elco VG2.120 M/TC, VG2.160 M/TC, VG2.210 M/TC, VG 6.1600 M/TC, VG 6.2100 M/TC Original Operating Instructions

Page 1

en

VG2.120 M/TC

VG2.160 M/TC

VG2.210 M/TC

Original operating instructions

For authorised specialist engineers

Gas burners ...........................................2-31

de, fr.....................................4200 1038 2500

it, nl ......................................4200 1038 2600

............................................. 4200 1038 2400

09/2014 - Art. Nr. 4200 1038 2700A

Page 2

Overview

Contents

Overview Contents .....................................................................................2

Operation Operation, safety function ..........................................................4

Assembly Burner assembly ......................................................................11

Commissioning Setting data ..............................................................................15

Maintenance Servicing............................................................................. 26-27

Important information

VG2.120/160/210 M/TC burners are

designed for the low-pollutant combustion of

natural gas and propane gas. The design and

function of the burners meet standard EN

676. They are suitable for use with all heat

generators complying with standard EN 303

or for use by hot air generators complying

with standard DIN 4794 or DIN 30697 within

their respective performance range. Any

other type of application requires the

approval of ELCO.

Installation, start-up and maintenance must

only be carried out by authorised specialists

and all applicable guidelines and regulations

must be complied with.

This device is not designed for use by

individuals (including children) whose

physical, sensory, or mental abilities are

reduced, or by persons lacking in experience

or knowledge, except if they have benefited

from supervision or prior instructions

concerning the use of the device given by a

person responsible for their safety. Children

must be supervised to ensure they do not

play with the device.

Burner description

VG2.120/160/210 M/TC burners are

modulating, fully automatic, monoblock type

burners with electronic cam. The special

design of the combustion head enables

combustion with low levels of nitrogen oxide

and increased output. Class 3 type-approval

in accordance with EN676 certifies that the

lowest emission values have been achieved

and means that the national environmental

regulations have been met

AT: KFA 1995, FAV 1997

CH: LRV 2005

DE: 1.BImSChV

Emissions values may differ, depending on

furnace dimensions, furnace load and the

firing system (three-pass boilers, boilers with

reverse firing). For specifying warranty

values, the conditions for the measuring

equipment, tolerances and humidity must be

observed.

Important information .................................................................2

Burner description ......................................................................3

Control and safety unit BT 3xx ...................................................5

Terminal allocation chart ........................................................ 6-7

Control and safety unit BT 3xx gas operation ............................8

BT 3xx menu overview ...............................................................9

MBC-SE gas train.....................................................................10

Gas train...................................................................................12

Checking the combustion components ....................................13

Electrical connection ................................................................14

Testing before commissioning..................................................14

Ionisation current measurement ...............................................14

Air regulation, MBC SE gas train setting ..................................16

Pressure regulator setting ........................................................16

Confirming the "Manual Handshake" data................................17

Menu 1: setting the servomotors ....................................... 18-23

Pre-setting without flame.................................................... 18-19

Setting with flame ............................................................... 20-23

Operating mode........................................................................23

Setting the gas pressure switch/air pressure switch ................24

Displaying the setting data from the manual control display ....25

Menu 3: Fault memory, Entering a telephone

number for the maintenance company and the

maintenance contract number............................................ 28-29

Menu 4: operating statistics......................................................30

Setting the brightness and contrast of the display....................31

Packaging

The burner is supplied in three packaging

units:

- Burner housing with operating instructions,

circuit diagram and spare parts list.

- Burner head with flange seal and securing

screws.

- Compact gas train with integrated filter

The following standards should be observed

in order to ensure safe, environmentally

sound and energy-efficient operation:

EN 226

Connection of fuel oil and gas burners with

blast air to the heat generator

EN 60335-1, -2-102

Specification for safety of household and

similar electrical appliances, particular

requirements for gas burning appliances

Gas lines

When routing the gas lines and fittings, the

general installation instructions and

guidelines, as well as the following national

regulations, must be observed:

CH: - G1 instruction text from SSIGE

- EKAS form no. 1942,

liquefied gas directive, part 2

- Cantonal authority guidelines (e.g.

directives for the pilot valve)

DE: - DVGW-TVR/TRGI

Installation location

The burner must not be used in rooms with

aggressive vapours (e.g. hair spray,

tetrachloroethylene, carbon tetrachloride),

high levels of dust or high air humidity (e.g.

laundry rooms).

There must be a supply air inlet measuring:

DE: up to 50 kW: 150 cm

for each additional kW: + 2.0 cm

CH: QF [kW] x 6= ...cm2; but 200 cm2

minimum.

Variations may arise as a result of local

regulations.

Page

Declaration of conformity

for gas burners

We, certified company under the name

"Site A" declare under our sole

responsibility that the products

VG2.120 M/TC

VG2.160 M/TC

VG2.210 M/TC

conform to the following standards

EN 50165

EN 55014

EN 60335-1

EN 60335-2-102

EN 60555-2

EN 60555-3

EN 676

Belgian royal decree dated 08/01/2004

These products bear the CE mark in

accordance with the stipulations of the

following directives

2006/ 42/EC Machinery Directive

2004/108/EC EMC Directive

2006/ 95/EC Low

Voltage Directive

92/ 42/EEC Efficiency Directive

Annemasse, June 1st 2012

F. DECIO

We accept no responsibility for damage

arising from:

- inappropriate use

- incorrect installation and/or repair on the

part of the buyer or any third party,

including the fitting of non-original parts.

Final delivery and instructions for use

The firing system fitter must supply the

operator of the system with operating and

maintenance instructions on or before final

delivery. These instructions should be

displayed in a prominent location at the point

of installation of the heat generator.They

should include the address and telephone

number of the nearest customer service

centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year. Depending

on the type of installation, shorter

maintenance intervals may be necessary! It

is advisable to take out a maintenance

contract to guarantee regular servicing.

2

2

09/2014 - Art. Nr. 4200 1038 2700A2

Page 3

Overview

en

Burner description

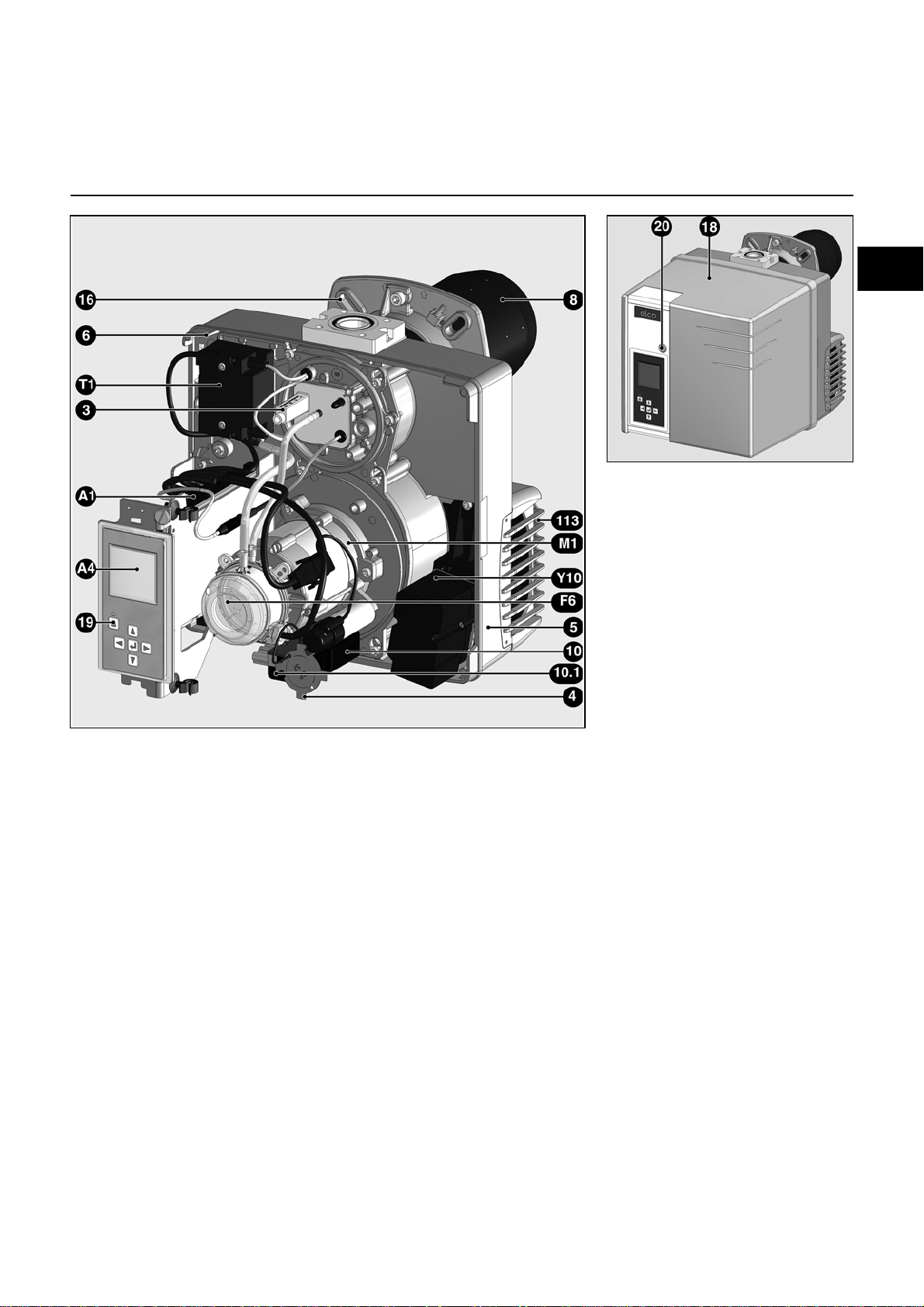

A1 Control and safety unit

A4 Display

F6 Air pressure switch

M1 Blower motor

T1 Igniter

Y10 Air flap servomotor

3 Adjusting knob for dimension Y

4 Propane diffuser

5 Housing

6 Plate hanging device

(Maintenance)

