at 1900 mAH or greater may be charged with the KXBC3.

Installation involves opening the KX3 as if you were changing batteries and then using a screwdriver to remove

the KX3 battery retainer and replace it with the KXBC3 module.

The KXBC3 module and many components inside your KX3 may be damaged by

Electrostatic Discharge (ESD) simply by touching them or a circuit board containing

them unless you take specific steps to prevent such damage. See Preventing

Electrostatic Discharge Damage on page 5 before opening the package containing the

KXBC3 module or working inside your KX3.

Specifications

Battery Compatibility:

Read Charging Batteries on pg 3 for important safety information before charging batteries!

Charging Current:

Charging Temperature:

External Power Supply:

Real Time Clock:

Clock Holdup Time:

CAUTION

NiMH type batteries with a capacity of 1900 mAH or higher.

200 mA

0º C to 40º C.

13.8 V at 500 mA for receive only when charging; approx. 3 amperes when

transmitting and charging.

Time of day (hh:mm:ss) with 24 hour alarm that will wake up the KX3 if

power is off.

≥ 5 minutes. Allows changing the internal batteries without losing time or

alarm setting. The clock continues to run during this time.

1

Page 2

Setup and Operation

If you haven’t already done so, follow the instructions starting on pg 5 to install your KXBC3 module.

You must have firmware revision 01.22 or later installed in your KX3 for the KXBC3 module to operate as

described here. Check the firmware currently installed as follows:

1. Turn the KX3 on (hold the

BAND- and ATU TUNE switches simultaneously).

2. Hold MENU to enter the menu and then turn the OFS/VFO B knob to select FW REVS.

See Firmware Upgrades in your Owner’s manual for details about how to upgrade your firmware if needed.

Real-Time Clock and Alarm

The real-time clock operates in 24 hour time format and includes an alarm that can be used to wake up the KX3

at a preset time.

Set the real- time clock as follows:

3. Turn the KX3 on (hold the

4. Hold MENU to enter the menu and then turn the OFS/VFO B knob to select TIME.

5. Enter the current time as follows:

Tap

1 and turn the VFO A knob to display the correct hours on the display (the clock displays

times in 24-hour format).

Tap

2 and turn the VFO A knob to display the correct minutes on the display.

Tap 3 and turn the VFO A knob to display the correct seconds on the display.

DISP

6.

Tap

to exit the menu.

BAND- and ATU TUNE switches simultaneously).

The clock will continue to run for up to 5 minutes with the power disconnected so you can change batteries

without needing to reset the time.

Set the alarm as follows:

1. Turn the KX3 on (hold the BAND- and ATU TUNE switches simultaneously).

2. Hold MENU to enter the menu and then turn the OFS/VFO B knob to select ALARM.

3. Enter the time that you want the KX3 to alert you as follows:

Tap

Tap 3 and turn the VFO A knob to the minutes.

Tap 1 and to turn the alarm on. The display will change from OFF to ON.

4. Tap DISP

2 and turn the VFO A knob to set the hour.

to exit the menu.

An asterisk ( ) will appear to the left of the time in the VFO B area of the display indicating that the alarm has

been set.

At the selected alarm time, the KX3 will emit a series of short beeps and the alarm will shut off automatically.

If you have turned the KX3 off, it will turn on automatically, with the volume set at the same level that it was

when turned off, and emit the series of short beeps. Only a few microamperes of current are required to keep the

clock running when the KX3 is off. This is supplied by either the external power supply or the internal batteries.

2

Page 3

Charging Batteries

For best results, use a set of cells of the same manufacture, age and mAH rating. Most cells will show some

charge even when new but they will have different levels of charge. It is normal to require several

charge/discharge cycles to balance the charges of all the cells making up the battery and give the best

performance.

WARNING!

To avoid injury to yourself or to the KX3:

Install only NiMH batteries rated for 1900 mAH or greater. Do not attempt to charge

any other type of battery.

Check the plastic coating on each cell for damage. The coating prevents shorts between

cells and the shield on the KXBC3 module or other metallic objects.

Do not install or change batteries with external power applied.

To start a charging cycle:

1. Connect the KX3 to an external power source and turn it on (hold the

simultaneously).

2. Hold MENU to enter the menu and turn the OFS/VFO B knob to select BAT CHG.

3. Turn the

VFO A knob to select CHG 4 Hr, 12 Hr or 16 Hr to set the charging time (see calculating

charging time below for help choosing the correct charging time).

4. Tap

DISP

to exit the menu and start the charging cycle.