8 Burner tube

10 7-pin connector

10.1 4 pin connector

16 Gas connecting flange

18 Cover

19 Release knob

20 Hood securing screw

113 Air intake box

09/2014 - Art. Nr. 4200 1038 2700A 3

Page 4

Operation

Compact train

Operation

Safety function

Description of functions

When first powering up, after a power

cut or a lockout, after the gas supply has

been cut or after a shutdown for 24

hours, a gas valve sealing test is

performed before the burner is started,

with the fan motor in operation. A preventilation time of 24 seconds begins

after the sealing test.

During the pre-ventilation time

- the air pressure is monitored

- a check is made for the presence of

any abnormal flame signals.

At the end of the pre-ventilation time

- the ignition is switched on

- the main and safety solenoid valves

are opened

- burner start-up

Monitoring

The flame is monitored by an ionisation

probe. The probe is fitted with insulation

to the gas head and is routed through

the turbulator into the flame zone. The

probe must not have any electrical

contact with earthed parts. The burner

switches to malfunction if a short circuit

occurs between the probe and the

burner earth. During burner operation,

an ionised zone is produced in the gas

flame through which a rectified current

flows from the probe to the burner tip.

The ionisation current must be at least

8 µA.

Safety functions

- If no flame is produced when the

burner is started (gas release), the

burner is switched off at the end of the

safety time which lasts no more than

3 seconds and the gas valve closes.

- If the flame is lost during operation,

the gas supply is cut within a second.

A new start-up sequence is activated.

If the burner starts, the operating cycle

starts running. Otherwise a lockout

occurs.

- If there is an air failure during preventilation or operation, a lockout

occurs.

- If there is a gas failure, the burner

either stops or will not start. As soon

as sufficient gas pressure is available

again, the burner restarts.

During the regulator shutdown

- The control thermostat interrupts the

heating request

- The gas valves close

- The flame goes out

- The blower motor stops

- The burner is ready for operation

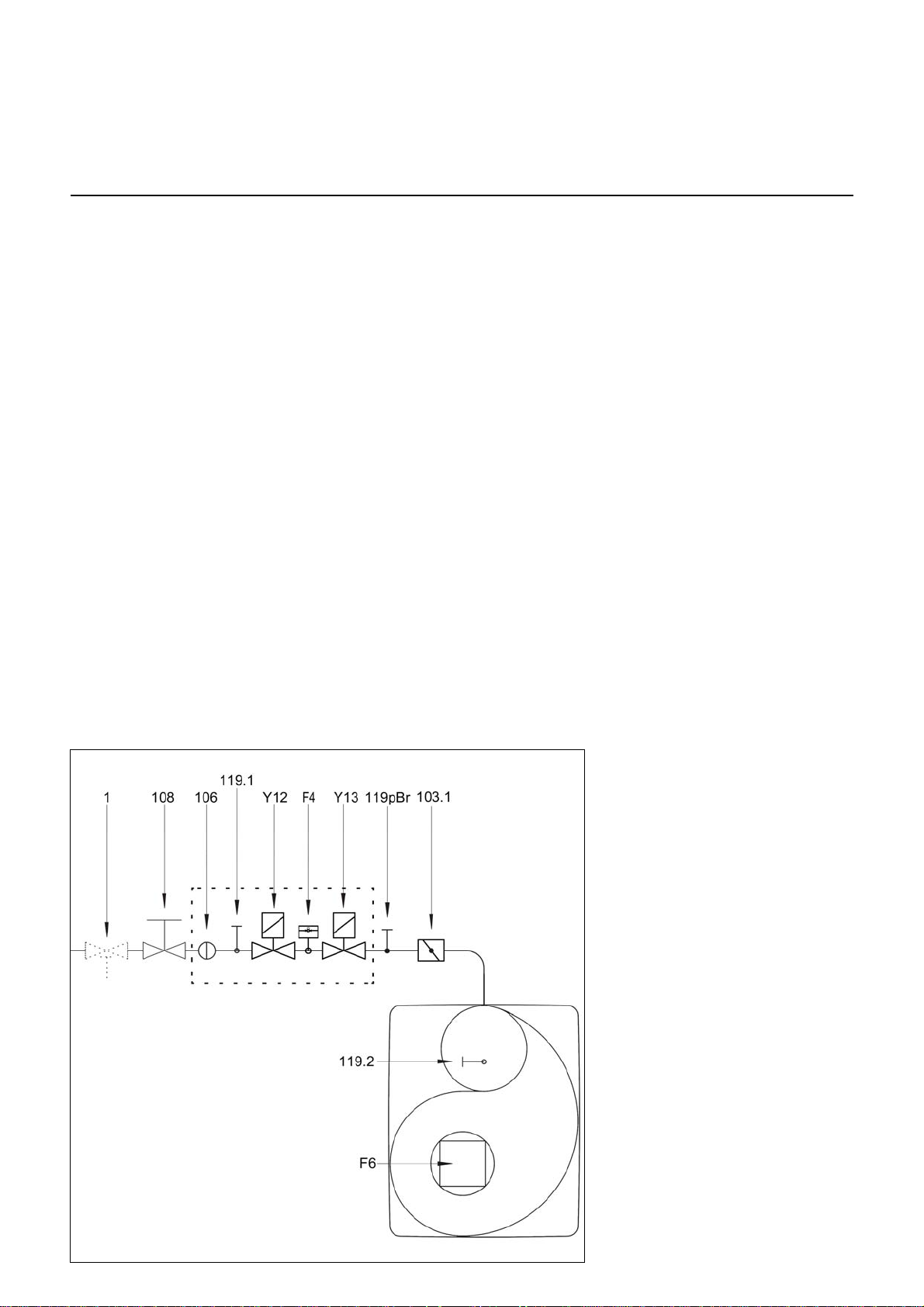

F4 Gas pressure switch

F6 Air pressure switch

Y12 Safety solenoid valve

Y13 Main solenoid valve

1 Thermal safety valve (to be

installed by the fitter)

103.1 Gas throttle

106 Screen

108 Gas cut-out valve (to be

installed by the fitter)

119pBr Gas pressure measuring point

at the valve outlet

119.1 Gas pressure measuring point

upstream of the valves

119.2 Air pressure measuring point

CH note

In accordance with SSIGE instructions,

it is compulsory to install a gas safety

valve (mark 1) in the pipe.

DE Note

In compliance with the reference layout

applicable to boiler rooms, sites with gas

furnaces must be fitted with a thermal

gas shut-off valve (1).

09/2014 - Art. Nr. 4200 1038 2700A4

Page 5

Operation

en

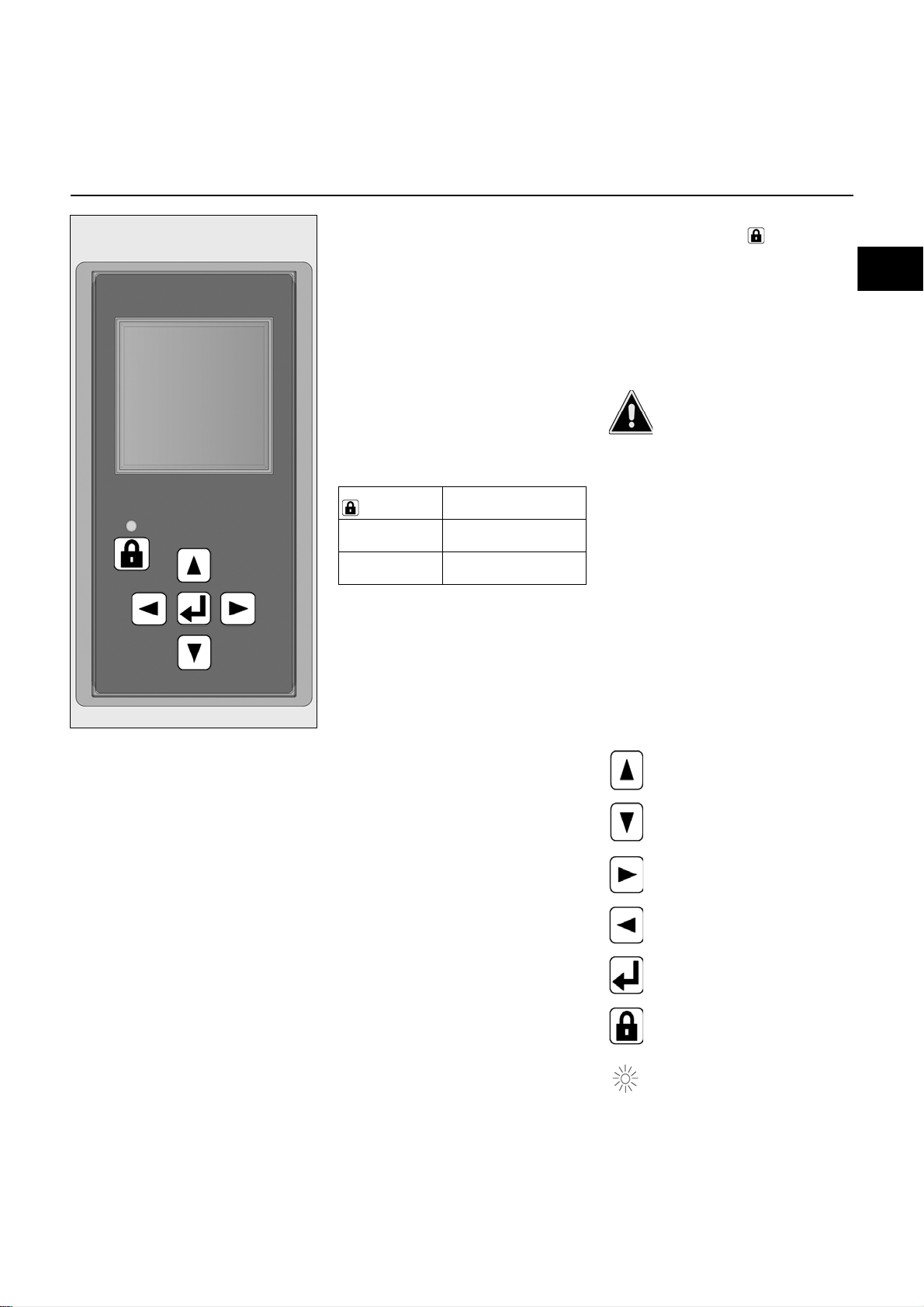

Control and safety unit BT 3xx

The control and safety unit BT 3xx

controls and monitors the forced draught

gas burner. The microprocessorcontrolled program sequence ensures

the maximum consistency of the cycle

times involved, regardless of

fluctuations in the mains voltage or

ambient temperature. The control and

safety unit is designed to detect power

failures. Depending on the parameter

assignment, the unit either switches to

malfunction mode or goes into the

standby position if the power supply falls

below the mains voltage. In the standby

position, there is an automatic restart as

soon as the set threshold value is

exceeded by 105%.

Pressing button

for ...

... 1 second ... the control and safety

... 2 seconds ... the control and safety

… causes ….

unit to unlock.

unit to lock

Manual locking and unlocking

Using the reset button , the control

and safety unit can be locked manually

(interlocked) or unlocked, provided the

unit is connected to the mains power

supply. This function must not be

confused with automatic locking and

fault acknowledgement in case of an

error.

Before installing or removing the unit or

any operation in the connection area,

switch off the supply to the device, check

for the absence of voltage and prevent

any reactivation. Otherwise there is risk

of electric shock. The control and safety

unit must not be

opened or repaired.

- Moves the cursor upwards

- Moves the cursor downwards

- Increases the marked value

- Moves the cursor to the right

- Reduces the marked value

- Moves the cursor to the left

Modifies/confirms the value shown

- Unlocks the control and safety unit

Red LED (flashes if a fault is

present)

09/2014 - Art. Nr. 4200 1038 2700A 5

Page 6

Operation

Air pressure

switch

Ignition

device

Terminal

Connector

Remote

unlocking

Solenoid valves

(1+2)

Heating

request

Min. gas

pressure

switch

Burner

safety

circuit

Boiler

safety

circuit

Solenoid

valve 3

Flame check

Fault

display

Burner motor

Terminal

L1 power supply

Grounding of

the burner

UV detector

additional

Ionisation

Flame

monitor

Connector

1 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 1 2 3 4

1 2 3

1 2 3

1 2 3

Pin

Pin

1 2 3 1 2 3

1 2 3

1 2 3 1 2 3 1 2

1 2

Terminal allocation chart

Pin Terminal Description Connector Pin Terminal Description Connector

1 1 Phase gas solenoid valve 1

2 2 Earth 1 30 Neutral conductor of the fuel-oil

3 3 Neutral conductor 2 31 Earth

1 4 Phase gas solenoid valve 2 3 32 Phase

2 5 Neutral conductor 1 33 Neutral conductor

3 6 Earth 2 34 Earth

1 7 Phase fuel valve 3 (optional)

2 8 Earth 1 36 Neutral conductor

3 9 Neutral conductor 2 37 Earth

1 10 Phase ignition transformer

2 11 Earth 1 39 Neutral conductor

3 12 Neutral conductor 2 40 Earth

1 13 Phase gas pressure switch min.

2 14 Earth 1 42 Neutral conductor

3 15 Phase 2 43 Earth

1 16 Phase burner safety circuit

2 17 Earth 1 45 UV flame monitor (-)

3 18 Phase 2 46 UV flame monitor (+)

1 19 Phase boiler safety circuit

2 20 Phase 2 48 Phase

1 21 Phase air pressure switch

2 22 Phase 4 50 Flame monitor (-)

1 23 Load (-)

2 24 Load (+)

3 25 Phase

1 26 Malfunction reset

2 27 Burner ON

3 28 Phase

X01

+

X02

X03

X04

X05

X06

X07

X08

X09

X10

1 29 Grounding of the burner

pump

3 35 Phase burner motor

3 38 Alarm output

3 41 L1 power supply

3 44 L1 power supply output

1 47 Ionisation probe

3 49 Flame monitor (+)

X26

X25

X24

X23

X22

X21

X20

09/2014 - Art. Nr. 4200 1038 2700A6

Page 7

Operation

Terminal

Display

PC interface

Gas

servomotor

Air

servomotor*

Fuel oil

servomotor*

1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6

Pin

Connector

en

Terminal allocation chart

Pin Terminal Description Connector

11

22

33

44

55

66

17

28

39

410

511

612

113

214

315

416

517

618

119

220

321

422

523

624

125

226

327

428

529

630

Display

PC interface

Servomotor gas

Servomotor air*

Servomotor fuel oil*

X30

X31

X32

X33

X34

* Terminal allocation depends on the design of the burner

09/2014 - Art. Nr. 4200 1038 2700A 7

Page 8

Operation

Boiler safety circuit

Gas safety circuit

Burner on

Minimum gas pressure swi t ch

Air pressure switch

Flame signal

Air flap

Gas flap

Transformer

Gas valve 1

Gas valve 2

Air motor

Fault

Control and safety unit BT 3xx gas operation

Legend to the sequence diagram

t1 Awaiting boiler safety circuit

Air pressure switch min. request

t2 Time for pressure build-up in the gas control line (only

when sealing test mode is activated, program sequence

for density test can vary, see sequence diagram for

density test)

t3 Servomotor running time

t4 Closing of gas flap

t5 Ventilation time

t6 Transformer activation time

Sealing test sequence diagram - no gas pressure at start of sealing test. Sealing test sequence diagram - gas pressure present at start of sealing

Legend to the sequence diagrams

t1 Ventilation time, always 2 seconds

t2 Delay time, always 2 seconds

t3 Sealing test time, configurable

t4 Filling time, configurable

The diagrams on this page have been taken from the operating instructions of the BurnerTronic BT300 BT320 BT340 from Lamtec.

Print no. DLT1200-11-aDE-002 Copyright© 2011 LAMTEC

t9 Safety time

t10 Operating phase

t11 Regulation

t12 Time for pressure release in the gas control line

t13 Postventilation time

t14 Servomotors under base load

t15 Post combustion time

t16 Flame extinction test

t17 Sealing test gas valve 2

test.