BAND- and ATU TUNE switches

When charging is in progress, an asterisk ( ) will appear after BT when checking the battery voltage on the

VFO B display. (Tap

DISP and turn the OFS/VFO B knob to select BT.)

To stop a charging cycle:

1. Hold MENU to enter the menu and turn the OFS/VFO B knob to select BAT CHG.

2. Turn the

VFO A knob to select CHG OFF.

Power-Off Pending Mode

If you turn the KX3 off while charging is in progress, the KX3 switches to a Power-Off Pending Mode in which

the charger keeps operating and the charging cycle count-down timer is shown on the display although the KX3

is otherwise off. When the charging cycle is completed, the KX3 switches off entirely.

To exit the Power-Off Pending Mode, hold the BAND- and ATU TUNE switches to turn the KX3 on again,

enter the

BAT CHG menu and set the entry to CHG OFF.

Determining the Charging Time

NiMH cells are reasonably tolerant of over-charging. However, their life and capacity will be shortened by

routinely charging already fully charged or nearly full charged batteries.

NiMH cells have a fairly large self-discharge rate. Typically they will lose about 2% of their charge each day.

There are some types of NiMH cells available that have a lower self-discharge rate, but they typically have less

total capacity.

3

Page 4

The KXBC3 charges at 200 mA throughout the charging time set, suggesting that 2000 mAH cells would be

charged in 10 hours (referred in battery literature as a C/10 rate). However, the charging process is not 100%

efficient, so additional charging time must be added, typically 20%. So a fully depleted 2000 mAH battery

would require about 12 hours to reach full capacity.

The charging time must be adjusted for batteries of different capacity as follows:

Charging Time (hours) = 1.2 X (cell mAH rating) / 200

For example, to charge fully depleted 2500 mAH cells: 1.2 X 2500 / 200 = 15 hours (Set charger for 16 hours)