09/2014 - Art. Nr. 4200 1038 2700A8

Page 9

Operation

en

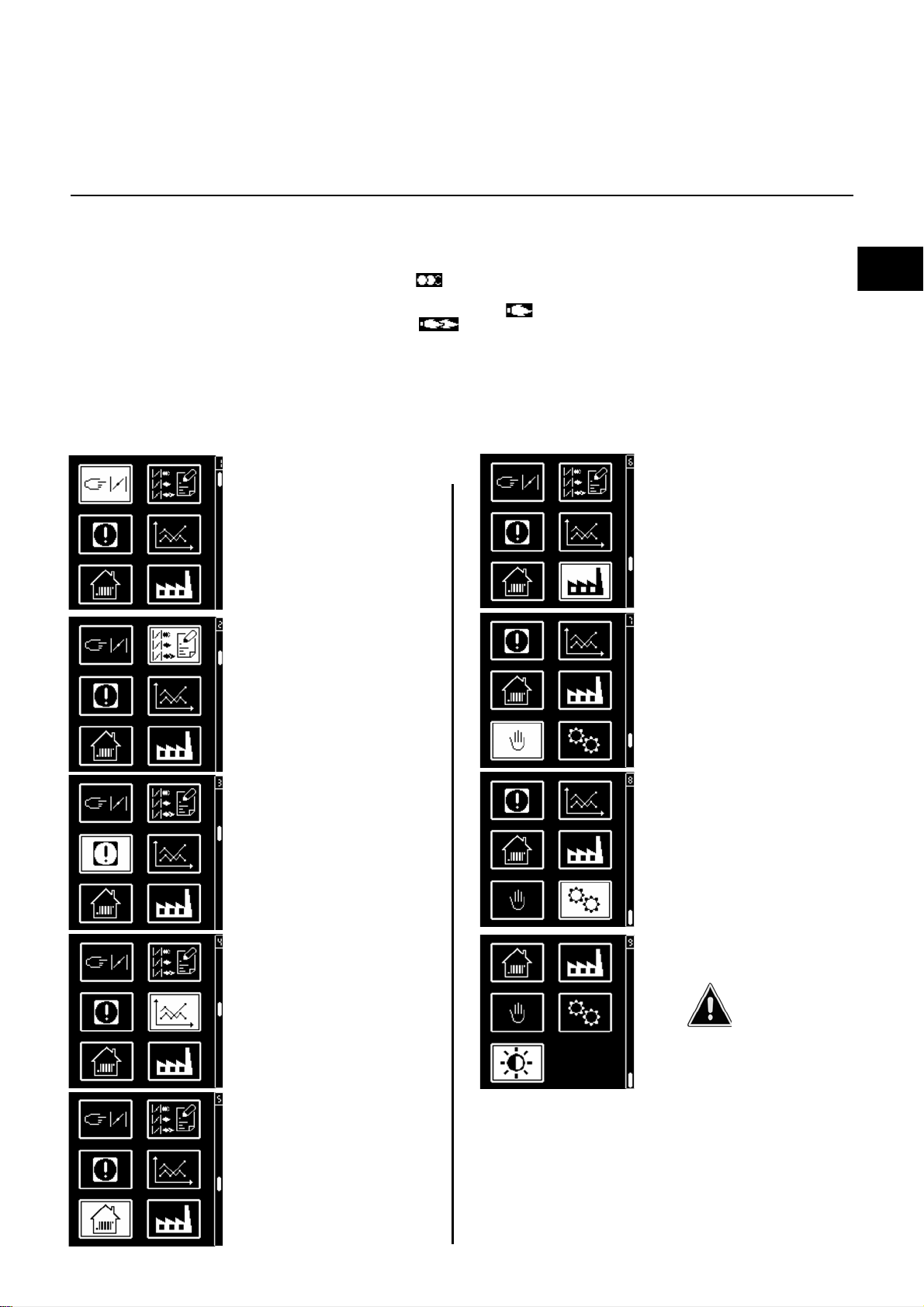

BT 3xx menu overview

In addition to the function of control and

safety unit, the control and safety unit BT

3xx also modulates the burner output by

controlling the air flap, gas flap, fuel oil

quantity regulation and frequency

converter (optional) in one electronic

circuit.

The electronic circuit controls the

opening of the gas flap and fuel oil flow

regulation proportional to the air flap

along a curve based on 10 setting points

During start up, the setting points are

defined based on the measurement

values of the combustion gas analysis.

This guarantees optimal combustion

• Menu 1: Setting the

• Menu 2: Display of the

over the burner's entire output

modulation range.

A separate burner ignition load can be

defined with the "Ignition position"

setting point .

The limit values of the control range are

defined by the min. output " " and

max. output " " setting points. In

addition, other optional functions, such

as sealing tests, reventilation or waiting

times can be activated.

The combustion control unit is operated

via a display and operating unit. The

parameters for the control and safety

unit are set using the display and 5 keys.

servomotors

setting points of the

servomotors in the

display unit

Operating values are shown in real time

on the display.

Pressing the keys gives access to 9

menus:

• Menu 6: Setting/

modification of

configurations for

industrial applications

• Menu 7: Manual mode

• Menu 3: Displaying

faults

• Menu 4: Statistical data

• Menu 5: Setting/

modification of

standard configurations

• Menu 8: Setting mode

- Menu 8 currently not

available

• Menu 9: Setting the

brightness and contrast of

the display

In these menus, it is

possible to adjust the

standard configurations of

the control unit. These are

pre-set in the factory.

The nearest customer

service department must be

contacted before any onsite modifications are made.

09/2014 - Art. Nr. 4200 1038 2700A 9

Page 10

Operation

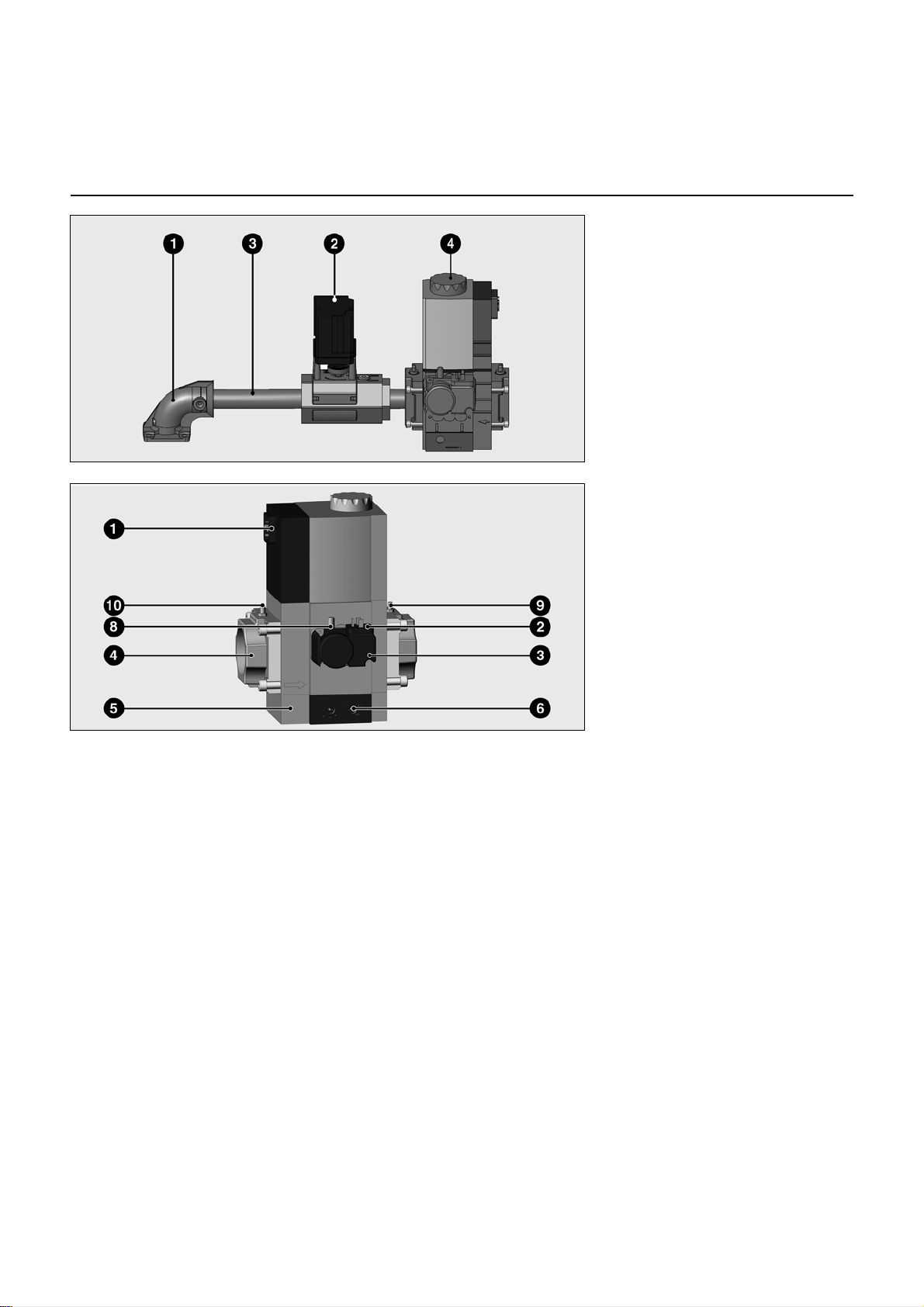

MBC-SE gas train

The gas train consists of:

- a gas connection flange 1 with O-ring

- a gas throttle 2, controlled by a

servomotor

- a gas connection pipe 3

- an MBC-SE gas valve train with gas

filter 4 (mini filter)

MBC SE gas valve

1 Electrical connection of solenoid

valves (DIN 43650)

2 Electrical connection of gas

pressure switch (DIN 43650)

3 Gas pressure switch

4 Gas inlet flange

5 Mini filter (under cover)

6 Gas pressure adjustment

screw pBr

8 Gas pressure measurement

tap G1/8 (inter-valve pressure)

9 Gas pressure measurement

tap G1/8 (outlet pressure pBr)

10 Gas pressure measurement

tap G1/8 (inlet pressure)

Installation position:

vertical with the coils facing upwards.