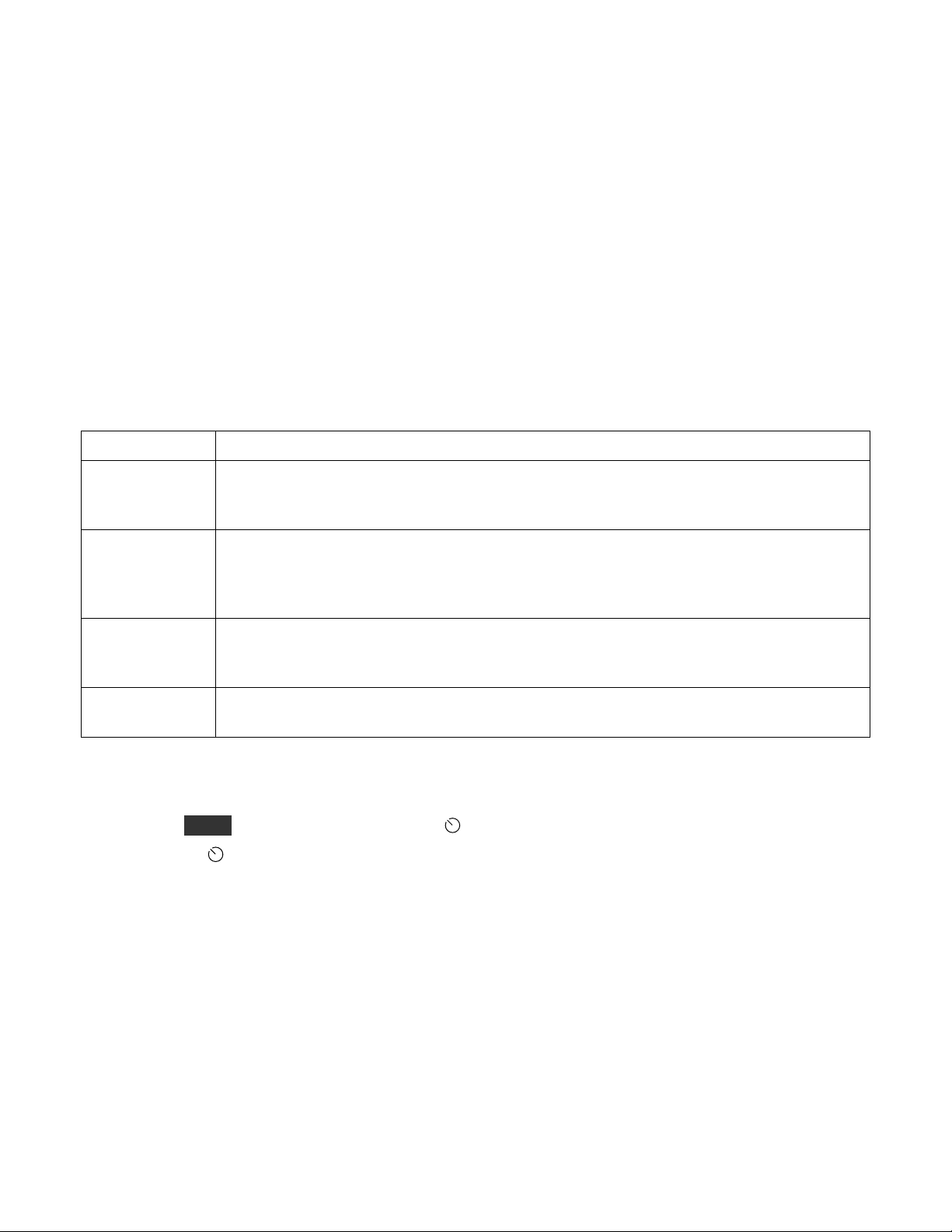

Protective Circuits

In addition to monitoring the requested charging time, the charging system monitors the battery temperature,

battery voltage and the power supply voltage. An error message will appear when you are in the

menu or when the battery is charging in Power-Off Pending Mode (pg 3) if any of the following conditions

exist:

Error Message Description

BAT CHG

NOT 0-40C

Battery temperature too high or too low. If this occurs when trying to start a charging cycle,

tap any switch to clear the message. If this occurs during a charging cycle, the charging

cycle will resume automatically when the condition is corrected.

LO SPPLY

The external power supply voltage is too low for charging the internal battery. If this occurs

when trying to start a charging cycle, tap any switch to clear the message. If this occurs

during a charging cycle, the charging cycle will resume automatically when the condition is

corrected.

BAT ERR

Battery missing or battery voltage out of range due to a fully charged pack or a defective or

missing cell. With the KX3 on, tap any switch to clear the message. The charging cycle is

terminated (does not restart automatically when the condition is corrected).

SYS FLT

KXBC3 system fault. With the KX3 on, tap any switch to clear the message. The charging

cycle is terminated (does not restart automatically when the condition is corrected).

Changing Battery Types

If you wish to replace the NiMH batteries with a different type, first turn the charger off;

1. Hold MENU to enter the menu and turn the OFS/VFO B knob to select BAT CHG.

2. Turn the

Leave the charger off until such time as you replace the battery with NiMH cells.

VFO A knob to select CHG OFF.

4

Page 5

Installing the KXBC3 Module

Preparing for Installation

Preventing Electrostatic Discharge Damage

ESD damage may occur with static discharges far too little for you to notice. A damaged component may not

fail completely at first. Instead, the damage may result in below-normal performance for an extended period of

time before you experience a total failure.

We strongly recommend you take the following anti-static precautions (listed in order of importance) to ensure

there is no voltage difference between the components and any object that touches them:

Leave the KXBC3 module in its anti-static packaging until you install it.

Wear a conductive wrist strap with a series 1-megohm resistor that will constantly drain off any static

charge that accumulates on your body. If you do not have a wrist strap, touch a ground briefly before

touching any sensitive parts to discharge your body. Do this frequently while you are working. You can

collect a destructive static charge on your body just sitting at the work bench.

WARNING

DO NOT attach a ground directly to yourself without a current-limiting resistor as this poses a

serious shock hazard. A wrist strap must include a 1-megohm resistor to limit the current flow. If

you choose to touch an unpainted, metal ground to discharge yourself, do it only when you are

not touching live circuits with any part of your body.

Use a grounded anti-static mat on your work bench (see below).

If you pick up a pc board that was not placed on an anti-static mat or in an anti-static package, touch

first a ground plane connection on the board such as a connector shell or mounting point.

If you use a soldering iron to work on a circuit board, be sure your iron has an ESD-safe grounded tip

tied to the same common ground used by your mat and wrist strap.

Choosing an Anti-Static Mat

An anti-static mat must bleed off any charge that comes in contact with it at a rate slow enough to avoid a shock

or short circuit hazard but fast enough to ensure dangerous charges cannot accumulate. Typically, a mat will

have a resistance of up to 1 Gigaohm (10

recommend that you choose an anti-static mat that comes with published resistance specifications and clean it as

recommended by the manufacturer. Testing has shown that many inexpensive mats that do not specify their

resistance have resistance values much too high to provide adequate protection, even after they were cleaned

and treated with special anti-static mat solutions.