Where the lines are vertical, the coils

must be horizontal.

Description, technical data

The MBC-SE gas compact valve train is

a compact unit with 2 Class A solenoid

valves, a Class A servo pressure

regulator, a mini filter and a pressure

switch.

- Pressure switch GW A5: adjustment

range 5.....50 mbar

- Solenoid valve V1/V2 (fast-opening/

fast-closing)

- Adjustable servo pressure regulator

- Max. operating pressure 500 mbar

- Inlet pressure range

15-500 mbar

- Voltage/frequency:

230 V/50-60 Hz

Pressure regulator setting

The outlet pressure is set using

adjustment screw 6.

09/2014 - Art. Nr. 4200 1038 2700A10

Page 11

Installation

en

Burner installation

Burner installation

Burner flange 3 is equipped with

elongated slots and can be used with a

hole Ø of 150 - 184 mm. These

dimensions comply with EN 226.

The insertion depth of the combustion

components can be adjusted to the

geometry of the combustion chamber by

sliding pipe bracket 2 on the burner's

flame tube. The installed depth remains

the same during fitting and removal.

The burner is secured to the connecting

flange, and therefore to the boiler, via

pipe bracket 2. This completely seals off

the combustion chamber.

Burner tube installation depth and

brickwork surround

Unless otherwise specified by the boiler

manufacturer, heat generators without a

cooled front wall require brickwork or

insulation 5 as shown in the illustration

opposite. The brickwork must not

protrude beyond the leading edge of the

flame tube, and should have a maximum

conical angle of 60°. Space 6 must be

filled with an elastic, non-flammable

insulation material.

Installation:

• Secure connecting flange 3 to the

boiler using screws 4

• Fit pipe bracket 2 to the burner pipe

and secure using screw 1. Tighten

screw 1 to a maximum torque of 6 Nm.

• Turn the burner slightly, guide it into

the flange and secure using screw 5.

Removal:

• Loosen screw 5

• Turn the burner out of the bayonet

socket and pull it out of the flange.

For assembly in the position with

the volute facing upwards, unclip

the display from its support, turn it

over 180° and refit it.

Exhaust gas evacuation system

To avoid unpleasant noise emissions,

right-angled connectors should not be

used on the flue gas side of the boiler.

On boilers with reverse firing, the

minimum flame tube insertion depth A

should be observed as per the boiler

manufacturer's instructions.

Inspection glass cooling

The burner body can be equipped with

an R1/8" connection to support a line for

cooling the boiler's inspection glass.

• To do this, drill through cast iron

projection 6 and cut a 1/8" thread.

• Use accessories article no. 12 056

459 for the threaded union and

connection hose.

09/2014 - Art. Nr. 4200 1038 2700A 11

Page 12

Installation

Gas train

Gas train installation

• Check the correct position of the O-

ring J1 in the connecting flange.

• Secure the gas train on the burner so

that the gas train coils are in the upper

vertical position.

• Pay attention to the direction of

circulation.

• Route the connection cables C for the

gas train through cable gland and

connect it to the gas train.

On VG2.160/210 M/TC burners,

insert the diaphragm 2 delivered

with the gas train mounting parts

into the flange of the burner body.

09/2014 - Art. Nr. 4200 1038 2700A12

Page 13

Installation

VG2.120

VG 2.120

VG2.160/210

VG2.120

VG2.160/210

en

Checking the combustion components

Checking the combustion

components

• Remove the three screws W from the

cover.

• Remove the cover.

• Loosen lock nut E on the gas pipe

bracket

• Loosen the retaining bolt.

• Remove combustion components.

Setting to propane gas operation

VG2.120 burner

• Remove the shutter 3 and the

turbulator 4.

• Fit the adaptor 5 (supplied with the

housing).

• Fit the turbulator 4 without

shutter 3.

Setting to propane gas operation

VG2.160/210 burner

• Remove the shutter 3 and the

turbulator 4.

• Fit the adaptor 5 (supplied with the

housing).

• Fit the turbulator 4 and the shutter 3.

the

Checking the combustion

components

• Check the setting of the ionisation

probe and the ignition electrode in

accordance with the illustrations.

09/2014 - Art. Nr. 4200 1038 2700A 13

Page 14

Installation

Electrical connection

Checks before commissioning

Ionisation current measurement

General regulations applying to the

gas connection

• The gas train must only be connected

to the gas mains by a recognised

specialist.

• The cross-section of the gas line

should be of a size designed to

guarantee that the gas flow pressure

does not drop below the specified

level.

• A manual shut-off valve (not supplied)

must be fitted upstream of the gas

train.

• In Germany, a thermally triggered

shut-off valve (to be installed by the

customer side) must be fitted as

specified by the draft combustion

ordinance.

It is the responsibility of the fitter or his

representative to obtain approval for the

system at the same time as the burner is

commissioned. Only the fitter or his

representative can guarantee that the

system meets applicable standards and

regulations. The fitter should be in

possession of the corresponding official

permit, and should carry out the

corresponding sealing tests and purge

the system of air.

Electrical installation and connection

work must only be carried out by a

suitably qualified electrician. All

applicable regulations and directives

must be observed.

N.B. The applicable guidelines

and directives must be

observed, as well as the

electrical circuit diagram

supplied with the burner.

Electrical connection

• Check to ensure that the power supply

is as specified (230V, 50 Hz single

phase with neutral and earth).

Boiler fuse: 6.3A

Electrical connection

It must be possible to disconnect

the burner from the mains using an

omnipolar shutdown device

complying with the standards in

force. A device to protect against

short circuits must also be fitted

upstream of the burner's electrical

power supply.The burner and heat

generator (boiler) are connected by

a 7-pin connector 1 and a 4-pin

connector 2 (not supplied). The

diameter of the cables connected

to these connectors must be

between 8.3 and 11 mm.

Connecting the gas train

Connect the gas train to the plugs on the

burner (black to black, grey to grey).

Checks before commissioning

The following must be checked before

initial commissioning:

• That the burner is assembled in

accordance with the instructions given

here.

• That the burner is pre-set in

accordance with the values in the

adjustment table.

• Setting the combustion components.

• The heat generator must be ready for

operation, and the operating

regulations for the heat generator

must be observed.

• All electrical connections must be

correct.

• The heat generator and heating

system must be filled with water and

the circulating pumps must be in

operation.

• The temperature regulator, pressure

regulator, low water detectors and any

other safety or limiting devices that

might be fitted must be connected and

operational.

• The exhaust gas duct must be

unobstructed and the secondary air

system, if available, must be

operational.

• An adequate supply of fresh air must

be guaranteed.

Ionisation current measurement

To measure the ionisation current,

disconnect connector B10 and connect

a multimeter with a measuring range of

0-100 µA.

nd

The 2

at least 7 µA. It is also possible to read

the ionisation current on the display.

stage ionisation current must be

• The heating request must be

available.

• Sufficient gas pressure must be

available.

• The fuel supply lines must be

assembled correctly, checked for

leaks and bled.

• A standard-compliant measuring point

must be available, the exhaust gas

duct up to the measuring point must

be free of leaks to prevent anomalies

in the measurement results.

09/2014 - Art. Nr. 4200 1038 2700A14

Page 15

Commissioning

P3(°) P6 (°) P3(°) P6 (°)

40 80 10 0,8 0 0 10 20 30 5 5 10 20 28 13,0

50 100 20 0,9 10 10 20 30 45 15 15 25 38 55 10,0

60 120 30 1,3 15 15 30 40 80 15 15 30 35 65 14,0

40 80 10 0,8 0 0 10 20 30 5 5 10 20 28 17,5

50 100 20 0,9 10 10 20 30 45 15 15 25 38 55 15,0

60 120 30 1,3 15 15 30 40 80 15 15 30 35 65 18,0

40 80 10 0,8 0 0 10 20 30 5 5 10 20 28 7,5

50 100 20 0,9 10 10 20 30 45 15 15 25 38 55 7,5

60 120 30 1,3 15 15 30 40 80 15 15 30 35 65 8,0

40 130 10 1,4 0 0 20 40 60 12 12 26 43 57 10, 0

50 150 15 1,5 5 5 30 55 75 15 15 35 48 70 10, 0

60 160 25 1,7 13 13 30 60 90 17 17 30 44 55 13,0

40 130 10 1,4 0 0 20 40 60 12 12 26 43 57 12, 5

50 150 15 1,5 5 5 30 55 75 15 15 35 48 70 13, 0

60 160 25 1,7 13 13 30 60 90 17 17 30 44 55 16,0

40 130 10 1,4 0 0 20 40 60 3 3 20 36 50 6,5

50 150 15 1,5 5 5 30 55 75 5 5 27 40 65 7,5

60 160 25 1,7 13 13 30 60 90 12 12 25 36 65 8,0

45 140 10 1,4 0 0 20 40 60 13 13 26 50 65 10, 0

50 150 20 1,5 6 6 25 45 65 14 14 32 48 65 10, 0

60 185 35 1,7 10 10 35 65 90 15 15 35 45 75 13,0

45 140 10 1,4 0 0 20 40 60 13 13 26 50 65 12, 5

50 150 20 1,5 6 6 25 45 65 14 14 32 48 65 13, 0

60 185 35 1,7 10 10 35 65 90 15 15 35 45 75 16,5

45 140 10 1,4 0 0 20 40 60 5 5 20 40 65 0,6

50 150 20 1,5 6 6 25 45 65 8 8 27 40 60 0,6

60 185 35 1,7 10 10 35 65 90 10 10 30 42 75 8,0

Burner

Partload

Dimension

Y mm

gas

Bur ner output

kW

Ga s throttle positi on

Pressure

regulator

PBr

setting

mbar

Full

load

Ignition

load

(°)

Partload

P0 (°)

Full

load

P9 (°)

Ignition

load

(°)

Partload

P0 (°)

Full

load

P9 (°)

Furnace

press ure

mbar

Air flap position

VG2.210

M/TC

G20

G25

G31

VG2.120

M/TC

G20

G25

G31

VG2.160

M/TC

G20

G25

G31

en

Adjustment data

Type of

Only for the VG2.210 burner:

• When operating at low gas pressure, it

is necessary to remove the diaphragm

4 from the gas inlet.

The adjustment values above are guide values and facilitate commissioning. The factory settings are in bold set against a grey

background. The final settings are essential in ensuring that the burner functions as well as possible.

Setting the gas pressure switch

• Remove the transparent cover.

• Provisionally set to 15 mbar.

Setting the air pressure switch

• Remove the transparent cover.

• Provisionally set to 1 mbar.

09/2014 - Art. Nr. 4200 1038 2700A 15

Page 16

Commissioning

Air regulation

MBC-SE gas train setting

Pressure regulator setting

Air regulation

Combustion air is regulated at two

points:

• on the pressure side, using the gap

between the turbulator and the burner

tube.

• on the vacuum side, by the air flap

driven by servomotor Y10.

The regulation of air in the burner head

affects not only the air flow but also the

mixing zone and the air pressure in the

burner tube. Turning screw A

- to the right for more air

- to the left for less air

• Adjust dimension Y in accordance

with the settings table.

Air regulation by air flap

Air is regulated on the vacuum side by

an air flap. This is driven by servomotor

Y10.

MBC-SE gas train setting

Pressure regulator setting

The gas pressure regulator is set at 10

mbar in the factory. Check the gas

pressure after the first time the burner is

started (measuring point at gas train

outlet flange) and if necessary, correct

gas pressure pBr via adjustment screw

S in accordance with the table on page

15. After start up, no further changes

should be made.

09/2014 - Art. Nr. 4200 1038 2700A16

Page 17

Commissioning

en

Confirmation of "Manual Handshake" data

The following sequence for confirming or cancelling the data entry is the same for a number of different changes to the

parameters. For this reason, this sequence is not illustrated in detail for each of the parameter settings outlined below. The

parameter modifications which require a "Manual Handshake" are highlighted on the following pages.

These parameter modifications are assigned the following reference:

Manual Handshake

You are now asked to confirm the modifications that have been made.

Accept or cancel the entry

The "Manual Handshake" is explained below using menu 5 as an example.

The following parameters have been modified in the example:

- Density test activated after burner cycle

- Post-ventilation time activated (5 seconds)

The following screen appears once the parameter has been set and the data entry confirmed.

You are asked to confirm the data within 7 seconds. In this case: "Density test after burner cycle

activated".

A counter displaying the remaining time appears in the bottom right-hand corner of the screen.

Only confirm the displayed settings if they correspond with your specifications. The

entry can be accepted if both values are identical. The entry can be cancelled if there

is a deviation in values.

To confirm and save the parameter modification, select symbol and confirm with key .

To cancel the modifications, select symbol and confirm with key . Alternatively, you can

wait until the time has expired.

No modifications are made.

Note:

You will return to the previous menu if the procedure is cancelled. The previous unmodified

settings are displayed.

If you accept these values, a second screen appears.

In this case: "Post-ventilation time activated, duration 5 seconds".

Once again, the data must be confirmed within 7 seconds.

Only confirm the displayed settings if they correspond with your specifications. The

entry can be accepted if both values are identical. The entry can be cancelled if there

is a deviation in values.

Confirm the data or stop the procedure as described above.

If all values of the "Manual Handshake" have been confirmed, the data is saved in the

BurnerTronic. The modifications have been made and the procedure is completed. You return

to the starting screen.

Note:

If several parameters of a menu have been changed simultaneously (as in the example), the

individual modifications must be confirmed separately.

09/2014 - Art. Nr. 4200 1038 2700A 17

Page 18

Commissioning

Menu 1: setting the servomotors

Pre-setting without flame

Setting is carried out in 2 phases:

- Pre-setting without flame

- Setting the flame, to fine tune the

settings based on the combustion

results

Important

At this point, no setting position for the

servomotors has been defined,

therefore the burner cannot be started

under these conditions.

When the burner is switched on, the

control and safety unit displays the

screen below.

Access codes must be entered for the individual menus at various points in these instructions. Menu areas

protected by access codes are solely reserved for authorised, qualified and trained personnel.

The following menu description explains the menu for gas operation (figures), but is also valid for fuel oil operation.

Any deviations are noted where relevant.

• For the next step, press

key .

The control and safety unit

then opens the settings mode.

The screen displays the

factory pre-settings for the

different positions of the fuel

and air flap (here: for an

electronically modulated gas

burner)

The menu displays all the

The overview of the menus is

displayed, and the air and gas

flap position settings menu is

settings data using three

consecutive screens (air and

gas flap positions), i.e. for:

selected.

- Ignition position: (when

• Open the settings menu by

pressing the key.

the menu is opened, the

cursor is positioned here)

- Output points P0 to P9

The access code must be

entered at this point

(Access code 1)

• Increase or decrease the

value in increments by

repeatedly pressing

or .

• When the first figure has

been set, move the cursor to

the right by pressing .

• Repeat the operation until

you reach the last figure.

• Confirm the access code by

pressing key .

Special feature for

operation with

the frequency converter:

The fan motor is activated when menu

1 is accessed. Activation must be

confirmed, the screen is displayed as

shown on the left (Manual Handshake).

Continuous ventilation is activated for

the pre-set time period in menu 1. This

is necessary to obtain a feedback value

for the frequency converter channel.

This setting is deactivated again at the

end of menu 1.

09/2014 - Art. Nr. 4200 1038 2700A18

Modifying a value for the servomotor position:

- To modify the value of a position, move the cursor to the

corresponding location with the key.

- Select the value to be modified using the key, the

selected value will flash.

- Increase or decrease the value (in increments of 0.1°) by

repeatedly pressing or . For large modifications, press

and hold the or key, the value will scroll quickly up or

down.

- Confirm the new value using the key. The value stops

flashing.

Page 19

Commissioning

en

Menu 1: setting the servomotors

Pre-setting without flame

End of settings menu without flame

When all the positions of the servomotors have been determined according to the required

settings, it is possible to move on to the next set-up stage, setting with flame.

To do this, place the cursor in the lower part of the screen on the symbol and confirm by

pressing the key.

Only for operation with the frequency regulator:

Manual Handshake

Accept or cancel the entry.

Note: continuous ventilation is deactivated when this menu is exited.

If you want to exit the menu without saving the pre-settings, position the cursor on the symbol

and confirm with the key.

A processing screen now appears for a short time. The "Setting with flame" comes after this

(see page 20).

You are now asked to confirm the modifications that have been made.

It is also possible to delete all the settings at this point. To do this, position the cursor on the

symbol and confirm with the key.

The screen opposite appears.

At this point, it is possible to:

- delete the values; to do so, move the cursor to the symbol and confirm with the key. A

processing screen appears for a short time

- Exit the screen without modification using the symbol.

The previous menu is displayed.

General advice before starting the burner

Function check

All safety equipment must be checked to

Risk of deflagration

Continue to monitor the CO, CO2 and O2

and soot content of the exhaust gases

during setting. Improve combustion

values in the event of CO emissions and

soot formation. The CO content should

be <10 ppm. The soot content should

be <1.

ensure that it is fully functional as part of

initial commissioning and also after

servicing or if the system has been out of

operation for any significant period of

time.

The check must be carried out following

the guidelines in the section entitled

Checking the safety equipment.