Suitable anti-static table mats are available from many sources including:

U-line (Model 12743 specified at 10

Desco (Model 66164, specified at 10

3M

TM

Portable Service Kit (Model 8505 or 8507, specified at 106 to 109 ohms)

9

ohms). Testing a mat requires specialized equipment, so we

7

ohms)

6

to 108 ohms)

5

Page 6

Tools Required

1. ESD Protection (see Preventing Electrostatic Discharge Damage, pg 1).

2. #1 size Phillips screwdriver. To avoid damaging screws and nuts, a power screwdriver is not

recommended.

3. Soft cloth or clean, soft static dissipating pad to lay cabinet panels on to avoid scratching.

Parts Supplied

Be sure you have the following components in your kit. If anything is missing, contact Elecraft customer

support (pg 13).

ILLUSTRATION DESCRIPTION QTY.

KXBC3 Module

ESD SENSITIVE! Do not remove

1 E850485

ELECRAFT

PART NO.

from ESD-Safe Bag without taking

ESD precautions.

CP Board Shield 1 E100444

4-40 3/16" (4.8mm) Black Flat Head

Screw

2-56 5/32” (4.0mm) Black Pan Head

Screw

#4 Lock Washer, Split Ring 1 E700004

2 E700173

1 E700170

4-40 3/16” (4.8mm) Nylon Standoff 1 E700263

6

Page 7

Installation Procedure

Taking ESD precautions, remove the KXBC3 module from its ESD-safe envelope and mount the

nylon standoff as shown in Figure 1.

CAUTION!

Handle the KXBC3 module carefully to avoid damaging the components on the

reverse side.

Figure 1. Mounting the Nylon Standoff on the KXBC3 Module.

7

Page 8

Locate the area on the KXBC3 module marked “Affix Shield Here”. Peel the protective covering off of the

adhesive on the back of the metal shield and align the shield carefully with the lines and edges of the module as

shown in Figure 2 with the hole centered over the screw opening. Press the shield against the KXBC3 module,

working over the entire surface, but take care not to damage any of the components on the other side. You may

notice a slight dimple appear where it covers the screw installed in the previous step. That is normal.

CAUTION!

If the shield is not firmly attached to the KXBC3 module it may cause a short circuit

to the internal batteries.

Do not damage the electronic components on the opposite side of the KXBC3 module

while affixing the shield.

Figure 2. Positioning the Shield on the KXBC3.

Place the KXBC3 module back in its ESD-safe bag until needed later.

Disconnect all cables attached to the KX3 and remove the KXPD3 paddles if installed.

Open the KX3 just as you would to install or remove batteries (see Internal Batteries in your

Owner’s Manual for details about how to do this).

Remove the internal batteries (if present).

8

Page 9

Carefully remove the two screws holding the battery retainer and lift the retainer free of the KX3 (See

Figure 3). Be careful not to lose the lock washer under the 2-56 screw inside the KX3. Note that some areas of

the control panel board may have a milky white coating over it (see Figure 4). That is normal.

Figure 3. Removing the Battery Retainer.

Figure 4. Typical PC Board Coating.

Set the battery retainer and hardware that you have removed aside. It will not be used again unless you

choose to remove the KXBC3 module in the future.

9

Page 10

Locate P3 on the control panel pc board. It is between the battery connector and the microphone jack on the

end panel (see Figure 5). J2 on the KXBC3 will plug into this connector.

Figure 5. Connector P3 on the Control Panel Board.

Hold the KXBC3 module so you can see that each pin on P3 is started into the corresponding opening in J2

on the module (see Figure 6). Hold the module against the pins while carefully tilting it parallel to the control

panel board so the pins insert straight into J2, then press on the module to engage the pins. There is normally

some resistance at the very beginning, which is why it is important to have the connectors properly aligned.

Figure 6. Positioning the KXBC3 Module on P3.

10

Page 11

Secure the KXBC3 module as shown in Figure 7 using the new hardware supplied.

Note: No lock washer is used under the 2-56 screw , even if one was removed with the battery retainer.

Figure 7. Securing the KXBC3 Module.

Initial Tests

Be sure the battery connector is fully seated and the battery cable is positioned so it will not become trapped

between the flex cable connectors (see Figure 8).

CAUTION! Be sure the battery cable is routed as shown below. If either wire is

trapped between the flex cable connectors when the case is closed, the battery cable

or the flex cable may be damaged.

Figure 8. Positioning the Battery Cable.

11

Page 12

Reassemble the KX3 case halves and apply external power. Do not install the batteries yet.

Turn the KX3 on (hold the

MENU to enter the menu and turn the OFS/VFO B knob to select BAT CHG.

Hold

BAND- and ATU T UNE switches simultaneously).

Turn the VFO A knob to select CHG OFF.