09/2014 - Art. Nr. 4200 1038 2700A 19

Page 20

Commissioning

Menu 1: setting the servomotors

Setting with flame

- If the boiler heating

request is not present, the

burner remains on standby.

In this case, it is still possible

to return to the previous

setting menu "Pre-setting

without flame". To do so,

confirm with the key.

- As soon as there is a

boiler heating request

(contacts X10-2 and X10-3

closed), the burner starts.

The air flap is opened to move

to the pre-ventilation position.

Air pressure switch test

The air flap switches to the

ignition/pre-ignition position.

The fuel valve opens.

Awaiting flame signal

If no flame is detected at the

end of the safety time, the

control and safety unit

switches to malfunction mode.

Gas valve sealing test*

(the remaining time is

displayed in the menu in the

bottom right-hand corner)

Pre-ventilation

* only for burners with integrated sealing test and only

for gas operation

Flame detected

Flame stabilisation

The control and safety unit

awaits regulation

authorisation.

09/2014 - Art. Nr. 4200 1038 2700A20

Page 21

Commissioning

en

Menu 1: setting the servomotors

Setting with flame

Setting the ignition position

If a flame has been detected, the control and safety unit sets the burner to the ignition position as

soon as it receives the regulation authorisation.

- Set the fuel controller position and the air flap position according to the desired output level.

While doing so, constantly check the combustion values (CO, CO2 O2, soot, NOx). If required,

adapt the gas and fuel oil pressures at the valve and fuel-oil pump.

- Modify the position of the servomotors in the ignition position (lines with symbol). Proceed

as described on page 18, in the paragraph "Modifying the value of a servomotor position

setting".

- Warning: when modifying the value, the servomotor will move in real time. As a consequence,

the combustion values must be constantly checked.

The burner remains in ignition load.

Setting points P0-P9.

• Check the gas and fuel oil pressure. In the event of subsequent modifications, all setting values

must be corrected. For this reason, fine setting of the burner from point P9 must be carried out,

if necessary. At each setting point, check the combustion values and if necessary, change the

fuel controller position or the air flap position. To do so:

• Select air or fuel with or .

• Activate via (the cursor flashes).

• Change the value via or .

• Confirm with .

The next setting point is accessed using the key.

Note:

The values for each setting point are not saved until the next setting point is accessed. Each point

must be defined. It is not possible to skip individual points, as opposed to when setting without

flame. Only when all points (P0...P9) have been defined can the limit values for minimum and

maximum be set.

Further procedure:

• Enter the setting values in the log.

• Initiate all setting points individually

• Check the burner output at the maximum setting and raise or lower the fuel and air values if

necessary.

• Once all setting points P0 to P9 have been optimised, confirm them by navigating to the next

screen. To do so, press the key at point 9.

Note: The next screen can only be activated once all points (P0...P9) have been defined

• The burner moves to the lower operating point, symbol .

• Check the exhaust gas temperature, emissions and output at low load, if required, adapt the

burner output by correcting .

- To change:

• Activate with (the cursor flashes).

• Change the value via or

• Confirm with

Continue with the key

The burner moves to the upper operating point, symbol .

• Check the exhaust gas temperature, emissions and output at low load, if required, adapt the

burner output by correcting .

- To change:

• Activate with (the cursor flashes).

• Change the value via or

• Confirm with

•

Continue with the key

The setting procedure is completed at this point, the burner switches to operating mode.

The burner switches to the lower operating point and waits for a heating request. The burner

operates within the preset output range ( - ) according to the settings of the control

thermostat.

09/2014 - Art. Nr. 4200 1038 2700A 21

Page 22

Commissioning

Menu 1: setting the servomotors

Setting with flame

It is only possible to adjust (limit) the low load and high load if, for each higher power point, all of

the channels also have setpoint values which are always higher. If this is not the case, the screen

opposite is displayed.

As it is not possible to limit the power range configured, the minimum and maximum operating

points (P0....P9) are automatically defined as the limit.

Example: 1

When the working field is set to always increase, it is possible to adjust the low load and high load.

Example: 2

When the working field is set to not always increase, it is not possible to adjust the low load and

high load.

The highlighted values in the box do not constantly increase.

Take care with dual fuel burners. The limits for low load and high load apply to both gas and fuel

oil operation. It is not possible to define the different limits for fuel oil and gas. If, for example, the

values are modified during gas mode, these values are also modified automatically for fuel oil

mode.

If values have already been defined, the values for the limits of low and high loads previously

specified for the other fuel are displayed in the menu point (left image).

If the values are modified, they must be confirmed for both fuels.

09/2014 - Art. Nr. 4200 1038 2700A22

Page 23

Commissioning

en

Menu 1: setting the servomotors

Setting with flame

Operating mode

Closing the "Setting with flame" menu

The burner setting is now complete. It is still possible, however, to correct the individual values.

To do this, position the cursor on the value to be modified, using the or key.

At any time, the following options can always be used to close the "Setting with flame" menu:

- Restart the burner setting procedure, passing through the presetting phase (without entering a

password). To do this, position the cursor on the symbol and confirm with the key. All

the setting values already saved remain available. This is especially essential for testing a new

ignition position.

- Save the specified values and end the setting procedure. To do this, position the cursor on the

symbol and confirm with the key. Confirm and close the selected settings with symbol .

Manual Handshake

You are now asked to confirm the modifications that have been made.

Accept or cancel the entry

- The burner is now ready to operate and can be immediately controlled by the boiler regulation.

- Exit the settings menu without reaching the end of the setting procedure. To do this, position

the cursor on the symbol and confirm with the key. All the servomotor positions saved

up to this point are recovered by calling up the settings menu again.

Operating mode - Display of the operating status, the flame signal and the operating time

Once setting of the burner has been completed, it switches to operating mode.

The current operation of the burner (operation at min. output, medium output or max. output) is

indicated by the cursor.

When ionisation is employed for flame monitoring (gas operation only), the strength of the signal

is shown at the bottom of the display. The possible display range is between 0 μA and 30 μA. A

good quality signal is one that is above < 9 μA in all load points.

If ionisation is not employed for flame monitoring, either 0% or 100% is displayed.

0% - there is no flame signal

100% - there is a flame signal

If O2/CO regulation is employed, the current O2 value can be read in the bottom right-hand

corner of the display.

09/2014 - Art. Nr. 4200 1038 2700A 23

Page 24

Commissioning

Setting the gas pressure switch

Setting the air pressure switch

Setting the gas pressure switch

• To set the switch-off pressure: remove

the gas pressure switch cover.

• Install a gas pressure pBr measuring

instrument.

• Start the burner. Switching to

maximum power.

• Reduce the pressure upstream of the

gas train by gradually closing the

manual valve, until

- the gas pressure pBr upstream of

the gas train drops

- the stability of the flame is reduced

- the CO level increases

- or the flame signal deteriorates

considerably

Setting the air pressure switch

• Install a pressure measuring device.

To do this, install a T union in the air

tube.

• Set the burner to its maximum

operating power.

• Set the switch-off point to

approximately 15% below the switchoff pressure read.

• Turn the dial clockwise until the gas

pressure switch shuts down the

burner.

• Continue turning the dial clockwise to

set the gas pressure switch to 10%

above the shutdown value determined

above.

Checking the switch-off pressure

• Open the manual shut-off valve

• Start the burner

• Close the manual shut-off valve

The gas failure procedure should start

without the control unit locking.

09/2014 - Art. Nr. 4200 1038 2700A24

Page 25

Commissioning

en

Displaying the setting data from the manual control display

Displaying the setting data from the manual control display

Once the burner setting procedure has been successfully

completed, the servomotor positions for all the operating states are

fixed in the control and safety unit. A backup copy of the values is

saved in the display.

To do this, press the key, the screen opposite is displayed.

Using the key select the menu "Displaying the setting data"

and confirm with the key.

The screen opposite appears. All setting data is displayed in three

consecutive screens. Scroll through by selecting symbols or

and confirming with the key.

The top right-hand corner of the display shows the fuel to which the

current values apply. To switch between the fuel oil and gas

parameters, you must navigate to the corresponding symbol and

confirm with .

Exit the menu using the symbol.

Note: setting points are automatically stored at the end of the

Caution: the values shown in this menu correspond with the values that were last successfully set with the current

manual control display using menu 1 (menu 1 must have been completed in its entirety). However, these values

do not have to correspond with the values saved in the BT300. Any modifications to curve parameters which were

carried out after the last start-up or burner setting with the manual control unit using PC software, are not taken into

consideration. If the values in the menu deviate from the ones in the BT300, the values can be synchronised with

a restart (using the manual control unit - menu 1).

setting procedure for servomotors (menu 1).

The setting procedure (menu 1) must be entirely

completed in order to save the data. Only once the

burner has switched to regulation for the first time are

the setting values in the display saved.

09/2014 - Art. Nr. 4200 1038 2700A 25

Page 26

Maintenance

Maintenance

Burner and boiler servicing must only be

carried out by a professionally qualified

heating engineer. The system operator is

advised to take out a maintenance

contract to guarantee regular servicing.