Set the real-time clock to the current time (see pg 2). Set it within one minute of another clock so you can

confirm that the real-time clock does not stop while performing the next steps

.

Hold the BAND- and ATU TUNE switches simultaneously turn the KX3 off and remove power from the

KX3 (always turn your KX3 off with the front panel switches before removing external power when no batteries

are installed). Wait about 1 minute and then reapply power and turn the KX3 on again. The KX3 runs a selfdiagnostic as it starts. The installation is good if no error messages are displayed.

DISP and turn the VFO B knob to show the time on the VFO B display. Confirm that the clock did

Tap

not lose time during the time the KX3 was off with no power applied. This indicates that the “hold up” feature

the clock is working. Normally you can have the KX3 disconnected from external power and have the batteries

out for up to 5 minutes without the clock losing the correct time.

Final Steps

Disconnect power, open the case again and install eight NiIMH batteries with a capacity of 1900 mAH or

greater. Inspect each cell for damage to the plastic covering over the outside. Never use a cell with a damaged

covering. The plastic covering protects the cell from shorting against other objects such as the shield on the

KXBC3 module. The short circuit can produce extreme heat and may cause a cell to rupture, causing extensive

damage inside your KX3.

WARNING!

Install only NiMH batteries. Attempting to charge any other type of battery may result in

personal injury, fire and damage to the KX3.

Return your KX3 to normal operating configuration:

Replace the KXPD3 paddles, if used.

Reconnect any station cabling including antenna, microphone, etc., to your KX3.

That completes the Installation and Testing of your KXBC3 Module.

12

Page 13

Customer Service and Support

Technical Assistance

You can send e-mail to kx3support@elecraft.com and we will respond quickly – typically the same day

Monday through Friday. If you need replacement parts, send an e-mail to parts@elecraft.com

assistance is available from 9 A.M. to 5 P.M. Pacific time (weekdays only) at 831-763-4211. Please use e-mail

rather than calling when possible since this gives us a written record of the details of your problem and allows us

to handle a larger number of requests each day.

Repair / Alignment Service

If necessary, you may return your Elecraft product to us for repair or alignment. (Note: We offer unlimited email

and phone support, so please try that route first as we can usually help you find the problem quickly.)

IMPORTANT: You must contact Elecraft before mailing your product to obtain authorization for the

return, what address to ship it to and current information on repair fees and turnaround times. (Frequently we

can determine the cause of your problem and save you the trouble of shipping it back to us.) Our repair location

is different from our factory location in Aptos. We will give you the address to ship your kit to at the time of

repair authorization. Packages shipped to Aptos without authorization will incur an additional shipping charge

for reshipment from Aptos to our repair depot

.

Elecraft 1-Year Limited Warranty

. Telephone

This warranty is effective as of the date of first consumer purchase (or if shipped from the factory, the date the

product is shipped to the customer). It covers both our kits and fully assembled products. For kits, before requesting

warranty service, you should fully complete the assembly, carefully following all instructions in the manual.

Who is covered: This warranty covers the original owner of the Elecraft product as disclosed to Elecraft at the time

of order. Elecraft products transferred by the purchaser to a third party, either by sale, gift, or other method, who is

not disclosed to Elecraft at the time of original order, are not covered by this warranty. If the Elecraft product is being

bought indirectly for a third party, the third party’s name and address must be provided at time of order to ensure

warranty coverage.

What is covered: During the first year after date of purchase, Elecraft will replace defective or missing parts free of

charge (post-paid). We will also correct any malfunction to kits or assembled units caused by defective parts and

materials. Purchaser pays inbound shipping to us for warranty repair; we pay shipping to return the repaired

equipment to you by UPS ground service or equivalent to the continental USA and Canada. For Alaska, Hawaii, and

other destinations outside the U.S. and Canada, actual return shipping cost is paid by the owner.

What is not covered: This warranty does not cover correction of kit assembly errors. It also does not cover

misalignment; repair of damage caused by misuse, negligence, battery leakage or corrosion, or builder modifications;

or any performance malfunctions involving non-Elecraft accessory equipment. The use of acid-core solder, watersoluble flux solder, or any corrosive or conductive flux or solvent will void this warranty in its entirety. Also not

covered is reimbursement for loss of use, inconvenience, customer assembly or alignment time, or cost of

unauthorized service.

Limitation of incidental or consequential damages: This warranty does not extend to non-Elecraft equipment or

components used in conjunction with our products. Any such repair or replacement is the responsibility of the

customer. Elecraft will not be liable for any special, indirect, incidental or consequential damages, including but not

limited to any loss of business or profits.

13

Loading...

Loading...