Depending on the type of installation,

shorter maintenance intervals may be

necessary.

• Switch off the power supply before all

maintenance and cleaning work.

• Use original spare parts.

Work recommended as part of annual

burner maintenance:

- Burner test run, input measurement in

the boiler room

- Clean the combustion components

and replace defective parts if

necessary

- Clean the fan wheel and the fan

- Clean the gas filter; replace it if

necessary

- Visual inspection of burner electrics,

repair if necessary

- Check burner start characteristics

- Sealing test

- Burner safety devices function check

(air pressure/gas pressure switches)

Cleaning the fan wheel

• Remove the plate and attach it in the

service position (see illustration).

• Remove and clean the fan wheel and

replace it if necessary. Refit in the

reverse order.

- Flame monitor and automatic

combustion control unit function check

- Commissioning the burner

- Check the gas flow

- Correct the adjustment values if

necessary

- Draw up a measurement report

General checks

- Emergency stop button function check

- Visual inspection of gas lines in the

boiler room

Checking the combustion

components

• Remove the burner hood.

• Disconnect the ignition cable on the

transformer side.

• Remove the three screws W from the

cover.

• Remove the cover.

• Loosen lock nut E on the gas pipe

bracket

• Loosen the retaining bolt.

• Remove the combustion components.

• Check the condition of the baffle plate.

• Check the position of the ignition

electrode and the ionisation probe.

• When refitting, make sure that the

cable is routed correctly and that Oring J2 is correctly seated.

• Check it is airtight.

Fitting the fan wheel

When changing the motor or the fan

wheel, refer to the positioning diagram

opposite. The internal flange A of the fan

wheel must be aligned with the plate B.

Insert a straight edge between the

blades of the fan wheel and bring A and

B to the same height. Tighten the conepoint screw on the fan wheel.

09/2014 - Art. Nr. 4200 1038 2700A26

Page 27

Maintenance

en

Maintenance

Replacing the flame tube

It is necessary to remove the burner for

this work.

• Loosen the clamping screw on the

connecting flange.

• Turn the burner out of the bayonet

socket, lift it slightly and pull it out of

the connecting flange.

• Place the burner on the floor.

• Undo the 4 screws S.

• Pull the flame tube out towards the

front.

• Fit and secure the flame tube.

The flame tube may be hot

Filter replacement

• The filter element of the multiblock

must be checked at least once a year

and replaced if clogged.

• Loosen the screws of the filter cap on

the multiblock.

• Remove the filter element and clean

its housing.

• Do not use any pressurised cleaning

products.

• Replace the filter element with a new

element.

• Screw the cover back into place.

• Reopen the manual shut-off valve.

• Check it is airtight.

• Check the combustion values.

Cleaning the cover

• Do not use abrasive products or

products containing chlorine.

• Clean the cover with water and a

suitable cleaning product.

• Refit the cover.

Important

Combustion values must be checked

under normal operating conditions

(boiler room door closed, hood fitted,

etc.) after any work is carried out

inside the unit. Record the results in

the relevant documents.

Checking the flue gas temperature

• Check the flue gas temperature at

regular intervals.

• Clean the boiler if the flue gas

temperature is more than 30 °C above

the value measured at the time of

commissioning.

• Use a flue gas temperature gauge to

make the check easier.

Cleaning the air box

• Remove fastening screws V from the

air box.

• Remove the air box, clean it and refit it

in reverse order.

• Check that the air flap and the

servomotor are correctly positioned.

09/2014 - Art. Nr. 4200 1038 2700A 27

Page 28

Servicing

Menu 3: Fault memory

Entering a telephone number for the maintenance company and the

maintenance contract number

Menu - Fault memory

To access the fault memory menu, press any key when the burner is ready for operation or in operation, or

when it is in malfunction mode. It is not possible to access the fault memory menu during the start-up phase.

The general menu screen will appear. Using the , , , or keys, place the cursor on the fault

memory menu symbol, and confirm using the key.

The details of the last fault to appear are indicated by the flashing symbol. This includes the fault code, flame

intensity, air and fuel controller position and burner operating time up to the lockout point.

Using the and keys, it is possible to call up the details of the last 5 faults to have appeared (the fault

number is displayed in the upper left corner of the display). After the details of the last 5 faults, the telephone

number of the after-sales department as well as the maintenance contract number (no values are entered in

the factory) and the menu point "Delete fault memory" are shown.

• Exit the menu using the key.

Entering a telephone number for the maintenance company and the maintenance contract

number

When the corresponding symbol appears on the display:

• Press the key, the first digit starts to flash.

• Using the or keys, change the figure to the value required (underscore = empty field).

• Using the key, move on to the next figure.

• When the number is complete, save using the key.

• The last menu point of menu 3 makes it possible to delete the fault memory (see explanation on the

next page).

Fault diagnosis help symbols

Note: The fault displays described below only show fault diagrams for gas operation (images); however, they

are also valid for fuel oil operation. Any deviations are noted where relevant. The symbol shown in the top

right-hand corner of the display indicates the fuel for which the fault has occurred.

Symbol Cause Symbol Cause Symbol Cause

The control and

safety unit has been

manually locked

Air pressure switch

malfunction at burner

startup

(air pressure switch

activated)

- Combustion air still

present

- Pressure switch

defective (contacts are

welded)

- Pressure switch

incorrectly set

Air pressure switch

malfunction at burner

startup (air pressure

switch not switching)

- No combustion air

- Pressure switch

defective

- Pressure switch

incorrectly set

Stray light

Flame extinguishing

during operation

Internal fault with the

air servomotor

Internal fault with

fuel servomotor

Gas pressure switch

malfunction

- No gas pressure

- Pressure switch

defective

- Pressure switch

incorrectly set

Safety valve fault (gas

operation only)

- Leak in safety gas valve

- Main gas valve not

opening (defective)

- Pressure switch

defective (contacts are

welded)

No defined curve

Fault in boiler safety

circuit during

operation

Fault in burner

safety circuit during

operation

No flame at end of

safety time

Main gas valve fault (gas

operation only)

- Leak in main gas valve

- Safety valve not opening

(defective)

- Insufficient gas pressure

- MIN pressure switch

defective

- MIN pressure switch

incorrectly set

Unknown fault

For details, see the

fault code list

09/2014 - Art. Nr. 4200 1038 2700A28

Page 29

Servicing

en

Menu 3: Fault memory

Entering a telephone number for the maintenance company and the

maintenance contract number

Continued: Fault diagnosis help signals:

Symbol Cause Symbol Cause Symbol Cause

Power supply fault

- min. supply

voltage not reached

Boiler safety circuit

fault when starting

burner

The following message appears in the display for the last menu point:

Using , navigate to and confirm with the key to delete the fault memory.

Burner safety circuit

fault when starting

burner

Fuel oil pressure switch

malfunction

- No fuel oil pressure

- Pressure switch

defective

- Pressure switch

incorrectly set

- Pump defective

- Fault in fuel oil supply

Air pressure switch

malfunction during

burner operation

(decreased air

pressure switch signal)

- No combustion air

(fan has failed)

- Pressure switch

defective

- Pressure switch

incorrectly set

You are now asked to confirm that you want to delete the fault memory.

Navigate to and confirm with the key to delete.

Navigate to and confirm with the key to quit and exit the menu.

09/2014 - Art. Nr. 4200 1038 2700A 29

Page 30

Servicing

Menu 4: Operating statistics

Operating statistics menu

To access the operating statistics menu, press any key when the burner is ready for operation or

in operation, or when it is in malfunction mode. It is not possible to access the operating statistics

menu during the start-up phase.

The general menu screen will appear. Using the , , , or keys, place the cursor on the

operating statistics menu symbol, and confirm using the key.

The operating statistics menu comprises 3 screens. You can navigate between the different

screens using the and keys.

- Flame detection time for last burner start-up

- Average flame detection time for the last 5 burner start-ups

- Total number of burner start-ups

- Number of burner start-ups, gas operation

- Number of burner start-ups, fuel oil operation (if available)

- Total operating time since the last counter reset

- Total number of operating hours in gas operation since the last counter reset

- Total number of operating hours in fuel oil operation since the last counter reset

09/2014 - Art. Nr. 4200 1038 2700A30

Page 31

Servicing

en

Setting the brightness and contrast of the display

This menu offers access to the display contrast and brightness settings.

To access the menu, press any key when the burner is ready for operation or in operation, or

when it is in malfunction mode.

• The general menu screen will appear. Position the cursor on the symbol for setting the display

and confirm with the key.

• Modify the settings using the and keys for the contrast (in increments of 2), or the

and keys for the brightness (in increments of 10).

• Position the cursor on the symbol and confirm the setting with the key.

• All modifications entered are discarded using the symbol. The burner returns to the previous

operating mode.

09/2014 - Art. Nr. 4200 1038 2700A 31

Page 32

www.elco.net

Made in EU.

Non contractual document.

09/2014 - Art. Nr. 4200 1038 2700A32

Loading...

Loading...